Page 1

120 VAC SYSTEM CONTROL KIT

Model: CK-61

Designed for use on SWG Series Power Vent Hoods for controlling oil fired

heating appliances with 120 VAC controls.

ITEMS INCLUDED IN KIT:

1- Junction box with mounted pressure switch and solid state post purge control

1

1- 2 Ft. Length of

1

⁄4" tubing connector

1 1- Flexible conduit connector

1- WMO-1 Secondary Safety Switch

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

This device MUST be installed by a qualified agency in accordance with the manufacturer's installation instructions. The definition of

a qualified agency is: any individual, firm, corporation or company which either in person or through a representative is engaged

in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all the

precautions required, and has complied with all the requirements of the authority having jurisdiction.

Installed By: Phone:

⁄4" aluminum tubing

Please retain these instructions after installation.

Installation Date:

www.fieldcontrols.com

Page 2

INSTALLATION

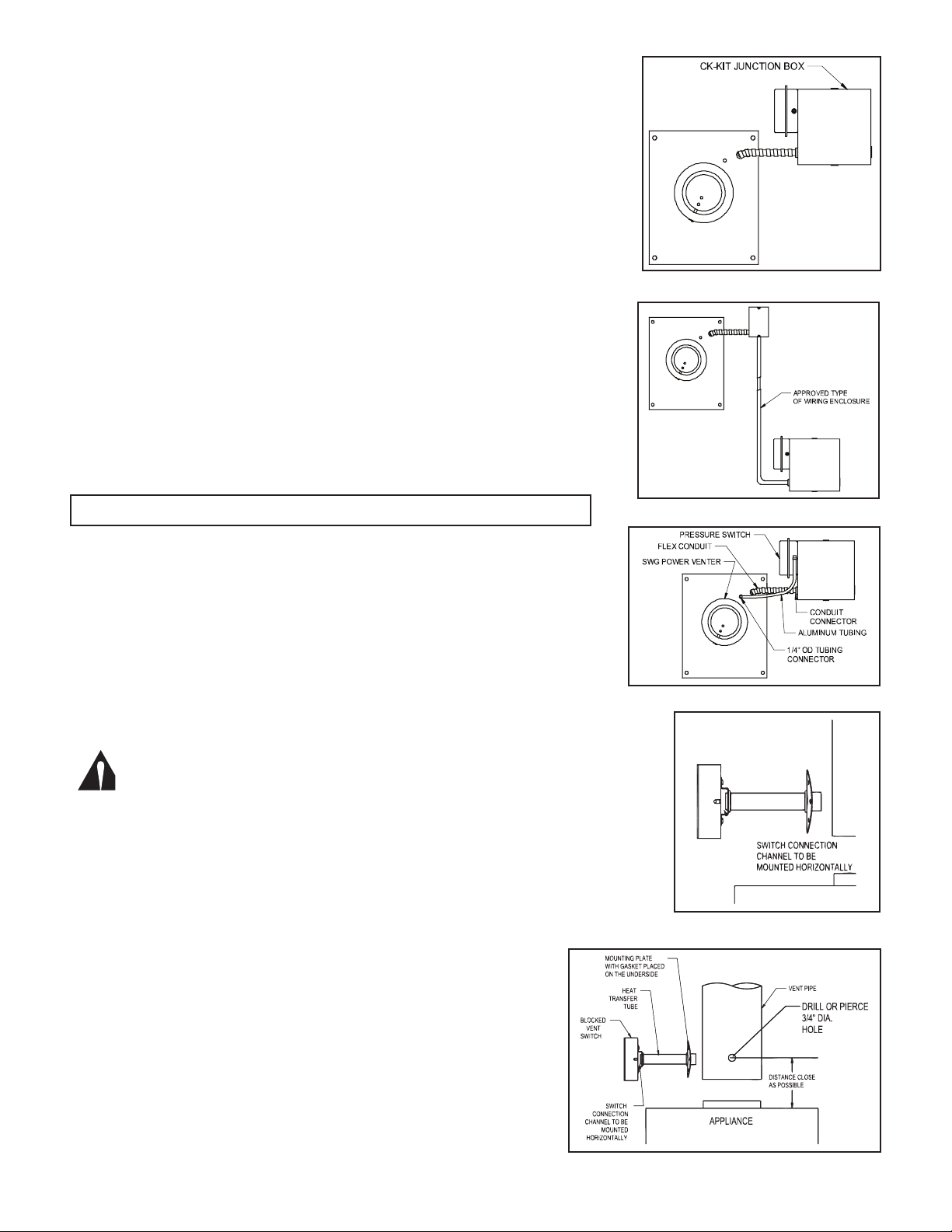

MOUNTING JUNCTION BOX

The junction box can be mounted at the venter or remotely mounted away

from the venter. (See Figure 1 & Figure 2)

Remove one of the knockouts from the side of the junction box where 1.

the pressure switch is mounted. Install the flexible conduit connector

onto the CK-61 junction box and secure with fastening nut. If remote

mounting the CK-61 junction box, mount the flexible conduit connector

onto a 2” x 4” installer supplied junction box.

