Fieldbus Specialists Profibus User Manual

MCD 3000 – PROFIBUS GATEWAY

PROFIBUS Gateway

for MCD 3000 Series Soft Starters

P/N FS-1135

User Manual

Ver. 1.9

10 October 2003

MCD 3000

© Copyright 2002 Fieldbus Specialists

SERIES 1 USER MANUAL

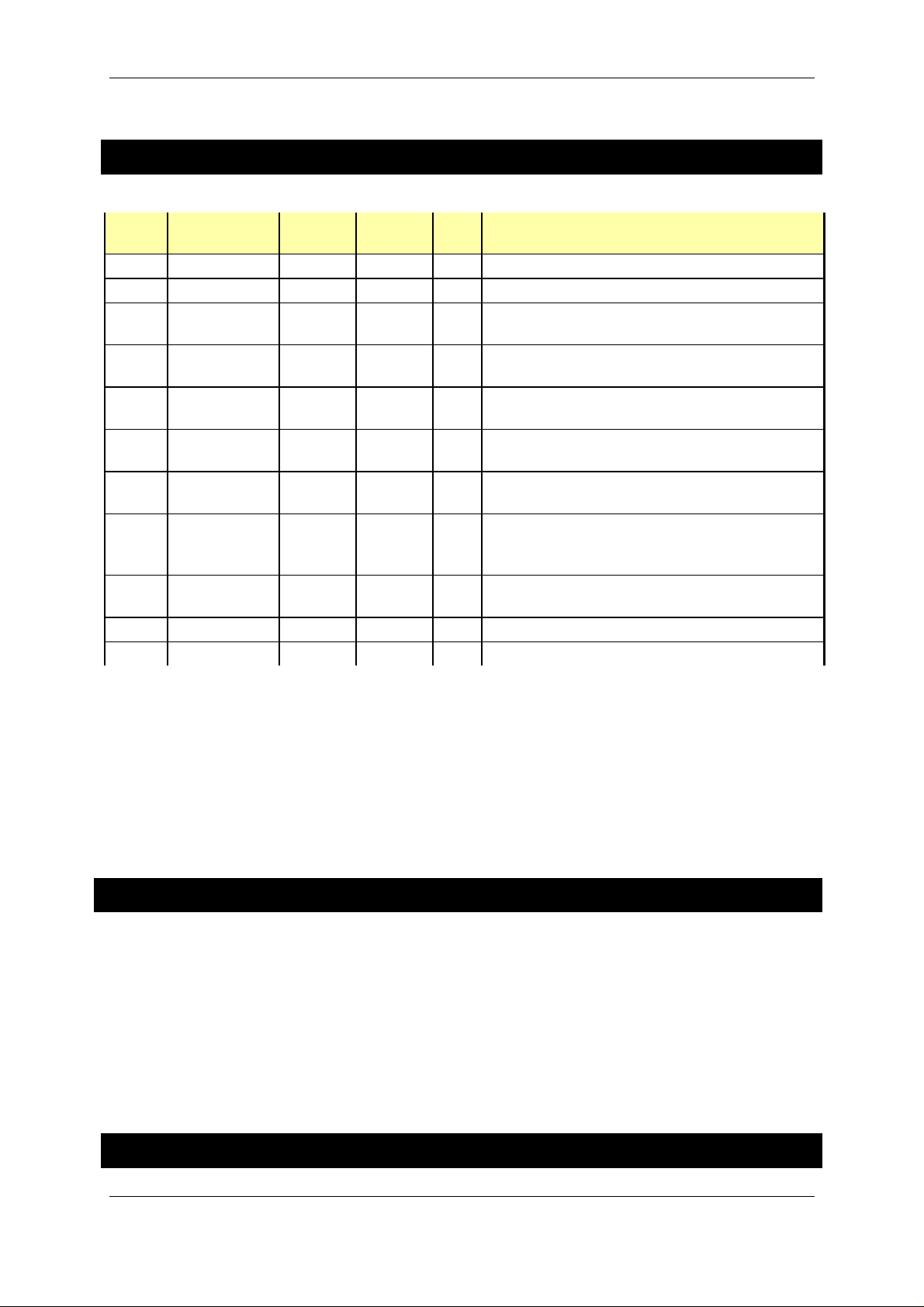

REVISION NOTES

Index Date

1

2

3

4

5

6

7

8

9

10

04-Feb-2002 All

11-Feb-2002 All

10-Mar-2002 All

14-Mar-2002 2.6.2, 7 AJ

4-April-2002 2.6.1

5-MAY-2002 All

25-OCT-2002

1-OCT-2003

9-OCT-2003

10-OCT-2003

Chapte

r

AJ

JP

JP

Author Rev. Revision note

AMcN 1.0 Created

AJ

AJ

AKJ

AmcN,

AJ

JP/AJ

1.1 Various corrections

1.2 Extended indications for invalid PROFIBUS

address

1.3 Local/Remote setting recommendations,

corrections to Specifications

1.4 Wiring diagrams added, mapping of read

memory corrected

1.5 Unified format, added functions to handle

comm. breakdown

1.6 Added comments related to Siemens S7

PLC

1.7 Added comments re. firmware version 2.02

and code compliance with Danfoss

manual AMB00000 Rev. G

1.8 Modified to reflect compliance with

AMB00000 Rev. G

1.9 Note re.byte sequencing in 2.10

MCD 3000 – PROFIBUS GATEWAY

TECHNICAL SUPPORT

In case of any questions or problems, please contact Fieldbus Specialists on

sales@fieldbus.com.au.

We will endeavour to reply immediately.

PREFACE

MCD 3000

SERIES 2 USER MANUAL

MCD 3000 – PROFIBUS GATEWAY

The data and illustrations in this manual are not binding.

Fieldbus Specialists reserve the right to modify our products in

line with our policy of continuous product development. The

information in this manual is subject to change without notice

and should not be considered as a commitment by Fieldbus

Specialists.

Fieldbus Specialists assume no responsibility for any errors that

may appear in this document.

Although this product has been developed with great care

and extensively tested, Fieldbus Specialists cannot guarantee

the suitability of this product for any purpose. Warranty claims

shall be limited to the right to require rectification of faults.

Liability for any damages, which may have arisen from the use

of this product or its documentation, shall be limited to cases of

