Page 1

DRAFT REGULATORS

Model: B34

LISTED UNDER RE-EXAMINATION SERVICE OF UNDERWRITERS LABORATORIES, INC.

LISTED UNDER LABEL SERVICE OF CANADIAN STANDARDS ASSOCIATION.

NOT CSA CERTIFIED FOR SOLID FUELS.

The regulator contained in this package is manufactured with careful precision. It is designed to

regulate chimney draft with a high degree of accuracy and fuel efficiency.

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

Page 2

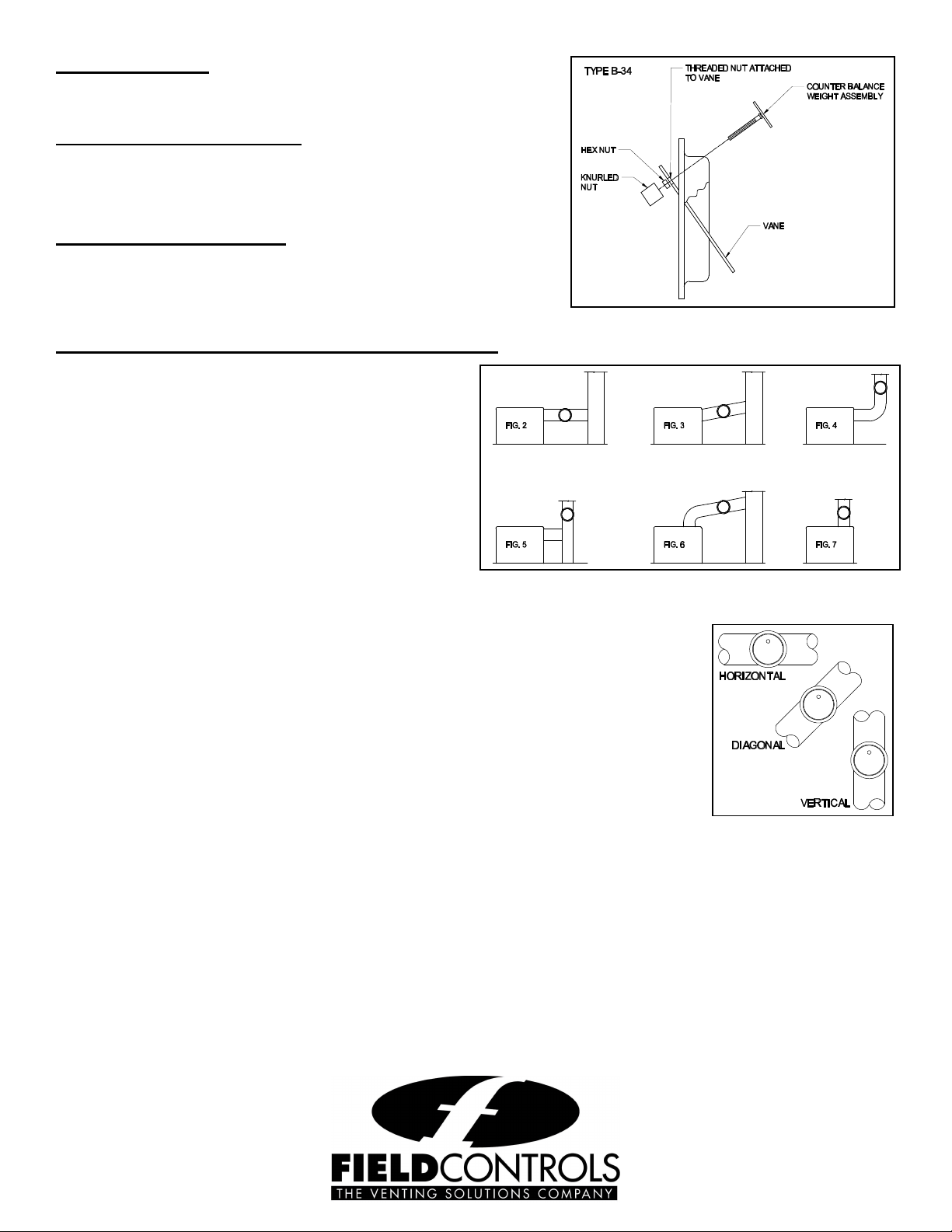

WEIGHT ASSEMBLY

Attach weight assembly to damper prior to its installation in flue pipe.

Refer to Figure 1.

LOCATION OF DRAFT CONTROL

BEST LOCATIONS FOR SOLID FUELS

Determine the best locations to mount the draft regulator using Figures

2-7.

MOUNTING CONSIDERATIONS

Damper must be mounted with the hinge pins horizontal and the face

of the damper plumb for correct operation. This is done by rotating the

damper section within the collar for any pipe position. Tighten screw to

hold firmly in place. (See Figure 8)

BALANCING WEIGHT ASSEMBLY AND DRAFT ADJUSTMENT

FOR WOOD AND COAL FIRED APPLICATIONS

1. Assemble the "counter balance weight assembly" to

the draft control as shown in Figure 1. Thread "counter

balance weight" through "threaded nut" attached to the

gate. Assemble "hex nut" and "knurled nut" on front of

gate as shown in Figure 1.

2. Installation of this Draft Control should be made in

accordance with the stove manufacturer's instructions.

When this is not possible, follow the directions below.

(NOTE: For the regulator to operate properly, the

chimney must be clean and free of obstructions.)

3. The best setting for wood and coal burners is a draft

*Selected sizes CSA and UL approved. Figures 2-7

Not CSA certified for solid fuels.

gauge reading of .04" to .08" W.C. If a draft gauge is

not available, with the draft regulator fully installed and a good fire burning, adjust the

counterbalance weight closer to the gate for as low a draft setting as possible, without

the fire dying or getting smoke-back with the stove door slightly open. To obtain higher

heat levels, move the weight away from the gate to increase the setting.

Figure 1

4. Turn "knurled nut" counter clockwise for less draft, clockwise for more draft.

5. When adjustment is made for desire draft, lock the "counter balance weight assembly"

in place by tightening the "hex nut" located under the "knurled nut" against the gate.

6. For best combustion efficiency, stack temperature (below the draft regulator) should be

350°F to 450°F for dry wood. Recommended stack temperatures and draft settings for

coal vary according to the manufacturer of the stove.

Figure 8

FOR OIL FIRED APPLICATIONS

1. Assemble the "counter balance weight assembly" to the draft control as shown in Figure 1. Thread "counter balance

weight" through "threaded nut" attached to the gate. Assemble "hex nut"" and "knurled nut" on front of gate as shown

in Figure 1.

2. Proper operation of the regulator depends upon proper installation and adjustment. Use a CO2 indicator, stack

thermometer and draft gauge to adjust draft for oil fired burners. Domestic oil burners work best with the draft over fire

of .01 to .02-inches W.C.

3. Turn "knurled nut" counter clockwise for less draft, clockwise for more draft.

4. When adjustment is made for desired draft, lock the "counter balance weight assembly" in place by tightening the

"hex nut" located under the "knurled nut" against the gate.

Page 2

P/N 46068600 Rev B 01/01

Loading...

Loading...