Page 1

SIDEWALL POWER VENTER KIT

Model: SWG & SWG Stainless Series

*Patented

TYPICAL VENTING SYSTEM COMPONENTS

1 - SWG Series Power Venter

1 - CK Series Control Kit (sold separately)

OPTIONAL SYSTEM COMPONENTS

SWG SERIES THROUGH-WALL EXTENSION KIT

For installation in wall thickness over 8 inches. Models PEK-4 through PEK-8 are available.

FOR MOST MULTIPLE HEATING EQUIPMENT SYSTEMS

One CK Series Control Kit for each appliance. Except for a 24V gas furnace or boiler and a 30mV

water heater multiple venting system, use the CK-90 Series Control Kit.

CONTENTS

Available Control Kits ....................................2 General Inspection ........................ 8

Installation Instructions ................................2 Maintenance .................................... 9

Wiring .................................................................7 Repair Parts ......................................9

Air Flow Adjustments ....................................8 System Information .................... 12

GENERAL SYSTEM INFORMATION

Designed for operation with natural gas, LP gas and #2 fuel oil appliances.

1. The thermostat (wall thermostat or aquastat) calls for heat and energizes a relay which activates the

power venter. After the venter motor has come up to speed, the pressure switch closes. This closes the

circuit to the burner and allows the burner to re.

2. For millivolt controlled water heaters using the CK-20 Series Control Kit, the gas valve pressure switch

activates the power venter at the same time as the burner res.

3. After the heating requirement has been satis ed, the thermostat circuit will open and de-activate the

burner and power venter circuit.

4. For venting systems equipped with a post purge device, the power venter operates for a period of time

after the burner has shut o to purge remaining ue gases.

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

CK series control kit

sold separately

This device MUST be installed by a quali ed agency in accordance with the manufacturer's installation instructions. The de nition of

a quali ed agency is: any individual, rm, corporation or company which either in person or through a representative is engaged

in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all the

precautions required, and has complied with all the requirements of the authority having jurisdiction.

Please retain these instructions after installation.

Installed By: Phone:

www. eldcontrols.com

Installation Date:

Page 2

CONTROL KITS

CK-20F/HWK:

For operation with 30 or 750 millivolt gas- red water heaters, gas- red space heaters, and gas red pool or spa heaters with an internally mounted thermostat. Includes a xed post purge.

CK-21:

CK-40F/41F:

CK-43/43F:

CK-61:

CK-62:

CK-63:

CK-81:

CK-91/91F:

CK-92/92F:

For operation with gas- red instantaneous water heaters with a pressure tap port in the

burner manifold.

For operation with gas- red furnaces, boilers, unit heaters and water heaters operating with a

24 VAC gas valve. For systems not equipped with factory mounted spillage switches, use the

CK-41F which includes two GSK-3 spill switches. Includes a xed post purge.

For draft induced 24 VAC gas valve systems. Includes a 4” MG-1 draft control and electronic

post purge. The CK-43F includes a xed post purge.

For operation with oil- red systems. Has electronic post purge.

For operation with oil- red systems. Has thermally activated post purge.

For operation with oil- red systems. Has electronic post purge. For operating venter with or

without burner motor.

For operation with 750 millivolt operated boilers, furnaces, water heaters, pool or spa heaters,

and gas- red replaces when operating with remote mounted thermostat. Operated o a 24

VAC thermostat. For operation o of a 120 VAC thermostat or wall switch, use the CK-80.

For gas red draft induced 24 VAC gas valve systems and a 30 millivolt operated water heater.

Includes a 4” MG-1 draft control and an electronic post purge. The CK-91F includes a xed post

purge.

For operation with gas- red furnaces, boilers, unit heaters and water heaters operating with a

24 VAC gas valve and a 30 millivolt operated water heater. Includes an electronic post purge.

The CK-92F includes a xed post purge.

INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a quali ed installer in accordance with the manufacturer's installation

instructions. Appliances should have a minimum of 75% combustion e ciency or have a maximum measured ue

gas temperature of 550°F (Stainless steel units maximum temperature rating 650°F US/575°F CA) at the inlet of

the power venter.

1. The power venting system must be installed by a quali ed installer. "Quali ed Installer" shall mean an

individual who has been properly trained or a licensed installer. The installer must write or imprint his name,

phone number and date of installation on the installation tag. The tag should be attached to the power

venting system control kit box or power venter unit. Recording burner and venting system initial operational

information is strongly recommended as a guide for service or burner tune-up. Enter this in the space later in

this manual.

2. Safety inspection of a venting system should be performed before and after installing a power venting system

on an existing or new appliance. Procedures to follow are those recommended by the National Fuel Gas

Code ANSI Z223.1, or refer to the General Installation Inspection section of this manual.

3. Plan the vent system layout before installation to avoid the possibility of accidental contact with concealed

wiring or plumbing inside walls.

