Page 1

COMBUSTION AIR SYSTEM

MODEL: CAS-4

This product is designed for use with any natural gas or LP burning furnace, water heater, or boiler with a

24 VAC control system. It may be used with a millivolt powered system with additional hardware. It may

also be used with more than one appliance. The CAS unit mechanically draws air into a structure and

disperses it near the combustion air intake of an appliance. If an optional Vacuum Relief Valve (VRV) is

used, the incoming air is tempered before entering the structure’s airspace. Refer to Diagrams A and B for

guidance in setting up the CAS system based on the size and length of the connecting ductwork and the

input rating of the appliance.

ITEMS INCLUDED IN KIT:

1- Motorized Blower

1- 4" galvanized intake air Vent Hood

2- Mounting brackets to secure the CAS to a wall

2- Wire/conduit connectors

1- 4" x 6" Pipe Increaser Fitting

1- 6" Orifice Ring

1- Instruction Sheet

1- High/Low Motor Speed Switch

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

This device MUST be installed by a qualified agency in accordance with the manufacturer's installation instructions. The definition of

a qualified agency is: any individual, firm, corporation or company which either in person or through a representative is engaged

in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all the

precautions required, and has complied with all the requirements of the authority having jurisdiction.

Please retain these instructions after installation.

Installed By: Phone:

Installation Date:

www.fieldcontrols.com

Page 2

GENERAL SYSTEM OPERATION

The thermostat (wall thermostat, or aquastat) calls for heat and energizes a relay which activates the 1.

CAS unit. After the CAS fan has come up to speed, an internal air pressure switch closes and completes

the circuit to allow the burner to fire. If the appliance is power vented, the venter and CAS activate

simultaneously. After the CAS comes up to speed, a pressure switch in the unit closes and allows the

appliance to fire.

After the heating requirement has been satisfied, the thermostat circuit will open and deactivate the 2.

burner and CAS unit.

For power vented systems with a post purge device, the power venter and CAS operate for a period of 3.

time after the burner has shut off to purge remaining flue gases from the vent system.

INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a qualified installer in accordance with the manufacturer’s

installation instructions.

This combustion air system must be installed by a qualified installer. “Qualified Installer” shall mean an 1.

individual who has been properly trained or a licensed installer.

Plan the system layout before installation to avoid the possibility of accidental contact with concealed 2.

wiring or plumbing inside walls.

Disconnect power supply before making wiring connections to prevent electrical shock and 3.

equipment damage.

SIZING AND SETUP

Diagrams A and B and Table 1 show the maximum equivalent length and size of duct pipe that should be

used when installing the CAS system. Using these charts will help ensure that the proper amount of air is

drawn into the structure as needed by the appliance. The defined regions shown correspond to the CAS's

airflow characteristics when using 4" and 6" diameter sheet metal duct pipe and the included orifice ring.

Follow the guidelines below to properly size and setup the CAS.

Determine the maximum input firing rate of the appliance, or the maximum total firing rate of multiple 1.

appliances that will be used.

Position the motorized CAS unit according to the guidelines in the Installation section.2.

Determine where the intake air vent hood will be located based on the recommendations in the 3.

Installation section.

The CAS is equipped with a High/Low motor speed control switch. When calculating the maximum 4.

equivalent feet, determine which speed is appropriate for the application. (Refer to Diagram A or B or

Table 1)

Calculate the total equivalent length of duct pipe including elbows and fittings needed to connect the 5.

CAS unit to the vent hood. (Refer to Diagram A or B or Table 1)

On Diagram A or B, locate the point that corresponds to the firing rate along the horizontal axis and the 6.

equivalent length of the duct pipe along the vertical axis, if using for make up air.

