Page 1

Air Booster

Model: AB-1

Instruction Manual

Instructions D’Installation

Instrucciones de Instalación

Page

English....................................2

Français.................................. 5

Espanõl...................................8

Page 2

Installation Instructions

GENERAL INFORMATION

Your AB-1 Air Booster is designed to boost air flow to hard-to-heat or hard-to-cool rooms. READ THE

FOLLOWING INSTRUCTIONS CAREFULLY BEFORE ACTUALLY INSTALLING YOUR NEW AIR

BOOSTER.

INSTALLATION

1. The unit can be mounted on round ducts 5” in diameter and larger, or on rectangular or square

ducts 4” and wider and as shallow as 3”.

2. Locate the Booster in the BRANCH DUCT supplying the problem room – where the duct is warm

to the touch while the furnace is operating. NOTE: Do not install the Air Booster where the

temperature of the air within the duct is above 200ºF. It is rare that this temperature is found in

forced warm air systems; however, it could exist on gravity warm air systems if mounted close to

the furnace. It is suggested that the Air Booster be located near the outlet end of the branch duct

for maximum performance. The same location will also apply to air conditioning.

3. On horizontal and inclined installations, the slot for the Air Booster can be cut in the bottom or top

of a horizontal duct. On vertical installations, the slot can be cut on any side of the duct. In either

horizontal or vertical installations, the motor shaft must be in a horizontal position.

4. To assure longer motor life, oil the motor twice a year with ONLY A FEW DROPS of SAE 20 oil.

Two oil holes are located and marked on top of the motor for this purpose. Please note these oil

hole locations prior to installation. If the AB-1 is to be operated continuously, the motor should be

lubricated every three months. NOTE: The motor used on the Air Booster is an accepted

component of the listed fan unit by UL, Inc. This motor is designed as a normally HOT running

motor and should feel hot to the touch. Tests indicate that a normal 50 Watt household

incandescent light bulb is considerably hotter than the maximum motor temperature of your Air

Booster. This motor temperature will not effect the performance of your Air Booster, provided

installation and mounting instructions outlined herein are observed.

MOUNTING INSTRUCTIONS

Once the location for the Air Booster is established, you are now ready to mount the unit as follows:

READ THESE INSTRUCTIONS CAREFULLY:

1. Attach the mounting template to duct in desired location. (See No. 2 above.) Place mounting

template in the center of the selected duct for best performance.

2. Cut out the metal duct work along template lines according to the size duct you have. BE

CAREFUL NOT TO CUT OPENINGTOO LARGE.

