Page 1

OIL VENT DAMPER SYSTEM

4

Model: OVD - 4 through 8

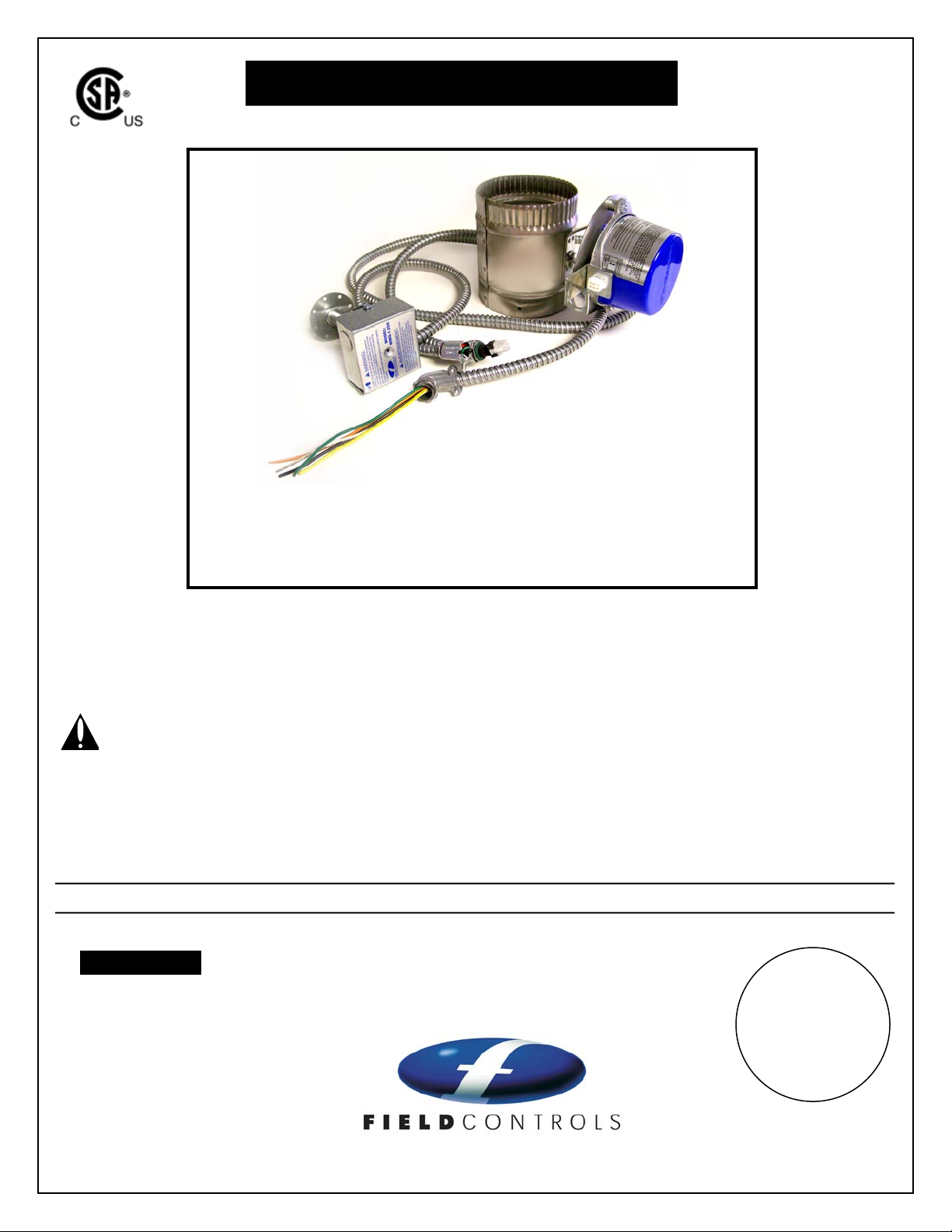

Items Included: 1) Oil Vent Damper Assembly

1) WMO-1 with gasket

1) Wiring Harness

Listed to UL-17 Standard and CSA B140.1

Field Controls (OVD) oil vent damper reduces off cycle losses through oil fired heating appliances. When the

appliance is in a standby mode, heat escapes up the chimney. The heat comes from the appliance and the

conditioned space. To significantly reduce these losses, install a Field Controls Oil Vent Damper. The damper is

installed in the vent system between the draft control and chimney. The WMO-1 blocked vent safety shut off

installs between the draft control and appliance. When properly installed, the damper opens before the burner fires

and closes after the burner shuts off.

WARNING: The Oil Vent Damper CANNOT be used on an appliance that employs a constant burning

pilot.

The Field Controls Oil Vent Damper MUST be installed by a qualified agency in accordance with the

manufacturer’s installation instructions.

The definition of a qualified agency is: any individual, firm, corporation or company which either in person or

through a representative is engaged in, and is responsible for, the installation and operation of oil appliances, who

is experienced in such work, familiar with all the precautions required, and has complied with the requirements of

the authority having jurisdiction. The oil vent damper is designed to service one appliance only.

DO NOT DESTROY

AFTER INSTALLATION, THESE INSTRUCTIONS MUST REMAIN WITH THE EQUIPMENT FOR SERVICE OF THE APPLIANCE.

CAUTION

1. Read this manual carefully and completely.

2. Be sure to follow all procedures and safety inspections.

3. Do not over ride the action of any safety or operational controls.

Before installing the oil vent damper system:

Tape Plug

Here

2630 Airport Road · Kinston, NC 28504

Phone: 252-522-3031· Fax: 252-522-0214

www.fieldcontrols.com

Page 2

FEATURES

1. Service Switch – Holds damper open and allows the appliance to operate without the damper operating.

2. 18 month limited warranty on motorized assembly from manufactured date.

3. Two internal safety switches

4. Power open, power close – extends product life. Reduced electrical consumption

5. Metal shielded cable wire harness.

6. WMO-1 Blocked Vent Safety Shut Off

7. Flex Seal provides self cleaning action

8. Stainless steel pipe assembly.

OPERATION

When the oil heating appliance receives a call for heat, the damper rotates to the open position before the burner circuit is

energized. If the damper does not rotate to the open position, the burner circuit will not be energized and will not allow the

burner to fire. When the call for heat is satisfied the damper will remain open for approximately 3 minutes to allow the residual

flue gases to escape before closing. When properly installed, the electrical circuits in this product are designed not to override

the existing limit and safety controls of the appliance.

TO THE USER

For continued safe operation, the heating appliance should be inspected annually by a qualified service agency. It is

recommended that the homeowner should have the vent system and the damper device examined annually for deterioration

from corrosion or other sources. This inspection should be performed prior to each heating sea so n.

GENERAL INFORMATION

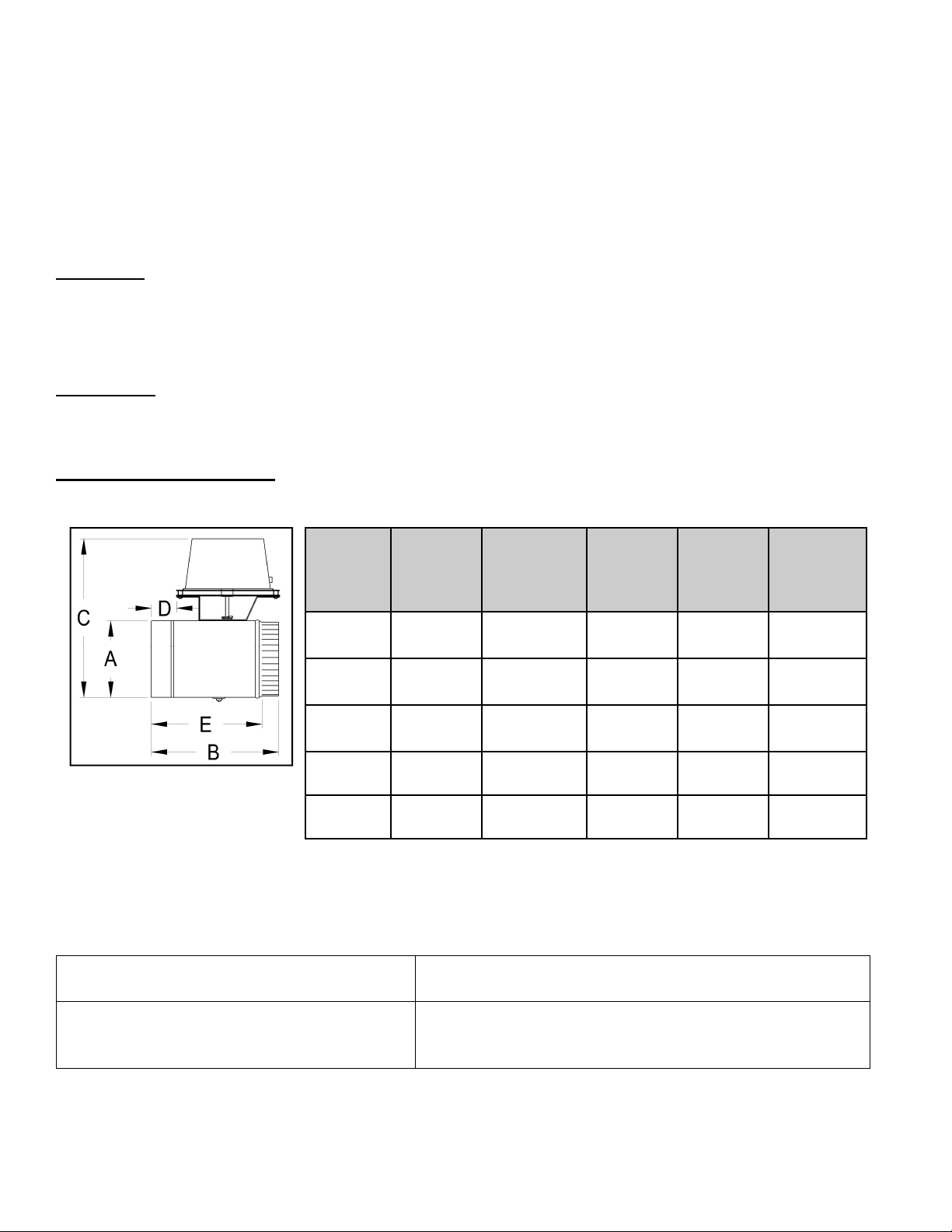

DIMENSIONAL DATA

Dim ‘A’

in inches

(102mm)

(127mm)

(152mm)

Figure 1

(178mm)

(203mm)

ELECTRICAL DATA

Burner and Transformer Electrical Rating

Timing

Pipe

Size

4

5

6

7

8

Dim ‘B’

Length

in inches

6

(152mm)

6 (

152mm)

6-1/2

(165mm)

7-1/16

(179mm)

8-1/16

(205mm)

Dim ‘C’

Total

Height

in inches

10-1/16

(256mm)

11-1/16

(281mm)

12-1/16

(306mm)

13-1/16

(332mm)

14-1/16

(357mm)

Burner motors rated up to 1/6 hp, 5.8 Amps

Ignition Transformer rated at 250 VA or less

Approximately 3 minute time delay to close

Dim ‘D’

in inches

15/16

(24mm)

15/16

(24mm)

1-1/8

(29mm)

1-3/8

(35mm)

1-7/8

(48mm)

5 sec, Power open

5 sec, Power close

Dim ‘E’

in inches

(127mm)

(127mm)

(140mm)

(154mm)

(179mm)

dimension

5

5

5-1/2

6-1/16

7-1/16

Pipe

removal

in inches

3-1/2

(89mm)

3-1/2

(89mm)

4

(102mm)

4-9/16

(116mm)

5-9/16

(141mm)

2

Page 3

PRE-INSTALLATION WARNINGS

1. The Field Controls Oil Vent Damper must be installed by a qualified agency in accordance with the

manufacturer’s installation instructions. The definition of a qualified agency is: any individual, firm, corporation

or company which either in person or through a representative is engaged in, and is responsible for, the

installation and operation of oil burning appliances, is experienced in such work, familiar with all the precautions

required, and has complied with all the requirements of the authority having jurisdiction. The oil vent damper is

designed to service one appliance only.

2. The qualified agency shall fill in the agencies name, address and installation date on the label attached to the

vent damper device.

3. The Field Controls automatic oil vent damper can only be installed on automatically operated oil appliances that

utilize atomizing power oil burners.

4. The Field Controls automatic oil vent damper must not be installed on oil appliances utilizing a direct vent

system, sealed combustion system or vaporizing type burners.

5. Do not override the action of any existing safety or operational controls.

6. When servicing controls, all wires must be LABELED prior to disconnection. Wiring errors can cause improper

and dangerous operation.

7. Device must be installed by a qualified agency, in accordance with the following standards:

In the US

• NFPA 31 Standard for the Installation of Oil -Burning Equipment

• NFPA 211 Standard for Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

• NFPA 70 National Electric Code

In Canada

• CSA B139 Installation Code for Oil Burning Equipment

• C22.1 Canadian Electrical Code Part 1

8. The maximum temperature of the selected location must not exceed 1000 degrees F (538°C) Measure the flue

gas temperature at the appliance flue collar.

9. Install downstream from the appliance draft control, as close to the draft control as practical, and without

modification to the draft control or the vent damper unit.

10. Locate the WMO-1 between the draft control and the flue collar of the single appliance for which it services.

11. Locate damper in a venting system or section of a venting system so that it services only the single appliance

for which it is intended.

12. A minimum clearance of 18 inches (457 mm) between the damper device and combustible construction must be

maintained and that there be provisions for access and service of the damper device.

13. Position indicator and service switch must be accessible to the user.

14. This device must be installed only on a oil appliance connected to a factory built chimney or vent system

complying with a recognized standards, or a masonry or concrete chimney lined with a lining material

acceptable to the authority having jurisdiction.

