Fiberfab Jamaican 1976 Body Assembly Manual

THE

JAMAICAN

APPLICATION:

V-8

VW

Body

Assembly

manual

XNG

548

Baldwin

Street

Bridgeville, PA

1501

7

Phone

4 1 2-221 4200

COPYRIOHT

1876

n/&,rt

",,d

1

,,,."""+

~~n.,C"l.rr,,."r

.I

C

7-:L

-rr-l,.-,

".-.

-.-

-

p-.-.

"

"

FREE @ WWW.TJKUSTOMS.COM

Revised: Jan. 1974

INTRODUCTION TO

FIBERFAB'S JAMAICAN V8 and

VW

BODY KITS:

Early in 1968, the JAMAICAN body style was introduced as a completely

new model to supplement the famous Valkyrie and Avenger line.

The original JAMAICAN was designed as a direct replacement body for

several popular front-engined sports cars,

6.9. Austin-Healey, Triumph

and

MGA.

These replacement bodies are still currently in production.

Following the

JAMAICAN'S introduction, Fiberfab's engineering staff was

deluged with questions concerning the use of

V8 engines in the JAMAICAN

body style. To answer these questions, several installations wore de-

and tested,

e.g. the

JAMAICAN/MGA/BU~C~

V8 unit road tested by

TRACK magazine, March 1969.

Based on the interest shown in and performance of the hybrid

LIB'S,

Fiberfabls

engineers decided to build a "pure bred" JAMAICAN V8.

At

the outset, the project seemed simple

-

-

just build a frame to accept

a

V8 engine and that fits under a JAMAICAN body. However, the JAMAICAN

body was designed for a relatively short-wheelbase, narrow-track chassis.

A

no compromise V8 chassis would be too long and too wide for the ex-

isting body

-

thus started a six month development

of

a

brand new, wider,

tougher-looking JAMAICAN

V8 body and high performance chassis to match.

Shortly after the introduction of the JAMAICAN

V8 kit, requests for JAM-

AICAN adaptation to

VW

chassis started coming in. Seems as though people

are never satisfied, so

-

-

back to the drawing board.

An inner-liner was developed to use in the JAMAICAN

V8 body, so that

it

could be utilized on the

VW

"Bug" chassis with only minor modifications.

Since the wheelbase of the JAMAICAN

V8 and

VW

chassis are equal, the

adaptation was ideal.

Current production of the JAMAICAN series now includes the JAMAICAN

V8

body and frame kit; an identical JAMAICAN

\hI

body kits; similar body

styles for the TR3, TR4,

TR250, Austin-Healey 3000 and

MGA

chassis.

A

NOTE OF INTEREST:

A

Japanese import appeared on the American market in

1970. An immediate hit with the American people, the import bore a remarkable resemblance to our JAMAICAN series. Not surprising though, since

it

has been reported that a Fiberfab JAMAICAN V8 was in the possession of

the American importer of this car, some 18 months before the imported two

seater appeared on the American market.

FUTURE

PLANS

call for the development and introduction of JAMA1CA.N 11; a

body and frame kit using the

JAMAICAkI

V~/WW

body styling and a new frame,

utilizing complete Pinto drive-train components, rack and pinion steering

and all. An excellant "ECONOMY" car.

THANK YOU FOR YOUR INTEREST IN OUR PRODUCTS!!

The management

FIBERFAB, Inc.