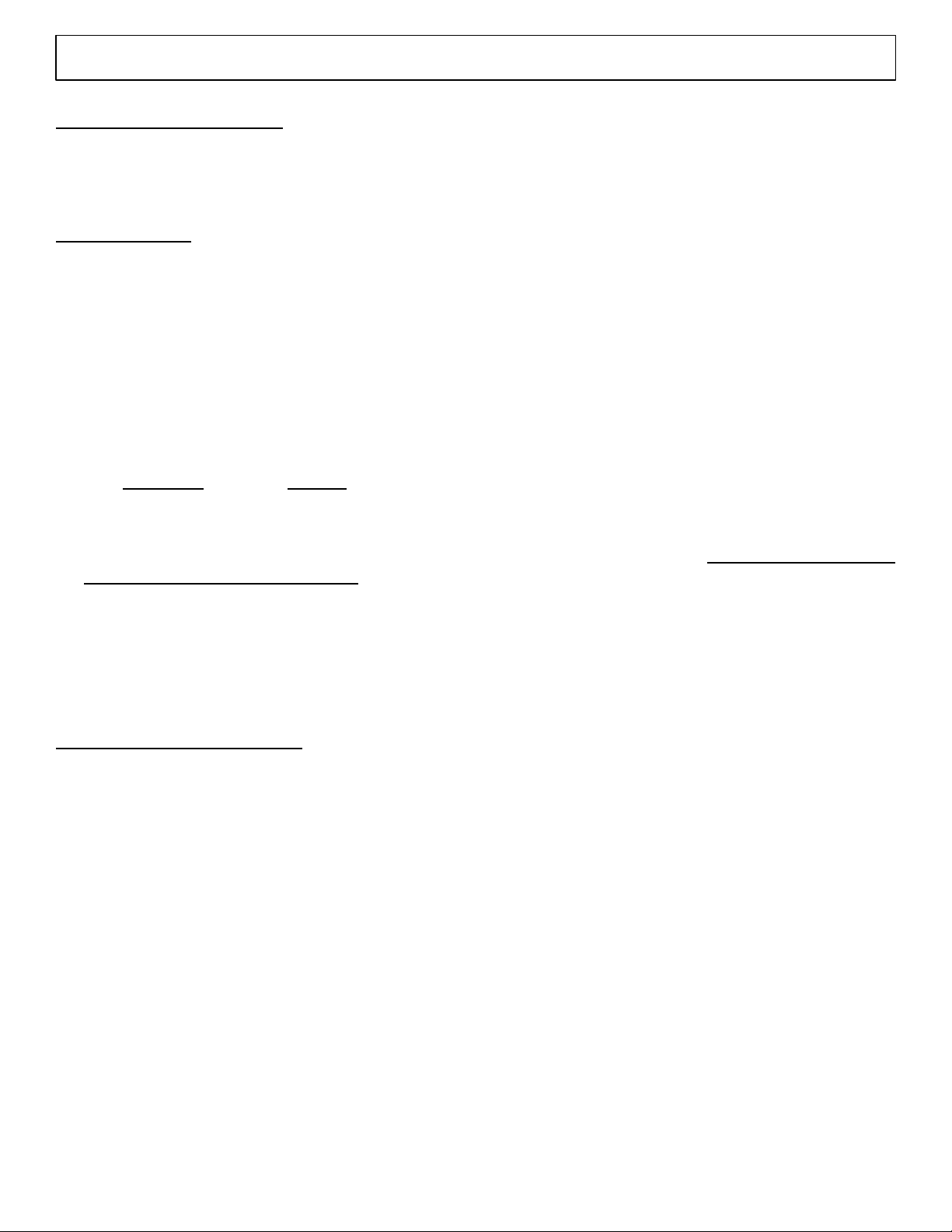

3. After the duct work has been properly cut, insert the Air Booster lip INSIDE the duct opening, (See

Figs. 1 & 2) pushing the Air Booster housing forward and upward at the same time so that the Air

Booster housing fits snugly into the opening. The side flanges should be on the OUTSIDE of the

duct. (See Figs. 1 & 2) NOTE: Be certain that the Air Booster “Deflector Plate” (See Figs. 1 & 2),

which curves above the blower wheel, is pointing in the direction of the air flow.

4. With the housing pushed tightly against the duct, drill or punch four 3/32” holes into the duct using

the Air Booster side flange mounting holes as locators.

5. Fasten Air Booster to air duct with 4 sheet metal screws, pulling the Air Booster up snugly against

duct. If necessary, bend the side flanges (Figs. 1 & 2) to conform to your particular duct size and

shape.

Page 2

Page 3

Figure 2

ce physical wiring

arrangements may differ from diagram.

To avoid fire or shock hazard, all

installations involving connection to

existing furnace wiring must be made

Figure 1

OPERATION

The Air Booster can be operated and controlled in several manners:

AUTOMATIC OPERATION:

