Page 1

DRAFT REGULATOR

Model: B-34TJ

LISTED UNDER RE-EXAMINATION SERVICE OF UNDERWRITERS

LABORATORIES, INC. LISTED UNDER LABEL SERVICE OF CANADIAN

STANDARDS ASSOCIATION. NOT CSA CERTIFIED FOR SOLID FUELS.

The regulator contained in this package is manufactured with

careful precision. It is designed to regulate chimney draft with a

high degree of accuracy and fuel efficiency.

English.......Page 1

Français .....Page 4

Espanõl......Page 6

Page 2

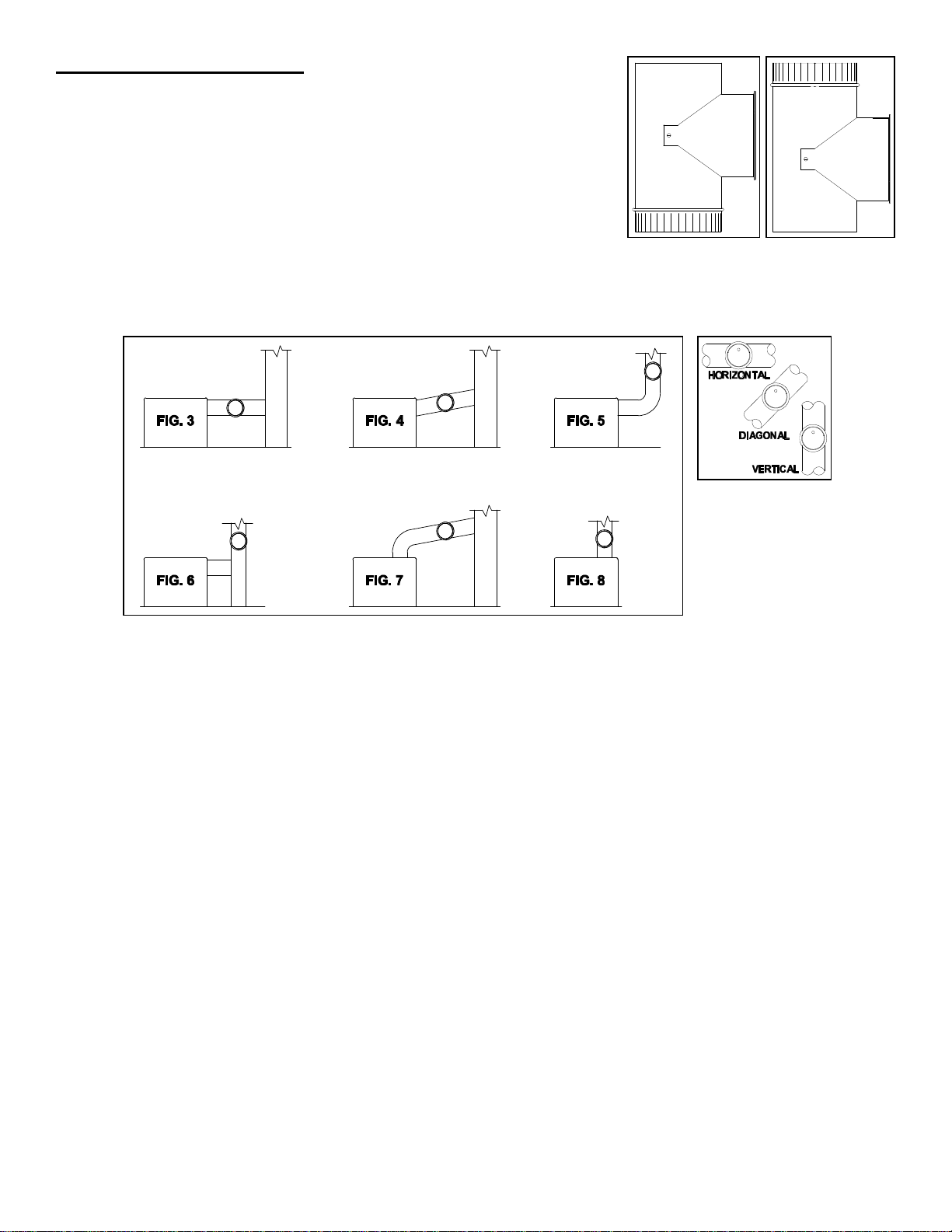

INSTALLATION OF TEE SECTION

Figure 9

Locate the draft control as near to the furnace or boiler as possible. If the

installation has a smokepipe stack control, locate the regulator at least 18" away

from the stack control. (See Figures 3-9)

FOR WOOD FUEL

When burning wood, creosote builds up in the flue pipe. For this reason the tee

should be assembled so that the beaded and crimped end is pointed downward.