PRE- INSTALLATION INSPECTIONS

PROCEDURE FOR SA FETY INSPECTION OF AN EXISTING APPLIANCE INSTALLATION

The following procedure is intended as a guide to aid in determining that an appliance is properly installed and is in a

safe condition for continuing use.

This procedure is predicated on central furnace, boiler and water heater installations, and it should be recognized

that generalized procedures cannot anticipate all situations. Accordingly, in some cases deviation from this

procedure may be necessary to determine safe operation of the equipment.

1. This procedure shall be performed prior to installation of the automatic v ent damper system.

2. If it is determined there is a condition which could result in unsafe operation, the appliance should be shut

off and the owner advised of the unsafe condition. Do not install the automatic vent damper system until the

unsafe condition has been corrected.

3

Page 4

SAFETY INSPECTION

1. Conduct a visual leakage test of the oil appliance piping and control system downstream of the oil shutoff valve

in the supply line to the appliance.

2. Visually inspect the venting system for proper size, horizontal pitch and vent termination, and determine there is

no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

3. Determine that the chimney or vent is acceptable to the authority having jurisdiction.

4. Inspect burner, combustion chamber and flue passages for blockage and cor rosion.

5. Applicable only to furnaces

6. Applicable only to water heaters and boilers

7. Insofar as is practical, close all building doors and windows and all doors between the space in which the

appliance is located and other spaces of the building. Turn on clothes dryers, stove top barbecues and central

vacuum cleaners. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers. If, after completing Steps 9

through 12, it is believed sufficient combustion air is not available, refer to local codes or in the absence of local

codes, in the United States NFPA 31- Standard for the Installation of Oil Burning Equipment; NFPA 211- Stand ard

for Chimneys, Fireplaces, Vents and Solid- Fuel Burning Appliances for guidance. In Canada CSA B139

Installation Code for Oil Burning Equipment.

8. Place in operation the appliance being inspected. Follow the appliance manufacturer’s startup instructions.

Adjust the thermostat so appliance will operate continuously.

9. Adjust the air and head settings according to the burner appliance manufacturer instructions. Determine that

the burner is operating properly, by carbon dioxide co ncentration, flue gas temp erature and sm oke density tests.

Check the cadmium sulfide cell to determine it is operating properly.

10. Turn on all other fuel-burning appliances w ithin the same room so they will operate at their full inputs. Follow

start up instructions for each appliance.

11. Test for spillage at the draft control opening after 5 minutes of main burner operation. Use a match, candle or

smoke from a cigarette. Vent connected power atomizing oil burning equipment shall be operated for several

minutes and checked to see that the combustion products are going up the chimney, or vent. Take a draft

reading to assure the system over fire draft is according to the burner and appliance manufacturer instructions.

If the chimney or vent is drawing properly a negative pressure will be in the vent system. If not, the combustion

products will tend to be drawn out of the draft control. If the combustion products are escaping from the

opening of the draft control, the equipment should not be operated until proper adjustmen ts or repairs a re made

to provide adequate combustion air or draft through the chimney or vent system.

12. Repeat Step 11 on all other fuel burning appliances.

13. Return doors, windows, exhaust fans, fireplace dampers and any other fuel burning appliances to their p revious

conditions of use.

14. Applicable only to furnaces

appliance control manufacturer instructions for checking the fan and limit controls.

15. Applicable only to boilers

a. Determine that the water pumps are in operating condition.

b. Test low water cutoffs, automatic feed controls, and relief valves in accordance with the manufacturer’s

recommendations to determine they are in operating condition.

16. Applicable only to water heaters

with the manufacturer’s recommendations to determine they are in operating condition.

– inspect heat exchanger for cracks, openings or excessive corrosion.

– inspect for evidence of water or combustion product leaks.

– Check both the limit control and the fan control for proper operation. Follow the

–

– Test relief valve, combination aquastat and high limit control in accordance

UNPACKING INSTRUCTIONS

1. The Field Controls OVD Series Oil Vent Damper is packaged in a single carton. It contains an assembled OVD, a

prewired WMO-1 safety switch with fiber gasket and attached metal shielded cable w ire harness, instruction

manual and a vent plug.

2. Remove assembly and examine each component for possible dam age.

3. If damage is apparent do not install the oil vent damper system.

4

Page 5

INSTALLATION OF THE UNIT

WARNING: Install the oil vent damper system to service only the single appliance for

which it is intended. If improperly installed a hazardous condition such as an explosion

or carbon monoxide poisoning or death could result.

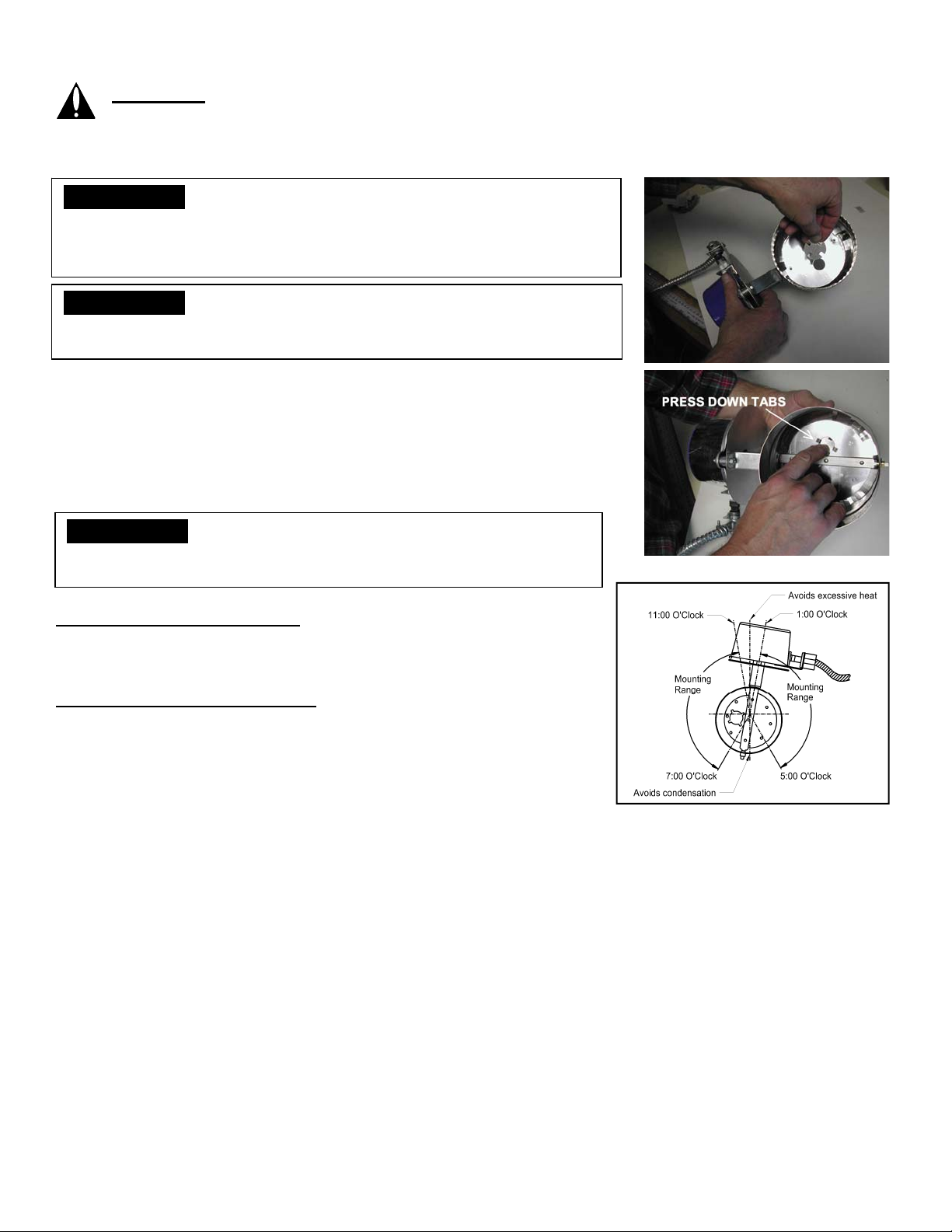

INSTALLATION OF THE VENT PLUG

CAUTION

nozzle after drip occurs, the plug may be removed to allow minimal

ventilation through the appliance burner. The ventilation helps to cool the

burner nozzle in the standby mode.

CAUTION

problems and minor property damage. Do not install the vent plug on s ystems

with a brick combustion chamber.

1. The vent plug is to be installed for a tight seal. To avoid motor assembly

damage, be careful not to turn the damper gate manually, while installing the

vent plug.

2. The vent plug is located on the front cover of this installation manual.

3. Insert the vent plug into the hole in the damper gate. To secure the vent plug,

bend the four tabs on the vent plug outward (See Figure 2).

The plug is installed for minimum leakage. If an odor or

Failure to follow these instructions can cause odor

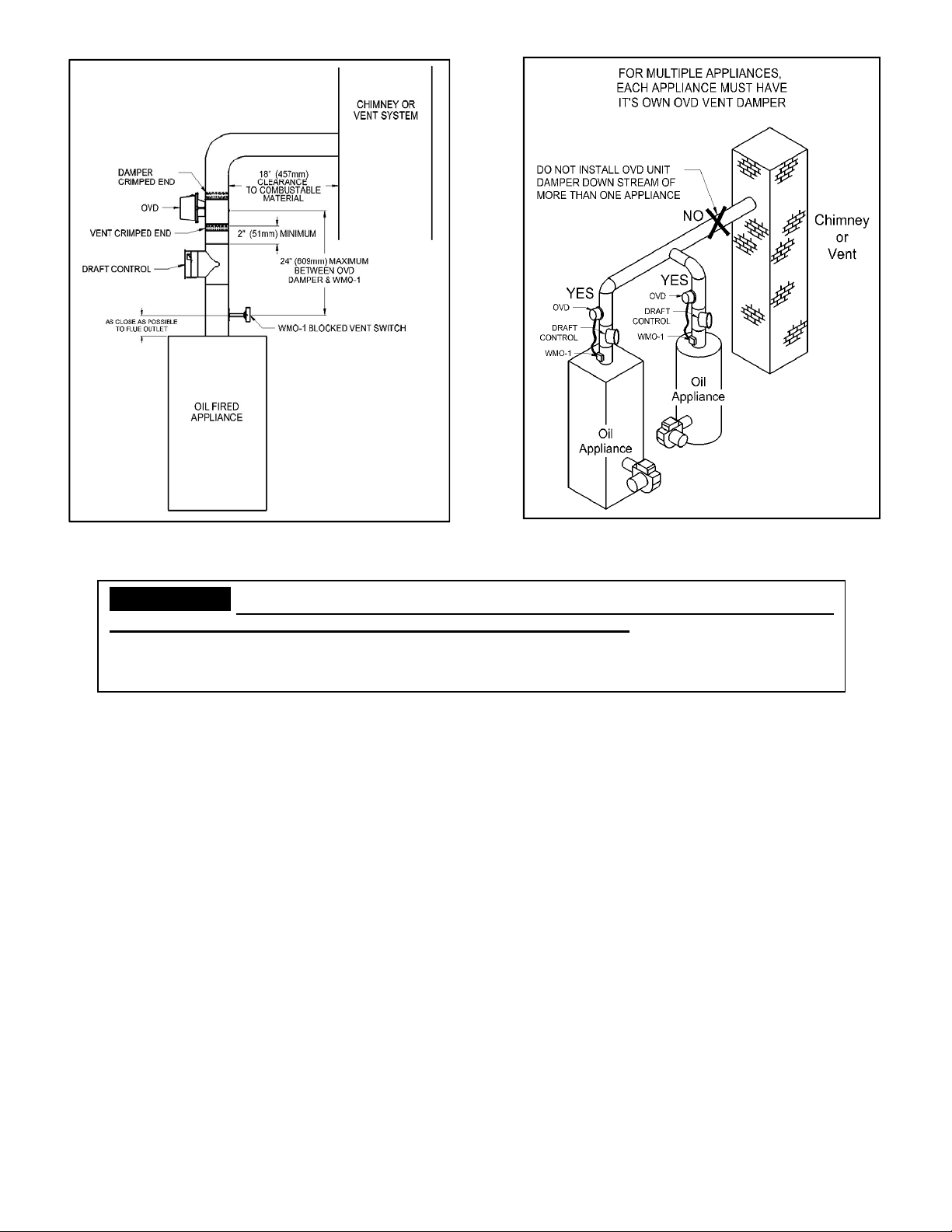

INSTALLATION OF THE VENT DAMPER

CAUTION

pipe that services a single appliance for which it is electrically connected

and controlled.

VERTICAL PIPE INSTALLATIONS: The oil vent damper is not position

sensitive. You may mount the vent damper in any position. Maintain a

minimum of 18 inches (457 mm) between the damper pipe surface and

combustible material.

HORIZONTAL PIPE INSTALLATIONS

vent damper refer to Figure 3. Avoid mounting the damper directly above

or below the vent pipe. We suggest 1:00 to 5:00 or 7:00 to 11:00 ‘o clock

positions. Maintain a minimum of 18 inches (457 mm) between the damper

pipe surface and combustible material.

1. Before starting the installation, turn off all electrical power to the

appliance at the appliance service switch or circuit breaker.`

2. Locate a position in the vent pipe between the draft control and

chimney for the damper device. Install the oil vent damper, as close to the draft cont rol as practical (within a

minimum of two inches from the draft control collar), without modification of either the draft control or the vent

damper device. (Layout A)

3. The WMO-1 Blocked Vent safety shut off must be installed between the appliance flue collar and draft control.

(NOTE: The metal shielded cable wire harness from the WMO-1 safety switch and vent damper is only 24 inches

(609 mm)). (Layout A) Wire harness plugs into motor assembly. Push and lock keyed wire harness into motor

assembly receptacle. Push and lock metal y-connector into strain relief bracket.