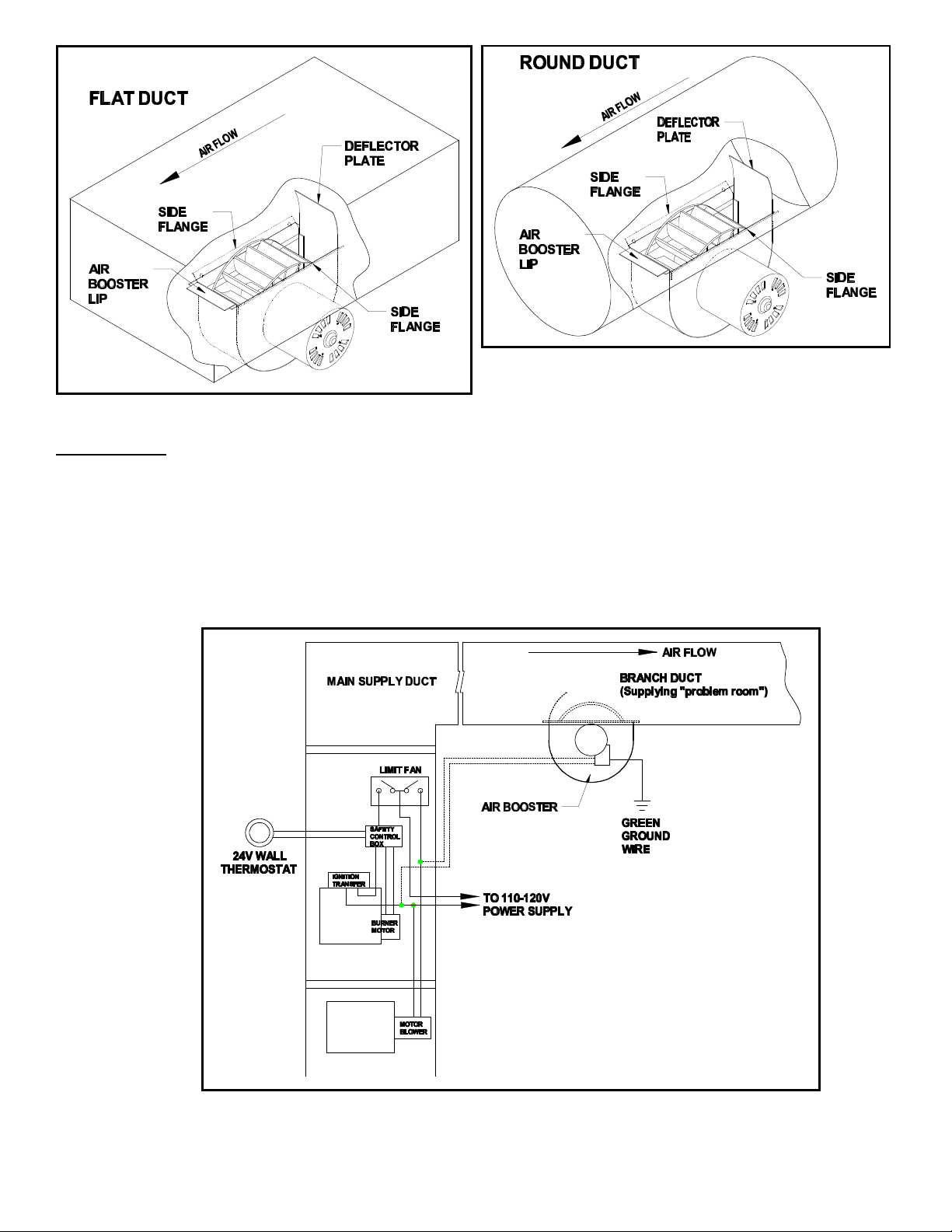

Wire in parallel with furnace blower motor. With central heating/air conditioning systems, it is

recommended that the Air Booster be wired in parallel with the furnace blower motor for simultaneous

operation. (see Fig. 3)

Figure 3

CAUTION: Furna

within furnace splice box.

