Page 1

OPERATING

MANUAL

EN

THE HEAT CONTROLLER

RADIATOR THERMOSTAT

FGT-001

CONTENTS

#1: Description and features 3

#2: Basic activation 4

#3: Adding to Z-Wave network 5

#4: Removing the device 6

#5: Controlling the temperature 7

#6: Extra temperature sensor 8

#7: Dismounting the device 9

#8: Menu 10

#9: Local protection 11

#10: Head calibration 12

#11: Standby Mode 13

Manual v1.3

Firmware v4.6

#12: Factory reset 14

#13: Z-Wave range test 15

#14: Battery and charging 16

#15: Normal Schedules 17

#16: Override Schedule 18

#17: Z-Wave specication 19

#18: Advanced parameters 23

#19: Specications 24

#20: Accessory specication (FGBRS-001) 26

#21: Regulations 27

Page 2

2

Important safety information

Read this manual before attempting to install the device!

!

Failure to observe recommendations included in this manual

may be dangerous or cause a violation of the law. The manufacturer,

Fibar Group S.A. will not be held responsible for any loss or damage

resulting from not following the instructions of operating manual.

This product is not a toy. Keep away from children and animals!

CR2032 coin cell battery is harmful if swallowed!

Battery pack warning!

The Heat Controller contains lithium-ion polymer battery pack, heed all

following warnings:

• If an unusual odor or malfunction is detected, avoid sources of

open ame and remove the device from the radiator.

• In the event of damage from crashes, etc., carefully remove to a

safe place for at least a half hour to observe.

• Do not leave the device unattended while charging.

• Do not attempt to replace the battery!

General information about

the FIBARO System

FIBARO is a wireless smart home automation system, based on the

Z-Wave protocol. All of available devices can be controlled through

a computer (PC or Mac), smartphone or tablet. Z-Wave devices are

not only receivers, but can also repeat the signal, increasing the

Z-Wave network’s range. It gives advantage over traditional wireless

systems that require direct link between transmitter and receiver, as

a result the construction of the building could aect network’s range

negatively.

Every Z-Wave network has its unique identication number (home

ID). Multiple independent networks can exist in the building without

interfering. Transmission security of FIBARO System is comparable to

wired systems.

Z-Wave technology is the leading solution in smart home automation.

There is a wide range of Z-Wave devices that are mutually

compatible, independently of manufacturer. It gives the system the

ability to evolve and expand over time. For more information visit:

www.baro.com.

Page 3

#1: Description and features

FIBARO Heat Controller is a remotely controlled thermostatic head

to control temperature in your room. It measures the temperature

and automatically adjust the heat level.

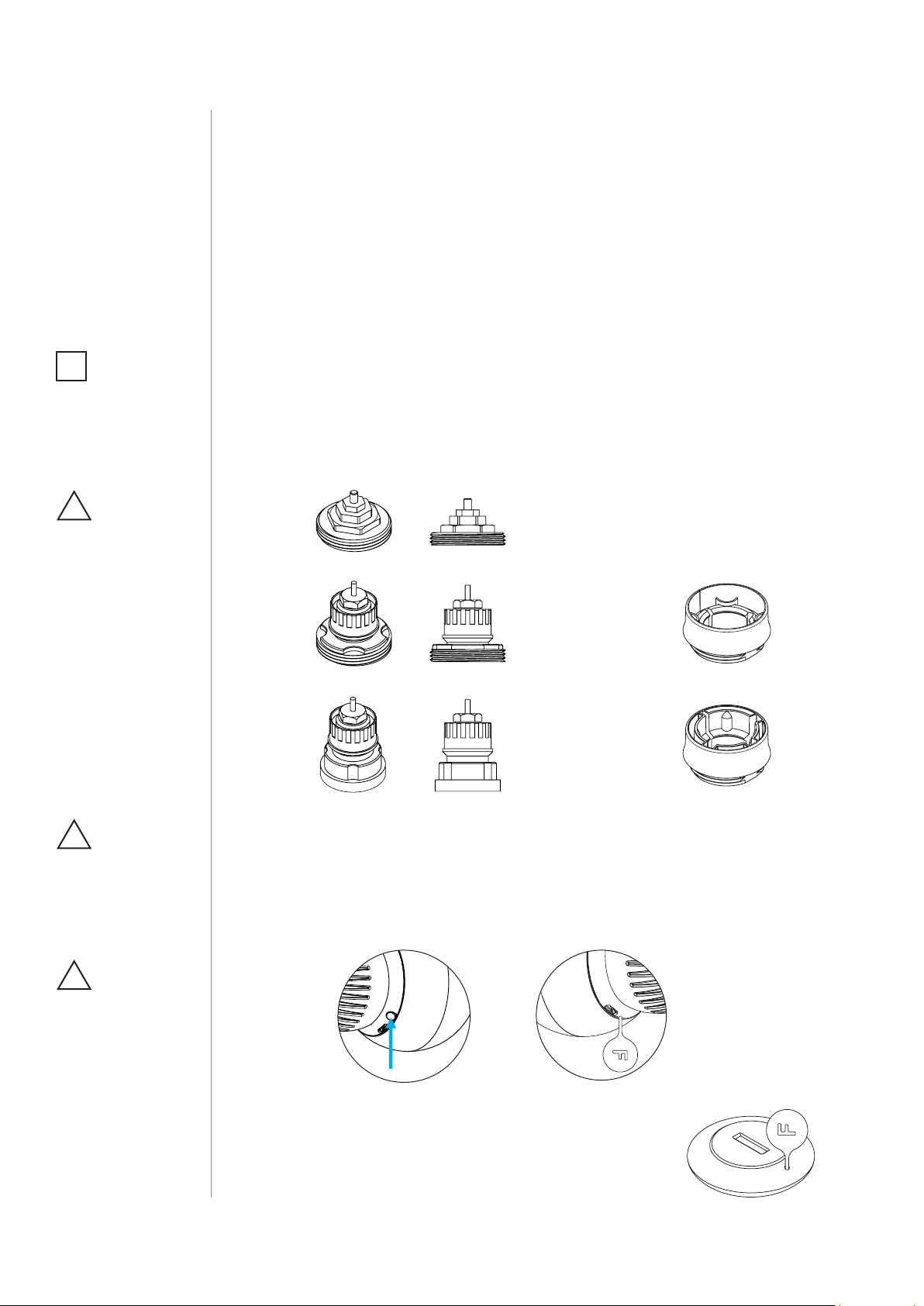

It can be mounted without tools on three types of thermostatic

radiator valves.