FREE @ WWW.TJKUSTOMS.COM

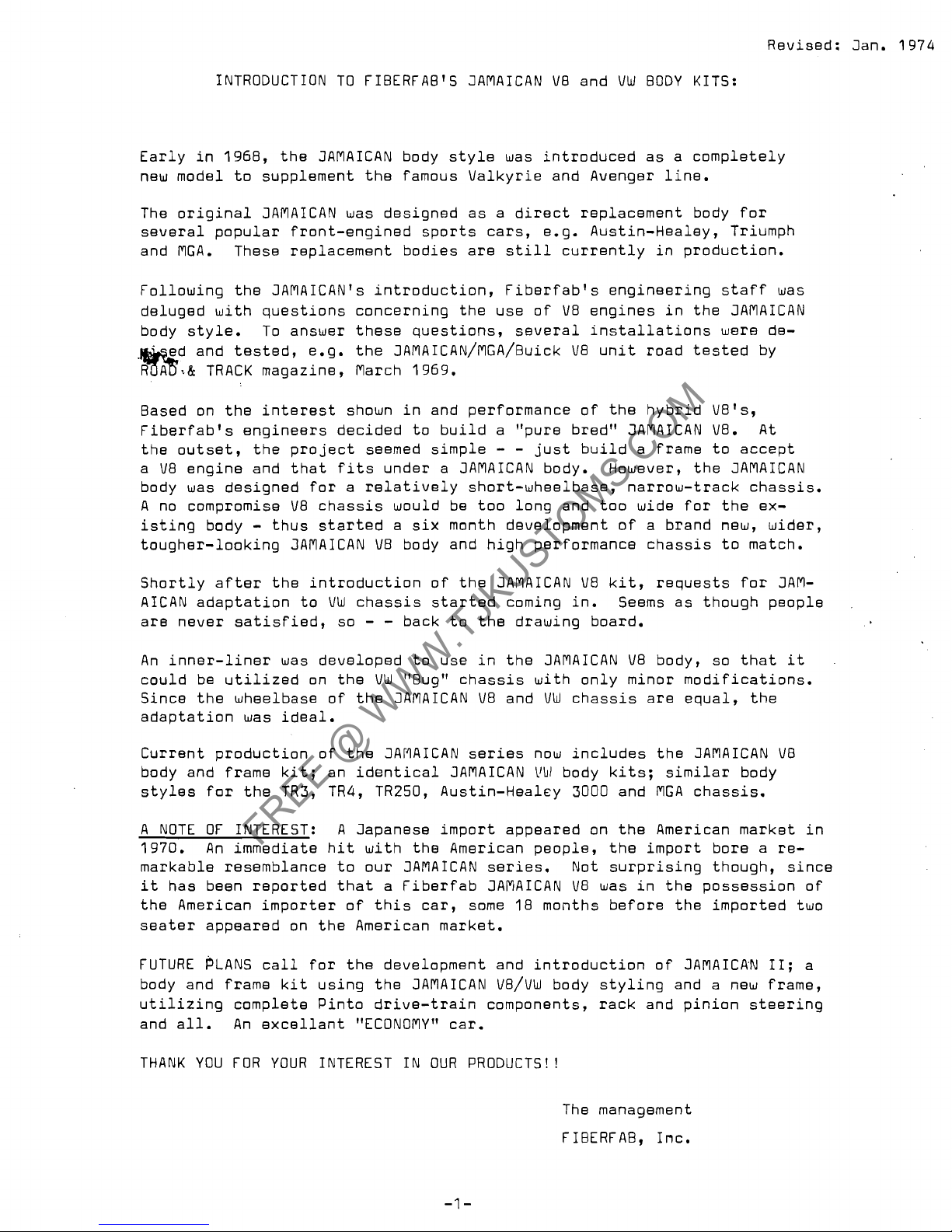

Prior to mounting the main body section to the chassis/frame, cut out door openings,

as

well

as

Front and

rear

glass openings, as follows:

Cut

all

openings with sabre

saw:

1.

Using windshield glass a tmmplate, place

glasa in recessed

area,

center from top to bottom and side to side, using

small

blocks of wood

at

the bottom of glass to hold up in place.

Scribe or mark outline of glass and remove.

mark an additional line

1/2"

to

5/8"

inside the outline of the glass.

Cut on inner marking, leaving

a

lip

on which glass

will

rest

later

when installed with BUTYL TAPE (available from

all

local glass installers).

2.

Place

rear

qlaas in recessed arRa so that

qao

between glass and edge of body

are

equal all round. mark body nlonq edqe of glass and remove glass.

a.

If

using Porschn

rear

window

"H"

rubber to install glass, cut on mark.

b. If installing with

hutyl tape (as with windshield method) mark

as

section

line inside and follow instructions as above for windshield cutout.

c.

If undecided

~t

this

time,

cut

as

for windshi~ld type installation, as more

can be cut

later,

prior to installation.

3.

Cut out door openinqs. Mark openings as shown bmlosl and cut. Follow dimensions

given or

cut hole

9msiller

as more can be cut when installing doors.

REflEflBER: When making any cuts in the body, you can always cut more, but once you

have cut too much,

it

is

difficult to repair.

