Page 1

Fiat Spider - 2000

^,^:^y.^,v:;;-;-0^:

$$M

Page 2

SERVICE NETWORK

When your car needs Service look

for the sign which identifies all autho rized Fiat Dealers where trained personne!, specially designed equipment

and faciiities are available.

Our organization is at your füll

disposal for any Suggestion or advice

you may need.

SPARE PARTS

Authorized FIA T parts are the bsst

guarantee for top Performance and

satisfactory Operation of all compo-

nents.

When ordering, p/ease quote (see

page 2) :

— Car Model.

— Nurnber for Spates.

— PartNumber(s) of Spare (s) Ordered.

BREAK-IN RECOMMENDATIONS

Current progress in design and

manufacturing technology is so ad-

vanced that no hard-and-fast rule

need be given for break-in, However,

a few simple rules should be fol!owed for the first 1000 mües:

Avoid fierce accelerations soon after

starting and allow time for the

engme to warmup (a good habit

even after break-in).

Do not fully depress the accelerator pedal and avoid high engine

speeds, when operating in the

lower gears, that is, never allow

the tachometer pointer to move

into the yellow sector indicating

hfgh rpm rates.

Change your road speed occasionally, especially on long trips. Avoid

long drives at constant high or

Iow speeds,

Downshift whenever necessary to

cope with driving conditions on

route: you will avoid engine lugging at excessively iow rpm.

Avoid, if possible, severe stops at

sustained speeds during the first

few hundred miles: brakes will

set properly and improve their life

and effectiveness.

Remember that satisfactory Operation and iong life are dependent to a

great extent on the care with which

the car is handled during break-in.

Page 3

Fiat Spider 2000

This Manual provides the Information

necessary for satisfactory

Operation and maintenance

of your car.

We wish you pieasant motoriny

and trust the Information providsd

will help to ensure the

fang Ufe and safety of your car.

Operation maintenance specifications

Page 4

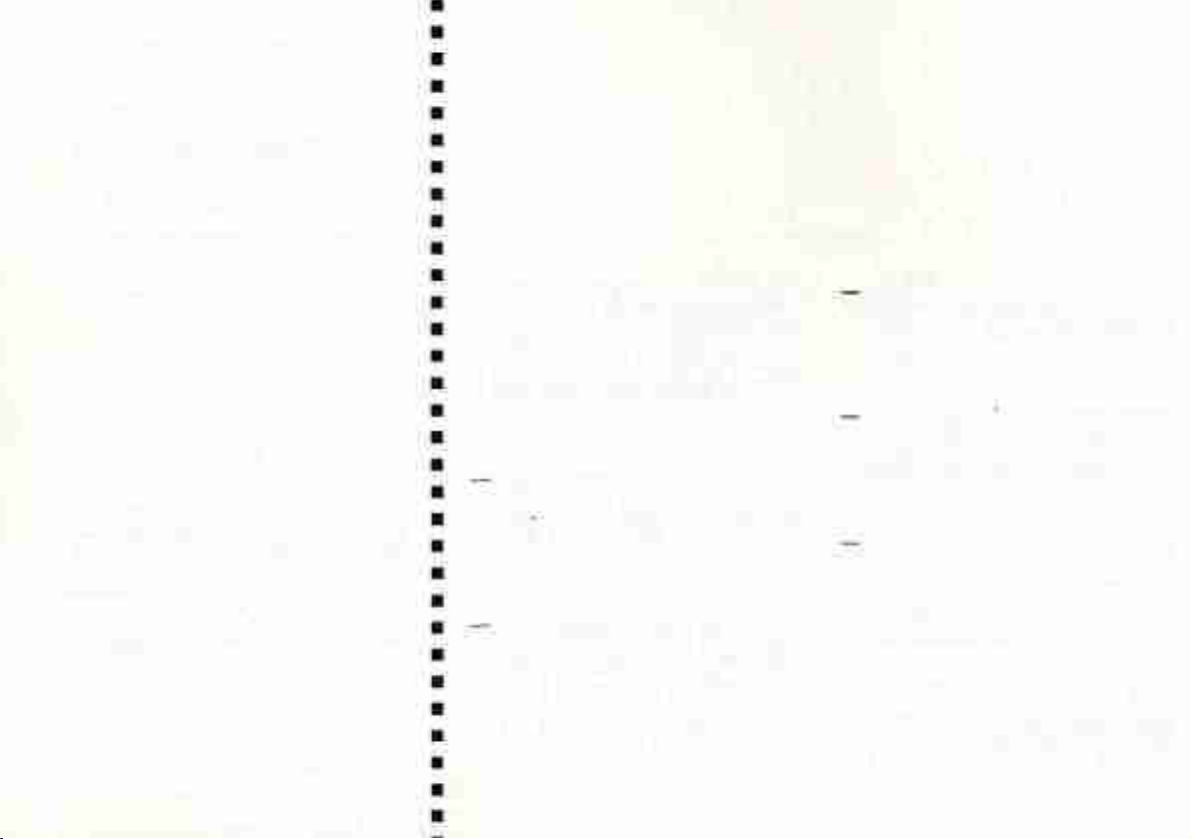

KEYS

IDENTIFICATION

DATA

Each vehicle is provided with two

keys in duplicate; quoting the number

stamped on each key is essential to

obtain a replacement from FIAT's

Sales Organization.

