FiatAgri 411Rb Service Manual

IPHCIDPS

IE}

BHSMI

1

PH

ENGINE

5

3

Z

...M..,_.

.~....,...w_.....--__~_-._..~...

v,\V)Q'I—%V

i

3

OVERHAUL

E

é

AND

REP/MR

Z

INSTRUCTEONS

.

1

.

.»i;=_;~_v_;

"

.-»»

’

.

,5‘13,,

F

7

7

_J

f

\

‘--

‘:w=\-

W.

5‘?

‘:1;_1L‘§€-i-."‘

»

.,~,_!=;‘

"1-2:‘?

;1;¢

~

J"

~

;=-,'-"

_

‘---.‘4

*

X

"':{f-“

\

f;"r-;<=»';s;.,=r;

'?

J

‘

T

\\

~

*s‘<

fix

.-..,,\;<»»:='

My

.1

-

~

l

7“

'=*-4-'~.~:‘"--.,..

A

“‘_

Y

*:

,,-'1-1,

'

‘~'

.1

_=‘:‘-

_

'

,

‘

~

'-

;1=

:1»

'~.=-~12

-‘

;.~f

'1"

‘~

.,)

1

‘

.

1

"

.

_

.~

_.'=‘:';m‘#71:“N“"fix,

-

ii

-

'

’

*

-=‘<15?-“.2

.

»_

""

'>"-"":»@-i;;4_;.§~.

.;'~:¢~

9:1

%

.

~‘"‘-"gh'Q

1*,

‘

=-»j‘;__

,'-.=-

"1":‘:'"'3-T‘?

,—<,_.

.1;

»

,,‘.\_'._C.'

71*

‘-

“n>=;

. .

M

V--»:-3.,

"

*—_""‘~.;'.-‘T.-.>-51‘.-'$F:-:.»%:=3_

1-

‘_7L7E';1?':::‘

1

.':£i=*t'

‘y

H-C,‘;_-D

1

';§JI=L;1»~Er{':6'1;-I;

‘

'

‘

v

1.

j

'A.-

_:

”i—j‘i"Y'=r1;~»‘*~:1<

.

'\"~'-?‘l'~"~'#AL='-‘-‘;i~';.;;§\'.-__

F-\""

_

1",-.~1:‘,1=-'.~?~=_.=,.»-=,._—~,~.

1

1'.‘-'

I:-=1‘-51$‘)

éfiflb

'~

\;_-41;.

'

'-‘l=-'=5‘\'=.

'

1'

-/'/Z

.

-1

'2

‘

''

,

H

‘>3

-I

1

,

__~

5

-=\__

v-'.

$4

‘~;_

-.-,@=:-

‘.-J‘

_

"“'

._;

mm.w, .

“=‘~'-

ii)?"

.,-—

7.:--=

;,~_».1"'.._-‘~15:--;‘H.:\_.;_.;,_,\_‘_

"Y-

:1-~'-'-'-u'>

‘

*\_

"

'_V

‘.7’.

_"‘;"

_.

/

'

.5,-_.fi-xwn

~

’f‘f"’”rT>

-

‘

:=T‘!'3':ziT;,

:;:~-,

,.\1’=~_‘-

1.»

M:

‘3i;‘l$§?=‘;"1T31‘1-'L-‘3#1§&3‘53Y5‘i5i§EF’="1i."-"§—'é'5;"-';=.'~-"Y

%>W

'\'->.

.

‘-11

.~

‘.7,».

~'-1-1~;~=-.".

‘*'

-£-~==».eH¢I.-=-_-1,.-~-M,

.5,-,.-4A\,-

‘,.

l"‘l_'_'7

:""f“:‘>;}:‘

‘ ‘

M"-~

Y

-

;F,I}-‘=:-:~,~1§."¢,_,M“

""

1%

W

»

J:

4\'—F:-~-1'1’

.~'z;'-,F_~-1

<fi.,;..,.*‘-

#3:‘:W‘l-‘F

'-

1~=-~z.-:

;':*_'

‘W

»

,

'-

-.,;-§;>-;{,j-53;!-1:.

~,‘‘,,~,,,

_‘M_..

._.;

‘~‘~'.‘g¢\¢_1)_:7,

_,',

,...,;,

‘:"l‘3‘1?I=i"'=;’~§;

.1

'

_

ll:

1‘

{Q

__

§

W?

°

A

.

".*5?$"*f'£I¥'fi@”.11

~»5*--"=~

_,

Z‘i:fE'T’:‘_%_?;"iI7\-5-'3‘’

->2,-F‘-<"

'7:

i

ll.-_-?

-~1:'~,<i¢I>,

>.»:;§;=¢,»~¢;'"€*§*::;;w'»r;1%._“>"a;»,

._

:,§;,-

.3‘'

"E9

$4»-_~\‘=-"KP-1

E

'1

<_-=H,

W-»

H

~;,'=71_’>“=v";@:z.‘w:A<-=_-:3.>.Q"~*=-:7

<1

‘kg’

1

_

rs-2;,_=>

‘>n;r;:.\‘

\;1;»,'=:

'5-S‘:-'€

,-T

M

HI»-1";-I'.»,;,"*1-;#‘<~g,7_1’J<\'.

'**

7.,’

.

.

M,

.~

,

-‘"-;:w.

_

I-<__.

‘ii

I‘

.

~

I*»-“.2;-=“.s_-21::

~

»w-

—?*1>

C

‘-

:,_-Q5‘-,._,.

2'2-.11.‘

‘-‘;;f3"-:}''

an

I"

1?

*7-£Zm\;’1

*

F

';“»_::w‘U

‘{

11;‘

,>,_:v“<:g_V;:‘,“‘_;_$.§;-_j

¢‘I

L

K,»">

.

7.;;,‘,9

,

M

V.,7-

‘T

S

.é

-

,

_

‘

é

-

~.‘V

'

if

V

1.-~

'~L-u

’/Q“

.-5.‘

_,

_.‘

_ _

~

3’*;§;.'=‘§g_g

ii"?

~=

,

'

.;afi!;a,

d

~<Y3‘

,

vs:

i

;%;e,¥$.jLI

_5;:53};

GK“;

:>.»-.

V’;__

.,-.

9

:ޤ;

*

, _.

7

'

-

-

'~~=‘=11

.‘,,.‘

Ir

%

,/""“‘~*»-

.-

'

£(

‘

‘

mm}

'

-

‘

1, _

‘i

\\

‘

I

¢

1

<

:i"3§;?1§'

=.-Y:.~,,-=

Kw‘M25,,

\

y

I>V

_;‘=

;.,§.-..,

_.»,¢‘--:.:~->‘w‘l':‘*"'i¥rF-"'j§‘:T§L"

4*‘

51;J‘T‘,

;

:v._';J

’‘"

$3¢§I\x51-$15-_-,A‘,‘;>‘?§:;..+V

.>.1~~~*7~1-1.1.‘,

ml,

V

~5;§=<_$;§*?§~*"fi2vi=@;*§£~2r:?>_ar_137Tr*-;%¢-;»

.

,1»:.

..

I~'1'-»--Y»

-55:‘.

*

vL._..~_7;;€:,-,,_,“‘V,

.'_;;;._;

1'

."?‘3->!::1,;<*~.:¢'._H

,.

'£;\,=-,>‘;»_

.:_5~;‘.;.~;

2,»;~"_-V‘

..

.,,._»»»

'>-3*;-.v~:.

"-I’??.Z'iI*.lTY7i»1z>»l§§j_;:,T’“3*Xi»*P"*"'*_‘

'~—“.=‘_.'§i‘_»,3’

5?

*».\"§‘?\

fir-v

11%‘-"-

f

*»*v-4

§.

~*’

"

"

~»-r"

.‘

,,_

,.;¢'@W-"-

..,~.,.,_:--

,a;3q_~\

"TE

‘£1

é

‘-‘

V

_

».¢

“lg

@

‘%;»y

A

é:-=¢~

.__

'1':

'~*.H

$5‘

1""

'1

_

‘r

.

\

Y

WU

.

.

*

‘

-

~

{

_’;-~"

».1_

.

.

wag

.

_Y

T‘

_,_:.r'-;'

"

\

*fi%

.1‘.'"~

,

-

1*

Q

*4?

>-

,

-,

,.='

,-‘—-""‘

J*'lj*=:m

,

'“"Qv"":<-

‘

~,.'r~\

._:’=~>1/W

,~->;:<<~_a[1;-_-=-_—

33>

cw

.,~\

3

‘

,:;."___

1‘-V

5'2

wag

VI\

ml

.

Ha

.

..

‘*‘.*\2;%‘%'Zj1<I:*r,"‘-";'_As:_'_

3-<,;*

é?

‘-\

""7"r’f.~?;,"-3!-=r..§.

3

'~

‘X

I

-\’

,>______3.j‘

J;‘E

.

-

~

‘*"'

éfi

W~“wagiw

‘f’.

'gi_.=\.;

.5

2;:

'*'r.

A

’€r’$>v .'V

*4»

‘’-=7

Q

gm;-,

-:1:

%‘__:.%_§

fin

—

,_,,._-xi’

<

:3

w

_V‘

’i"'“'-=~\~.».‘1

am‘?

%

A-‘\-1"-*.P.~,,_'»--

x

'

~‘

'1

‘»<_

\*

'

~».

WK

'“».

U,

,,,.-;rL.Q>‘-

"‘“*--..

'

i»

,-

4

‘HQ!

"

,.;,,

-

,1

XXL

=3,-‘L-—;_:=

_

{::'..<§’,¢

1:;é_‘,$$?

'-.

1:

‘~

r-"'“"""

‘V.

_.M,...r<-

-e

1

..-.

,»

_*_

':-.V.

-""2

;7';;.#’»'TT-"

;~-:=~i.¢".fi‘;~$

¢3,w.¢_;._:.%

..

;::'

~,'

,.Ȣ;_-L

. .

fa

1

.

’

(-_)

;;__»;.,;_3;~;_‘ ;v.

">~»==>'

1

K

.~"“

A’

__

\

»

--

¢.»~»_-*‘>‘~~>.*~*‘

_

6‘

3:‘=?~T‘ei-*:.»;‘~'-==*'z§~¢,,,‘~*'.'2.~‘-;z'

‘*‘

—=*¢~"'>=‘1.'-*?:*“-i’:':5%'_l~i"

--..,=

,

‘Z3;

I

-

_..

v§

fa,

'

"\

.

_.=,;,,

7

5%}

.-.

Q

,<>@_»jr,_;~_

1

'.-

<--s»~.”-L-(».+,..¢=:

§=1<:v-=‘~$~;@'“=.

W...“

gfiéé

k

.

K

._

t

"‘5=5=<“'“

'

~

Q?

"~1:.1=

-»-fir

~<-1:-*~@_,%~

RM

1

_‘

i

‘

:".~*1»

~;

,,

Q3

-'1

ff

‘

-,

:=:?:zaH->~'-'1

»_..,,_

'

11~,=~

.,v-fig

‘

“fa

_.

,..~,.~.~

I-

. .-_.v_l§.;

é~='~

~

_'*

‘~

-_§'==;';j-fige»-v;_‘_;;:_—.,_»,—

L35"

r

4

my

.

,

‘

“

-‘~

'¢=<__

_

%;-»=1,;~s:F

.

1-;=‘—-—;:15.-51-

TE-=—~

"-"='-;1V-

~_"*Y:-i'x-v\:'-_-“1-I‘§'4'-:7Mi“!

H

9

,w’,,

*~‘--w-&_».'¢,,-;,

3:

F

..-M1:-;»*

M‘1"?‘--(‘--I-3-.1--&~>1;?I;-’

15,:W;;,}_

'~~-

~»»,.:1

£9

‘

‘R

4;

.15":

-~__

»~

-

-

.

(,.\

‘v.

':'3"f-‘Iv

aw»-

;;.,,_-_r=._.~..,

>

,

_;-,;:_;_'?_

P"

r1.;:~'-.1

,--¢--,-

l

_;‘

1.

_

=i

!\

ii

ii

5;

;a

:1

4

FOREWORD

This

publication

the

technical

gasoline

herein,

series

I.

II.

engine

For

the

repairofthe

please

tractors

This

publication

Overhaul

The

characteristics,

tor

411

Rb.

NOTE:

Conversionsofmeasures

is

destined.toRepair

data,

instructions

105.615

fitted

other

refertoOverhaul

(Prim

and

354.6%‘).

is

divided

adjustment

performances

(from

mmtoin.)ofthe

and

on

Tractor

tractor

and

as

of

engine

illustrations

41131).

components,

Repair

follows:

and

and

quoted

Shops

and

presents

relatedtothe

not

discussed

Instructions

its

components;

of

480

B

impiementsof’I"1'a<:-

‘Figures

are

listedonpage

66,

3

.

.

<1.

cno.i

z

i

DESCRIPTION

A

four-511-@143,

408

Rb.

Special-casting

Aluminum

Steel

cylinder

counterweighted

Thin-shell-type

friction

located

trolled

cation

a

shunt

a

thermostat

metal.

Inlet

and

in

the

A

gear-type

by

adjustment

system

cartridge-type

Water

circulation

Carburetor

Solex

non~frost

discharge

crankcase,

pump

includes,inaddition,asuction

fitted

air

Storage-battery-actuated

and

ignition

coil.

Centrifugal-Weight

rear-end.

Electrical-motor

0110

cycle,

cylinder

heads

crankshaft,

journal

bearings

valves

and

driven

valveinthe

filter.

engine-cooling

in

the

Water

through

horizontal

'

governor

r

'

r

startidg,

ENGINE

four-cylinder-in-line

liners

oil-bath

ignition,

provided

fitted

with

cast

at

controlled

chain-driven

by

the

camshaft

main

by

passage

filter,

intake

type,

the

controlling

of

in

iron

having

crankshaft

by

system

centrifugalpump

between

provided

distributor

electromagnetic

the

inserted

rocker

by

filter,

and

engine

engine

crankcase

integral

and

arms,

the

crankshaft.

supplies

fitted

directly

cylinders

gasoline

of

being

speed,

type

105.615,

and

Water

valve

seats.

Webs,

bearing

connecting-rod

push

rods

pressure

outside

thelefl:

connectedtothepump

'

and

controlled.

and

radiator.

ieeding

starting

by

primer.

controlled

fitted

at

clutch.

fitted

on

cooled.

on

three

big

ends,

and

tappets

lubrication;

circulation

crankcase

as

engineiscooled,

diaphragm-pump.

_

by”

the

distribution

-

generator

armature

Tractor

supports.

lined

with

by

"

side,“

The

suction

series

anti-

camshaft,

con-

lubri-

and

by

shaft,

spindle

.4.--,1.

1...

.,,..

:5.

-

§

~w=t<».¢

:x».&Ié8i’e'>l£

-1

>a

*1

Q

v

é

L3

>

L

_

»

z

F1‘

i

|

r

J

.

‘-1

e

i

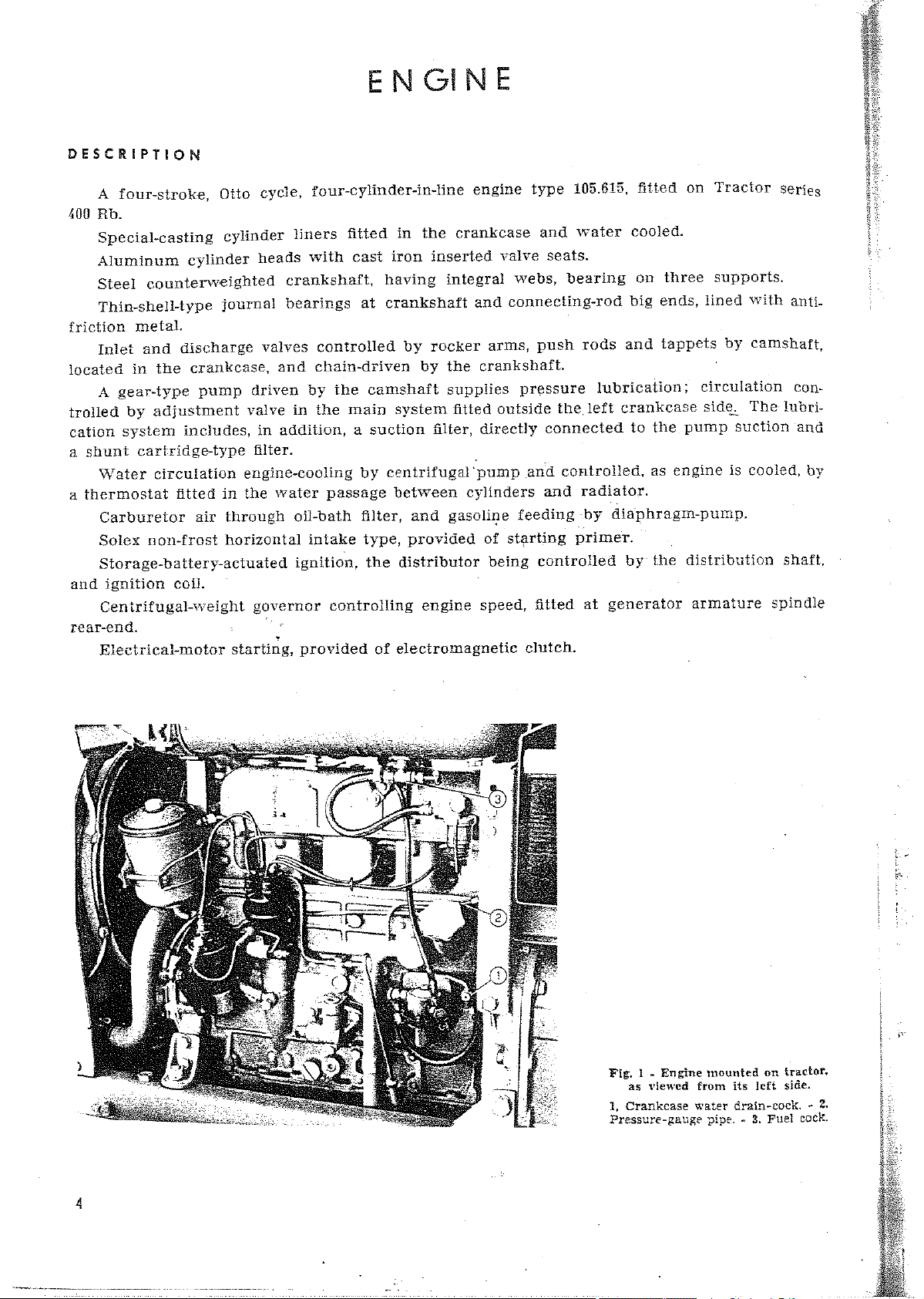

Fig.1-

I.