You can create schedules via app to easily manage temperature

throughout the week.

Main features of FIBARO Heat Controller:

• to be installed on three types of valves: M30 x 1.5, Danfoss RTD-N

and Danfoss RA-N,

3

• compatible with any certied Z-Wave Controller,

• supports Z-Wave network Security Modes: S0 with AES-128

encryption and S2 with PRNG-based encryption,

• built-in battery recharged through standard micro-USB port,

• easy installation - no tools required,

• can use a dedicated temperature sensor - FGBRS-001,

• supports heating schedules,

• automatic calibration,

• anti-freeze function,

• descaling function,

• unconstrained rotation spherical knob to set desired temperature.

FIBARO Heat Controller is a fully

compatible Z-Wave PLUS device.

NOTE

i

This device may be

used with all devices

certied with Z-Wave

Plus certicate and

should be compatible

with such devices produced by other manufacturers.

NOTE

i

Z-Wave Controller

must support Z-Wave

Security Mode in order to fully utilize the

product.

DESCRIPTION AND FEATURES

Page 4

4

NOTE

i

First charging may take

up to 3 hours.

CAUTION

!

If you use one of the

adapters, double check

that it is mounted

properly. It should

click when putting on

the valve, hold tight

after installing and

not rotate!

#2: Basic activation

1. Connect the charger to the micro-USB port to charge the device.

The LED ring will pulse red if it’s not fully charged; otherwise, it

will pulse green.

If you have the temperature sensor:

a. Use a coin to open the battery cover by turning it coun-

ter-clockwise.

b. Remove the sticker underneath the battery.

c. Use a coin to close the battery cover by turning it clockwise.

2. Disconnect the charger when the LED ring pulses green (device

fully charged).

3. Dismount your current thermostatic head.

Proceed normally

M30 x 1.5

Use adapter:

Danfoss RTD-N

CAUTION

!

If the device is installed

in vertical position, set

bit 5 in parameter 2.

CAUTION

!

Do not cover or veil the

thermostatic head.

BASIC ACTIVATION

Use adapter:

Danfoss RA-N

4. Depending on type of your thermostatic valve:

5. Mount the device on the valve and tighten it by turning the cap

clockwise.

6. Press and hold the button for at least one second (A) or use the

included key to quickly triple click the button (B).

B.A.

7. The LED ring will start blinking blue.

If you have the temperature sensor:

a. Click the button on the temperature sensor

now.

b. The LED ring on the thermostatic valve will

blink green 5 times if the connection was successful.

Page 5

#3: Adding to Z-Wave network

Adding (Inclusion) - Z-Wave device learning mode, allowing to add

the device to existing Z-Wave network.

To add the device to the Z-Wave network:

1. Make sure the device is within the direct range of your Z-Wave

controller.

2. Set the main controller in (security/non-security) add mode (see

the controller’s manual)

3. Quickly triple click the button on the thermostatic head (A) or use

the included key (B).

A. B.

5

4. The LED ring will start blinking white.

5. If you are adding in S2 authenticated mode, type in the device pin

code (underlined part of the public key on the label).

6. Wait for the adding process to end.

7. Successful adding will be conrmed by the Z-Wave controller and

green LED colour.

ADDING TO ZWAVE NETWORK

Page 6

6

#4: Removing the device

NOTE

i

Removing the device

from the Z-Wave network restores all the

default parameters of

the device.

Removing (Exclusion) - Z-Wave device learning mode, allowing to

remove the device from existing Z-Wave network.

To remove the device from the Z-Wave network:

1. Make sure the device is within the direct range of your Z-Wave

controller.

2. Set the main controller into remove mode (see the controller’s

manual).

3. Quickly triple click the button on the thermostatic head (A) or use

the included key (B).

A. B.

4. The LED ring will start blinking white.

5. Wait for the removing process to end.

6. Successful removing will be conrmed by the Z-Wave controller

and red LED colour.

REMOVING THE DEVICE

Page 7

#5: Controlling the temperature

You can set temperature using app (10-30°C) or directly on the device

(16-24°C).

During manual temperature change LED ring colour corresponds to

the temperature set-point.

To check and change the temperature on the device:

1. Bring your hand close to the sphere.

2. LED ring will:

• Glow if temperature was set manually,

• Pulse slowly if device is in schedule mode,

• Pulse quickly if device is in override schedule mode.