4. Single wall vent pipe (refer to Diagram B) may be used to join an appliance to the venting system, but if

proper clearances cannot be maintained from combustible materials, Class B Vent Pipe should be used for

gas appliances and Class L Type Vent Pipe for oil appliances. Refer to national or local codes for guidelines.

5. Disconnect power supply before making wiring connections to prevent electrical shock and

equipment damage.

6. This equipment is designed to overcome minor negative pressure conditions. To ensure extreme negative

pressure does not exist, follow the General Installation Inspection section of this manual.

7. Heating appliances equipped with draft hoods, such as boilers or furnaces, LP gas appliances, and Natural

gas appliances SHOULD have a secondary spillage switch installed. On appliances without draft hoods, it is

recommended that a secondary safety switch such as a WMO-1, GSK, FTS, or TSP-1 be used. Gas- red 30

millivolt power systems MUST be equipped with a spillage switch.

page 2

Page 3

8. Air ow adjustment MUST be made to ensure appliance e ciency. This should be done at the appliance

exhaust outlet with a velocity meter, draft gauge, or by "match test procedure". A match test is in accordance

with National Fuel Gas Code ANSI Z223.1, Section 8.6.

9. On oil- red and gas- red heating appliances not equipped with a draft hood, a barometric draft control

MUST be installed to regulate proper air ow and uctuations in the system’s air ow during operation.

Fluctuations may come from wind loads on the outlet of the power venter, house de-pressurization during

windy days, and the di erent house ventilation requirements between summer and winter operation. For

gas appliances, use a Field Controls Type MG-1 Barometric Draft Control. For oil appliances, use a Field

Controls Type M or RC Barometric Draft Control. Gas- red draft induced systems should have a single-acting

barometric draft control installed.

