Page 1

24 VAC SYSTEM CONTROL KIT

Model: CK-92F and CK-92FG

Designed for use with the SWG Series Power Venter for controlling Natural

Gas or L.P. Gas appliances with a 24 VAC Gas Valve and a 30-millivolt

controlled Natural or L.P. Gas Water Heater.

I

TEMS INCLUDED IN KIT:

1) Junction box with mounted pressure switch and post purge timer

1) Fan control gas pressure switch with built in post purge option

1) 2 ft. length of 1/4 inch aluminum tubing

1) 1/8" NPT x 3 inch pipe nipple

1) 1/8" NPT x 1/4 inch OD tubing elbow

1) 1/8" NPT pipe tee

1) TCA-1 Thermocouple Adaptor (CK-92F)

1) TCA-2 Left Handed Thermocouple Adaptor (CK-92FG)

1) 6 ft. length of 12-2 wire

1) 8 inch jumper wire

2) Flexible conduit connector

2) GSK-3 Spillage Switch

1) 1/4 inch tubing connector

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

Page 2

INSTALLATION

M

OUNTING JUNCTION BOX

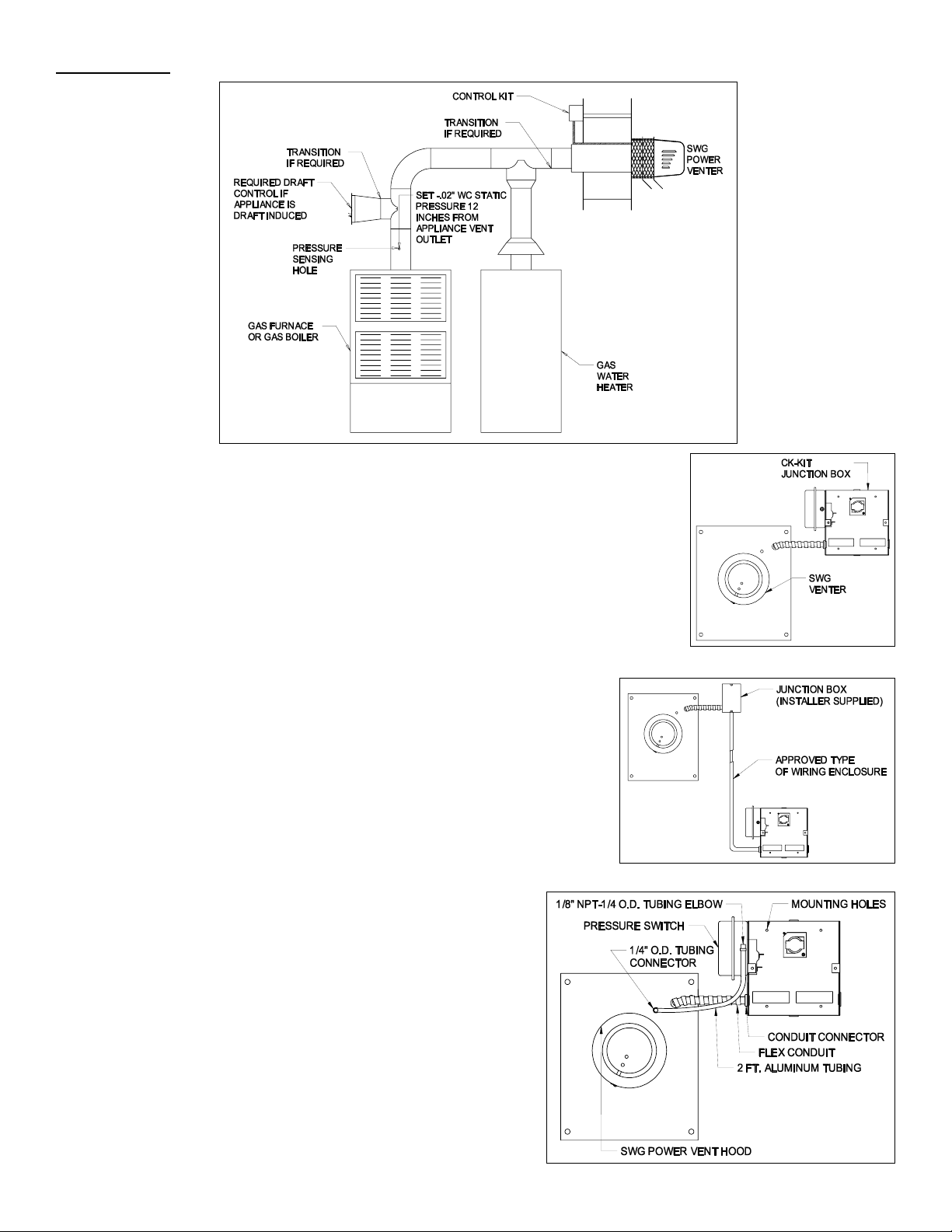

The junction box can be mounted at the venter or remotely mounted away from the

venter. (See Figure 1 & Figure 2)