With colour depending on set temperature:

7

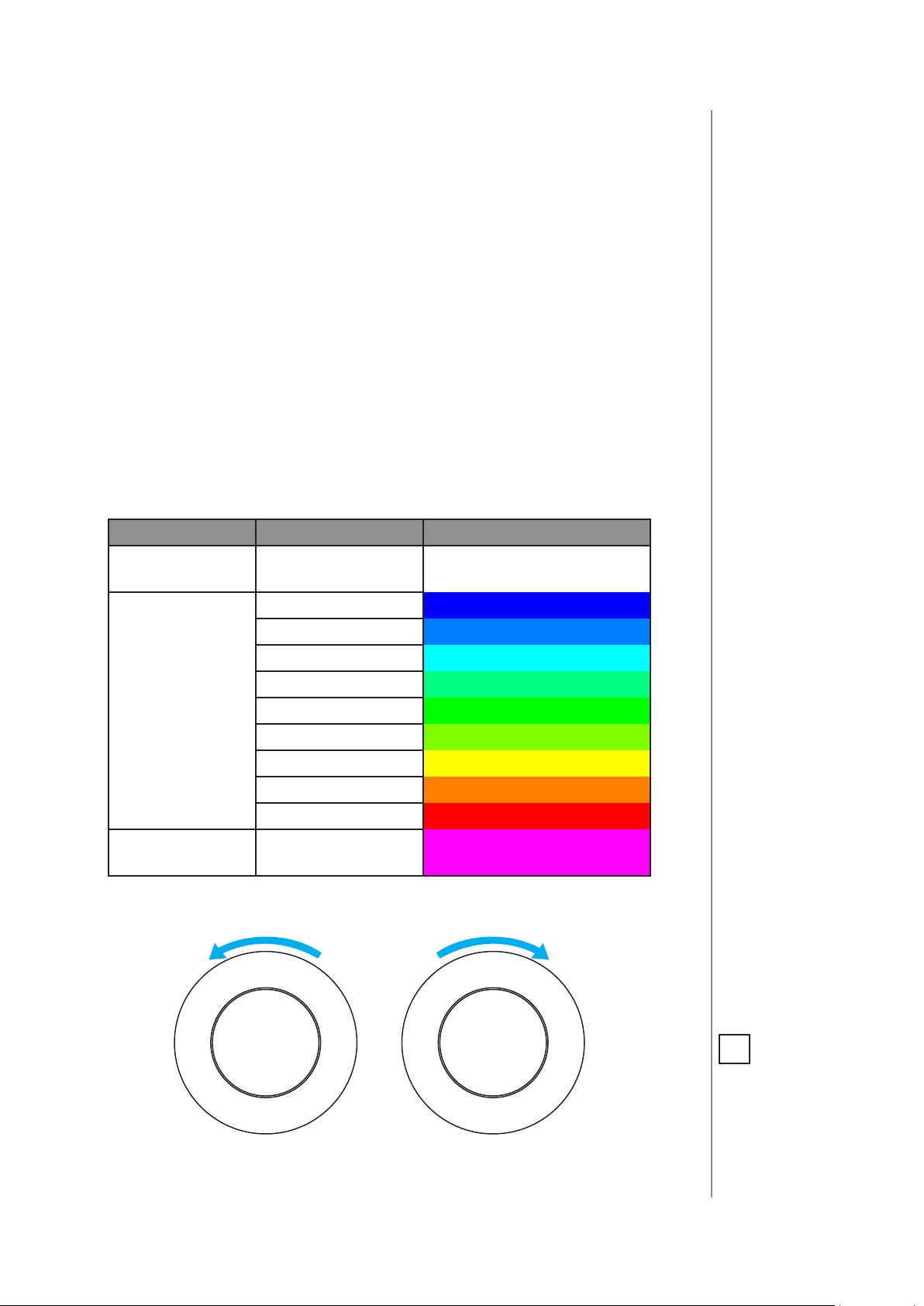

Z-Wave Mode Temperature [°C] Colour

OFF

Valve closed

(anti-freeze)

White

16°C or lower Blue

17°C Azure

18°C Cyan

19°C Spring green

HEAT

20°C Green

21°C Chartreuse

22°C Yellow

23°C Orange

24°C or higher Red

MANUFACTURER

SPECIFIC

Valve fully opened Magenta

3. Turn the sphere counter-clockwise to lower temperature or turn

clockwise to raise the temperature.

Lower temperature Raise temperature

4. Remove the hand from the sphere, after 5 seconds LED will fade

and new temperature will be set.

CONTROLLING THE TEMPERATURE

NOTE

i

If device is currently

during normal schedule, setting temperature manually will set

Override Schedule

(see “Override Schedule” on page 18).