Pressure-gauge

Engine

as

viewed

Crankcase

mountedoniraolof.

from its

water

pipe.-3.

left

drain-cock.-Z-

Fuel

side.

cock.

4

r

3133.“

9%

§i$wW&vw¢

l

#49”

=

er}.

.

3_,

4,_1,.

-_.,*_~

>

*1

1

i

=

duo.‘

'~..1:é:~=»

,1

»

'

1

1

,

z

e

Remfivcloiengine

We

Suggest

the

and

following

clutch

from

tractor.

proceduretoremove

the

engine-clutch

group

from

tractor‘

Removalofcomponents.

Rat!‘-_

;1Ԥ

_h

‘‘»'

I

_

é

£3-".—1(

.

3

-

_

Y

_

“'15

=;§i<¥7

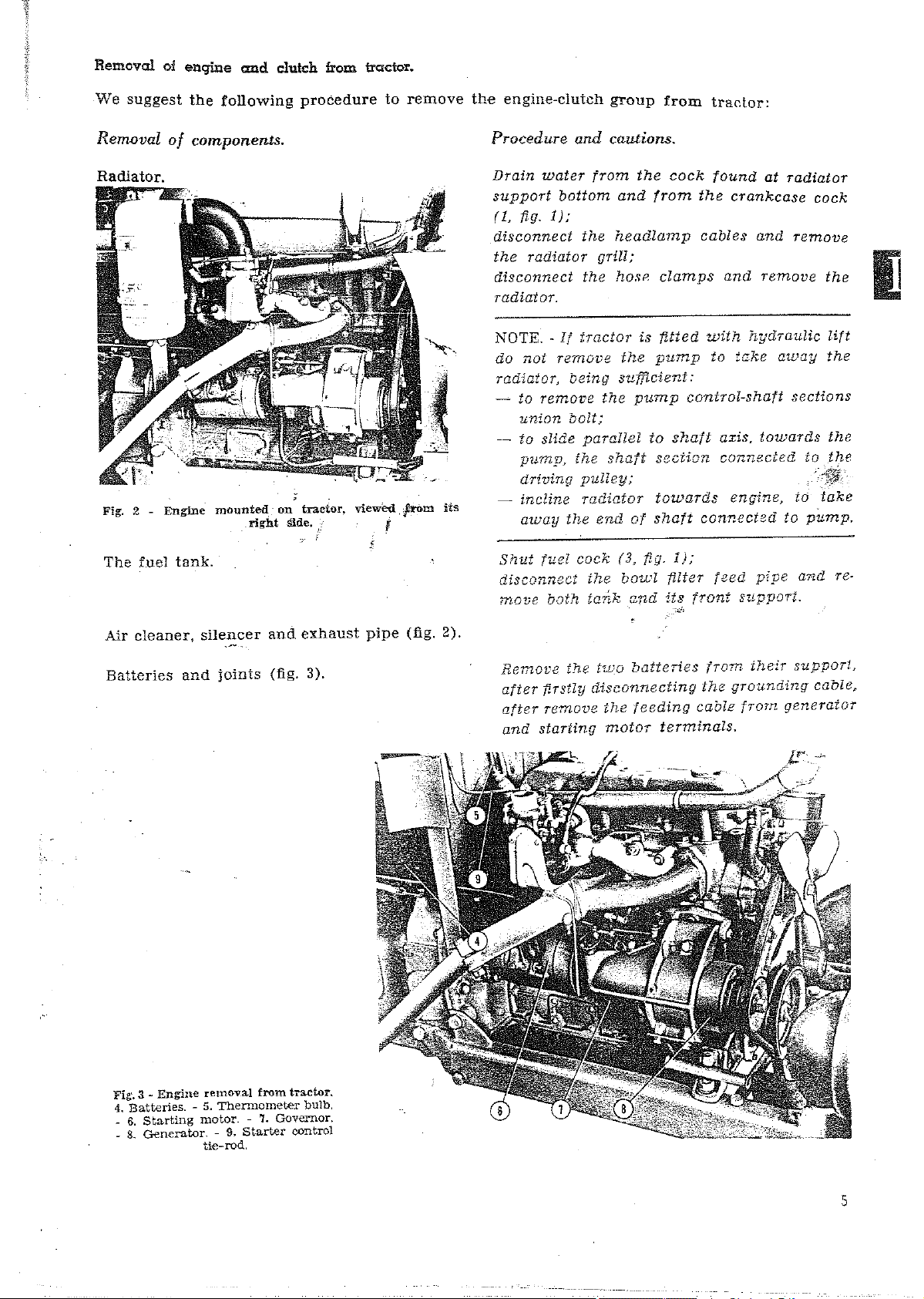

Fig.2-

The

V‘E

fuel

é;

.\‘.

->.=-

,1-‘

~-"4

Engine

tank.

re;

.}f.-"-1-1'.

%___

>‘Ak_

.

-

A

,.,\

-~

1*I.=-:¢:,=21T‘-=T1§T".‘

.::;:,,

v--R

>

:l‘

mo1mtefl_-

_right

_

_

_

"‘

on’

Side.

¢_

5;

M

“M,

tractor,

1

::

'

A

‘V

A

H31

;

"5

f

wj

.

“—:

,

A

viewirdjgrom

E

r.,

,5

‘J;

_;

,

oz‘P

'

if

___fl_,

=‘%1J,;-

-

;.T

5

~%\

‘—‘*-—

}-I

iis

Y

,,

Procedure

Drain

support

(1,

disconnect

the

water

739-

1)!

radiator

dwoonnect

radiator.

We

NOTE.-If

do

not

rociicior,

—

to

remove

amen

——toslzde

pum;9,

e

inciizze

away

7

,,

Shut

fueZ

disconnect

move

and

from

bottom

the

grill;

the

tractor

remove

being

bolt;

pomllei

the

pulfey;

rodioiocr

the

endofshan

——__

cock

the

iacéic

cautions.

the

and

headlamp

home

is

the

sufficient:

the

pump

to

shaft

(3,

fig.

bowl

and

cock

from

the

clamps

fitted

pump

control-shaft

shaft

section

towards

__

__,__,_

E);

fiéier

its

from‘

found

at

crankcase

cables

and

and

remove

Iz.yd1'o~u1ic

io

Zeke

axzs,

towards

connected

engine,

connected

feed

pipe

support.

radiator

Temovg

owcy

sections

ioifle

V

to

to

and

cock

the

lift

the

the

take

_

'~

re-

Air

cleaner,

Batteries

silencer

and

y

joints

and

(fig

exhaust

3),

pipe

(fig.

1“-3

‘“

§>»=3>~=:¢>.-;L.:,@-_»

‘:;*~t@:¢;

~

wzawdl

--*..~_

2).

Remove

after

after

and

’.

0

1

1

'

,

/4‘

¢~-*4

-3-4;;

1'1:

"3-_

‘__‘.‘_,‘,

-~~<-T:;;.=w;=.

=

1

J4

15.».

firsily

remove

stariing

Y!

2

...¢'

'-=3:-I-'

-»~

""t.

.»'‘~'11-V..

~~.-‘J,

”

'

,<»

—~

-H",I

>=

,%

1‘?

'

‘~,..‘.»:j:h}-3‘-;_~:~;

A4

g

‘

Q

C7‘

M-

C1

(E

in

otieries

disconnecting

the

feeding

motor

-

‘

3-v-»~.>w-..._

4*‘

.

Y

Q

the

cable

terminals.

‘<'V

-,~¢,.......,.....\

~

'

'-

__\'-'2_"/1":§'--'¢,>-,-,,-_~"_--=,~,+_u

,.':=2:<..=?~1;'§~":

-:~

V‘.'

$~.p

it

.a~'R&'.-\

-'-"_'-r:‘V

from

grounding

»

‘

'>"i:i;1,‘-1;’,

*2

<1?'~.-

their

from

e

.»

~'

--as

,

generator

1‘

-

V

\

Y

1r_1r.--~“'-

*

*=?*'

.45

support,

cable,

»—

'%IlI—

5-?‘

V

»

-=,.-<.€-

-W,

~-

'<

"

-

Q

7

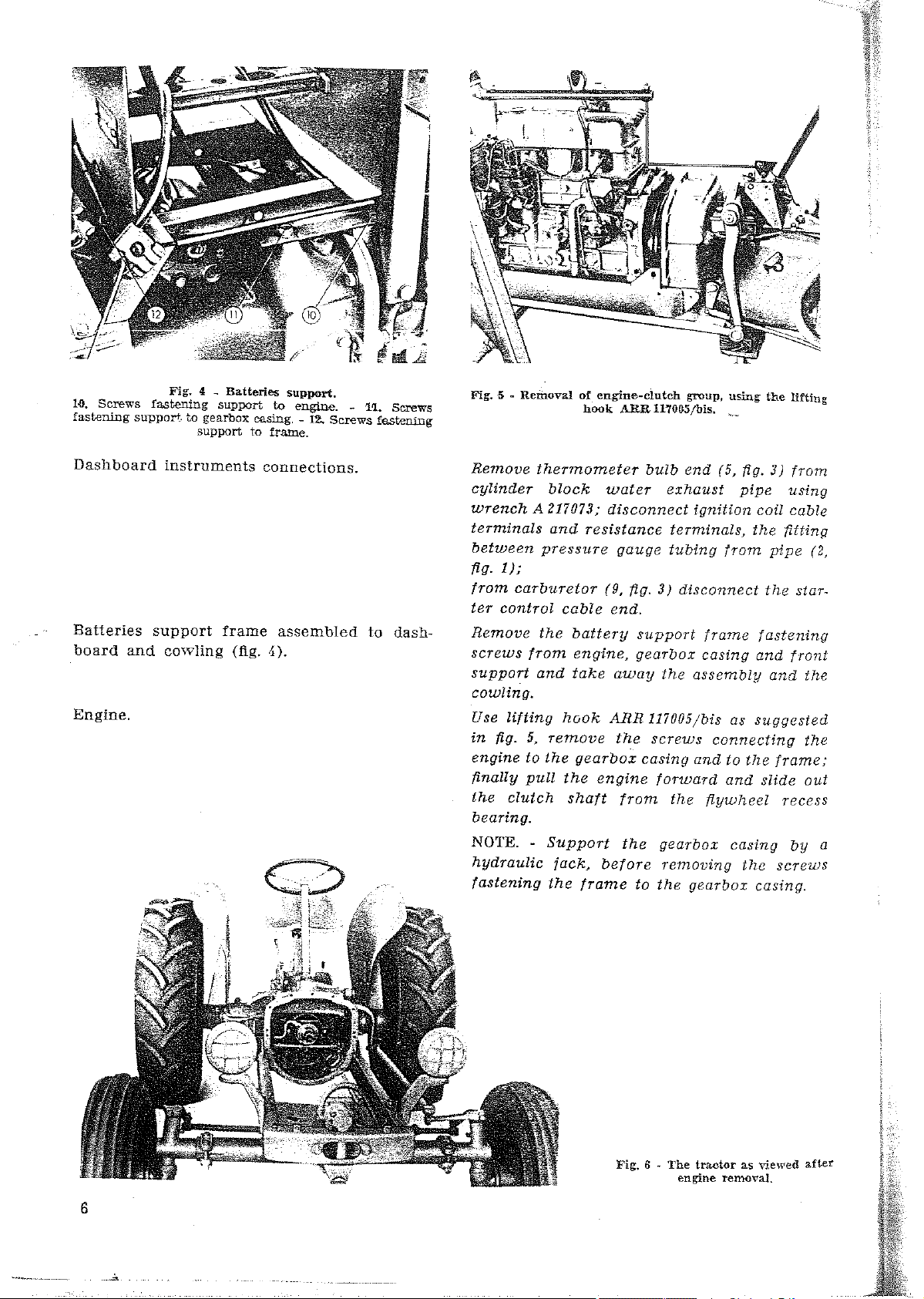

Fig.3-

Engine

4.

Batteries.-5.

-6.Starting

_8.G~enerat;or£ie-_$ta.r!;ex‘

r-=m<>vr»1

motor.-1'.

from

Thermometer

Governor.

tmw.

bulb.

control

0

‘

‘-=-

"

‘‘g-‘I:‘{£,?“-1*

-

:‘_-‘,:"¢,?,*-,5’-~~_-,='~"~1-'-Q'~__'=,

'‘A,‘

~

Wu“.

.

‘I-;:';__

5

J

i'_jj;

._M_c_Wwe*1e

1

F»)

E

_;

5|

.1

1,

r

_

1/:

-1.!

1-0,

Screws

fa.s!;e-ning

support.togearbox

Dashboard

Batteries

board

Engine.

and

Fig.4-

fastening

supporttoframe.

instruments

support

oowling

Batteries

supporttoengine.~11.

support.

casing.-1%

Screws

connections.

frame

(fig.

assembled

4).

to

Screws

tesbening

dash-

-_~_€

.1‘

.,J'~-

s

D

-

,»

-I,»

'1‘\

Fig.5-

Remove

cylinder

wrenchA217073;

terminals

between

fio

from

ter

Remove

screws

support

cowlirtg.

Use

in

enginetothe

finally

the

bearing.

NOTE.-Support

hydraulic

fastening

\-.*-—-*11:

tcv.I/W

-V

_r::i<v

Remove!

thermometer

block

and

pressure

1);

carburetor

control

lifting

fig.

clutch

the

from

and

5,

pull

cable

hook

remove

the

shaft

iack,

the

of’

hook

resistance

battery

engine,

take

gearbox:

frame

“

e

1|-r

"1

-1;“--_

engine-clutch

ARR117085/bis.

bulb

water

disconnect

gauge

(9,

end.

exhaust

terminals,

tubing

fig.3)disconnect

.S'UppOTt

gearbox

away

ARR

engine

before

the

117005/bisassuggested

the

screws

casing

forward

from

the

the

gearbox

removing

to

the

-

>1,‘

r.

"

group,

using

W

end

(5,

ignition

from

frame

casing

assembly

connecting

andtothe

and

flywheel

casing

gearbox

~

-.

P

4

\\\_

the

lifting

fig.3)from

pipe

coil

the

pipe

the

using

cable

fitting

star-

fastening

and

front

and

the

the

frame;

slide

out

recess

by

the

screws

casing.

i”

><

(2,

s

'

a

~.__

1

2

%

i

§

.

Fig,6-

6

._

. .

,

.

_

_

_

,_v,____________________

The

tractorasviewed

engine

removal.

after

‘<.

@w@@e»\M

fii

1:

"iii?

V,

..

_.,.‘,

\,,¢

a

;=

'<~.

/rg<4

1

2

6‘

_\_g__/

\

if!