FREE @ WWW.TJKUSTOMS.COM

1

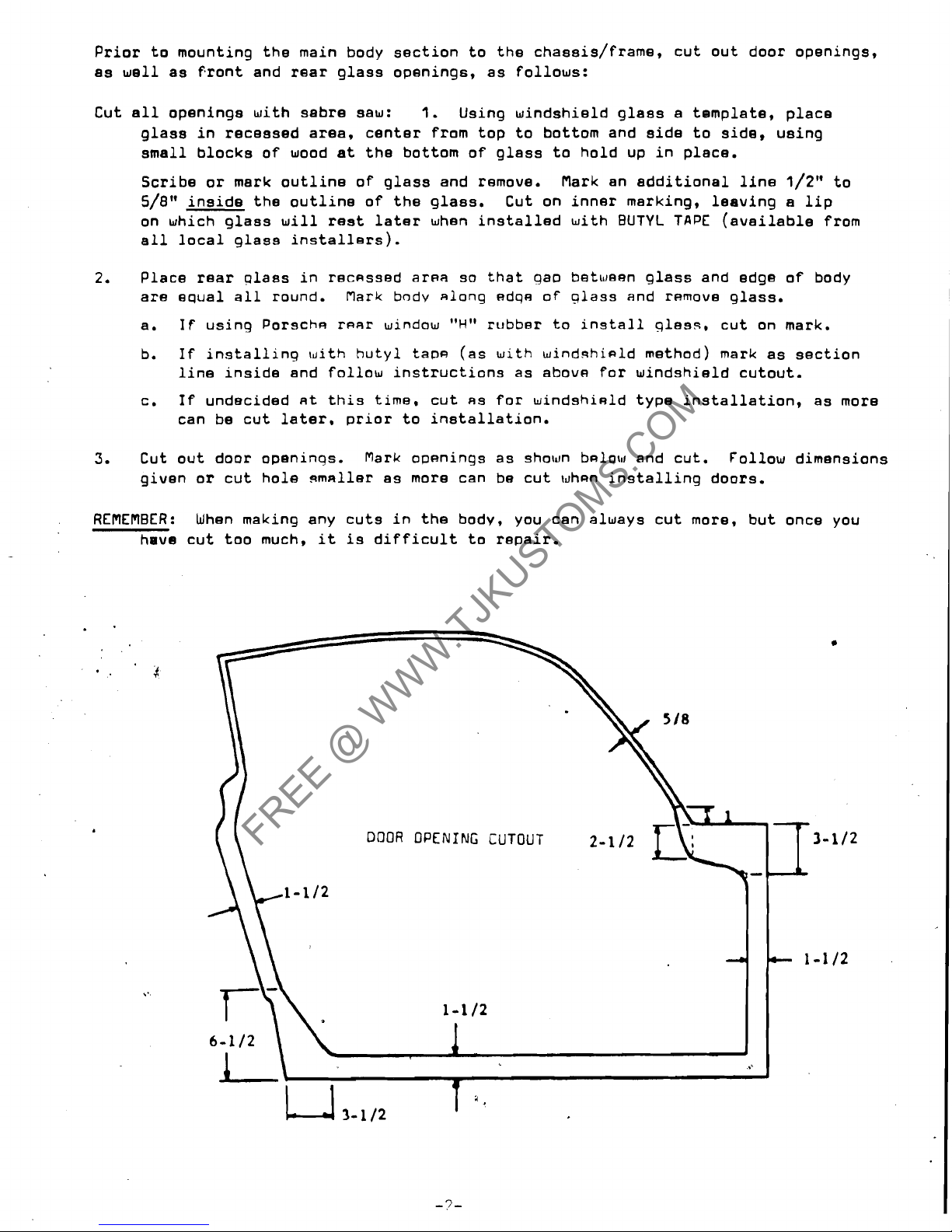

Cut out trunk opening

(VW engine access, if being mounting to

VW

chassis) as per

below:

Note: Cut on dotted line for

Vl~l

chassis ingtallation or

if

you do not

deaire to use this as you qas tank filler location.

4

I

3

/&

3"

Dl*.

/:OLE

IDTEAL3

(03s

filler lncatinr)

I

71"

Din.

Hola -ant.nrnr!

h~ln,,*

-,"