Page 8

8

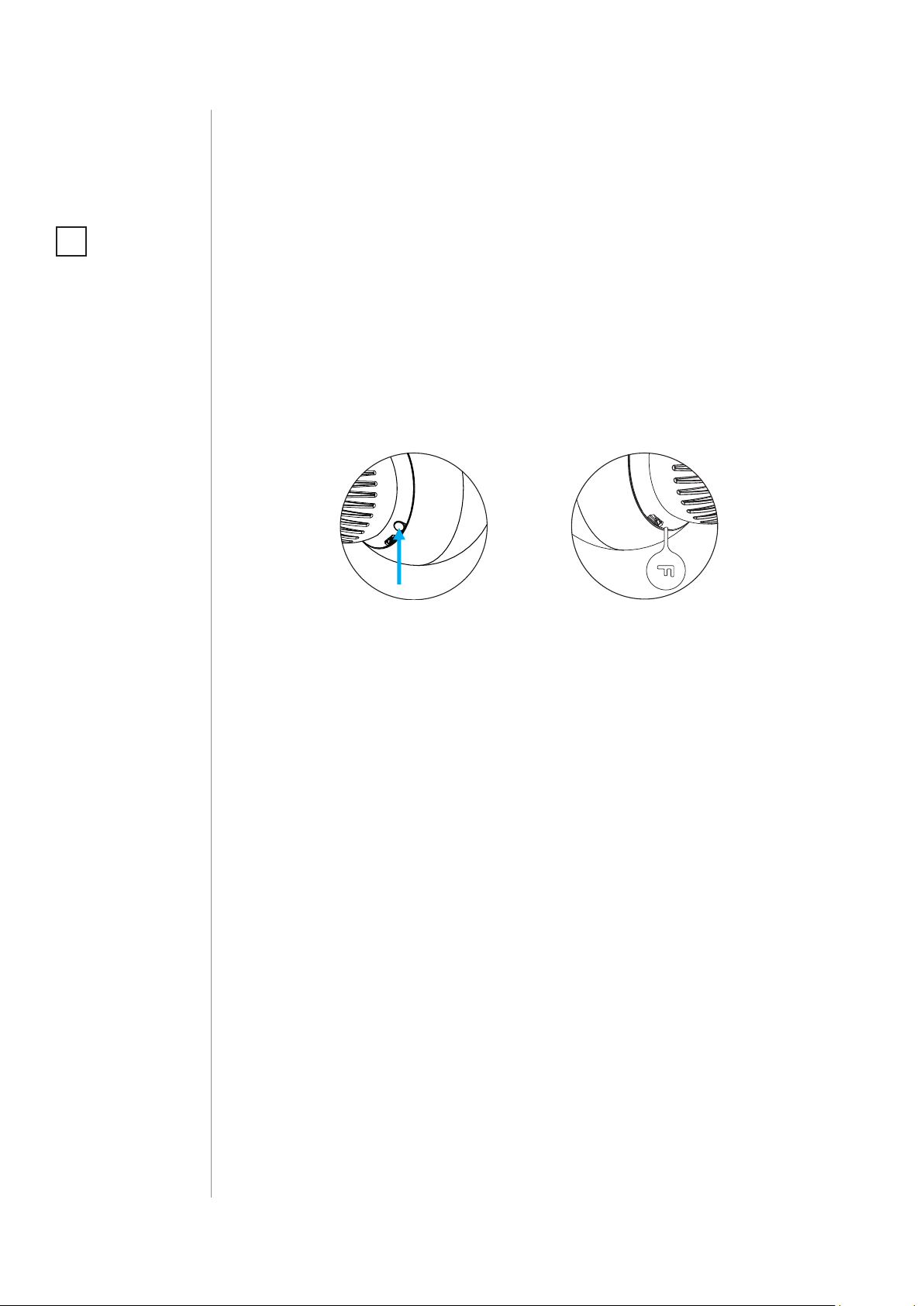

#6: Extra temperature sensor

NOTE

i

FGBRS-001 is the only

compatible temperature sensor.

CAUTION

!

This product is not a

toy. Keep away from

children and animals!

The device can be used with an additional, dedicated temperature

sensor (FGBRS-001) to provide the best temperature regulation.

It should be placed in the same room or heating zone as the thermostatic head which will use it as a reference point for the room temperature.

Before using, the sensor must be paired with the thermostatic head.

One thermostatic head can be paired with only one sensor, but one

sensor can be paired with up to three thermostatic heads.

To pair the FGBRS-001 with the device:

