FIBER FOX Mini 22A User Manual

www.fiberfox.co.kr

Mini 22A

User Manual

website youtube

Sales : sales@fiberfox.co.kr

Technical Support : support@fiberfox.co.kr

80, Dongseo-daero 179beon-gil,

yuseong-gu, Daejeon 34159, Korea

www.fiberfox.co.kr

Contents

Introduction

·

Technical specifications

·

Splicer description & Part name

·

How to the replace the fiber folder

·

Cleaning

·

Splice Program

·

- Stabilize Electrodes

- Arc Calibration

- Splice Menu

1) Splice Mode

2) Splice Option

3) Heater Mode

4) Data Storage

5) Menu Lock

6) Reset

- Maintenance

- Setting

1) System Setting

2) Language

3) Power Save Option

4) Set Calendar

4

4

6

7

7

8

8

9

10

11

13

14

15

18

19

20

21

- 2 -

5) Password

23

6) System Information

Notice : Warning and Cautions

·

Appendix I

·

Appendix II

·

Appendix III

·

24

25

27

29

32

Important

FiberFox highly recommend that all users read this manual before operating Mini 22A.

This manual is valid for the recent software version.

Cautions

The Battery must be taken out of the splicer, when stored in the Hand carrying case.

- 3 -

Introduction

Thank you for choosing Mini 22A FTTx Master from FiberFox. The Mini 22A with innovative design

and excellent manufacturing technology gives customers assurance of trust.

Exceptional splicing experience and new technology greatly reduces splicing and heating time.

Advanced estimate method and clad alignment technique ensure the accuracy of the splice loss

estimation. Its small size, compact design and reliable protective casing make it suitable for any

operating environment. Dynamic operation interface and automatic splice mode give the custom-

ers great user-friendliness. For more information, please contact your local distributor or visit our

website at www.fiberfox.co.kr

This manual explains the features, specifications, operation, maintenance and warnings about Mini

22A. The primary goal of this manual is to make the user very familiar with the splicer operation.