4. A minimum clearance of 18 inches (459 mm) between the vent damper pipe and combustible material must be

maintained and there must be provisions for access to service the oil vent damper system.

5. Remove the appropriate section of vent pipe connector on the downstream side of the draft control and shorten

the pipe to make clearance for the vent damper pipe (See Table 1 for proper dimensions and Layout B). If

needed, crimp the end of the vent pipe near the outlet of the draft control. The vent pipe and vent damper pipe

assembly joints should overlap 1¼ Inches (32 mm).

The vent damper system must be located only in the vent

Figure 2

: To avoid premature failure of the oil

Figure 3

5

Page 6

p

CAUTION

Layout A

Make sure not to egg shape the pipe assembly when installing, it can create binding

Layout B

of the damper gate and cause premature motor failure and nuisance calls. Install the vent damper with

the directional arrow and crimped end of the vent damper pipe pointed toward the chimney. Reinstall

the shortened length of vent pipe connector and vent damper. Position the motor assembly according

to the

osition limitation listed above.

6. Secure the oil vent damper to the vent pipe with 1/2 inch (13mm) sheet metal screws or pop rivets. The spacing

should be equally spaced 120° apart around the circumference. T hree fasters shall be used at th e inlet and outlet

of the pipe assembly. Be careful not to allow the fas teners to obstruct th e vent damper gate. It may be necessary

to provide suitable pipe hangers to support the oil vent damper independent of the venting sy stem.

7. Check the damper service switch on the side of the damper motor assembly and it’s in the automatic position.

8. Check to see the flat shaft is fitted into the motorized assembly. The flat shaft must have a factory installed

washer and cotter pin.

6

Page 7

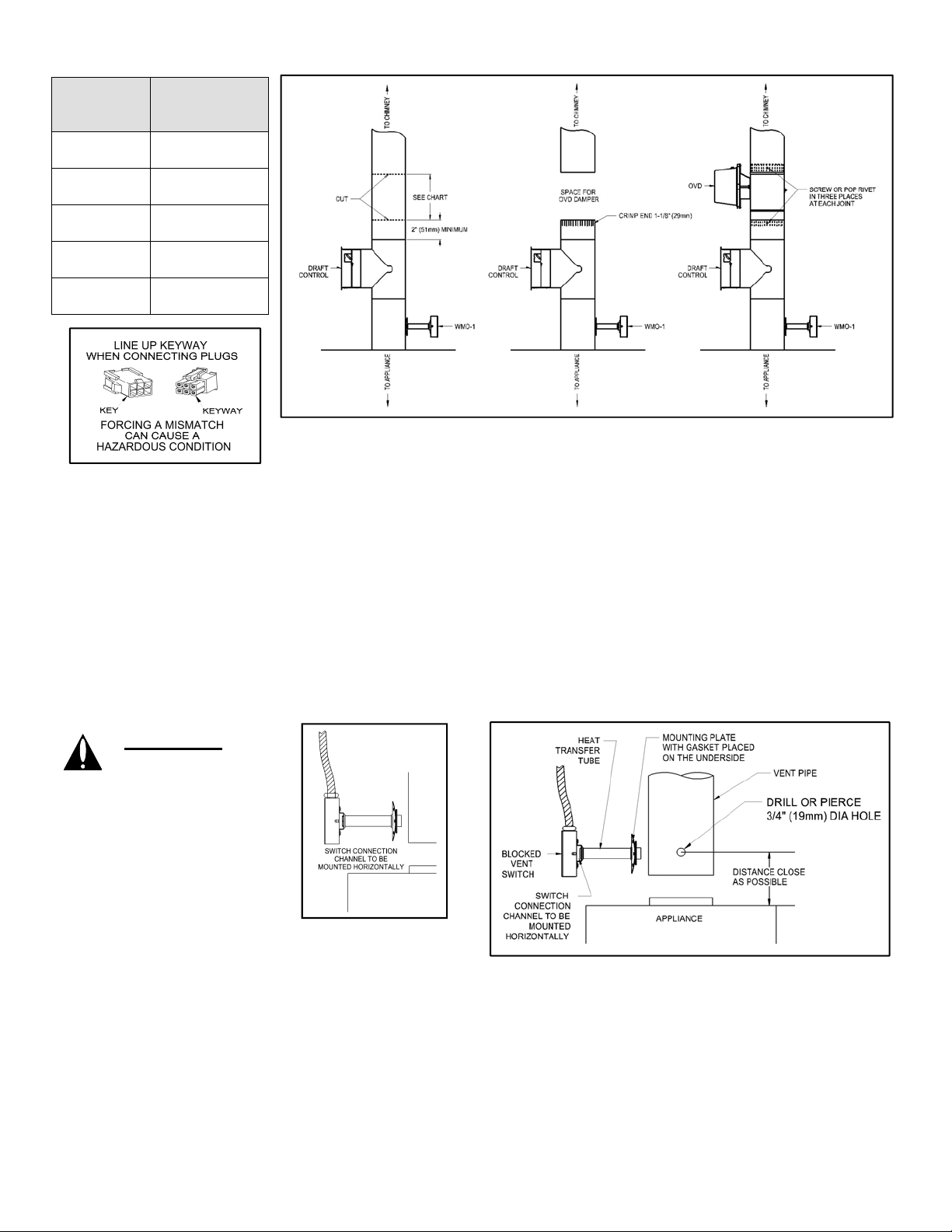

Dim ‘A’

Pipe Size

in inches

4

(102mm)

5

(127mm)

6

(152mm)

7

(178mm)

8

(203mm)

Pipe removal

dimension

in inches

3-1/2

(89mm)

3-1/2

(89mm)

4

(102mm)

4-9/16

(116mm)

5-9/16

(141mm)

Layout C

Keyway Diagram

INSTALLATION OF THE WMO-1 BLOCKED VENT SAFETY SHUT OFF

1. The WMO-1 Blocked Vent safety shut off must be installed between the appliance flue collar and draft control.

(NOTE: The metal shielded cable wire harness from the WMO-1 safety switch and vent damper is only 24 inches

(609 mm)). Wire harness plugs into motor assembly. Push and lock keyed wire harness into motor assembly

receptacle. (See Keyway Diagram) Push and lock metal y-connector into strain relief bracket.

2. Drill or pierce a 3/4” diameter hole in the vent pipe near the appliance outlet. (See Figure 4)

3. The heat transfer tube must have the fiber gasket installed against the mounting plate before attaching the unit

to the vent pipe. Insert the heat transfer tube with gasket into the 3/4” diameter hole.

4. Secure the assembly to the vent pipe with a minimum of 4 sheet metal screws. The channel must be mounted

horizontally, unless specified differently by the appliance manufacturer. (See Figure 4)

WARNING:

Switch connection

channel must be

mounted

horizontally, unless

specified differently

by the appliance

manufacturer.