The point should fall within one of the three regions on the table. Each region corresponds to a duct pipe 7.

diameter of 4", 4" using the orifice ring, and 6" respectively. If the point falls near the rightward border

of a particular region then the VRV is not necessary. If the point falls away from the rightward border,

then a VRV is needed to reduce the amount of air drawn in.

page 2

Page 3

Draw a horizontal line on Diagram A or B that passes through the point located in step 5. The position of 8.

the point along this line relative to the left and right borders of the region it falls into indicates the relative

position that the balance weight of the VRV should be adjusted to. If the point falls near the leftward

border of a region, then the VRV balance weight should be adjusted to its minimum position. This

corresponds to turning the balance weight screw as far counterclockwise as possible.

EXAMPLE: A gas fired appliance firing at 100,000 BTU/hr. where the CAS unit needs to be placed 30

equivalent feet from the intake hood.

From Diagram A or B, the point at 100,000 BTU/hr. on the Gas Firing Rate scale and 30 equivalent feet

2

falls in the 4" Duct, Hood, and Orifice Ring region. The point is approximately

⁄3 of the horizontal distance

between the left and right boundary of the region. The left boundary is the edge of the graph, the right

boundary is the diagonal line that says 4" Duct, Hood & Orifice Ring. Therefore, place the Orifice Ring into

the inlet of the CAS so that it sits on the ledge above the fan. It does not matter which way the Orifice Ring is

turned as long as it is pushed down against the ledge completely. Use 4" diameter pipe to connect the vent

hood and the CAS unit. Install a VRV and the included 4"x 6" increaser on top of the CAS unit and adjust the

2

balance weight to

⁄3 of the distance of its full adjustment range from its minimum setting. The minimum setting

is with the balance weight turned all of the way counterclockwise.