hnlp

c

3/&

1

1

I

t

b

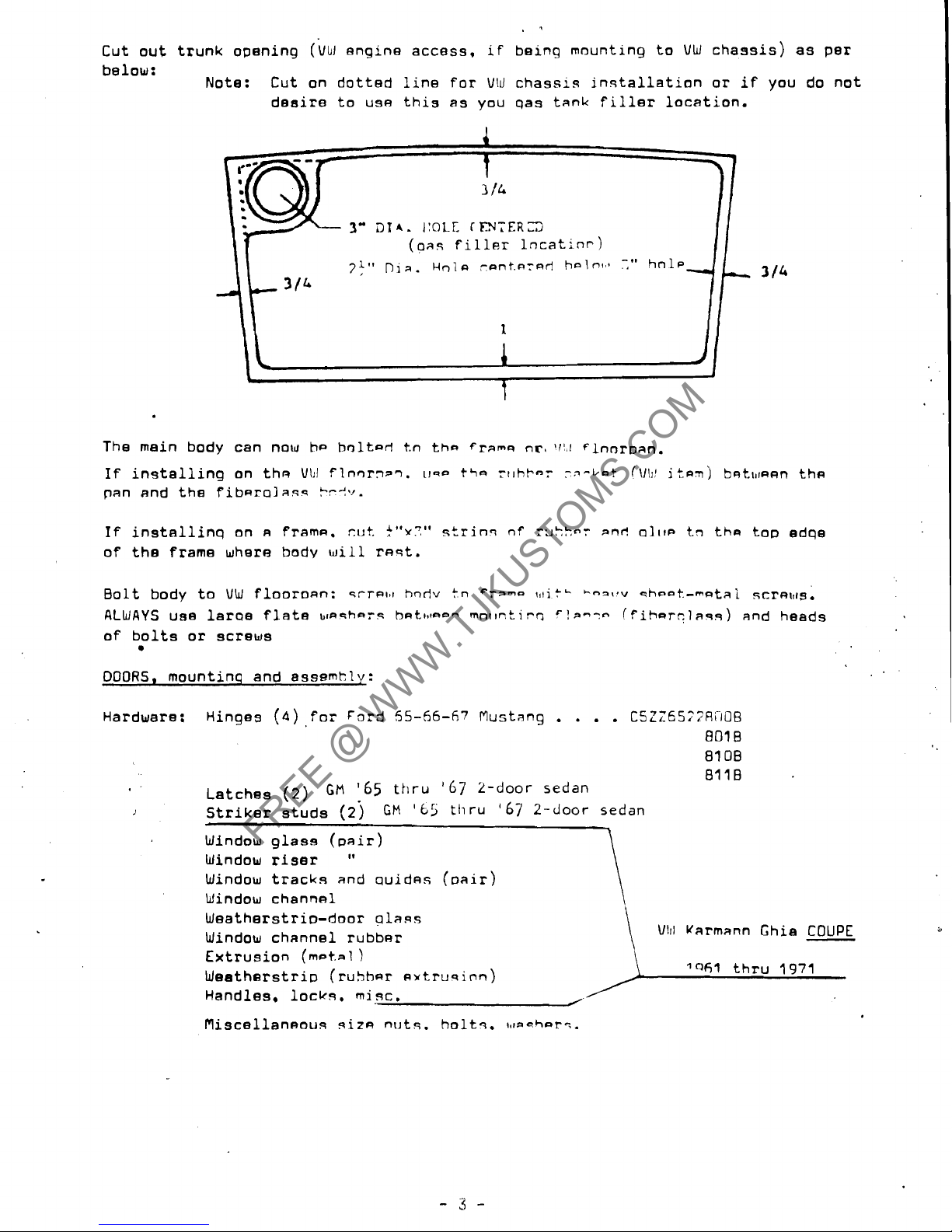

The main body can now he holtarl

t.n

thn

fram~

nr,

rrl,~

rlnnr~an.

If

installing on thn V\II

flnnrrt~?.

~rqo

~LIQ

ft~hb-~

:fi-b~t

(\/\I'

itnnj bFit\lrA~n thcl

pan end the fib~rolaqs

?--!v.

If

installinq on A fram~. cut.

!"Y?'

strinn

of

rzkkor

ant!

Q~IIP

tn

tha top edqe

of the frame where body

will

rnst.

Bolt body to

VW

flooronn: srrnl,r

hodv tn cr3mo

c,titc

Coarqv

shoot.-matai scrnlllg.

ALWAYS

use larQ8 flate

blnnhers

h~tc~taom

mnt1ntir.n r!a--o (fihar?las5) and heeds

of bolts or screws

w

DOORS, mountinq and assemkly:

.

Hardware: Hinges

(4)

for

Ford

55-66-67

Mustang

. . . .

CSZZ65;7RClOB

801 B

Bl

OB

Latches

(2)

GM

'65

thru

'67

2-door sedan

,

.

J

Striker studs

(2j

GM

'65

thru

'67

2-door sedan

.

-

Window glass (pair)

Window riser

"

Window tracks and ~uid~s (oair)

Window channel

\

Weatherstrio-door plaqs

Window channel rubber

\

Vlrl

Uarmann Ghia

COUPE

Extrusion

(m-t.al

)

Weetherstri~ (ruhhnr cl~trusinn)

Handles, lock5. mi3c.

fliscellansous giza

n~tq.

holtl. ~,larharq.

