Page 1

Chapter

Maintenance & Disassembly

5.1 Introduction

This section contains preventive and corrective maintenance procedures for the MB02

notebook. The first part of the section describes the computer cleaning procedures and

preferred handling procedures for sensitive components (e.g. disk drives, LCD, CPU,

batteries).

The second part of the chapter identifies all field replaceable parts with the remainder

explaining the removal and replacement procedures for the field replaceable parts.

5.2 Preventive Maintenance

Preventive maintenance is limited to cleaning the plastic case, the keyboard, and the display

screen and cleaning the floppy drive heads as required.

5.2.1 Cleaning the Computer

When it is necessary to clean the plastic case and keyboard, use a soft lint-free cloth, slightly

dampened with a mild detergent solution, or use the contents of any commercially available

computer cleaning kit.

i Never use alcohol, petroleum-based solvents, or harsh detergents to clean the

notebook. Also, do not spray any liquids directly on the computer case,

keyboard, or screen. If the liquid-crystal display (LCD) screen has become

smeared or dusty, clean the screen by first applying a mild glass cleaner to a

soft, clean, lint-free cloth, and gently wipe the glass. Never apply liquids directly

on the screen surface. Moreover, do not use paper towels to clean the display

screen. Paper can scratch the display screen matte.

5.2.2 Maintaining the LCD Quality

When it comes to screen problems, heat plays a big part. After a good working session, the

typical routine is to shut the machine and close the cover. But the display surface - no matter

what type it is - and the components inside the computer radiates heat; when you close the

cover, you trap the heat against the screen. Leave the computer's cover open for about ten

minutes while the heat disperses. Make this a habit.

FIC MB02 Service Manual 5-1

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 2

Maintenance & Disassembly

5.2.3 Maintaining the Hard Disk Drive

The hard disk drive is one of the most common parts that always gets problem. Here is some

preventive maintenance that you can do when handling the hard disk.

• Always back up the data files from the hard disk.

• Run a virus detecting program for possible virus infected area on the hard disk.

• Use SCANDISK to correct any errors found in the directory and File Allocation Table

(FAT). This will also free up space from any unused sectors.

• Never turn the computer off when the hard disk is being accessed.

• Never move or raise the computer while the hard disk is being accessed, most especially

don't jar the hard disk as this may cause a hard disk crash.

• Use hard disk system tools like Disk Defragmenter under Windows. This reorganizes

your hard disk by eliminating fragmentation and improves the hard disk access time.

5.2.4 Handling the Computer Battery Packs

The battery packs furnished with the computer require reasonable care and handling to ensure

efficient operation and maximum life. Periodically inspect the battery terminals and the

batteries for evidence of corrosion and oxide build-up.

To ensure that the battery packs endure normal life cycle, always observe the following

precautions when handling the battery packs:

• Do not drop the battery packs or subject them to excessive shock and vibration.

• Do not expose the battery packs to direct sunlight, moisture, or chemical compounds.

• Do not disassemble the battery packs.

• Do not use the battery packs to power other devices.

• Do not short the battery leads or connect the battery with reversed polarity.

• Never attempt to charge the battery packs in any way other than as described in this

manual and the User’s Manual.

• Always charge the battery packs as soon as possible after a low battery indication.

5-2 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 3

Maintenance & Disassembly

5.3 Required Tools and Equipment

To troubleshoot and repair PC systems properly, you need a few basic tools:

• Tweezers

• Small flat-blade screwdriver

• Small Cross screwdriver

• Regular size Cross screwdriver

• Small Hex-bolt screwdriver

i All boards, options, and peripherals contain components that are sensitive to

static electricity. When handling any of these items, use wrist or ankle grounding

straps and grounded working mats. When moving or storing items, use the antistatic bags supplied with the items.