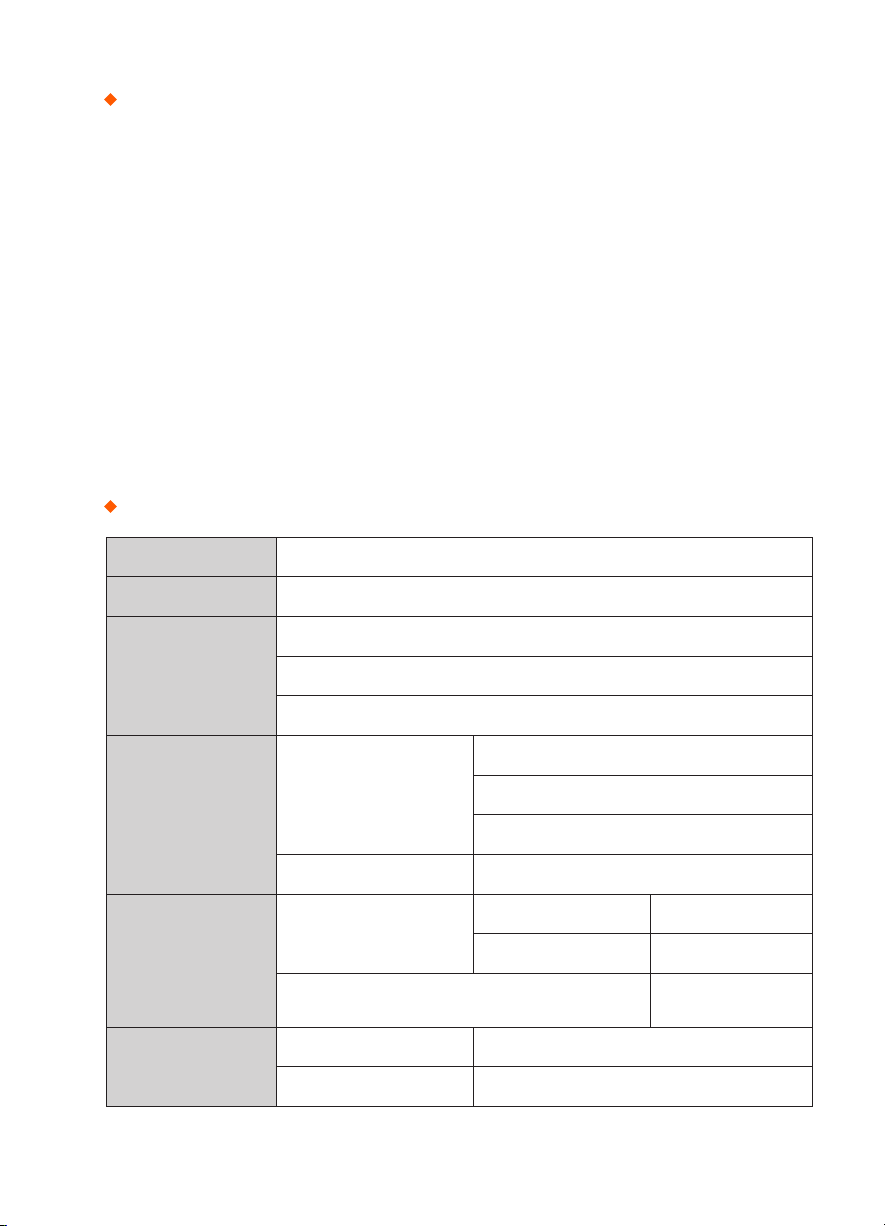

Technical specifications

Camera High precision dual camera

Display 4.3” wide color reinforced LCD

x150 : X&Y axis dual view

Microscope

Power Supply

Data Capacity

Splice Speed

x300 : X axis single view

x300 : Y axis single view

AC 100~240V

Splicer

Li-ion Battery DC 11.1V

Factory pre-set 11 ea

Splice Mode

Edit Mode 128 ea

Data Storage (Splicing result)

SM Quick mode (SQM) 7 Sec.

SM AUTO mode 9 Sec.

- 4 -

50~60HZ

DC 9~14V

5,000

Max 10,000

Applicable Sleeve

Standard : 20, 25, 30, 35, 40, 60mm

Custom : 4*32mm sleeve (For SOC)

Heating Time 8~900sec (Typical: 18sec)

Heater

Applicable

Fiber

Applicable

Cable

Splice Loss

Heater mode

Factory pre-set 4 ea

Edit Mode 23 ea

Standard 1 ea(Pre-installed)

Heating block

SOC Customized 1 ea(In Package)

Fiber count : Single core

Fiber Type : SM(ITU-TG.652)/ DS(ITU-TG.653)/ NZDS(ITU-TG.655)/

ITU-TG.657 A,B Type / MM(ITU-TG.651)