INSTALLATION OF SWG POWER VENTER

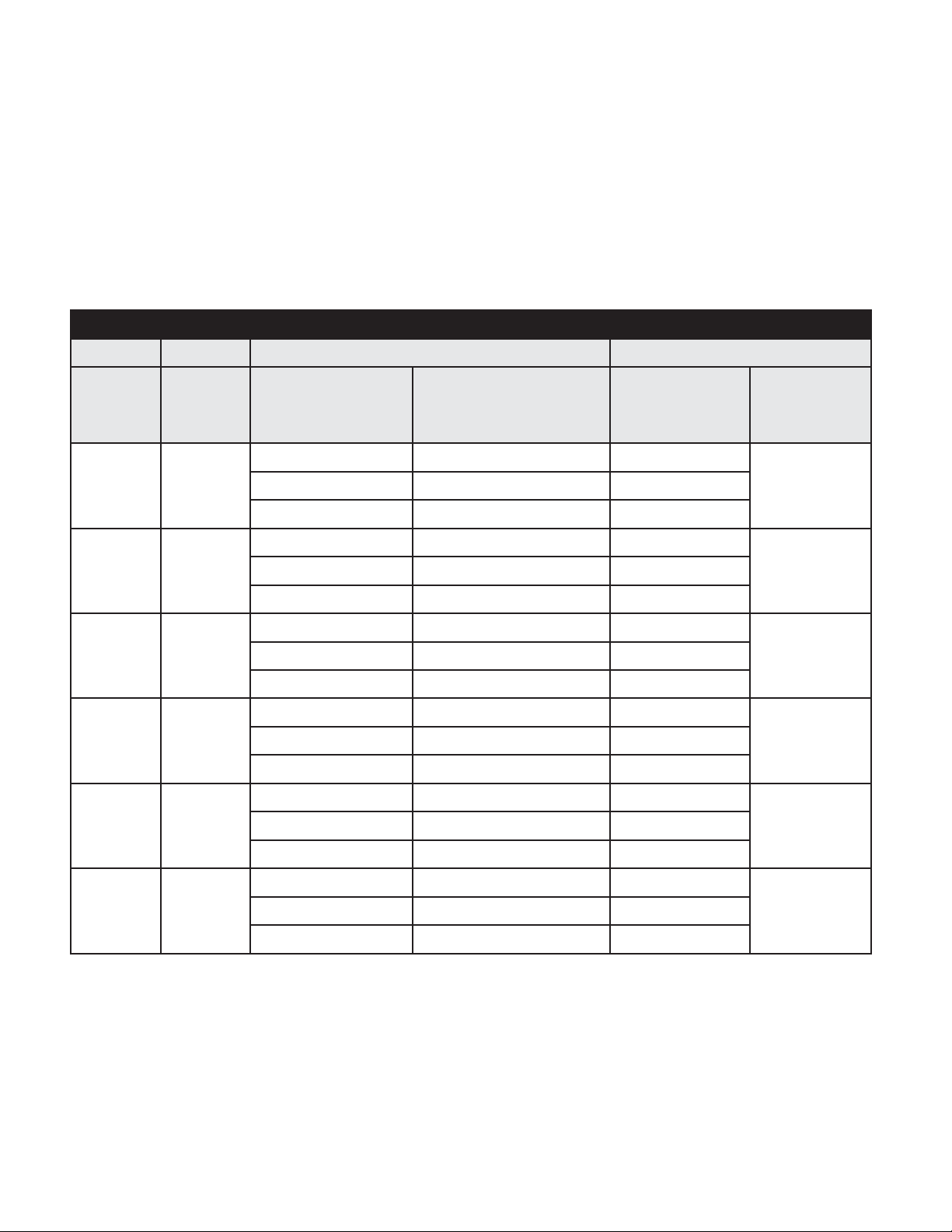

Table 1

UNIT SIZING CHART

OIL GAS MAXIMUM EQUIVALENT FEET OF VENT PIPE

MAX*

OIL GPH

INPUT

MAX**

BTU/HR

INPUT

N/A 70,000

1.10 170,000

1.85 290,000

2.65 416,000

3.60 566,000

AT MAX BTU/HR

INPUT

AT 60% OF MAX BTU/HR

INPUT

21 80 3"

--- --- ---

--- 23 3"

35 100 4"

65 100 5"

16 44 4"

51 10 0 5"

95 100 6"

28 78 5"

68 100 6"

100 100 7 "

28 78 6"

VENTING WITH

VENT PIPE SIZE

MODEL

SWG–350 100 4"

SWG–4HD

SWG–4s

SWG–5

SWG–5s

SWG–6

SWG–6s

SWG–761 100 7 "

90 100 8"

26 72 7"

4.75 740,000

SWG–851 100 8"

70 100 9"

*Rating at 100 psi. Sizing based on appliance maximum input rate not actual ring rate.

**Do not exceed maximum BTU/HR input rating or maximum oil GPH input. For multiple venting system applications, add the input for

each appliance. Category I gas- red draft induced systems require an SWG-4HD or larger. Category III gas- red draft induced systems

require an SWG-5 or larger.

PROCEDURE FOR CALCULATING TOTAL EQUIVALENT PIPE LENGTH IN FEET

1. Calculate the total equivalent feet for each type of tting used in the venting system from Table 2.

2. Calculate the total amount of feet for the straight lengths of vent pipe.

3. Add the equivalent feet for the tting with the total amount of feet of straight lengths. This will

approximate the total equivalent feet of the vent system.