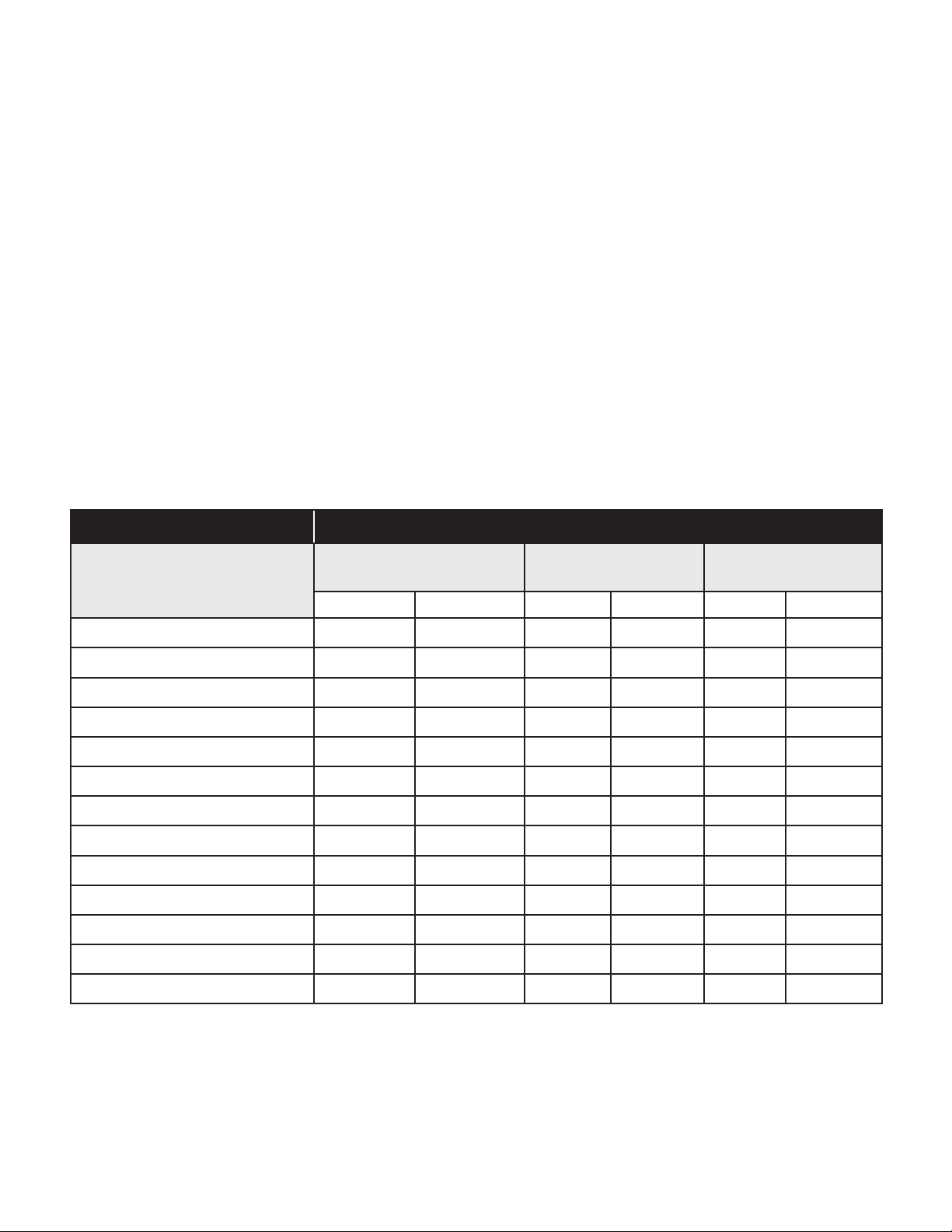

Table 1

TOTAL INPUT OF APPLIANCE MAXIMUM EQUIVALENT FEET OF INSTALLATION

CAS-4, 4mV Gas

4" Duct And Hood w/

Restrictor

4" Duct and 4"

Intake Air Hood

6" Duct and 6"

Intake Air Hood

(BTU/hr.)

HI LOW HI LOW HI LOW

50,000 300 300 300 300 300 300

75,000 300 300 300 300 300 300

100,000 300 300 300 300 300 300

125,000 300 220 300 220 300 300

150,000 174 108 232 118 300 300

175,000 99 48 152 63 300 300

200,000 52 14 102 32 300 300

225,000 20 NA 68 13 300 239

250,000 NA NA 45 NA 300 150

300,000 NA NA 16 NA 300 53

350,000 NA NA NA NA 193 8

400,000 NA NA NA NA 109 NA

450,000 NA NA NA NA 56 NA

page 3

Page 4

LOW SPEED SIZING CHART

0

50

100

150

200

250

300

50 100 150 200 250 300 350 400

GAS INPUT FIRING RATE (1000 BTU/hr.)

MAX. EQUIVALENT DUCT LENGTH (ft.)

0.0 0.50 1.00 1.50 2.00 2.50

OIL INPUT FIRING RATE (gallons per hour)

(1 gallon oil/hr = 140,000 BTU/hr.)

6" Duct &Hood

4" Duct &Hood

4" Duct &Hood w/ Orifice

Diagram A

Diagram B

page 4

Page 5

INSTALL ATION

PLACEMENT OF THE CAS UNIT

The motorized CAS unit should be located on a flat horizontal

surface within the same space as the appliance and within

3' of the combustion air intake as possible. Two mounting

brackets are provided for securing the unit against a solid

structure, such as a wall, column, or the side of the appliance

itself. Use the included screws to attach the brackets to the

CAS housing as shown in Figure 1. Secure the brackets to a

solid structure with appropriate fasteners. It is not required to

use the brackets as long as the unit is located so that it may

not be bumped, moved, or tipped over. The optional Vacuum

Relief Valve (VRV) should be placed directly on the air inlet of

the CAS unit if using 6". (See Figure 2) Refer to Diagram A to

determine if the VRV is needed. The VRV should be oriented

so that the axis of the swinging gate is horizontal.

ASSEMBLING THE WEIGHTS ON THE VRV

Refer to Figure 3 to assemble the weight assembly, hex nut,

and knurled nut to the VRV gate. After the weight is correctly

positioned, tighten the hex nut against the gate to prevent the

weight assembly from moving during operation.