intent.

MCD 3000

SERIES 3 USER MANUAL

MCD 3000 – PROFIBUS GATEWAY

CONTENTS

1 INTRODUCTION .............................................................................................................................6

1.1 I

1.2 G

2 INSTALING THE GATEWAY..........................................................................................................8

2.1 G

2.2 F

2.3 I

2.4 P

2.5 PROFIBUS

2.5.2 G

2.6 MCD3000

3 PROGRAMMING THE MASTER CONTROLLER ........................................................................ 18

3.1 GSD

3.2 D

3.3 S

3.4 M

3.5 D

3.6 D

3.7 I

MPORTANT USER INFORMATION

ENERAL

ATEWAY CO NNECTION DIAGRAM

RONT PANEL

NSTALLATION SEQUENCE

OWER CONNECTION

2.5.1 Cabling..........................................................................................................................................12

2.6.1 Cabling..........................................................................................................................................14

2.6.2 MCD3000 configuration .............................................................................................................16

ECLARING MODULES

ETTING

ASTER-SLAVE DATA EXCHANGE

ATA WRITE AREA

ATA READ AREA

SSUING COMMANDS

.................................................................................................................................................. 6

........................................................................................................................................... 9

.............................................................................................................................. 11

CONNECTION

ATEWAY CO NFIGURATION

CONNECTION

FILE

................................................................................................................................................ 18

............................................................................................................................ 18

PROFIBUS

PARAMETERS

.................................................................................................................................. 21