A For ignitron switch

B For door and trunk locks.

B

50022

• Manufacturer's Plate

A - Name of manufacturer

B - Vehicls identification code

C - Chas&is Number

D - Engine type

E - Version code

F - Number for spares

G - Space reserved for Diesel vehicles

Kg

o

MOTOFtE-ENGINE

YEFSIONF- VERSION

N'PERRICAMBI-NäFDR

1-

2-

Kg

Kg

Kg

SPAR£S

0

i i

1 1

39090

— J

Page 5

• Engine Type (132 C3.031) and

Identification Number - Punched

on crankcase, near oil filter mount.

• Chassis Type (124 CS2} and

Identification Number - Punched

on engine compartment bulkhead

(permanent structure) right side.

• F.M.V.Safety Standard 115Tag

Type of vehicle and chassis number,

located on panel top between instrument cluster and windshield.

• F.M.V.Safety Standard 110Tag

Tire data and car capacity, located

on R.H. door pillar, above striker.

• A) F.M.V. Safety Standard Conformity Tag - Month and year

of manufacture, gross vehicle weight

rating, gross axle weight rating,

chassis number and car type, located

on left door pillar.

• B) Vehicle Emission Control Information Label - Located on left

door pillar.

• E.P.A. and California Regulations Conformity Tag - Air pollution

control specifications for correct engine

tuneup and adjustments, located in

engine compartment, on cowl.