This prevents seepage at the joints. (See Figure 1)

FOR OTHER FUEL

Figure 2Figure 1

Install tee with beaded and crimped end pointed upward. (See Figure 2)

NOTE: Damper must be mounted with the hinge pins horizontal and the face of the damper plumb for correct operation.

This is done by rotating the damper section within the collar for any pipe position. Tighten screw to hold firmly in place.

BEST LOCATIONS FOR OIL OR SOLID FUELS Figures 3-8

*Selected sizes CSA and UL approved. Not CSA certified for solid fuels.

Page 2

Page 3

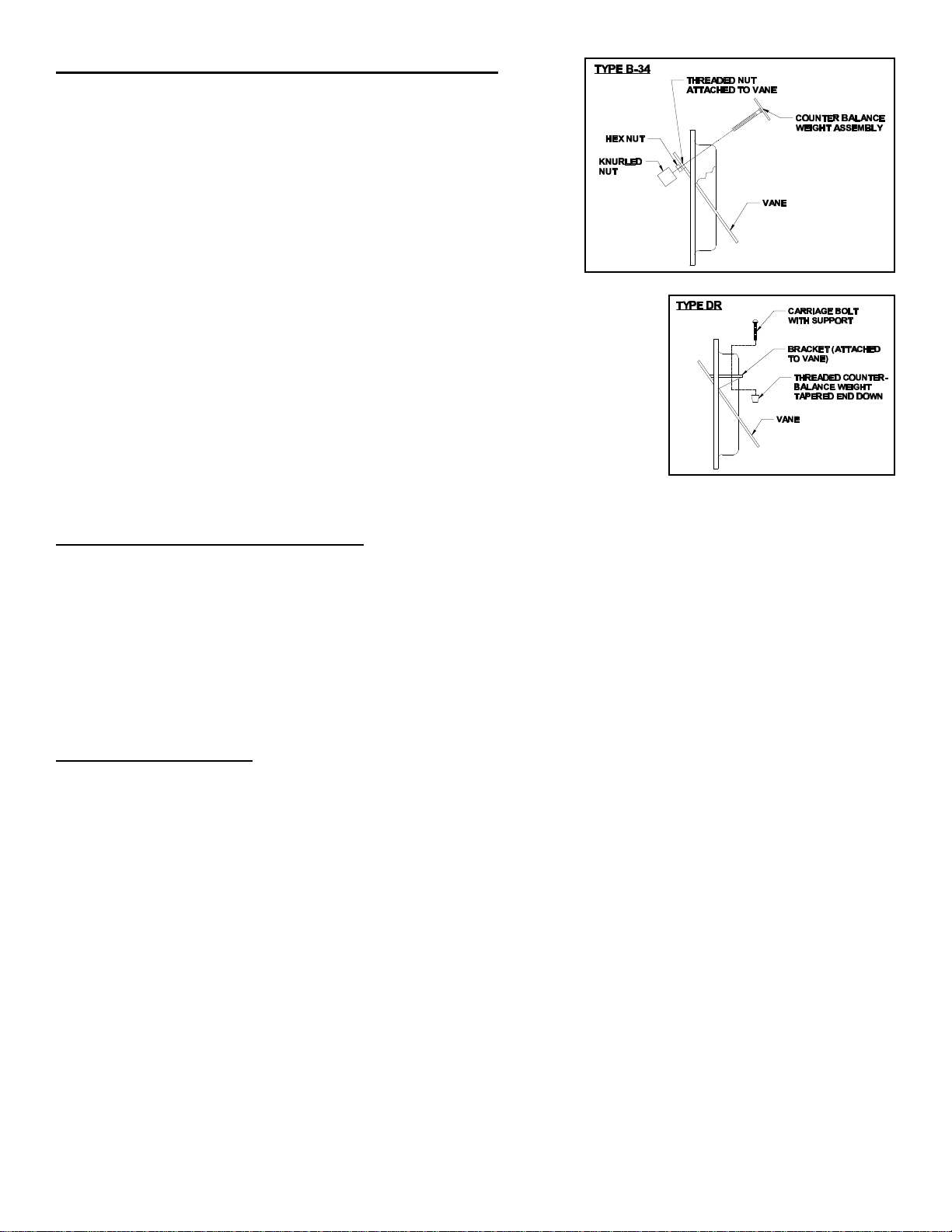

BALANCING WEIGHT ASSEMBLY AND DRAFT ADJUSTMENT

Figure 10

Figure 11

TYPE B-34 (See Figure 10)

1. Assemble the “counter balance weight assembly” to the draft control

as shown in Figure 10 Thread “counter balance weight” through

“threaded nut” attached to the vane. Assemble “hex nut” and “knurled

nut” on front of vane as shown in Figure 10.

2. Turn “knurled nut” counter clockwise for less draft, clockwise for more

draft.

3. When adjustment is made for desired draft, lock the “counter balance

weight assembly” in place by tightening the “hex nut” located under

the “knurled nut” against the vane.

TYPE DR (See Figure 11)

1. Assemble the “carriage bolt” through the “weight support bracket” attached to

vane.

2. Thread tapered “counter balance weight” on “carriage bolt” (tapered portion of

weight must point toward bottom of draft control). For less draft, slide “counter

balance weight assembly” toward “Lo” position marked on the bracket; for more

draft, slide “counter balance weight assembly” toward “Hi” position.

3. When adjustment is made for desired draft, tighten weight securely to “carriage

bolt”. Vertical installation: The 8” and 9” sizes, when mounted in vertical installations

only, require a small screw and nut (supplied) assembled in the hole at the bottom

vane. The 6” and 7” regulators do not require this additional hardware in vertical installation.

WOOD AND COAL FIRED APPLICATIONS

1. Installations of this Draft Control should be made in accordance with the stove manufacturer's instructions. When this