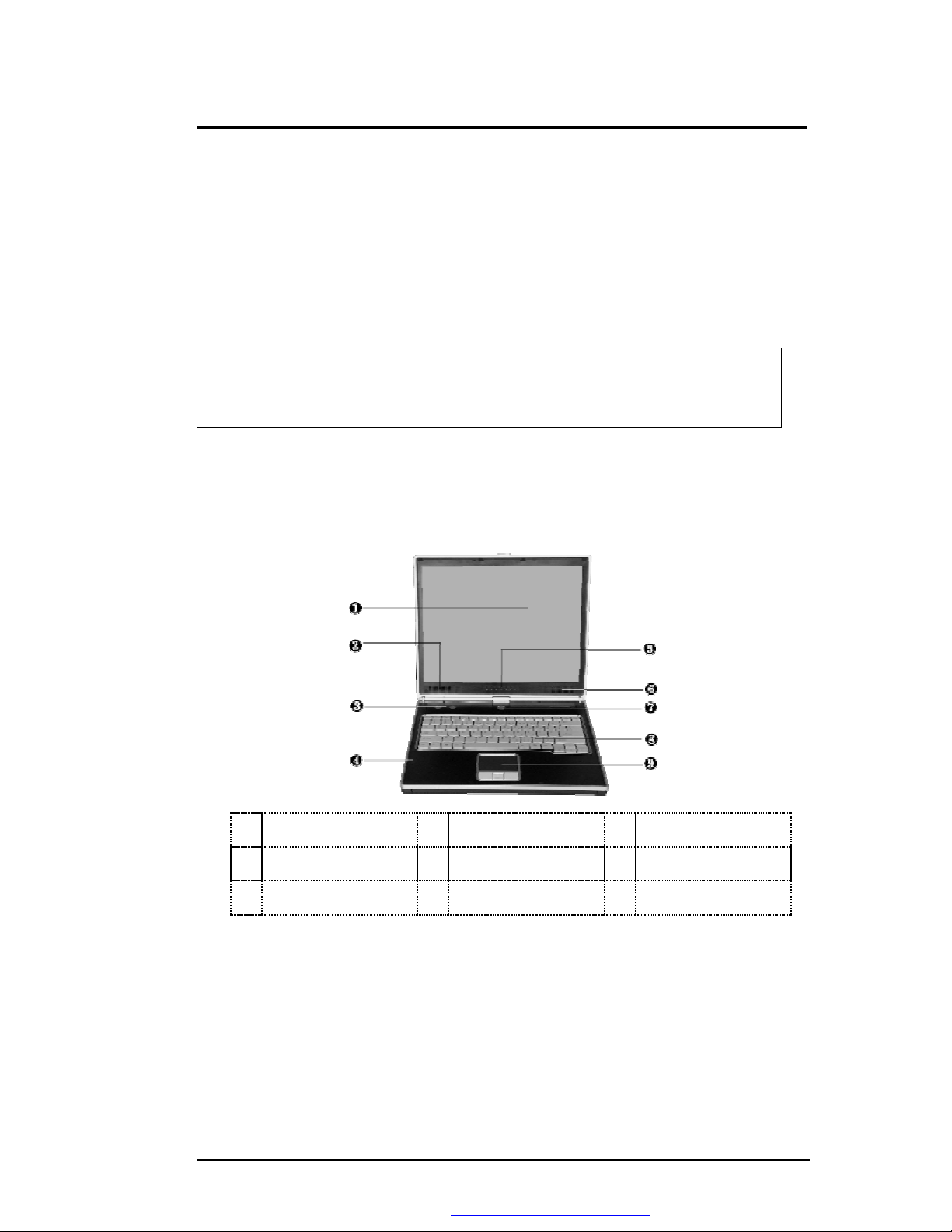

5.4 Notebook Field-Replaceable Parts and Assemblies

The notebook contains two major assemblies: The Cover Display LCD Assembly and the

System Unit Assembly.

Color LCD Display

Œ

•

’

Integrated

Microphone

Power On/Resume

Button

Figure 5-1 Cover Display and System Unit Assembly

Built-in Stereo

•

Speakers

Status LED Indicator

•

➑

Keyboard

FIC MB02 Service Manual 5-3

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Easy Buttons

Ž

‘

❾

Built-in Stereo

Touchpad Pointing

Speakers

Device

Page 4

Maintenance & Disassembly

5.4.1 Cover-Display LCD assembly

The Cover-Display LCD Assembly includes the following major Field Replaceable

Units/parts (FRUs):

• LCD Face and Back Panel Cover

These parts are used to cover the whole LCD Panel assembly, which includes the LCD

Display Module, the LCD FPC cables, and inverter board.