Figure 1

INTAKE AIR HOOD LOCATION

The 4" galvanized vent hood should be located on an

outside wall maintaining minimum clearances to other intake

and exhaust vents in accordance with the National Fuel Gas

Code, ANSI Z223.1, manufacturer's recommendations and/

or local codes which are applicable. The hood should be

located at least 10' from a power vented exhaust outlet and

should be on the same wall. The intake air hood should be a

Figure 2

minimum of 1' above grade or snowlines where applicable.

INSTALLATION OF INTAKE AIR HOOD

After determining the location of the vent hood, cut a 4

1

⁄2" round or square hole in the wall. Insert the vent hood

and secure with appropriate fasteners. Take precautions

to avoid interference with wiring or other plumbing in the

wall to be cut.

INSTALLATION OF DUCT

Refer to Diagram A or B to determine what size pipe is

needed. Connect the duct pipe from the top of the CAS

unit to the Vent Hood in the wall. If using 4" diameter pipe

attach the provided 4" x 6" Pipe lncreaser Fitting to the top

of the CAS unit (or the VRV, if installed). The duct should

Figure 3

be supported with appropriate mounting straps from floor joists,

walls, or other solid structures. The straps should be placed so as to keep the ductwork out of passageways.

(See Figure 2) A minimum of 12' of pipe should be run to help temper outside air being drawn in. The VRV

may also be installed near the intake air hood and adjusted to mix room air with outside air to help temper

air in cold climates.

page 5

Page 6

WIRING INSTRUCTIONS

Black

White

White

White

Red

Red

Common

Common

Wire the CAS unit in accordance with the National Electric Code and applicable local codes. UNIT MUST

BE GROUNDED. Check the ground circuit to make certain that the unit has been properly grounded. The

wiring should be protected by an over-current circuit device rated at 15 amperes. CAUTION must be taken

to ensure that the wiring does not come in contact with any heat source. All line voltage and control circuits

between the CAS unit and the appliance MUST be wired in accordance with the National Electrical Code

for Class I wiring or equivalent.

Remove the wiring access cover to access the wiring terminals. Use the enclosed conduit connector(s) to

route the appropriate wires through the CAS housing. The incoming ground wire must be attached to the

green colored ground screw near the wire terminals. The following sections describe the most common

applications. The references to various series of control kits implies that any kit in that series may be used. If

further information or additional wiring diagrams are needed please consult Field Controls' technical support.

INTERNAL WIRING CONNECTIONS FOR THE CAS UNIT

Refer to Figure 4 for the internal wiring of the CAS-4 unit.

External Wiring Connections

WIRE KEY WIRE COLOR

MOTOR MANUFACTURER W1 W2 W3

McLean Engineering Black Blue Brown

All Others Brown Black Blue

Refer to Figures 5-12 for appropriate wiring method.

Figure 4

Figure 5- Chimney Vent Single 24V Furnace

page 6

Page 7

White

White

White

White

White

Black

Black

BlackBlack

Red

Red

Common

Common

Black

Black

Black

White

Red

Red

Common

Common

Figure 6- Power Vent Single 24V Furnace

page 7

Figure 7- Chimney Vent 24V Furnace and 30mV

Water Heater With CK-20FV or CK-20FG

Page 8

Figure 8- Chimney Vent 24V Boiler

Figure 9- Power Vent Single 24V Boiler

page 8

Page 9

Figure 10- Chimney Vent Two 24V Gas Appliances With CAC-24

page 9

Page 10

Note: Pressure sensing tubes

of CK Control Kits needs to

be “teed” together the hooked

up to SWG, DI, or PV Unit.

Note: DIP 1 needs to be

“teed” into pressure

sensing tube on CAS 4.

Figure 11- One Power Venter Two 24V Gas Appliances With DIP-1

page 10

Page 11

Figure 12

Figure 12 shows how the DIP-1 should be attached to the CAS. Note that the 1⁄4" OD plaster tubing on the top

3

of the CAS unit must be cut and a 3-way male barb TEE suitable for

⁄16" I.D. tubing placed as shown in order

to connect the DIP-1.