Fiber count : Single core fiber in cable

Applicable diameter : 0.25mm / 0.9mm / 2.0mm / 2.4mm / 3.0mm

Applicable buffer Diameter

: Cladding diameter : 80~150µm, Coating diameter : 100~1,000 µm

SM : 0.02dB

MM : 0.01dB

DS : 0.05dB

NZDS : 0.05dB

G.657 : 0.02dB

Reliability

Operating

Condition

Storage

Condition

Altitude 0~5,000M

Humidity 0~95%

Temperature

Wind Speed 15m/s

Humidity 0~95%

Splicer

Temperature

Battery

- 5 -

-10

-20~60

-20~40

~50

℃

℃

℃

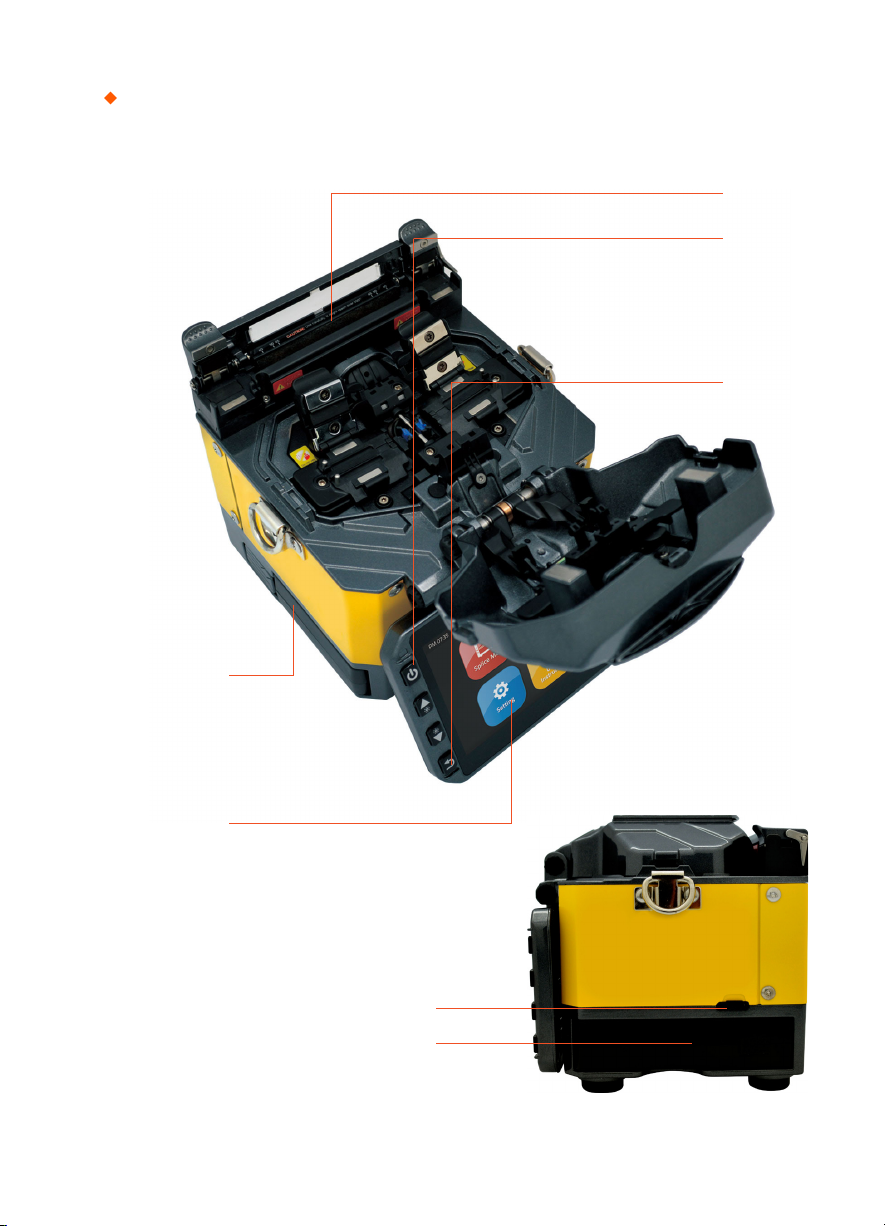

Splicer description & part name

Power Supply / Battery

Sleeve Heater

ON/OFF Button

Return Button

Monitor

Micro HDMI Port

Connector for Charging Battery

- 6 -

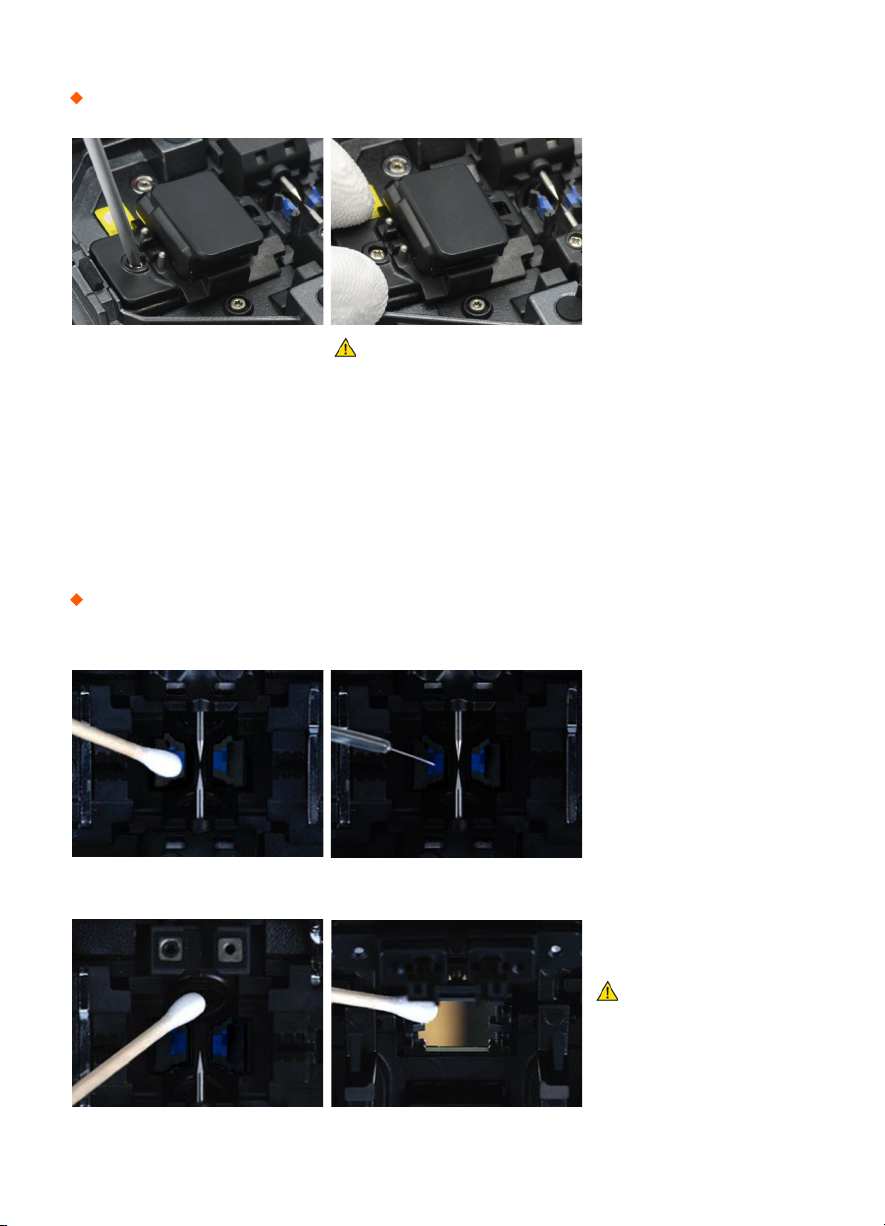

How to replace the fiber holder

1) Loosen the screws

2) Take out the universal holder

3) Replace compatible with holder

4) Tighten the screw

Caution

1) The unscrewed screws remain in the holder

(Do not remove the screws out)