Page 3

Page 4

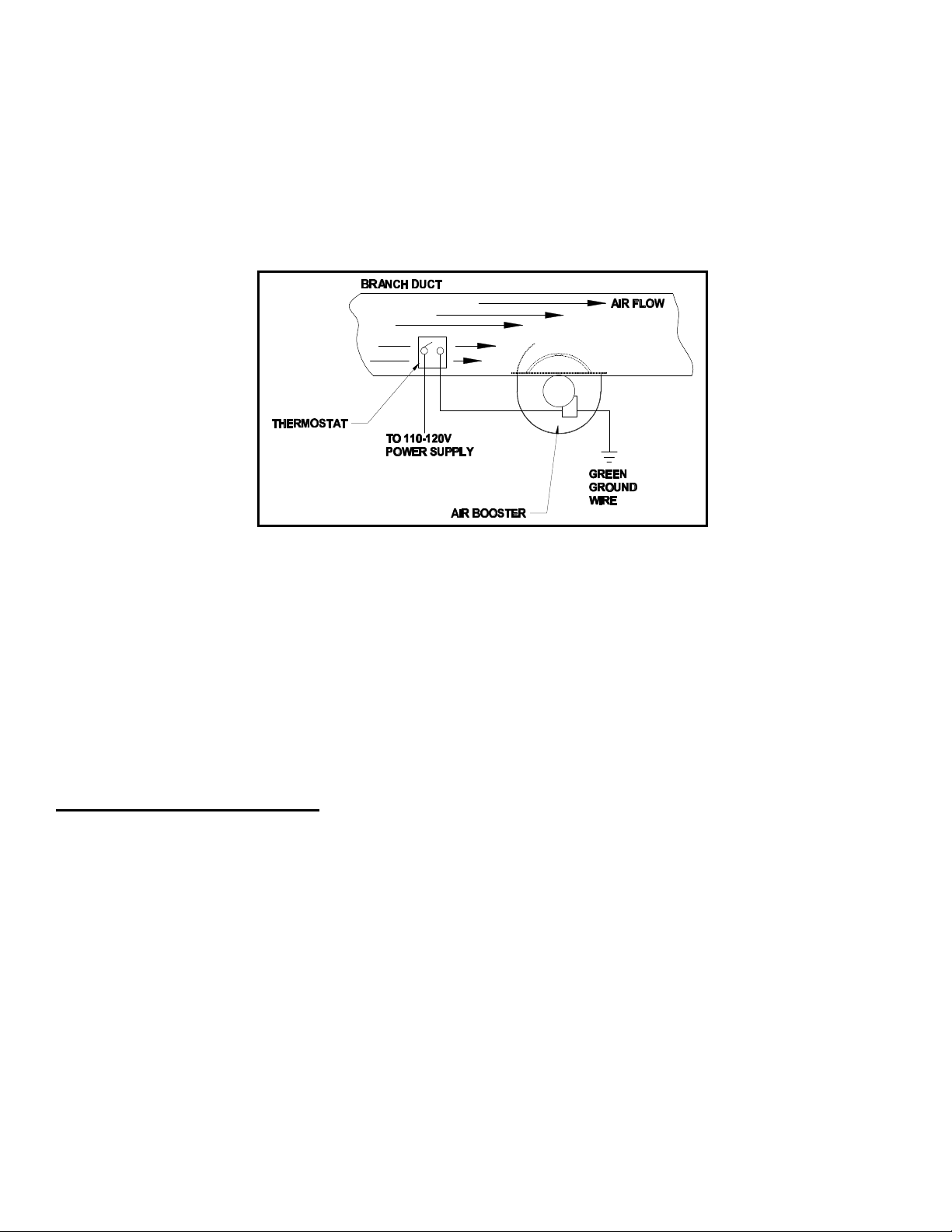

OPTIONAL THERMOSTAT HOOK UP:

For heating applications, the Air Booster may also be operated by the use of a line voltage

thermostatic switch which can be purchased from your local heating supply house or dealer. The

thermostatic switch will operate the Air Booster only when the temperature of the air in the duct is

above the per-set temperature. If a thermostatic switch is used, it is recommended it be located as

close to the main truck line duct as possible, for the fastest response to the change of air temperature

within the duct. (See Fig. 4.) However, follow the thermostatic switch manufacturer’s

recommendations. NOTE: For air conditioning applications, a heating/cooling thermostatic switch with

manual changeover must be used.

Figure 4

1. Gas or oil-fired central furnaces may include refrigerant cooling coils, however, it must be

equipped with 120 VAC single phase blower motors. AIR BOOSTER SHOULD NOT BE

WIRED IN PARALLEL WITH 240 VAC BLOWER MOTORS.

2. The basic furnace wiring and components should not be disturbed except for wiring

interconnection of the Air Booster and furnace blower at a splice box in the furnace.

3. The rating of the furnace blower motor controller must be adequate to control blower motor

and Air Booster motor. The Air Booster motor is rated at 0.50 amps.

Important: Blower motor controller should not be a variable speed tap type, solid state speed

control or any other type not suitable for dual motor control.

UNIT WIRING INSTRUCTIONS

1. For electrical supply connections, use wires suitable for at least 90ºC when Booster is used on a

heated duct system.

2. Electrical conduit must be routed away from warm air system ducts. Use adequate supports if

necessary.

3. The two black motor lead wires that are interchangeable are connected to power source. The

green wire is used for grounding purposes only.

4. The existing short circuit and ground fault protection for the furnace blower motor should be of a

size and type which will adequately protect the Air Booster motor. Refer to Section 430-53 of the

National Electrical Code.

5. The wiring from the furnace to the Air Booster must be 14 AWG and the furnace should be

protected by over current protection (fuses or circuit breakers) rated 15 amperes or less (as

applicable for 14 AWG conductors).

Important: Refer to section 430-53 (d) and Table 310-16 for the National Electrical Code for additional limitations.

