fiberon SYMMETRY SIGNATURE Installation Instructions Manual

®

SYMMETRY

SIGNATURE

Low-Maintenance Composite Railing

6-ft. and 8-ft.

INSTALLATION INSTRUCTIONS

Manufactured by

berondecking.com

800.573.8841

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Line

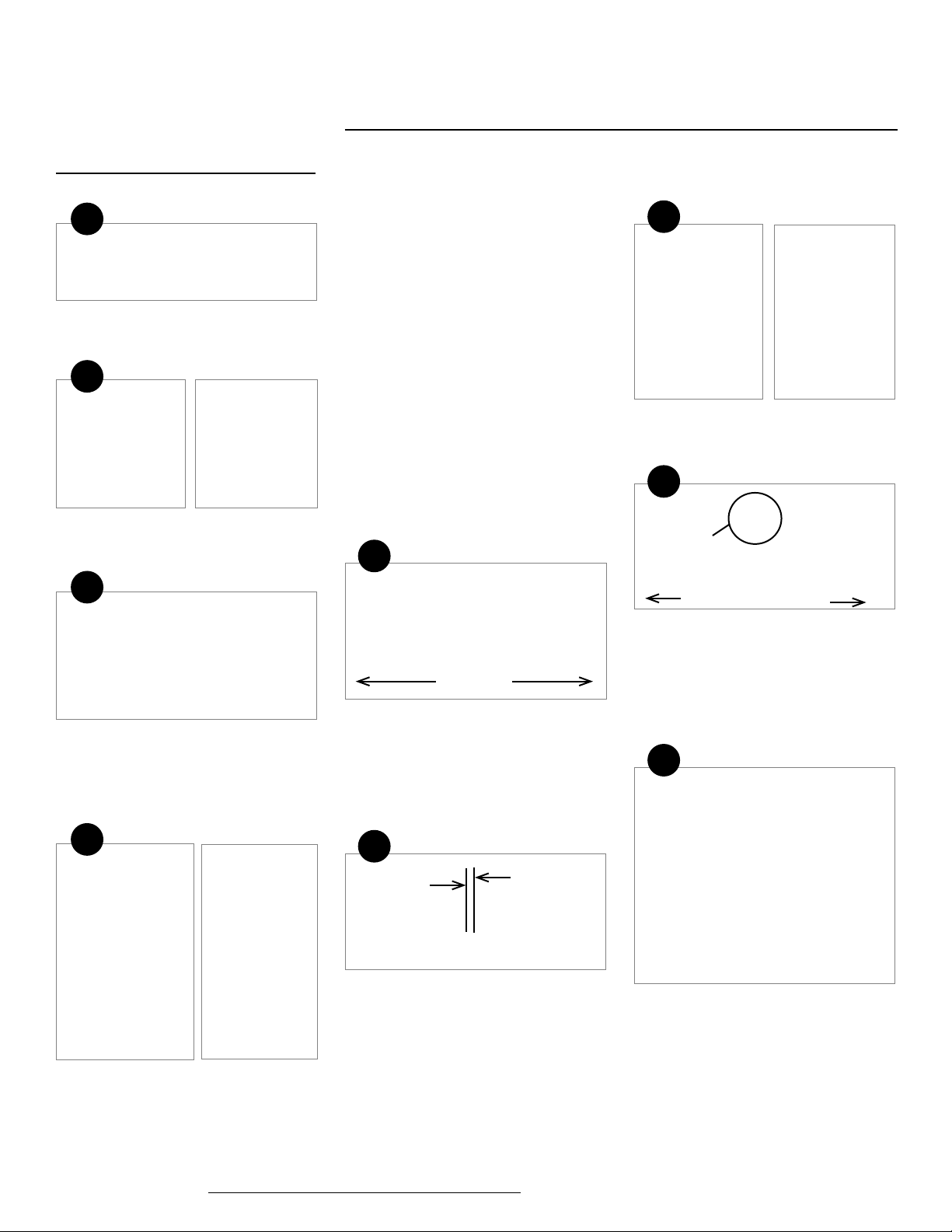

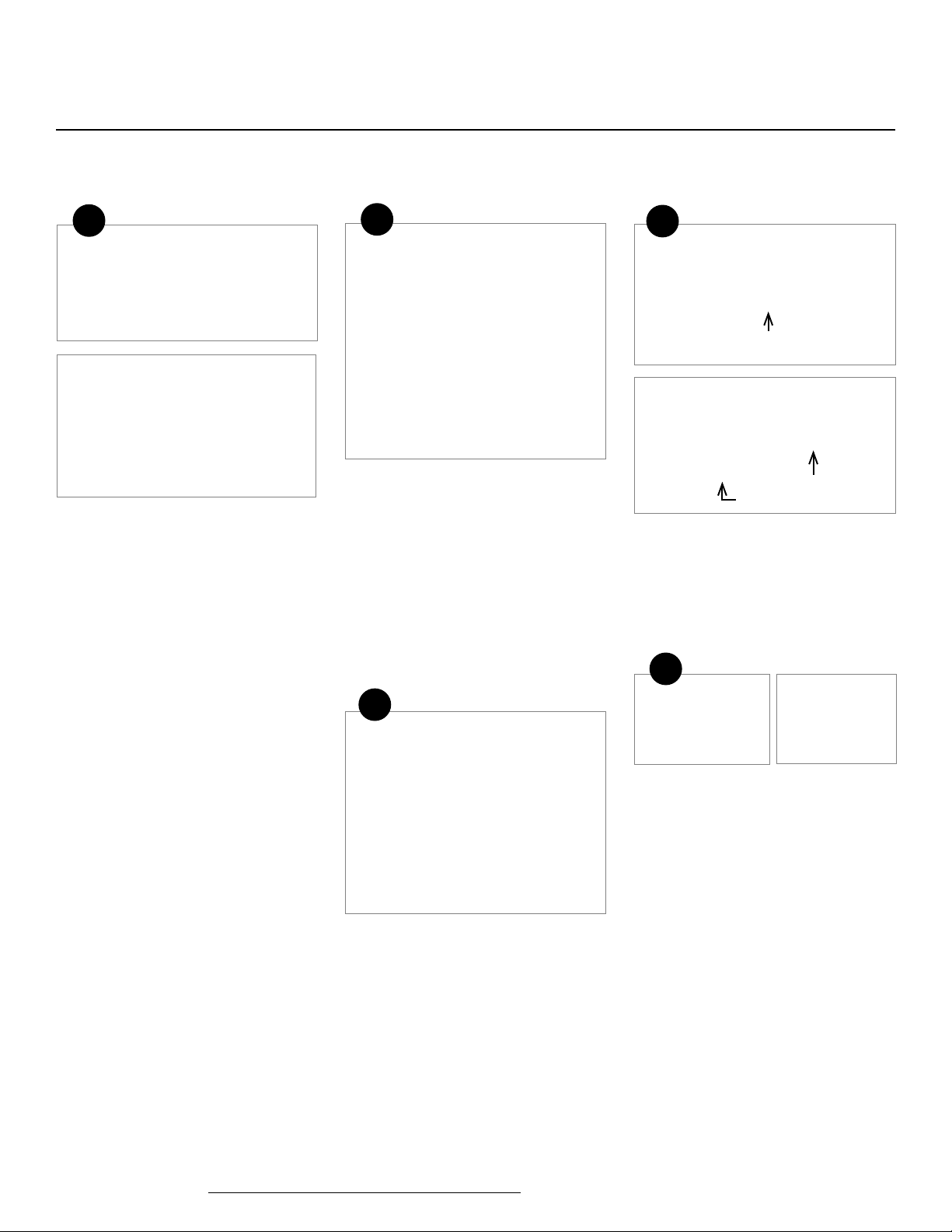

Railing component list for 6-ft. section:

Maximum length between post sleeves is 67 inches.

Post Sleeve Cap

• Top Rail