FREE @ WWW.TJKUSTOMS.COM

off

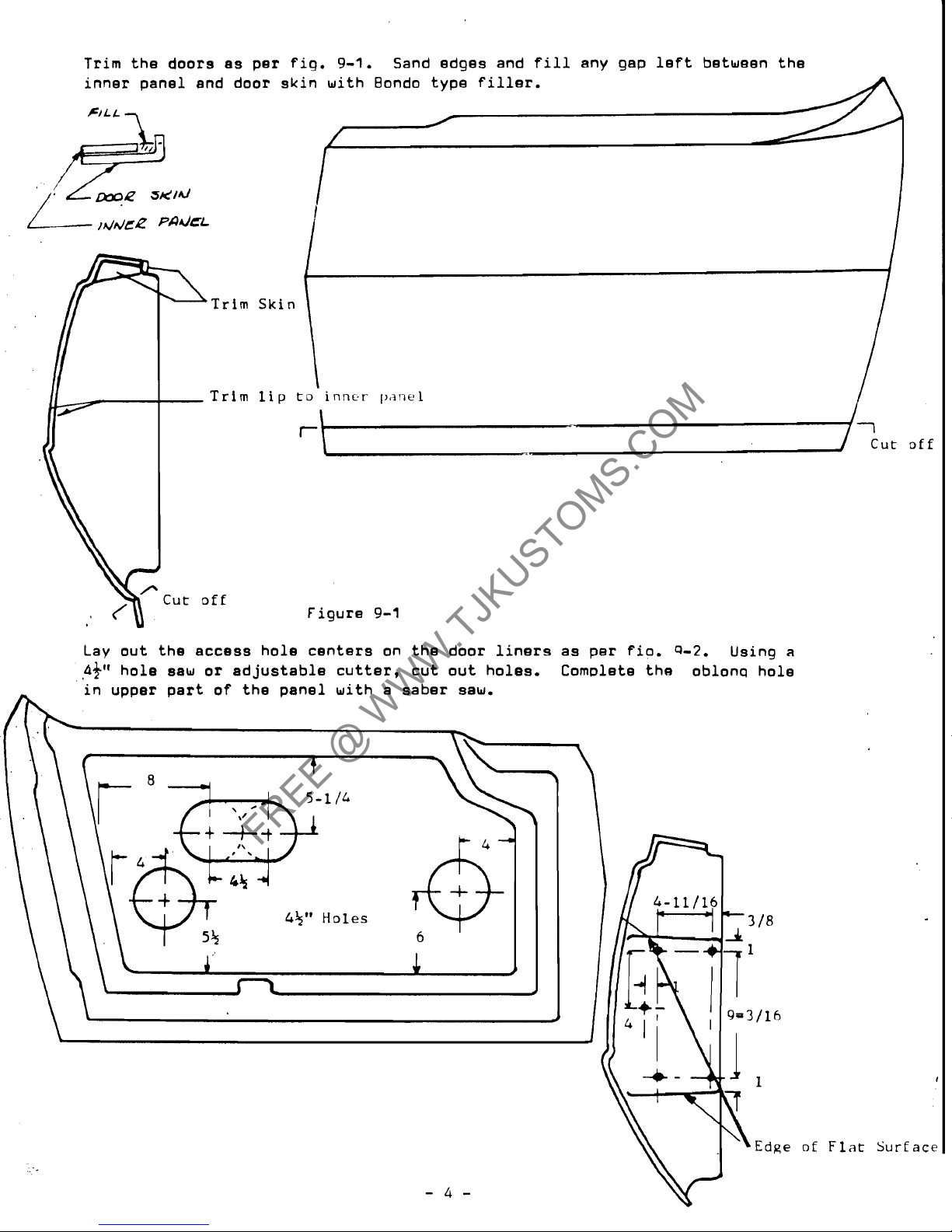

Lay out the access hole centers on the door liners as per

fio.

9-2.

Using

a

43"

hole saw or adjustable cutter, cut out holes. Cornolete the oblon~ hole

in upper part of the panel with a saber saw.