• LCD Display Module

“13.3” LCD (Liquid Crystal Display) screen is used for output display. This part is

assembled together with LCD Power Inverter Board, and LCD cables contained inside the

whole LCD Panel. Handle this part with care against static electricity and accidents that

can break the LCD.

• LCD Power Inverter Board

This part or PCB (Printed Circuit Board) is used to provide high voltage to the CCFT

(Cold Cathode Fluorescent Tube) of the notebook’s LCD backlighting. It is connected to

the right side of the LCD display screen and attached to the back panel by a screw.

Exercise safety electrical precautions in handling and servicing this part. The circuit board

also includes the function for displaying the power status and battery charge LED

indicators.

• LCD FPC Cable

The LCD FPC cable is used to convert output signals from the motherboard in driving the

LCD display screen. The cable is connected to the back of the LCD Panel.

5.4.2 System Unit Assembly

The System Unit Assembly comprise of several assemblies of which can be divided into two

major sub-assemblies.

• The System Top Unit Assembly.

• The System Base Unit Assembly.

The following System Top Unit Assembly includes the following major Field Replaceable

Units/parts (FRUs):

• Glidepad Touch Pad Module Assembly

The touch pad (glide pad) pointing device module is assembled at the underside of the top

cover with the sensor pad exposed on the top. The assembly comprises of the glide pad

board, the glide pad converter board, the select buttons bracket casing, the insulator sheet,

the glide pad FPC cable, and the glidepad wire cable. The glide pad board is assembled

just underneath the select button assembly. It provides a FPC cable connector for the

mother board.

• Keyboard Panel Assembly

The keyboard is assembled on top of the system unit and connected to the main board ’s

keyboard FPC type connector. The keyboard is also secured on the system’s top unit

casing. There are no screws attached to the keyboard.

5-4 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 5

Maintenance & Disassembly

• Heat Plate and Fan Exhaust Unit

The Fan Exhaust unit is assembled on the upper-right side of the system unit. It comprises

of a heat plate and one fan. There are seven screws securing the heat plate to the CPU

module inserted on the motherboard. The exhaust fan is secured beside the heat plate.

• Keyboard Cover Assembly

The keyboard cover is a thin bracket for holding the keyboard as well as covering the

base unit. It is also includes the power button, easy buttons, and status LED cover

moldings.

The following System Base Unit Assembly includes the following major Field Replaceable

Units/parts (FRUs):

• Battery Pack

This is one of more easily replaceable parts. The battery pack is found on the right side on

the base unit and can be easily removed by pressing the latch underneath the unit and

pulling the battery on its handle. The battery pack is replaced as a whole and must not be

opened for repair.

• Hard Disk Drive Module

The Hard Disk Drive is attached on the lower-left side of the system base unit located just

below the keyboard. The HDD is secured by only one screw. The HDD module is a 2.5inch hard disk drive with a maximum height of 9.5mm. The hard drive module assembly

is attached to the motherboard through the HDD connector.

• CD-ROM / DVD-ROM Drive Assembly

The CD-ROM / DVD-ROM / Drive Assembly is attached on the right side of the base

unit and is lock with one latch.

• CPU

The Pentium socket is found on the top right part of the motherboard. You will need a flat

screwdriver and CPU tooling for removing or installing the CPU. Refer to Chapter 2 on

how to install and upgrade the CPU.

• Speaker Assembly

The internal speakers of the notebook are assembled into front side of the system. They

are secured into a slot and speaker cable connector is attached into the main board.

• Motherboard Assembly

The Motherboard assembly is the most important part of the notebook. It contains the

entire major chipsets including the core logic, PCMCIA, memory, and BIOS to operate

the whole computer. It also includes the sockets, connectors and ports completing the

functionality.

• Internal Modem / LAN / Combo Module Assembly

If the computer includes an internal modem, LAN

FIC MB02 Service Manual 5-5

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 6

Maintenance & Disassembly

• System Base Unit Case

The System Base Unit Case is where the Motherboard is placed. It includes openings for

the battery, FDD, CD-ROM and PCMCIA equipment.