Top Rail Bracket

• Bottom Rail

• H-Channel

• Hardware and Screws

• 14 Balusters

Square

Composite

Balusters

• Crush Block

• Post Caps

Post

Sleeve

• Post Sleeves

• Post Skirt

Bottom Rail Bracket

Post Sleeve Base Moulding

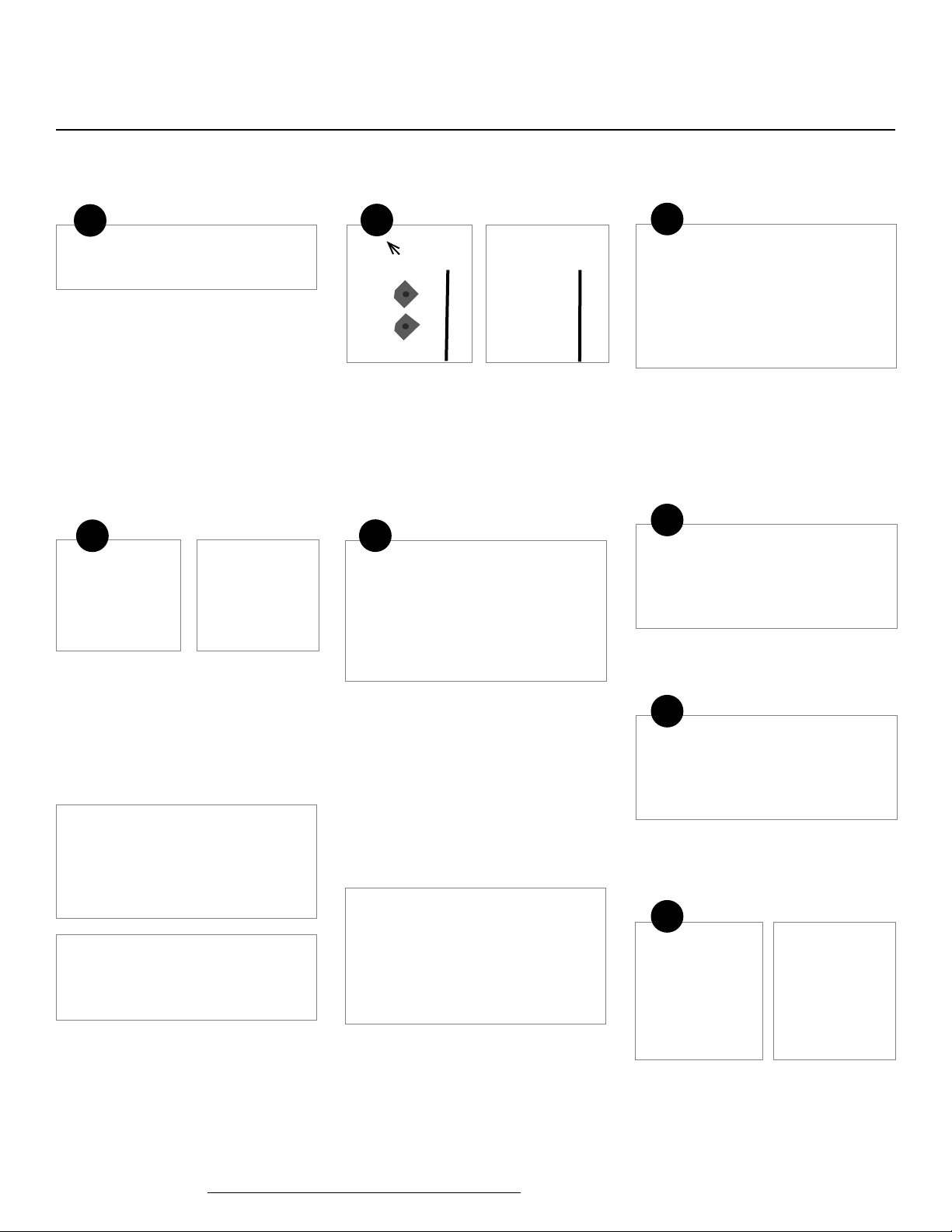

Railing component list for 8-ft. section:

Post Sleeve Cap

Top Rail

Top Rail H-Channel

Round

Metal

Balusters

Crush Block

Bottom Rail

Maximum length between post sleeves is 91 inches.

