Page 1

COMBUSTION AIR SYSTEM

Model: CAS-2B, 2C & 2W

AIR BOOT™

4” VRV

4” IAH HOOD

ITEMS INCLUDED IN KIT:

1 - Air Boot™

1 - Set of Gaskets

1 - 4” VRV

1 - 4” IAH Hood

1 - Burner Coupling Set

2 - Mounting Bolts

1 - Flow Restrictor Pan (CAS-2B ONLY)

This product is designed for use on the following burners, for the purpose of routing

combustion air directly to the burner, with the added safety feature of the vacuum relief valve.

NOTE: For burner inputs up to 2.0 GPH at 100 PSI input pressure or equivalent.

This device MUST be installed by a qualified agency* in accordance with the manufacturer’s

installation instructions.

The definition of a qualified agency is: any individual, firm, corporation or company which

either in person or through a representative is engaged in, and is responsible for, the

installation and operation of oil appliances, who is experienced in such work, familiar with all

the precautions required, and has complied with all the requirements of the authority having

jurisdiction.

“The Air Boot™ models CAS-2B, CAS-2C and CAS-2W are for use only on the designated

burner(s) as described in these instructions only when the specific burner includes this Air

Boot™ when shipped from the burner manufacturer or where the burner instructions

specifically reference the models CAS-2B, CAS-2C or CAS-2W Air Boot™ as an optional air

intake system .”

NOTE: This product brings combusti on air only to the burner; must have adequate venting air

in accordance with NFPA-31.

CAS-2B BECKETT-AF/AFG

CAS-2C CARLIN-EZ-1/CRD/FRD

CAS-2W WAYNE-MSR

2630 Airport Road · Kinston, NC 28504

Phone: 252-522-3031· Fax: 252-522-0214

www.fieldcontrols.com

INSTALLER SUPPLIED ITEMS:

Duct Piping and Elbows

90° Elbows;

¼ “ NPT Female x ¼” NPT

Male for routing oil line

Page 2

THE PURPOSE OF THE VRV

The Vacuum Relief Valve is a

safety device to guard against

combustion problems

associated with directly

connecting oil burners to the

outside. Typical problems can

be caused by blockage of the

intake termination, icing up of

the duct work and effects of

leeward side wind effects on a

building.

VRV O

PERATION

The VRV gate operates on

changes in the vacuum

pressure generated by the inlet

to the oil burner. The VRV gate

will remain closed during

normal burner operation.

During an abnormal operation

(i.e., blockage of the intake or

change in external building

pressures) an increased

negative pressure on the intake

of the burner causes a

reduction in burner air flow.

Under this condition, the VRV

gate opens, stabilizing and

maintaining proper air flow to

the burner. The VRV gate

closes again once the

abnormal condition is

corrected.