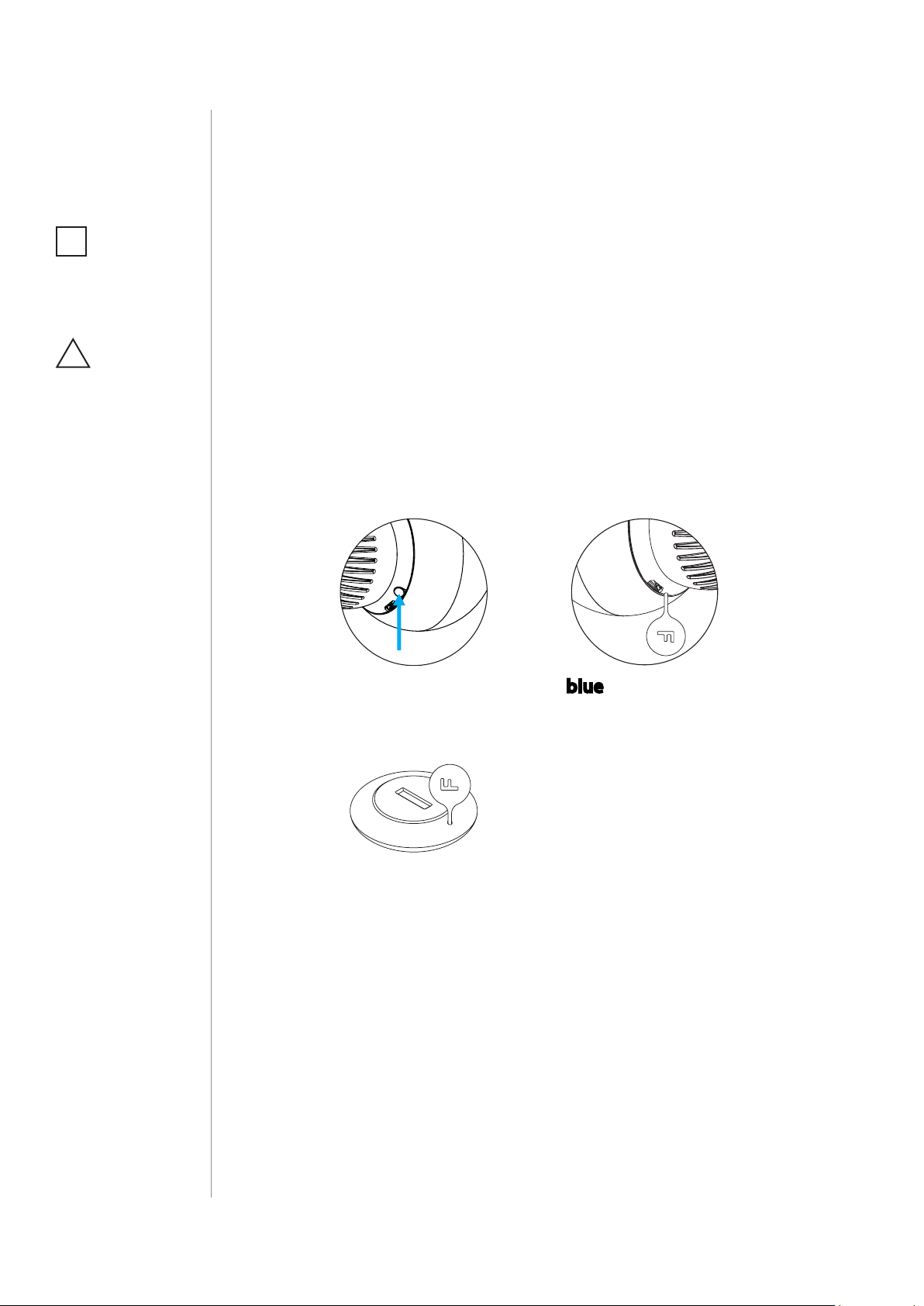

1. Press and hold the button on the thermostatic head (A) or use the

included key (B).

A. B.

2. Release the button when you see blue LED colour.

3. Click the button to conrm the selection, the LED ring will start

blinking blue.

4. Within 1 minute click the button on the sensor.

5. The LED ring on thermostatic head will glow green to conrm successful pairing.

6. Place the sensor in same room as head, no further than 5 meters

from it.

To remove all paired heads from the sensor’s memory:

1. Press and hold the button on the sensor for 2 seconds.

2. The LED on the sensor will blink 3 times to conrm unpairing.

EXTRA TEMPERATURE SENSOR

Page 9

#7: Dismounting the device

Before dismounting, the device must be put in Standby Mode to

ensure safe removal. See chapter „Standby Mode” on page 13 for

more information.

To dismount the device:

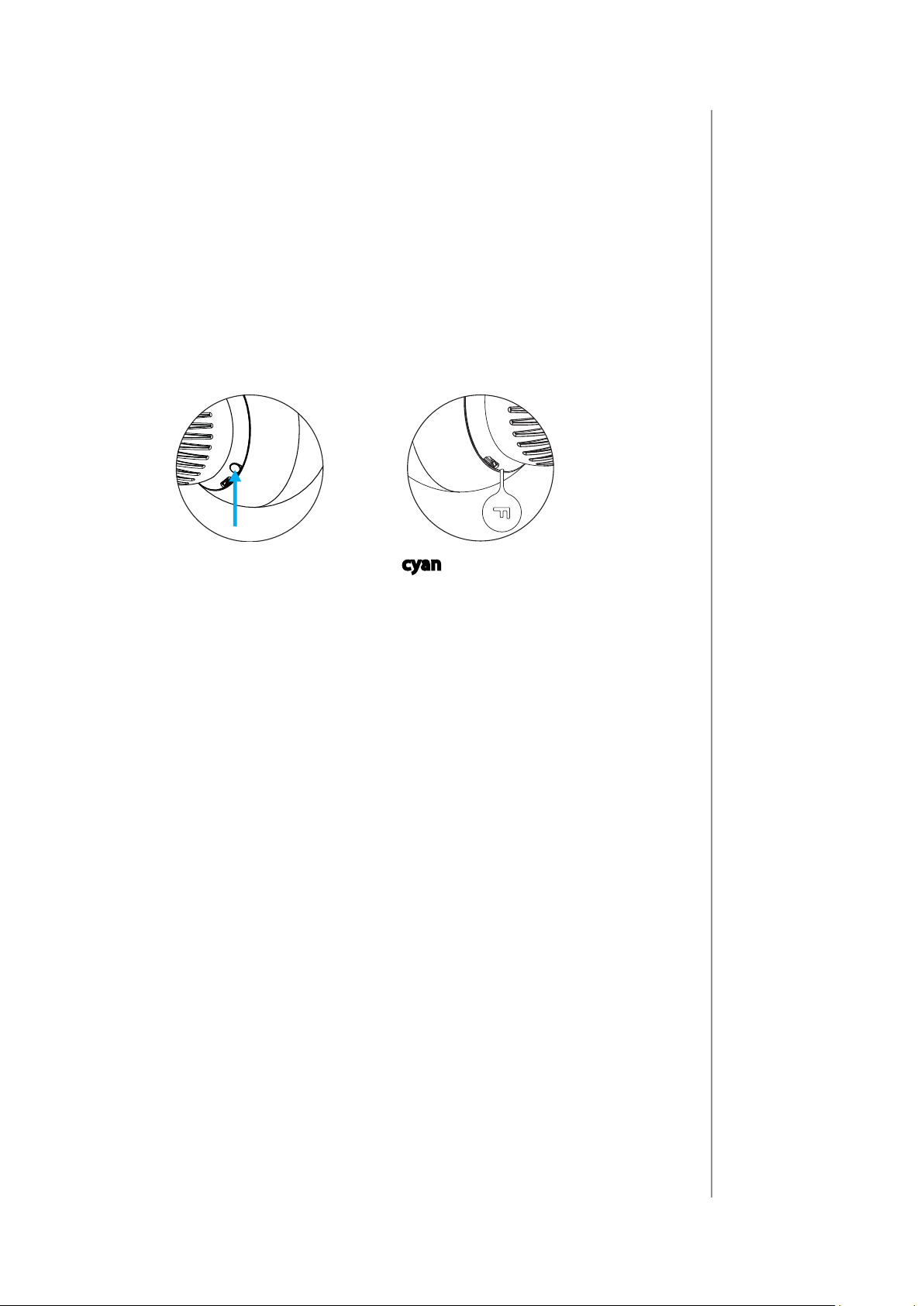

1. Press and hold the button (A) or use the included key (B).

A. B.

9

2. Release the button when you see cyan LED colour.

3. Click the button to conrm the selection.

4. Turn the cap counter-clockwise and remove adapter if used.

5. Store the device in temperature: -10°C to 25°C.

DISMOUNTING THE DEVICE

Page 10

10

#8: Menu

Menu allows to perform important conguration and maintenance

actions. In order to use the menu:

1. Press and hold the button (A) or use the included key (B).

A. B.

2. Release the button when you see desired LED colour:

Colour Action

Blue pair dedicated temperature sensor

Red

White perform head calibration

Green

Magenta Z-Wave network’s range test

Cyan put device in Standby Mode

Yellow factory reset

enable/disable local control protection

adding/removing to/from Z-Wave

network

3. Click the button to conrm the selection.

MENU

Page 11

#9: Local protection

After enabling the local protection changing temperature directly on

the device (by turning it) will not be possible.