Top Rail

• Top Rail

• Bottom Rail

• H-Channel

• Hardware and Screws

• 20 Balusters

• 2 Crush Block

• Post Caps

• Post Sleeves

• Post Skirt

1

Top Rail Bracket

Square

Composite

Balusters

Post

Sleeve

Bottom Rail Bracket

Post Sleeve Base Moulding

Note: Rail lengths will vary slightly due to manufacturing processes. Ensure rails are cut to

correct length with hole pattern centered between posts before securing.

The most recent installation instructions can be found on our website.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

Crush Blocks

Top Rail H-Channel

Round

Metal

Balusters

Bottom Rail

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Line

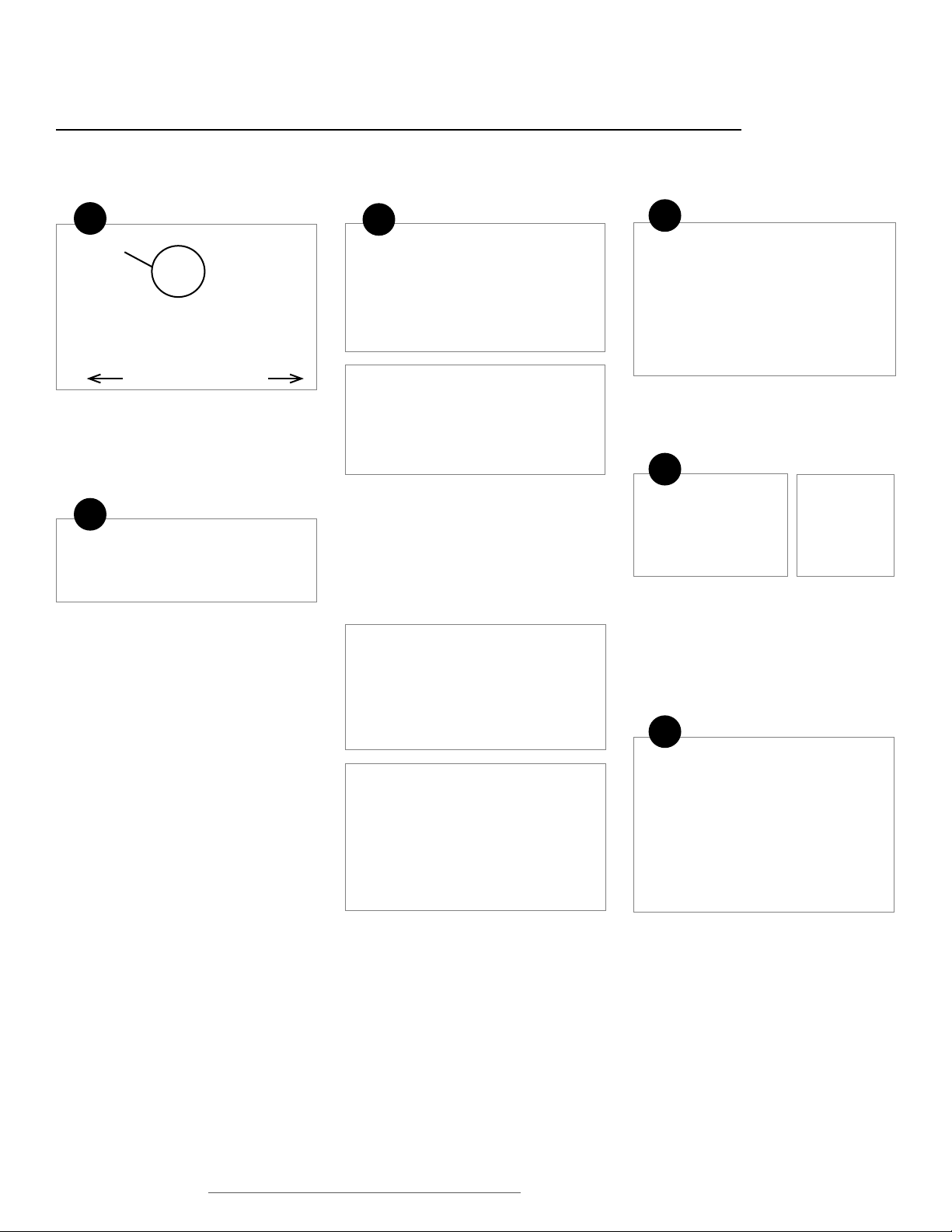

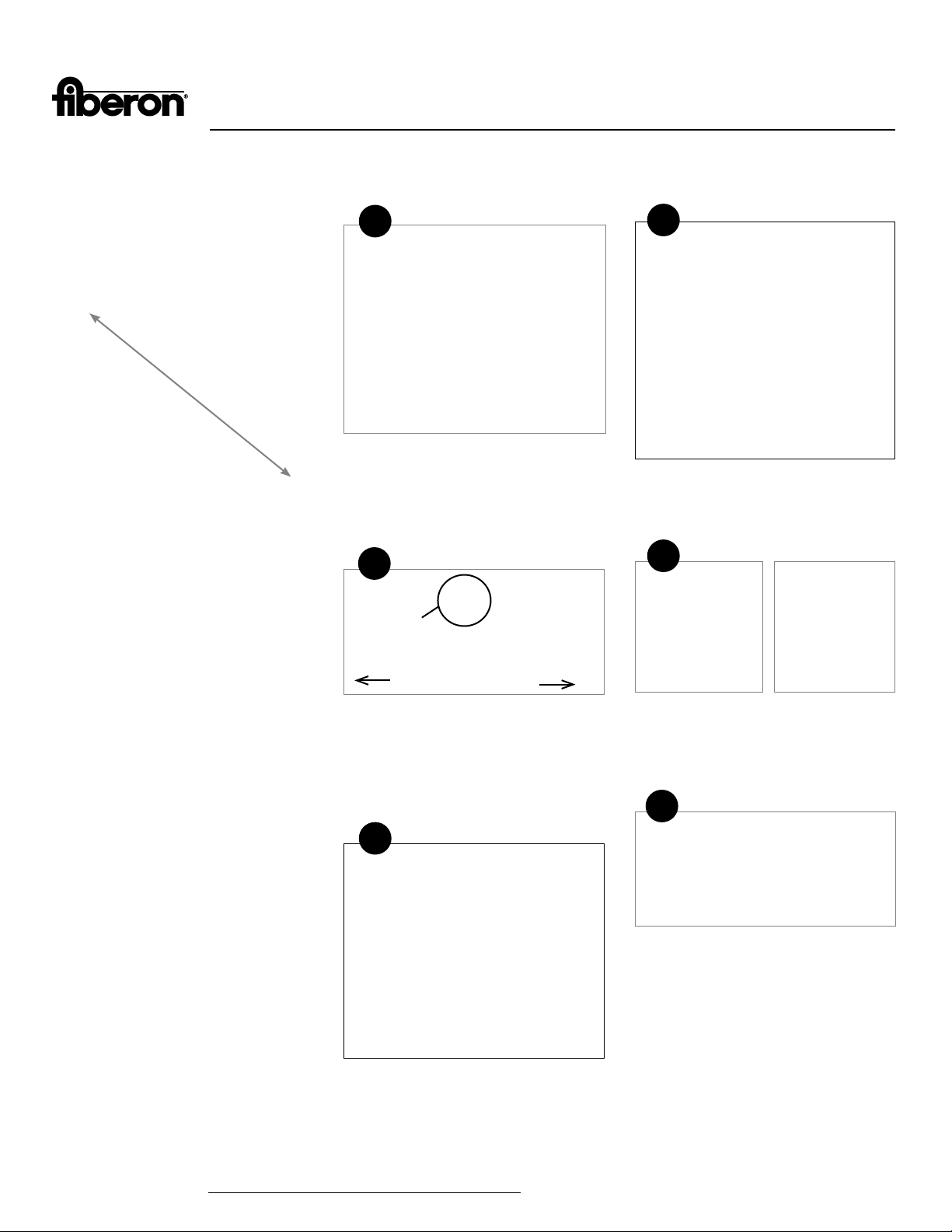

Required Tools and Supplies:

Top Rail Prole

• Power Drill

• Protective Eye Wear

• Pencil

• Adjustable Square

• Tape Measure

• Level

• Speed Square

• Miter Saw

Bottom Rail Prole

Prior to installing railing: Please consult local zoning laws regarding load requirements and bottom space requirements for rails. All supporting

structures must be in accordance with applicable building codes. Neighborhood associations and/or historic districts may regulate size,

placement, and type of railing. Apply for permits if required by local authorities and codes. Ensure compliance prior to installation. Local building

code requirements will always supersede any and all suggested procedures and measurements in the following instructions. The following

installation instructions are intended as a general guideline based on common building practices used in railing installation.

YES

NO

1-1/2-in. minimum from rail end to baluster

Rail Installation: When top and bottom rail length is greater than the distance between posts, trim both ends of the rail to maintain uniform

baluster spacing. It is critical to ensure the trim mark does not interfere with the balusters once installed.

1

Note: Make sure posts are plumb and level

prior to installing the railing.

Cover 4x4 posts or Fiberon surface mount

bracket with post sleeve and verify spacing.

Posts should be plumb in both directions.

Place post sleeve base moulding over post

sleeve and slide it down to the deck surface.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