INSTALLATION

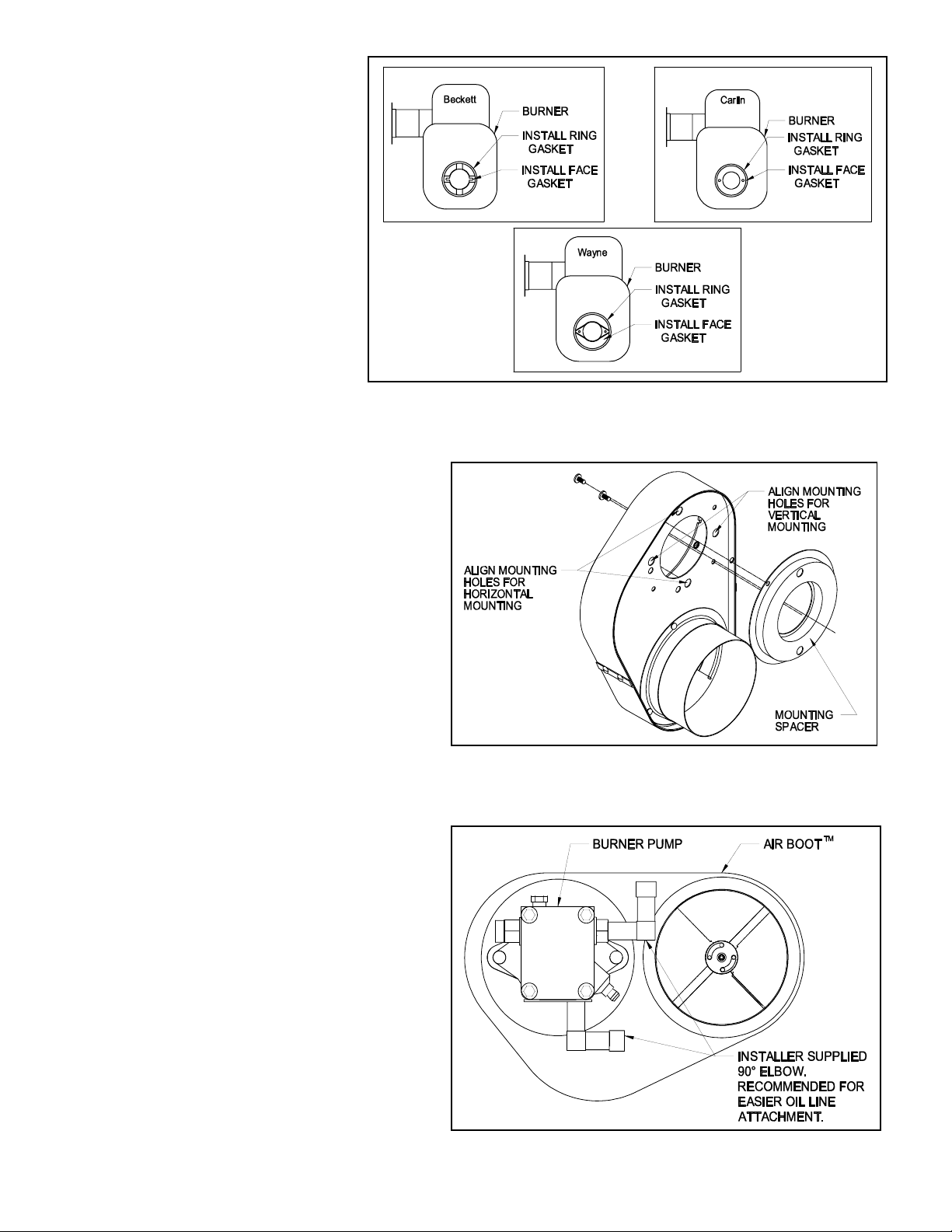

Figure 1

Figure 2

1. Remove the oil pump and air

bands from the burner housing.

Install the sealing gaskets

onto the burner housing.

Failure to install the ring

gasket onto the burner

housing will result in unlevel

boot, noisy operation, and

improper CO

2

readings. (See

Figure 1) Install mounting

spacer onto Air Boot™. (See

Figure 2) Position the Air

Boot™ over the burner

housing on the intake. The Air

Boot™ can be mounted onto

the burner in a horizontal or

vertical position. Install

mounting spacer onto Air

Boot™. Align the holes in the

Figure 3

Page 2

Page 3

Air Boot™ with the holes in the

housing and re-attach the oil pump.

(See Figure 3) Important: Replace

pump coupling with the coupling

supplied with kit or pump operation

problems may occur. Note that the

Air Boot™ may be oriented either

vertically or horizontally as space

allows. The round spacer plate

attached to the Air Boot™ must be

removed and rotated 90° if vertical

mounting is needed.

2. FOR LOW FIRING RATE

APPLICATIONS WITH BURNER

INPUTS UP TO .75 GPH (CAS-2B

ONLY)

a. Insert flow restrictor pan in the

inlet collar with the flat of the

pan inward. (See Figure 4)

b. Push the pan in all the way,

approximately 5/8” from the air

adjustment blades. (See Figure

5)

Mount VRV tee assembly or

90° elbow onto the Air Boot™

intake. Fasten using three (3)

sheet metal screws spaced

120° apart on all joints. (See

Figure 6)

Figure 4

3. Assemble VRV balance weight

onto the gate. Screw the weight all

the way in. Then attach lock nut

and knurl nut. (See Figure 7)

4. Mount the VRV assembly onto the

tee and fasten with a screw and

nut in collar tabs. To ensure

proper operation, check the gate

for being level across the pivot

points and plumb. (See Figure 8)

5. Refer to Figure 9 for general

installation layout.

T

ERMINATION LOCATION GUIDELINES

1. Mount intake hood 12 inches above

finished grade. If mounting on the

side of a building prone to drifting

snow, mount 12 inches above the

snow line.

2. Mount at least 12 inches from either

side of the vent termination and on

the same wall if sidewall venting.