page 3

Page 4

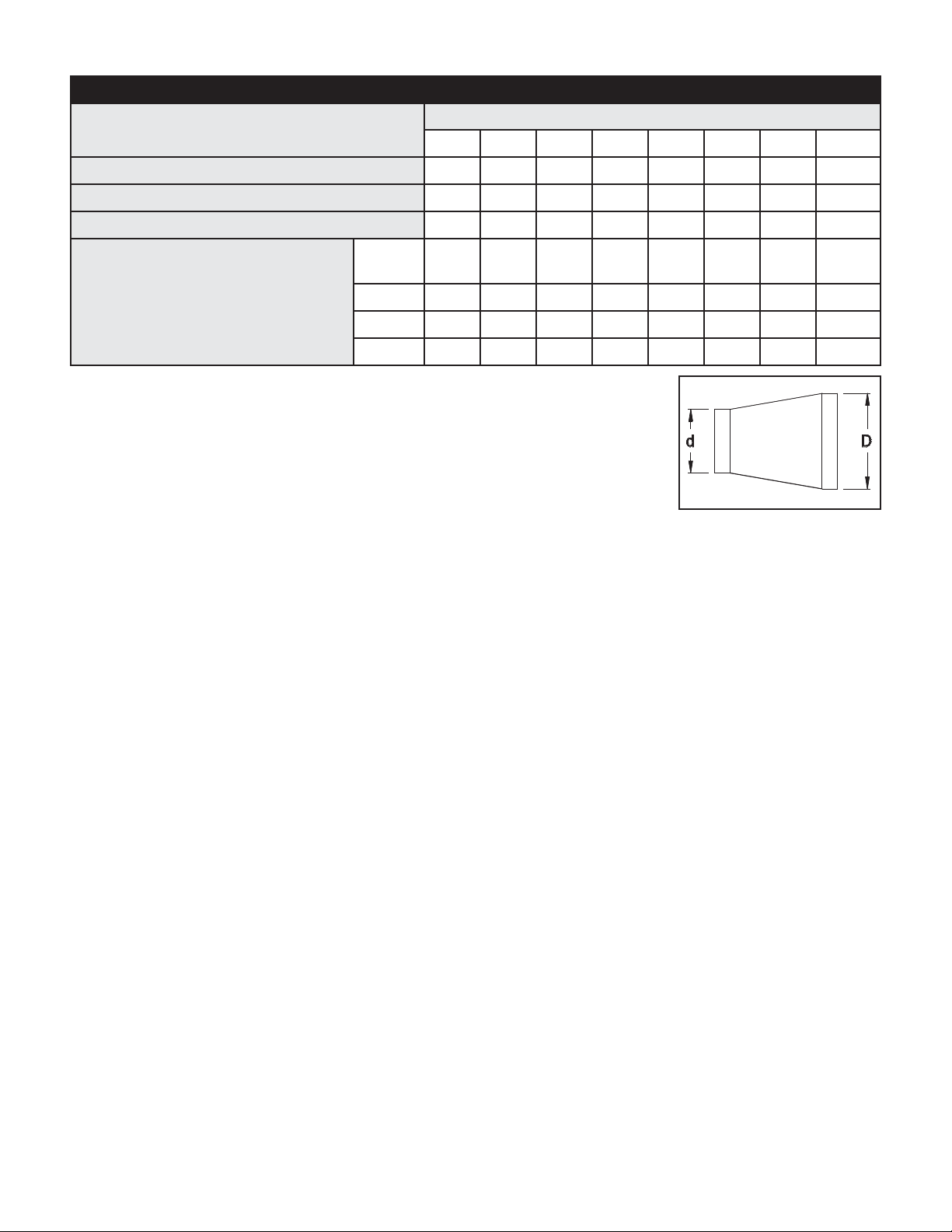

Table 2

EQUIVALENT LENGTH (FEET) OF VENT PIPE FITTING

VENT PIPE FITTINGS

VENT PIPE DIAMETER

3" 4" 5" 6" 7" 8" 9" 10"

TEE 19 25 31 38 44 50 56 63

90º ELBOW 5 7 9 11 12 14 16 18

45º ELBOW 3445678 9

d/D

SUDDEN REDUCER OR INCREASER

FOR 3 *RATIOS (d/D)

*Reducer or increaser ratio (d/D) small diameter divided reducer ratio is d/D = 4⁄8 = 1⁄2.

To estimate the equivalent foot length for the tting, use the smaller pipe diameter for the

equivalent length gure. Example 4” to 8” reducer; the reducer ratio is 1/2 and the smaller

pipe diameter is 4”. So, from the chart, the equivalent feet would be 7 feet. (See Figure 1)

1

⁄4 811141719222528

1

⁄2 5781012131517

3

⁄4 2334456 6

Example: System Pipe Size = 4”

Step 1 Two 4” 90° elbows @ 7 feet each = 14 ft.

Step 2 Ten 2 foot lengths of 4” pipe = 20 ft.

Step 3 Total equivalent feet = 14 ft. + 20 ft. = 34 ft.

Figure 1

INSTALLATION

CAUTION: Failure to install, maintain and/or operate the power venting system in accordance with

manufacturer's instructions will result in conditions which may produce bodily injury and/or property damage.

1. Remove power venter from packaging and inspect unit for damage. If the packaging has been crushed or

mutilated, check unit very carefully for damage. Rotate blower wheel to ensure that the motor and blower

wheel rotate freely. DO NOT install if any damage is apparent. Refer to unit sizing chart to check proper

venting sizing.

2. Location of the termination of the venting system should be installed in accordance with the National Fuel

Gas Code ANSI Z223.1, manufacturer's recommendations and/or local codes which are applicable. See

requirements below or refer to installation location, Diagram A, for typical locations.

a.

The exit termination of mechanical draft systems shall not be less than 7' above grade when located adjacent to

public walkways.

b. A venting system shall terminate at least 3' above any forced air inlet located within 10'.

c. The venting system of other than a direct vent appliance shall terminate at least 4' below, 4' horizontally from or

1' above any door, window or gravity air inlet into the building. When venting oil red equipment with a Field

Control's CAS-2 series Airboot® kit, the intake air hood can be mounted within 12 inches of the power venter

exhaust.

d. The vent termination of a direct vent appliance with an input of 50,000 BTUs per hour or less shall be located at

least 9" from any opening through which vented gases could enter the building. With an input over 50,000 BTUs

per hour, a 12" termination clearance shall be required.

e. The vent termination point shall not be installed closer than 3' from an inside corner of an L-shaped structure.

f. The vent termination should not be mounted directly above, or within 3' horizontally from an oil tank vent or gas

meter.

g. The bottom of the vent terminal shall be located at least 12" above nished grade.

3. After determining the location of the venting system termination point (See Diagram A), cut a square hole

through the wall at least 1" larger than the outer pipe diameter of the power venter. Mount the power

venter through the wall, keeping the outer pipe centered in the hole. (See Figure 3) Fasten the power venter

to the outside wall with appropriate fasteners, sealing the edges of the power venter base plate to the wall

with a high temperature silicone sealant. DO NOT enclose the spaced plates on the power venter body.

This will result in reduced cooling of the power venter body. Wood or vinyl siding should be cut so that the

unit mounts directly on the wall board to provide a stable support. If the siding is greater than

1

⁄2" thick use

a spacer plate or board behind the power venter mounting plate. (See Figure 2)

page 4

Page 5

SWG SERIES POWER VENTER INSTALLATION LOCATIONS

SWG Series Power

Venter Must Be At

Least 1 Foot Above

Doors Or Windows.