2) Do not screw down the holder too tight

Cleaning

V-Grooves

Lens Mirrors

Check fiber after cleaning

with cotton swab

- 7 -

Caution

1) Do not disturb

the electrode tips

2) Use only 99% or better

purity alcohol

Splice Programs

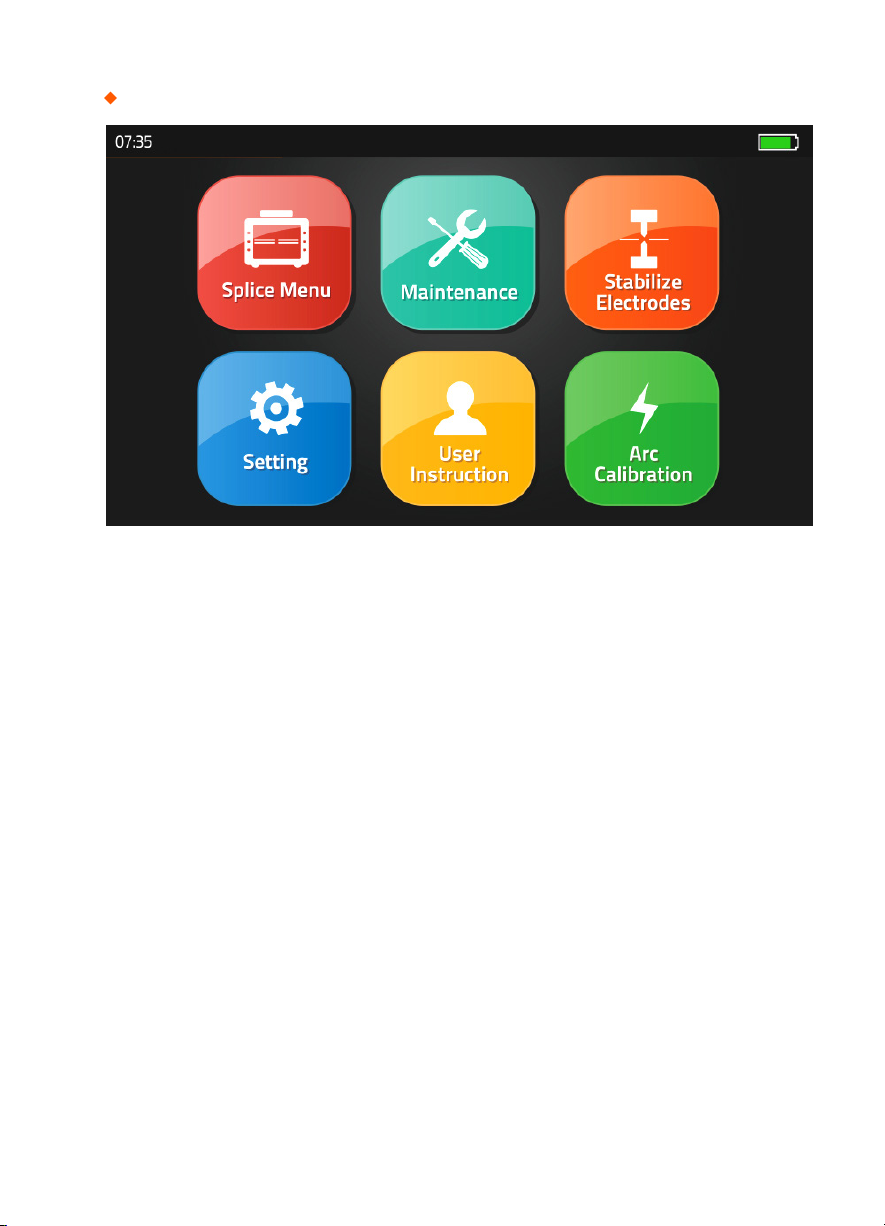

Splice Menu, Maintenance, Stabilize Electrodes, Setting, User Instruction, Arc Calibration

[Stabilize Electrodes]

In the event of sudden change in environmental conditions or after cleaning electrodes, the arc power

sometimes becomes unstable, resulting in higher splice loss. This is especially a concern when the

splicer is moved from lower altitudes to higher , it takes time for the arc power to stabilize. In this case,

stabilizing electrodes will expedite the process to normalize the arc power. If many tests are required

to get the “Test ok” message appearing the [Arc calibration], use this function as well.

[Arc Calibration]

Atmospheric conditions such as temperature, humidity, and pressure are constantly changing, which

creates variability in the arc temperature. This splicer is equipped with temperature and pressure

sensors that are used in a constant feedback monitoring control system to regulate the arc power

at a constant level. However, changes in arc power due to electrode wear and glass adhesion cannot

be automatically corrected. Also, the center position of arc discharge sometimes shifts to the left or

to the right. In this case, the fiber splicing position has to be shifted in relation to the arc discharge

center. It is necessary to perform an arc power calibration to eliminate these problems.

Note : Performing [Arc calibration] function changes the arc power “Factor” value. The factor value is

used in the algorithm program for all splicing. The arc power value will not change in the splice modes.

Standard Factor value is changed within 11 ± 2, It shows “Complete” word. otherwise, it shows

*

“Retry” which means failure arc test, User needs to reload the optic fiber, retry arc calibration test.