5.5 Parts Removal and Replacement Procedures

This section contains the field service-level removal/ replacement procedures for the

notebook. The notebook is designed for optimum modularity in order to make field

replacement and maintenance easy and efficient.

5.5.1 Removing the Battery Pack

The procedure for removing and replacing the battery pack is as follows:

To remove the battery pack, slide the latch to right side and hold it, then take out the battery

pack with your finger.

Figure 5-2 Removing the battery pack

5.5.2 Removing the Keyboard

The internal keyboard is located above the system top unit and is fitted in without screws on

the top unit case. Follow the steps below on how to remove the keyboard:

1. There are four screws on the bottom case and that should be removing as the picture

indicated.

Figure 5-3 Four screws of Keyboard cover

5-6 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 7

Maintenance & Disassembly

2. Remove keyboard cover by gently bending it and sliding it towards in front of you.

Figure 5-4 Remove Keyboard Cover

3. Lift the keyboard and tilt it towards the LCD panel.

4. Release keyboard cable by sliding the ZIF connector towards up direction.

Figure 5-5 Remove keyboard

5.5.3 Removing the Internal Hard Disk Drive

The notebook provides a built-in hard disk for the primary IDE controller. The HDD is an

industry standard 2.5” IDE disk drive with a maximum height of 9.5mm.

1. Find out the built-in hard disk secured with four screws at the upper lift of the bottom

case. Remove this screw and carefully pull the hard disk module from the connector.

FIC MB02 Service Manual 5-7

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 8

Maintenance & Disassembly

Figure 5-6 The disassembly of Hard Disk Drive

2. Remove four screws of frame HDD bracket plate.

Figure 5-7 Screws Locations of the frame HDD bracket plate

5.5.4 Removing the LCD Panel

The procedure for removing the LCD Panel is as follows:

1. There are three screws as the picture indicated for removing LCD panel .

5-8 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 9

Maintenance & Disassembly

Figure 5-8 Removing the three screws on the bottom case

2. To remove the two screws and two hex-bolds of rear side for the system unit.

Figure 5-9 Two Screws and two hex-bolds

3. Removing the two screws of LCD connector and one LCD cable.

Figure 5-10 Two Screws and one LCD cable

2. Slowly pullout the LCD panel from the system unit.

FIC MB02 Service Manual 5-9

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 10

Maintenance & Disassembly

5.5.5 Removing the Heat Sink and Sub-board

1. Removing the heat sink, there are four screws and one FAN cables as the picture shown.

Figure 5-11 Removing Heat Sink and Sub-board

5.5.6. Removing the Intel CPU

The MB02 features Intel Pentium M uFC-PGA Processors. It is located on the upper left side

of the system motherboard.

To install or replace the CPU, follow the steps below:

1. Before removing the CPU module, you need first to disassemble keyboard and heat sink

plate.

2. Using a flat screwdriver, turn the socket lock counter-clockwise direction to unlock CPU

from the socket.

Figure 5-12 CPU Assembly

5-10 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 11

Maintenance & Disassembly

5.5.7 Removing the Top Cover

The procedure for removing the top cover is as follow:

Please see the location of top cover as the below picture shown.

1. To remove the top cover, you also need to remove the three screws and four cables ----

one is called MDC cable, the other one is Microphone cable and another one is MDC

FPC and also G/P FPC from the Top case .

Figure 5-13 Location of Top Cover

2. There are total eleven screws on the bottom case

FIC MB02 Service Manual 5-11

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Page 12

Maintenance & Disassembly

Figure 5-14 Removing the eleven screws of bottom case

5.5.8 Removing / Replacing the Motherboard

The motherboard contains the major chipset and components needed to run the MB02

notebook. Follow the steps below on how to remove and replace the motherboard:

1. Before removing the motherboard, you need first to disassemble the all basis unit

modules mentioned in the previous sections.

2. On the motherboard, there are two screws and one hex bolt . Remove these hex bolts and

screws.

Figure 5-15 Motherboard Screws Location

3. When all screws ,bolts, slowly detached the main board from the base unit casing. Notice

the close gap between the volume control knob and button case and may use the specific

tooling to separate them more easily.

5-12 FIC MB02 Service Manual

PDF created with FinePrint pdfFactory trial version http://www.fineprint.com

Loading...

Loading...