Page 1

SYSTEM CONTROL KIT

Model: CK-81

Designed for use with the SWG Series Power Venter for controlling 750 millivolt controlled Natural

and L.P. Gas appliances with a 24AC voltage thermostat or wall switch, such as a gas fireplace.

NOTE:

is recommended. Manual operation controls to gas valve must be rendered inoperative.

The use of flue gas spillage switches such as The Field Controls Model GSK-3, or equivalent,

I

TEMS INCLUDED IN KIT:

1) Junction box with mounted pressure switch

1) 1 ft. length of 1/8 inch aluminum tubing

1) 1/8" tubing connector

1) 1/8" tubing to 1/8" NPT elbow

1) Flexible conduit connector

1) Mounted 115 VAC/24 VAC transformer

1) Mounted post-purge timer (non-adjustable)

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

Page 2

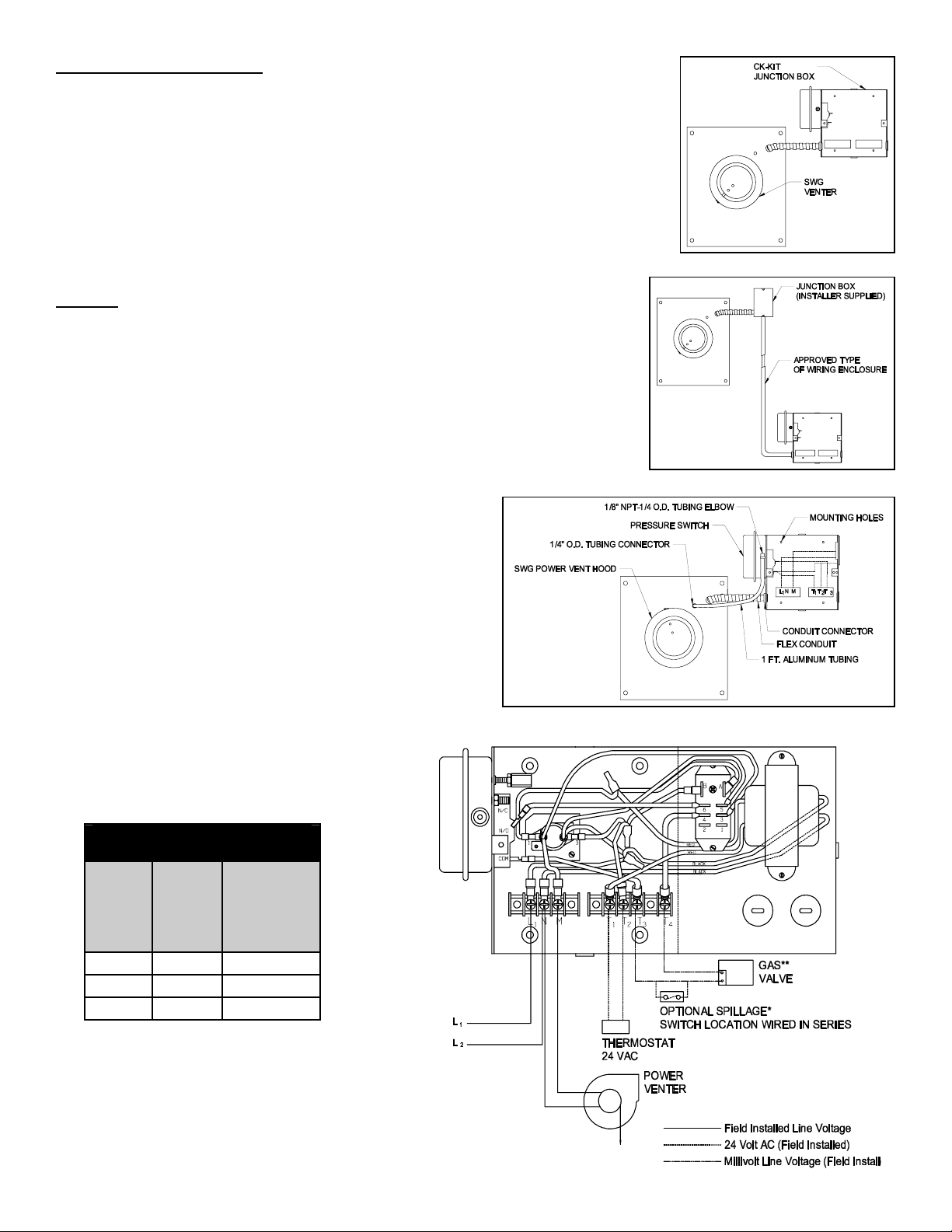

MOUNTING JUNCTION BOX

The junction box can be mounted at the venter or remotely mounted away from the

venter. (See Figures 1 & 2)

1. Remove one of the knockouts from the side of the junction box where the pressure

switch is mounted. Install the flexible conduit connector onto the CK-81 junction box

and secure with fastening nut. If remote mounting the CK-81 junction box, mount

the flexible conduit connector onto a 2" x 4" installer supplied junction box.