SWG Power Venter

Must Be At Least 7

Feet Above Public

Walkways.

SWG Series Power Venter

Must Be At Least 3 Feet Above

Any Outside Air Intake Within

10 Feet.

SWG Series Power Venter

Must Be At Least 4 Feet To

The Side Of Any Doors Or

Windows.

SWG Power Venter Must Be

Mounted At Least 1 Feet

Above Finished Grade.

NOTE: If mounting the power venter though a combustible wall material

and the ue gas temperature is above 400ºF at the power venter inlet,

line the square hole with a piece of corrosion resistant sheet metal or

non-combustible material. The liner piece should be the same width as

the wall section. (See Figure 3) The power venter has a maximum ue

gas temperature of 550ºF at the venter inlet. For installation in wall

thicknesses over 8 inches, use SWG Series Through Wall Extension Kit,

Model PEK.

SWG Series Power

Venter Must Be Mounted

At Least 3 Feet From

Inside Corners.

SWG Series Power Venter

Must Be At Least 4 Feet Below

Windows.

Diagram A

4. Backing Plate Installation

a. One Piece Backing Plate Installation (3", 6", 8" Models) Remove

the end pipe cover screws on the sides of the outside pipe and

remove end pipe cover. Then mount the backing plate over the

outer pipe and route the exible conduit and pressure switch

tube (if applicable) through the holes provided in the backing

plate. Fasten the backing plate to the inside wall with appropriate

fasteners. (See Figure 4) Re-install the end pipe cover and screws.

b. Two Piece Backing Plate Installation (4" and 5" Models):

i. Position the Upper Backing Plate Half on the inside wall by

placing the plate half on the inside wall and up to the venter

body, locating the air pressure sensing tube through the small

slot in the plate half and the exible conduit through the

larger slot, as shown in Figure 5. Install an appropriate

fastener in the upper right corner hole in the

plate half.

ii. Cut o or bend the two tabs of the Lower Backing

Plate Half inward (See Figure 6) and position it

on the inside wall as shown in Figure 7 and install

appropriate fasteners through the upper left and

lower right corner holes in both plate halves.

iii. Install an appropriate fastener in the lower left

corner hole.

Figure 2

Figure 3

page 5

Figure 4

Page 6

Figure 5

Figure 6

Figure 7

CONNECTING POWER VENTER TO APPLIANCE

Diagram B

Venting system should be installed and supported in accordance with the National Fuel Gas Code ANSI

Z223.1, or in accordance with any local codes. A vent pipe connector shall be supported for the design and

weight of the material employed, to maintain clearances, prevent physical damage and separation of joints. A

vent pipe increaser or reducer may be required for connecting the power venter to the vent system. If needed,

place the reducer close to the power venter. Smaller vent pipe sizes than a chimney-vented system may be

used for the vent system.

If mounting venting system near combustible materials, refer to Diagram B for allowable installation

clearances. Clearances are based on an installation using single wall galvanized steel vent pipe. For metal

thickness of galvanized steel pipe connectors, refer to NFPA 211 or NFPA 54 Standards for guidelines. If

manufactured double wall vent pipe is required or used for the installation, clearance should be based on the

vent pipe’s rated clearance. Always check local code requirements for code restrictions.

Route the vent pipe from the appliance to the power venter using as few elbows as possible. The horizontal

section of the vent pipe should have a slight upward slope from the appliance to the power venter. For

clearances to combustible materials, multiple appliance venting and other installation requirements, refer to

the National Fuel Gas Code ANSI Z223.1, and/or any applicable local codes or appliance manufacturer’s

installation instructions.

page 6

Page 7

INSTALLATION USING SINGLE WALL VENT PIPE

Table 3

INSTALLATION CLEARANCE WITH SINGLE WALL VENT PIPE

DOUBLE PIPE SYSTEM SINGLE PIPE SYSTEM

Allowable inlet

temperature SWG

Stainless Steel

400ºF or less 400ºF or less

Allowable inlet

temperature

SWG

1

⁄2" minimum 400ºF or less 400ºF or less 3" minimum

Clearance

(A)

Allowable inlet

temperature SWG

Stainless Steel

Allowable inlet

temperature

SWG

Clearance

(B)

400ºF to

650ºF US/575ºF CA

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF 1" minimum

1

400ºF to 550ºF

⁄2" minimum with

sheet metal liner

400ºF to

650ºF US/575ºF CA

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF 4" minimum

400ºF to 550ºF

Use a PEK series extension kit or follow installation method below for a double

pipe system. To install an outer pipe extension to the SWG power venter, the end

pipe cover on the power venter must be removed. Then, cut a 1 inch square notch

into the vent pipe extension before attaching the power venter. (See Figure 8) This

allows clearance for the adjustment damper. Install the needed pipe extensions and

terminate the outer pipe extension with the end pipe cover. (See Diagram B) The

table above shows minimum allowable clearances when using single or double pipe

systems. When the outer pipe is extended over the inner pipe, use the double pipe

guidelines when determining clearances. Figure 6 shows how the air ow pattern

through an SWG reduces the required clearances to combustibles.