Fasten the flexible conduit from the SWG Venter into the conduit 2.

connector. Mount the CK-61 junction box or installer supplied junction

box onto the wall or floor joist without straining the flexible conduit.

Fasten the CK- 61 junction box through the four dimpled locations on

the base of the box. (See Figure 3)

OIL FIRED SECONDARY SAFETY SWITCH (WMO-1)

Installation of a SECONDARY SAFETY SWITCH (WMO-1) is recommended

for detecting flue gas spillage from a blocked flue system and/or

inadequate draft.

MOUNTING IN THE VENT PIPE

SEE THE APPLIANCE MANUFACTURER’S INSTRUCTIONS FOR THE SPECIFIC LOCATION.

IF THE APPLIANCE MANUFACTURER DOES NOT SPECIFY A LOCATION, REFER TO FIGURE 5.

3

Drill or pierce a clean hole (about 1.

⁄4” diameter) in the vent pipe near

the appliance outlet. (See Figure 5)

The heat transfer tube must have the fiber gasket installed against the 2.

mounting plate before attaching the unit to the vent pipe.

3

Insert the heat transfer tube with gasket into the 3.

⁄4” diameter hole

placed in the vent pipe during step 1.

Secure the assembly to the vent pipe with a minimum of 4 sheet 4.

metal screws. The channel must be mounted horizontally, unless

specified differently by the appliance manufacturer. (See Figure 5)

Figure 1

Figure 2

Figure 3

WARNING: Switch connection channel must be mounted horizontally,

unless specified differently by the appliance manufacturer.

CAUTION: Disconnect electrical power supply to the appliance when wiring the

blocked vent switch.

PRESSURE SWITCH SENSING TUBE INSTALLATION

1

Attach the 1.

⁄4" tubing connector to the pressure tube on the SWG Venter.

(See Figure 3)

1

Connect the supplied 2.

⁄4" aluminum tubing to the tubing

connector. Route the tubing to the CK- 61 junction box and

connect the tubing to the pressure switch. When routing the

tubing, avoid kinking the tubing by bending the tubing

too sharply.

1

For remote mounted CK-61 junction box, use a 3.

⁄4" OD

copper, aluminum or plastic tubing and route the tubing to

avoid contact with any heat source.

Refer to the SWG Venter installation instructions for setting

system airflow.