Figure 5

Figure 6

3. Always mount with the inlet vent termination opening pointing down.

NOTE: Make sure hood is kept free of debris.

Page 3

Page 4

INLET VENT TERMINATION INSTALLATION

1. Cut a 4-1/4” diameter hole through the sidewall of the building.

2. Slide the inlet vent pipe through the hole and fasten to the wall with appropriate fasteners. Seal the

edges of the mounting plate with a silicone sealant or equivalent.

Figure 7

Figure 8

Figure 9

Page 4

Page 5

DUCT WORK INSTALLATION

1. Duct length distance, a maximum of 30 linear feet of standard duct pipe and two (2) 90° elbows at

maximum firing rate. Subtract 7 feet from the maximum linear feet for every 90° elbow added.

Longer pipe lengths require the use of a larger pipe between the VRV and the intake

hood. It also requires the use of a vent pipe increaser at the VRV and a reducer at the

intake hood. (See Table 1)

Table 1

Pipe

Diameter

Maximum Equivalent

Pipe Feet (between Air boot™

and duct termination)

Elbow*

Equivalent

Feet

Reducer or

Increaser

Equivalent Feet

4” 44’ 7’ 5” 60’ 9’ (4” to 5”) 3’

6” 90’ 11’ (4” to 6”) 6’

*Note: Subtract the elbow or reducer equivalent feet from the maximum

equivalent feet to get maximum linear feet of pipe.

2. Route the duct work from the VRV tee to the inlet vent termination with as minimum a number of

elbows as possible.

3. Secure and support the duct work for the design and weight of the material used, to prevent physical

damage and separation of joints. For guidelines refer to recognized national building codes or

according to any local codes.

4. To reduce uncontrolled air leakage into the duct, tape all joints and seams using standard duct tape.

NOTE: Try to run a minimum of 12 feet of duct to help temper the outside air being brought into

burner.

AIR ADJUSTMENT

1. Adjust the air adjustment knob on the side of the Air Boot™ (See Table 2) to rough air setting.

NOTE: For proper burner operation, burner should be set up by using a combustion analysis

test set.

Table 2

2. Start the burner and adjust the air control as needed to achieve the required CO

fire draft to appliance manufacturers’ specifications (typically -.02” of water). Secure air control knob with

indicator bracket. If draft levels are not obtainable or controllable, use standard industry methods to control the

draft or call the Field Controls Tech Line at 1-800-742-8368 for more information, or check the website at

www.fieldcontrols.com.

ROUGH AIR SETTING

GPH

CAS-2B CAS-2C CAS-2W

.75 25° 15° 70°

1.00 60° 25° 90°

1.50 160° 105° 135°

Knob Setting

and smoke levels. Set over

2

3. Next, adjust the VRV gate by screwing the adjustment weight in until the VRV gate is just closed.

4. Re-check the burners operation and adjust accordingly.

5. Lock the adjustment weight in position by tightening the hex nut on the VRV gate.

Page 5

Page 6

TROUBLE SHOOTING

PROBLEM:

Low CO2 after AIR BOOT™ installation.

Solution:

1. Burner gaskets improperly installed. Check ring gasket to burner housing.

2. Flow restrictor pan not installed on Beckett Burners only with inputs to .75 or less.

PROBLEM:

Pump coupler failure or noisy right after installation.

Solution:

1. Oil pump mounting bolts are over torqued or unevenly torqued.

2. Face gasket has been installed unevenly.

3. Check burner fan wheel. It may be out of balance. Probably bent and needs to be

replaced.

4. Supplied coupling was not installed.

REPLACEMENT PARTS

The following items are available for replacement, if needed. In order to replace these parts, power

must be disconnected and the unit must be disassembled. If this is necessary, take note of the

positions and locations of whatever items that may need to be removed to replace other items. If in

doubt, please consult the Field Controls Technical Support at 1-800-742-8368.

Item Description Field Part Number

VRV-4 46257100

IAH-4 46292000

Page 6

Page 7

NOTES:

Page 7

Page 8

INSTALLATION INFORMATION

MODEL NO.: _____________________________________________________

CAS-2B, 2C, or 2W

INSTALLER'S NAME:______________________________________________

INSTALLER'S COMPANY: __________________________________________

INSTALLER'S PHONE NO.: _________________________________________

DATE OF INSTALLATION:__________________________________________

Page 8

PN 46273500 Rev E 10/06

Loading...

Loading...