NOTE: Vent pipe joints should be secured with at least three (3) sheet metal screws.

3" minimum

with sheet

metal liner

Figure 8

Figure 9

CLASS B AND CLASS L DOUBLE WALL VENT PIPE INSTALLATION

(Follow vent pipe manufacturer's listed or recommended clearances from combustible material.)

1. Using a hand crimper or a like device, crimp the inner pipe of the SWG power venter approximately 1"

long. (See Figure 10)

2. Attach the vent pipe over the crimped end of the SWG power venter inner pipe.

3. Secure the vent pipe to the SWG power venter inner pipe with at least three (3) #8 sheet metal screws.

Pre-drilling the holes through both pipes will allow easier fastening.

WIRING

NOTE: Refer to appropriate control kit for proper installation instructions.

Wire the power venter motor and controls in accordance with the National Electrical Code and applicable

local codes. UNIT MUST BE GROUNDED. Check ground circuit to make certain that the unit has been

properly grounded. The wiring should be protected by an over-current circuit device rated at 15 amperes.

CAUTION MUST be taken to ensure that the wiring does not come in contact with any heat source. All

line voltage and safety control circuits between the power venter and the appliance MUST be wired in

accordance with the National Electrical Code for class 1 wiring or equivalent.

page 7

Figure 10

Page 8

AIR FLOW ADJUSTMENTS

In order to obtain proper system draft, the power venter has an air ow adjustment

damper built in. When used in a system with a barometric draft control, this damper

should be used to make coarse draft adjustments, while the barometric should be used

for ner adjustments. Loosen the locking screw on the air ow adjustment damper

on the outer pipe of the power venter. (See Figure 11) Adjust the damper to the full

open position. Follow appliance manufacturer’s procedures for starting the heating

appliance. Then adjust the thermostat to call for “Heat”. After the system has operated

for several minutes to stabilize ue gas temperatures, check for negative draft or updraft at the heating appliance outlet or air ow into the draft hood. Use a draft gauge,

velocity meter or match test procedure. Adjust the adjustment damper closed to obtain

the minimum air ow required to maintain draft. Then increase air ow slightly (10%

over minimum air ow rate) to ensure proper venting. For oil- red or gas- red power

burners, adjust draft to proper over- red draft.

Figure 11

If proper draft has been established, tighten the adjustment locking screw. For gas- red systems, shut o

thermostat and check for residual heat spilling from draft hood. If this occurs, a post purge timer may be

required. If so, use a Field Controls PPC-5 Electronic Post Purge or a Control Kit which includes one. Before

installing, refer to the General Installation Inspection to check for negative pressure problems in the building.

If su cient combustion air for the burner is not provided, a ow reversal during the o cycle could occur

within the venting system. This may cause combustion problems as well as condensation that could block the

air pressure sensing tube. It may also contribute to premature motor failure. Combustion, and/or make-up air,

should be supplied from outside the structure and the air inlet should be on the same wall as the power venter

discharge. For example, tightly constructed homes and homes retro tted from electric heated systems are

more likely to experience combustion and/or make-up air problems. For further information consult “The Field

Report–E ects of insu cient combustion air on draft and heating systems”. Refer to the appropriate control

kit installation instructions for pressure switch adjustment procedure and system checkout procedures before

operating continuously.

NOTE: After proper venting has been established, it is recommended that a combustion test on gas and oil

units, a check for CO levels on gas units, and a smoke test on oil systems be performed to ensure maximum

burner e ciency. Oil burner air adjustments should be set at a zero to a trace smoke at the highest or

recommended CO

% setting set by heating equipment manufacturer.

2

GENERAL INSTALLATION INSPECTION

Recommended procedures for safety inspection of an appliance in accordance with the National Fuel Gas

Code ANSI Z223.1. The following procedure will help evaluate the venting system. It is intended as a guide

to aid in determining that the venting system is properly installed and is in a safe condition for continuous

use. This procedure should be recognized as a generalized procedure which cannot anticipate all situations.

Accordingly, in some cases, deviation from this procedure may be necessary to determine safe operation of

the equipment. If it is determined that a condition exists which could result in unsafe operation, the appliance

should be shut o and the owner advised of the unsafe condition. Corrections must be made before the

appliance is put into continuous operation. The following steps should be followed in making a safety

inspection.

1. Visually inspect the venting system for proper size and determine that there is no ue gas spillage,

blockage, restriction, leakage, corrosion or other de ciency which could cause an unsafe operation.