................................................................................................................................... 22

.............................................................................................................................. 24

............................................................................................................... 6

............................................................................................................ 8

....................................................................................................................... 11

....................................................................................................................... 12

................................................................................................................... 13

......................................................................................................................... 14

........................................................................................................ 19

.......................................................................................................... 21

4 OPERATION OF THE GATEWAY................................................................................................ 29

4.1 S

4.2 S

4.3 O

5 SPECIFICATIONS......................................................................................................................... 32

6 TROUBLESHOOTING .................................................................................................................. 33

CANNING SLAVES

CANNING TIMES

FFLINE SLAVES

.................................................................................................................................. 29

.................................................................................................................................... 29

..................................................................................................................................... 31

MCD 3000

SERIES 4 USER MANUAL

MCD 3000 – PROFIBUS GATEWAY

Table List

Table 1 – LED Indication.......................................................................................................................................10

Table 2 – PROFIBUS socket pin assignment .......................................................................................................12

Table 3 – RS-485 pin assignment.........................................................................................................................14

Table 4 – MCD 3000 Local/Remote modes..........................................................................................................17

Table 5 – MCD 3000, RS-485 baud rate values....................................................................................................17

Table 6 – MCD 3000 node address on RS-485 network.......................................................................................17

Table 7 – Gateway parameter, RS-485 link baud rate..........................................................................................19

Table 8 – Gateway parameter, gateway operation on communication loss..........................................................20

Table 9 – PROFIBUS Write / Out Memory in control module................................................................................22

Table 10 – Command result codes .......................................................................................................................22

Table 11 – PROFIBUS Read / In memory.............................................................................................................24

Table 12 – Valid commands..................................................................................................................................25

Table 13 – New Command / Command Acknowledge handshaking....................................................................27

Table 14 – Result Ready / Result Acknowledge handshaking..............................................................................27

Table 15 – Scanning cycle length for different baud rates and the number of MCD 3000 devices present..........30

Table 16 – Maximum time to detect return of an offline device.............................................................................30

Table 17 – Gateway specifications........................................................................................................................32

Table 18 – Troubleshooting guide.........................................................................................................................33

Figure List

Figure 1. Typical diagram of a PROFIBUS network, a gateway and an RS-485 sub-network...............................8

Figure 2. Gateway front panel................................................................................................................................9

Figure 3. Entering address via dip switches, an example....................................................................................13

Figure 4. Recommended wiring diagram for one MCD3000 device.....................................................................15

Figure 5. Wiring diagram for a number of MCD3000 devices connected to a single gateway.............................15

MCD 3000

SERIES 5 USER MANUAL

1

INTRODUCTION

1.1 Important user information

1.2 General

MCD 3000 – PROFIBUS GATEWAY

This manual describes operation and programming of a

PROFIBUS gateway for MCD3000 series soft starters, gateway

firmware revision 2.11.

Gateway with firmware version 2.11 complies with MCD3000

protocol as described in Danfoss manual AMB00000 Rev. G

and is likely to be incompatible with earlier versions of the soft

starter. Remote programming of parameters is not supported

at the moment. Contact Fieldbus Specialists if you require a

firmware version that supports earlier models.

Observe all the necessary safety precautions when controlling

any MCD 3000 series device over the serial communications

link, including alerting personnel that the machinery may start

without warning.

The MCD 3000 series of solid state soft starters incorporate a

serial communications facility that allows for the remote

control and interrogation of the MCD 3000 from an intelligent

host (master) via a multi-drop RS-485 communications network

using a proprietary protocol, specific to MCD 3000 devices.

The RS-485 link may be used to interface a MCD 3000 device to

a PROFIBUS network using the PROFIBUS to MCD 3000 gateway.

The PROFIBUS Master can then control any connected MCD

3000 device – start it, stop, reset trip conditions and read

operational status, motor conditions or trip status.