WM“

W

wt

ll

‘A

A:

A A

Q

F

\LW

I‘

’I4_\

_:.|Lw

‘fir’7,_‘

F~‘m

_

\\

é

I

~

3

\I__J“maMgt

WV]

U_/km“

___?_}

\fifixUh_n_3_Fr1I

:1):_"”(”_’N~Hg

5%,“__.|} |wl“{lMhrJ

_

§M\

‘__Hh|_'

_,kw‘QI‘_|flw3Hl]|1‘|I_i*F_|‘!J

éu

__

J

(I

X

I!;M\\__g’m_“_iM_,FH“r__&

MHMN

W

Q\_

_w“\@_

M,

‘x\HV_I’‘A_

g_x

‘§____h_U__’,

‘_\\x

‘_\__\‘X\\A\‘\‘V_\;

_\

mw

_,

‘‘AmlU‘‘_\_

__

HA,

{PEI}

L

(_f‘CO

k

IV’IWL

?_@\

xxmxm

_1Pl‘LLW“\\

_wV‘“IW

J;

MMy1:

/__VI

//_,III_'

‘Efifan

_‘J /NH”?

WV‘‘///_//_

/// V_‘U¢WV‘V_

W?/_

x

IIJHI

‘

-\vI\i

_

9%

3ii_?

r____:E

ti,_\

\_

_mL”"/__

1;;Kuh6AEDH__Z,Ikx

‘_____‘QVE_

$1

ijilfllirl

\4?ii

j

A

W

___

/g.//_§“J}_

(‘A_

‘

kr__',_Sam/X‘

2

it

____1I?/_WI;_m_’_\,I_

J11_u_1

ll‘

0..

\

__w'_‘m__

zg}I_\%“\:

\\_‘

fl’__“X

_\_\\_

Q.

_

1/

‘Wtv_i

Q

;“_§;_7Vi">’

j

gwww

_H7A_‘

_’‘Ii

/_IW

(/I’,\_,

\1n/3

P///_f)_

‘_____‘‘_KN\“Q\

‘ow.

x_if

_”_’//W/

/\7V\\é(VW\

V

!!!!S‘__‘__VJ’’O_]W\_\\_VX‘‘ ‘

0%"

[UI/‘J1

Ii‘

_a\Q£f__>\H3‘_,/

‘ ‘

3_It_44)

)‘_‘

‘II

-_fiV\kWWn_‘N__\k

AL”

1‘A

t

iW_T;I,I_

T

“E7

{é

H_

mu_fl

V/5

(‘J

_

_

17,,’xI__j_(?,%+

%

//_

4444

__i|__!__r_!|i_|!

J

i

I//H1:/,”t,:h‘/L1

I>/w‘x2_\_~_\__\_\\ i

_@

“///L_‘J

:H','’i,},

'iimk

A“

P

hm

Lmvm

‘__

’

F:_€__”__fM!l_m__:v||%)__

n

UM]

map

WQ_j%

vjjlm-.

_f___

v

____

iI\ifI

flr__

/I

W5

EH

"\__\M,

A

1

W

@]p

I_EL

w

iii

__qu"__.‘mm.m4:_‘r_h[_‘}HWH‘_M_

_¢Aj_0

IV‘>_Y_£§___;§_hi_i§A_{3MfiA,d‘J5u‘M%z§§§

“Pu

mi“

h‘>V1%‘___\IIII’NHI__(AkwK

may

M‘

>

}Y’___Q"‘i/V/////J‘‘

\V‘

‘

rk_‘____

___[

/y_’m/7/m'm1~’m‘!/‘

WI‘

VVMVVvV’PWVH{Z

_>_VNMMHUH_‘_wH“w%%Wuvb“m¢"UH

K\\‘_‘\__V‘_,U‘I/

,///V)_

V‘/_fl/V"?/__Hh‘

m_TJ

Q

C___

‘

iv‘

\“__.

\_>_,m\'\‘__v

llkiililllirylvhv

I_‘1Uh___

_'|___4_

.1,‘‘K_vV_

5W__wH_

#

‘__}]l___

C\{

___

__|y_LflH/

|

Q/_A_//Z

_fl

X‘

‘ta

V

i

~

F

ha

I

7

M

_

_m

_G

R

I

H

g

n

d

3

a

U

C

50

1

F

O

"hm

5

S

5

1

1

f_

gn

E

-1

S

6

H

E

E

R

G

I

/

I

l

/

U

U

/M

‘J

,J_

/

/

i

/:

/'

7

Q

/

/

/

/W

_/

H

/

/,

flaw_@:>_%

_

Mp

___

mi

_un_‘_

J

‘3‘iii:

I

ii?!‘

WT

W

__r_’_AdrH;_”H‘,_gvruv//I//fihhVpm__$%J\

{_;_;

/WM_“__i__[WIk

K‘MSway//J/Vy/VwML_/,

Vhpmmy

/£1

//J},

f L?

‘mam,

“_

llIii

\

\

_\

’/IW

I

I

___I\

fI4”

\

I

//7

I

g

u_%_w

_

_m

'II‘

I

(,\

/

\

_VI/

1/

imfim

.

/ii

(___

EL

n

“a

“E

\_

/V

E”

A

RE

mm

m_

j

S)‘

WW

VHiM

,1”

_

IJ”1hW;AH"____

V

'35

‘

_‘J_;II/I‘7M“__

\|_|ad‘. &V_

(I’A_?ukri

_7f

i

_"_h_*¢(

”W_@“\\

_

‘&M“&’

:_-v__

:'_-W‘i

_

_I.__

‘_§‘

{$1

“\“\\\%_/’Ifi

h

L2’

anafifi

EIF‘’

_KV\HIE;‘‘£n“%.“

'

A

_'

‘

§\“‘Mv‘

‘*“Ii‘.\‘

vw_‘|‘__'!X|_!___‘_‘_\‘\

‘

A

_

J“

£3

gm

“Q1(FVOL/H/MT‘

£.\'/

_uu//J’/AyjE‘_

mm;

Em’J//1

‘§_i_~‘~i

F}

\‘_JJ /rU

__‘v

‘E

_‘“r‘_".¢

$5-'_¢\MWW\~W_

Jif

§,‘%HO“I(P_"

‘

flwl3/1

_>‘

Mb“._\3P

_______

EV

_m_

Q

a

¥“_‘Z/#4;

“____A

AA

/A;/////%

'_IfII‘uW‘I‘U‘i‘W’.¢“‘u%./‘X

‘éflfifl

W

H

‘IQ‘_‘I-“I

:...:

g

AA

A

A

§%r%__m

_fl]g

_

I

‘Ci

_"._

_

N

‘;”L___

_

PL,__VVW\/‘

’if‘ii?

Q

J_Hmflflw/,~__H_/_

F

__

_HTH

///_1_/K/I

(/’/(/_mlfiflf/i/,W/My__N

my

V

___‘’///////VV__/_I__l_

.¢ \Xa\

_W__

V

Am:

my

\

\

“Yii

/FZ

aw

“Ii

\¢{

{

‘

%__

____

m______E__

\

fi____~

_W\J\

IE

L7‘llV_

‘_/_//p////"//

‘I‘I__

__

1|_“_\_§a?|:

“i\\

m___wWM“_F___‘

‘Q

m

‘RItw

,//)w/R\\_,

‘Q*fl%’“iKm_

V’/_

A)\A

/$M“_x.§%

(H

/I‘S/1”

‘I-wm“\.\

/\xx_/I

\

'.~.“

.“.;‘

I

‘\‘'

Q.‘

_'

_%~__\_%

i

we

_

3

__I///,

‘ ‘

[III

/‘‘

DAiv

I//‘

xx

5QM

‘I

I

h

_

F

<

>‘

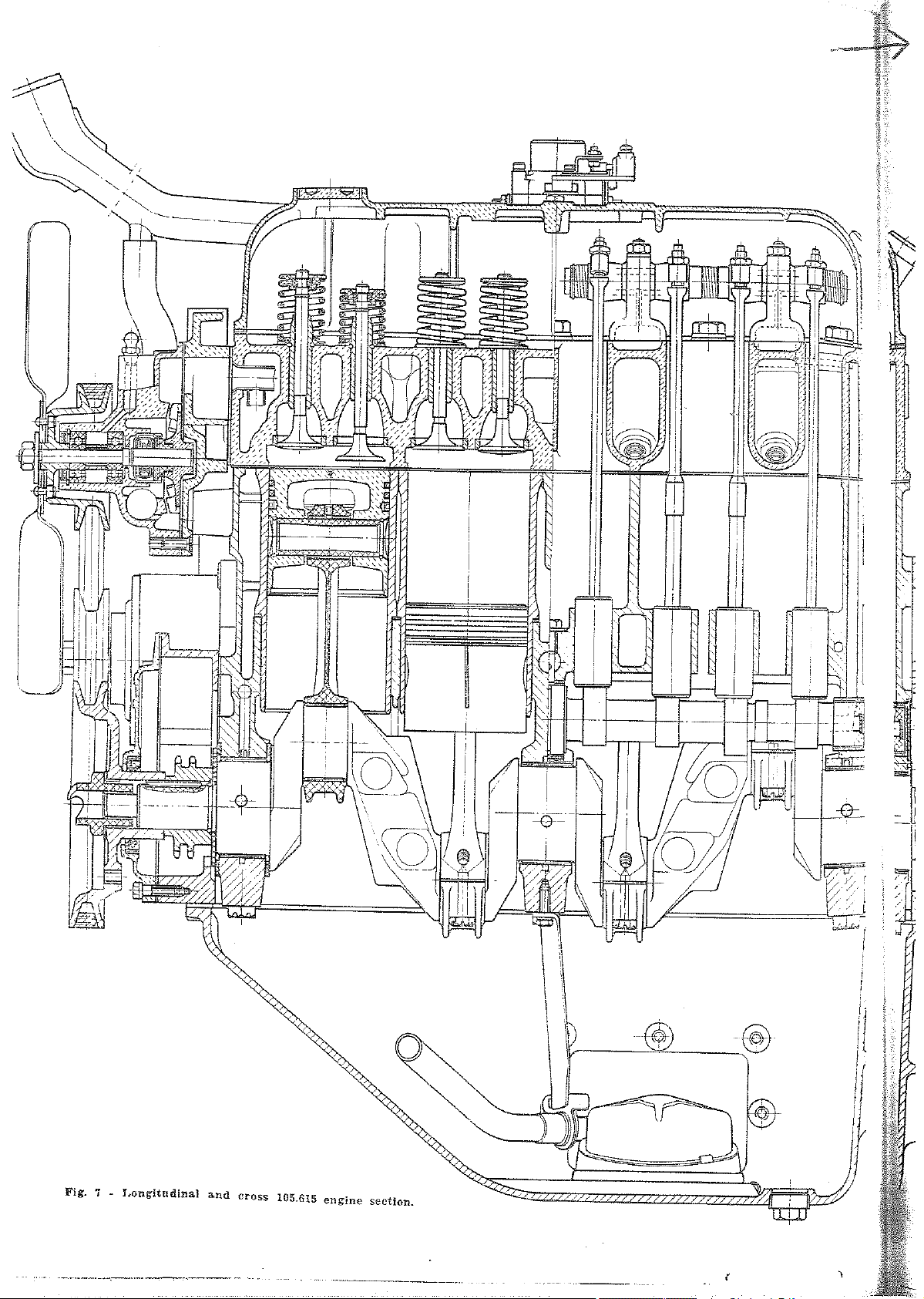

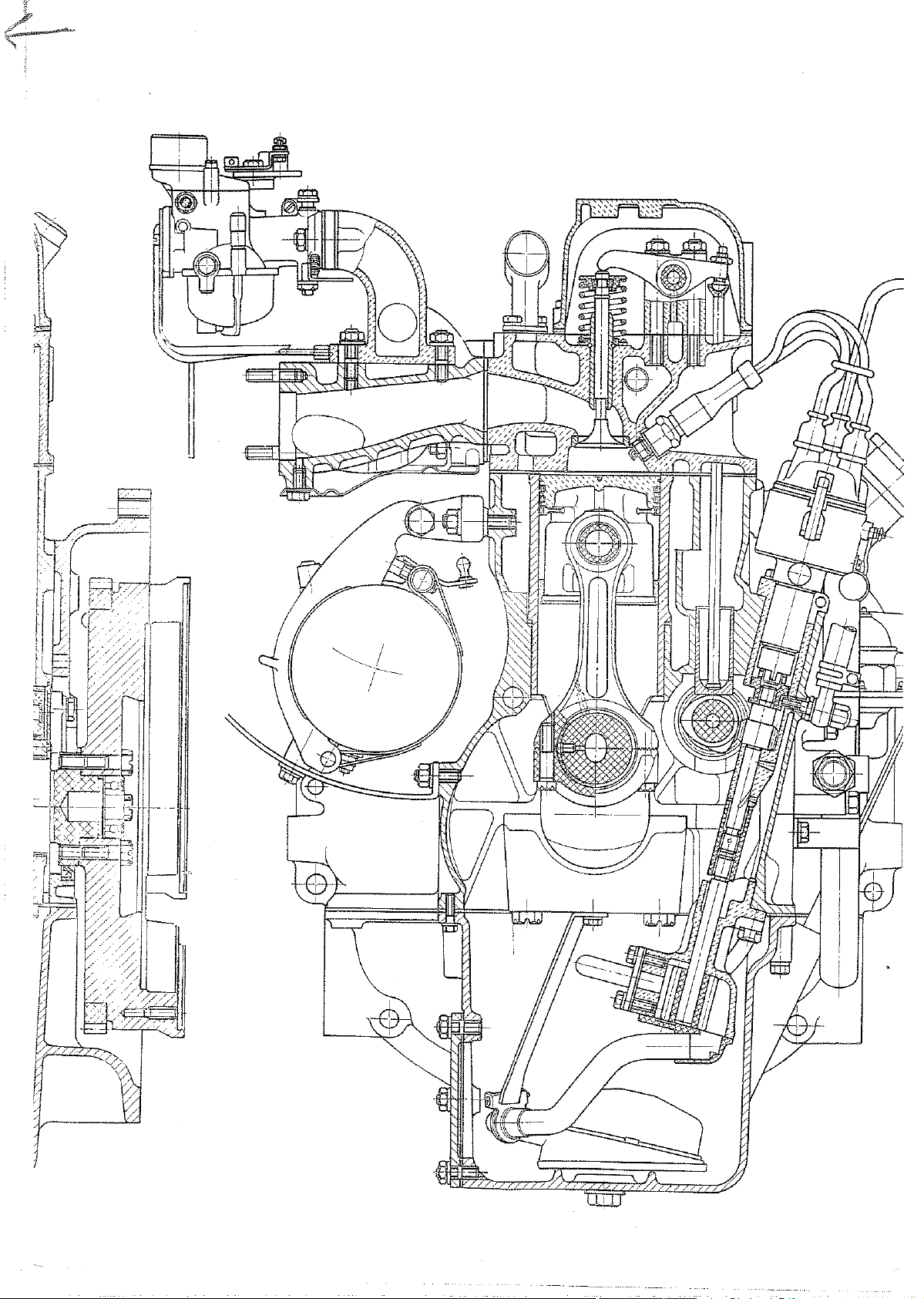

Engine

clamps

-

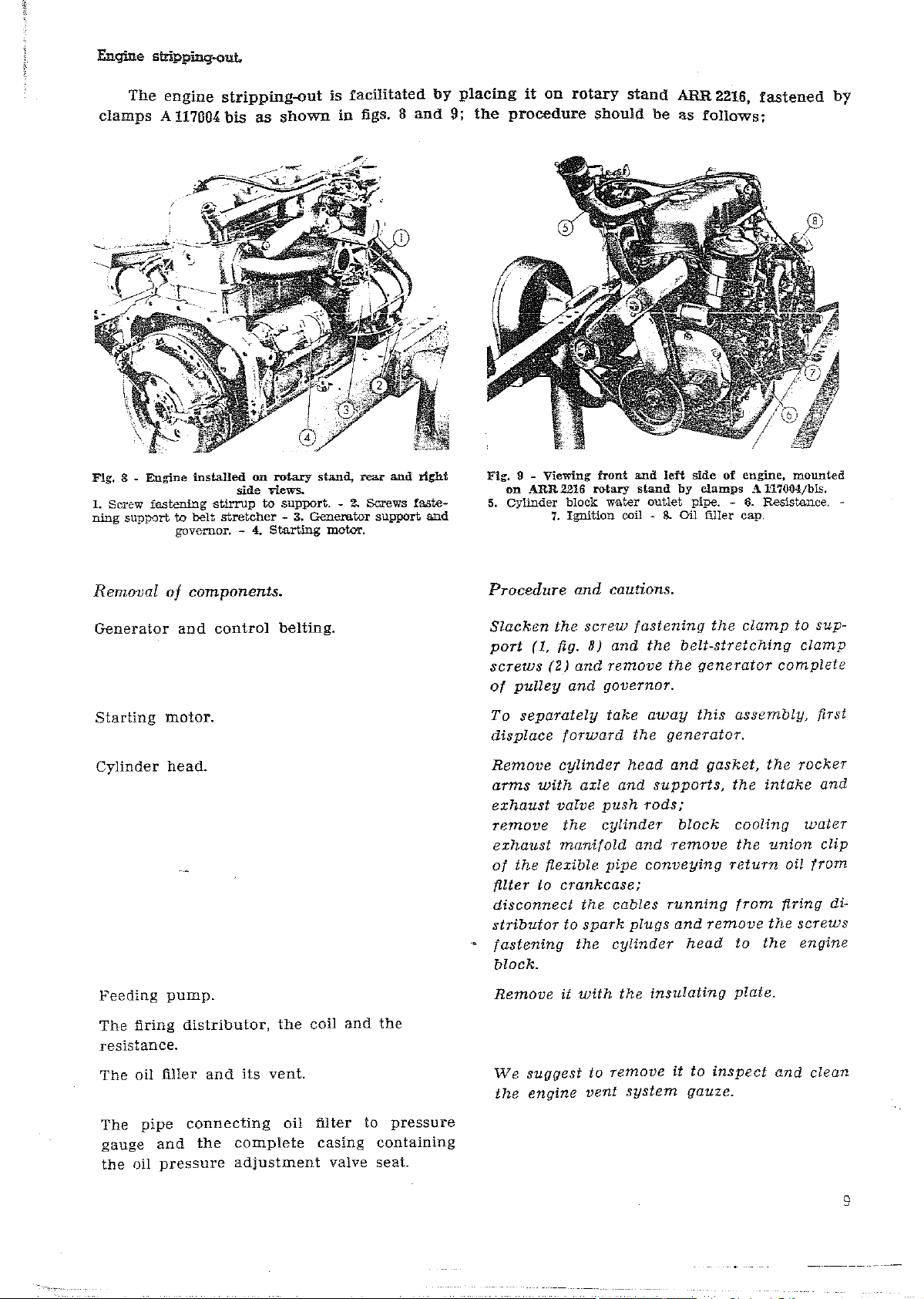

Fig.8-

1.

ning

stripping-out,

The

engine

A117BB4

/4’»1xyv

I

_

"

;_.