3

Page 6

1

2 3 4 5 6 7 8 9

10

11

12 13 14 15

16

35 34

33

32

31

30 27

Page 7

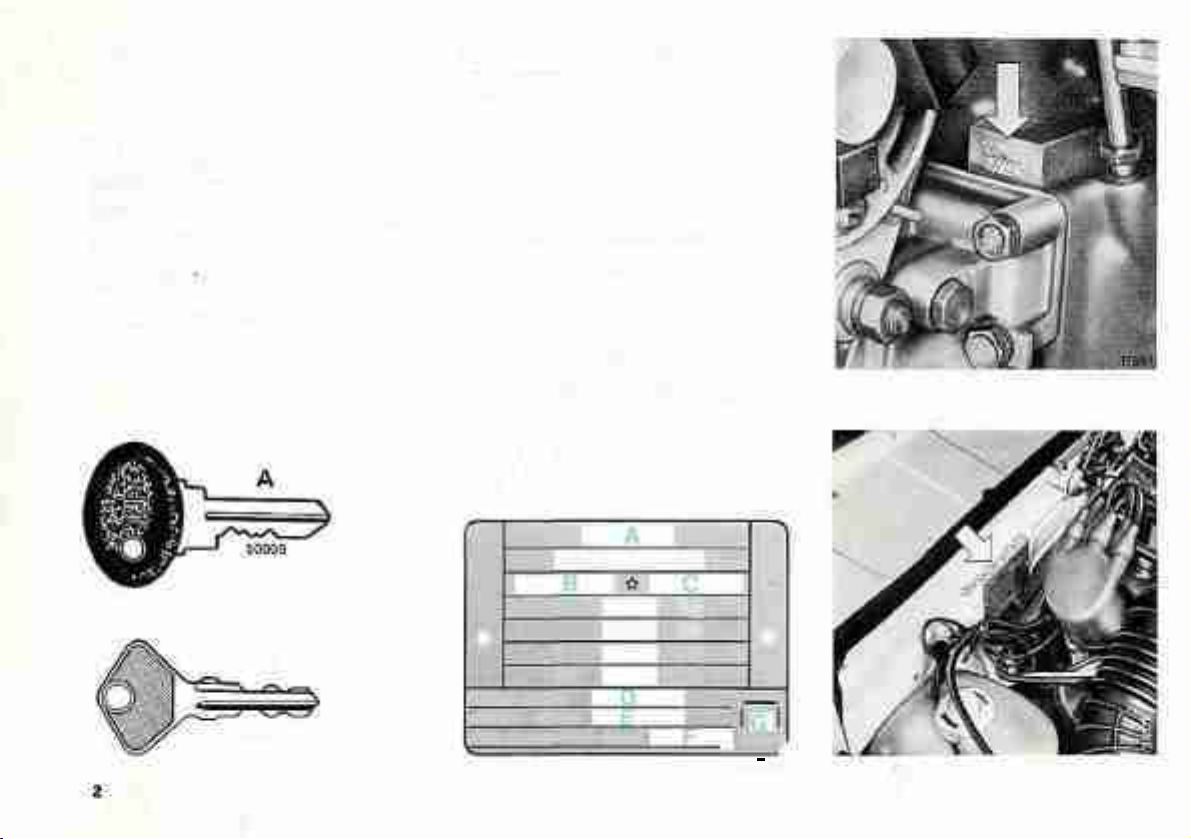

INSTRUMENTS AND CONTROLS

1 lighting switch, three-position

2 Turn signal lights switch levei

3 High/Low beams change-over

switch lever

4 Inspection lamp receptacle

5 Instrument cluster

6 Horn button

7 Steering lock ignition switch

8 Windshield washer and wiper

switch lever, three-position

9 Air outlets

10 Windshield wiper sweep rate knob

11 Low brake fluid level/hand brake

ON indicator

12 «EX. GAS SENSOR)) indicator

13 Fasten belts indicator

14 Knob switch and rheostat for

instrument cluster lighting

15 Glove compartment

16 Glove compartment lock

17 Utility recesses (two)

18 Power window switches housing

19 Courtesy light with switch

20 Vehicular hazard warning signal

indicator and switch

21 Gearshift lever

22 Lever controlling air flow through

outlets 9 and/or under dash

23 Cigar lighter

24 Optional radio housing blanking

lid

25 Ash tray

26 Hand brake lever. To release the

lever press in button on top of

handgrip

27 Two-speed heater fan switch,

three-position

28 Air volume control lever

29 Air temperature control lever

30 Accelerator pedal

31 Service brake pedal

32 Clutch pedal

33 Fusebox

34 Hood release emergency cable

35 Hood catch release lever

Page 8

FIAT Dealer for a cooling system

check (including fan circuitry).

a b

n i m n

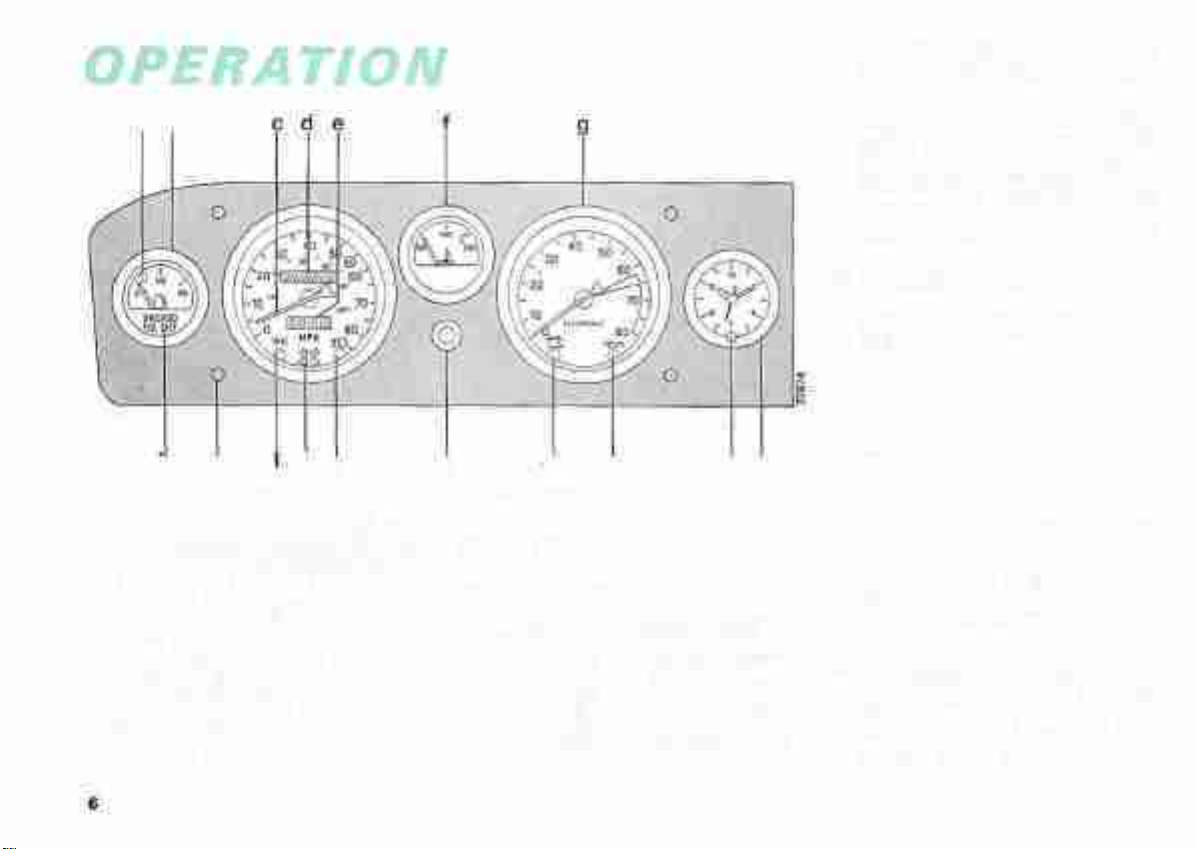

Instrument Cluster

a) Fuel Reserve Indicator (Red) -

Warning that the fuel supply available in the tank is between 5

and 7.5 liters {173to2 Gals).

