Page 1

Field Control s * 2630 Airport R oad * Kinston, NC 28504 * (252) 522-3031 * www.fieldcontrols.co

Page 2

Table of Contents

Important Safety Instruction ……………………………………….. 3

Specifications ……………………………… … …………………………… 4

Operation ……………………………………………………………………. 5

Air Cycles / HHSC+ ……………………………………… ………………. 5

Service ……………………………………………………………………….. 6

Changing Filters ………………………………………………………….. 6

Replacement Filters and Germicidal UVC Lam ps …………….. 7

Resetting Remote Service Panel ………...…………………………. 8

Installation ………………………………………………………………….. 9

Transitions for In-Duct Mounting …………………………………… 9-10

Electrical Schematic ……………………………………………………. 11

Performance Data ………………………………………………………… 12

Warranty ……………………………………………………………………… 13

Page 3

3

SAFETY INSTRUCTIONS

Before installing the Cube, inspect packing for any signs of damage. During handling and installation, take care

to protect the PRO-Cell™ honeycomb catalytic side of the product from physical damage, as the aluminum

honeycomb substrate is soft and can easily be scored.

Warning - Always unplug the power cord from the Cube air purification system when changing the filter or

germicidal ultraviolet lamps. Never look into an illuminated ultraviolet lamp as severe damage to the eyes will

result.

The Cube is rated for standard ambient air temperatures during heating and cooling functions. The Cube is

not rated for temperatures in excess of 125 Degrees Fahrenheit / 52 Degrees Celsius.

Do not attempt to clean the PRO-Cell™ honeycomb catalyst with cleaning solutions. The PRO-Cell™ catalyst

is radiated with short wave germicidal ultraviolet light during periods of airflow and is self-cleaning.

Do not install insulation within 76mm or 3 inches of any illuminated ultraviolet lamps.

Access for service is required when mounting above suspended ceilings, and / or behind walls.

Do not install in a position where the interior modules can fall from an elevated positon and cause injury to

people or equipment.

Page 4

SPECIFICATIONS 4

Power

110V/60Hz / 1.8 Amps 150watts

220V/50Hz /.09 Amps 150watts

Fuse

Replace only with AGC-6 Fuse

Max Air Flow

2500 CFM 70.8 m3/min

Max Face Velocity

720 FPM 220 m/min

Repl. Lamp Part No.

46636400

Repl. Lamp Model No.

22LAMP

Lamp Life Efficiency

2 Years

Lamp Service

Recommended Replacement every 12-24 months

UVC Range

253.7nm

PRO-Cell™ Catalyst

Titanium Dioxide TiO2 - 30,240 in2 195,096 cm2

PRO-Cell™ Substrate

Honeycomb Aluminum Cells

Unit Weight

92 lbs 42 kg

Dimensions

23"H x 31"W x 29"D

585mm H x 787mm W x 737mm D

Standard with MERV13 Media Pre Filter and 3 PRO-Cell™ Modules

(1 Master Module [MM], 2 Slave Module [SM])

CFM

in W.C.

pa

1200

0.19

47.326

1600

0.26

64.763

2000

0.35

87.181

Frame body between flanges

Flange height

Cover for MERV13 Pre Filter

W L H

1/2" all around

W H D

24-3/4"

30-3/4"

22"

12mm all around

3-5/16"

19"

1/2"

620mm

784mm

560mm

84mm

484mm

12mm

Outside dimensions of flanges at both ends

Cover optional formaldehyde or carbon post filter

W

L

W H D

25-3/4"

23"

1-1/2"

19"

1/2"

659mm

585mm

38mm

484mm

12mm

Cover for electronics

2 electric connectors (protruding from covers)

W H D

1-1/2" x 1" Dia

18-1/2"

20-1/8"

2-7/8"

38mm x 25mm Dia

470mm

510mm

72mm

Page 5

OPERATION 5

The Cube installs in the air inlet side of any heating and air conditioning system. Operation of air handler fan

unit is required for air purification to take place.

Note: UVC Germicidal ultraviolet lamps are wired to operate continuously. This feature allows the PRO-Cell™

catalyst to burn off surface impurities, cleaning and reactivating itself during periods of non-use or no airflow.