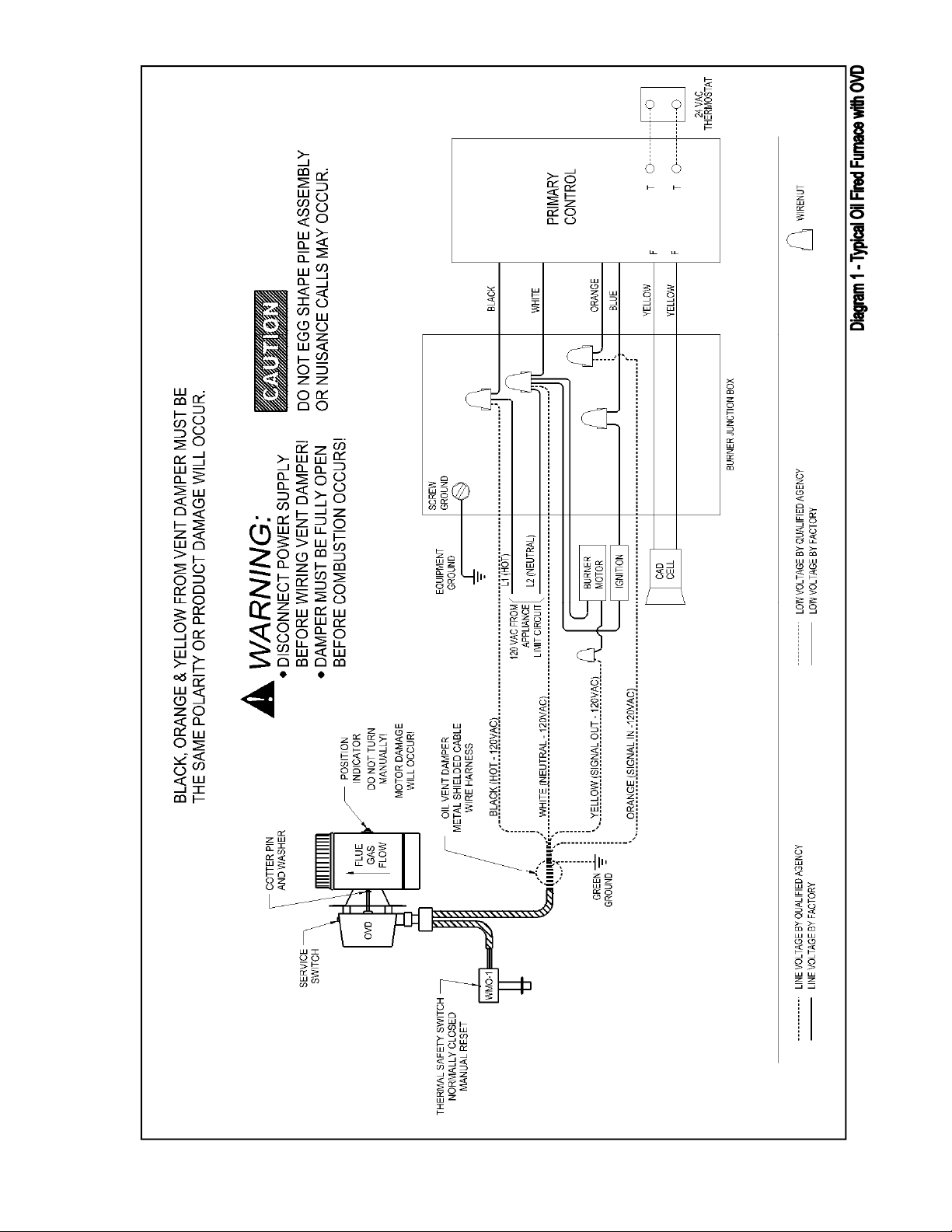

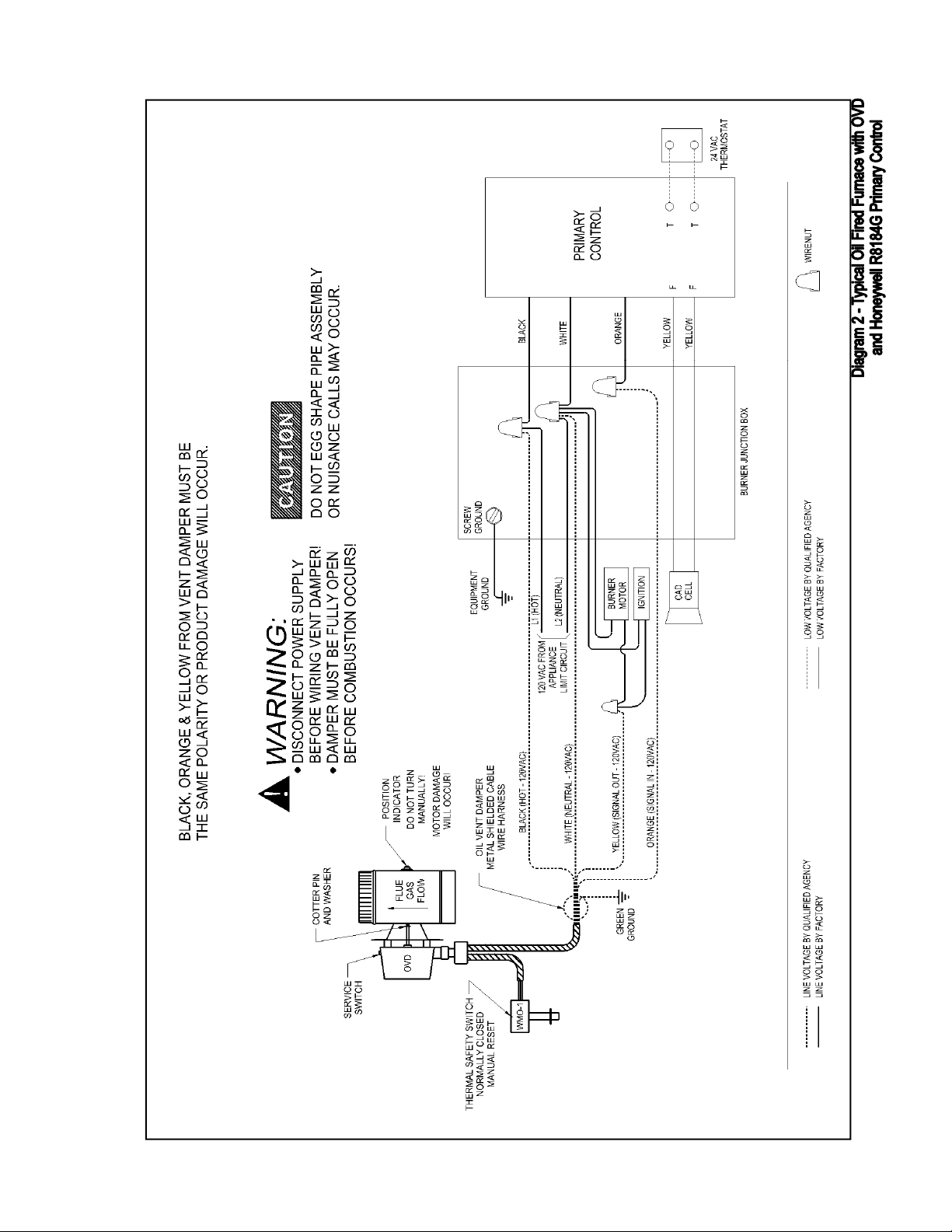

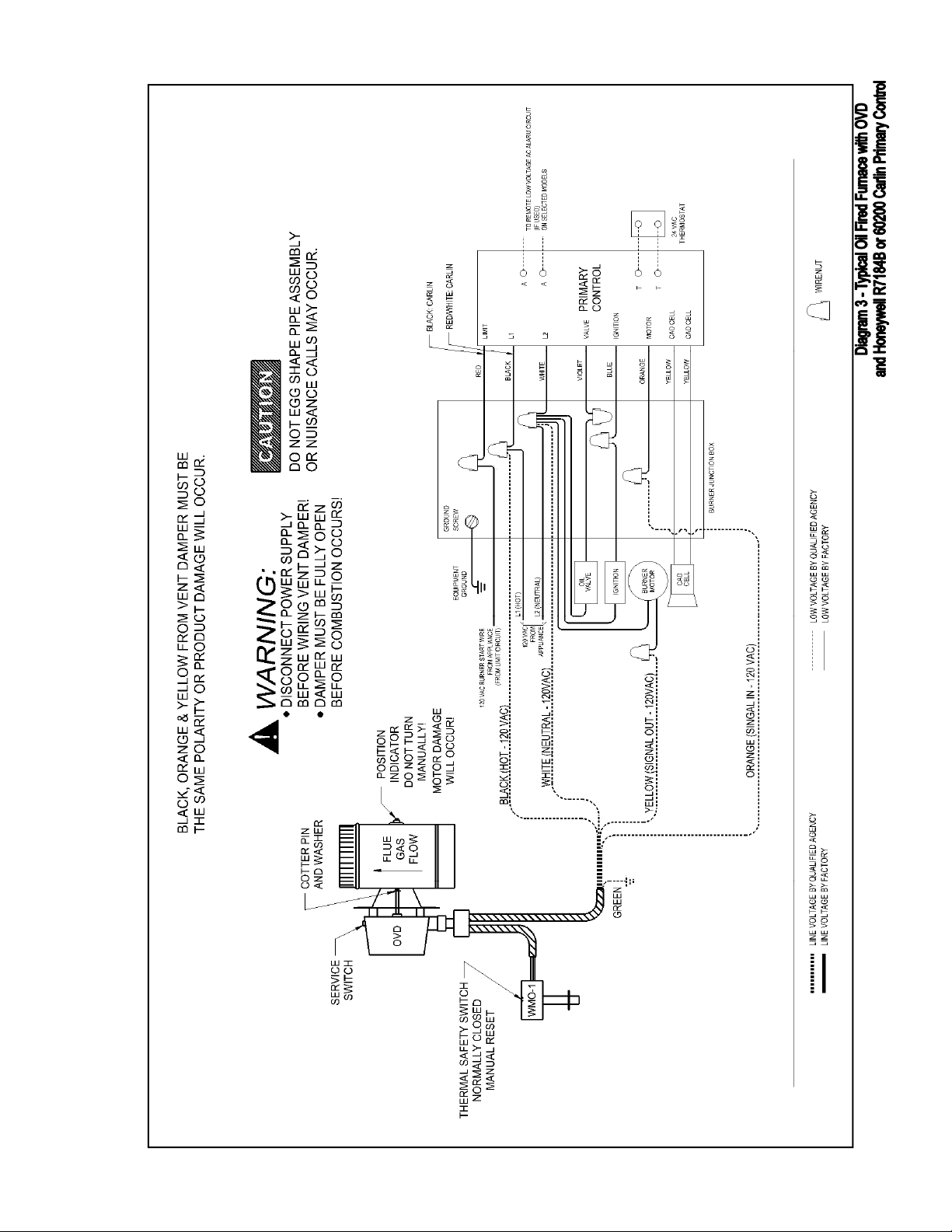

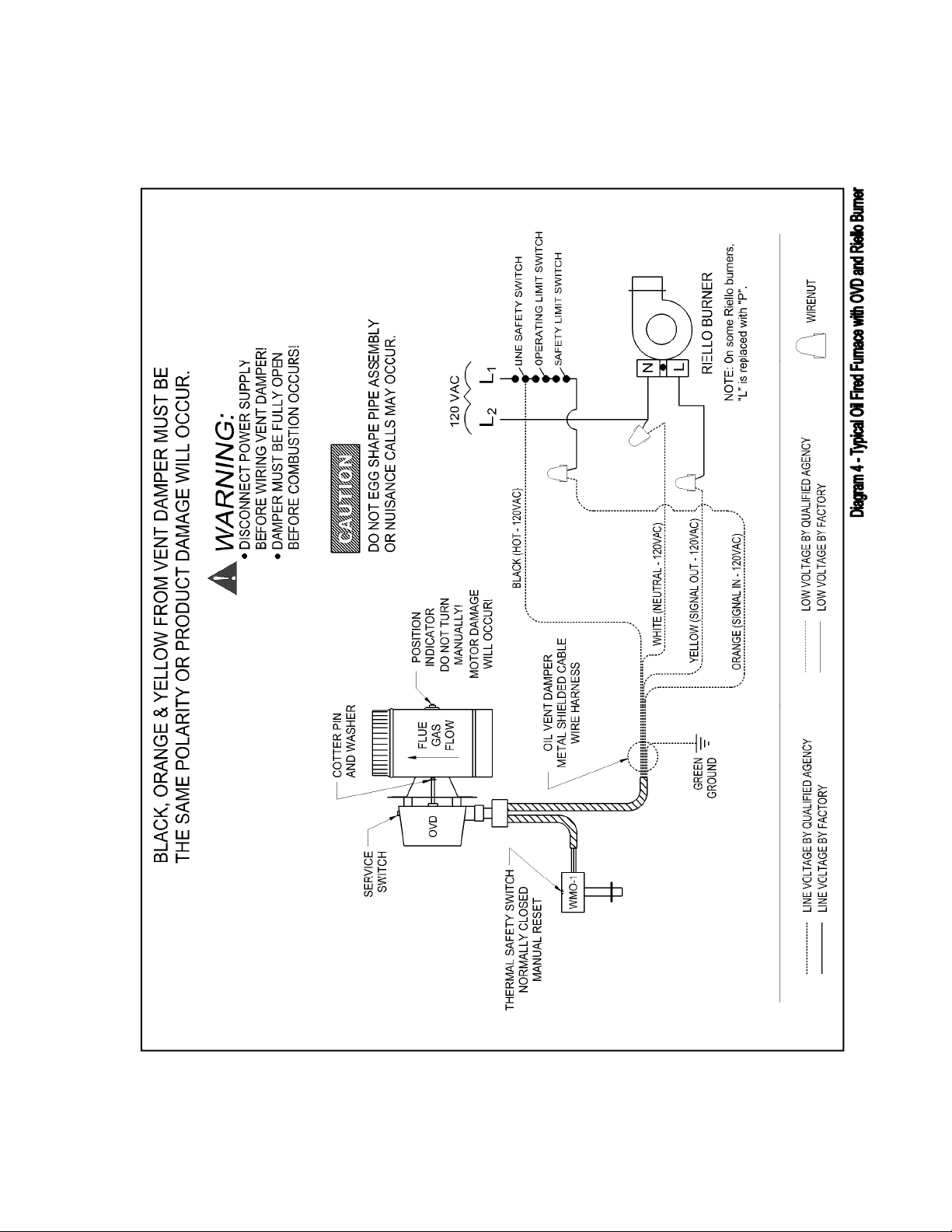

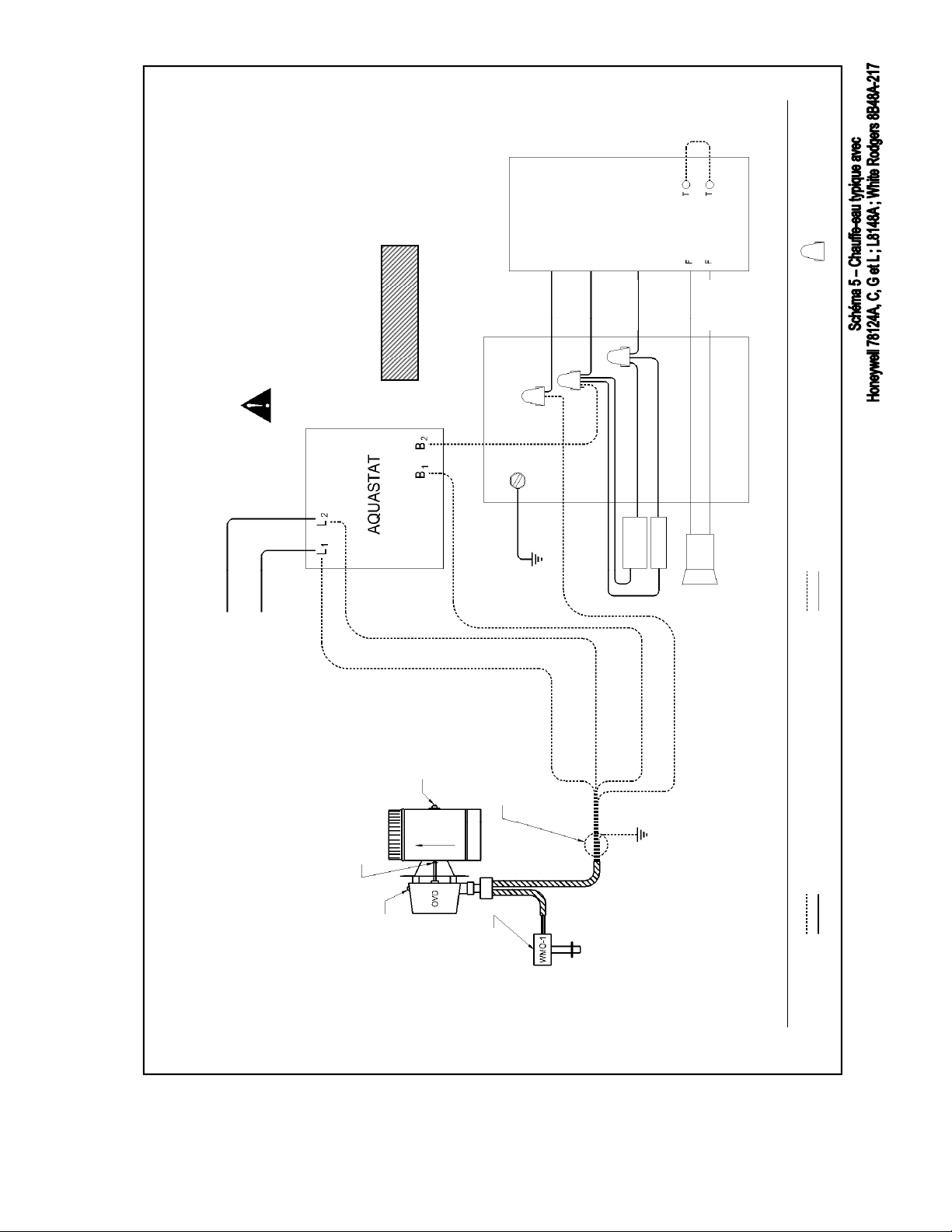

WIRING INSTRUCTIONS

Wire the vent damper and controls in accordance with the National Electrical Code, manufacturer's

recommendations and/or applicable local codes. THE UNIT MUST BE GROUNDED. Check ground circuit to make

certain that the unit has been properly grounded. The wiring should be protected by an over current circuit device

rated at 15 amperes. Caution must be taken to ensure that the wiring does not come into contact with any heat

source. All line voltage and safety control circuits, between the vent damper and the appliance, MUST be wired in

accordance with the National Electrical Code for Class I wiring or equivalent methods.

Figure 4

BEFORE STARTING WIRING, TURN OFF ALL ELECTRICAL POWER TO THE APPLIANCE AT THE

APPLIANCE SERVICE SWITCH OR CIRCUIT BREAKER!!

7

Page 8

8 9 10 11 12 13 14

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

MAINTENANCE

WMO-1

For continued safe operation, the appliance-switch combination is required to be inspected and maintain

annually by a qualified agency.

BLOCKED VENT SAFETY SHUT OFF

1. Disconnect power to the appliance.

2. Loosen the two screws holding on the WMO-1 blocked vent switch assembly cover.

3. Remove the cover.

4. Remove the screw holding the control box to the heat transfer tube assembly. Slide the control box

off the heat transfer tube assembly.

5. Carefully remove any buildup from the thermal switch surface. DO NOT DENT OR SCRATCH THE

SURFACE OF THE THERMAL SWITCH. IF THE THERMAL SWITCH IS DAMAGED, REPLACEMENT IS

REQUIRED

6. Check and remove any buildup or obstruction inside the heat transfer tube.

7. Remount, lock and refasten the control box with the screw removed in step 4.

8. Reattach the box cover and tighten screws loosened in step 2.

9. Re-establish power to the appliance.

.

Step 1 Step 2 Step 3

Step 4

Page 15

PROBLEM SOLUTION GUIDE

CAUTION

• When servicing controls, all wires must be labeled prior to disconnection. Wiring errors can cause

improper and dangerous operation.

• Do not turn damper open manually or motor damage will occur and Void the Warranty.

DO NOT CUT PLUG OFF OF DAMPER MOTOR ASSEMBLY OR THE WARRANTY WILL BE VOID.