The PROFIBUS to MCD 3000 Gateway is a certified PROFIBUS

slave device. A number of gateways and other PROFIBUS

slave devices can be connected to the same network, subject

only to standard PROFIBUS limitations.

The gateway is a master on the RS-485 multi-drop MCD 3000

communications network.

connected to a single Gateway. In this way up to 30 MCD

3000 devices will share one PROFIBUS address on the PROFIBUS

communications network.

This manual describes how the PROFIBUS to MCD 3000

gateway operates, how to connect MCD 3000 series soft

starters to the gateway and how to connect and operate the

gateway on a PROFIBUS network.

Up to 30

MCD 3000 devices may be

MCD 3000

SERIES

6 USER MANUAL

MCD 3000 – PROFIBUS GATEWAY

When reading this manual, it may help to refer to the MCD

3000 Operating Instructions, Danfoss document no. AMB00000.

MCD 3000

SERIES

7 USER MANUAL

2

INSTALING THE GATEWAY

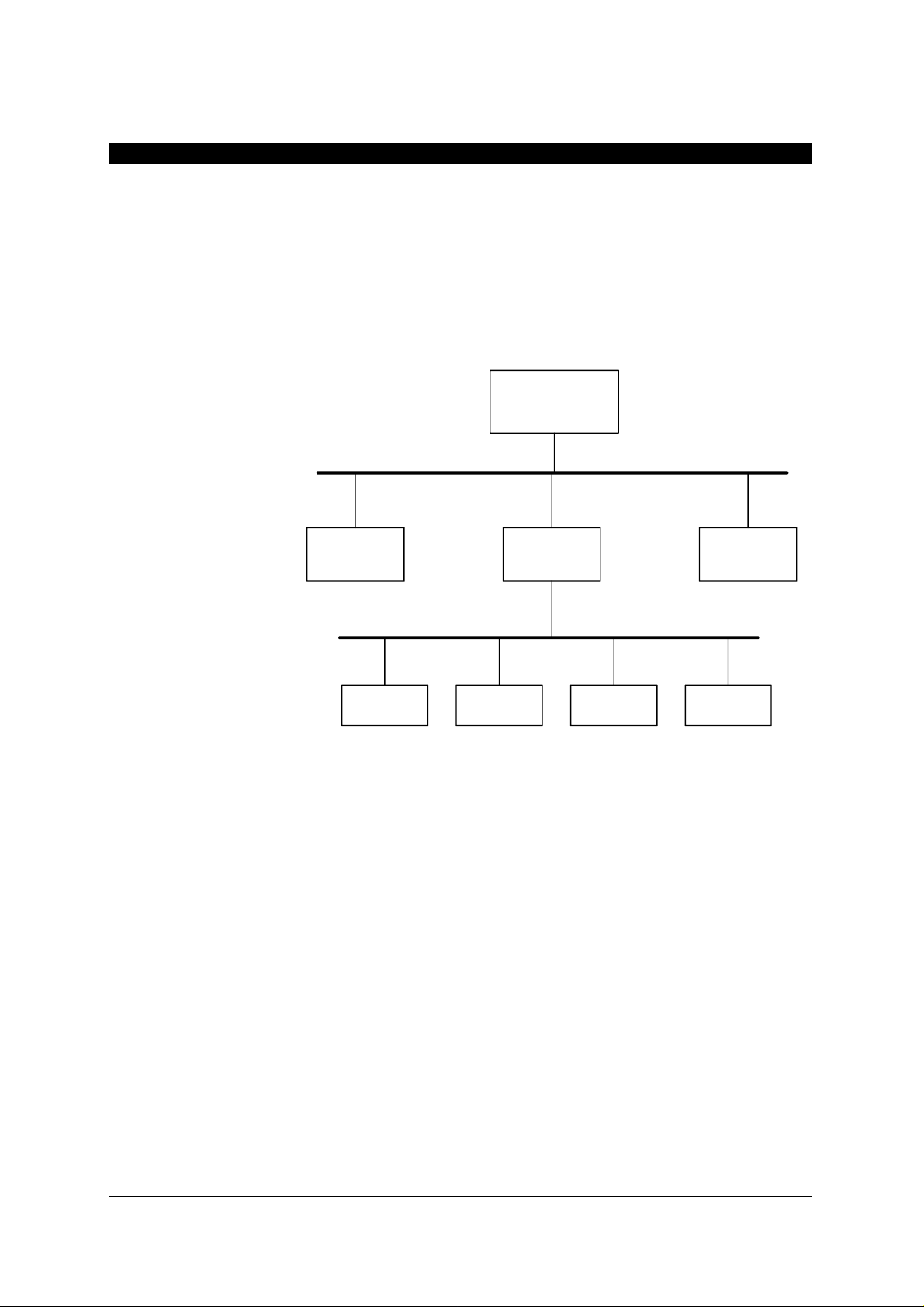

2.1 Gateway connection diagram

The diagram below shows how the gateway is connected to

the PROFIBUS network and to the RS-485 sub-network.

PROFIBUS DP

PROFIBUS network

Master

MCD 3000 – PROFIBUS GATEWAY

DP Slave

RS-485 sub-network

MCD 3000

device

MCD 3000

Gateway

MCD 3000

device

MCD 3000

device

DP Slave

MCD 3000

device

Figure 1. Typical diagram of a PROFIBUS network, a gateway

and an RS-485 sub-network.

A gateway can coexist with a number of other PROFIBUS

nodes, including other gateways. Each gateway constitutes a

single PROFIBUS node, even if it connects to a number of MCD

3000 devices.