is not possible, follow the directions below: (NOTE: For the regulator to operate properly, the chimney must be clean

and free of obstructions.

2. The best setting for wood and coal burners is a draft gauge reading of .04” to .08 W.C. If a draft gauge is not

available, with the draft regulator fully installed and a good fire burning, adjust the counterbalance weight closer to the

gate for as low a draft setting as possible, without the fire dying or getting smoke-back with the stove door slightly

open. To obtain higher heat levels, move the weight away from the gate to increase the setting.

3. For best combustion efficiency, stack temperature (below the draft regulator) should be 350° to 450° F for dry wood.

Recommended stack temperatures and draft settings for coal vary according to the manufacturer of the stove.

OIL FIRED APPLICATIONS

Proper operation of the regulator depends upon proper installation and adjustment. Use a CO2 indicator, stack

thermometer and draft gauge to adjust draft for oil fired burners. Domestic oil burners work best with the draft over fire of

.01 to .02-inches W.C.

Page 3

Page 4

INSTALLATION DE LA SECTION EN “T”

Schéma 9

Placer le régulateur de tirage aussi près de la fournaise ou de la chaudière

que possible. Si l’installation est dotée d’une commande de tuyau de

cheminée, placer le régulateur à au moins 18 po de cette commande. (Voir

les Schémas 3-9)

POUR BOIS DE CHAUFFAGE

Lorsqu’on fait brûler du bois, de la créosote se forme à l’intérieur du tuyau de

fumée. Pour cette raison, le joint en “T” devrait être assemblé de façon que le

bout embouti et ondulé pointe vers le bas. Cela évite le suintement aux joints.

(Voir le Schéma 1)

Schéma 1

Schéma 2

POUR AUTRE COMBUSTIBLE

Installer le joint en “T” de façon que le bout embouti et ondulé pointe vers le haut. (Voir le Schéma 2)

NOTA: Le registre doit être monté de façon que les axes de charnières soient à l’horizontale et que la face du registre soit

d’aplomb, pour assurer un fonctionnement adéquat. Pour ce faire, tourner la section de registre à l’intérieur du collier pour

toute position de tuyau. Serrer la vis pour bien tenir en place.