Page 4

Page 5

Instructions d’Installation

RENSEIGNEMENTS GÉNÉRAUX :

Le pulvérisateur d’air AB-1 est conçu pour augmenter le débit d’air jusqu’aux pièces difficiles à

chauffer ou à climatiser. LIRE ATTENTIVEMENT LES INSTRUCTIONS SUIVANTES AVANT

D’INSTALLER LE NOUVEAU PULVÉRISATEUR D’AIR.

L’INSTALLATION

1. Cette unité peut être montée sur des conduits ronds de 5 po de diamètre et plus, ou sur des

conduits rectangulaires ou carrés de 4 po de large et plus, et aussi étroits que 3 po.

2. Placer le pulvérisateur dans la BRANCHE DE CONDUIT approvisionnant la pièce difficile à aérer

— là où le conduit est chaud lorsque la fournaise est en marche. NOTA : Ne pas installer le

pulvérisateur d’air là où l’air dépasse 200 °F. Il est rare que les systèmes d’air pulsé chaud

atteignent cette température ; cependant, cette température est possible avec les systèmes de

chauffage par gravité si l’appareil est monté à proximité de la fournaise. Il est recommandé de

placer le pulvérisateur d’air près de la sortie de la branche de conduit pour un rendement

maximal. Le même emplacement s’applique pour la climatisation.

3. Pour les installations à l’horizontale ou sur un plan incliné, la fente pour le pulvérisateur d’air peut

être découpée dans le bas ou le haut d’un conduit horizontal. Pour les installations à la verticale,

la fente peut être découpée sur tout côté du conduit. Que ce soit pour l’installation à l’horizontale

ou à la verticale, l’arbre de moteur doit être placé à l’horizontale.

4. Pour assurer la durabilité du moteur, huiler ce dernier deux fois par année avec SEULEMENT

QUELQUES GOUTTES d’huile SAE 20. Deux trous de graissage se trouvent dans le haut du

moteur. Localiser l’emplacement de ces trous avant l’installation. Si l’AB-1 doit fonctionner de

façon continuelle, le moteur doit être lubrifié tous les trois mois. NOTA : Le moteur du

pulvérisateur d’air est une composante acceptée de l’unité homologuée UL, Inc. Ce moteur est

conçu comme ayant un fonctionnement normalement CHAUD, et devrait être chaud au toucher.

Des tests indiquent qu’une ampoule à incandescence domestique standard de 50 watts est

beaucoup plus chaude que le moteur du pulvérisateur d’air à sa température maximale. Cette

température n’affectera pas le rendement du pulvérisateur d’air, à condition de respecter les

instructions d’installation et de montage décrites dans le présent document.

INSTRUCTIONS DE MONTAGE

Une fois que l’emplacement du pulvérisateur d’air a été établi, on peut monter l’unité comme suit :

LIRE CES INSTRUCTIONS ATTENTIVEMENT :

1. Fixer le gabarit de montage au conduit, à l’emplacement désiré. (Voir n° 2 ci-dessus.) Placer le

gabarit de montage au centre du conduit choisi pour assurer un meilleur rendement.

2. Couper le conduit en métal le long des lignes du gabarit, selon les dimensions du conduit. FAIRE

ATTENTION DE NE PAS FAIRE UNE OUVERTURE TROP GRANDE.

3. Une fois que le conduit est découpé de façon appropriée, insérer la lèvre du pulvérisateur d’air

DANS l’ouverture du conduit (voir les Schémas 1 et 2) et pousser le boîtier du pulvérisateur d’air

vers l’avant et vers le haut à la fois, de façon qu’il entre parfaitement dans l’ouverture. Les rebords

latéraux devraient être à L’EXTÉRIEUR du conduit (voir les Schémas 1 et 2). NOTA : S’assurer

que le « déflecteur » du pulvérisateur d’air (voir les Schémas 1 et 2), qui forme une courbe audessus de la roue de ventilation, pointe dans la direction du débit d’air.

Page 5

Page 6

4. En s’assurant que le boîtier repose bien contre le conduit, percer ou couper au pointeau quatre

Le câblage réel de la

fournaise peut différer de l’illustration.

Pour éviter un incendie ou des chocs

électriques, tous les raccordements à un

câblage de fournaise déjà en place

doivent se faire à l’intérieur de la boîte de

trous de 3/32 po dans le conduit en utilisant les trous de montage des rebords latéraux du

pulvérisateur comme guides.