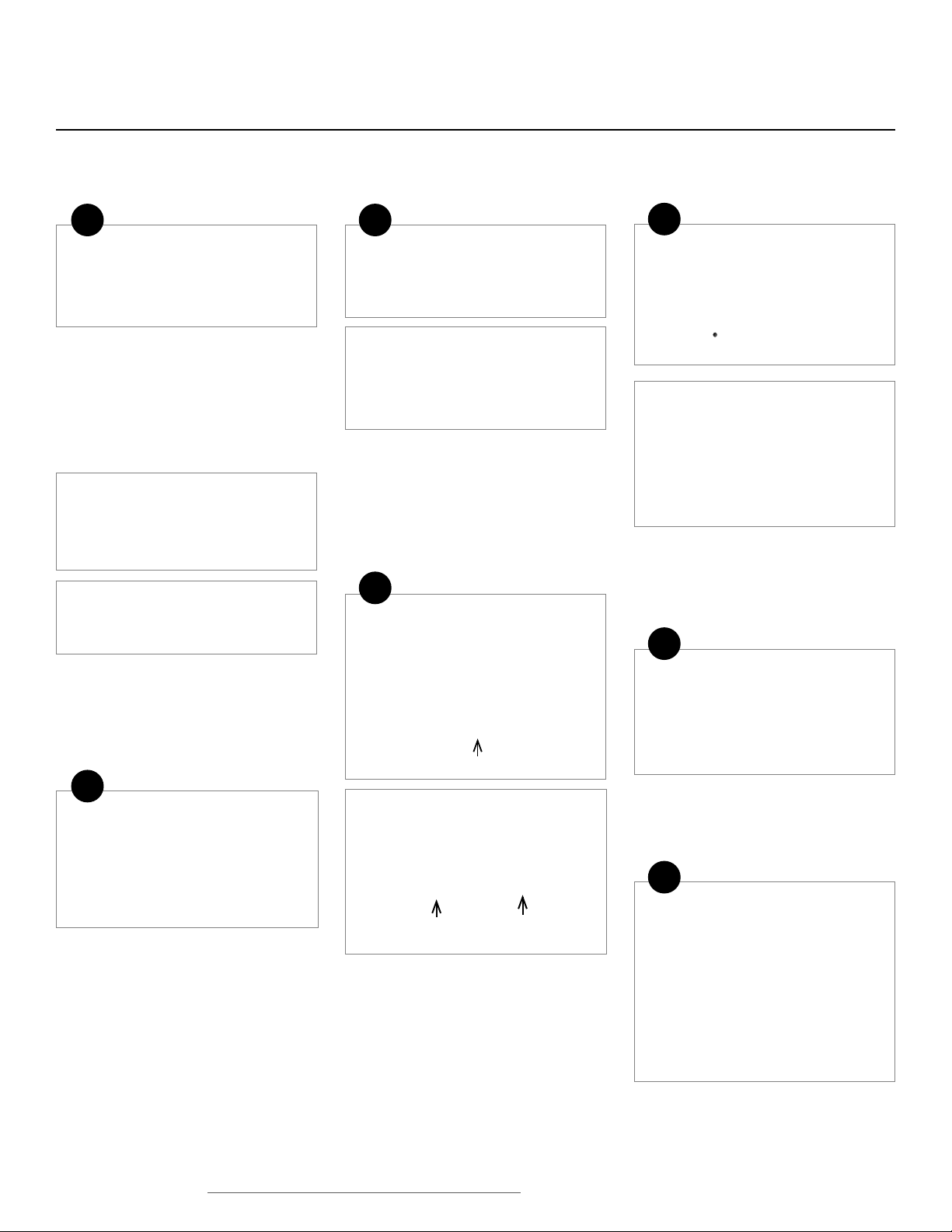

2

Measure the distance between the posts

for the bottom rail. Center the hole pattern,

then mark the cutting points. Check for t.

Center the bottom rail with the top rail. Mark

and cut to length.

The most recent installation instructions can be found on our website.

3

7/32-in.

Align the H-bar and the cut bottom rail hole

patterns. Mark the length of the bottom rail

on the H-bar, then subtract 7/32-in. from that

measurement on each end of the H-bar (7/16in. total to allow for top bracket thickness) and

mark. Cut the H-bar and set aside for step 7.

2

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Line

4

Aligning feature

Yard Side Deck Side

Ensure that the bottom rail is positioned

correctly prior to installation. The bottom rail

has an aligning feature on the top, which

should be on the yard side of the rail opposite

to the deck side.

5

Square Composite Balusters: Measure and

trim all balusters to the required length.

Remove the baluster guide from the railing

box, place on a at surface, and insert the

balusters into the precut slots.

Note: Square composite baluster lengths

will very slightly due to manufacturing

processes. Insure balusters are cut to

uniform length.

Note: Round metal balusters do not

require trimming.

6

Square Composite Balusters: Align the bottom

rail with the balusters on the same end as the

baluster guide. Hold square balusters securely

against the aligning feature on the bottom rail

and secure the balusters to the bottom rail

with the supplied #10 x 1-1/2-in. screws. Do

not over-tighten

7

H-bar Bracket

Bottom Rail Bracket

Ensure that the brackets are positioned

correctly prior to installation. The brackets

indicate which side will be facing the decking.

8

Fully insert top brackets into both ends of

the aluminum H-bar with the arrow pointing

upward.

Using integrated screw template, secure with

self-drilling #10 x 5/8-in. screws. Do not overtighten.

9

Round Metal Balusters: Align baluster with

predrilled holes in bottom rail. Insert supplied

#10 x 1-1/2-in. screw through hole and

into the center (“X”) of the ns inside of the

baluster. Do not over-tighten.

Align the aluminum H-bar with the balusters

with the side holes facing upward.

Square Composite Balusters: Slide the baluster

guide to the opposite end of the balusters.

Insert the top of the balusters fully into the

channel of the aluminum H-bar rail.

Note: When securing composite or metal

balusters, shim the H-bar with a 1/2-in. –

5/8-in. spacer to help ensure balusters

remain perpendicular to the H-bar.

3

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

The most recent installation instructions can be found on our website.

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Line

10

Square Composite Balusters: Position the top

of the balusters tightly against the inside of

the top H-bar. Center the balusters under the

side-mounting screw holes. Working from one

end to the other, secure each baluster using

the supplied #8 x 1-1/2-in. at head screws.

Do not over-tighten.

12

Dry t, measure, and trim crush block to the

required nal length. Secure crush block to

holder using supplied at head screw.

Note: When using the bracket template, a

3-3/4-in. tall crush block is required. The

screw will be off-center in the crush block.

13

14

Pre-drill the two holes with a 1/8-in. bit, taking

care not to drill through the top of the bottom

rail. Secure with the supplied at head screws.

Do not over-tighten.

15

Round Metal Balusters: Insert supplied #10 x

1-1/2-in. screw through holes in the H-bar,

and into the center (“X”) of the ns inside of

the baluster. Drive until secure. Do not overtighten.

11

Locate the Symmetry Signature bottom line

bracket template (included on the post sleeve

carton and inside the rail kit box).

Using the bottom bracket template, position

and secure bottom brackets using the

supplied #10 x 2 ½-in screws, ensuring the

bracket is positioned correctly (see step 7).

The template will create a 3-in. gap under the

bottom rail.