.

Screw

or

T.'*

..

P

-

-»-

Y

.

\'

I.

ogm

v;

Q--»I.H)%i‘\

Engine

fastening

supporttobelt

governor.-4.

strippingout

bzsasshown

_-_

'‘..

-e

*

~~1'fi~.~

‘re;-f=~‘

~

v

.57...,._

_

.1~

-

'\““.%

i

L

<5-

installedonrotary

stirruptosupport.-2.

stretcher-3.

.

. I

'

=.~r4q‘g_"‘".

i

23*.;\

"

'1.-.;>*»»-»

\

.

.

V.

J

X

2%,‘?

side

views.

Starting

is

-'5-‘=1:~;

‘

.£‘

~31

ii

iii;.“

‘

1’

-§-'">=:\~.--'

-<=*

-..~-

.3

T1‘K

stand,

Generator

motor.

facilitated

1n

figs.8and

.»

-'7-'

"

:

*

%‘i2’

A‘

-~

_=.1a=1~r-

-H_‘

-Fl’!I

rear

Screws

support

\

‘

and

by

;~-_.-

2*

-!.

4.‘.

right

(aste-

and

placing

9,

,

'1.

"

the

.

»

.

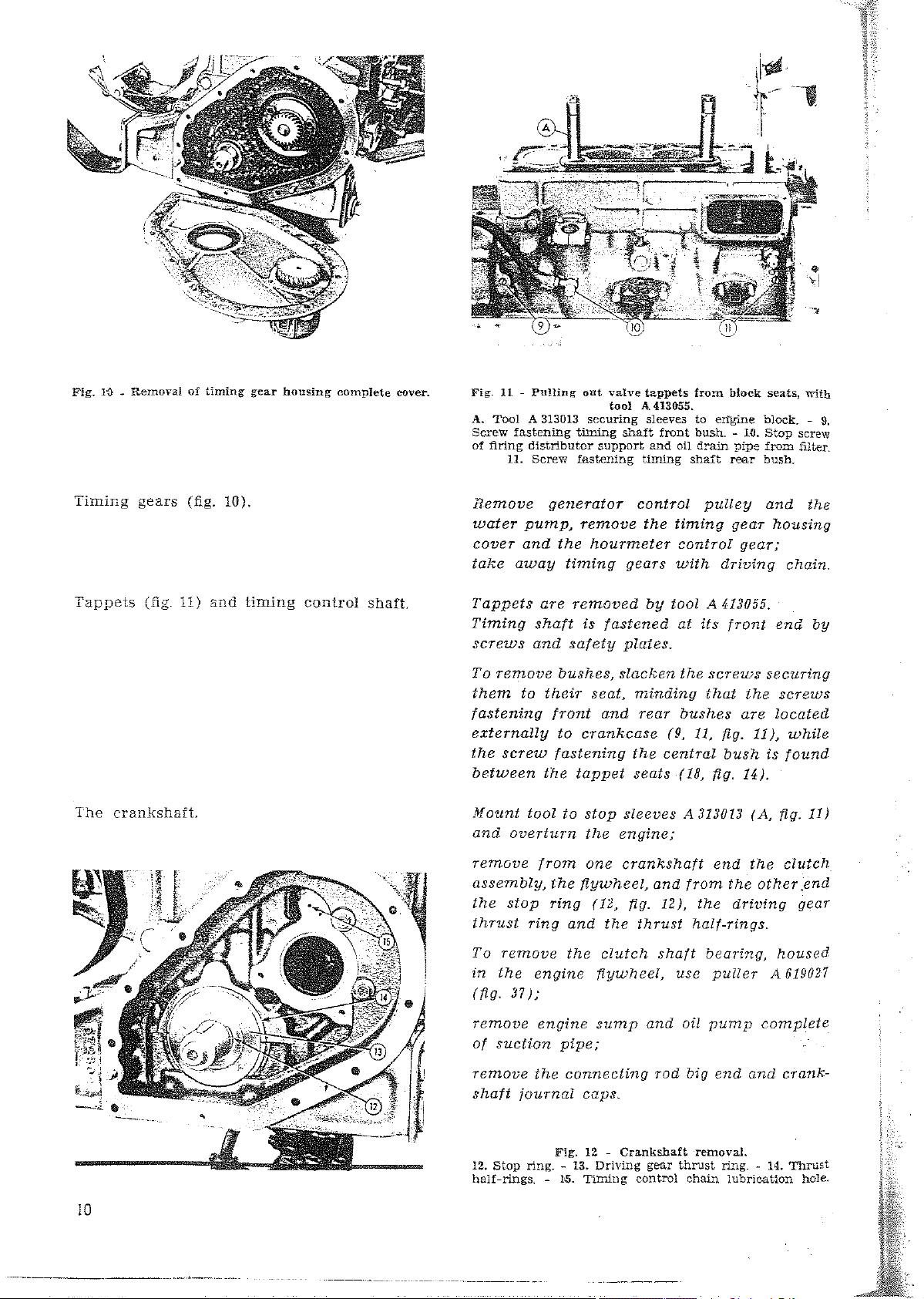

Fig.9-

5.

it

on

procedure

"~;fl.n

6

/

..-,.-As_~_.

.'

z__'V

-

w

.

‘W’

.-_

5.7

""‘z~‘.l1:4f_~.‘

.'

1:

A

~

.

Viewing

on

ARR2216

Cylinder

block

7.

Ignition

rotary

stand

should

---.~N>_.

'

\

'

-

‘

“

_ 3

'-—

*%:;’<-?;-‘=‘-**

9.»

..

._:--

_~_..=~,;_,.,.-\,

“Q’.’%~;;i;;.~i;;}Zv1.;7f?

1:1?

. .e~“~‘=

2'»

.-.

:“'»‘*=‘->"~

~‘,--:~~:~.;

\_._

-“Ty

front

anti

rotary

stanébyclamps

water

coil-8.

Z‘.“‘‘

ARR2215,

beasfollows:

.;.—._—;<.:.---~~

9»,.§-,"T;*?.1'~‘7

“

If

'1

C

}

1-.

V

V_~Q».

oar».

J\-~____

vg.‘,>__:v~

V.»

.

left

outlet

“'7’?F''k/>

Oil

<?;‘=‘9-:»$1Q~‘»z‘4"

“.5

,1,_“\\\¢3-

Q

’

'

14,

..\'

~:a.~1

._»

'5-*2-5%-:;~:fi~

sideofengine,

pipe.-6.

filler

fastened

.1

3

‘

7

--h

W

V‘

t

‘-‘-=‘~=-;'.,

>

2

1;-4»

-

K’

.4?".

=

"

.

(*3\x

‘.17

1/

,

»_-..~

A117004/bis.

Resistance.

cap.

by

\\

(Ti

ow

av

I‘

-

_;{

-'

.1.

_-‘

“K

molmtefi

~

Removal

Generator

Starting

Cylinder

Feeding

The

firing

resistance.

of

components.

and

control

motor.

head.

pump.

distributor,

belting.

the

coil

and

the

Procedure

Slacker:

port

screws

of

pulley

To

separately

displace

Remove

arms

exhaust

remove

exhaust

of

the

filter

disconnect

stributor

fastening

the

(I,

fig.

(2)

forward

cylinder

with

valve

the

manifold

flexible

to

crankcase;

to

and

screw

and

and

axle

the

spark

the

block.

Removeitwith

cauiions.

B)

and

remove

governor.

take

and

push

cylinder

pipe

cables

cylinder

the

fastening

the

the

away

the

generator.

head

and

supports,

rods;

and

remove

conveying

running

plugs

insulating

the

clamp

belt-stretching

generator

this

assembly,

gasket,

the

block

cooling

the

return

from

and

remove

head

to

plate.

to

complete

the

rocker

intake

union

oil

firing

the

screws

the

sup-

clamp

first

and

water

clip

from

di-

engine

The

The

gauge

the

oil

oil

filler

pipe

and

pressure

and

its

connecting

the

complete

adiustment

vent.

oi!

filter

casing

valve

to

pressure

containing

seat.

We

suggesttoremoveitto

the

engine

vent

system

inspect

gauze.

and

clean

9

A.

i

.

i

<

"

~‘

_

,'

e/’.'

3

I

i54@‘:7-—’§}_<,a-,,

-‘

'>..‘‘,=‘-"'

-

gr

.\_:_

#1.

~-;,;,=

\

\;:,,‘&_~:

,

..

~

_.;:;.,,

Y

*

c

"5'

12:1-".»‘*~’;>'

=~*'1;.+

'j-_-r;éé.2,_,Q~=,;:

-x

\

‘_

-."

r

41-1»

-,-1')-»,'_-.~

~.e~~:

\;<~‘~:>._fl,..~,_,».,.i;;_,..-

_

,-.

~-

-*‘.w-

*1;

M

"-,.

=§‘.'~,“?<-;.--

-

».,(.¢-'»'~,;-~'»-W‘.

~-

-X§y>

1

."t,~_~‘

v

.,

.1'».'\;Mu,.r1

‘a_1

a

-.

.-15

Le

,_“:vi:,vd_T‘,,wr“_:;r_

=-.§,_.»;.

1»

..-

._

l

‘

-=2»

'

-~~-

'9

'_'»

wfl,

.

311

£-ea

E

g,§!‘;f

»-"""

ie

We

._

‘I

~_

i

;

1‘

A4-

,.1c

,V»f

K

f»:

T’;

—¢

.'V

-Ki-3-'~-,.1-.2

,

-:1:-~.-_~1-

.

~.-~*~=-====:5-‘~::"*'

:

‘Ar-»'i~-‘1L.;Y='r\~iI}~i.e{'

}

.

'

.;;_~e

;:,'.

.-

i;

‘*.-"o

"

i

~

~

(75)

V

,-

I

>1

_.;1/§.34___{_

,-.-'—;_~,.,

,¢.1=..i*=-@.5~1~:'<’K..‘.'.,'»=ie=.;-2.‘;=1"v

j

11*‘

w

10

'\_/

‘

_--,:~_+-

='1~':»'_‘'___

'_‘l"~"»r:--»§.~A'

k

.

,.*w<1=ee,1w'a;r~'»=-'-'>.-,

,—

V~.‘.._

1

f“'Y}*;<"]‘,§‘"T:.*‘1{'I-*_L'*

~

'

,$@M

2

_

_,_~‘at.._-.W.

/5*)’

\J,

_

K\_

I

-;'3R

*

'.‘;'

-7»

,E

‘.“‘

l

‘,Lv;'§_

"

r

Q

ti

'

5

2

-(

Fig.19-

Timing

Tappets

The

R-emc-valoftiming

gears

(fig.

(fig.

ll)

Crankshaft.

and

19).

gear

timing

housing

control

complete

shaft.

cove-r.

Fig.11~

A.

Tool

Screw

fastening

of

firing

11.

Remove

water

cover

take

pump,

and

away

Tappets

Timing

screws

To

remove

them

to

fastening

externally

the

screw

between

Mount

and

overturn

Pulling

A313013

out

securing

timing

distributor

Screw

support

fastening

generator

remove

the

hourrrzeter

timing

are

removed

shaft

and

is

safety

fastened

bushes,

their

seat,

front

to

crankcase

and

fastening

the

iappei

tooltostop

the

valve

teppets

tool

A-$13055.

sleevestoengine

shaft

front

and

timing

control

the

gears

by

plates.

slacken

minding

rear

{9,

the

central

seats

sleeves

engine;

from

block

block.-9,

bush.-10.

oil

drain

shaft

pipe

rear

Stop

from

bush.

pulley

timing

control

with

gear

gear;

driving

toolA413055.

at

its

front

the

screws

that

the

bushes

11,

fig.

are

II),

bushisfound

(18,

fig.

14).

A3136l3

(A,

seats,

with

screw

filter.

and

the

housing

chain.

"

and

securing

screws

located

while

fig.

11)

by

'1?‘

L-15.15

‘E151;

2,

-

I'3

IU

.,..____‘

remove

assembly,

the

$33;

H

=

1

A

I

.

-a":'

,1?

1.1%

4

v

thrust

\

.-.~;':1-*“”'I...€5'_'

-

‘*5

41"

-5:“

"5"

.5'21‘???<‘l5'=':*“.T"?-”I"'§i.¢_-a;;’?.

"

=

i‘

V“-¥-7

g

To

in

(fiO-

remove

w

I“*,_

k

.

‘i

r'l

r

3

-

U}

»\_d_~_’_

A

_

~

f

....

..

"'1-"‘

._

'1»‘1

"

-

:

‘Y

ll.

4%‘,

,

if‘

<v»

‘

Tn

r-z::~'

4'»-32:1

L.‘

IA

.

\

.‘—

"'~’-"'

0

‘

~-

y

___,'.

*

=

,

,,._,___..,¢.__.-..

J:

,

A

W»-‘'I

..

'-

I

P""=~§-._

‘

.

_

i

___

of

remove

shaft

12.

ha1f—rings,-15.

_.

_.___.____.

stop

remove

the

37);

suction

journal

Stop

____Vi.Y

from

the

flywheel,

ring

ring

and

the

engine

engine

pipe;

the

connecting

Fig.12-

ring.-13.

one

(12,

the

clutch

flywheel,

sump

caps.

Driving

Timing

,,.

.,..___

crankshaft

and

fig.

12),

thrust

shaft

use

and

oil

rod

Crankshaft

gear

thrust

control

_____.

endvthe

from

the

the

driving

half-rings.

bearing,

puller

pump

big

end

removal.

ring.-M.

chain

lubrication

clutch

otherend

housed

A619027

complete

and

crank-

Thrust

gear

hole-

>3

E

5

1.

M,»

'

§g,jmi;1@115~

-,

K

=>-'4"

=1-5*“

,Ax

~»;‘€‘Zi=w»i1

_

“W

......._e,_____________,_,__,_______v_

6'

e.