MEILLEURS EMPLACEMENTS POUR Schémas 3-8

MAZOUT OU COMBUSTIBLES SOLIDES

* Formats sélectionnés approuvés UL et ACNOR. Non certifiés ACNOR pour les combustibles solides.

Page 4

Page 5

ÉQUILIBRAGE DE L’ASSEMBLAGE DE POIDS ET RÉGLAGE DE TIRAGE

Schéma 10

TYPE B-34 (Voir Le Schéma 10)

1. Fixer “l’assemblage de contrepoids” au régulateur de tirage,

comme montré dans le Schéma 10. Fileter le “contrepoids”

dans “l’écrou fileté” fixé au volet. Assembler “l’écrou

hexagonal” et “l’écrou moleté” à l’avant du volet, comme

montré dans le Schéma 10.

2. Tourner “l’écrou moleté” dans le sens antihoraire pour un

tirage plus faible, dans le sens horaire pour un tirage plus

puissant.

3. Une fois que le tirage est réglé, bloquer “l’assemblage de

contrepoids” en serrant “l’écrou hexagonal” situé sous “l’écrou

moleté” contre le volet.

TYPE DR (Voir Le Schéma 11)

1. Insérer le “boulon de carrosserie” dans le “support de poids” fixé au

volet.

2. Fileter le “contrepoids” conique dans le “boulon de carrosserie” (la

portion conique du poids doit pointer vers le bas du régulateur de

tirage). Pour un tirage plus faible, glisser “l’assemblage de

contrepoids” vers la position “Lo” marquée sur le support; pour un

tirage plus puissant, glisser “l’assemblage de contrepoids” vers la

position “Hi”.

3. Une fois le réglage effectué pour le tirage approprié, bien serrer le

poids contre le “boulon de carrosserie”. Installation verticale: Les

régulateurs de 8 et 9 po, lorsque montés sur une installation

verticale seulement, requièrent une petite vis et un écrou (inclus)

assemblés dans le trou au bas du volet. Les régulateurs de 6 et 7 po

ne requièrent aucune ferrure supplémentaire sur une installation

verticale.

BOIS ET CHARBON

1. L’installation de ce régulateur de tirage doit se faire conformément aux instructions du fabricant du poêle. Si cela est

impossible, suivre les directives ci-dessous. (NOTA: Pour un fonctionnement adéquat du régulateur, la cheminée doit

être propre et exempte de toute obstruction.)

2. Le meilleur réglage pour les brûleurs à bois et à charbon est de 0.04 à 0.08 po à la colonne d’eau sur l’indicateur de

tirage. En l’absence d’indicateur de tirage, une fois que le régulateur de tirage est entièrement installé et qu’il y a une

bonne combustion, placer le contrepoids plus près du registre de façon que le tirage soit à la position la plus basse

possible, sans que le feu s’éteigne ou qu’il y ait un retour de fumée quand la porte du poêle est entrouverte. Pour

obtenir des niveaux de chaleur plus élevés, éloigner le poids du registre pour augmenter le réglage.

3. Pour une combustion plus efficace, la température de cheminée (sous le régulateur de tirage) devrait être de 350 à

450°F pour le bois sec. La température de cheminée et le réglage de tirage recommandés pour le charbon varient

selon les recommandations de chaque fabricant de poêles.

MAZOUT

Le fonctionnement adéquat du régulateur dépend de l’installation et du réglage. Utiliser un indicateur de CO2, un

thermomètre de cheminée et un indicateur de tirage pour régler le tirage des brûleurs à mazout. Les brûleurs à mazout

domestique sont plus efficaces lorsque le tirage est de 0.01 à 0.02 po à la colonne d’eau.

Schéma 11

Page 5

Page 6

INSTALACIÓN DE LA SECCIÓN EN “T”

Figura 9

Ubique el control de circulación tan cerca del generador como sea posible.

Si la instalación tiene un control de chimenea, ubique el regulador por lo

menos a 18” de distancia del control de la chimenea. (Ver Figuras 3-9)

PARA COMBUSTIBLE DE MADERA

Cuando se quema la madera, la creosota se acumula en la tubería de humo.