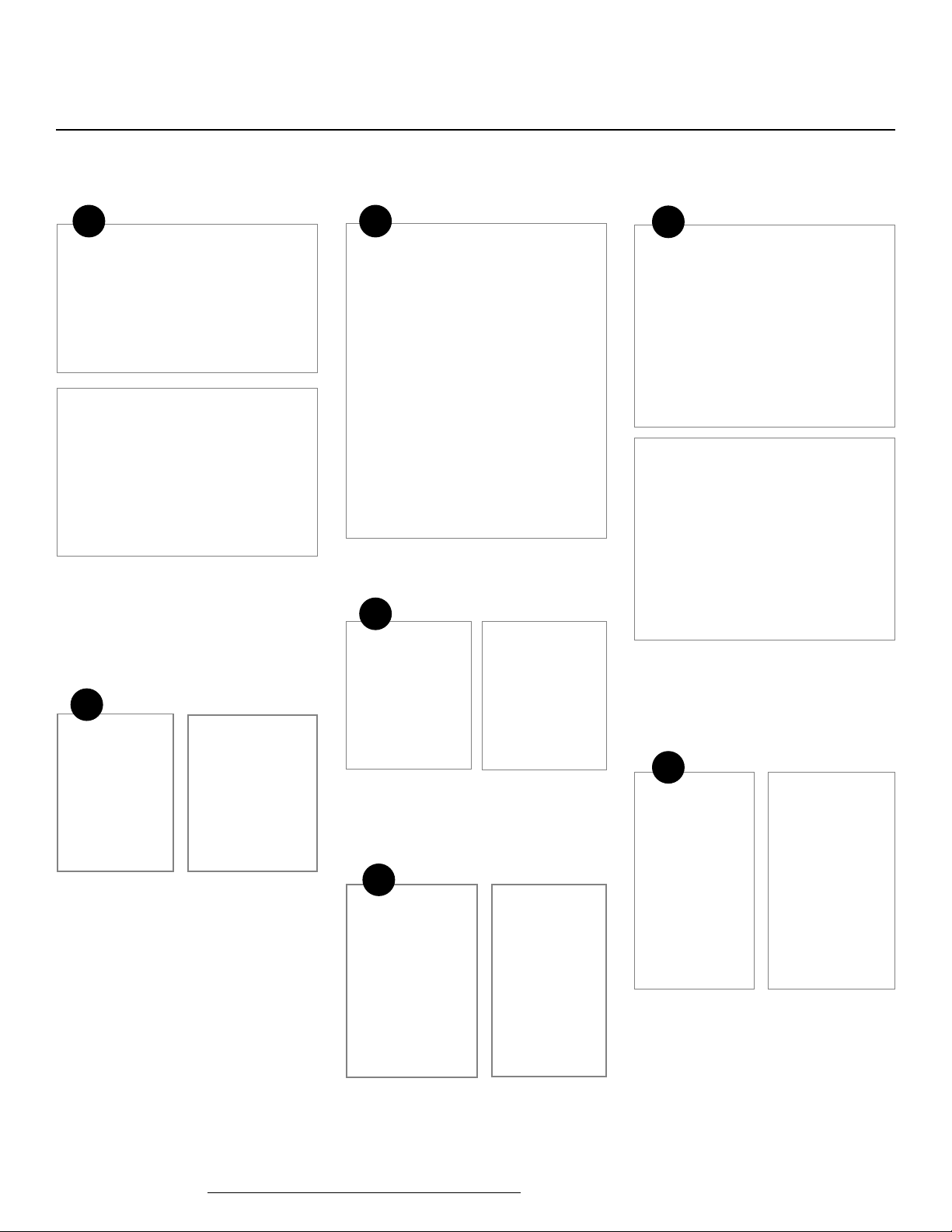

Approximate center on a rail section up to 6 ft.

Carefully position the pre-assembled railing

inll between the posts, then slowly lower over

the bottom brackets until fully seated.

16

Approximate 1/3 and 2/3 on a

rail section longer than 6 ft.

For 6-ft. rail sections, position the crush

block and holder inside the bottom rail at the

approximate center point.

For 8-ft. rail sections, position the two crush

blocks and holders inside the bottom rail at

the approximate 1/3 and 2/3 points.

Center the H-bar on the post and check rail

for plumb.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

The most recent installation instructions can be found on our website.

4

Symmetry Signature Railing

Installation Instructions 6-ft. and 8-ft. Line (cont.)