WARNING: Do not negate the action of any existing safety or operational controls

Voltage readings are 120 VAC. Voltage readings are taken at the wire harness attached

where it attaches to the appliance. Make sure the vent damper service switch is in the

automatic position.

Normal Voltage Readings Note: Black, Orange & Yellow must be the same polarity

120 VAC POWER Power On Damper Position

White # 4 & Black #1 All Times Open or Closed

White # 4 & Orange # 2 Calling for Heat Open or Opening

White # 4 & Yellow # 3 During Combustion Damper Open

• White # 4 120 VAC Neutral

• BLACK # 1 120 VAC HOT

• ORANGE # 2 120 VAC SIGNAL IN TELLS VENT DAMPER TO OPEN

YELLOW # 3 120 VAC SIGNAL OUT ONCE VENT DAMPER IS OPEN

•

•

REMOVE 120 VAC SIGNAL FROM ORANGE # 3. DAMPER CLOSES IN APPROXIMATELY 3 MINUTES

NOTE: The first cycle to close may take up to 12 minutes. The capacitors must fully charge. Before Normal

closure times will occur.

CONDITION POSSIBLE CAUSE RECOMMENDED SOLUTION

Vent Damper Doesn’t Close

Do not turn damper manually.

Motor damage will occur.

Warranty will be Void!

1. Vent damper can take up to 12

minutes to close the first cycle. After

the first cycle it closes in

approximately 3 minutes.

2. Service switch in hold open position

3. Wired Wrong

4. Vent Damper Pipe is egg shaped

causing the internal gate to bind

5. Obstruction in damper pipe.

(a) Vent pipe is shoved in to far

(b) sheet metal screws over ½ inch

6. Loose or broken connection

7. Defective vent damper motor

assembly

1. Make sure service switch is in the

automatic position.

2. Review wiring diagrams

3. 120 VAC between White # 4 and

Black # 1 must be present to power

the damper closed. No power

should be between White # 4 &

Orange # 2.

4. Tighten, repair or replace

connection

5. Replace vent damper motor

assembly.

15

Page 16

Damper Sticks

Damper Rotates Continuously

CONDITION POSSIBLE CAUSE RECOMMENDED SOLUTION

No 120 VAC Between

White # 4 & Black # 1

No 120 VAC Between

White # 4 & Orange # 2

120 VAC Power Between

White # 4 & Black # 1

When Calling For Heat

120 VAC Power Between

White # 4 & Black # 1

120 VAC Between

White # 4 & Orange # 2

DAMPER OPEN

No 120 VAC Power

Between

White # 4 & Yellow # 3

Damper Open

No combustion

1. Something obstructing damper

blade.

2. Damper pipe egg shaped.

Out of round / binding.

3. Crimped end of vent pipe inserted

in too far.

1. Defective damper motor

assembly.

1. Off on high or secondary limit

2. Loose or broken connections.

3. Check fuse or circuit breaker.

4. Disconnect or emergency switch

off

5. Wired wrong see diagrams

6. Check Blower Door Switch

1. Thermostat not calling for heat.

2. Loose or broken connections.

3. Off / On operating limit, pressure

control or low water cut off.

4. Wired wrong

1. Loose or broken connection.

2. Off on Manual Reset

WMO-1 Blocked Vent Safety

3. Remove WMO-1 cover

120 VAC should be present

between each switch terminal

and the green ground wire.

4. Blocked Vent or Chimney

5. Insufficient Combustion Air

6. Insufficient Make Up Air

7. Defective WMO-1

8. Defective Damper Motor

Assembly.

1. Make sure damper gate is free of

all obstructions.

2. Adjust damper pipe or replace

vent damper.

3. Properly align and secure vent

pipe making sure damper gate

will NOT touch vent pipe.

1. Replace damper motor assembly.

1. Wait for limit to reset

2. Repair loose or broken connections

3. Replace fuse or reset circuit breaker

4. Turn on switch

5. Rewire according to diagram

6. Close blower door

1. Turn thermostat up to call for heat.

2. Replace thermostat

3. Tighten, repair or replace

connection.

4. Wait for the operating limit,

pressure control or lower water cut

off to close.

5. Revisit wiring diagrams

1. Repair or replace connection.

2. Manually reset WMO-1 safety

3. Check for Blocked or Insufficient

Vent or Chimney

4. Check for Adequate Combustion

Air

5. Check for Adequate Make Up Air

6. Replace WMO-1

7. Replace Damper Motor Assembly

16

Page 17

INTIAL BURNER AND VENTING SYSTEM OPERATIONAL INFORMATION

List the following for appliance operating with an OVD attached to its venting system, as a guide for

tune-up or service information annually.

Date

FOR OIL FIRED EQUIPMENT

Oil Burner Nozzle Size

Oil Burner Operating Pressure

Pump Operating Vacuum Pressure

Smoke Number

Over-fire Draft

Equipment Outlet Flue Gas Temperature

CO2 Measurement

17

Page 18

Limited Warranty

FieldControls,L.L.C.warrantsthatthefollowingFieldControls,L.L.C.productssoldhereunder,shallbefreefromdefectsin materialandworkmanshipunder

normaluseforeighteen(18)monthsfromdateofmanufacturingbytheconsumerexceptingtheprovisionsnumberedbelow.

Provisions:

1. Field Controls shall have no obligation in the

product(s)oraccuratedatecodeinformation.

2. Theproductmustbeproperlyinstalled,maintainedandoperatedundernormalconditions.

3. Field Controlsshallnotbe liablefor anyconsequential andincidentaldamages,resultingfromfailure

deliver, delay in delivery, delivery in nonconforming condition, or for any breech of contract or duty between Field Controls, L.L.C. and the

customer.

4. Field Controls,L.L.C.productsareoften intendedfor usein specificapplications.Field Controls,L.L.C.makesnowarrantyif

productisusedinapplicationsotherthanintended.

5. Field Controls, L.L.C. makes no warranty of any kind in regard to any othermanufacturer’s products distributed by Field Controls, L.L.C. Field

event the customer is unable to provide receipt showing the date the customer purchased the

ofaField Controls,L.L.C.product, failure to

aFieldControls,L.L.C.

18

46567100 Rev. A 01/09

Page 19

SYSTÈME DE REGISTRE D’ÉVACUATION POUR MAZOUT

Modèle : OVD – 4 à 8

Articles inclus : 1) Ensemble registre d’évacuation

1) WMO-1 avec joint

1) Faisceau de câbles

Homologué UL-17 et CSA B140.14

Le registre d’évacuation pour mazout (OVD) Field Controls réduits les pertes à vide à travers les appareils de

chauffage au mazout. Lorsque l’appareil est en mode de veille, la chaleur s’échappe par la cheminée. Cette

chaleur provient de l’appareil et de l’espace environnant. La pose d’un registre d’évacuation pour mazout Field

Controls permet de réduire ces pertes de façon significative. Le registre se pose dans le système d’évacuation

entre la commande de tirage et la cheminée. Le système de coupure de sécurité WMO-1 se place entre la

commande de tirage et l’appareil. Lorsqu’il est correctement installé, le registre s’ouvre avant que le brûleur

s’allume et se ferme après qu’il s’éteint.

AVERTISSEMENT : L'amortisseur de passage d'huile NE PEUT PAS être employé sur un appareil qui

emploie un pilote brûlant constant.

Le registre d’évacuation Field Controls doit IMPÉRATIVEMENT être installé par un organisme qualifié en

conformité avec les instructions de pose du fabricant.

La définition d’un organisme qualifié est : toute personne, société, corporation ou entreprise qui, soit en personne,

soit par l’intermédiaire d’un représentant, assure l’exécution et assume la responsabilité de la pose et du

fonctionnement d’appareils au mazout, qui a de l’expérience dans ce type de travaux, est familiarisée avec les

précautions de rigueur et est en règle vis-à-vis des autorités compétentes. Le registre d’évacuation est conçu

pour servir sur un seul appareil.

DÉTRUISEZ PAS

APRÈS INSTALLATION, CES INSTRUCTIONS DOIVENT DEMEURER AVEC L'ÉQUIPEMENT POUR LE SERVICE DE L'APPAREIL.

ATTENTION

1. Bien lire le manuel en entier.

2. Veiller à respecter toutes les procédures et contrôles de sécurité.

3. Ne neutraliser l’action d’aucun mécanisme de sécurité ou d’exploitation.

Avant de poser le système de registre d’évacuation :

2630 Airport Road · Kinston, NC 28504

Téléphone : 252-522-3031· Télécopie : 252-522-0214

19

www.fieldcontrols.com

Page 20

CARACTÉRISTIQUES

1. Commutateur de servie – Tient le registre ouvert et permet à l’appareil de fonctionner sans que le registre

fonctionne.

2. Garantie limitée de 18 mois sur le mécanisme motorisé à compter de la date de fabrication.

3. Deux contacteurs de sécurité internes.

4. Ouverture et fermeture motorisées – allonge la durée de vie du produit. Consommation électrique réduite.

5. Faisceau de câbles à blindage métallique.

6. Système de coupure de sécurité WMO-1.

7. Joint flexible à action autonettoyante.

8. Conduit en acier inoxydable.

FONCTIONNEMENT

Lorsque l’appareil de chauffage au mazout reçoit un appel de chaleur, le registre pivote jusqu’en position ouverte avant que le

circuit du brûleur soit activé. Si le registre ne tourne pas jusqu’en position ouverte, le circuit du brûleur n’est pas activé et ne

permet pas au brûleur de s’allumer. Une fois que l’appel de chaleur est satisfait, le registre reste ouvert pendant

3 minutes environ pour permettre aux gaz de combustion résiduels de s’échapper avant de se fermer. Si l’installation est

correcte, les circuits électriques de ce produit sont conçus pour ne pas neutraliser les mécanismes de limite et de sécurité

existants de l’appareil.

À L’INTENTION DE L’UTILISATEUR

Pour assurer un fonctionnement sans danger, l’appareil de chauffage doit être contrôlé chaque année par un organisme de

maintenance qualifié. Il est conseillé que le propriétaire fasse contrôler le système d’évacuation et le registre chaque année

pour détecter toute détérioration éventuelle par la corrosion ou autres sources. Le contrôle doit être effectué avant chaque

saison de chauffage.

INFORMATIONS GENERALES

DONNEES DIMENSIONNELLES

Figure 1

DONNEES ELECTRIQUES

Caractéristiques électriques du brûleur et du

transformateur

Temporisation

Section

tuyau A

mm (po)

102

(4)

127

(5)

152

(6)

178

(7)

203

(8)

Longueur B

mm (po)

152

(6)

152

(6)

165

(6-1/2)

179

(7-1/16)

205

(8-1/16)

Transformateur d’allumage de 250 VA ou moins

Délai de temporisation de 3 minutes environ avant la fermeture

Hauteur

totale C

mm (po)

256

(10-1/16)

281

(11-1/16)

306

(12-1/16)

332

(13-1/16)

357

(14-1/16)

Moteurs de brûleur jusqu’à 1/6 hp, 5,8 A

5 s, activation de l’ouverture

5 s, activation de la fermeture

Dim. D

mm (po)

24

(15/16)

24

(15/16)

29

(1-1/8)

35

(1-3/8)

48

(1-7/8)

Dim. E

mm (po)

127

(5)

127

(5)

140

(5-1/2)

154

(6-1/16)

179

(7-1/16)

Longueur

de tuyau à

couper

mm (po)

89

(3-1/2)

89

(3-1/2)

102

(4)

116

(4-9/16)

141

(5-9/16)

20

Page 21

AVERTISSEMENTS AVANT INSTALLATION

1. Le registre d’évacuation Field Controls doit impérativement être installé par un organisme qualifié en

conformité avec les instructions de pose du fabricant. La définition d’un organisme qualifié est : toute

personne, société, corporation ou entreprise qui, soit en personne, soit par l’intermédiaire d’un représentant,

assure l’exécution et assume la responsabilité de la pose et du fonctionnement d’appareils de combustion

au mazout, qui a de l’expérience dans ce type de travaux, est familiarisée avec les précautions de rigueur et

est en règle vis-à-vis des autorités compétentes. Le registre d’évacuation est conçu pour servir sur un seul

appareil.

2. L’organisme qualifié doit indiquer son nom, son adresse et la date d’installation sur l’étiquette attachée au

système de registre d’évacuation.

3. Le registre d’évacuation automa tique Field Contr ols peut unique ment être posé sur de s appareils au mazou t

à fonctionnement automatique qui utilisent des brûleurs électriques à atomisation.

4. Le registre d’évacuation automatique Field Controls ne doit pas être posé sur des appareils au mazout à

ventouse, à chambre de combustion fermée ou à brûleurs à vaporisation.

5. Ne neutraliser l’action d’aucun mécanisme de sécurité ou d’exploitation existant.

6. Lors de travaux sur les commandes, tous les fils doivent être ÉTIQUETÉS avant d’être débranchés. Les

erreurs de câblage peuvent résulter en un mauvais fonctionnement dangereux.

7. Le dispositif doit être installé par un organisme qualifié, en conformité avec les normes suivantes :

Aux États-Unis

• NFPA 31 Standard for the Installation of Oil -Burning Equipment

• NFPA 211 Standard for Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

• NFPA 70 National Electric Code

Au Canada

• CSA B139 Code d’installation des appareils de combustion au mazout

• C22.1 Code canadien de l’électricité 1ère partie

8. La température maximale de l’endroit choisi ne doit pas dépasser 538°C (1000°F). Mesurer la température

des gaz brûlés au niveau du collier de fumée de l’appareil.

9. Installer en aval de la commande de tirage de l’appareil, aussi près que possible de la commande de tirage,

mais sans modifier la commande de tirage ni le registre d’évacuation.

