Page 1

24 VAC SYSTEM CONTROL KIT

Model: CK-51

Designed for use on SWG Series Power Vent Hoods for controlling Natural

Gas and L.P. Gas State Industries water heaters.

ITEMS INCLUDED IN KIT:

1) Junction box with mounted pressure switch and relay base.

1) 24 VAC Relay

1) Ft. Length of 1/4 inch aluminum tubing

1) 1/4 inch tubing connector

1) Flexible conduit connector

1) GSK-3 Spillage Switch

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

Page 2

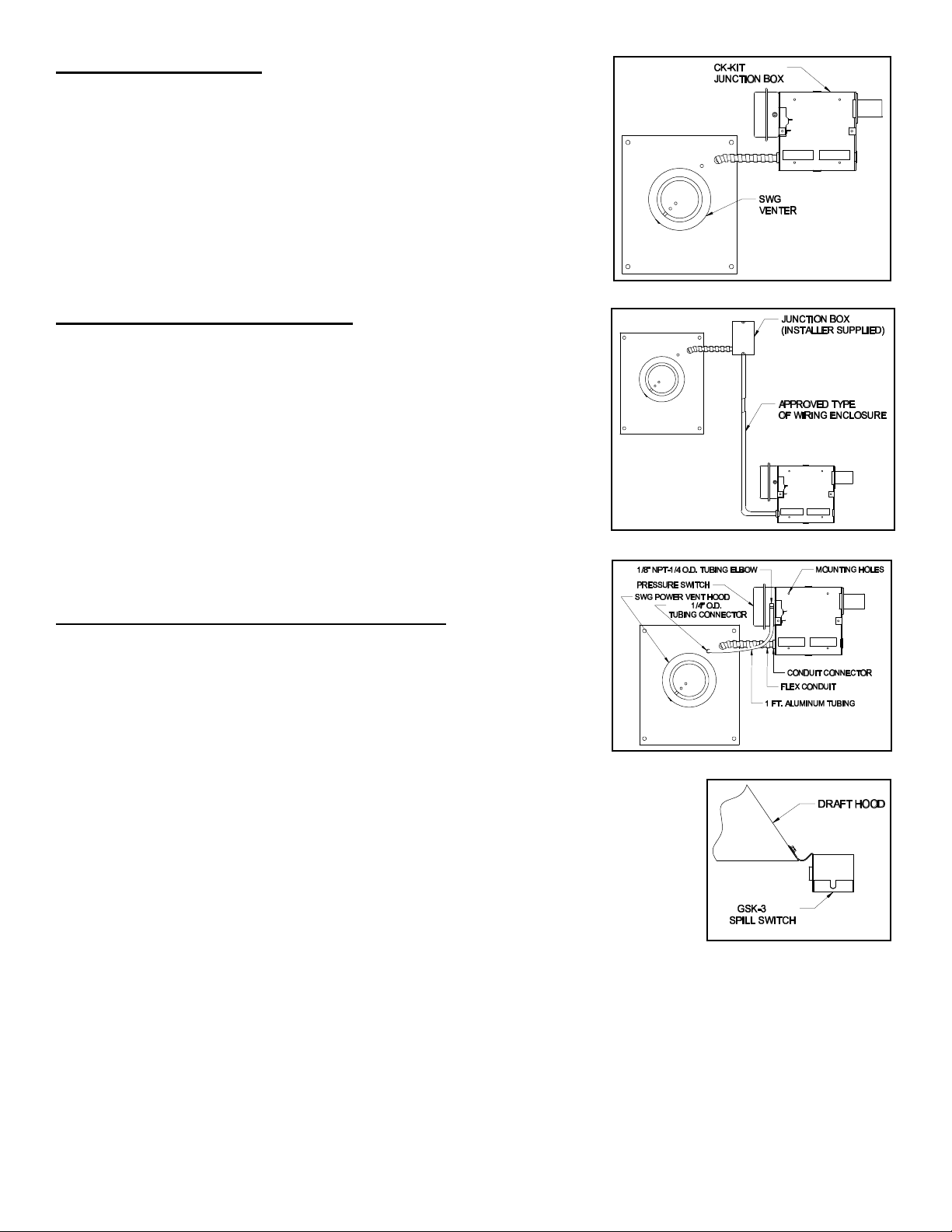

MOUNTING JUNCTION BOX

The junction box can be mounted at the venter or remotely mounted away

from the venter. (See Figure 1 & Figure 2)

1. Remove one of the knockouts from the side of the junction box where the

pressure switch is mounted. Install the flexible conduit connector onto the

CK-51 junction box and secure with fastening nut. If remote mounting the

CK-51 junction box, mount the flexible conduit connector onto a 2" x 4"

installer supplied junction box.