I

Surf

ace

FREE @ WWW.TJKUSTOMS.COM

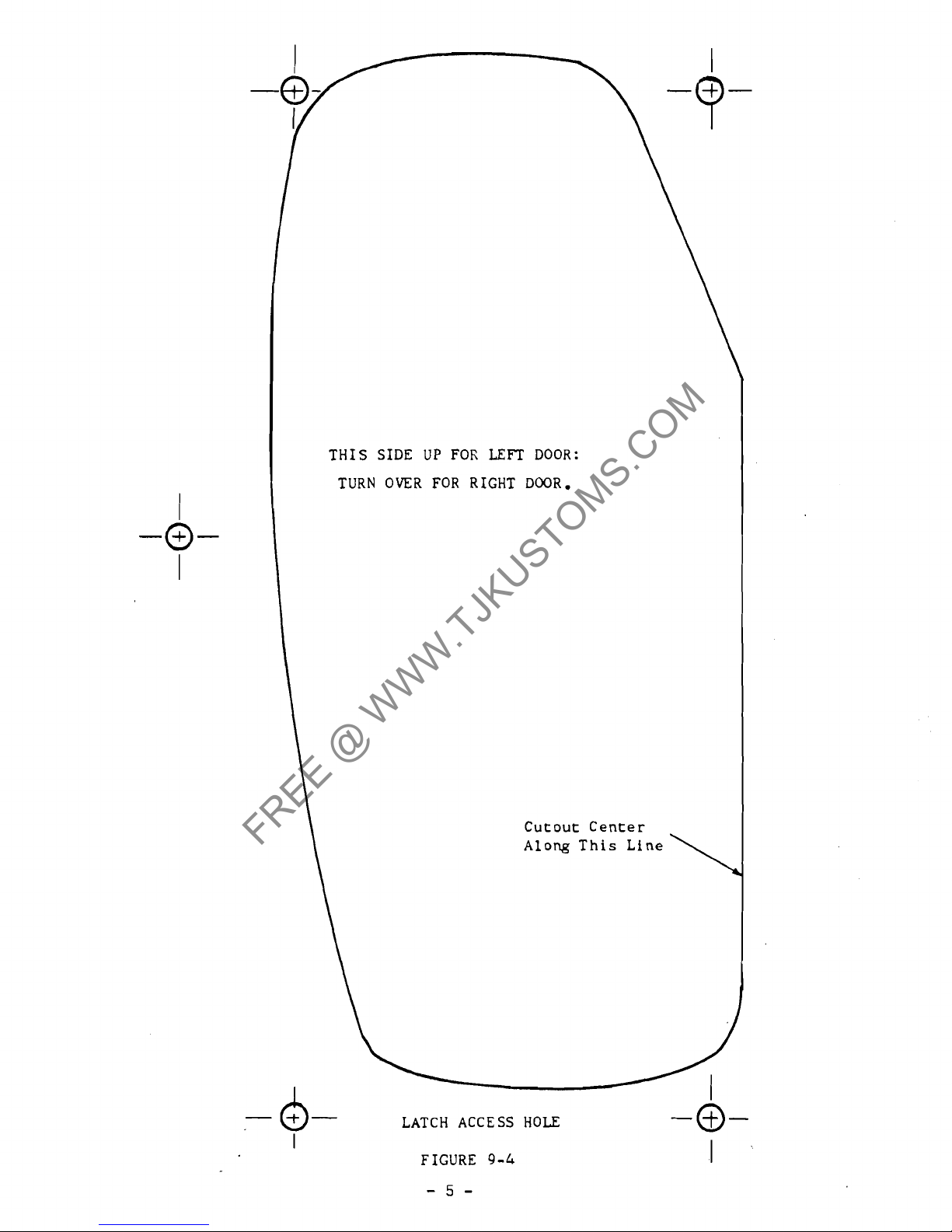

THIS SIDE UP FOR

LEFT

DOOR:

TURN OVER FOR RIGHT DOOR.

Cutout Center

Along This Line

LATCH ACCESS HOLE

-0-

I

FIGURE

9-4

I

FREE @ WWW.TJKUSTOMS.COM

112

1

J

\

1

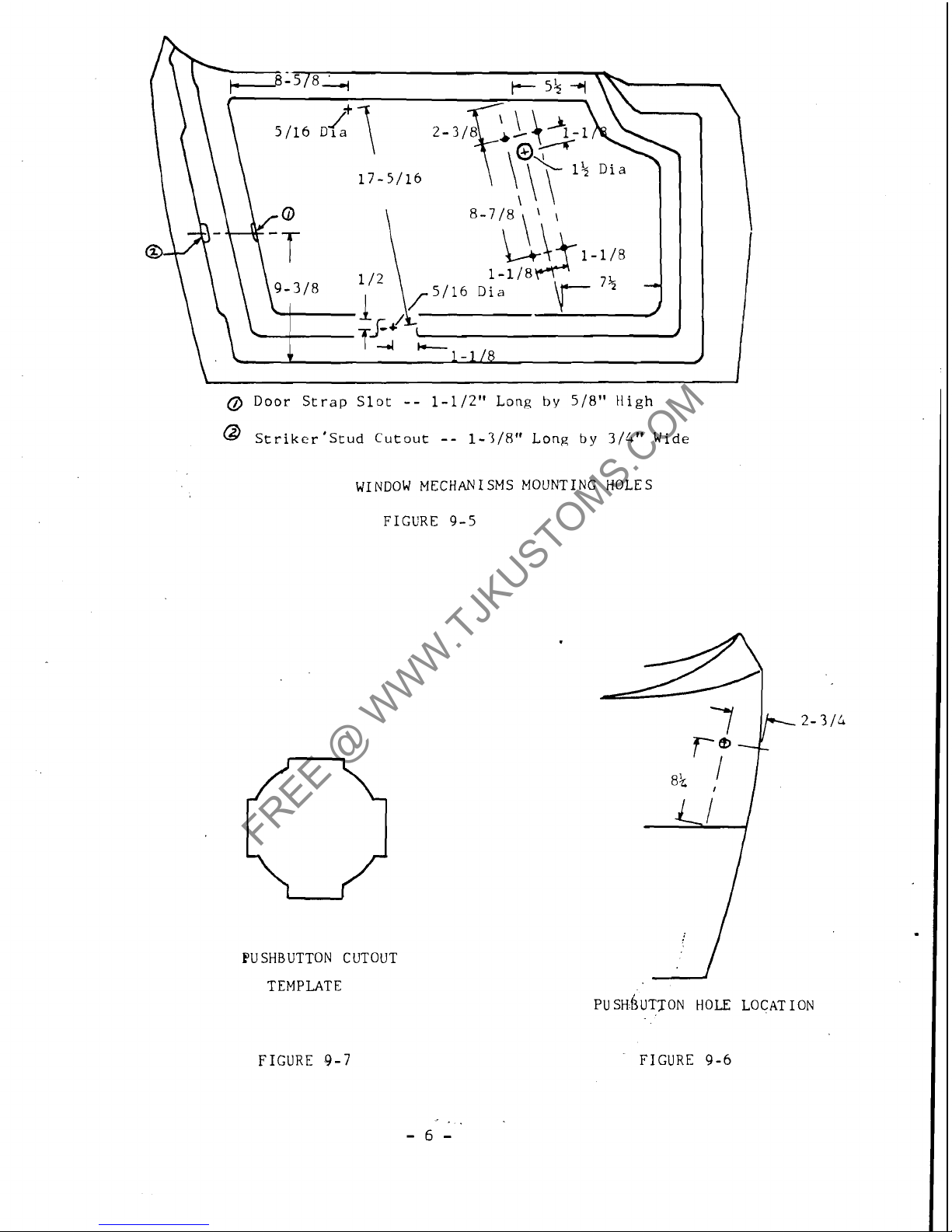

Door Strap Slot

--

1-112" Long

by

518"