- 8 -

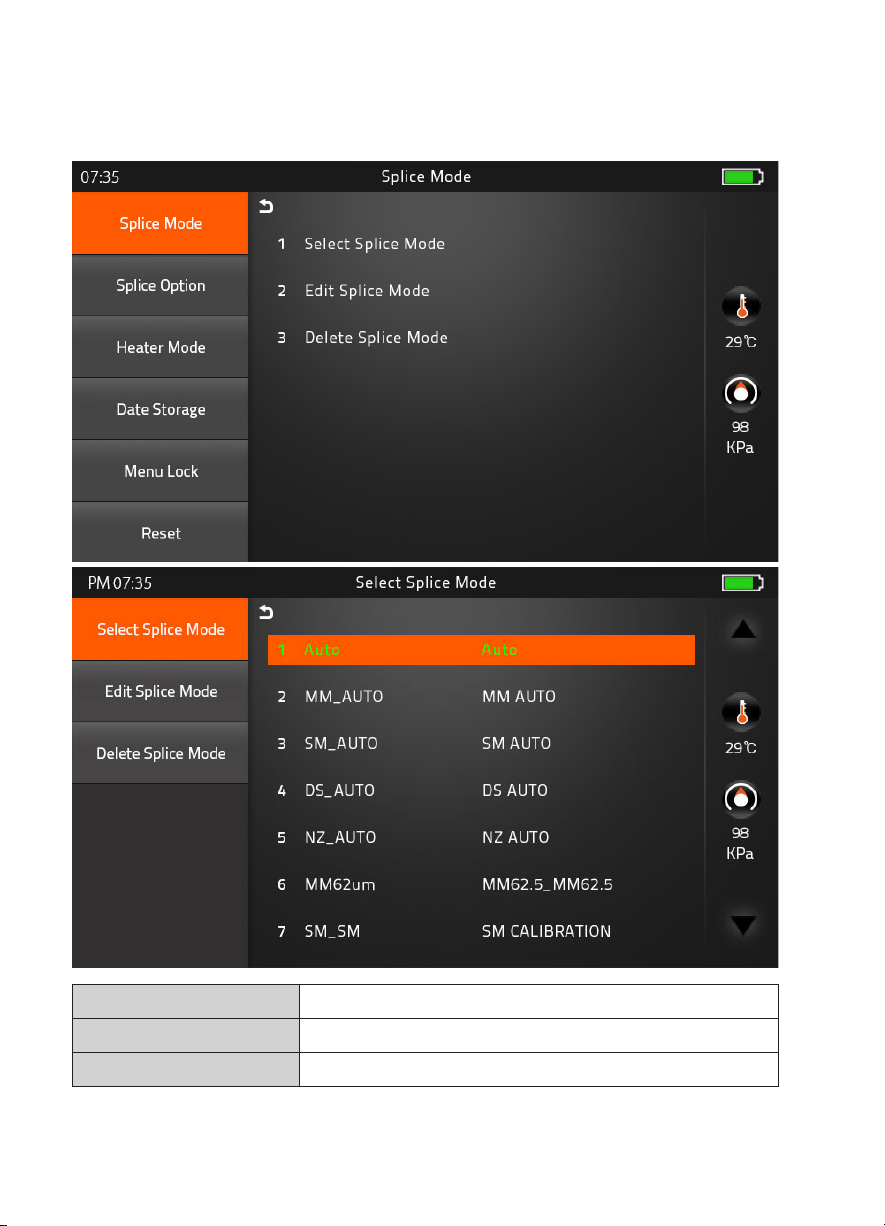

[Splice Menu]

1) Splice Mode

Factory Pre-Set Mode 11 ea

User Mode User Edit : 128 ea

Delete Splice Mode -

- 9 -

2) Splice Option

Auto Start

ON : Automatic splicing procedure

OFF : Manual Splicing procedure

Pause 1

(Press Motor)

Pause 2

(Align Motor)

ON : Pause after the fiber gap position process

OFF : Proceeding without the pause

ON : Pause after camera focus & Axis alignment process

OFF : Proceeding without the pause

ON : Automatically proceed realignment

Realign After Pause 2

OFF : Proceeding without the pause

Ignore Splicing Error ‘splicing error’ message is not displayed

Fiber Image On Screen Select display structure for each splicing process

- 10 -

Loading...

Loading...