1. Remove one of the knockouts from the side of the junction box where the pressure

switch is mounted. Install the flexible conduit connector onto the CK-92F junction

box and secure with fastening nut. If remote mounting the CK-92F junction box,

mount the flexible conduit connector onto a 2" x 4" installer supplied junction box.

2. Fasten the flexible conduit from the SWG Venter into the conduit connector. Mount

the CK-92F junction box or installer supplied junction box onto the wall or floor joist

without straining the flexible conduit. Fasten the CK-92F junction box through the

four dimpled locations on the base of the box. (See Figure 3)

P

RESSURE SWITCH SENSING TUBE INSTALLATION

1. Attach the 1/4 inch tubing connector to the pressure tube on the SWG

Venter. (See Figure 3)

2. Connect the supplied 1/4" aluminum tubing to the tubing connector. Route

the tubing to the CK-92F junction box and connect the tubing to the

pressure switch. When routing the tubing, avoid kinking the tubing by

bending the tubing too sharply.

For remote mounted CK-92F Junction Box, use a 1/4" OD copper, aluminum

or plastic tubing and route the tubing to avoid contact with any heat source.

Figure 1

Figure 2

Page 2

Figure 3

Page 3

ADJUSTMENTS

ROVING SWITCH ADJUSTMENTS

P

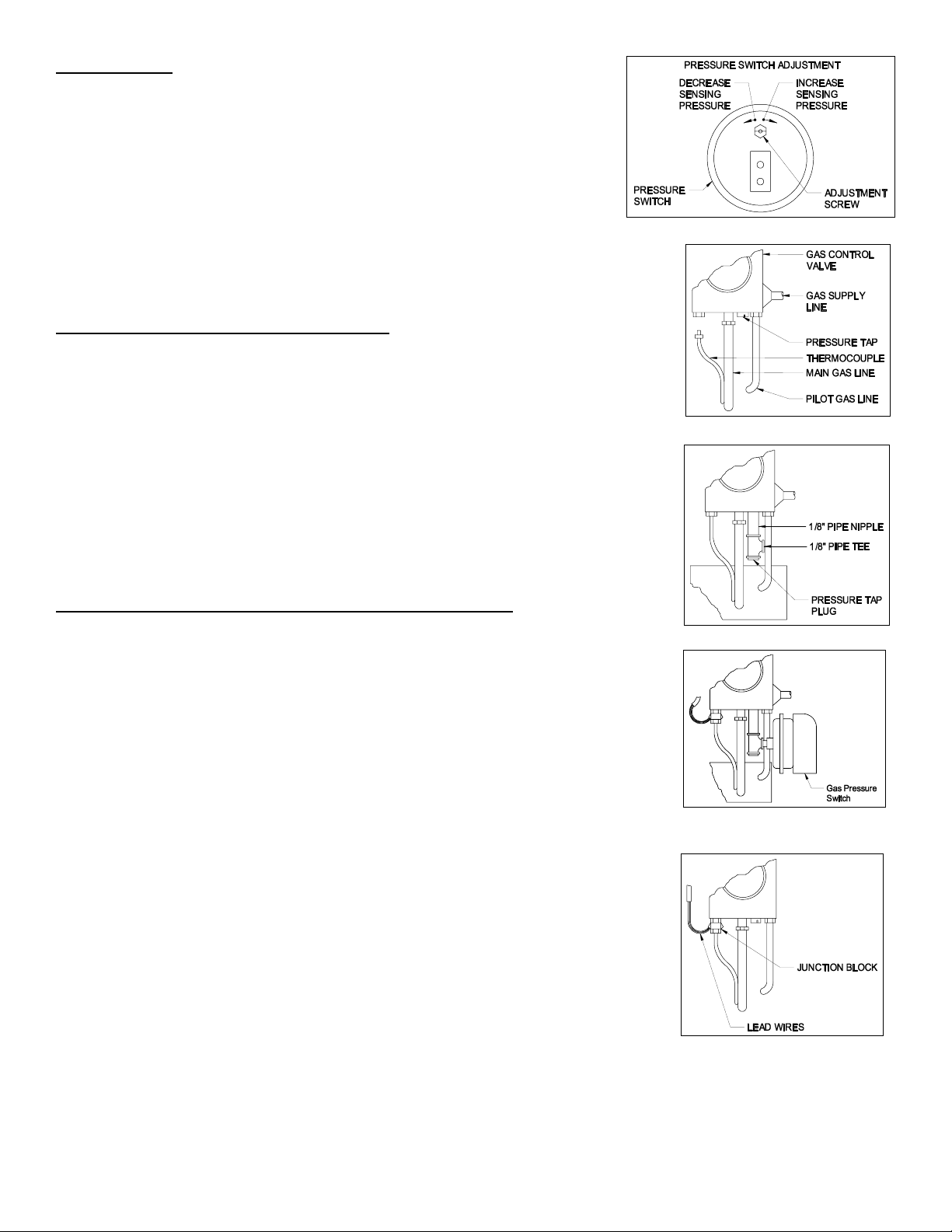

After proper air flow is established, the pressure switch adjustment is made by

turning the pressure switch adjustment screw clockwise (See Figure 4) until

burner operation stops. Turn the adjustment screw counterclockwise until

burner ignites. Turn the adjustment screw an additional 1/4 to 3/4 turn

counterclockwise to ensure adequate switch adjustment.

WARNING: Failure to properly adjust the pressure switch as specified above

could lead to improper operation of the pressure switch which will result in a

hazardous condition and bodily harm!

T

HERMOSTAT HEAT ANTICIPATOR ADJUSTMENT

After venting kit installation and checkout, check the amperage current draw through the

thermostat circuit and adjust the thermostat anticipator accordingly.

INSTALLATION OF GAS PRESSURE SWITCH

CAUTION: Check gas control valve pressure. Pressure MUST NOT exceed 14" WC

pressure.

1. Remove pressure tap plug in gas valve. (See Figure 5) NOTE: If installing on an

existing appliance, shut off gas supply to gas valve before plug removal.

2. Replace the pressure tap plug with the 1/8" pipe nipple and pipe tee. Install pressure

tap plug at the bottom of the pipe tee. (See Figure 6)