MCD 3000

SERIES

8 USER MANUAL

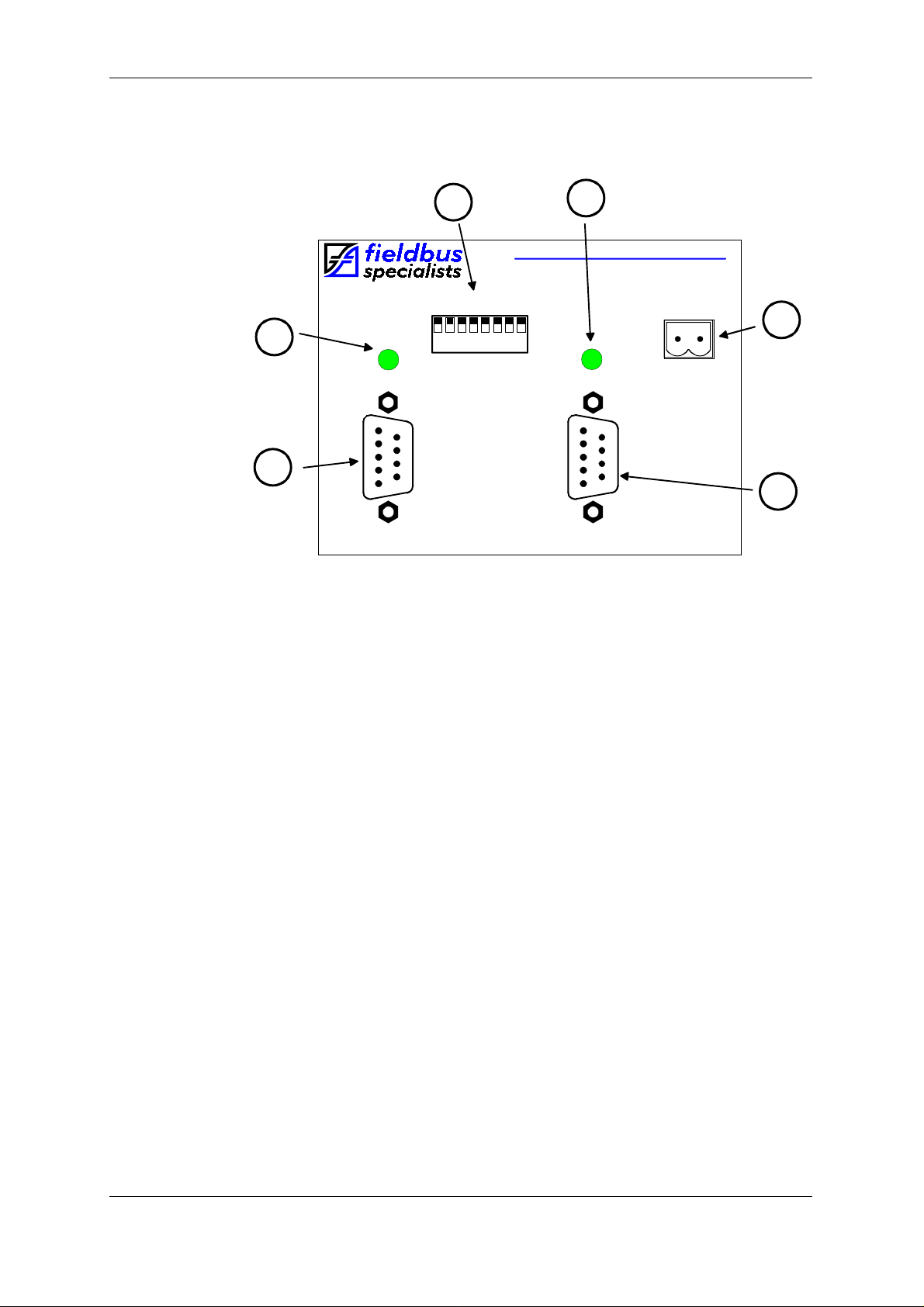

2.2 Front panel

MCD 3000 – PROFIBUS GATEWAY

6

MCD 3000 - PROFIBUS Gateway

RS485

STATUS

5

ADDRESS

1ON2 3 4 5 6 7 8

LSB

RS485

4

PROFIBUS

STATUS

FS-1135

POWER

_

+

24V DC

PROFIBUS

3

1

2

Figure 2. Gateway front panel

Fig. 2 shows the front panel of the gateway. Located on the

front panel are:

1. RS-485 sub-network connector for connecting up to 30

MCD 3000 devices, DB9, male,

2. PROFIBUS network connector, DB9, female,

3. Power connector, 2 pin removable terminal block,

4. Bi-colour PROFIBUS status LED,

5. Bi-colour RS-485 status LED,

6. Dip switches for PROFIBUS address selection.

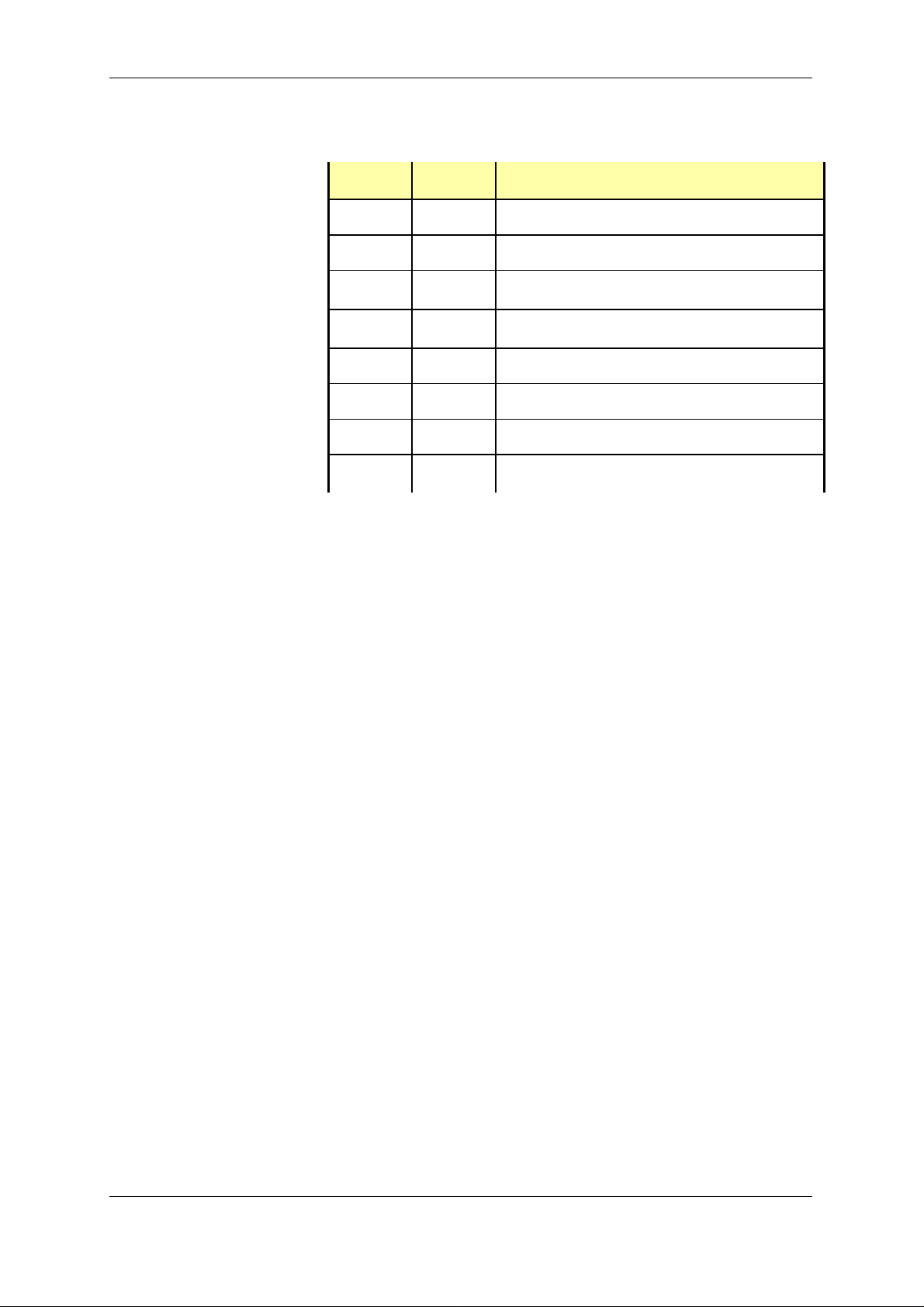

The following table indicates the status of the PROFIBUS

connection.

MCD 3000

SERIES

9 USER MANUAL

MCD 3000 – PROFIBUS GATEWAY

PROFIBUS

LED

B

R/B

RS-485

LED

B

ANY

Gateway status

Gateway starting (max. 6 sec) or no power

Invalid PROFIBUS address

R/B

G/R/B

G

ANY

ANY

G

ANY

ANY

ANY

R/B

G/R

G

PROFIBUS link down – no PROFIBUS Maste r,

incorrect address or no connection,

PROFIBUS link error – wrong configuration or

parameter in Master

PROFIBUS link up and problem-free

No communication on the RS-485 link

Occasional errors on the RS-485 link

Both PROFIBUS and RS-485 links operational

and error-free

Legend:

- LED off

B

- LED steady green

G

- LED flashing red/off

R/B

LED flashing green/red

G/R

G/R/B

-

LED flashing green/red/off

-

ANY – applies irrespective of LED status

Table 1 – LED Indication

These simple rules may be worth remembering:

- Flashing indicates errors on the relevant link,

- Flashing red means that the gateway attempts to

communicate but fails every time,

- Flashing red/green means that the gateway can

communicate, but errors occur.

MCD 3000

SERIES

10 USER MANUAL

Loading...

Loading...