5. Fixer le pulvérisateur d’air au conduit au moyen de quatre vis à tôle, en s’assurant qu’il repose

bien contre le conduit. Au besoin, plier les rebords latéraux (voir les Schémas 1 et 2) pour qu’ils

se conforment aux dimensions et à la forme du conduit.

Schéma 1

FONCTIONNEMENT

Le pulvérisateur d’air peut

être opéré et contrôlé de

plusieurs façons :

FONCTIONNEMENT

AUTOMATIQUE :

Câbler en parallèle avec le

moteur de ventilateur de la

fournaise. Pour les systèmes

centraux de chauffage /

climatisation, il est

recommandé de câbler le

pulvérisateur d’air en

parallèle avec le moteur de

ventilateur de la fournaise

pour un fonctionnement

simultané. (Voir le Schéma

3.)

Schéma 3

Schéma 2

ATTENTION :

jonction de la fournaise.

Page 6

Page 7

RACCORDEMENT DE THERMOSTAT FACULTATIF :

Pour les applications de chauffage, le

pulvérisateur d’air peut aussi être activé

par un interrupteur thermostatique à

tension de secteur, qu’on peut acheter

dans un magasin d’approvisionnement en

articles de chauffage ou chez un détaillant

local. L’interrupteur thermostatique

n’activera le pulvérisateur d’air que lorsque

la température de l’air dans le conduit

dépassera la température préréglée. Si

l’on utilise un interrupteur thermostatique,

il est recommandé de le placer aussi près

Schéma 4

du conduit principal que possible, de façon

que la réponse au changement de température de l’air dans le conduit se fasse le plus rapidement

possible. (Voir le Schéma 4.) Cependant, il faut respecter les recommandations du fabricant de

l’interrupteur thermostatique. NOTA : pour les applications de climatisation, un interrupteur

thermostatique de chauffage / climatisation avec permutation manuelle doit être utilisé.

1. Les fournaises centrales à gaz ou au mazout peuvent comprendre des serpentins de

refroidissement, mais doivent être dotées de moteurs de ventilateur à phase unique de 120 V

c.a. LE PULVÉRISATEUR D’AIR NE DOIT PAS ÊTRE CÂBLÉ EN PARALLÈLE AVEC DES

MOTEURS DE VENTILATEUR DE 240 V c.a.

2. Le câblage de base et les composantes de la fournaise ne devraient pas être modifiés, à

l’exception de l’interconnexion de câblage entre le pulvérisateur d’air et le moteur de

ventilateur de la fournaise, dans une boîte de jonction à l’intérieur de la fournaise.

3. La puissance nominale du contrôleur de moteur de ventilateur de la fournaise doit être assez

élevée pour contrôler le moteur de ventilateur ainsi que le moteur du pulvérisateur d’air. Le

moteur du pulvérisateur d’air est classé à 0.50 A.

IMPORTANT : Le contrôleur de moteur de ventilateur ne devrait pas être de type dérivation à

vitesse variable, à réglage de vitesse transistorisé ou tout type non conçu pour le contrôle de deux

moteurs.

INSTRUCTIONS TOUCHANT LE CÂBLAGE DE L’APPAREIL

1. Pour les raccordements d’alimentation électrique, utiliser des câbles convenant à une température

minimale de 90 °C lorsque le pulvérisateur d’air est utilisé avec un système de chauffage.

2. Le conduit électrique doit être acheminé loin des conduits du système d’air chaud. Utiliser les

supports adéquats au besoin.

3. Les deux conducteurs noirs du moteur, qui sont interchangeables, sont branchés à la source

électrique. Le fil vert est utilisé à des fins de mise à la terre seulement.

4. Le court-circuit et la protection contre les défauts à la terre pour le moteur de ventilateur de la

fournaise devraient être de format et de type approprié pour protéger adéquatement le moteur du

pulvérisateur d’air. Se reporter à la section 430-53 du Code national de l’électricité.

5. Le câblage de la fournaise au pulvérisateur d’air doit être de calibre 14 AWG. La fournaise devrait

être munie d’un dispositif de protection de surintensité (fusible ou disjoncteur) classé à 15 A ou

moins, selon ce qui s’applique aux conducteurs 14 AWG.

IMPORTANT : Se reporter à la section 430-53(d) et au tableau 310-16 du Code national de l’électricité pour des

limitations supplémentaires.