Enabling local protection is recommended if you want to prevent accidental temperature change, e.g. by children.

When attempting to change temperature if local protection is enabled:

• The device will not set new target temperature,

• The LED ring will blink red 3 times.

To change the temperature use the app or disable the local protection.

11

To enable/disable local protection using the menu:

1. Press and hold the button (A) or use the included key (B).

A. B.

2. Release the button when you see red LED colour.

3. Click the button to conrm the selection.

NOTE

i

Local protection can

also be enabled/

disabled remotely

through Z-Wave controller.

LOCAL PROTECTION

Page 12

12

#10: Head calibration

NOTE

i

Calibration cannot

be performed while

the device is being

charged.

Calibrating the device to your radiator valve is required for proper

controlling the temperature.

Calibration is performed:

• Automatically, after 10 minutes from turning on if no operation on

the device has been made (only at rst installation),

• Automatically, after 10 minutes from last state change (only at

rst installation),

• Manually, using the menu (see below).

To perform calibration using the menu:

1. Press and hold the button (A) or use the included key (B).

A. B.

2. Release the button when you see white LED colour.

3. Click the button to conrm the selection.

HEAD CALIBRATION

Page 13

#11: Standby Mode

In Standby Mode the device is in deep sleep state allowing safe dismounting, transporting and low as possible battery consumption.

The device is shipped in Standby Mode. It should be fully charged

before rst use.

Entering the device in Standby Mode will not factory reset the device

nor will result in loosing any data, but calibration and sensor pairing

(after long Standby) is lost.

We recommend unpairing temperature sensor before putting the device into Standby Mode.

To enter Standby Mode:

1. Press and hold the button (A) or use the included key (B).

13

A. B.

2. Release the button when you see cyan LED colour.

3. Click the button to conrm the selection.

To exit Standby Mode click the button once, the device will enter

rst installation procedure.

STANDBY MODE

Page 14

14

#12: Factory reset

NOTE

i

Resetting the device is

not the recommended way of removing

the device from the

Z-Wave network. Use

the reset procedure

only if the primary

controller is missing or

inoperable.

Reset procedure allows to restore the device back to its factory settings, which means all information about the network and user conguration will be deleted.

To perform factory reset:

1. Press and hold the button (A) or use the included key (B).

A. B.

2. Release the button when you see yellow LED colour.

3. Click the button to conrm the selection.

4. After nishing resetting the device will be put in Standby Mode.

Click the button to activate it again.

FACTORY RESET

Page 15

#13: Z-Wave range test

The device has a built in Z-Wave network main controller’s range

tester.

To perform range test:

1. Press and hold the button (A) or use the included key (B).

A. B.

15

2. Release the button when you see magenta LED colour.

3. Click the button to conrm the selection.

4. LED ring will indicate the Z-Wave network’s range:

• Pulsing green - the device attempts to establish a direct communication with the main controller. If a direct communication attempt fails, the device will try to establish a routed communication, through other modules, which will be signaled by

visual indicator pulsing yellow.

• Glowing green - the device communicates with the main

controller directly.

• Pulsing yellow - the device tries to establish a routed communication with the main controller through other modules

(repeaters).

• Glowing yellow - the device communicates with the main

controller through the other modules. After 2 seconds the

device will retry to establish a direct communication with the

main controller, which will be signaled with visual indicator

pulsing green.

• Pulsing magenta - the device does communicate at the maximum distance of the Z-Wave network. If connection proves

successful it will be conrmed with a yellow glow. It’s not recommended to use the device at the range limit.

• Glowing red - the device is not able to connect to the main

controller directly or through another Z-Wave network device

(repeater).

5. To exit Z-Wave range test, press the button briey.

ZWAVE RANGE TEST

Page 16

16

#14: Battery and charging

CAUTION

!

Make sure you are using

certied charger Class

II, marked which

complies with parameters specied in the

manual.

CAUTION

!

Do not leave the device unattended while

charging.

CAUTION

!

Set the device to OFF

(white) before charging or dismount the

thermostatic head if

not possible.

NOTE

i

The device is equipped with a rechargeable lithium-polymer battery pack that can be charged via micro-USB port using standard 5V

charger (not included).

When battery is low the LED ring will start to blink red. The device

will also report low battery status of itself and dedicated temperature

sensor (if paired) to the controller.

The device does not operate the valve during the charging and maintains the last valve position.

If the battery is discharged the device will open valve completely to

allow easy dismounting.

To charge the battery:

1. Connect charger to the micro-USB port.

2. During charging the LED ring will pulse red and valve control will

be disabled.

3. When LED starts pulsing green, disconnect the charger.

4. The device will restore its previous operation.

Do not use cables longer than 3 meters for

charging the device.

CAUTION

!

Make sure the device

won’t discharge during the heating season

or it may cause high

temperatures!

BATTERY AND CHARGING

Page 17

#15: Normal Schedules

The device allows to create multiple heating schedules to manage

temperature in the room throughout the week. Schedules are created

via controller interface or app.

• Up to 253 normal schedules can be created.

• The lower the schedule ID number, the higher the priority.