b) Fuel Gage

c) Speedometer - This instrument

(which includes the odometer) is

factory-sealed: any tampering by

unauthorized persons will invalidate the warranty.

o p q f s

d) Odometer (Totalizer)

e) Trip Recorder

f) Engine Water Temperature

Gage - If the pointer enters the

red area it means that the engine is

overheating: it will then be necessary to immediately rev down the

engine to idle speed (do not $witch

off). Should the pointer remain

on the red area, contact the nearest

g) Tachometer - Electronically-op-

erated from the ignition distribu-

tor. The yellow area indicates ma-

ximum engine speed for all gears

whereas the red area shows

dangerous engineoperating speeds.

h) Type of Fuel Used (see page 33)

i) Cluster Panel Mounting Knobs

(Four)

I) Parking and Tail Lights Indi-

cator (Green)

m) Turn Signal Arrow Indicator

(Flashes green)

n) High Beams Indicator (Blue)

o) Trip Recorder Zeroing Knob -

Turn knob clockwise but never

when car is running.

p) Battery Charge Indicator (Red)

With engine inoperative, and ignition key in position MAR, the

charge indicator is on and must

go out when engine is started;

Page 9

should indicator turn on while

engine is running, this is a warn-

ing of a fault in the battery recharging system: turn immediately to a FIAT Dealer for assist-

ance.

Fasten Belts Indicator (Red) and

Buzzer - Both are operative for a

few seconds when a starting attempt

is made with seat belts (driver and/or

passenger) unfastened.

q) Insufficient Oil Pressure In-

dicator (Red) - The light should

go off when oil pressure is sufficient to ensure adequate engine

lubrication,

r) Clock Reset Knob - Push and

turn clockwise making sure that

it springs back when released.

5) Quartz Crystal Clock

Lighting Switch

Up = All lights OFF.

With Ignition Key at MAR:

Down — Parking and tail lights,

headlight low or high beams and

flashers (main beams).

With Ignition Key Removed:

Center (night parking oniy) = Park-

ing and tail lights.

Down = All lights OFF.

Low Brake Fluid Level/Hand Brake

ON Indicator (Red)

With ignition key at MAR the indicator

lights up to warn the driver that the

bulb is efficient. In case the indicator

remains ON it means either that the

hand brake lever is pulled upwards

(brake applied) or that the brake fluid

level is too low.

Should the indicator turn on while

the vehicle is moving, stop and check

the fluid level in reservoir. If the level

is too low, great care should be taken

when applying the brakes and the

nearest FIAT Dealer contacted for a

brake system check.

Vehicular Hazard Warning Signal

Switch - Turns ON (independently of

key position in lock switch) the front

and rear turn signal lights which will all

flash simultaneously to warn of the presence of the vehicle stopped on the road.