2. Insofar as practical, close all building doors, replace dampers, windows and all doors in area in which

the appliance is located. Turn on clothes dryers, any exhaust fans, such as range hoods and bathroom

exhausters so they operate at maximum speed. Do not operate a summer exhaust fan. If, after completing

Steps 3 through 7 it is believed su cient combustion air is not available, refer to the National Fuel Gas

Code ANSI Z223.1, or any applicable local codes for guidance.

3. Place in operation the appliance being inspected. Follow the lighting instructions and adjust thermostat so

appliance will operate continuously.

4. Determine that the pilot or burner is operating properly and that the main burner ignition operates

satisfactorily, by interrupting and re-establishing the electrical power of the appliance in any convenient

manner. Test the pilot or burner safety device to determine if it is operating properly by extinguishing the

pilot or disconnecting the ame safety circuit and pressure switch sensing tube from the pressure switch.

page 8

Page 9

5. Visually determine that the main burner is burning properly; i.e., no oating, lifting or ashbacks. When

performing smoke test on oil- red systems, the burner should operate at a zero to a trace smoke. This can

indicate reduced available combustion air to burner.

6. If appliances are equipped with high and low ame control or ame modulation, check for proper main

burner operation at low ame.

7. Test for spillage at draft hood or barometric draft control opening and burner inlet air location after 5

minutes of main burner operation. Use a draft gauge, ame of a match or candle, smoke from a cigarette,

cigar or pipe. If spillage occurs, adequate air is not available. Shut o heating appliance thermostat and

check for spillage around the draft hood, barometric draft control or burner inlet air location after power

venter has stopped operation. If a ow reversal is noticed, house de-pressurization is occurring and make up

air is required. For oil- red systems, this may be noticed by oil fume smell after post purge cycle.

8. Turn on all fuel burning appliances within the same room so that they will operate at their maximum input.

Then repeat Steps 5 through 7.

9. Return doors, windows, exhaust fans, replace dampers and any other fuel-burning appliances to their

previous condition of use.

MAINTENANCE

1. Motor: Inspect the motor once a year - motor should rotate freely. To prolong the life of the motor, it must be

lubricated with six drops of SWG Superlube, Part # 46226200, annually. NOTE: Some models may have sealedbearing motors, which do not require lubrication.

2. Wheel: Inspect the power venter wheel annually to clear any soot, ash or coating which inhibits either rotation

or air ow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion and for ue

gas leakage. Replace, seal or tighten pipe connections if necessary. Check the power venter choke plate

to ensure it is secured in place. Check the barometric draft control, if installed, to ensure the gate

swings freely.

4. System Safety Devices: With the heating system operating, disconnect the pressure sensing tube from

the pressure switch on the CK Kit. This will stop the burner operation. Re-connecting the tube will relight

the burner. For 30 millivolt operating systems, disconnect one lead of the spill switch circuit from the

thermocouple junction block. This will shut o the pilot and the burner. Re-connection will allow relighting

the pilot.

REPLACEMENT PARTS

Should the motor or blower wheel need replacing, the following replacement items are available. The Repair

Motor Assembly contains the Motor and Blower Wheel factory assembled to a mounting bracket.

Table 4

PAR T NUMBERS

MODEL REPAIR MOTOR ASSEMBLY BLOWER WHEEL

SWG–3 46196601 46131800

SWG–4HD, SWG–4s

SWG–5, SWG–5s

SWG–6, SWG–6s

SW G–7 461524 01 46154700

SWG–8 46460101 46154800

SWG Repair

Motor Assembly

SWG Repair

Motor Assembly

page 9

46234800 46310400

46234900 46213800

46235000 46385800

Blower

Wheel

Page 10

REMOVAL AND INSTALLATION OF THE SWG SERIES POWER VENTER MOTOR ASSEMBLY

1. Remove the screws securing the motor enclosure cover. (See Figure 12)

2. Remove the screws securing the motor assembly. Rotate the motor assembly counterclockwise and slide

the assembly into the center. Then pull the motor assembly out of the unit. (See Figure 13)

3. Clean o any build-up inside the blower wheel housing and the blower wheel. CAUTION: Avoid

applying excess pressure on the blower wheel when cleaning o any build-up of material. This will cause

an imbalance of the blower wheel which will result in excessive vibration and premature

motor failure.

4. If replacing the motor assembly with a new assembly, disconnect the conduit from the old motor and cut

the wires close to the motor. The new motor assembly will have an electrical box and connector for the

conduit.

INSTALLATION

1. Insert the blower wheel through the hole in the front plate of the power venter housing. (See Figure 14)

2. Using two nails or awls, align the two center holes of the motor mount bracket and cover plate. Locate

the motor assembly into position by sliding the assembly over the mounting holes in the front plate. Use

the nails or awls to hold the assembly in position. Secure motor assembly into position at the four corners,

then secure center two holes. (See Figure 15)

3. Re-attach the exible conduit and wires to the motor and secure the cover on the electrical box.

4. Seal the top edge of the motor mount bracket against the front plate with a high temperature

silicone sealant.