MAINTENANCE

Inspect the system annually to ensure proper operation by observing that the fan activates when a call for 1.

heat occurs and deactivates when the call for heat is satisfied.

Disconnect power to the CAS unit and repeat Step 1. Note: The unit should not run and the appliance 2.

should not fire in this condition.

Inspect the duct pipe for cracks and security to the CAS unit, VRV (if installed), and vent hood.3.

Clear any obstructions, if present, from the inlet of the vent hood and the outlet of the CAS unit.4.

Periodically, the fan blade chamber may need cleaning. First, disconnect the power supply to the CAS. 5.

Next, disconnect the duct pipe from the unit. Then remove the top pan and clean the fan housing area as

needed. Reattach the top pan, reconnect the duct pipe and the power supply.

REPLACEMENT PARTS

The following items are available for replacement, if needed. In order to replace these parts, power must be

disconnected and the unit must be disassembled. If this is necessary, take note of the positions and locations

of whatever items that may need to be removed to replace other items.

If in doubt, please consult Field Controls Technical Support at 1-800-742-8368.

ITEM DESCRIPTION FIELD PART NUMBER

Motorized Fan 4 62 741 00

Air Pressure Switch 46273100

24 VAC Relay for CAS-4 461614 00

page 11

Page 12

LIMITED WARRANTY

Field Controls, LLC (“Company”) warrants that its products shall be free from defects in material and workmanship

under normal use for the limited period indicated, from the date of manufacture, subject to the provisions 1-8 below.

Eighteen (18) months

All Field Controls Products (except for those listed below as 5 years or 90 days).

Five (5) years

Field Controls Direct Vent Systems (FDVS), Field Oil Vent Kits (FOVP), and ComboVents (CV).

Field Controls warrants that the products listed below shall be free from defects in material and workmanship under

normal use for the limited period indicated, from the date of purchase by the consumer, subject to the provisions

1-8 below.

Ninety (90) days

UV lamps/bulbs

Provisions:

1. During the limited warranty period, Company, or its authorized service representative, will repair or replace, at Company’s

option, without charge, a defective Product. Product that is repaired may be repaired with new or refurbished replacement

parts. Product that is replaced may be replaced with a new or refurbished product of the same or similar design. Company

will return repaired or replacement Product to customer in working condition. Labor charges are not covered as part of the

limited warranty.

2. With regard to UV lamps/bulbs, customer shall be required to include a "valid proof of purchase" (sales receipt) identifying

the Product purchased (Product model or accurate date code information) and the date the Product(s) was purchased.

3. Product whose warranty/quality stickers, Product serial number plates or electronic serial numbers have been removed,

altered or rendered illegible shall not be covered under the limited warranty.

4. Defective Product must be returned to Company, postage prepaid.

5. IN NO EVENT SHALL COMPANY BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR SIMILAR

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS OR REVENUE, INABILITY TO USE PRODUCT, OR OTHER

ASSOCIATED EQUIPMENT, THE COST OF SUBSTITUTE EQUIPMENT, AND CLAIMS BY THIRD PARTIES) RESULTING FROM

THE USE OF PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

6. THIS WARRANTY AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, REMEDIES AND

CONDITIONS, WHETHER ORAL, WRITTEN, EXPRESS, STATUTORY OR IMPLIED. TO THE EXTENT PERMITTED BY LAW,

COMPANY DISCLAIMS ALL IMPLIED AND STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

7. Company makes no warranty of any kind in regard to other manufacturer’s products distributed by Company. Company will

pass on all warranties made by the manufacturer and where possible, will expedite the claim on behalf of the customer, but

ultimately, responsibility for disposition of the warranty claim lies with the manufacturer.

8. Product that has been subjected to misuse, accident, shipping or other physical damage, improper installation or application,

abnormal operation or handling, neglect, fire, water or other liquid intrusion are not covered by the warranty.

© Field Controls, LLC P/N 46284600 Rev H 11/09

Phone: 252.522.3031 • Fax: 252.522.0214

www.fieldcontrols.com

Loading...

Loading...