• Schedules with higher priority override those with lower priority

in case of overlapping schedules.

• Schedules can be disabled without deleting it.

• Schedules allow to set target temperature for HEAT mode (using

Thermostat Setpoint CC) and one of operating modes: HEAT, OFF

or MANUFACTURER SPECIFIC (using Thermostat Mode CC)

• Only SET commands are permitted.

17

To create normal schedules user must specify:

• Day of the week,

• Starting time (hour and minute),

• Duration,

• Temperature Setpoint for HEAT mode in range 10-30°C (using

Thermostat Setpoint CC)

• One of the operating modes (using Thermostat Mode CC):

» HEAT for setting temperature,

» OFF for valve fully closed,

» MANUFACTURER SPECIFIC for valve fully opened.

NOTE

i

Schedule CC Set command payload must

not be greater than

22 bytes limit or it

would be rejected.

NORMAL SCHEDULES

Page 18

18

#16: Override Schedule

Override Schedule is a special type schedule with highest priority;

thus it overrides other schedules.

The Override Schedule starts right after setting and lasts for specied

time, then it is removed and current schedule or normal operation is

restored.

To create Override Schedule user must specify:

• Starting time (START NOW),

• Duration,

• Temperature Setpoint for HEAT mode in range 10-30°C (using

Thermostat Setpoint CC)

• One of the operating modes (using Thermostat Mode CC):

» HEAT for setting temperature,

» OFF for valve fully closed,

» MANUFACTURER SPECIFIC for valve fully opened.

Override Mode can be enabled in two ways:

• By turning the knob, while normal schedule is active. The LED ring

will pulse with selected adjustment.

• Via controller, by creating schedule with ID set 255, start time set

to NOW and duration (in minutes/hours/days).

To exit Override Mode grab knob with your hand for 5 seconds.

OVERRIDE SCHEDULE

Page 19

#17: Z-Wave specication

Endpoint 1:

Generic Device Class: GENERIC_TYPE_THERMOSTAT

Specic Device Class: SPECIFIC_TYPE_THERMOSTAT_GENERAL_V2

Description: represents thermostatic head, allows to set temperature, schedules and check its battery level.

Endpoint 2:

Generic Device Class: GENERIC_TYPE_SENSOR_MULTILEVEL

Specic Device Class: SPECIFIC_TYPE_ROUTING_SENSOR_MULTILEVEL

Description: represents temperature sensor:

• Extra temperature sensor paired – reports temperature measured by the extra sensor and its battery level,

19

• No extra temperature sensor paired – reports temperature measured by the built-in sensor and head battery level.

Response to Basic Command Class:

Value Action

0 Set OFF mode (unfreeze function)

99 Set HEAT mode (last set temperature)

255 Set MANUFACTURER SPECIFIC mode (valve fully opened)

Association Command Class:

The device supports only “Lifeline” association group that reports

the device status and allows for assigning single device only (main

controller by default).

ZWAVE SPECIFICATION

Page 20

20

Supported Command Classes:

Command Class Version Secure

ZWAVEPLUS_INFO [0x5E] V2

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

BASIC [0x20] V1 YES

APPLICATION_STATUS [0x22] V1

THERMOSTAT_MODE [0x40] V3 YES

THERMOSTAT_SETPOINT [0x43] V3 YES

SCHEDULE [0x53] V1 YES

TRANSPORT_SERVICE [0x55] V2

ASSOCIATION_GRP_INFO [0x59] V2 YES

DEVICE_RESET_LOCALLY [0x5A] V1 YES

MULTI_CHANNEL [0x60] V4 YES

SUPERVISION [0x6C] V1 YES

NOTIFICATION [0x71] V8 YES

MANUFACTURER_SPECIFIC [0x72] V2 YES

POWERLEVEL [0x73] V1 YES

PROTECTION [0x75] V1 YES

FIRMWARE_UPDATE_MD [0x7A] V4

BATTERY [0x80] V1 YES

CLOCK [0x81] V1 YES

VERSION [0x86] V2 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

CONFIGURATION [0x70] V1 YES

CRC_16_ENCAP [0x56] V1

SENSOR_MULTILEVEL [0x31] V5 YES

OVERRIDE SCHEDULE

Page 21

Multichannel Command Class:

Command Class Version Secure

Endpoint 1

ZWAVEPLUS_INFO [0x5E] V2

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

BASIC [0x20] V1 YES

THERMOSTAT_MODE [0x40] V3 YES

THERMOSTAT_SETPOINT [0x43] V3 YES

SCHEDULE [0x53] V1 YES

ASSOCIATION_GRP_INFO [0x59] V2 YES

SUPERVISION [0x6C] V1 YES

NOTIFICATION [0x71] V8 YES

BATTERY [0x80] V1 YES

CLOCK [0x81] V1 YES

PROTECTION [0x75] V1 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

Endpoint 2

ZWAVEPLUS_INFO [0x5E] V2

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

SENSOR_MULTILEVEL [0x31] V5 YES

ASSOCIATION_GRP_INFO [0x59] V2 YES

SUPERVISION [0x6C] V1 YES

NOTIFICATION [0x71] V8 YES

BATTERY [0x80] V1 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

21

OVERRIDE SCHEDULE

Page 22

22

Notication Command Class:

The device uses Notication Command Class to report dierent events

to the controller (“Lifeline” group).

Endpoint 1:

Notication

Type

Power

Management

[0x08]

System

[0x09]

Endpoint 2:

Notication

Type

Power

Management

[0x08]

Event Event Parameters

Charge battery soon [0x0E]

Charge battery now! [0x0F]

Battery is charging [0x0C]

Battery is fully charged [0x0D]

System Hardware Failure

[0x03]

Event Event Parameters

Replace battery soon [0x0A]

Replace battery now! [0x0B]

External sensor

remove [0x02]

Motor error [0x03]

Calibration error

[0x04]

OVERRIDE SCHEDULE

Page 23

#18: Advanced parameters

23

The device allows to customize its operation to user’s needs. The settings are available in the FIBARO interface as simple options that may

be chosen by selecting the appropriate box.