_

-"*--L-._//'7

5

’

_

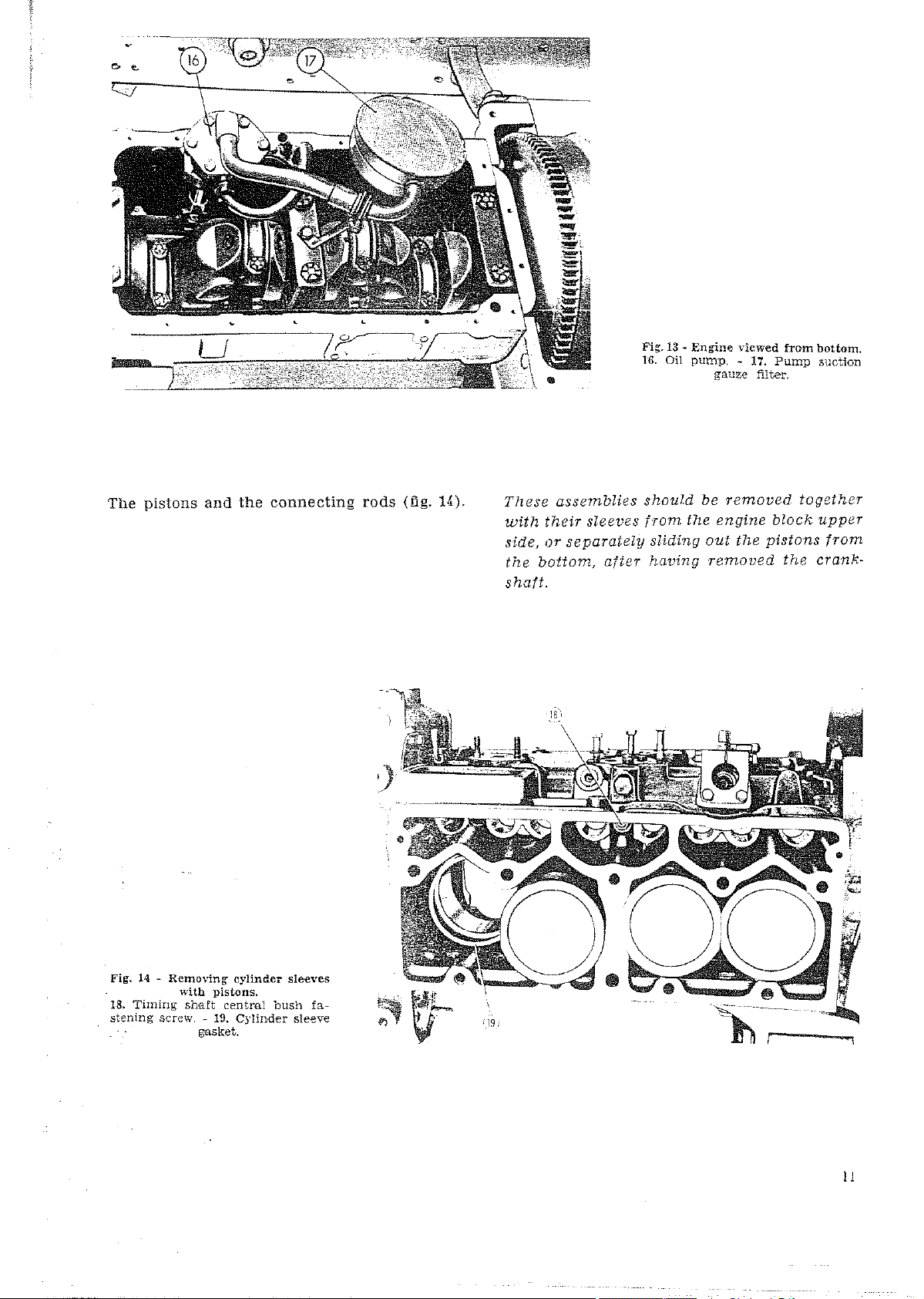

The

Fig.14-

-

13

Timing

stening

.'5

~

rs_______

pistons

Ren_1oving

__W1th

Shaft

screw-19.

*"

I

f

and

pistons.

central

gasket.

.»,

.,

the

connecting

cylinder

Cylinder

""”""

,

‘

mush

‘

sleeves

£a-

sleeve

0 19

/C/I

._

.

rods

}‘

1

L,

¢>

F'

-'

(fig.

1

K14»

~'1=““1,:_‘

°

%::{;_j

W

Y1:

“R

,

‘

_

#7;

;'

,‘

~

,,.,.,,‘

I

"

14).

“,._v

“___.<7—

~__:_e

Ms».

_‘.:2:,_

_@

;?_;§fi§T1C,“;,,~3‘,~I5'

I

.,

1“

--

s.

@

R

V

19

'

These

with

side,

the

shaft.

'.\\;,5

_

q

.

_

_

assemblies

their

01'

separately

bottom,

J5."

~

‘V,’

M

sleeves

;'

;,,

s

Fig.

16-

should

from

after

___

*1

3%!

_

':7“§ =f~:‘;:‘1‘F‘

‘

‘

-7

g

"""

_

13:-Engine

011

sliding

having

_

&§;~.:]

s

Q

viewed

pump.~1'1.

gauze

filter.

be

removed

the

engine

out

the

removed

.~

‘T

*

.

E

-=1-‘-‘

_W_.,,

'~*

E

from

Pump

block

pistons

the

~Q_"

=

_

‘

Q

bottom.

suction

together

upper

from

crank-

-

s

'

.

§’:

‘

Q

Q

\

;:...¢1=

s

fie

i

’

»

F

.

‘-4

'

~

2

.

I

1

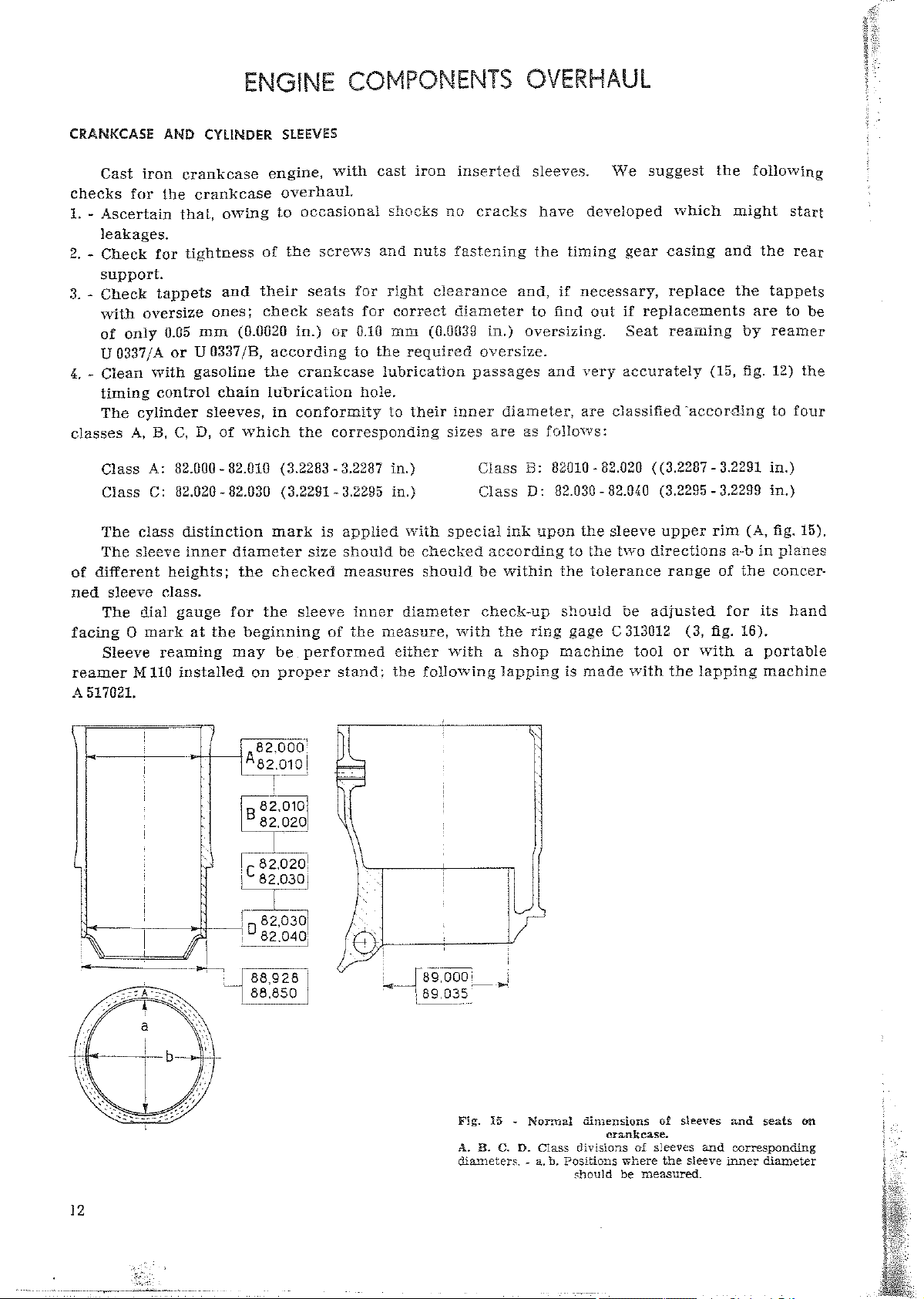

ENGENE

COMPQNENTS

OVERHAUL

._-34.1.

éssieiaiifisv

1

‘é

>

CRANKCASE

Cast

checks

1.-Ascertain

for

AND

1;-On

lhe

CYLINDER

crankcase

crankcase

that,

owing

engine,

leakages.

2.~Check

for

tightness

of

support.

3.-Check

with

of

U033?/A

4.~Clean

timing

The

tappets

oversize

only

with

control

cylinder

and

their

0.05

or

ones;

mm

H0337/B,

gasoline

(E].062E1

chain

check

the

lubrication

sleeves,inconformity

classesA,B,C,D,ofwhich

Class

Class

The

The

of

different

ned

The

facing

Sleeve

reamer

A

517821.

class

sleeve

sleeve

dial

O

mark

M118

A:

82.009-82.818

C:

82.020-82.339

distinction

inner

heights;

class.

gauge

at

reaming

installed

diameter

the

for

the

may

the

beginning

on

SLEEVES

with

overhaul-

to

occasional

the

screws

seats

for

seats

in.)

or

6.18

according

to

crankcase

the

corresponding

(32283-3.2287

(32291-3.2295

mark

checked

sleeve

be

performed

proper

is

size

applied

should

measures

inner

of

the

stand;

cast

shocks

and

right

for

correct

mm

the

lubrication

hole.

to

in.)

in.)

he

diameter

measure,

either

the

iron

no

nuts

clearance

(0.GEl39

required

their

sizes

with

special

checked

should

with

following

inserted

CI‘ElC1~1S

fastening

diameter

in.)

oversize.

passages

inner

are

Class

Class

according

be

check-up

with

the

a

lapping

sleeves.

have

the

We

developed

timing

ancl,ifnecessary,

to

find

out

oversizing.

and

very

diameter,

as

B:

D:

ink

Within

are

follows:

82818-82.020

82.930-82.940

upon

the

to

the

the

tolerance

sleeve

should

ring

gage

shop

machine

is

made

suggest

gear

casing

replace

if

replacements

Seat

reaming

accurately

which

the

and

(15,

following

might

the

the

tappets

aretobe

by

fig.

start

rear

reamer

12)

the

classified"accorel.ingtofour

((3.228?-3.2291

(32295-3.2299

upper

two

directions

range

be

adjusted

($313612

tool

or

With

the

rim

of

(3,

fig.

With.aportable

lapping

in.)

in.)

(A,

fig.

a-binplanes

the

concer-

for

its

hand

16).

machine

15).

I2

F‘

s

.

/

.

\.

1

.,

s s

,

-;.-.:A»~-

“Iii;

‘:‘“,"~"'

K

.1

V

‘I\

1

~»---»=

\

\\

.

'.

;

pp/"F

r—""'*_-"'-""""-

'

B2,ooo"

’°*a2.o1oi

"if"?

Bait?‘

s2,o20,

$582.05?!

1

a2.0a0'

[

lg,

82,055:

s2.o4o.

~~

§_j

~

asses

|

55,650

._.__.____.._..~_

\.

V

%

‘

'

I“

J

V

.~‘i

'

2

§_‘n_Fs2§ToW__»,_§

1

'

.

289.035

1-?“

...

Fig.

A.B.£3.D.Class

diameters.-2..b.Positions

T;

1

’

I5-Normal

dimensions

crankcase.

divisionsofsleeves

shouldbemeasured.

where

oi

the

sleeves

sleeve

and

and

corresponding

inner

seats

on

diameter

s,‘

x

t.

g..;..

s

'w2z<:.'.-

§s.‘,.

/.=..>¢,

.

V

--v-~-»_--...,..,-.-.-

.,.7

"$6.;-1.1‘.

_-;;..¢s;......._......__.

1

‘-‘:1

~'.'.*.»!

_

> >

I I>‘

_‘

P

.

The

mxty:

for

mended

Sleeve

tolerance

Between

bottom,

should

aseemblingsfcylinder

l1'1Sl;€ll1C8,aclassBpiston

not

only

for

standard

reaming

should

be

shouldbeaccording

the

and

normally

be

ascertained.

cylinder

to

sleeve

the

pin

sleeve-piston

should

pistons,

but

also

relatedtopiston

the

classA,B,C,D

and

the

maximum

axis

(F,

fig.

.=._

-

"-(wt

Y-:~-.=r:.

if

1-I4

~=.r'

=1:

1

V

_

~

':

-.

-‘~.“""':=;.

1;‘

~21/=

-’P;=;»-.

.,,;-~=.

¢..

=,.

».~-_<

fin

.

J‘

.

—.

":‘.1_.:_'§'.,_'i~,~—.'_

'4'-'\u_

1.1

1;;

~

e

/.1&f:;.7_

‘

,v.-

_

._,.

_..’:1c,,‘l,..

I

-T§11I~

r=’72A~§-I}-'>‘.':.

.<,i_<-4,

,mm

-'7’

1”:

-~V--

'=J;1~';E

.f.

should

be

oversizing

always

assembledtoa

for

the

oversized

(see

which

piston

41),aclearance

>.

'.'4-;

=,

'?~,-:1>7',»

.>:=..'-,_

..-

‘rec-.

,

lr-'

"

"

>.'-{)1-="

;;=-<'-¢»"v-,-'<.~.,.-1

§<

»

"~*Z‘*2

.1'

.

"

*/'

._.'-1"

~-

-

._

,

take

place

classBsleeve,

tableonpage

is

of

0.81

diameter,

of

ll.B5~0.87

accordingto@1355

this

ones.

42),

mm

(0.060-4

measuredatpiston

mm

(U.ilU2B~D.0£}23

and

in.).

being

the

unjfog-

remm-

W01-king

skirt

in.)

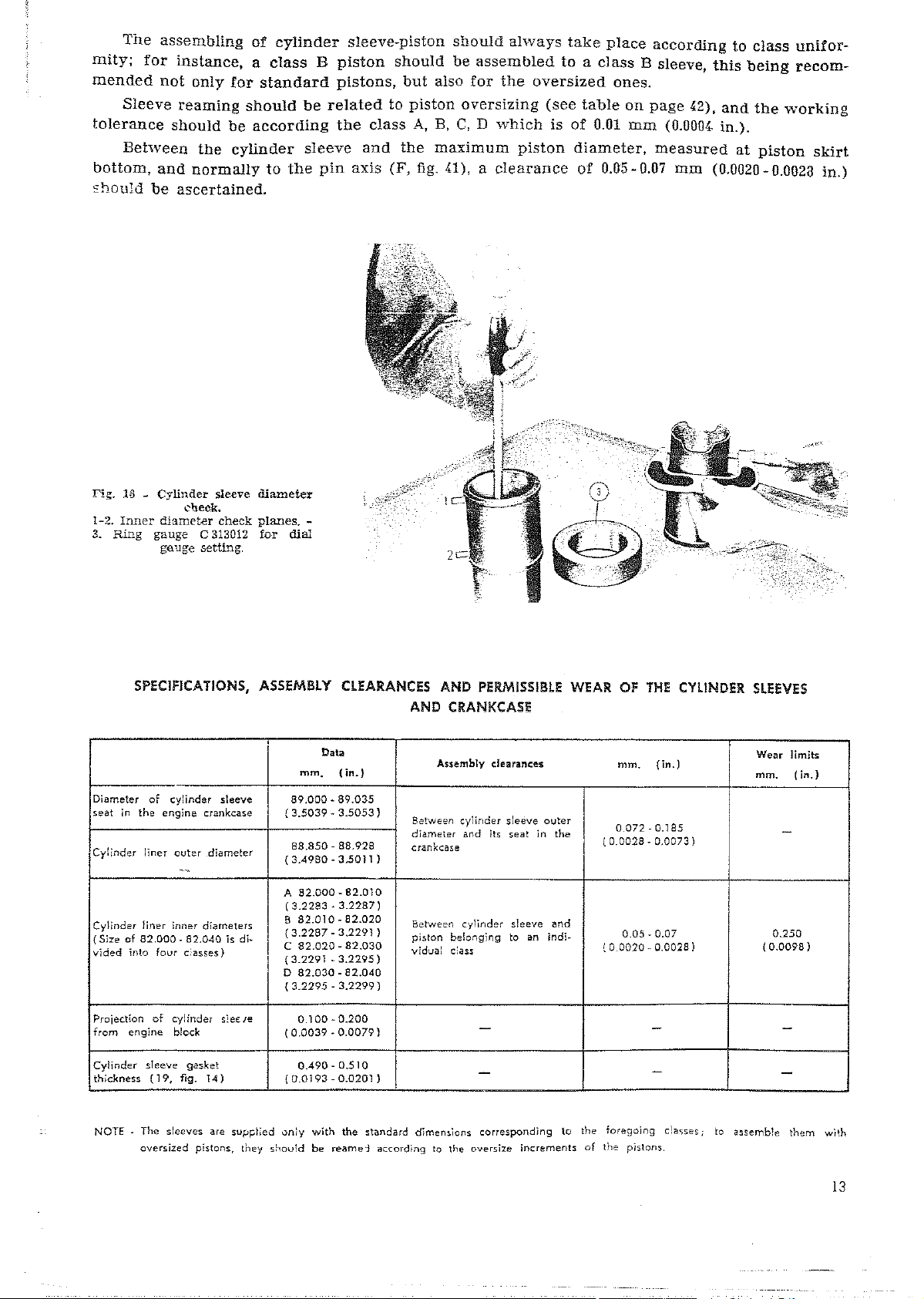

Fag.18-

I-2.