The Cube in recirculation mode combines three unique processes to protect against and significantly reduce

air pollutants. PRO-Cell™ Technology combines (1) MERV13 electrostatic high efficiency particulate removal

filter (2) UVC germicidal ultraviolet light that reacts to excite (3) a photo-catalytic oxidation (PCO) purification

process. This 3 stage purification process quickly removes submicronic particulate dust, inactivates

bioaerosols (germs, bacteria, mold spores), and eliminates volatile organic compounds (toxic gas-phase

chemicals) referred to as VOC’s.

There are many smart programmable thermostats that allow for automatic operation of the air-handler-fan unit

when there is no demand for heating or cooling. It is important that the Cube is operating twenty (20) to Thirty

(30) minutes every hour in a twenty four hour day to remove airborne contamination from the indoor

environment. Included with the Cube is the Healthy Home System Plus Control (HHSC+ by Field Controls).

The HHSC+ is a fan management control with a ventilation control option that is recommended to be installed

for precise air movement programming every half hour.

The length of operation depends on the location of the facility in relation to point source of pollution such as

refineries, processing plants, automobile traffic, hair salons, dog motels, fitness center locker rooms and areas

that produce high levels of pollutants. Individuals that are sensitive to mold spores, dust mites, chemicals or

have respiratory problems such as asthma, emphysema, and chronic allergies should extend run time 15 to 20

minutes every half hour in a 24 hour day.

AIR CYCLES PER HOUR

Fan Unit on 20 minutes per hour or 10 minutes every half hour

Fan Unit on 30 minutes per hour or 15 minutes every half hour

Fan Unit on 40 minutes per hour or 20 minutes every half hour

AIR CYCLES PER DAY (based on 24,000 cubic feet)

Fan Unit on 20 minutes per hour Air cycled (42) times per day

Fan Unit on 30 minutes per hour Air cycled (63) times per day

Fan Unit on 40 minutes per hour Air cycled (87) times per day

In the event, the existing thermostat does not have the capability to operate the air handler fan unit

independently of demand for heating or air conditioning, install Field Controls model HHSC+ Healthy Home

System Control Plus part number 46634200 included. The HHSC+ is a fan management and ventilation

control with the capability to program fan run time schedule every half hour for an even air cycle rate and a

more complete air purification operation.

The HHSC+ is simply wired in parallel with the existing thermostat. The HHSC+ memory tracks the time the

fan unit operates and only cycles the fan unit on when demand for heating and cooling have not met the fan

run time requirements for air purification. The HHSC+ also allows for programing notification for service of filter

and UVC germicidal lamp replacement.

Page 6

SERVICE 6

MERV13 Pre Filter is recommended to replace minimum every six (6) months. The service light turns from

green to yellow after five (5) months and to red after six (6) months. Change the pre filter before the red LED

light illuminates.

UVC Germicidal Ultraviolet Lamps is recommended to be replaced every twelve (12) to twenty four (24)

months. The service light turns from green to yellow as a thirty (30) notice to replace lamps. The service light

turns to red when it is time to replace lamps.

Choice Options available for Formaldehyde Post Filter or Carbon Post Filter

Formaldehyde (potassium permanganate) Post Filter is an onsite installed option. Order Field Controls part

number 1RK026 model number 1RK026. Field Controls recommends replacing minimum every six (6) months.

The service light turns from green to yellow after five (5) months and to red after six (6) months. Change the

post filter before the red LED light illuminates.

Carbon Post Filter is an onsite installed option. Order Field Controls part number 46728500 model number

1RK027. Field Controls recommends replacing minimum every six (6) months. The service light turns from

green to yellow after five (5) months and to red after six (6) months. Change the post filter before the red LED

light illuminates.

CHANGING THE FI LTER

1. Always wear protective eye goggles to prevent physical harm by UVC Ultraviolet light.

2. Unplug the power cord from main outlet on the Cube unit.

3. Unscrew the four (4) screws from both the MERV13 filter cover and pull out the loaded MERV13 filter

and replace. Discard as per local regulations if required.

4. The correct placement of the new MERV13 filter is with the wire side down stream of airflow.

5. Check that airflow arrow on MERV13 is pointing in the same direction as the airflow arrow found on

filter frame panel.

6. Reattach filter cover and tighten four (4) cover screws.

Page 7

REPLACING UVC GERMICIDAL LAMPS 7

1. Always wear protective eye goggles when servicing UVC germicidal lamps.

2. Unplug the power cord from main outlet on the Cube unit.

3. Remove the central Cube metal cover which is held in place with eight (8) screws. This will allow

access to the 3 PRO-Cell™ modules and electronics.