Por esta razón, el T se debe armar de manera que el extremo ensartado y

enrulado esté mirando hacia abajo. Esto evita que hayan fugas en las

juntas. (Ver Figura 1)

PARA OTROS TIPOS DE COMBUSTIBLE

Figura 1

Figura 2

Instale el T con el extremo ensartado y enrulado mirando hacia arriba. (Ver Figura 2)

NOTA: El regulador se debe colocar con los pasadores de bisagra en posición horizontal y la cara de la plomada del

regulador para una operación adecuada. Esto se logra haciendo girar la sección del regulador dentro del collarín para

cualquiera de las posiciones de la tubería. Apriete el tornillo para sostenerlo firmemente en su lugar.

LAS MEJORES UBICACIONES PARA EL Figuras 3-8

PETRÓLEO Y LOS COMBUSTIBLES SÓLIDOS

* Los tamaños seleccionados han sido aprobados por la CSA y UL. No han sido certificados por la CSA para

combustibles sólidos.

Page 6

Page 7

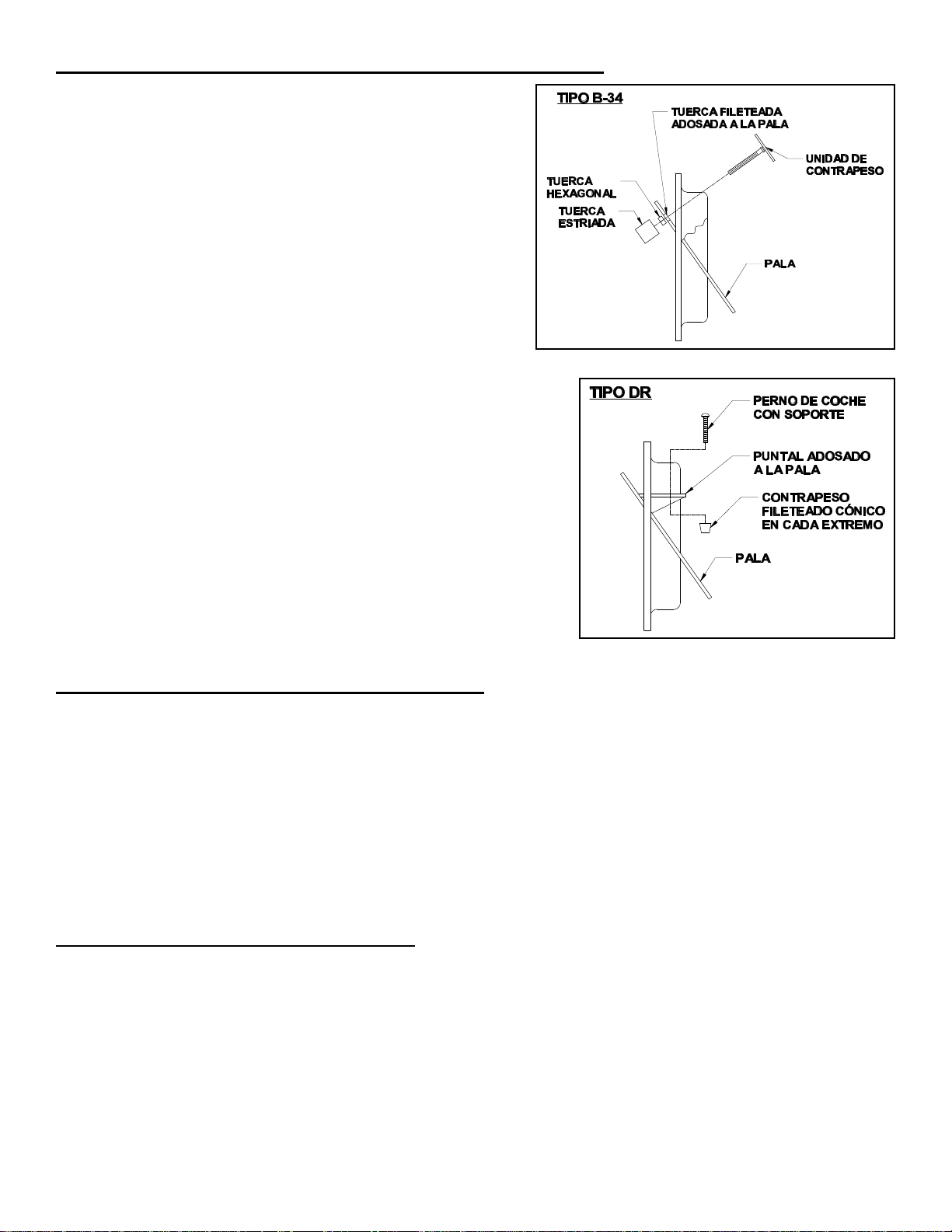

EQUILIBRIO DE LA UNIDAD DE PESO Y EL AJUSTE DE LA CIRCULACIÓN

Figura 10

Figura 11

TIPO B-34 (Ver Figure 10)

1. Arme la “unidad de contrapeso” en el control de circulación

según se ilustra en la Figure 10. Enrosque el “contrapeso” a

través de la “tuerca fileteada” adosada a la pala. Arme la

“tuerca hexagonal” y la “tuerca estriada” en el frente de la

pala según se ilustra en la Figure 10.

2. Gire la “tuerca estriada” en la dirección opuesta a las agujas

del reloj para menos circulación, y en la dirección de las

agujas del reloj para más circulación.

3. Cuando haya hecho los ajustes para la circulación deseada,

trabe la “unidad de contrapeso” en posición apretando la

“tuerca hexagonal” ubicada debajo de la “tuerca estriada”

contra la pala.

TIPO DR (Ver Figure 11)

1. Arme el “perno de coche” a través del “soporte del peso” adosado a

la pala.

2. Enrosque el “contrapeso” cónico en el “perno de coche” (la porción

cónica del peso debe indicar hacia el fondo del control de

circulación). Para menos circulación, deslice la “unidad de

contrapeso” hacia la posición baja “Lo,” marcada en el soporte; para

más circulación, deslice la “unidad de contrapeso” hacia la posición

alta “Hi.”