Inner

3.

Ring

SPECIFICATIONS,

lDiameter

lseatinthe

l

‘Cylinder

of

liner

Cyhnder

‘h

k

diameter

gauge

gauge

cylinder

engine

outer

sleeve

k

9'3

-

check

C3l3B12

setting.

sleeve

crankcase

diameter

diameter

planes.

for

-

dial

ASSEMBD!

mm_

39.000-89.035

{3.5039-3.5053)

83.850-88.928

(3.49B0-3_50ll)

CLEARA

Daia

(in.}

;

.

-1-—1'—»—L-_».-

.

._._

j~1i_'.-*5

W.--~

Za

NCES

AND

AND

CRANKCASE

Assembly

Between

diameter

crankcase

ime

F4V

1

~

fifi

5%

__ll

19;,

'*

-.;

ff;

”

PERMlSSiBl.§

clan

rances

cylinder

sleeve

and

its

seat

km

.

Y

,-

if

""%¢e¢wU'

2

in

_,,

_

OlJ5?£;

Q}

;

WEAR

_'»;@-"~;;"

.-

-,

_

1

»

;_~Pi

OF

THE

mm.

fin.)

0072_(‘U85

(Q0028-0.0073

eee

.

<

,

g

.>

'

Y

3‘

,

CYLINDER

l

'5

=

.

7--

e

£$%e$¥§

‘*~_~_

>

“

.1??R@

SLEEVES

Wear

limits

mm.

M

M

_

(m.)

K,

-

s>,,...-

"

w

.

‘

I

A

s2.ooo-22.010

(3.222:-i-2.2227)

Cylinder

(SizeofBZQUO-32.940l5di-

vided

into

liner

four

inner

diameters

classes)

s2.o1o-a2.o2o

(3.228?-3.2292)

c

e2.o2a-a2.o3o

(3.229:

o

4.2295)

a2.oao-132.040

Between

piston

vidual

cylinder

belonging

class

sleeve

and

toanindi»

5

3

i

M10020-0.

0.05-0.07

0028]

‘

0.250

(£10098)

5

(12295-3.2299)

engine

sleeve

oversized

cylinder

cl

block

(19,

iiH__

sleeves

Proiection

from

Cylinder

jthickness

on

_

NOTE-The

gasket

fig.

14)

are

pistons,

sies

__

supplied

/e

they

0.100

(CD039»0.0079l

OA90-0.510

\

(@0193-0.0201)

only

shouldbereamed

»O.200

_WiWm

with

the

l ‘ ‘

standard

dimensions

accordingtothe

_

corresponding

oversize

,_m

to the

incrementsoflhe

ioregoiflg

pistons

_

W

¢lB$5<-B5;toassemble

i_

l-hem

‘

i

with

13

CYLENDER

HEAD

>15

z

1

V4

“$1

.

.‘

B

very

Aluminium

Cylinder

The

valve

Check

thin

cylinder

need

]7e111()Va1asengineishot

heed,

removalisdescribedonDhge

the

cylinder

layer

head

of

lainpblack.

Useasur1‘ace~grindertogrind

an

amountofmatter

to

rockenarm

such

grinding

The

cylinder

gramoffig.

-»'..

5

Q

-l‘

»

=13?‘

\\

-.

*1

,

»s>'3‘,

1

=

~

,.-

--‘Q~r-

"~~*".-

.

=.

J""~‘§-'1':¢>";"’”\,

V.

~,,

.i"ca

7.-V-.l,-1-rat-;.att-Hz

\

-

-.:=I‘*v‘-:::e='=~*''__

"~\

‘

\._

‘

68,

,9»

J

‘$5

cover

should

untilafastening

.»i-._'

;-*-.v".-

-

,-

_t‘.,,r,_n‘-t-.l_~__,..,,,7m

2:-..A

L‘3“

"'-*''"

as

possible;

assembly

beof0.85-0.07

head

fastening

..

'

L

./-l.

L

,>~

Y’,

’-~“

_.L_

"

\.¢.§£

'.:~;:it»,_..~

..

.1;

“'

*"'-‘==‘4*‘

V-e\‘&

.£W1"-

.~-.-5-_;.-t

"-'

,_

4“

provided

of

cast

should

iron

inserted

be

15-

mating

surfacebymovingituponasurface-plate,

Spots

planeisof

torque

to

that

The

cylinder

the

cylinder

93.15

mm

(fi.0{}2E}-0.0828

block

of9kgm

.._-jig)’

‘*3.

aretobe

head

mm

calls

for

head.

(3.667

repeated

(65

Worked

height

in.).

ft-lb.)

_.~

,**

~;.

.=

1,1'_

~_‘:-

we

A

i

‘~*“_~*\

‘Lt‘-\

,.

-

'.‘7if

*=~

1-"

§-

1 ».

\

_

_,

~\

'Q_‘

:=

-1‘

>1-;‘

‘i‘?'?!;+

.

\

.

;

_

‘

l

\

E

_-

A

e

..._.

E

*%=.

-_*.-A72.‘

#42

5"‘?

55%

v

l’

valve

avoided,

Care

in.)

to

are

thus

shouldbetakentoremoveassn-1&1}

from

its

the

thicknesstobe

screw

is

attained.

Ta-'

,_=?:~-':_._

<.

f

,.

\--

in"$§¥;:21'1-'“¢':a§§=~-

-A~§,?E?*3#:;»=¢fls;;=:&w§€"”

-

-'

Ha

t,

~>-1.3”“

$1

8

Q

_

it

.r9-

;-»:-"=~~"-

-

e

.

.t._I

‘vii4-

"’<~',’-I

..-.

-~'§m¢:»'*'

->1»

"

'If'

=-.'T

J‘.-E-5'

-1~:':<=

'~¢"~'.

.,

I

seats.

prevent

assembly

deformation.

being

evidently

pointed

upon

smeared

engine

removed

tightening

P5

_

‘#3

k

>3:

'-»_-at

_

fie"?-_~.:?;»‘~..-.~.~‘~.Q;-.:_=;=:»;r.~-:ra=>'

:-. .-.~»;~V,lt,

%=

-

.‘

._a:-.;*-

>__‘,§~*_,

:

_?t-

-

~'*-'---aiinm-=

,;

;._;,1»l,:_;i}=;_;

.t

.,,,

‘T-Q‘-3.~>‘»

'

according

A

f‘-»=.t'~—

Y-l-»+.-=.,_.‘_~>

~

/.

11*_-

as

l

.

lltssis"~1

_.,y,;,.<

t-flliéefir-\’{‘"

.

.

géél_=1

.;1w_e¢,i"*'.£=lY‘-

'

=

,-Y

-

-

"

~

as

_

A-"-"~;'<

,=-

,4

.

qw‘

’

-..=<<

4;

with

out.

block

during

to

dia-

' '

-#29.-‘-.="7v'\1

v

'.-»-*?-:1'i-—‘£»-'-=r-'»?'¢-

.»

,

r

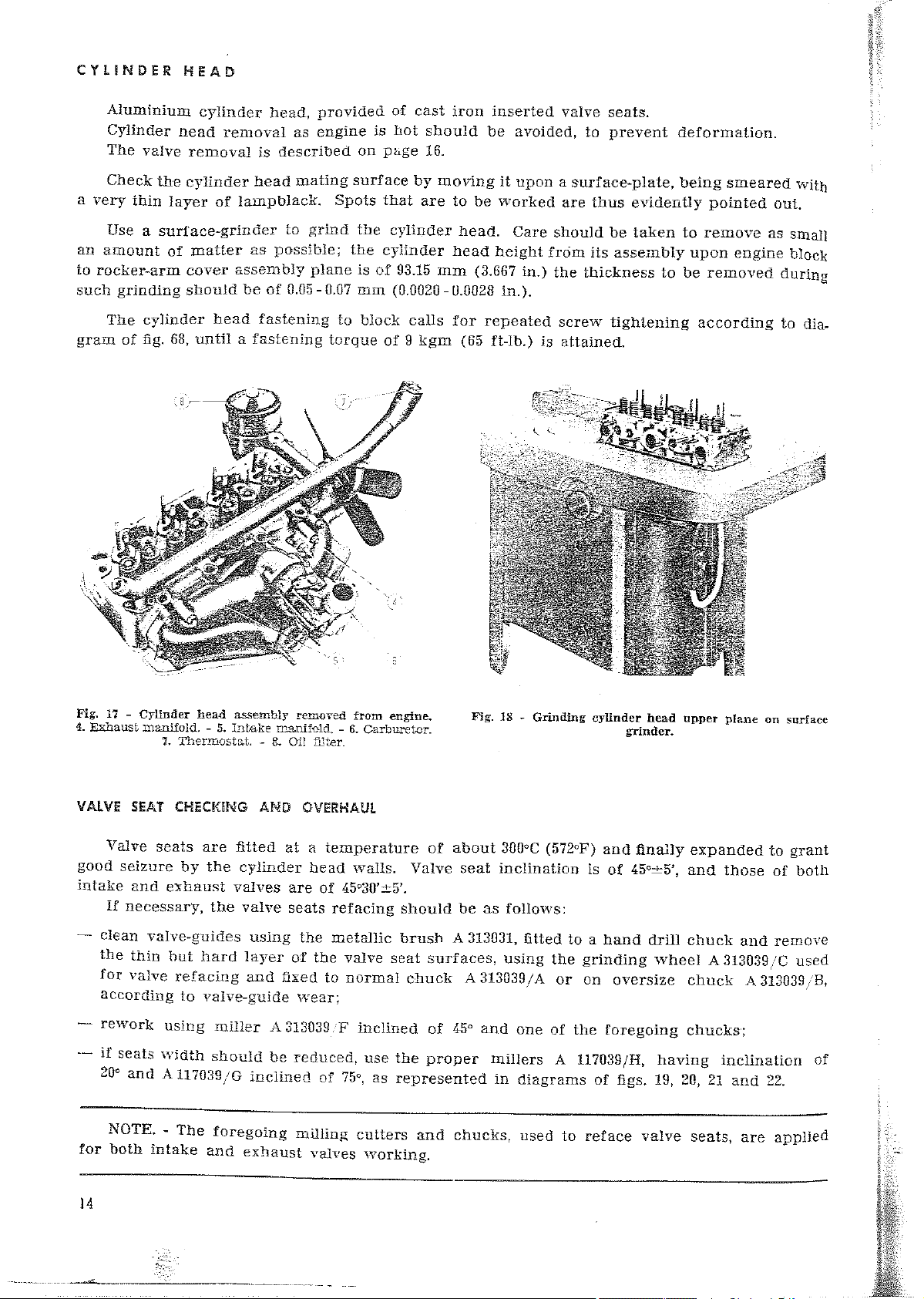

Fig.

1'1‘-Cylinder

4.

Exhaust

VALVE

manifold.-5.

SEAT

Valve

good

seizure

intake

——

and

If

necessary,

clean

the

thin

for

valve

according

-—

rework

~-ifseats

20°

and

NQTE"The

for

both

14

head

‘Z.

Thermostat.-8.

CHECKENG

seats

are

by

the

exhaust

the

valve»guides

but

hard

refacing

to

valve-guide

using

Width

miller

should

A117G39/G

fwcgfling

intake

and

assembly

Intake

ANS

fitted

cylinder

valves

valve

using

layer

and

inclined

exhaust

removed

nzanifeld.-6.

Oil

from

Carburetor.

filter.

GVERHAUL

atatemperature

head

Walls.

areof45°3t]’:5’.

seats

refacing

the

metallic

of

the

valve

fixedtonormal

Wear;

A

313039-Finclined

be

reduced,

milling

valves

use

of

75°,asrepresented

cutters

Working.

engine.

Valve

should

Fig.18-

of

about

seat

beasfollows:

brushA313031,

seat

surfaces,

chuck

the

and

of

45°

proper

chucks,

A3l3039/A

and

millers

Grinding

398°C

(572°F)

inclination

fitted

toahand

using

the

or

oneofthe

A

in

diagrams

usedtore-face

cylinder

head

grinder.

and

finally

isof45°15’,

drill

grinding

on

oversize

foregoing

117039/H,

of

figs.

valve

upper

plane

expandedtogrant

and

thoseofboth

chuck

Wheel

and

A313U39,»"C

chuck

chucks";

having

19,

inclination

28,21and

seats,

are

on

surface

remove

used

A

313839,/"B,

22.

applied

of

5

i

1-;

.11:

W.

,;;5‘,}...

,3-»

.

-t-352?,

_

‘Z’

¢-'-'

’*7~

‘ks?-$21.;

.,.

45

-5’

E

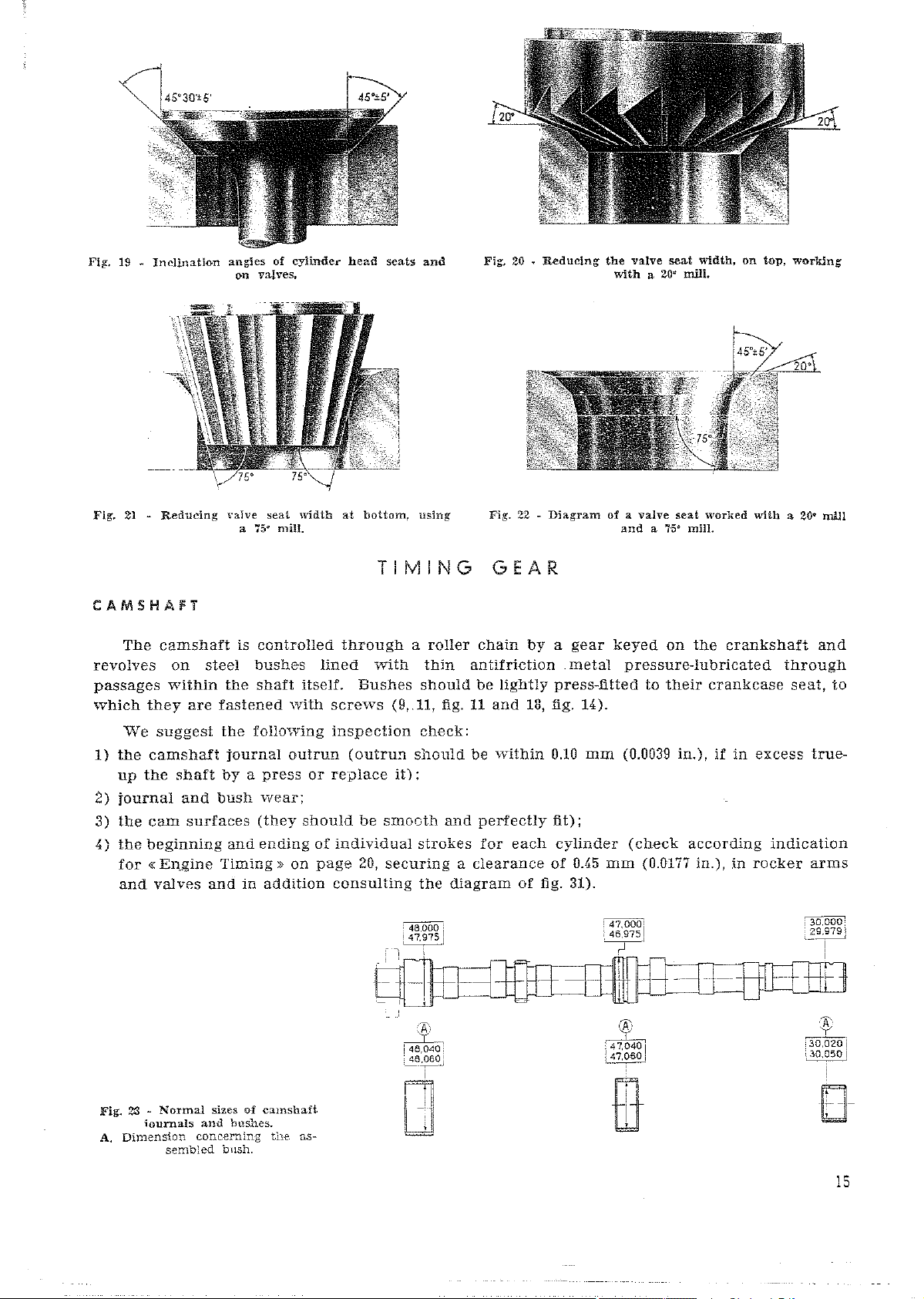

Fig.19~

Fig.