3. Install the gas pressure switch into the side of the pipe tee. The gas pressure switch

is supplied with a restrictor orifice in the inlet and outlet ports. With these orifices in

place, the switch does not need to be vented. This feature complies with current

ANSI standards for gas regulators. (See Figure 7).

CAUTION: If for any reason the system has shut down during operation, the cause of

the system failure should be investigated and corrected before resetting the safety

switch and restarting the system.

DRAFT HOOD SAFETY SWITCH INSTALLATION PROCEDURE

NOTE: 12 ga. wire should be used when wiring safety spillage switches, to reduce the

voltage drop in the thermocouple circuit.

1. Remove the thermocouple from the gas control valve. (See Figure 5)

2. Thread the junction block into the thermocouple port and thermocouple into the

bottom of the junction block. Connect lead wire from the junction block to the

jacketed lead wires or wire enclosed in an accepted wiring enclosure. (See Figure

8)

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Page 3

Page 4

NOTE: Draft spillage switches should be mounted 90 degrees apart, and

mounted opposite from the vent outlet direction. (See Figure 9)

3. Mount the two spillage switches onto the draft hood and connect

inside terminals of switches with jumper wire. Connect outside

terminals to lead wires which are connected to the thermocouple

junction block. (See Diagram A)

4. Route jacketed lead wires or accepted wiring enclosure on the outside

of the water heater enclosure. Secure them to the enclosure with an

accepted hold down tab. Keep wiring away from any HOT surface

area.

WIRING

Figure 9

CAUTION: Disconnect electrical power when wiring power venter.

Wire the venter motor and controls in accordance with the National Electrical Code, manufacturer's recommendations

and/or applicable local codes. UNITS MUST BE GROUNDED. Check ground circuit to make certain that the unit has been

properly grounded. The wiring should be protected by an overcurrent circuit device rated at 15 amperes. CAUTION must

be taken to ensure that the wiring does not come into contact with any heat source. All line voltage and safety control

circuits, between the venter and the appliance, MUST be wired in accordance with the National Electrical Code for class

one wiring or equivalent methods. Route the venter motor and control wiring with an appropriate wiring method. Refer to

Wiring Diagrams A and B.