page 2

Figure 4

Figure 5

Page 3

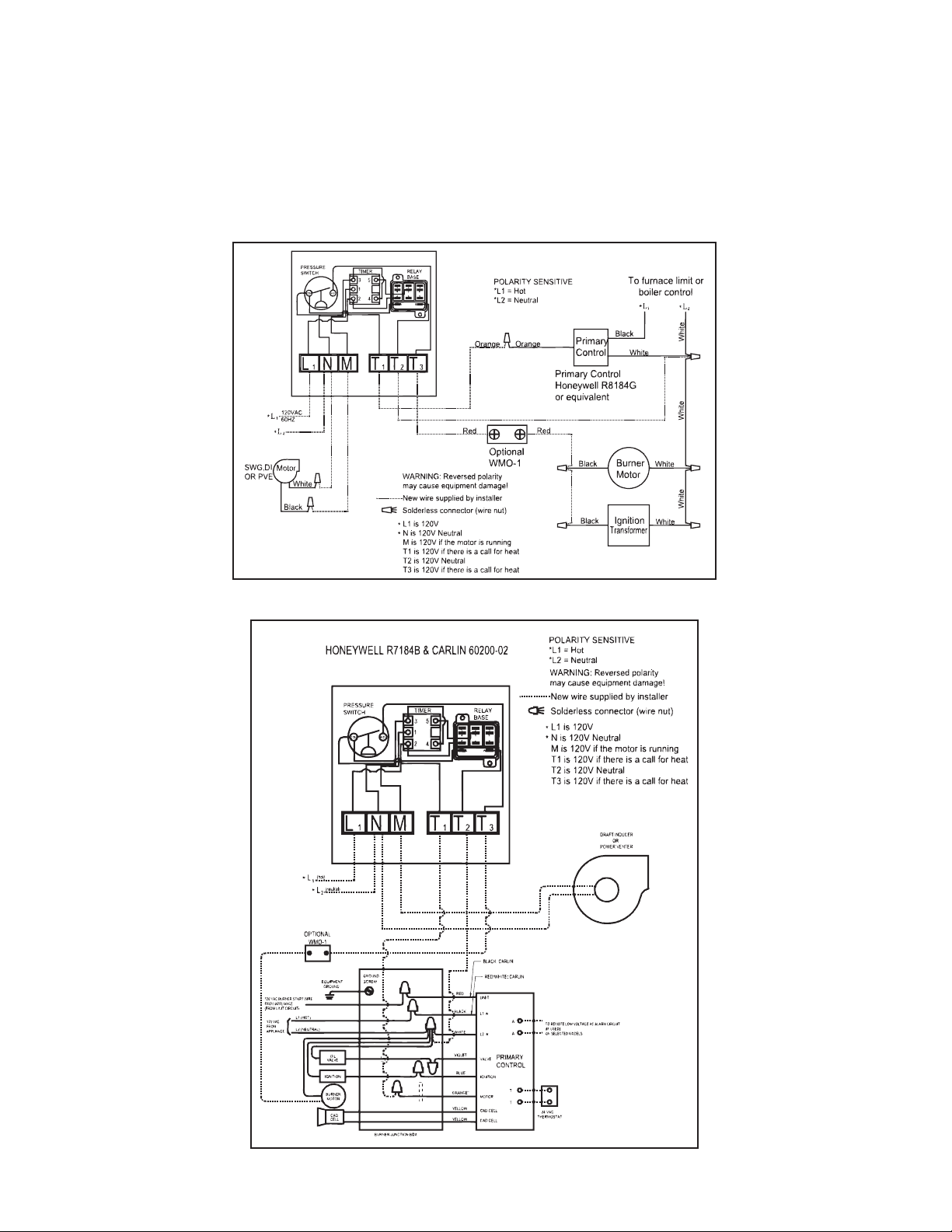

WIRING INSTRUCTIONS

Wire the venter motor and controls in accordance with the National Electrical Code, manufacturer's

recommendations and/or applicable local codes. UNIT MUST BE GROUNDED. Check ground circuit to make

certain that the unit has been properly grounded. The wiring should be protected by an over current circuit

device rated at 15 amperes. Caution must be taken to ensure that the wiring does not come into contact with

any heat source. All line voltage and safety control circuits between the venter and the appliance MUST be

wired in accordance with the National Electrical Code for Class I wiring or equivalent methods. Route the

venter motor and control wiring with an appropriate wiring method. (Diagrams A through E)

Diagram A - Oil Fired System: Single Unit Wiring

Diagram B - Oil Fired System: Wiring with Electronic Primary

page 3

Page 4

Diagram C - Typical Wiring for Oil Fired WarmAir

Furnace with a Honeywell ST9103 Control Board

page 4

Diagram D - Riello Burner Application

Page 5

page 5

Diagram E - Multiple Oil Fired Systems

Page 6

ADJUSTMENTS

PRESSURE SWITCH ADJUSTMENTS

With the venter air flow set and the appliance operating

at the best operating efficiency, adjust the pressure

switch by rotating the adjustment screw clockwise until

the burner shuts off, then rotate the adjustment screw

counterclockwise until the burner fires. Rotate the

1

adjustment screw an additional

⁄4 turn counterclockwise

to ensure proper switch setting.

(See Figure 6)

POST PURGE TIMING ADJUSTMENT

To adjust the post purge time, refer to

Figures 7 & 8.

For timer that looks like Figure 7: Rotate the timer

adjustment on the timer clockwise to increase the

operation time. To decrease the operation time,

rotate the timer adjustment counterclockwise.

For timer that looks like Figure 8: Rotate the

timer adjustment on the timer counterclockwise

to increase the operation time. To decrease

the operation time, rotate the timer adjustment

clockwise.

*Typical post purge time should be between 3 to

5 min.

Figure 6

Figure 7

page 6

Figure 8

Page 7

SYSTEM CONTROL CHECK OUT PROCEDURES

Adjust the thermostat to call for heat and observe the power venting system for proper sequence of 1.

operation: (Repeat if necessary).