High

@

striker8Stud Cutout

--

1-318" Long

by

3/4" Wide

WINDOW MECHANISMS MOUNTING HOLES

FIGURE 9-5

PU

SHBUTTON CUTOUT

TEMPLATE

FIGURE

9-7

FIGURE 9-6

FREE @ WWW.TJKUSTOMS.COM

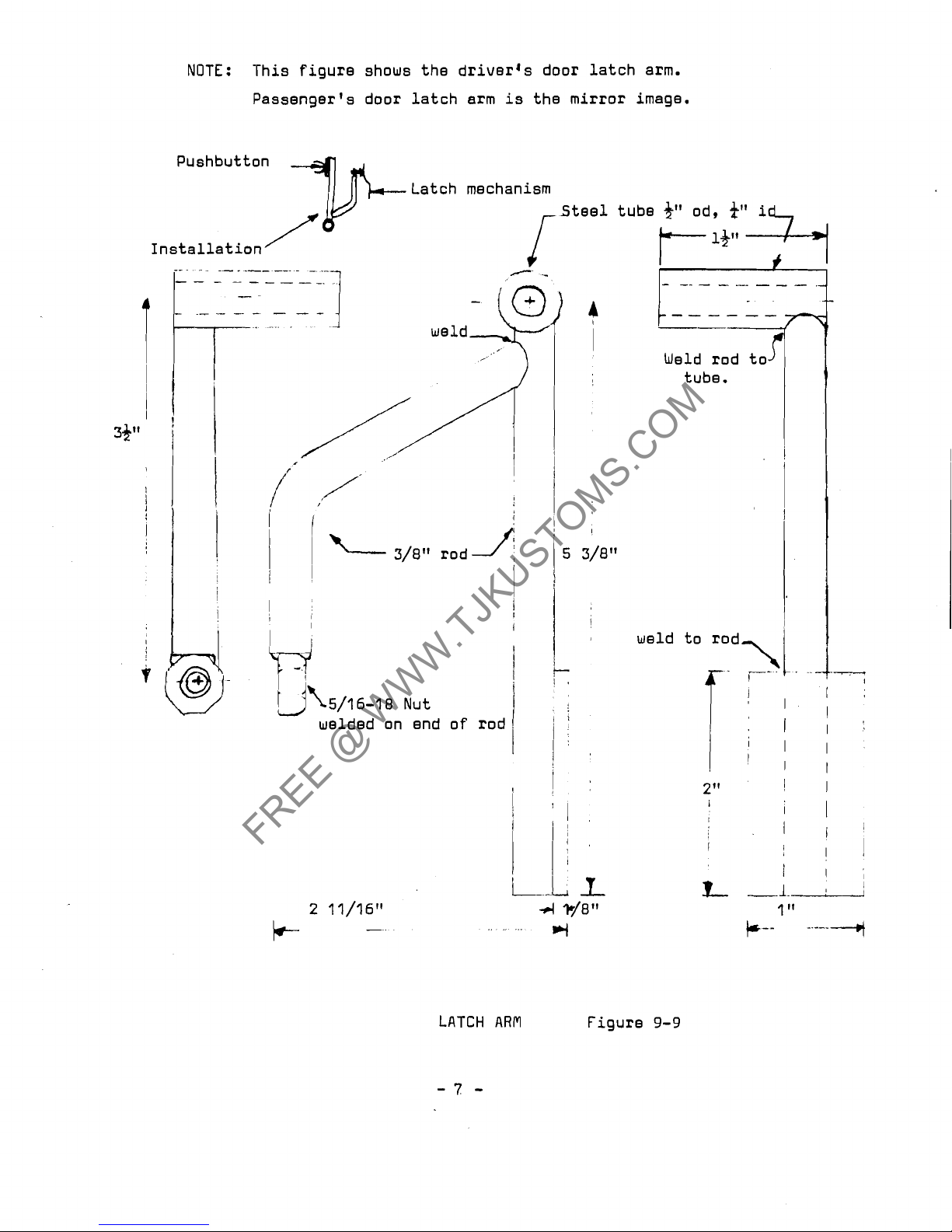

NOTE: This figure shows the driver's door latch arm.

Passenger's door latch arm is the mirror image.

Pushbutton

Latch mechanism

Steel tube

3''

od,

a"

i

Installation

---

--

-

- - -

- - - - -

.-

-.

-

-------

--

Weld rod to

I

!

tube.

33"

1

I

I

1

I

i

IT

5/16-18 Nut

welded on end of rod

I

2"

!

I

I

I

I

i

I

iI

.I

1'

I

i.L

1

1

;

L

1.

1

LATCH ARM

-7

-

Figure

9-9

FREE @ WWW.TJKUSTOMS.COM

Cut door latch holes: Lay out the five hole8 in the rear face of each door as

specified in fig.

9-3 and drill with bit.

Now take template, fig.

9-4 and cut out the five locating holes and the center

as

illustrated. Align template on the door using the five holes for locetion and

scribe the center cut-out

-

-

cut out the latch holes with a sabre saw.

Lay out

the striker stud cut-out and door strap holes as per fig. 9-5 and cut-out.

Cut holee for puah buttons (obtain buttons from Chrysler product truck lid, early

50's)

as

per fig. 9-6. Next, cut out the template, fig. 9-7, locate on door and scribe.