5. Install motor cover with side louvers pointing down.

Figure 12

Figure 14

page 10

Figure 13

Figure 15

Page 11

REMOVAL AND INSTALLATION OF THE SWG SERIES POWER VENTER MOTOR ASSEMBLY

Removal

1. Remove the motor enclosure cover by loosening the four screws. (See Figure 12)

2. Open the electrical box on the motor and disconnect the conduit and wires from the motor. (See Figure 16)

3. Remove the four nuts securing the motor assembly, and pull the motor assembly straight o of the unit. (See

Figure 17)

4. Clean o any build-up inside the blower wheel housing and the blower wheel. CAUTION: Avoid applying

excess pressure on the blower wheel when cleaning o any build-up of material. This will cause an

imbalance of the blower wheel which will result in excessive vibration and premature motor failure.

Installation

1. Align the holes in the circular cover plate with the holes in the motor mount bracket on the motor assembly.

(See Figure 17)

2. Slide the motor assembly onto the protruding threaded studs on the power venter body with the exhaust

chute pointing downward, and replace the four nuts securely to the threaded studs. (See Figure 17)

3. Re-attach the exible conduit and wires to the motor and secure the cover on the electrical box.

4. Install the motor cover with the side louvers pointing downward.

Figure 16

INITIAL BURNER AND VENTING SYSTEM OPERATIONAL INFORMATION

List the following for each operating appliance on the sidewall venting system, as a guide for tune-up or

service information annually:

DATE:

FOR GAS FIRED EQUIPMENT

Heating Appliance BTU/HR Input

Gas Valve Operation Pressure

Vent System Draft Above Draft Hood or Before

Barometric Draft Control

CO2 Measurement

CO Measurement

Equipment Outlet Flue Gas Temperature

FOR OIL FIRED EQUIPMENT

Oil Burner Nozzle Size

Oil Burner Operating Pressure

Pump Operating Vacuum Pressure

Figure 17

Smoke Number

Over- re Draft

Equipment Outlet Flue Gas Temperature

CO2 Measurement

page 11

Page 12

LIMITED WARRANTY

Field Controls, LLC (“Company”) warrants that its products shall be free from defects in material and workmanship

under normal use for the limited period indicated, from the date of manufacture, subject to the provisions 1-8 below.

Eighteen (18) months

All Field Controls Products (except for those listed below as 5 years or 90 days).

Five (5) years

Field Controls Direct Vent Systems (FDVS), Field Oil Vent Kits (FOVP), and ComboVents (CV).

Field Controls warrants that the products listed below shall be free from defects in material and workmanship under

normal use for the limited period indicated, from the date of purchase by the consumer, subject to the provisions

1-8 below.

Ninety (90) days

UV lamps/bulbs

Provisions:

1. During the limited warranty period, Company, or its authorized service representative, will repair or replace, at Company’s

option, without charge, a defective Product. Product that is repaired may be repaired with new or refurbished replacement

parts. Product that is replaced may be replaced with a new or refurbished product of the same or similar design. Company

will return repaired or replacement Product to customer in working condition. Labor charges are not covered as part of the

limited warranty.

2. With regard to UV lamps/bulbs, customer shall be required to include a "valid proof of purchase" (sales receipt) identifying

the Product purchased (Product model or accurate date code information) and the date the Product(s) was purchased.

3. Product whose warranty/quality stickers, Product serial number plates or electronic serial numbers have been removed,

altered or rendered illegible shall not be covered under the limited warranty.

4. Defective Product must be returned to Company, postage prepaid.

5. IN NO EVENT SHALL COMPANY BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR SIMILAR

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS OR REVENUE, INABILITY TO USE PRODUCT, OR OTHER

ASSOCIATED EQUIPMENT, THE COST OF SUBSTITUTE EQUIPMENT, AND CLAIMS BY THIRD PARTIES) RESULTING FROM

THE USE OF PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

6. THIS WARRANTY AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, REMEDIES AND

CONDITIONS, WHETHER ORAL, WRITTEN, EXPRESS, STATUTORY OR IMPLIED. TO THE EXTENT PERMITTED BY LAW,

COMPANY DISCLAIMS ALL IMPLIED AND STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

7. Company makes no warranty of any kind in regard to other manufacturer’s products distributed by Company. Company will

pass on all warranties made by the manufacturer and where possible, will expedite the claim on behalf of the customer, but

ultimately, responsibility for disposition of the warranty claim lies with the manufacturer.

8. Product that has been subjected to misuse, accident, shipping or other physical damage, improper installation or application,

abnormal operation or handling, neglect, fire, water or other liquid intrusion are not covered by the warranty.

Phone: 252.522.3031 • Fax: 252.522.0214

www.fieldcontrols.com

© Field Controls, LLC P/N 46139100 Rev O 10/12

Loading...

Loading...