10. Placer le WMO-1 entre la commande de tirage et le collier de fumée d’un appareil unique pour lequel il est

utilisé.

11. Placer le registre sur un conduit d’évacuation ou une portion de conduit d’évacuation tels que le registre

desserve seulement l’appareil unique auquel il est destiné.

12. Maintenir un dégagement de 457 mm (18 po) minimum entre le système de registre et des matériaux de

construction combustibles et prévoir un espace pour l’accès et l’entretien du registre.

13. L’indicateur de position et le commutateur de service doivent être accessible à l’utilisateur.

14. Ce dispositif doit être installé uniquement sur un appareil au mazout raccordé à une cheminée ou un

système d’évacuation manufacturés conformes à des normes reconnues ou à une cheminée en maçonnerie

ou en béton comportant une chemise dans un matériau admissible en vertu de la réglementation en vigueur.

CONTROLES AVANT INSTALLATION

PROCEDURE DE CONTROLE DE SECURITE POUR UNE INSTALLATION D’APPAREIL EXISTANTE

La procédure suivante est prévue en tant que guide pour déterminer si un appareil est correctement installé et qu’il

en état de fonctionner dans danger.

La procédure est basée sur des installations de appareil de chauffage central, chaudière ou chauffe-eau e t il doit être

reconnu que les procédures généralisées ne peuvent pas anticiper toutes les situations. Par conséquent, dans

certains cas, des écarts par rapport à cette procédure peuvent s’avérer nécessaires pour déterminer le bon

fonctionnement du matériel.

1. Cette procédure doit être effectuée préalablement à l’installation du système de registre d’évacuation

automatique.

2. Si une situation susceptible de causer un fonctionnement dangereux est identifiée, l’appareil doit être coupé

et le propriétaire informé de cette situation dangereuse. Ne pas installer le système de registre d’évacuation

automatique tant que la situation dangereuse n’a pas été corrigée.

21

Page 22

CONTRÔLE DE SÉCURITÉ

1. Effectuer un contrôle d’étanchéité visuel des conduits et du système de commande de l’appareil au mazout en

aval de la vanne d’arrêt sur la conduite d’alimentation de l’appareil.

2. Contrôler visuellement le système d’évacuation pour vérifier que la section, la pente horizontale et l’extrémité

d’évacuation sont correct et s’assurer qu’il n’y a aucune obstruction ou restriction, fuite, corrosion ou autre

défectuosité susceptible de présenter un danger.

3. S’assurer que la cheminée ou le conduit d’évacuation est admissible en vertu de la réglementation en vigueur.

4. Vérifier l’absence d’obstruction et de corrosion dans le brûleur, la chambre de combustion et les passages de

d’évacuation.

5. Générateurs d’air chaud uniquement

ouvertures ni corrosion excessive.

6. Chauffe-eau et chaudières uniquement

7. Autant que possible, fermer toutes les portes et fenêtres du bâtiment et toutes les portes entre l’espace dans

lequel se trouvent l’appareil et les autres locaux du bâtiment. Mettre en marche les sécheuses de linge, les

brûleurs de cuisinière et les aspirateurs centraux. Faire fonctionner tous les ventilateurs d’extraction, tels que

hottes de cuisine et ventilateurs aspirants de salle de bain, à leur vitesse maximale. Ne pas faire fonctionner de

ventilateur d’extraction d’été. Fermer les registres de foyer de cheminée. Si, après avoir effectué les étapes 9 à

12, l’air de combustion disponible est jugé insuffisant, se reporter aux indications des codes locaux ou, en

l’absence de codes locaux, aux États-Unis, à NFPA 31- Standard for the Installation of Oil Burning Equipment ;

NFPA 211- Standard for Chimneys, Fireplaces, Vents and Solid- Fuel Burning Appliances. Au Canada, consulter

CSA B139 Code d’installation des appareils de combustion au mazout.

8. Mettre en marche l’appareil à contrôler. Suivre les instructions de démarrage du fabricant de l’appareil. Régler le

thermostat de telle manière que l’appareil fonctionne en continu.

9. Ajuster les réglages d’air et de charge conformément aux instructions du fabricant de l’appareil à brûleur.

Vérifier que le brûleur fonctionne correctement, par la mesure de la concentration de dioxyde de carbone, de la

température des gaz brûlés et de la densité de fumée. Vérifier que la cellule au sulfure de cadmium fonctionne

correctement.

10. Mettre en marche tous les autres appareils au mazout installés dans le même local de manière à ce qu’ils

fonctionnent à leur puissance maximale. Suivre les instructions de démarrage de chaque appareil.

11. Vérifier l’absence de fuites au niveau de l’ouverture de la commande de tirage au bout de 5 minutes de marche

du brûleur principal. Utiliser une allumette, une chandelle ou la fumée d’une cigarette. Faire fonctionner

l’appareil au mazout à atomisation électrique raccordé à une évacuation pendant plusieurs puis vérifier que les

produits de combustion s’échappent par la cheminée ou le conduit d’évacuation. Effectuer une mesure de

tirage pour s’assurer que l’apport d’air secondaire du système est conforme aux instructions du fabricant du

brûleur et de l’appareil. Si la cheminée ou l’évacuation tire correctement, le système d’évacuation présente une

pression négative. Dans le cas contraire, les produits de combustion tendent à être refoulés hors de la

commande de tirage. Si des produits de combustion s’échappent par l’ouverture de la commande de tirage, ne

pas utiliser l’appareil avant d’avoir effectué les réglages ou réparations nécessaires pour assurer un apport

d’air de combustion et un tirage par le cheminée ou le système d’évacuation corrects.

12. Répéter l’étape 11 sur tous les appareils au mazout.

13. Remettre les portes, fenêtres, ventilateurs d’extraction, registres de foyer et tout autre appareil au mazout dans

leur état d’utilisation antérieur.

14. Générateurs d’air chaud uniquement

commande de soufflante. Pour cela, suivre les instructions du fabricant de la commande de l’appareil.

15. Chaudières uniquement

a. Vérifier que les pompes à eau sont en bon état de marche.

b.Contrôler le bon état de marche des coupures pour bas niveau d’eau, des commandes de régulation

automatique et des soupapes de décharge conformément aux conseils du fabricant.

16. Chauffe-eau uniquement

limite haute et aquastat combinée conformément aux conseils du fabricant.

–

– Contrôler le bon état de marche de la soupape de décharge et de la commande de

– vérifier que l’échangeur thermique ne présente pas de fissures,

– vérifier l’absence de fuites d’eau et de produits de combustion.

– Vérifier le bon fonctionnement à la fois de la commande de limite et de la

INSTRUCTIONS DE DÉBALLAGE

1. Le registre d’évacuation Field Controls série OVD est emballé dans un carton unique. Il contient un registre

OVD assemblé, un contacteur de sécurité WMO-1 précâblé avec joint en fibre et faisceau de câbles à

blindage métallique attaché, un manuel d’instructions et un bouchon d’évacuation.

2. Sortir le matériel et s’assurer que chaque pièce est en bon état.

3. Si des dommages sont visibles, ne pas installer le système de registre d’évacuation.

22

Page 23

POSE DU SYSTEME

p

’

AVERTISSEMENT : Poser le système de registre d’évacuation de manière à desservir

seulement l’appareil unique auquel il est destiné. Une pose incorrecte peut présenter un

danger d’explosion, d’intoxication au monoxyde de carbone ou de mort.

POSE DU BOUCHON D’ÉVACUATION

ATTENTION

Le bouchon se pose pour minimiser les fuites. Si une

odeur se produit ou que le gicleur goutte à l’arrêt, le bouchon peut être

enlevé pour permettre une ventilation minimale à travers le brûleur de

l’appareil. Cette ventilation contribue à refroidir le gicleur du brûleur en

mode de veille.

ATTENTION

Veiller à respecter ces instructions afin d’écarter le risque de

problèmes d’odeur et de dégâts matériels mineurs. Ne pas poser le bouchon

d

évacuation sur des systèmes à chambre de combustion en briques.

1. Le bouchon d’évacuation se pose pour produire une obturation étanche. Pour

éviter d’endommager le moteur, veiller à ne pas tourner le clapet du registre à

la main durant la pose du bouchon d’évacuation.

2. Le bouchon d’évacuation est attaché à la couverture du présent manuel de

pose.

3. Insérer le bouchon d’évacuation dans l’orifice du clapet de registre. Pour fixer

le bouchon d’évacuation, plier les quatre languettes du bouchon vers

l’extérieur (voir Figure 2).

POSE DU REGISTRE D’EVACUATION

ATTENTION

exclusivement sur un conduit d’évacuation qui dessert un appareil unique,

our lequel il est raccordé et commandé électriquement.

Le système de registre d’évacuation doit être placé

RABATTRE LES

LANGUETTES

Figure 2

Évite un échauffement

excessif

1 heure 11 heures

POSE SUR CONDUIT VERTICAL : Le registre d’évacuation n’est pas

sensible à sa position. Il peut être posé dans toute position. Maintenir un

minimum de 457 mm (18 po) entre la surface du conduit de registre et tout

matériau combustible.

POSE SUR CONDUIT HORIZONTAL

: Pour écarter le risque de défaillance

Plage de

fixation

Plage de

fixation

prématurée du registre d’évacuation, voir la Figure 3. Éviter de placer le

registre directement au-dessus ou en dessous du conduit d’évacuation.

Nous conseillons les positions de 1h00 à 5h00 ou de 7h00 à 11h00.

Maintenir un minimum de 457 mm (18 pouces) entre la surface du conduit

de registre et tout matériau combustible.

7 heures

Évite la condensation

5 heures

Figure 3

1. Avant de débuter la pose, couper toute alimentation électrique vers

l’appareil au niveau du commutateur de service de l’appareil ou du disjoncteur.

2. Repérer un emplacement sur le conduit d’évacuation entre la commande de tirage et cheminée pour la pose du

registre. Poser le registre d’évacuation aussi près que possible de la commande de tirage (à un minimum de 51

mm [2 po] du collier de la commande de tirage), mais sans modifier ni la commande de tirage ni le registre

d’évacuation (Configuration A).

3. Le système de coupure de sécurité WMO-1 doit être posé entre le collier de fumée de l’appareil et la commande

de tirage. (REMARQUE : Le faisceau de câbles à blindage métallique entre le contacteur de s écurité WM O-1 et le

registre d’évacuation mesure 609 mm [24 po] seulement) (Configuration A). Le faisceau de câbles se branche

sur le moteur. Enfoncer et enclencher la fiche à clavettes du faisceau dans la prise du moteur. Enfoncer et

bloquer le connecteur en Y métallique dans l’attache de serrage.

4. Prévoir un dégagement minimum de 459 mm (18 po) entre le conduit du registre d’évacuation et les matériaux

combustibles et un espace d’accès suffisant pour l’entretien du système de registre d’év acuation.

23

Page 24

’

A

CHEMINÉE OU

SYSTÈME

D’ÉVACUATION

EN CAS D’APPAREILS MULTIPLES,

CHAQUE APPAREIL DOIT AVOIR SON

PROPRE REGISTRE D’ÉVACUATION OVD

BORD RABATTU

DU REGISTRE

OVD

BORD RABATTU DU

TUYAU D’ÉVACUATION

COMMANDE DE

TIRAGE

USSI PRÈS QUE POSSIBLE DE

LA SORTIE D’ÉVACUATION

APPAREIL AU

MAZOUT

DÉGAGEMENT DE

457 mm (18 po)

VERS MATÉRIAU

COMBUSTIBLE

51 mm (2 po)

MINIMUM

609 mm (24 po)

MAXIMUM ENTRE

REGISTRE OVD

ET WMO-1

CONTACTEUR DE BLOCAGE

D’ÉVACUATION WMO-1

Configuration A

5. Déposer la portion appropriée de raccord de

conduit d’évacuation sur le côté aval de la commande de tirage et raccourcir le co nduit pour le placement du

conduit du registre d’évacuation (voir les dimensions correctes dans la Table 1 et la Configuration B). Le cas

échéant, rabattre le bord du conduit d’évacuation près de la sortie de la commande de tirage. Les raccords

d’assemblage du conduit d’évacuation et du conduit du registre doivent se chev aucher sur 32 mm (1¼ po).

NE PAS POSER LE

REGISTRE OVD EN AVAL

DE PLUS D’UN APPAREIL

OUI

OVD

COMMANDE

DE TIRAGE

WMO-1

OUI

OVD

COMMANDE

DE TIRAGE

WMO-1

NON

Cheminée

ou système

d’évacuation

Appareil

au mazout

Appareil

au mazout

Configuration B

ATTENTION

Veiller à ne pas ovaliser la section de tuyau durant la pose, car cela peut provoquer le

grippage du clapet de registre, une défaillance prématurée du moteur et des pannes. Poser le registre

d’évacuation avec la flèche directionnelle et le bord rabattu du conduit de registre pointés vers la

cheminée. Remonter la portion raccourcie de raccord de conduit d’évacuation et le registre

d

évacuation. Placer le moteur dans une position conforme aux limites indiquées plus haut.

6. Fixer le registre d’évacuation au conduit d’évacuation avec des vis à tôle de 13 mm (1/2 po) ou des rivets

aveugles. Les espacer régulièrement de 120° sur la circonférence. Utiliser trois vis ou rivets à l’entrée et la

sortie du conduit. Veiller à s’assurer que les vis ou rivets ne font p as obstruction au clapet du registre. Il peut

être nécessaire de prévoir des étriers de suspension adaptés pour soutenir le registre d’évacuation

indépendamment du système d’évacuation.

7. Vérifier que le commutateur de service du registre sur le côté du moteur de registre est en position

automatique.