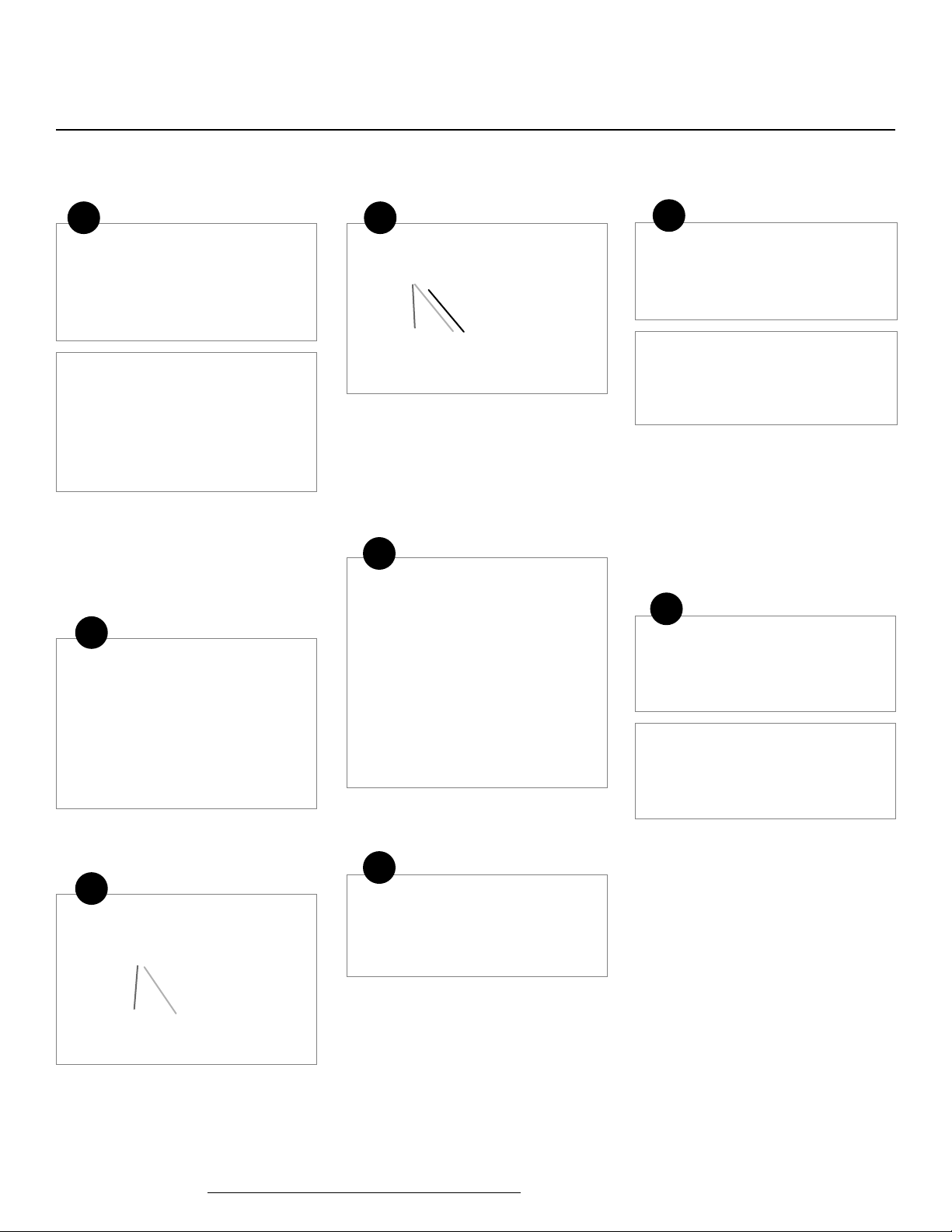

Symmetry Signature Railing Installation Instructions - Angled Line

17

Secure the top brackets with the supplied

#10 x 2-1/2-in. screws.

18

Position the top rail over the inll assembly and

carefully lower into place.

19

Using supplied 1-1/2-in. screws, secure

the top rail starting as close to the post as

possible. Space the remaining screws evenly.

Note: Angled installations require a

minimum 5x5 post.

1

Deck Side Yard Side

For angled line installation, the line brackets

must be installed with the angled edge on

the deck side of the railing.

Note: This is opposite of what is indicated

on the line bracket for basic line railing

installation.

3

Secure with supplied #10 x 2-1/2-in. selfdrilling screws. Do not over-tighten.

4

Aligning feature

Yard Side Deck Side

Ensure that the bottom rail is positioned

correctly prior to cutting the bottom rail

angle for installation. The bottom rail has an

aligning feature on the top, which should be

on the yard side of the rail opposite to the

deck side.

5

20

Complete the assembly by gluing the post

caps in place with a quality exterior-grade

adhesive.

5

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

2

7/32-in. - 1/4-in.

The template can still be used to locate

the height of the line bracket. The side-toside alignment needs to be approximately

7/32-in. – 1/4-in. off-centered from the

deck side of the railing for a full 45-degree

installation.

Note: If the bracket is not offset slightly,

the top rail may overhang the corner post

face and extend into the corner chamfer.

The most recent installation instructions can be found on our website.

Center the hole pattern in the bottom rail

between the posts. Transfer length and

angle to the top rail and cut both top and

bottom rails. When aligning the hole pattern,

transferring length, and cutting angles on

the H-bar, remember to subtract 7/32-in.

from each end to allow for top brackets.

Symmetry Signature Railing Installation Instructions - Angled Line

6

Square Composite Balusters: Measure and

trim all balusters to the required length.

Remove the baluster guide from the railing

box. Place on a at surface and insert the

balusters into the precut slots.

Note: Square composite baluster lengths

will very slightly due to manufacturing

processes. Insure balusters are cut to

uniform length.

Note: Round metal balusters do not require

trimming.

7

Square Composite Balusters: Align the bottom

rail with the balusters on the same end as the

baluster guide. Hold square balusters securely

against the aligning feature on the bottom rail

and secure the balusters to the bottom rail

with the supplied #10 x 1-1/2-in. screws. Do

not over-tighten

8

NO YES

Insert top brackets into the cavity of the

aluminum H-bar, ensuring that the top bracket

is located within the boundaries of the H-bar.

If the bracket is outside of the boundaries, the

top rail will not t over the H-bar and bracket.

Secure with the supplied #10 x 5/8-in. selfdrilling screws.

9

Square Composite Balusters: Position the top

of the balusters tightly against the inside of

the top H-bar. Center the balusters under the

side-mounting screw holes. Working from one

end to the other, secure each baluster using

the supplied #8 x 1-1/2-in. at head screws.

Do not over-tighten.

Note: The screws should penetrate fully

through the baluster.

10

Assemble and attach the crush block

following standard line railing instructions.

Position the assembled inll over the bottom

brackets and carefully lower into place and

secure the top brackets with the supplied #10

x 2-1/2-in. screws.

11

Position the top rail over the inll assembly,

and carefully lower into place.

12

Using supplied 1-1/2-in. screws, secure

the top rail starting as close to the post as

possible. Space the remaining screws evenly.

Round Metal Balusters: Align baluster with

predrilled holes in bottom rail. Insert supplied

#10 x 1-1/2-in. screw through hole and

into the center (“X”) of the ns inside of the

baluster. Do not over-tighten.

The most recent installation instructions can be found on our website.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

Round Metal Balusters: Insert supplied #10 x

1-1/2-in. screw through holes in the H-bar,

and into the center (“X”) of the ns inside of

the baluster. Drive until secure. Do not overtighten.

13

Complete the assembly by gluing the post

caps in place with a quality exterior-grade

adhesive.

6

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Stair

The maximum length between

post sleeves measured in line with

the guardrail cannot exceed 5 in.

short of full length, depending on

which kit is being used.

1

Cover 4x4 posts or Fiberon surface mount

bracket with post sleeve and verify spacing.

Posts should be plumb in both directions.

Place post sleeve base moulding over post

sleeve and slide it down to the deck surface.

2

Aligning feature

4

Center the hole pattern between the posts,

allowing a minimum 1-5/8-in. from rail end to

routed baluster holes.

5

Building codes are very specic on

allowable angles and widths. It is very

important to consult with your local building

code ofcials and plan your stair layout

accordingly. Leave adequate space for

graspable hand rail if applicable.

Note: The slope of the stairs can be 30-37

degrees.