38003

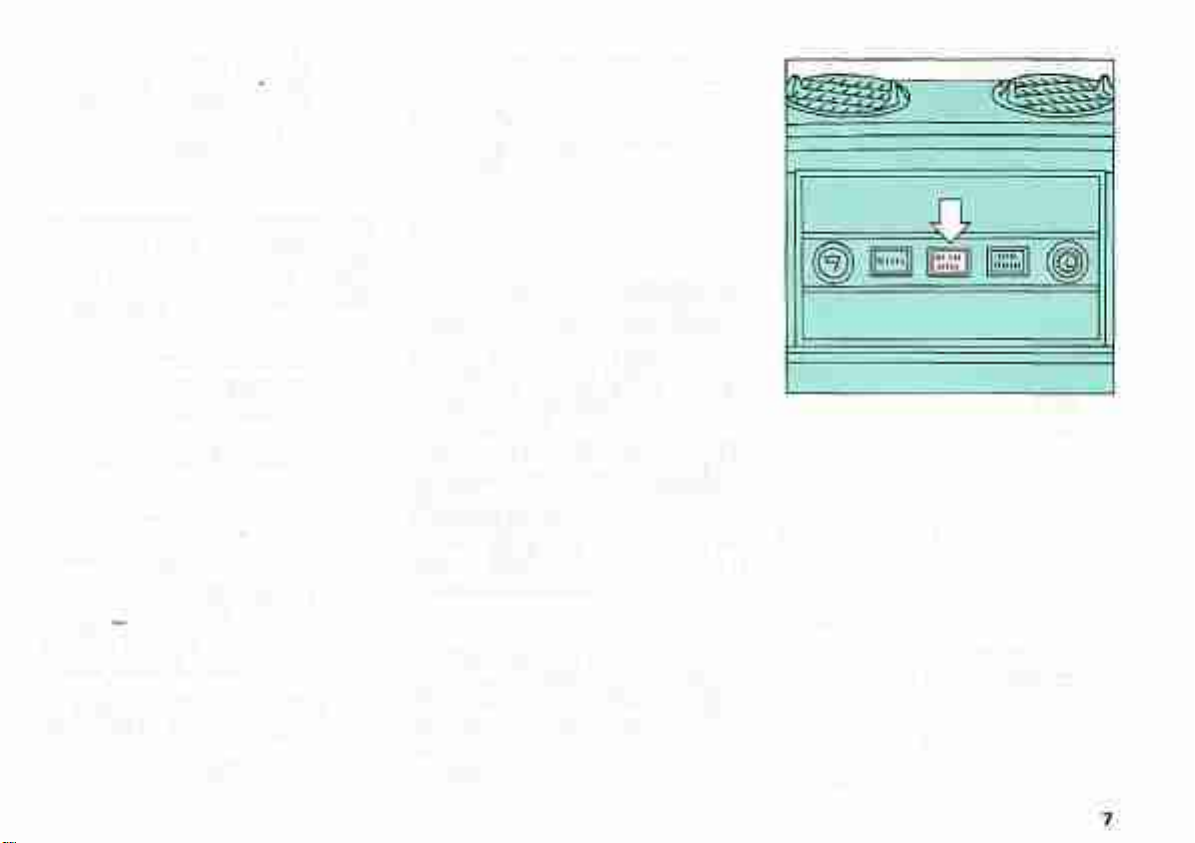

EXHAUST GAS SENSOR

INDICATOR (red)

Lights up:

— Every 30 000 miles to warn owner

of need to replace exhaust gas

sensor (Lambda probe);

— On starting; it should go out when

engine is started.

Page 10

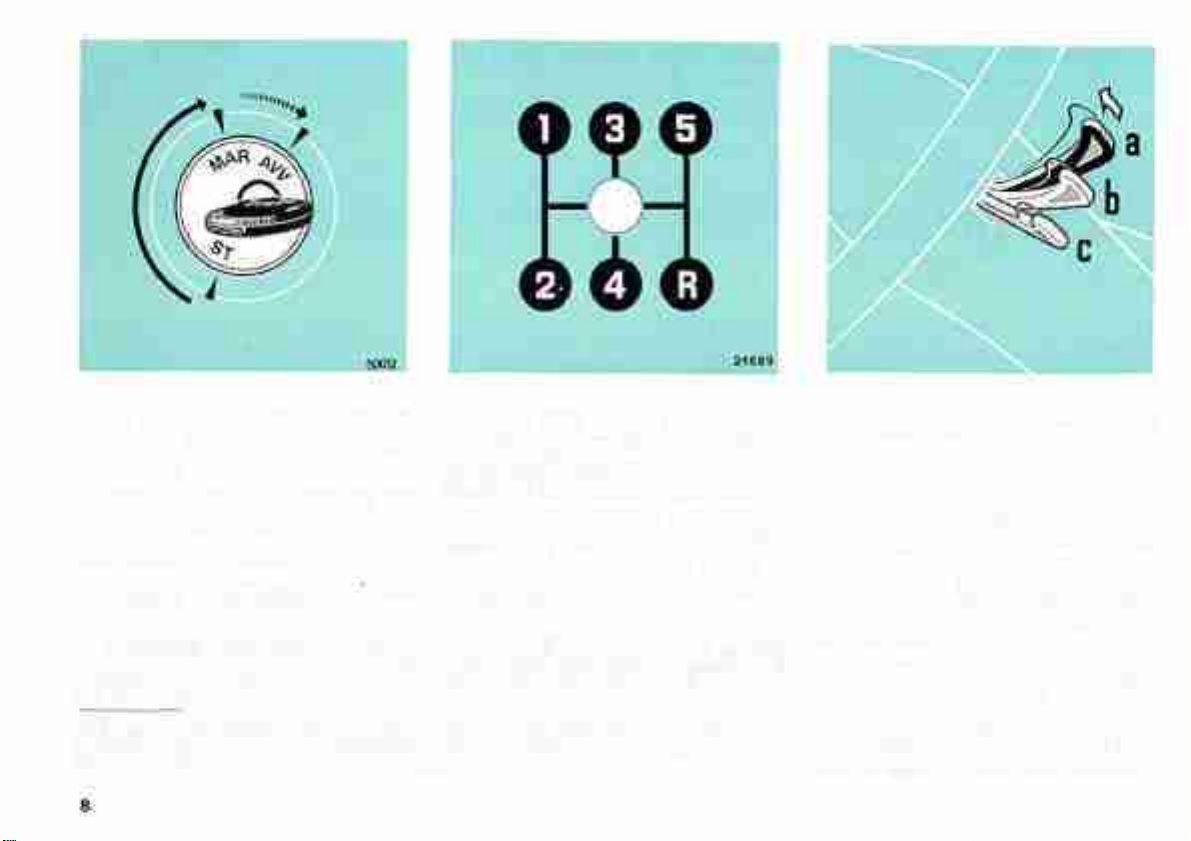

Steering Lock Ignition Switch (*)

(See page 16 for starting procedure

instructions)

MAR (Run) = Engine ignition ON and

accessories energized

Remove Key Buzzer - Operates

when the steering wheel side door is

opened to leave the car and the ignition key is forgotten in the lock switch.