Thermostat calls for heat.a.

Relay is energized, post purge timer is energized, and venter motor starts.b.

Pressure switch closes and burner starts.c.

Thermostat is satisfied, relay is de-energized, burner stops and post purge timer operates venter motor d.

for approximately 3 to 5 minutes.

While system is operating, disconnect power to the venter motor. This should open the pressure switch 2.

contacts and stop burner operation.

(If WMO-1 switch is installed) Allow vent system to cool. Disconnect the vent pipe between the venter 3.

inlet and the appliance outlet. Block the vent pipe with a noncombustible material. Activate the heating

system with the main burner operating. Allow approximately 2 minutes or less for the secondary safety

switch to deactivate the burner. Reset safety switch and repeat.

MAINTENANCE

Motor:1. Inspect motor once a year; the motor should rotate freely.

Wheel: 2. Inspect venter wheel annually, for oil fired heating systems, clear any soot, ash or coating which

inhibits either rotation or air flow. Remove all foreign material before operating.

Vent System:3. Inspect all vent pipe connections annually for looseness and for evidence of flue gas

leakage. Seal or tighten pipe connections if necessary.

TROUBLE SHOOTING HINTS

Main burner does not fire when thermostat calls for heat with venter operating.1.

Check pressure switch adjustment.a.

Check fuel flow.b.

Check wiring connections between pressure switch and burner.c.

Check pressure switch for continuity across terminals, during venter operation.d.

Venter does not activate when thermostat calls for heat.2.

Jump wire the terminals L1 and M to ensure motor operation.a.

Check wiring.b.

Flue gas odor.3.

Check system draft.a.

Check post purge venting time.b.

Check for negative pressure in building.c.

page 7

Page 8

LIMITED WARRANTY

Field Controls, LLC (“Company”) warrants that its products shall be free from defects in material and workmanship

under normal use for the limited period indicated, from the date of manufacture, subject to the provisions 1-8 below.

Eighteen (18) months

All Field Controls Products (except for those listed below as 5 years or 90 days).

Five (5) years

Field Controls Direct Vent Systems (FDVS), Field Oil Vent Kits (FOVP), and ComboVents (CV).

Field Controls warrants that the products listed below shall be free from defects in material and workmanship under

normal use for the limited period indicated, from the date of purchase by the consumer, subject to the provisions

1-8 below.

Ninety (90) days

UV lamps/bulbs

Provisions:

1. During the limited warranty period, Company, or its authorized service representative, will repair or replace, at Company’s

option, without charge, a defective Product. Product that is repaired may be repaired with new or refurbished replacement

parts. Product that is replaced may be replaced with a new or refurbished product of the same or similar design. Company

will return repaired or replacement Product to customer in working condition. Labor charges are not covered as part of the

limited warranty.

2. With regard to UV lamps/bulbs, customer shall be required to include a "valid proof of purchase" (sales receipt) identifying

the Product purchased (Product model or accurate date code information) and the date the Product(s) was purchased.

3. Product whose warranty/quality stickers, Product serial number plates or electronic serial numbers have been removed,

altered or rendered illegible shall not be covered under the limited warranty.

4. Defective Product must be returned to Company, postage prepaid.

5. IN NO EVENT SHALL COMPANY BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR SIMILAR

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS OR REVENUE, INABILITY TO USE PRODUCT, OR OTHER

ASSOCIATED EQUIPMENT, THE COST OF SUBSTITUTE EQUIPMENT, AND CLAIMS BY THIRD PARTIES) RESULTING FROM

THE USE OF PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

6. THIS WARRANTY AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, REMEDIES AND

CONDITIONS, WHETHER ORAL, WRITTEN, EXPRESS, STATUTORY OR IMPLIED. TO THE EXTENT PERMITTED BY LAW,

COMPANY DISCLAIMS ALL IMPLIED AND STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

7. Company makes no warranty of any kind in regard to other manufacturer’s products distributed by Company. Company will

pass on all warranties made by the manufacturer and where possible, will expedite the claim on behalf of the customer, but

ultimately, responsibility for disposition of the warranty claim lies with the manufacturer.

8. Product that has been subjected to misuse, accident, shipping or other physical damage, improper installation or application,

abnormal operation or handling, neglect, fire, water or other liquid intrusion are not covered by the warranty.

Phone: 252.522.3031 • Fax: 252.522.0214

www.fieldcontrols.com

© Field Controls, LLC P/N 4 61449 00 Rev J 12/09

Loading...

Loading...