2. Fasten the flexible conduit from the SWG Venter into the conduit connector. Mount

the CK-81 junction box or installer supplied junction box onto the wall or floor joist

without straining the flexible conduit. Fasten the CK-81 junction box through the

four dimpled locations on the base of the box. (See Figure 3)

Figure 1

WIRING

(See Figure 4 and Table 1)

Wire the venter motor and controls in accordance with the National Electrical

Code, manufacturer's recommendations and/or applicable local codes. UNITS

MUST BE GROUNDED. Check ground circuit to make certain that the unit has

been properly grounded. The wiring should be protected by an over-current circuit

device rated at 15 amperes. CAUTION must be taken to ensure that the wiring

does not come into contact with any heat source. All line voltage and safety control

circuits between the venter and the appliance MUST be wired in accordance with

the National Electrical Code for Class I wiring or equivalent methods.

1. Route the venter motor and control wiring with an appropriate wiring method.

2. All wiring to be Class I or equivalent for line voltage or

safety control circuits.

3. All manual operation controls to gas valve must be

rendered inoperative.

S

EQUENCE OF OPERATION

1. Thermostat calls for heat. The relay closes and the

power venter energizes.

2. After motor is up to speed, the pressure switch closes

and the gas valve energizes.

3. When the thermostat is satisfied, the thermostat opens

and stops the gas valve operation. The postpurge timer in the CK-81 will cause operation of

the venter motor for an additional period of

approximately one to three minutes.

Figure 2

Figure 3

Table 1

WIRE LENGTH FOR 750

MILLIVOLT WIRING

Max.

Wire

Sizes

Length

(2-wire

cable)

No. 18 30 ft. 60 ft.

No. 16 50 ft. 100 ft.

No. 14 80 ft. 160 ft.

Max.

Combined

Length

(2 single

wires)

*Floor furnace application must use

a gsk-3 spillage sensing switch.

**(Optional connections), connect to millivolt

thermostat connections on heating equipment.

Page 2

Figure 4

Page 3

PRESSURE SWITCH SENSING TUBE INSTALLATION

1. Attach the 1/4 inch tubing connector to the pressure tube on the SWG Venter. (See Figure 3)

2. Connect the supplied 1/4" aluminum tubing to the tubing connector. Route the tubing to the CK-81 junction box and

connect the tubing to the pressure switch. When routing the tubing, avoid kinking the tubing by bending the tubing too

sharply.

NOTE: For remote mounted CK-81 Junction Box, use 1/4" OD copper, aluminum or plastic tubing, and route the tubing to

avoid contact with any heat source.

Refer to the SWG Venter installation instructions for setting system airflow.

PRESSURE SWITCH ADJUSTMENTS

With the venter airflow set and the appliance operating

at the best operating efficiency adjust the pressure

switch by rotating the adjustment screw clockwise until

the burner shuts off, then rotate the adjustment screw

counterclockwise until the burner fires. Rotate the

adjustment screw an additional 1/4 turn

counterclockwise to ensure proper switch setting. (See

Figure 5)

SYSTEM CONTROL CHECK OUT PROCEDURES

1. Adjust the thermostat to call for heat and observe

the power venting system for proper operating

sequence. (Repeat if necessary).

a. Thermostat or wall switch calls for heat.

b. Venter motor starts.

Figure 5

c. Pressure switch closes and burner starts.

d. Thermostat is satisfied or wall switch is turned off. The burner stops; the venter runs for 1-3 minutes longer.

2. While system is operating disconnect power to the venter motor. This should open the pressure switch contacts and

stop burner operation.

TROUBLE SHOOTING HINTS

1. Main burner does not fire when thermostat or wall switch calls for heat with venter operating.

a. Check pressure switch adjustment.

b. Check wiring connections between pressure switch and burner.

c. Check pressure switch for continuity across terminals, during venter operation.

2. Venter does not activate when thermostat or wall switch calls for heat.

a. Check wiring.

3. Flue gas odor.

a. Check system draft.

b. Check for negative pressure in building.

MAINTENANCE

1. Motor: Inspect motor once a year, the motor should rotate freely.

2. Wheel: Inspect venter wheel annually to clear any soot, ash or coating which inhibits either rotation or air flow.

Remove all foreign material before operating.

3. Vent System: Inspect all vent pipe connections annually for looseness and for evidence of flue gas leakage. Seal or

tighten pipe connections if necessary.

Page 3

Page 4

INSTALLATION INFORMATION

MODEL NO.:____________________________________________________________

CK-81

INSTALLER'S NAME:_____________________________________________________

INSTALLER'S COMPANY: _________________________________________________

INSTALLER'S PHONE NO.: ________________________________________________

DATE OF INSTALLATION:_________________________________________________

Page 4

P/N 46161700 Rev B 06/04

Loading...

Loading...