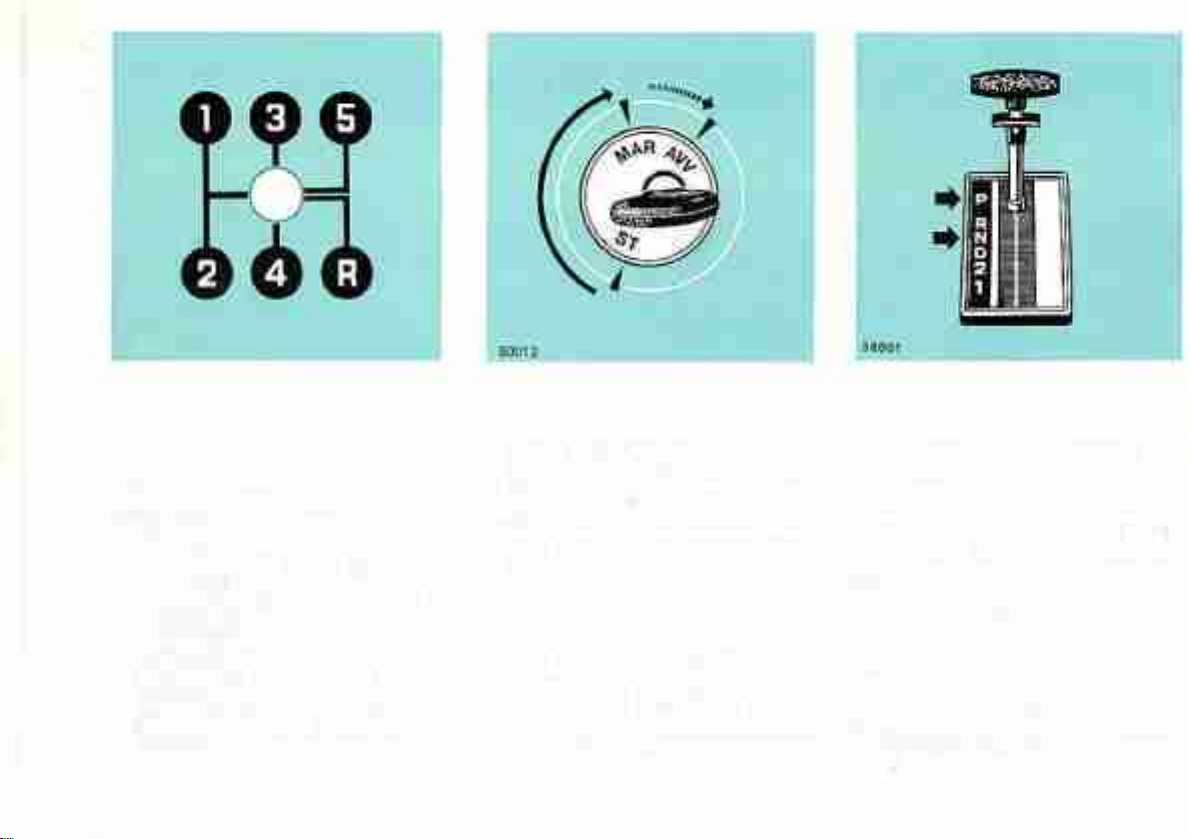

Gearshiftirtg Pattern - To engage

reverse (R), press the lever and shift

AW (Start) = Engine starting

ST [Stop) = Steering post antr-theft

lock in. Key removable

as indicated by the gating pattern.

Note: The use of fifth gear over 4B mph

improves fuel economy.

The total or partial removal oi key will lock the steering post even if car is in motion.

To facilitate the disengagement of steering post lock, slightly rock the steering wheel

while rotating the key. Key must not be left in position MAR when engine is inoperative

and must be removed only when leaving the car, especially if unattended.

(*) Even with key removed (position ST) the following circuits are stifl energized : courtesy

lights; horns; cigar lighter and housing indicator; vehicular hazard warning signal; remove

key buzzer; clock; inspection lamp receptacle.

Windshield Wiper/Washer Switch

Lever

a = Wiper off

b = Wiper On-Off intermittently (par-

ticularly useful in drizzly weather)

c = Wiper on continuously

Lifting the lever towards steering

wheel, whatever its position, will switch

on the washer.