Note: Rail lengths will vary slightly due to

manufacturing processes. Make sure rails

are cut to correct length.

Yard Side Deck Side

Ensure that the bottom rail is positioned

correctly prior to cutting the bottom rail

angle for installation. The bottom rail has an

aligning feature on the top, which should be

on the yard side of the rail opposite to the

deck side.

3

To establish the stair angle, use a 1x4 or

similar support to bridge at least three stairs.

Place the bottom rail between the stair posts.

Transfer the stair angle to both ends of the

bottom rail and cut to the required length

and angle. Test for a snug t and make

corrections as needed.

6

Square Composite Balusters: Transfer the stair

angle to the balusters, and cut the balusters

to desired length.

Note: Round metal balusters are pre-cut on

one end. If a custom angle is required, cut

the factory angled end, leaving the square

end as is. This will allow proper seating

when securing the top of the balusters later

in the installation.

7

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

The most recent installation instructions can be found on our website.

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Stair

7

To cut the H-bar, rst place the H-bar on

its side with the holes nearest to the cut

bottom rail. The bottom rail should be top

side up. Align the hole pattern with the cut

bottom rail.

8

10

The total length of the H-bar will be 7/16-in.

shorter than the cut bottom rail.

Scribe a second line 7/32-in. inside the rst

at both ends.

Note: This allows for the thickness of the

upper bracket.

11

13

Square Composite Balusters: Remove the

baluster guide from the rail box. Place on a

at surface and insert the balusters into the

precut slots.

Round Metal Balusters: Place cut bottom rail

on a at level surface. Align the cut-end of

the round metal baluster with the top surface

of the bottom rail.

14

Transfer the length of the cut bottom rail to

the H-bar.

9

Scribe the stair angle to the side of the

H-bar at both ends.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

Position the top brackets into the H-bar,

ensuring that they are inserted completely.

12

Secure the top brackets to the H-bar using

(two) 5/8-in. self-drilling pan head screws. Do

not over-tighten.

The most recent installation instructions can be found on our website.

Square Composite Balusters: Align the end

baluster with the predrilled hole in the bottom

rail. Secure the balusters using the supplied

#10 x 1-1/2-in. screws.

Hold each square composite baluster

securely against the aligning feature and

drive screws parallel with the balusters, not

perpendicular to the bottom rail. Do not overtighten.

Round Metal Balusters: Insert the screw into

the center “X” of the end baluster. It may be

necessary to slightly over-drill the factorydrilled holes by rocking the moving bit parallel

with the direction of the rail. Do not overtighten.

Continue working from one end until all the

balusters are secured into the bottom rail.

8

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Stair

15

Note: It is important to ensure balusters

are level when securing. Shim the H-bar

with a 1/2-in. - 5/8-in. spacer to ensure

the balusters remain fully inserted when

securing.

Square Composite Balusters: Move the

baluster guide to the top rail end of the square

composite balusters.

Position the top of the balusters tightly

against the inside of the top H-bar. Center

the balusters under the side-mounting screw

holes. Working from one end to the other,

secure each baluster using the supplied

#8 x 1-1/2-in. at head screws. Do not overtighten.

Note: The screws should penetrate fully

through the baluster.

Secure the remaining balusters working to the

other end. Do not over-tighten.

Round Metal Balusters: Insert the round

baluster holders into the aluminum H-bar,

ensuring that the angled hole is oriented

correctly and that the through hole aligns with

the side holes in the H-bar.

Fully seat all balusters into the holders. Secure

an end baluster rst, using the supplied #8 x

1-1/2-in. at head self-drilling screws through

the H-bar side holes.

Pivot the H-bar toward the remaining

balusters, inserting them into the holders.

Start from the secured end and work

to the other end. Secure the remaining

end baluster, and then the remaining inll

balusters.

16

Dry t the assembled section and use the

bottom rail to scribe a light line on the post

to determine the location of the bottom rail

bracket.

Note: For best results, predrill bracket holes

on post with a 1/8-in. - 5/32-in. bit to ensure

accurate screw placement and full insertion,

particularly as the stair angle increases.

Secure the bottom stair brackets to the post

using the supplied #10 x 2-1/2-in. at the

desired height. Do not over-tighten.

17

Before assembling the crush block, transfer

the stair angle to the end of the crush block,

dry t, and cut to t.

18

Approximate center on a rail

section up to 6 ft.

Approximate 1/3 and 2/3 on a

rail section longer than 6 ft.

For 6-ft. rails sections, position the crush

block and holder inside the bottom rail at the

approximate center point.

For 8-ft. rail sections, position the two crush

blocks and holders inside the bottom rail at

the approximate 1/3 and 2/3 points.

19

Secure crush block to crush block holder

using a supplied #8 at head screw. Do not

over-tighten.

Note: The screw will be off-center in the

crush block.

9

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

The most recent installation instructions can be found on our website.

Symmetry Signature Railing Installation Instructions - 6-ft. and 8-ft. Stair

20

Position the crush block and holder into the

bottom rail, and locate the two screw holes.

Remove the holder and pre-drill using a

1/8-in. drill bit. Reposition the crush block and

holder, and secure with the supplied #8 x 1-in.

screws. Do not over-tighten.

21

22

Center the H-bar on the post and check rail

for plumb.

23

25

Using supplied 1-1/2-in. screws, secure

the top rail starting as close to the post as

possible. Space the remaining screws evenly.

Carefully position the pre-assembled railing inll between the posts, then slowly lower over

the bottom brackets until fully seated.

Please visit https://www.berondecking.com/resources/installation-instructions or call Consumer and Technical Support at 800-573-8841.

26

Starting at the top, secure the H-bar to

the posts at both ends using the supplied

#10 x 2-1/2-in. self-drilling pan head screws.

Do not over-tighten.

24

Complete the assembly by gluing the post

caps in place with a quality exterior-grade

adhesive.

Position the top rail over the inll assembly,

and carefully lower into place.

The most recent installation instructions can be found on our website.

10

Loading...

Loading...