2. Fasten the flexible conduit from the SWG Venter into the conduit

connector. Mount the CK-51 junction box or installer supplied junction box

onto the wall or floor joist without straining the flexible conduit. Fasten the

CK-51 junction box through the four dimpled locations on the base of the

box. (See Figure 3)

GSK-3 SAFETY SWITCH INSTALLATION

Installation of a secondary SAFETY SWITCH is recommended by LP and

Natural gas fired systems with a draft hood. This device is installed to detect

flue gas spillage from a blocked flue system and/or inadequate draft.

1. Mount spillage switch on the draft hood. (See Figure 4)

2. Route lead wires along the appliance wall with an accepted wiring

enclosure in accordance with the National Electrical Code and applicable

local codes, keeping the wires away from any HOT surface area.

3. Wire the safety spillage switch into one side of the thermostat circuit.

Refer to unit wiring instructions.

4. After installing the safety spillage switch, check the amperage through the

thermostat circuit and adjust the thermostat anticipator accordingly.

CAUTION: If for any reason the system has shut down during operation, the

cause of the system failure should be investigated and corrected before

resetting the safety switch and restarting the system.

PRESSURE SWITCH SENSING TUBE INSTALLATION

1. Attach the 1/4 inch tubing connector to the pressure tube on the SWG

Venter. (See Figure 3)

2. Connect the supplied 1/4" aluminum tubing to the tubing connector.

Route the tubing to the CK-51 junction box and connect the tubing to the

pressure switch. When routing the tubing, avoid kinking the tubing by

bending the tubing too sharply.

For remote mounted CK-51 Junction Box, use a 1/4" OD copper, aluminum or

plastic tubing and route the tubing to avoid contact with any heat source.

Refer to the SWG Venter Installation Instructions for setting system airflow.