Page 7

Page 8

Instrucciones de Instalación

INFORMACIÓN GENERAL

Su Intensificador de Aire AB-1 ha sido diseñado para intensificar la circulación del aire en las

habitaciones difíciles de calentar o de enfriar. LEA LAS DETENIDAMENTE LAS SIGUIENTES

INSTRUCCIONES ANTES DE PROCEDER A LA INSTALACIÓN DE SU NUEVO INTENSIFICADOR

DE AIRE.

DE INSTALACIÓN

1. Se puede instalar la unidad sobre conductos redondos de 5”de diámetro, o conductos

rectangulares o cuadrados de 4” y más anchos, y con una altura mínima de 3”.

2. Ubique el Intensificador en el CONDUCTO SECUNDARIO que suministra aire a la habitación con

problemas – donde el conducto se siente tibio al tacto cuando la calefacción se encuentra

funcionando. NOTA: no instale el Intensificador de Aire en donde la temperatura del aire

contenido en el conducto sea mayor que 200°F. Es raro encontrar esta temperatura en sistemas

de aire caliente a presión; sin embargo, podría suceder en sistemas de aire caliente por

gravedad, si están instalados cerca de la calefacción. Para un mejor rendimiento, se sugiere que

el Intensificador de Aire se ubique cerca de extremo de la salida del conducto secundario. Use la

misma ubicación también para el aire acondicionado.

3. En las instalaciones horizontales y verticales, se puede cortar la ranura para el Intensificador de

Aire en el fondo o en la parte superior de un conducto horizontal. En las instalaciones verticales,

la ranura puede cortarse el cualquier lado del conducto. Tanto en las instalaciones horizontales

como verticales, el eje del motor debe encontrarse en posición horizontal.

4. Para asegurar una vida útil más larga del motor, lubríquelo dos veces al año con SÓLO

ALGUNAS GOTAS de aceite SAE 20. Existen dos orificios de lubricación sobre el motor, y se

encuentran marcados, para este propósito. Sírvase la ubicación de estos orificios de lubricación,

antes de la instalación. Si se hiciera funcionar constantemente el AB-1, el motor debe ser

lubricado cada tres meses. NOTA: El motor que se usa en el Intensificador de Aire en un

componente aceptado de la unidad del ventilador, incluido en el listado de UL, Inc. Este motor ha

sido diseñado para funcionar normalmente CALIENTE, y debe sentirse caliente al tacto. Las

pruebas indican que un foco de luz incandescente de 50 W normal es bastante más caliente que

la máxima temperatura del motor de su Intensificador de Aire. Esta temperatura del motor no

afectará el rendimiento de su Intensificador de Aire, siempre que se observen las instrucciones de

instalación y montaje que se describen aquí.

INSTRUCCIONES DE INSTALACIÓN

Una vez que se haya establecido cuál será la ubicación del Intensificador de Aire, está listo para

instalar la unidad de la siguiente manera:

LEA DETENIDAMENTE ESTAS INSTRUCCIONES:

1. Pegue la plantilla montaje al conducto, en el lugar deseado (vea la figura 2 arriba). Para mejor

rendimiento, pegue la plantilla en el centro del conducto elegido.

2. Corte la funda el conducto de metal a lo largo de las líneas, según el tamaño del conducto que

usted tenga. TENGA CUIDADO DE NO CORTAR UNA ABERTURA DEMASIADO GRANDE.

3. Después de cortar la funda del conducto adecuadamente, introduzca el reborde del Intensificador

de Aire DENTRO de la abertura del conducto, (vea las figuras 1 y 2) empujando la caja del

Intensificador de Aire al mismo tiempo hacia adelante y hacia arriba, de manera que la caja del

Page 8

Page 9

Intensificador de Aire encaje ceñidamente dentro de la abertura. Los salientes laterales deben

La disposición física de la

instalación eléctrica de la calefacción, puede

diferir del esquema. Para evitar peligros de

ben hacerse todas las

instalaciones que tengan conexiones a la

instalación eléctrica existente de la

calefacción, dentro de la caja de empalmes

de la calefacción.

quedar en la parte exterior del conducto (vea las figuras 1 y 2). NOTA: Asegúrese de que las

“Placa Deflectora” (vea las figuras 1 y 2), que se curva por encima de la rueda del ventilador,

quede orientada en la dirección de circulación del aire.