Inclination

\»

_

______

______.V

21-Refiucing

CAMSHAFT

The

camshaftiscontrolled

revolves

passages

which

on

within

they

anglesofcylinder

on

-.~;.-:'-"'

1

1??

|

‘U.

‘e-'.5'-_"Q11-"5-9

.

=Q!*5‘;

»~4~»=-.aw.

1

\ .-_c

_=\i>

.;41-.‘..

_;,-"

-.-.»

t.

.

45>

u

v

-

.

‘iii?

-1'-7'~~'‘’‘I'

.

*1

’

'“'*1;;-i

ii

-

-\|_21$

‘J:'41

vaive

a

steel

the

are

fastened

valves.

.

11;

»:~,.=>

,

J~fl‘

_

<1;

~‘m.:5'}?>-e

seat

75'

mill.

bushes

shaft

-~-..

¢_‘._

1».@I

I:

:.-,=~‘-»\,+;;v_-...;

.

~t7'~:

“’

width

lined

itself.

With

screws

head

seats

and

4’

"

__:._j

_

;

er

~.;’"1

art

-,=;[

V-,

.¢::’fi?7>‘..-..'»2~—

l

. . .

_,___,,_,,,_,__.,,_,

bettern,

using

TIMING

through:1roller

with

Bushes

thin

shouldbelightly

(9,.11,

Fig,20~

>-:1

...QQiv

GEAR

chain

antifriction

fig.11and

Reducing

=\<:.:-;-=r-"~=<-.;<,,L;3Ԥ:=-

5_,,¢,iy§kt.;1.;»._.--.,.».»..~,i.

--"'»

(,1;

,,N_

‘T

~.-

--’"£3

1*~‘

-

Diagramofa

byagear

‘

.

"Y’Ii

3-_

—.<.

‘

%

.metal

the

valve

witha,20°

—'."<

1?"

<‘.£'3

.;.'_'.

4.~,y—_,_~2,~.<;‘3.-.1

\~¢t-

"»’<*~".-—'-.:4»

..»~.~:.»

.>*-.-.

.

...—r.-.

._"';_..?}...-.‘~s~

._.'.»_;~.:

2:7

."i>“\!'.?;‘\;1’

mi»

».

5.

.

.

anda.75°

keyed

pressuredubricated

press-fittedtotheir

18,

fig.

14).

71;‘

.

valve

""“‘;E"*\-.

3

;;

14

_‘..

MM

~

.‘¢>

on

seat

=¢

-3,3»,

T

‘rm;

width.

":

;If:==."1.»:'-'

'

.

.53

,3.

'1'»;/.»"

.-<

\l

O1

I

A\"a'f°

worked

crankshaft

011

45°:

5

'»'a‘.=‘.<=*.a:="-

I

ff?

,

;:igJ.;=r<c~,Z4

.~--~.~_v,f1,v;;s3-=»i

»~~,,,---

-,»»

with229°

mill.

*5-I

-;._~-_e1l=1;‘J.

I::.'~:'-

. . .

seat

mill.

the

crankcase

WP,

'

\~-

Wflrking

20°

and

through

seat,

miil

to

We

1}

the

up

2)

iournal

3)

the

4)

the

for

and

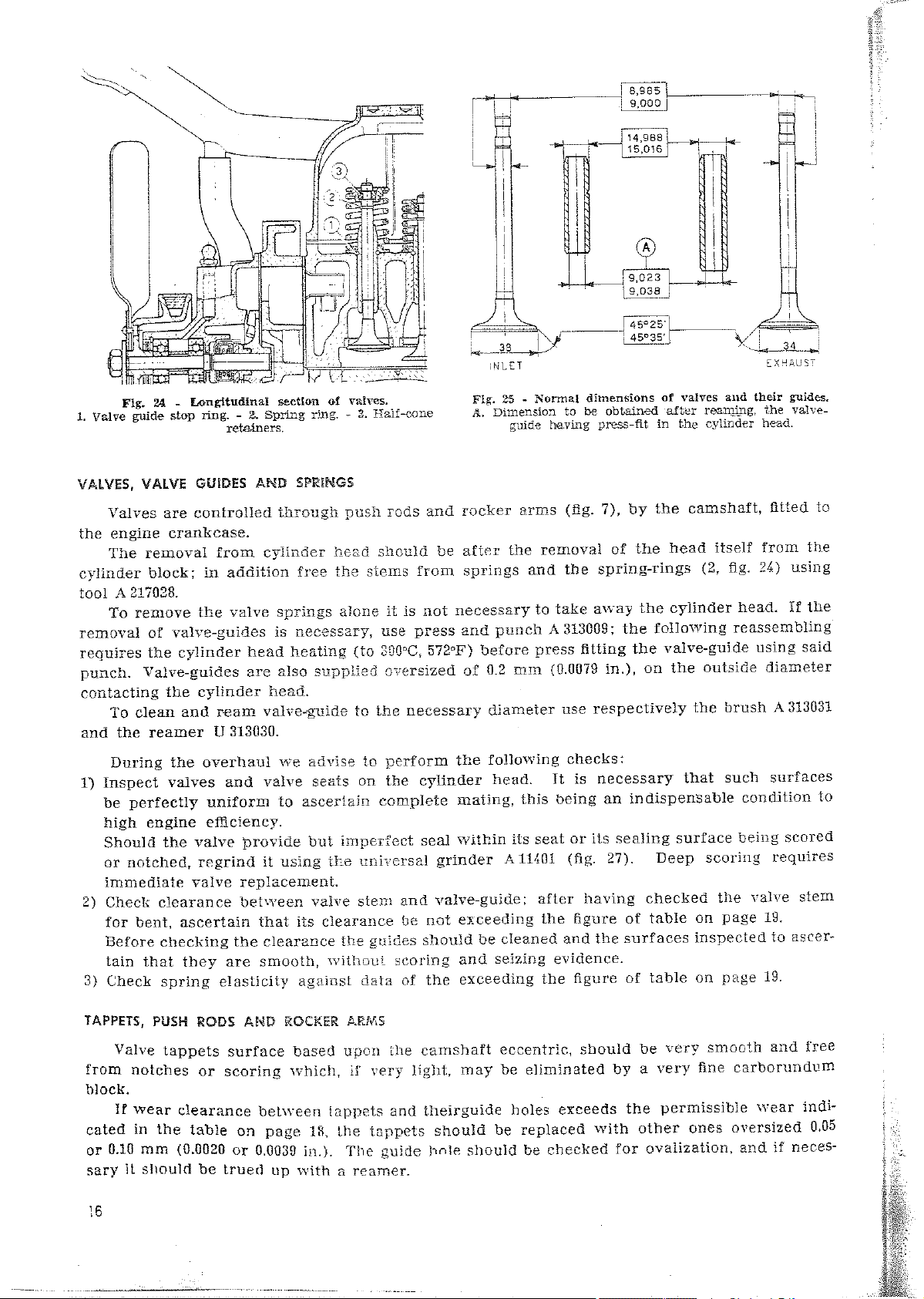

Fig,23-

A,

Dimensien

suggest

camshaft

the

shaft

and

cam

surfaces

beginning

<<Engine

valves

Normal

iournals

concerning

sembled

the

following

journal

outrun

byapressorreplace

bush

Wear;

(they

should

and

endingofindividual

Timing»

on

page

andinaddition

sizesofcainsnaft

and

bushes.

the

bush.

as-

inspection

(outrun

it);

be

smooth

20,

securingaclearanceof0.45

consulting

sf

check:

should

strokes

the

i

4a,ocF%

!

47.915

+_H

.1~

=

K:

L.

.

I

I

|

2

s:\

I

be

and

perfectly

diagram

j

_

Within

for

e

each

of

I-

fl_—I

fig.

——

e

9.18

mm

fit);

cylinder

31).

es

(R0839

in.),ifin

(check

mm

(0.017?

.i..,-W.

§

41°09‘

145-975!

L

H

:55:

1%)

1

7

Q53‘

A

,

'

i‘'

'i’

I I

excess

.

according

in.),inrocker

:|i:|:|:

true-

indication

arms

ri"i|

5

300901

t§_n19'979‘

{=9

-We

530,029

§30.U5O

A

I

'*

i

!

i

I

x

_"_

15

‘._&\‘-‘ax

1.

Valve

\.\_

__i_._._.c.M_i.c.__

,

.

.

._

.‘

1

-

ll

we

,E=,,=g._mg9;i

E."‘

Fig.

2A-Longitudinal

guide

stop

_

I

i

.

>

'_-v

**=---

ring.-2.

\

I

,

V

Q

‘

,.

V

ac}-f"

Spring

retainers.

1..I;

.I'

igi

section

-¢fl“'

y,A/Q‘

L11)

"J

(Hf_

4

L

..e‘

i,"

_

l

.~

oi

valves.

ring.-3.

;

.a.

,

mu

all

G‘uF‘

5l-.ll”'*

_

~_-=-.-_-.-in.

.=-»~_-~

-=<—.<¢—

..ii..

~

%Z,,;‘

'2

.1‘

Half—cone

A-33"

W.

3:425

'.:i.;»

_.

1

. .

_i,

l

Q’

V

01:11:,

w4urJ?,_,w

2

'

5

:

‘

i

.

'

K

INLET

Fig.25-

A.

Kenna!

Dimensiontobe

guide

F

‘Ir-nunmvlv

Ararsn-T“““

'

_

\

F

having

_

'

__

dimensions

obtained

press-fit

3

E

e,ses1

‘BOB

._J°

14

sea‘

15016

-9,023

's,ose_"'

_

Y_

1—'

45°25‘

‘asses’

‘—-~-~—’

of

valves

after

in

the

____

___,_.3_fi

§

1|

rJn'.rIJJJ*4vA".<pa.rJJa-.""‘

#

v.IJ'IJAw0niI.r'llg___

,

'

5

__,._

'

/=

*—-24-”-~

“>\._?34_,_

Z

‘-XH.l.L5..T

and

rearning,

cylinder

their

the

head.

.

,

'

~

a-_

u

Q

guides,

velve-

-

‘E

VALVES,

Valves

the

engine

The

cylinder

tool

A217028.

To

removal

requires

punch.

contacting

To

and

the

During

1")

Inspect

be

perfectly

high

Should

or

notched,

immediate

2)

Check

for

Before

tain

3)

Check

VALVE

are

G-UlDES

controlled

crankcase.

removal

block;

remove

of

the

the

valve-guides

cylinder

Valve-guides

the

cylinder

clean

and

reamer

the

valves

engine

the

valve

regrinditusing

valve

clearance

bent,

ascertain

checking

that

they

spring

AND

from

in

addition

valve

head

are

ream

U313830.

overhaul

and

uniform

efliciency.

provide

replacement.

between

that

the

are

smooth,

elasticity

SPRENGS

through

cylinder

free

springs

is

necessary,

heating

also

push

head

the

alone

{to

supplied

should

stems

use

398°C,

head.

valveeguidetothe

We

advise

valve

to

ascertain

seats

but

valve

its

clearance

to

on

complete

imperfect

the

universal

stem

clearancehenot

the

guides

Without

against

data

rods

and

be

from

is

not

press

5'72°F)

oyersized

necessary

perform

the

cylinder

seal

grinder

and

valve-guide;

should

scoring

of

the

rocker

after

springs

the

arms

removal

and

(fig.

the

necessarytotake

and

before

of

0.2

diameter

the

following

head.

mating,

Within

punch

press

ruin

this

its

seatorits

Al1401

A313tl09;

(00879

use

checks:

it

being

(fig.

after

exceeding

he

and

seizing

exceeding

the

cleaned

the

and

evidence.

7),

of

spring-rings

away

the

fitting

in.),

respectively

is

necessary

an

sealing

2'7).

having

figure

the

figure

by

the

camshaft,

the

head

(2,

the

cylinder

following

the

valve-guide

on

the

outside

the

that

indispensable

surface

Deep

scoring

checked

of

table

on page

surfaces

of

table

inspected

on page

fitted

itself

from

the

fig.

24)

using

head.

If

the

reassembling

using

said

diameter

‘crushA313631

such

surfaces

condition

being

scored

requires

the

valve

stem

19.

to

ascer-

19.

to

to

TAPPETS,

from

Valve

notches

PUSH

tappets

block.

if

wear

Cflifidinthe

O!‘

3-15

mm

saryitshould

E6

RODS

AND

ROCKER

surface

or

scoring

clearance

table

on

which,

between

page

(0.{l{l20or0.0039

be

truer?

up

based

18,

in.).

with

A5863

upon

ii‘

very

iappets

the

tappets

The

a

I‘433!‘1}e}f‘_

the

and

guide

camshaft

light,

may

theirguide

should

hole

eccentric,

be

be

should

eliminated

holes

replaced

be

checked

should

exceeds

with

be

very

byavery

the

permissible

other

for

ovalization,

smooth

fine

ones

and

free

carborundum

wear

indi~

oversized

£1.05

anditneces-

-

K

E

l

'-<;'<.*.»;-.

/,~,».

-.

‘E‘;4'L

F

;{"'5f§,-.’.~l.

:1»

"-.:¢:~.'=:lw

-

c

fv

’

F

fill.

fig

Fig.