Figure 1

Figure 2

Figure 3

Figure 4

Page 2

Page 3

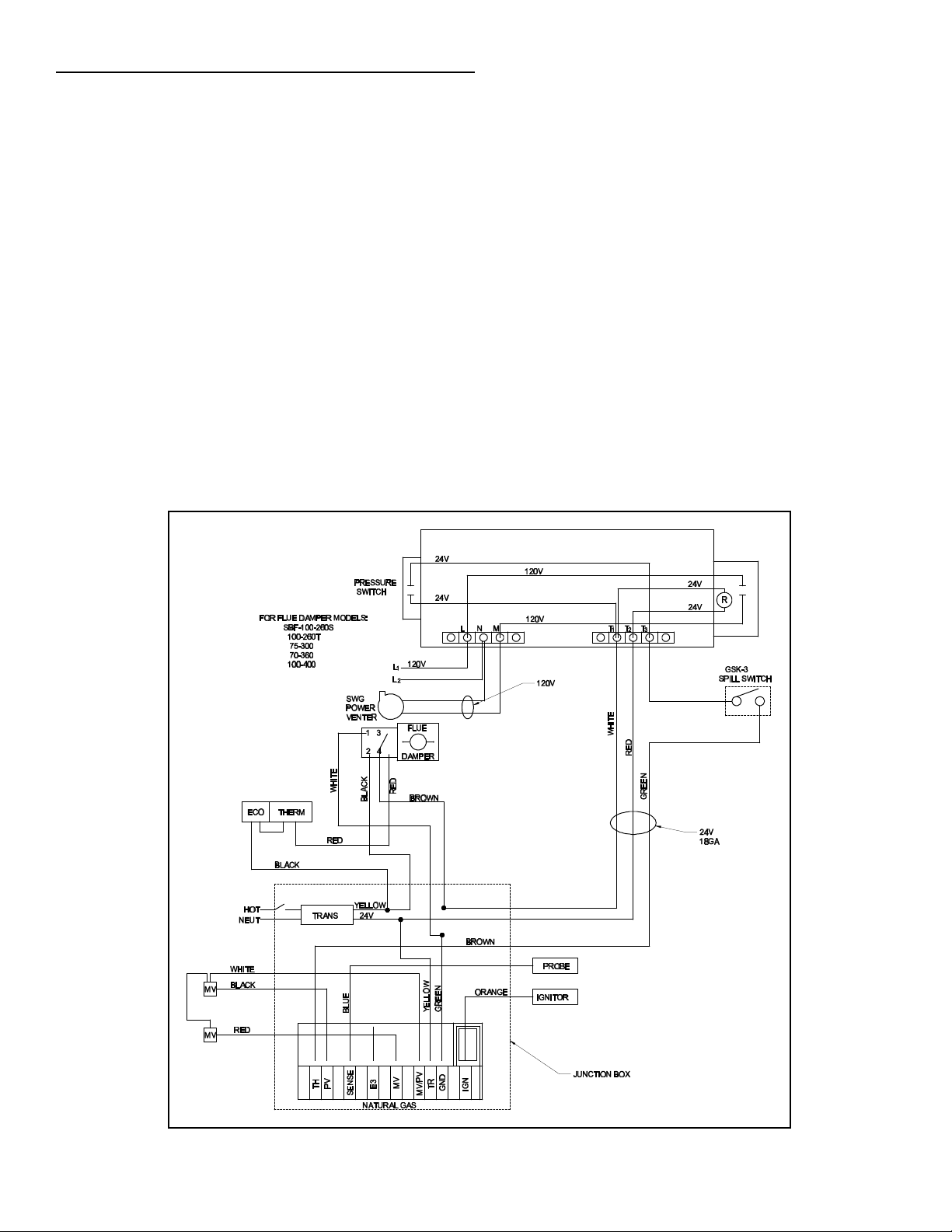

WIRING (See Diagrams A-C State Industries Water Heaters)

Diagram A

Wire the venter motor and controls in accordance with the National Electrical Code, manufacturer's recommendations

and/or applicable local codes. UNITS MUST BE GROUNDED. Check ground circuit to make certain that the unit has

been properly grounded. The wiring should be protected by an over current circuit device rated at 15 amperes. CAUTION

must be taken to ensure that the wiring does not come into contact with any heat source. All line voltage and safety

control circuits, between the venter and the appliance, MUST be wired in accordance with the National Electrical Code for

Class I wiring or equivalent methods.

NOTE: Route low voltage wiring through the supplied plastic grommet.

MINIMUM LINE VOLTAGE WIRE NO. 14 AWG

1. You must provide all wiring of the proper size outside of the water heater. You must obey local codes and electric

utility requirements when you intall this wiring.

2. This water heater must be electrically ‘grounded” by the installer. Using a screw on the water heater junction box, a

wire must be run to connect the water heater to an uninterrupted metallic ground.

3. This appliance must be electrically grounded in accordance with local codes or, in the absence of local codes, with the

latest edition of the National Electrical Code ANSI/NFPA No. 70.

NOTE: If any of the original wire as supplied with the water heater must be replaced, it must be replaced with 105°C

thermoplastic AWM wire or its equivalent.

Models: F75-120, F75-140, F30-150, F80-180, F30-199, F80-199, F100-199ES, F100-199ET, F30-225, F75-250, F100260ES, F100-260ET, F75-300, F70-360

NATURAL AND PROPANE (L.P.) MODELS

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

Page 3

Page 4

Diagram B

Page 4

Page 5

Diagram C

Page 5

Page 6

PRESSURE SWITCH ADJUSTMENTS

With the venter airflow set and the appliance operating at the best operating

efficiency, adjust the pressure switch by rotating the adjustment screw

clockwise until the burner shuts off, then rotate the adjustment screw

counterclockwise until the burner fires. Rotate the adjustment screw an

additional 1/4 turn counterclockwise to ensure proper switch setting. (See

Figure 5)

SYSTEM CONTROL CHECK OUT PROCEDURES

1. Adjust the thermostat to call for heat and observe the power venting

system for proper operation sequence (Repeat if necessary).

a. Thermostat calls for heat.

b. Relay is energized and venter motor starts.

c. Pressure switch closes and burner starts.

d. Thermostat is satisfied burner and venter motor stop.

2. While system is operating disconnect power to the venter motor. This should open the pressure switch contacts and

stop burner operation.

3. (If GSK-3 switch is installed) Allow vent system to cool. Disconnect the vent pipe between the venter inlet and the

appliance outlet. Block the vent pipe with a noncombustible material. Activate the heating system with the main

burner operating. Allow approximately 2 minutes or less for the secondary safety switch to deactivate the burner.

Reset safety switch and repeat.

TROUBLE SHOOTING HINTS

1. Main burner does not fire when thermostat calls for heat with venter operating.

a. Check pressure switch adjustment.

b. Check wiring connections between pressure switch and burner.

c. Check pressure switch for continuity across terminals, during venter operation.

2. Venter does not activate when thermostat calls for heat.

a. Check wiring.

b. Check relay for proper operation.

3. Flue gas odor.

a. Check system draft.

b. Check for negative pressure in building.

MAINTENANCE

1. Motor: Inspect motor once a year, the motor should rotate freely.

2. Wheel: Inspect venter wheel annually to clear any soot, ash or coating which inhibits either rotation or air flow.

Remove all foreign material before operating.

3. Vent System: Inspect all vent pipe connections annually for looseness and for evidence of flue gas leakage. Seal or

tighten pipe connections if necessary.

Figure 5

Page 6

Page 7

INSTALLATION INFORMATION

MODEL NO.:_____________________________________________________________

INSTALLER'S NAME:______________________________________________________

INSTALLER'S COMPANY:__________________________________________________

INSTALLER'S PHONE NO.:_________________________________________________

DATE OF INSTALLATION: _________________________________________________

CK-51

Page 7

Page 8

Page 8

P/N 46298500 Rev A 01/01

Loading...

Loading...