4. Next to the MERV13 filter is the PRO-Cell/MM2025C Master Module. Unplug the power cord, remove

service panel metal cover from the PRO-Cell/MM2025C Master Module and set aside metal cover.

5. The remaining two modules are the PRO-Cell/SM2025 Slave Modules. Unplug the low voltage wires

from the master module and the two slave modules.

6. Unplug the UVC germicidal lamp wires from each of the lamp connections.

7. Each module is held in place by a retaining bracket by two (2) thumb screws. Unscrew the thumb

screws. Set aside thumb screws and retaining brackets.

8. Carefully slide forward the PRO-Cell™ Module to a point where access to the far end of the UVC

germicidal lamps can be reached, or fully withdraw the module completely from the frame. Loosen the

UVC germicidal lamp clamp thumb screw located at the far end of the UVC germicidal lamp so as to be

able to carefully remove the lamp through the rubber grommet on the front of the module.

IMPORTANT

AVOID TOUCHING THE NEW UVC GERMICIDAL LAMPS WITH BARE HANDS AS THE OIL ON THE SKIN CAN IMPEDE LAMP

PERFORMANCE OR CAUSE PERMATURE FAILURE OF LAMP ILLUMINATION.

THE USE OF COTTON GLOVES OR PAPER TOWELS IS PREFERRED WHEN HANDLING THE UVC GERMICIDAL LAMPS.

9. Replace with new UVC germicidal lamps: re-insert the lamp through the rubber grommet at the front,

and insert into the UVC germicidal lamp clamp at the far end until the plastic shield of the lamp rests

softly against the frame.

10. Finger-tighten the thumb screws on far end of the UVC germicidal lamp holding clamp.

11. Replace all six (6) lamps in the same fashion.

12. Fully re-insert the 3 PRO-Cell™ modules into the frame. Replace retaining bracket and re-fasten each

with two thumb screws. Repeat steps on all modules.

13. Re-attach all low voltage wires and power cord.

14. Re-attach the central PRO-Cell™ module metal cover with screws supplied making sure the rubber

gaskets are properly seated to assure no air leakage.

15. Re-connect power cord and check through the six UVC germicidal lamp view ports for illumination.

Page 8

Healthy Home System Control Plus (HHSC+) 8

PART NUMBER

MODEL

DESCRIPTION

46636500

TrioRM13-2025

20x25x4 MERV13 Repl. Media Pre-Filter (6/MCTN)

46636700

TrioRM11-2025

20x25x4 MERV11 Repl. Media Pre-Filter (6/MCTN)

46678300

TrioRM8-2025

20x25x4 MERV8 Repl. Media Pre-Filter (6/MCTN)

46636400

22LAMP

22" UVC Lamp Set (2) for each Cube module &Trio

1RK026

1RK026

Potassium Permanganate Post Filter Option

46728500

1RK027

Activated Carbon Plated Post Filter Option

The HHSC+ intelligently manages, monitors, and engages the air handling system fan on a regular

schedule to keep air circulating throughout the air treatment space. The HHSC+ includes UV lamp

timer / change notification and filter timer/change notification. The control is easy to install and set up.

Please refer to installation instructions included with the HHSC+ for wiring and operation information.

REPLACEMENT FILTERS and UVC GERMICIDAL LAMPS

Replacement filters and UVC germicidal lamps are available from your authorized Field Controls

Wholesaler / Distributor or Contractor. You may contact Field Controls for information on a

Wholesaler / Distributor or Contractor at:

Field Controls

2630 Airport Road

Kinston, NC 28504

(252) 522-3031

www.fieldcontrols.com

Page 9

INSTALLATION 9

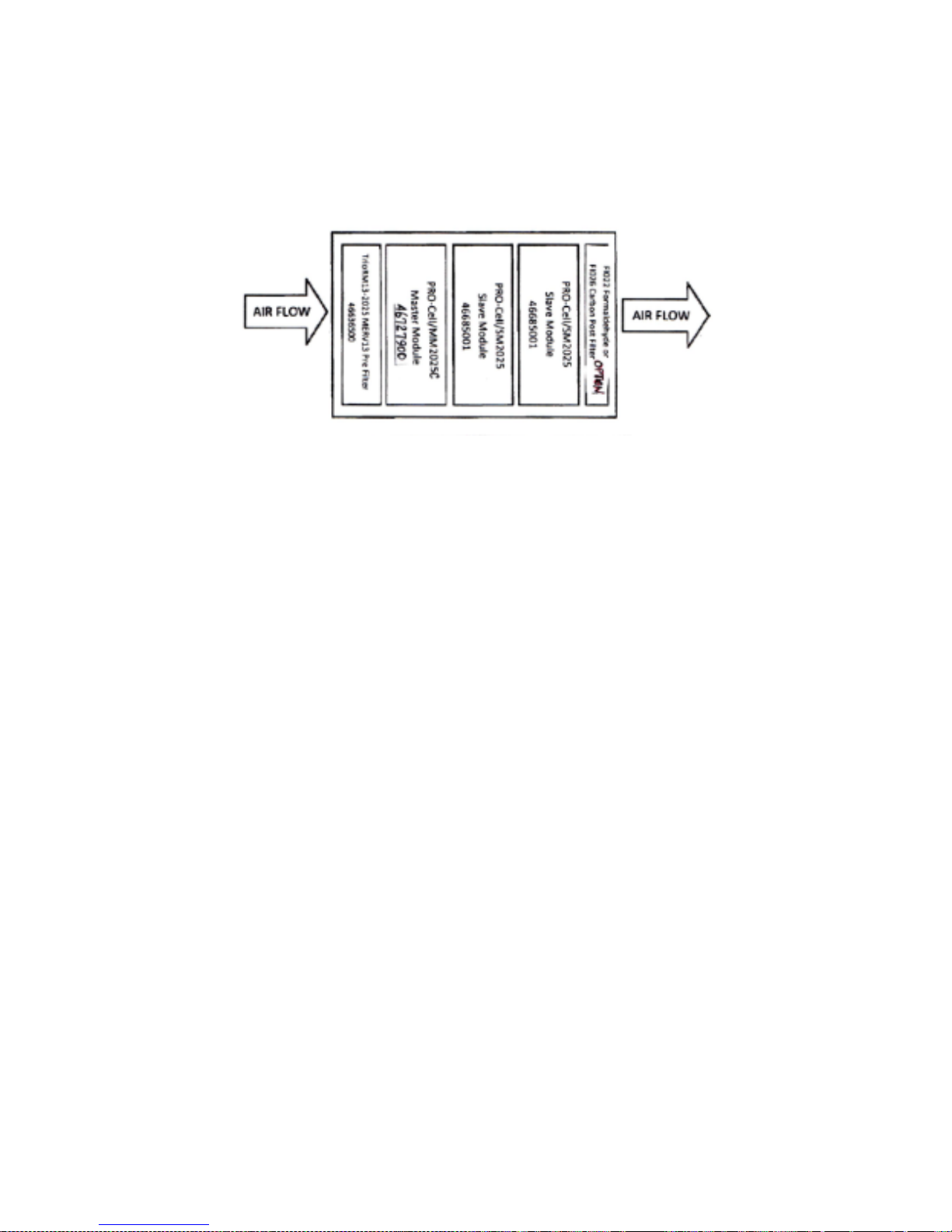

Note: Upon installation pay close attention to the Cube directional airflow inlet. Airflow inlet is at the MERV13

Pre Filter as illustrated in Figure 1 illustration below.

The Cube is designed to be installed into a HVAC or AHU distribution system. It is recommended that a

plenum is created into which the Cube can be integrated in a completely airtight installation. Several Cube

units may be installed side by side, one on top of the other, or both. Be certain to provide for a door open

access to service covers.

TRANSITIONS FOR IN-DUCT MOUNTING

Metal adapter of 18 gauge sheet metal or greater and insulated, should be fabricated to make suitable

transitions. Attach the transitions to the Cube and fasten with #10 x 1/2 self-tapping sheet metal screws.

(See Figure 2 illustration on following page)

1. Tape all seams between the air handler / blower return side and the outlet side of the Cube so not to

allow air bypassing the system.

2. Program the thermostat or HHSC+ Fan management control to operate fan for at least 10 minutes

every half hour. Increase cycle rate of fan run time to meet desired air quality requirements.

Page 10

FIGURE 2 10

Page 11

ELECTRICAL SCHEMATIC 11

Page 12

PERFORMANCE DATA 12

Page 13

WARRANTY 13

Refer to www.fieldcontrols.com

for complete warranty statement

Loading...

Loading...