Windshield Wiper Sweep Rate

Knob - Provides high or low sweep

rates in either wiper continuous or

intermittent operation, depending on

the position of wiper lever switch.

Page 11

25947

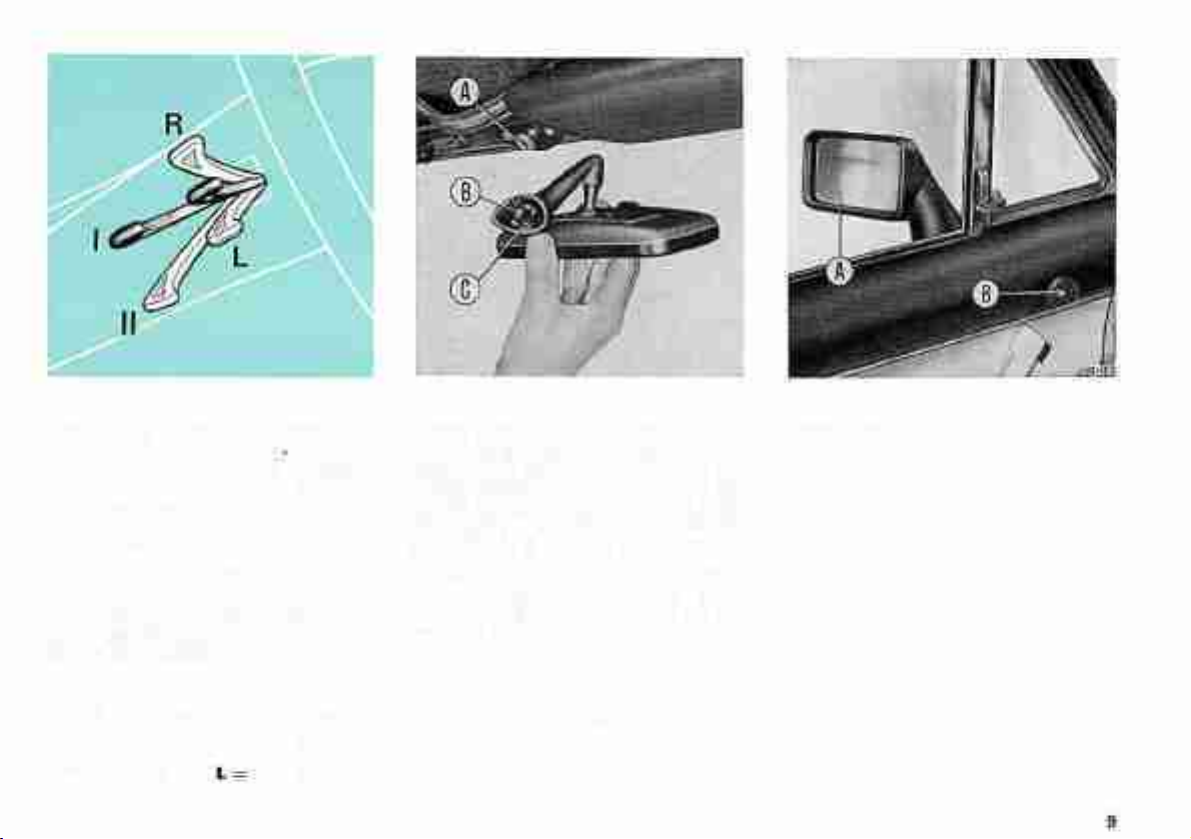

High/Low Beams Change-Over

Switch Lever {With lighting switch

down and ignition switch at MAR)

I = Low beams

II = High beams

By lifting the lever towards steering wheel headlight high beam flashes

are obtained even with all lights out

(Daylight signals).

Turn Signal Lights Switch Lever

Automatically trips back to OFF.

R = Right turn

Left turn

Inner Rear View Mirror - Collap-

sible, with anti-glare (Day/Night) po-

sition controlled by a lever. If the

mirror comes off its seat, following

an impact, refit by engaging spring B

on stud A — make sure the two

location dowels are properly registered

with relevant seats — and press

on base C. Engagement is of the

snap-on type.

Outer Rear View Mirror A on

steering wheel side door is adjustable

from driver's seat, by means of lever B.