I

NTERNAL WIRING FOR CK-CONTROL KIT

Diagram A

Page 4

Page 5

Diagram B

L1 to 1 on post purge timer T2 to timer relay base

M to 3 on post purge timer T3 to N/O on pressure switch

T1 to common on pressure switch Timer base to common on pressure switch

LOW VOLTAGE WIRING INSTRUCTIONS FOR BOILERS AND WARM AIR FURNACES

1. With boilers, locate terminal on spark ignition module or gas valve (if standing pilot) which would normally be 24 volts

hot on a call for heat. With spark ignition systems, this terminal could be TH-W, 24 V, THS or T1 depending on the

spark ignition control.

2. With warm air furnaces, locate terminal W in furnace junction box.

3. Remove wire from this terminal and reroute to T1 on CK-92F.

4. With boilers, connect T3 on CK-92F to hot side of gas valve (if standing pilot) or to terminal TH-W, 24 V, THS or T1 if

spark ignition.

NOTE: Remember, the correct terminal is the one that would normally be hot on a call for heat.

5. With warm air furnaces, connect T3 on CK-92F to terminal W in furnace junction box.

6. Connect T2 on CK-92F to a 24 volt neutral where convenient.

L

INE VOLTAGE WIRING INSTRUCTIONS

1. Connect 120 volts hot power source wire to terminal L1 on CK-92F.

2. Connect 120 volts neutral power source wire and white wire from venter motor to terminal N on the CK-92F.

3. Connect black wire from venter motor to terminal M on the CK-92F.

Refer to the SWG Venter installation instructions for setting system airflow.

Page 5

Page 6

SYSTEM CONTROL CHECK OUT PROCEDURES

1. For furnaces or boilers, adjust the thermostat to call for heat and observe the power venting system for proper

operation sequence. (Repeat if necessary)

a. Thermostat calls for heat.

b. Relay is energized and venter motor starts.

c. Pressure switch closes and burner starts.

d. Thermostat is satisfied, the burner stops.

e. This starts the post purge cycle. Purge time 1 to 2 min.

2. While system is operating, disconnect power to the venter motor. This should open the pressure switch contacts and

stop burner operation.

GAS PRESSURE SWITCH FOR WATER HEATER

1. Follow water heater manufacturer's instructions to light pilot. Turn the gas control valve to the ON position. Then

adjust the thermostat to call for heat, which will energize the venter motor. (May see a 1 to 8 sec. delay of venter

motor)

2. Turn gas control valve to the PILOT position, which will start a 1 to 3 min. post purge of the venter motor.

3. Repeat Step 1 and 2 to ensure proper operation.

SPILLAGE SWITCHES

1. Allow the water heater to heat up to operating temperature, then disconnect the power to the gas pressure switch.

2. Adjust the thermostat to call for heat with the venter inoperative. Allow approximately 2 minutes of flue gas spillage for

the spillage switches to sense the spillage and disrupt the thermocouple circuit, halting the gas flow to the pilot and

burner.

3. Wait 2 to 3 minutes. Reset the spillage switches and light the pilot, then perform a second safety spillage test (Steps 1

and 2).

CAUTION: If for any reason the system has shut down during operation, the cause of the system failure should be

investigated and corrected before resetting the safety switch and restarting the system.

TROUBLE SHOOTING HINTS

1. Venter does not activate when thermostat calls for heat.

a. Check wiring.

b. Check gas pressure switch for continuity across terminals when gas valve is pressurized.

c. Check gas pressure.

2. Flue gas odor:

a. Check system draft.

b. Check for negative pressure in building.

3. Pilot will not stay lit on water heater:

a. Solder all spillage switch wire terminal connections.

b. Check reset buttons on spillage switches.

REPAIR AND REPLACEMENT PARTS LIST

MODEL PART NUMBER

Gas Pressure Switch 46284200

GSK-3 Spillage Switch 46086400

Post Purge Timer 46282800

Pressure Switch 46083000

TCA-1 Thermocouple Adaptor 46082700

TCA-2 Left Handed Thermocouple Adaptor 46429900

Page 6

Page 7

INSTALLATION INFORMATION

MODEL NO.:____________________________________________________________

INSTALLER'S NAME:_____________________________________________________

INSTALLER'S COMPANY: _________________________________________________

INSTALLER'S PHONE NO.: ________________________________________________

DATE OF INSTALLATION:_________________________________________________

CK-92F/CK-92FG

Page 7

Page 8

Page 8

P/N 46285400 Rev C 10/03

Loading...

Loading...