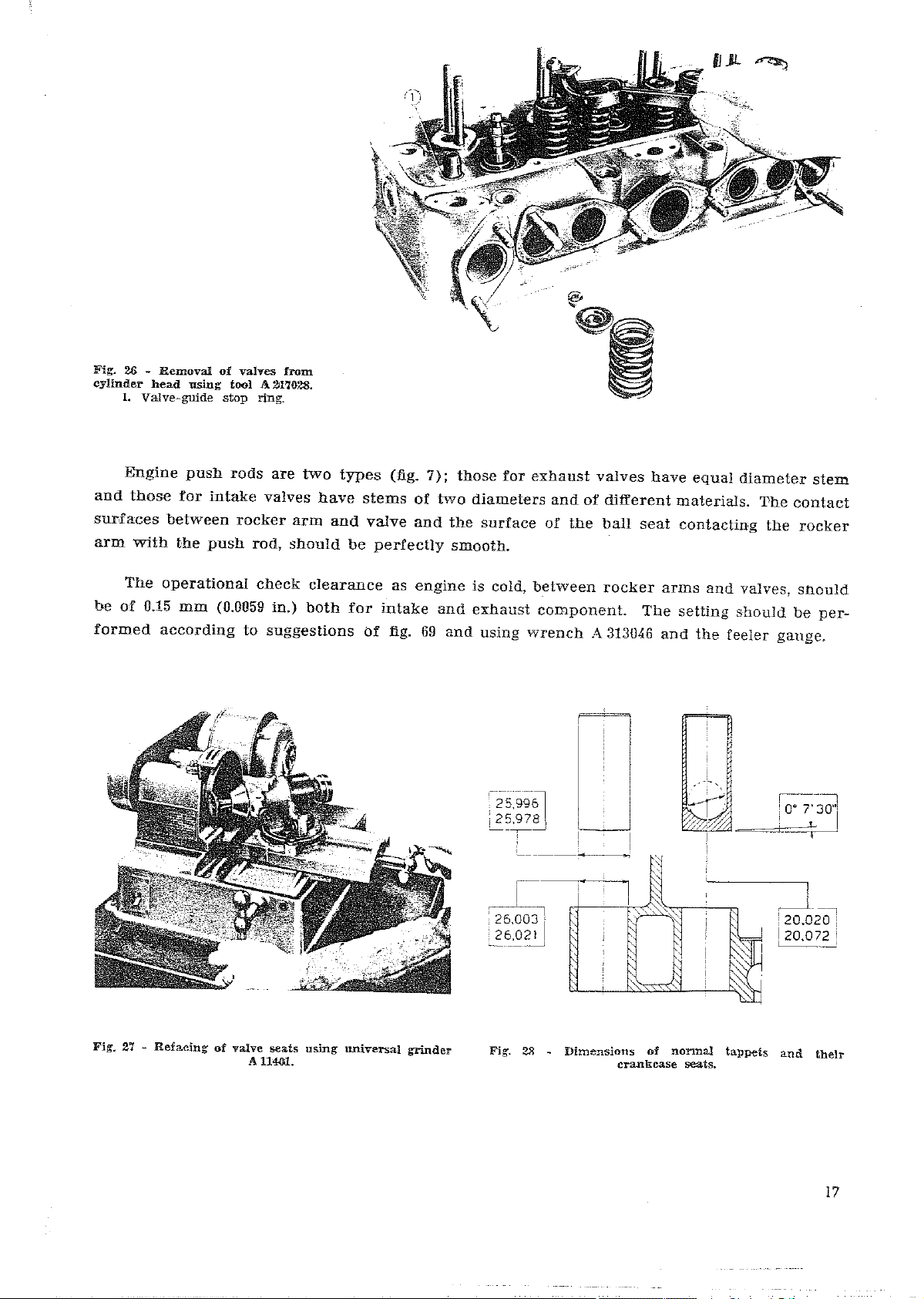

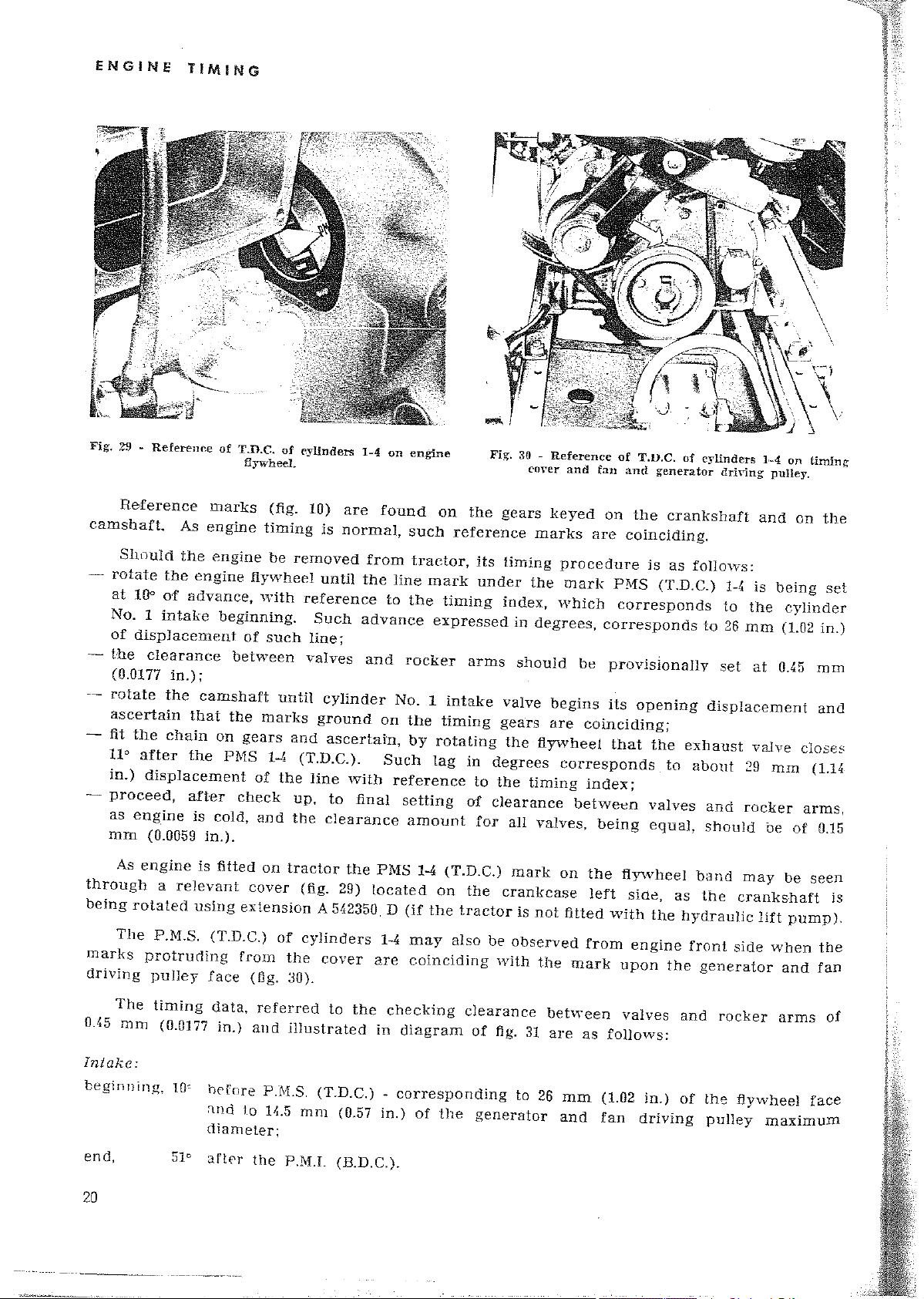

26-Removalofvalves

cylinder

and

sur-faces

arin

head

I.

Valve-guide

Engine

those

with

using

push

for

between

the

tool

stop

rods

intake

rocker

push

froin

A21’2028.

ring.

are

two

valves

arm

rod,

should

types

have

and

be

;_¢:-":~»-

it

‘s.i*;i'"

is-Q

(-fig.

7);

stemsoftwo

valve

and

the

perfectly

w7in

\

‘L1

those

diameters

surface

smooth.

Q’

.

:3

for

,.

»

/7

’

ii,

ii;

__._

'

.

*

Mt

“

@‘@

~_’.

-_;

,—~'-/

(ti

exhaust

of

valves

andofdifferent

the

bail

i

.

U1

»-

r/__/~~.

i""l’~e*‘~

'

1

’

have

seat

Y

~.1

E

equal

materials.

contacting

diameter

The

the

stem

contact

rocker

The

be

of

formed

operational

6.15

mm

according

check

(011059

to

clearance

in.)

both

suggestions

for

intake

of

as

engineiscold,

and

fig.

69

and

-~..

between

exhaust

using

€"2§1§§q

525.9781

_‘T—

I

;

component.

WrenchA313646

=____

26.863

|

‘

rocker

I

:

_.._._;_,\

_

;

*

i

EX

»

\\\,

‘A

arms

The

setting should

and

the

\

‘ow

.\_\‘\\-w\\\\\\\u\-_-»

-

"

.1

i

and

feeler

a

1“

\

I

\.

VS-__

.

"M"“‘*

___._\_...

..<_.....

._._.

._

'

I

i.‘

1/

valves,

snould

be

per-

gauge.

@~1;;1

A,

so-—

I

‘I

*2w?_t

J

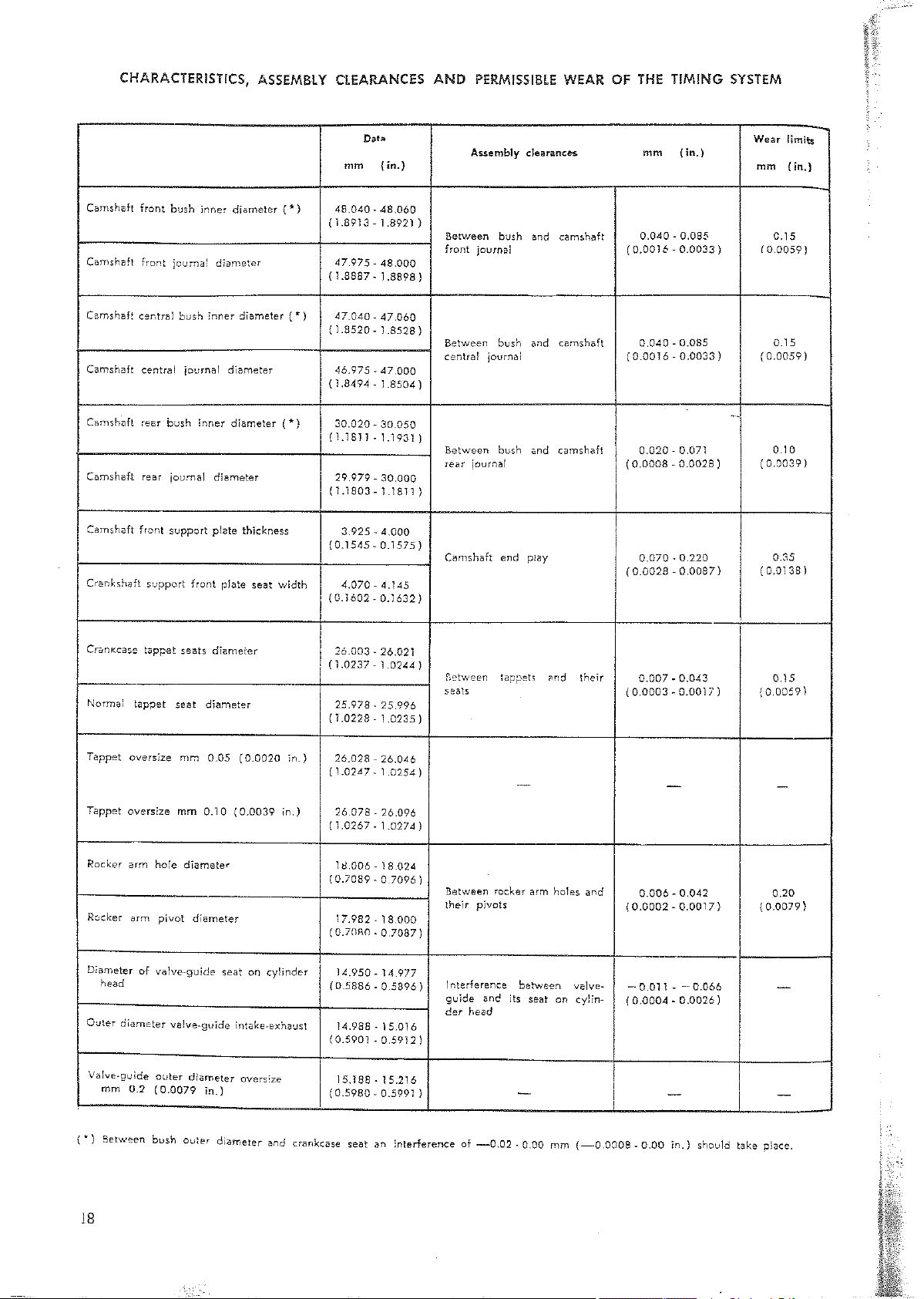

Fig.27-

Refacingofvalve

seats

,:\114{h1,

using

universal

grinder

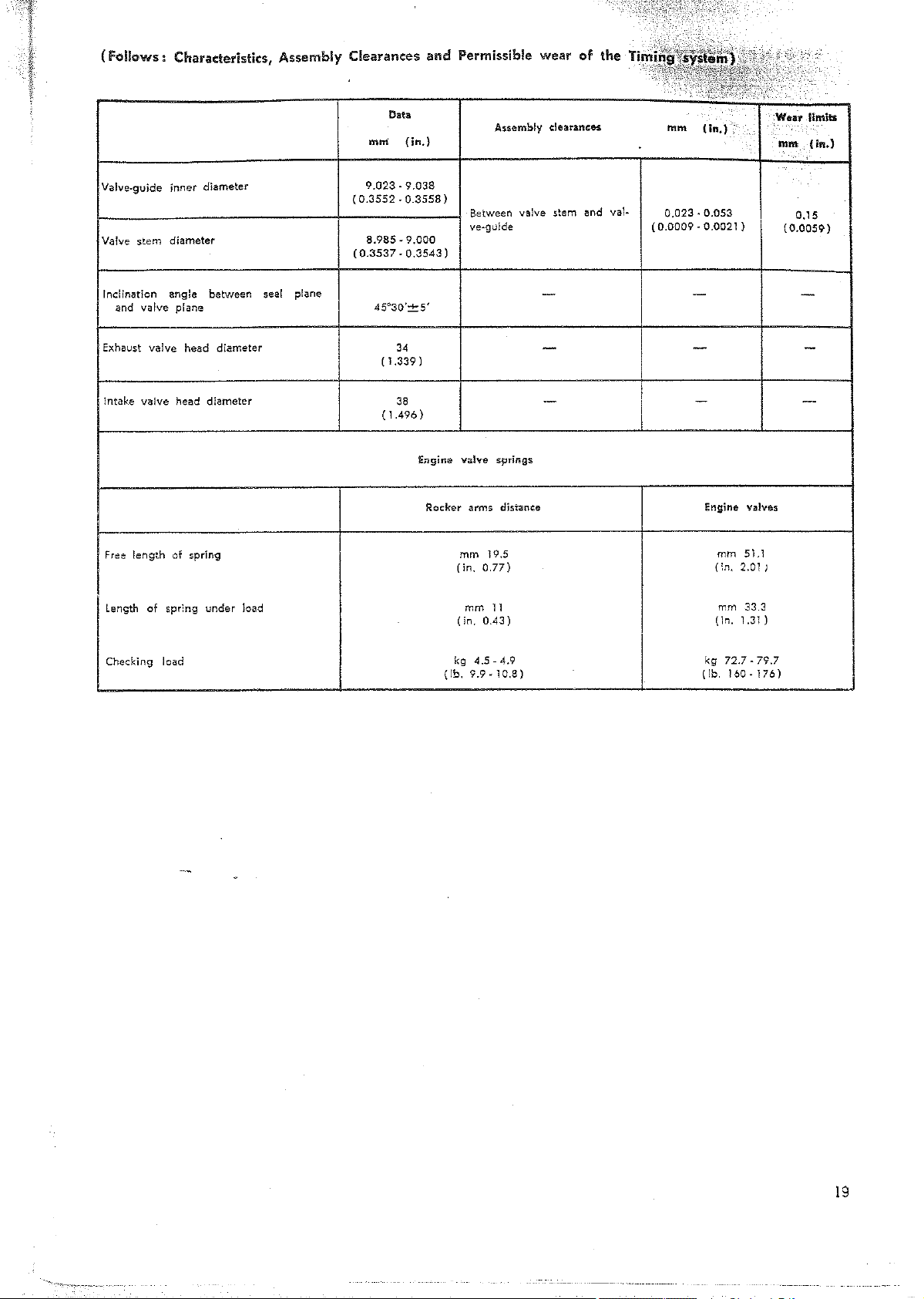

Fig.

28-Dimensions

of

crankcase

nurlnfll

seats.

lapneis

and

their

17

rs.

V

6

CHARACTEIUSTICS,

Camshaft

Camshaft

Camshaii

Camshaft

Camshaft

J

Camshaft

front

front

central

central

rear

rear

bush

_

bush

‘coma?

I

bush

to-urnai

..

iourriai

inner

inner

inner

diameter

diameter

diameter

diameter

diameter

diameter

ASSEMBLY

i i ‘

(*)

‘

.

I

i

(*)

.

(*)

CLEARANCES

Dari.

mm

(ii-1.}

_

40.040-4s.0c>o

(i.89i3-1.8921)

i

47.975—4B.000

(¥.88B7-

{L8520-P8528)

(R8494

i.889B)

47.040-4.7.060

46.975-47.000

-1.8504]

30.020-30.050

(L181?-1.1931)

29.979-30.000

(13803-1.1811)

AND

i

Between

i

i

front

Between

centre!

Between

rear

PERMISSIME

Assembly

clearances

.

bush

bush

iournat

bush

and

and

and

journal

iournal

WEAR

OF

1:1,...

camshaft

camshaft

i

‘

i

camshaft:

THE

mm

TEMiNG

(in.)

SYSTEM

Wear

mm(iI1.)

limits

..*.*_.::_..._._....-._.:_._

0.940-0.035

(CD016~0.0033)

0.040-0.085

(0.0016-

0.0033)

-

3-19

(0.005?)

0.15

(000521)

.1

0.020-0.071

0.10

t0.o00a-0.0023)\;(00030)

__

"'1

i

msheft

front

m

(3

‘

.

Crankshaft

.

.

Cranncase

1

Normai

i

i

Tappet

Tappet

Rocker

‘

Rocker

1

I

Diameterofvetve-guide

i

head

1

Outer

diameter

i

support

support

topper

tappet

seat

oversize

oversizemm0.10

arm

hole

arm

pivot

,

vaive-guide

front

seats

diameter

mm

diameter

diameter

plate

thickness

piate

seat

diameter

0.05

{D0020

(00039

seatoncy!inder

iniakevexhaus!

width

En.)

in.)

3.925~4.000

(01545-0.1575

1£.070w4.i-$5

-|

[C‘.i6o2'0.i632)

25.002»20.021

(1.023?~1.0244)

.

25.978W25.996

7.0228

a-

26.028-26.046

H.020-1.0254)

3

2a.07s-20.0%

j

(1.020?-1.0274)

36.006

(07089-0.7096)

17.982-18.000

(07020 07057)

.

,

14.950-14

;

(05830-0.52%)

14.938-35.016

(0.5‘?0i

V7'W"Wseats

-1.0235)

-18.024

977

»0.59i.'2i

~_'

"H

i

Camshaft

1

Rstween

Between

their

i

‘

Interference

guide

der

pivots

head

and

end

tappets

rocker

its

pzay