In order to congure the device (using the FIBARO Home Center controller):

1. Go to the device options by clicking the icon:

2. Select the „Advanced” tab.

3. Modify values of chosen parameters.

4. Save the changes.

GENERAL SETTINGS

1. Override Schedule duration

This parameter determines duration of Override Schedule after turning the knob while normal schedule is active (set by Schedule CC).

Available settings: 10-10 000 (in minutes)

Default setting: 240 (4h) Parameter size: 4 [bytes]

2.

Additional functions

This parameter allows to enable dierent additional functions of the

device.

Available settings: 4 (bit 2) - increase receiver sensitivity (shortens

battery life)

8 (bit 3) - enabled LED indications when controlling remotely

16 (bit 4) - protect from setting Full ON and Full

OFF mode by turning the knob manually

NOTE

i

Entering invalid value

of parameter will result in not setting the

value and response

with Application Rejected or Supervision

CC frame (depending

on the controller).

NOTE

i

Parameter 2 values

may be combined,

e.g. 1+8=9 means

that Open Window

Detector and LED indications when controlling remotely are

enabled.

32 (bit 5) - device mounted in vertical position

64 (bit 6) - change regulator behaviour from

Rapid to Moderate

Default setting: 1 Parameter size: 4 [bytes]

3.

Additional functions status (READONLY)

This parameter allows to check statuses of dierent additional functions.

Available settings: 1 (bit 0) - optional temperature sensor connect-

ed and operational

2 (bit 1) - open window detected

Default setting: 0 Parameter size: 4 [bytes]

NOTE

i

Parameter 3 values

may be combined, e.g.

1+2=3 means optional

sensor works properly

and open window detection was triggered.

ADVANCED PARAMETERS

Page 24

24

#19: Specications

NOTE

i

Charger type: Unit shall

be supplied by a source

certied as Limited

Power Source (LPS) as

dened in clause 2.5

of IEC60950-1 2nd edition + Amd. 1 + Amd. 2.

CAUTION

!

SELV power supply

(USB supply) is used

only for battery charging. The device does

not operate the valve

during the charging.

Power supply:

Charging port:

Charger voltage (not included):

Minimum charger current

(not included):

Operating temperature:

Storage temperature

(standby mode)

Maximum water temperature:

Temperature measuring accuracy:

Regulator class:

Device Firmware Class:

Motor protection:

Actuator action:

Actuator stroke:

Purpose of control:

Construction of control:

Degree of protection by enclosure:

Classication of control according

to protection against electric shock:

Action type:

Control pollution degree:

Rated impulse voltage:

Dimensions

(Diameter x Length):

EU Directive compliance:

3.7V Li-Poly battery pack (non-replaceable)

micro-USB

5V DC (±5%)

0.5A

0–40°C

-10–25°C

90°C

0.5°C (within 0–40°C range)

Type 1 class

A-grade

Impedance Protected

Linear variable position actuator

5mm

Operating control

Integrated control

IP20

Class III

type 1

pollution degree 2

330V (when connected to the USB

power supply)

56 x 74 mm (without the adapter)

56 x 87 mm (with the adapter)

RoHS 2011/65/EU

RED 2014/53/EU

SPECIFICATIONS

Page 25

For communication with the controller:

25

Radio protocol:

Radio frequency bands:

Maximum transmit power:

For communication with the extra sensor (FGBRS-001):

Radio frequency band:

Maximum transmit power:

Z-Wave (500 series chip)

868.0-868.6 MHz

869.7-870.0 MHz

6dBm

2402-2480 MHzMax

7dBm

SPECIFICATIONS

Page 26

26

#20: Accessory specication

(FGBRS-001)

CAUTION

!

Using batteries other

than specied may result in explosion. Dispose of properly, observing environmental

protection rules.

CAUTION

!

CR2032 coin cell battery is harmful if swallowed!

Power supply:

Operating temperature:

Storage temperature:

Temperature measuring accuracy:

Dimensions

(Diameter x Height):

Radio frequency band:

Maximum transmit power:

EU Directive compliance:

CR2032, 3.0V battery (included)

0–40°C

-10–40°C

0.5°C (within 0–40°C range)

38 x 12 mm

2402-2480 MHz

1dBm

RoHS 2011/65/EU

RED 2014/53/EU

ACCESSORY SPECIFICATION FGBRS001

Page 27

#21: Regulations

Legal Notices

All information, including, but not limited to, information regarding the

features, functionality, and/or other product specication are subject

to change without notice. Fibaro reserves all rights to revise or update

its products, software, or documentation without any obligation to notify any individual or entity.

FIBARO and Fibar Group logo are trademarks of Fibar Group S.A.

The Bluetooth word mark and logos are registered trademarks owned

by Bluetooth SIG, Inc. and any use of such marks by Fibar Group S.A. is

under license.

All other brands and product names referred to herein are trademarks

of their respective holders.

27

Warning

This product is not a toy. Keep away from children and animals! CR2032

coin cells are harmful if swallowed!

Declaration of conformity

Hereby, Fibar Group S.A. declares that the device is in compliance with the essential requirements and other relevant

provisions of Directive 2014/53/EU. The full text of the EU

declaration of conformity is available at the following internet address:

www.manuals.baro.com

WEEE Directive Compliance

Device labelled with this symbol should not be disposed with

other household wastes. It shall be handed over to the applicable collection point for the recycling of waste electrical and

electronic equipment.

REGULATIONS

Loading...

Loading...