8. Vérifier que l’arbre plat est engagé dans le mécanisme moteur. L’arbre plat doit comporter une rondelle et

une goupille fendue installées à l’usine.

24

Page 25

l

’app

É

Section

tuyau A

mm (po)

102

(4)

127

(5)

152

(6)

178

(7)

203

(8)

ALIGNER LES RAINURES POUR

BRANCHER LES FICHES

CLAVETTES RAINURES

FORCER DES FICHES

INCOMPATIBLES PEUT

PRÉSENTER UN DANGER

Fiches à clavettes

Longueur de

tuyau à

couper

mm (po)

89

(3-1/2)

89

(3-1/2)

102

(4)

116

(4-9/16)

141

(5-9/16)

COUPER VOIR TABLEAU

COMMANDE

DE TIRAGE

VERS LA

CHEMINÉE

51 mm (2 po) MINIMUM

COMMANDE

DE TIRAGE

VERS

L’APPAREIL

VERS LA

CHEMINÉE

ESPACE POUR

REGISTRE OVD

VERS

L’APPAREIL

VIS OU RIVET

AVEUGLE EN

TROIS

ENDROITS

SUR CHAQUE

RACCORD

BORD RABATTU

29 mm (1-1/8 po)

COMMANDE

DE TIRAGE

WMO-1 WMO-1WMO-1

VERS LA

CHEMINÉE

VERS

L’APPAREIL

Configuration C

OVD

LE FAISCEAU

DE FILS DE

WMO SE

BRANCHE

SUR LE

MOTEUR

POSE DU SYSTEME DE COUPURE DE SECURITE WMO-1

1. Le système de coupure de sécurité WMO-1 doit être posé entre le collier de fumée de l’appareil et la commande

de tirage. (REMARQUE : Le faisceau de câbles à blindage métallique entre le contacteur de s écurité WM O-1 et le

registre d’évacuation mesure 609 mm [24 po] seulement). Le faisceau de câbles se branche sur le moteur.

Enfoncer et enclencher la fiche à clavettes du faisceau dans la prise du moteur (voir le schéma des fiches à

clavettes). Enfoncer et bloquer le connecteur en Y métallique dans l’attache de serrage.

2. Percer un trou de 19 mm (3/4 po) de diamètre dans le conduit d’évacuation près de la sortie de l’appareil (voir

Figure 4).

3. Le tube de transfert thermique doit avoir le joint en fibre en place contre la plaque de fixation avant de poser le

dispositif sur le conduit d’évacuation. Insérer le tube de transfert thermique muni du joint dans l’orifice de

19 mm (3/4 po) de diamètre.

4. Fixer le dispositif au conduit d’évacuation avec un minimum de 4 vis à tôle. Le profilé doit être monté

horizontalement, sauf indication contraire du fabricant de l’appareil (voir la Figure 4).

AVERTISSEMENT :

Le profilé de

raccordement du

contacteur doit

être monté

horizontalement,

sauf indication

LE PROFILÉ DE

RACCORDEMENT DE

CONTACTEUR DOIT ÊTRE

HORIZONTALEMENT

MONT

contraire du fabricant

de

areil.

INSTRUCTIONS DE CABLAGE

Câble le registre d’évacuation et les commandes en

conformité avec le National Electrical Code, les

conseils du fabricant et/ou les codes locaux en vigueur.

TUBE DE

TRANSFERT

THERMIQUE

CONTACTEUR

DE BLOCAGE

D’ÉVACUATION

LE PROFILÉ DE

RACCORDEMENT

DE CONTACTEUR

DOIT ÊTRE MONTÉ

HORIZONTALEMENT

PLAQUE DE FIXATION

AVEC JOINT PLACÉ

SUR LE DESSOUS

DISTANCE AUSSI

COURTE QUE POSSIBLE

APPAREIL

CONDUIT

D’ÉVACUATION

PERCER UN TROU DE

DIAM. 19 mm (3/4 po)

Figure 4

LE DISPOSITIF DOIT ÊTRE RACCORDÉ À LA TERRE. Contrôler le circuit de terre pour s’assurer que le dispositif est

correctement mis à la terre. Le câblage doit être protégé par un dispositif de protection contre les surintensités de

valeur nominale de 15 ampères. Veiller à s’assurer que le câblage ne vient pas contact d’une quelconque source de

chaleur. Tous les circuits de tension de ligne et de commande de sécurité entre le registre d’évacuation et l’appareil

doivent IMPÉRATIVEMENT être câblés en conformité avec le National Electrical Code pour les câblages de Classe I

ou des méthodes équivalentes.

AVANT DE DEBUTER LE CABLAGE, COUPER TOUTE ALIMENTATION ELECTRIQUE VERS L’APPAREIL

AU NIVEAU DU COMMUTATEUR DE SERVICE DE L’APPAREIL OU DU DISJONCTEUR !!

25

Page 26

É

24 VCA

(

S

)

THERMOSTAT

VACUATION DOIVENT

AVERTISSEMENT :

ATTENTION

NE PAS OVALISER LA SECTION DE TUYAU

POUR ÉVITER LES APPELS PARASITES.

VIS DE

TERRE

MASSE

ÉLECTRIQUE AVANT DE CÂBLER

LE REGISTRE D’ÉVACUATION !

COMPLÈTEMENT OUVERT AVANT

• DÉBRANCHER L’ALIMENTATION

QUE LA COMBUSTION AIT LIEU !

• LE REGISTRE DOIT ÊTRE

NOIR

E

PHA

L1

L2 (NEUTRE)

LIMITE

CIRCUIT DE

120 VCA DU

COMMANDE

BLANC

D’APPAREIL

PRIMAIRE

BLEU

ORANGE

MOTEUR DE

BRÛLEUR

ALLUMAGE

MARETTE

JAUNE

JAUNE

BOÎTE DE JONCTION DE BRÛLEUR

M

CELLULE

CADMIU

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

POSITION

À LA MAIN !

INDICATEUR DE

NE PAS TOURNER

CECI ENDOMMAGE

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’

GOUPILLE FENDUE ET

RONDELLE

DE SERVICE

COMMUTATEUR

BRÛLÉS

DES GAZ

ÉCOULEMENT

OVD

LE MOTEUR !

FAISCEAU DE

REGISTRE OVD

MÉTALLIQUE DU

CÂBLES À BLINDAGE

CONTACTEUR DE

SÉCURITÉ THERMIQUE

NOIR (PHASE – 120 VCA)

WMO-1

NORMALEMENT FERMÉ

RÉARMEMENT MANUEL

BLANC (NEUTRE – 120 VCA)

JAUNE (SORTIE SIGNAL – 120 VCA)

ORANGE (ENTRÉE SIGNAL – 120 VCA)

VERT

TERRE

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

26

Page 27

É

24 VCA

(

)

É

THERMOSTAT

VACUATION DOIVENT

ATTENTION

NE PAS OVALISER LA SECTION DE TUYAU

POUR ÉVITER LES APPELS PARASITES.

VIS DE

TERRE

MASSE

NOIR

BLANC

PHASE

L1

L2 (NEUTRE)

LIMITE

CIRCUIT DE

120 VCA DU

PRIMAIRE

COMMANDE

ORANGE

MOTEUR DE

D’APPAREIL

MARETTE

JAUNE

JAUNE

BOÎTE DE JONCTION DE BRÛLEUR

CELLULE

ALLUMAGE

BRÛLEUR

CADMIUM

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

BRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT DE CÂBLER

LE REGISTRE D’ÉVACUATION !

COMPLÈTEMENT OUVERT

AVANT QUE LA COMBUSTION AIT

AVERTISSEMENT :

• D

• LE REGISTRE DOIT ÊTRE

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’

GOUPILLE FENDUE ET

RONDELLE

LIEU !

NE PAS

INDICATEUR

DE POSITION

BRÛLÉS

DES GAZ

ÉCOULEMENT

OVD

DE SERVICE

COMMUTATEUR

CECI

LA MAIN !

TOURNER À

CONTACTEUR DE

ENDOMMAGE

SÉCURITÉ THERMIQUE

27

LE MOTEUR !

NORMALEMENT FERMÉ

RÉARMEMENT MANUEL

MÉTALLIQUE DU REGISTRE OVD

NOIR (PHASE – 120 VCA)

FAISCEAU DE CÂBLES À BLINDAGE

WMO-1

BLANC (NEUTRE – 120 VCA)

JAUNE (SORTIE SIGNAL – 120 VCA)

ORANGE (ENTRÉE SIGNAL – 120 VCA)

VERT

TERRE

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

Page 28

É

É

A

R

(

)

VERS CIRCUIT D’ALARME CA BASSE

(

)

TENSION À DISTANCE (LE CAS ÉCHÉANT)

SUR CERTAINS MODÈLES

24 VCA

THERMOSTAT

VACUATION DOIVENT

NOIR : CARLIN

ROUGE/BLANCH : CARLIN

LIMIT

ROUGE

ATTENTION

NE PAS OVALISER LA SECTION DE TUYAU

POUR ÉVITER LES APPELS PARASITES.

VIS DE

TERRE

MASSE

L’APPAREIL

BRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT DE CÂBLER

LE REGISTRE D’ÉVACUATION !

COMPLÈTEMENT OUVERT

AVANT QUE LA COMBUSTION AIT

AVERTISSEMENT :

• D

• LE REGISTRE DOIT ÊTRE

LIEU !

FIL DE DÉMARRAGE DU

BRÛLEUR 120 VCA DE

PRIMAIRE

MARETTE

COMMANDE

L1

NOIR

BLANC

PHASE

NEUTRE

L1

L2

DE

120 VCA

(DU CIRCUIT DE LIMITE)

LVE

L2

V

VIOLET

VANNE

MAZOUT

L’APPARE

IGNITION

MOTO

CAD CELL

CAD CELL

BLEU

ALLUMAGE

JAUNE

JAUNE

ORANGE

BOÎTE DE JONCTION DE BRÛLEUR

DE

CELLULE

CADMIUM

MOTEUR

BRÛLEUR

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

POSITION

À LA MAIN !

NE PAS TOURNER

OVD

LE MOTEUR !

CECI ENDOMMAGE

CONTACTEUR DE

SÉCURITÉ THERMIQUE

NORMALEMENT FERMÉ

BLANC (NEUTRE – 120 VCA)

NOIR (PHASE – 120 VCA)

WMO-1

RÉARMEMENT MANUEL

JAUNE (SORTIE SIGNAL – 120 VCA)

VERT

ORANGE (ENTRÉE SIGNAL – 120 VCA)

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

INDICATEUR DE

ET RONDELLE

GOUPILLE FENDUE

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’

COMMUTATEUR

DE SERVICE

BRÛLÉS

DES GAZ

ÉCOULEMENT

28

Page 29

É

É

É

LECTRIQUE

VACUATION DOIVENT

BRANCHER L’ALIMENTATION

AVERTISSEMENT :

• D

AVANT DE CÂBLER LE REGISTRE D’ÉVACUATION !

OUVERT AVANT QUE LA COMBUSTION AIT LIEU !

• LE REGISTRE DOIT ÊTRE COMPLÈTEMENT

ATTENTION

NE PAS OVALISER LA SECTION DE TUYAU

POUR ÉVITER LES APPELS PARASITES.

MARETTE

CONTACTEUR DE SÉCURITÉ DU SECTEUR

CONTACTEUR DE LIMITE D’EXPLOITATION

CONTACTEUR DE LIMITE DE SÉCURITÉ

120 VCA

NOIR (PHASE – 120 VCA)

BRÛLEUR RIELLO

remplacé par « P ».

brûleurs Riello, « L » est

REMARQUE : Sur certains

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’

À LA MAIN !

INDICATEUR

DE POSITION

ET RONDELLE

GOUPILLE FENDUE

ÉCOULEMENT

DE SERVICE

COMMUTATEUR

NE PAS TOURNER

BRÛLÉS

DES GAZ

OVD

LE MOTEUR !

CECI ENDOMMAGE

REGISTRE OVD

FAISCEAU DE CÂBLES À

BLINDAGE MÉTALLIQUE DU

WMO-1

CONTACTEUR DE

SÉCURITÉ THERMIQUE

NORMALEMENT FERMÉ

RÉARMEMENT MANUEL

BLANC (NEUTRE – 120 VCA)

JAUNE (SORTIE SIGNAL – 120 VCA)

ORANGE (ENTRÉE SIGNAL – 120 VCA)

VERT

TERRE

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

29

Page 30

É

É

CAVALIER

(

)

AVERTISSEMENT :

VACUATION DOIVENT

ALIMENTATION

120 V

BRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT DE CÂBLER

LE REGISTRE D’ÉVACUATION !

COMPLÈTEMENT OUVERT AVANT

• D

• LE REGISTRE DOIT ÊTRE

QUE LA COMBUSTION AIT LIEU !

•

ATTENTION

NE PAS OVALISER LA SECTION DE TUYAU

POUR ÉVITER LES APPELS PARASITES.

PRIMAIRE

COMMANDE

NOIR

BLANC

VIS DE

TERRE

MASSE

ORANGE

MOTEUR DE

JAUNE

JAUNE

BOÎTE DE JONCTION DE BRÛLEUR

ALLUMAGE

BRÛLEUR

CELLULE

CADMIUM

MARETTE

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

POSITION

À LA MAIN !

NE PAS TOURNER

CECI ENDOMMAGE

CONTACTEUR DE

SÉCURITÉ THERMIQUE

LE MOTEUR !