Cut out the round portion of the shape and file out remainder.

Note:

If

you are going to use handlee in lieu of the buttons, the hole

will

be in

the same location but of a different shape.

Drill

holes to Locate

window

mechanisms, fig.

9-5

Fabricate latch plate (2) as per fig.

9-8.

Use

14 gauge steel plate or 1/1611

approximately.

Bolt latches to plates.

Be

sure the notch in the plate lines up with the striker

stud catch in the latch.

Now, bolt plate (with

latoh) to the doors.

Fabricate latch arms

as

per fig. 9-9. These arms are required to transmit the

push button action to the latch mechanism.

Install in the door using

$'I-20x2" oval head bolt through the remaining hole

next

to

the latch plate, mounting the

arm

on the bolt (inside the door)

as

per

fig.

9-9.

Secure with

)-20

self

lock

nut.

Do not over-tighten so that the arm

is

no longer free to rotate.

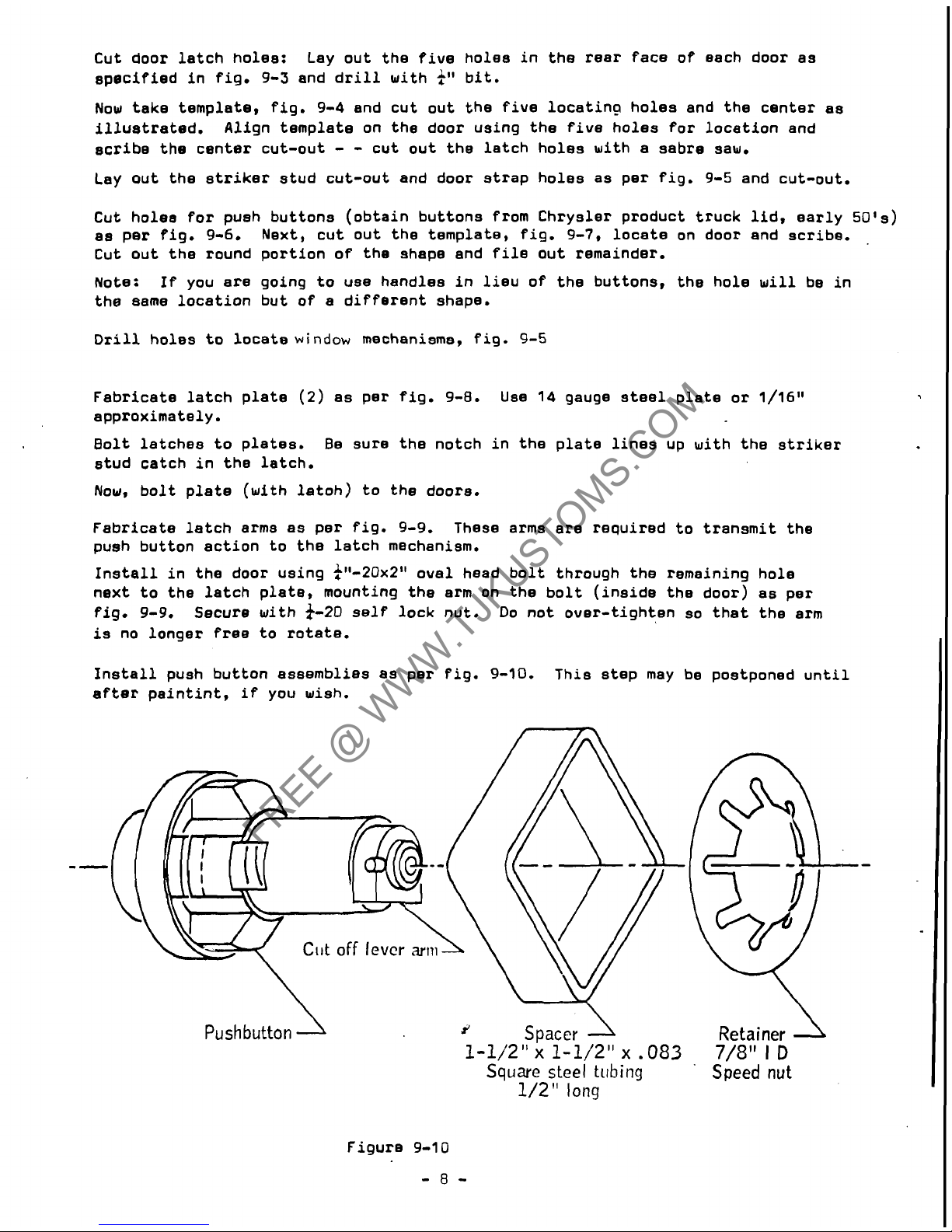

Install push button assemblies

as

per fig. 9-10. This step may be postponed until

after paintint, if you wish.

Pushbutton

J

Spacer

1

1-1/2" x 1-1/2"

x

.083

Square

steel tubing

1/2"

long

Figure 9-10

-8-

Retainer

7/8"

l

D

Speed

nut

FREE @ WWW.TJKUSTOMS.COM

Loading...

Loading...