3. Cuando haya hecho los ajustes para la circulación deseada, apriete

el peso con firmeza al “perno de coche”. Instalación vertical” Los

tamaños de 8” y 9”, cuando se montan en una instalación vertical

solamente, requieren un tornillo pequeño y una tuerca

(suministradas) armados en el orificio de la pala inferior. Los

reguladores de 6” y 7” no requiere estos accesorios adicionales en

la instalación vertical.

APLICACIONES DE COMBUSTIÓN A LEÑA Y AL CARBÓN

1. Las instalaciones de este control de circulación se deben realizar conforme a las instrucciones del fabricante de la

estufa. Cuando esto no sea posible, siga las instrucciones que aparecen a continuación: (NOTA: para que el

regulador funcione correctamente, la chimenea debe estar limpia y libre de obstrucciones.)

2. La mejor graduación para los quemadores de madera y carbón, es una lectura en el indicador de circulación de 0,4” a

0,8” W.C. Si no se dispone de un indicador de circulación, con el regulador de circulación completamente instalado y

una buena llama, ajuste el contrapeso más cerca de la compuerta para una graduación de circulación tan baja como

sea posible, sin que la llama se apague o sin que se reciba humo de regreso con la puerta del horno ligeramente

abierta. Para obtener niveles más altos de calor, mueva el peso lejos de la compuerta para aumentar la graduación.

3. Para la mejor eficacia en combustión, la temperatura de la chimenea (debajo del regulador de circulación) debe ser

entre 350° y 450° F para madera seca. Las temperaturas que se recomiendan para la chimenea y las graduaciones

de circulación para el carbón, varían según el fabricante del horno.

APLICACIONES DE COMBUSTIÓN A PETRÓLEO

La operación correcta del regulador depende de la instalación correcta y del ajuste. Use un indicador de CO2, un

termómetro de chimenea y un indicador de circulación para ajustar la circulación en los quemadores a petróleo. Los

quemadores de aceite doméstico funcionan mejor con una circulación sobre la llama de 0,1 a 0,2 pulgadas W.C.

Page 7

Page 8

Page 8

P/N 46107700 Rev C 11/00

Loading...

Loading...