4. Una vez que la caja ha sido empujada ceñidamente contra el conducto, taladre o perfore cuatro

orificios de 3/32” en el conducto, usando como guías los orificios de montaje de los salientes

laterales.

5. Fije el Intensificador de Aire al conducto de aire con 4 tornillos roscadores, ajustando el

Intensificador de Aire contra el conducto. Si fuera necesario, doble los salientes laterales (figuras

1 y 2) para que se adapten al tamaño y forma particulares de su conducto.

Figura 1

FUNCIONAMIENTO

Se puede hacer funcionar

y controlar del

Intensificador de Aire de

varias maneras:

FUNCIONAMIENTO

AUTOMÁTICO:

Instálelo en paralelo con

el motor del ventilador de

la calefacción. Se

recomienda que en los

sistemas centrales de

calefacción/aire

acondicionado, el

Intensificador de Aire se

instale en paralelo con el

motor del ventilador de la

calefacción, para que

funcionen

simultáneamente (vea la

figura 3).

Figura 3

Figura 2

Page 9

ADVERTENCIA:

incendio o choque, de

Page 10

CONEXIÓN OPCIONAL DE UN TERMOSTATO:

Para aplicaciones de calefacción, también se puede hacer funcionar el Intensificador de Aire usando

el interruptor termostático de la línea de voltaje, que puede adquirir en una tienda de artículos de

calefacción o un distribuidor local. El interruptor termostático hará funcionar el Intensificador de Aire

sólo cuando la temperatura del aire contenido en el conducto esté por encima de una temperatura

determinada. Si se usara un interruptor termostático, se recomienda que sea ubicado lo más cerca

posible al conducto principal para lograr la respuesta más rápida a los cambios de temperatura

dentro del conducto (vea la figura 4). Sin embargo, usted debe seguir las recomendaciones del

fabricante del interruptor termostático. NOTA: Para aplicaciones de aire acondicionado, debe usarse

un interruptor termostático de calefacción/refrigeración con conmutación manual.

Figura 4

1. Los sistemas de calefacción central a gas o a petróleo, pueden incluir serpentines con

refrigerante para enfriamiento, sin embargo, deben estar equipados con motores de

ventiladores de 120 V CA, monofásicos. EL INTENSIFICADOR DE AIRE NO DEBE

INSTALARSE EN PARALELO EN MOTORES DE 240 V CA.

2. La instalación eléctrica básica de la calefacción y sus componentes no deben ser alterados,

excepto para la interconexión del Intensificador de Aire y el motor del ventilador de la

calefacción, en la caja de empalmes que se encuentra en la calefacción.

3. El régimen nominal del control del motor del ventilador de la calefacción, debe ser el

apropiado para controlar el motor del ventilador y el motor del Intensificador de Aire. El

régimen nominal del motor del Intensificador de Aire es 0.50 amperios.

IMPORTANTE: El control del motor del ventilador no debe ser del tipo de conexión intermedia de

velocidad regulable, de estado sólido ni cualquier otro tipo que no sea adecuado para control de

dos motores.

INTRUCCIONES PARA LA INSTALACIÓN ELÉCTRICA

1. Para las conexiones de suministro eléctrico, use cables adecuados para por lo menos 90°C,

cuando se use el Intensificador con un sistema de conductos recalentados.

2. Los conductos eléctricos deben ser instalados lejos del sistema de conductos de aire caliente. Si

fuera necesario, use soportes apropiados.

3. Los dos hilos conductores negros, que son intercambiables, se conectan al suministro eléctrico.

El cable verde se usa sólo para la puesta a tierra.

Page 10

Page 11

4. La protección existente contra cortocircuitos y falla de la conexión a tierra del motor del ventilador

de la calefacción, debe ser del tamaño y tipo que proteja adecuadamente el motor del

Intensificador de Aire. Consulte la Sección 430-53 del Código Eléctrico Nacional.

5. La instalación eléctrica que va desde la calefacción al Intensificador de Aire debe ser de 14 AWG

y la calefacción debe estar protegida con protegida por un dispositivo de protección contra las

sobretensiones (fusibles o disyuntores) con un régimen nominal de 15 amperios o menos (según

corresponda a los conductores de 14 AWG).

IMPORTANTE: Consulte la Sección 430-53(d) Y LA Tabla 310-16del Código Eléctrico Nacional para determinar si

existen otras limitaciones.

Page 11

Page 12

P/N 46011100 Rev A 7/99

Page 12

Loading...

Loading...