NORMALEMENT FERMÉ

RÉARMEMENT MANUEL

INDICATEUR DE

BRÛLÉS

GOUPILLE FENDUE

ET RONDELLE

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’

DES GAZ

ÉCOULEMENT

DE SERVICE

COMMUTATEUR

PHASE – 120 VCA

NOIR

BLANC (NEUTRE – 120 VCA)

JAUNE (SORTIE SIGNAL – 120 VCA)

DU REGISTRE OVD

BLINDAGE MÉTALLIQUE

FAISCEAU DE CÂBLES À

ORANGE (ENTRÉE SIGNAL – 120 VCA)

VERT

TERRE

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

30

Page 31

•

LE NOIR, L’ORANGE ET LE JAUNE DU REGISTRE D’ÉVACUATION DOIVENT

É

ÊTRE DE MÊME POLARITÉ POUR ÉVITER LES DOMMAGES DU PRODUIT.

COMMUTATEUR

DE SERVICE

CONTACTEUR DE

SÉCURITÉ THERMIQUE

NORMALEMENT FERMÉ

RÉARMEMENT

MANUEL

GOUPILLE FENDUE ET

RONDELLE

INDICATEUR

COULEMENT

DES GAZ

BRÛLÉS

DE POSITION

TOURNER

À LA MAIN !

ENDOMMAGE

LE MOTEUR !

FAISCEAU DE

CÂBLES À BLINDAGE

MÉTALLIQUE DU

REGISTRE OVD

NE PAS

CECI

AVERTISSEMENT :

DÉBRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT DE CÂBLER

LE REGISTRE D’ÉVACUATION !

• LE REGISTRE DOIT ÊTRE

COMPLÈTEMENT OUVERT AVANT

ATTENTION

NE PAS OVALISER LA SECTION

DE TUYAU POUR ÉVITER LES

APPELS PARASITES.

NOIR (PHASE – 120 VCA)

BLANC (NEUTRE –120 VCA)

TERRE

Carte de commande de

chaudière typique câblée au

circuit de brûleur 120 V

COMMUTATEUR

DIP DE SÉLECTION

DELAY-OFF

VERT

JAUNE (SORTIE SIGNAL – 120 VCA)

ORANGE (ENTRÉE SIGNAL – 120 VCA)

NOIR

MOTEUR

DE

BRÛLEUR

BLC

BLC

NOIR

NOIR

(NOIR)*

COMMANDE PRIMAIRE INTERRUPTION MAZOUT

CELLULE CADMIUM

OR

BLC

OR JN BLEU

ORANGE

(BLANC)*

DÉTECTEUR DE FLAMME

FLAME DETECT

TENSION SECTEUR PAR FOURNISSEUR QUALIFIÉ

TENSION SECTEUR PAR L’USINE

BASSE TENSION PAR FOURNISSEUR QUALIFIÉ

BASSE TENSION PAR L’USINE

MARETTE

31

Page 32

ENTRETIEN

YSTEME DE COUPURE DE SECURITE WMO-1

S

Pour assurer un fonctionnement sans danger, la combinaison appareil-commutateur doit être contrôlée et

entretenue chaque année par un organisme qualifié.

1. Débrancher l’alimentation électrique de l’appareil.

2. Desserrer les deux vis de fixation du couvercle du contacteur de blocage d’évacuation WMO-1.

3. Déposer le couvercle.

4. Déposer la vis qui maintient le boîtier de commande sur le tube de transfert thermique. Glisser le

boîtier de commande hors du tube de transfert thermique.

5. Avec précaution, éliminer tout dépôt de la surface du contacteur thermique. NE PAS DÉFORMER NI

RAYER LA SURFACE DU CONTACTEUR THERMIQUE. SI LE CONTACTEUR THERMIQUE EST

ENDOMMAGÉ, IL DOIT ÊTRE CHANGÉ

6. Contrôler l’intérieur du tube de transfert thermique et éliminer tout dépôt ou obstruction.

7. Remonter, verrouiller et rattacher le boîtier de commande avec la vis déposée à l’étape 4.

8. Rattacher le couvercle du boîtier et serrer les vis desserrées à l’étape 2.

9. Rétablir l’alimentation électrique de l’appareil.

.

NETTOYER LE TUBE À

L’ÉCOUVILLON

DÉPOSER LES VIS DE

COUVERCLE ET LE COUVERCLE

Étape 1 Étape 2 Étape 3

DÉPOSER LA VIS

GLISSER LA BOÎTE WMO-1 HORS

DU TUBE DE TRANSFERT

THERMIQUE

Étape 4

32

Page 33

GUIDE DE RÉSOLUTION DES PROBLÈMES

ATTENTION

• Lors de travaux sur les commandes, tous les fils doivent être étiquetés avant d’être débranchés.

Les erreurs de câblage peuvent résulter en un mauvais fonctionnement dangereux.

• Ne pas ouvrir le registre à la main car cela endommage le moteur et annule la garantie.

NE PAS COUPER LA FICHE DU MOTEUR DE REGISTRE CAR CELA ANNULE LA GARANTIE.

AVERTISSEMENT : Ne neutraliser l’action d’aucun mécanisme de sécurité ou

d’exploitation existant.

La tension mesurée est de 120 VCA. Les mesures de tension se font au niveau du

faisceau de câbles à l’endroit où il se raccorde à l’appareil de chauffage. S’assurer que le

commutateur de service du registre d’évacuation est en position automatique.

Mesures de tension normales Remarque : Les fils noir, orange et jaune

doivent être de même polarité.

ALIMENTATION 120 VCA

Blanc n° 4 et noir n° 1 En permanence Ouvert ou fermé

Blanc n° 4 et orange n° 2 Appel de chaleur Ouvert ou en cours d’ouverture

Blanc n° 4 et jaune n° 3 Durant la combustion Registre ouvert

Sous tension Position du registre

• Blanc n° 4 Neutre 120 VCA

• NOIR N° 1 PHASE 120 VCA

• ORANGE N° 2 ENTREE DE SIGNAL 120 VCA COMMANDANT L’OUVERTURE DU REGISTRE

JAUNE N° 3 SORTIE DE SIGNAL 120 VCA UNE FOIS QUE LE REGISTRE EST OUVERT

•

•

COUPER LE SIGNAL 120 VAC DE L’ORANGE N° 3. LE REGISTRE SE FERME AU BOUT DE 3 MINUTES

ENVIRON

REMARQUE : Le premier cycle de fermeture peut prendre jusqu’à 12 minutes. Les condensateurs doivent être

totalement chargés pour qu’une durée normale de fermeture se produise.

33

Page 34

PROBLÈME CAUSE POSSIBLE SOLUTION CONSEILLÉE

1. Le registre d’évacuation peut prendre

jusqu’à 12 minutes pour se fermer lors

du premier cycle. Après le premier

cycle, il se ferme en 3 minutes environ.

2. Commutateur de service en position de

maintien ouvert.

Le registre d’évacuation ne se ferme pas

Ne pas tourner à la main.

Ceci endommage le moteur.

La garantie sera annulée !

Le registre accroche

Le registre tourne en continu 1. Moteur du registre défectueux. 1. Changer le moteur du registre.

Pas 120 VCA entre blanc n° 4 et noir n° 1

Pas 120 VCA entre blanc n° 4 et

orange n° 2

120 VCA entre blanc n° 4 et noir n° 1

durant l’appel de chaleur

120 VCA entre blanc n° 4 et noir n° 1

120 VCA entre blanc n° 4 et orange n° 2

REGISTRE OUVERT

Pas 120 VCA entre blanc n° 4 et

jaune n° 3

Registre ouvert

Pas de combustion

3. Mal câblé.

4. Le conduit de registre d’évacuation est

ovalisé, ce qui cause le grippage du

clapet interne.

5. Obstruction dans le conduit de registre.

(a) Le conduit d’évacuation est enfoncé

trop loin.

(b) Vis à tôle de plus de 13 mm (½ po).

6. Raccordement desserré ou coupé.

7. Moteur du registre d’évacuation

défectueux.

1. Quelque chose bloque le clapet de

registre.

2. Conduit de registre ovalisé.

Faux-rond / grippage.

3. Bord rabattu du conduit d’évacuation

enfoncé trop loin.

1. Coupure à la limite haute ou secondaire.

2. Raccordements desserrés ou coupés.

3. Vérifier le fusible ou disjoncteur.

4. Coupe-circuit ou interrupteur d’urgence

ouvert.

5. Mal câblé. Voir les schémas.

6. Contrôler le contacteur de porte de

soufflante.

1. Pas d’appel de chaleur par le

thermostat.

2. Raccordements desserrés ou coupés.

3. Contacteur de limite d’exploitation, de

régulation de pression ou de coupure

pour bas niveau d’eau.

4. Mal câblé.

1. Raccordement desserré ou coupé.

2. Réarmement manuel du contact du

système de coupure de sécurité

WMO-1.

3. Déposer le couvercle du WMO-1 ; il

doit y avoir 120 VCA entre chaque

borne de contacteur et le fil de terre

vert.

4. Conduit d’évacuation ou cheminée

obstrué(e).

5. Air de combustion insuffisant.

6. Air d’appoint insuffisant.

7. WMO-1 défectueux.

8. Moteur du registre défectueux.

1. S’assurer que le commutateur de

service est en position automatique.

2. Consulter les schémas de câblage.

3. Il doit y avoir 120 VCA entre blanc n° 4

noir n° 1 pour commander la fermeture

du registre. Il ne doit pas y avoir de

tension entre blanc n° 4 et orange n° 2.

4. Serrer, réparer ou changer le

raccordement.

5. Changer le moteur du registre

d’évacuation.

1. S’assurer qu’il n’y a aucune

obstruction au clapet de registre.

2. Ajusterle conduit de registre ou

changer le registre d’évacuation.

3. Aligner correctement et fixer le

conduit d’évacuation en s’assurant

que le clapet ne touche PAS le

conduit d’évacuation.

1. Attendre le réarmement du contacteur

de limite.

2. Réparer les raccordements desserrés

ou coupés.

3. Changer le fusible ou réarmer le

disjoncteur.

4. Fermer l’interrupteur.

5. Recâbler conformément au schéma.

6. Fermer la porte de soufflante.

1. Monter le thermostat pour créer un

appel de chaleur

2. Changer le thermostat.

3. Serrer, réparer ou changer le

raccordement.

4. Attendre la fermeture du contacteur

de limite d’exploitation, de régulation

de pression ou coupure pour bas

niveau d’eau.

5. Revoir les schémas de câblage.

1. Réparer ou changer le raccordement.

2. Réarmer manuellement le WMO-1.

3. Voir si le conduit d’évacution ou la

cheminée est obstrué ou insuffisant.

4. Vérifier que l’air de combustion est

suffisant.

5. Vérifier que l’air d’appoint est

suffisant.

6. Changer le WMO-1

7. Changer le moteur du registre.

34

Page 35

DONNEES D’EXPLOITATION INITIALES SUR LE BRULEUR ET LE SYSTEME D’EVACUATION

Consigner les données suivantes pour l’appareil fonctionnant avec un dispositif OVD sur son système d’évacuation, pour

référence lors des réglages ou de la maintenance annuels.

Date

APPAREILS DE COMBUSTION

AU MAZOUT

Taille du gicleur de brûleur au mazout

Pression d’exploitation du brûleur au mazout

Dépression d’exploitation de la pompe

Indice de fumée

Apport d’air secondaire

Température des gaz brûlés en sortie d’appareil

Mesure de CO2

35

Page 36

Field Controls, L.L.C. garantit que les produits Field Controls, L.L.C. suivants vendus aux présentes sont exempts de défauts de matériaux et de

FieldControls,L.L.C.warrantsthatthefollowing FieldControls,L.L.C.productssold hereunder,shall befreefromdefectsinmaterialandworkmanshipunder

main-d’œuvre dans des conditions normales d’utilisation pendant dix-huit (18) mois à compter de la date de fabrication par le consommateur sous

normaluseforeighteen(18)months fromdateofmanufacturingbytheconsumerexceptingtheprovisionsnumberedbelow.

réserve des dispositions ci-dessous.

Provisions:

Dispositions :

1. Field Controlsshall have no obligation in the

1. Field Control décline toute obligation dans l’éventualité où le client est incapable de fournir un reçu montrant la date d’achat du ou des

product(s)oraccuratedatecodeinformation.

produits par le client ni un code de date correct.

2. Le produit doit être correctemen installé, entretenu et exploité dans des conditions normales.

2. Theproductmustbeproperlyinstalled,maintainedandoperatedundernormalconditions.

3. Field Controls décline toute responsabilité pour de quelconques dommages consécutifs et indirects résultant d’une défaillance d’un produit

3. FieldControlsshallnotbe liablefor anyconsequentialand incidentaldamages, resulting fromfailure of

Field Controls, L.L.C., d’une non-livraison, d’un retard de livraison, d’une livraison dans un état non conforme ou de toute rupture de

deliver, delay in delivery, delivery in nonconforming condition, or for any breech of contract or duty between Field Controls, L.L.C. and the

contrat ou d’obligation entre Field Controls, L.L.C. et le client.

customer.

4. Les produits Field Controls, L.L.C. sont souvent destinés ou utilisés pour des applications spécifiques. Field Controls, L.L.C. n’offre

4. FieldControls,L.L.C.productsareoften intendedfor usein specificapplications. FieldControls,L.L.C.makesnowarrantyifa

aucune garantie si un produit Field Controls, L.L.C. est utilisé dans des applications autres que celles prévues.

productisusedinapplicationsotherthanintended.

5. Field Controls, L.L.C. aucune forme de garantie concernant les produits d’un quelconque autre fabricant distribués par Field Controls,

5. Field Controls,L.L.C. makes no warranty of any kindin regard to anyother manufacturer’s products distributed by Field Controls,L.L.C. Field

L.L.C.

Garantie limitée

Limited Warran ty

event the customer isunable to provide receipt showing the date the customer purchased the

a FieldControls,L.L.C. product,failure to

FieldControls,L.L.C.

36

46567100 Rév. A 01/09

Loading...

Loading...