Page 12

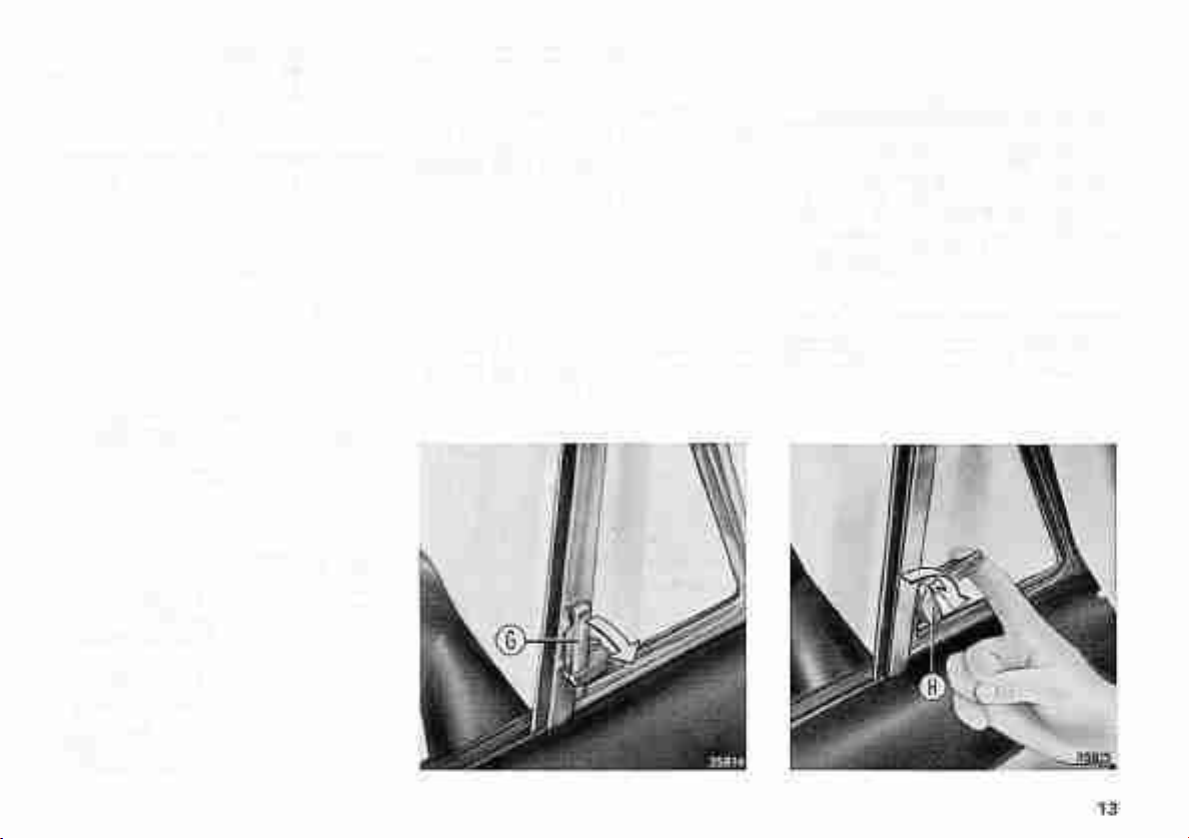

DOORS

Opening

From outside - Unlock and pull the

handle.

From inside - Pull up lever A.

From inside (safety latch) - With

door already shut set the lever A down.

The lever will thus first insert the

safety latch and then snap back to

rest.

SEATS

Seats may be adjusted for leg reach

after moving control lever A downwards.

Locking

From outside - Both doors are pro-

vided with key-operated locks. Step-

ping out of the car on the curb side

is thus also possible. Always use the

key; never lever A.

10

Note: Lubrication of lock cylinders is not

recommended. At most, blow some graphite powder into the cylinder keyhole.

In cold climates it is recommended to

squirt in some special antifreeze fuild for

locks. Repeat the operation every time

the car is washed or at least every 15 days,

if insertion of key in the frozen lock proves

difficult, simply warm up the key.

Once the desired position is found,

release the lever and make sure the

seat has locked.

The position of the backrest is ad-

justed by turning knob B.

Page 13

Warning

Before fastening the belts make sure

the seats and headrests are properly

positioned.

Each belt is intended for use by

one adult or one child over 6 years

of age.

For access to the rear compartment push down lever C and tilt

backrest downward.

On top of each seat backrest is fitted

a headrest: to re-set height pull up

or push down as required.

The headrest must be adjusted so

as to support the head and not the

neck of the occupant.

39078

SEAT BELTS

Seat belts provided as standard

original equipment are of the 3-point

lap type.

Pull belt fully out from retractors

without stopping as otherwise it will

be necessary to return the belt to the

stowed position to release the retractor stop mechanism.

To fasten, fit tongue A into buckle

B until a sharp click is heard.

Adjust the belt snugly around the

hips, not the waist, allowing excess

webbing to be pulled back into re-

tractor.

To free yourself from the belt

restraint: simply press in buckle

button C.

Occasionally, check that webbing

is in good condition.

In the event of an accident even

if the belt you were wearing is apparently undamaged it is suggested

that you replace it with a new belt

assembly of the same type.

To keep belts clean, wash only,

using warm water and mild soap.

Rinse and dry thoroughly. Do not

use strong detergents and avoid any

chemical that may weaken the equipment.

Users are warned to consult the

Manufacturers in case of doubt and

not to make any alterations of, or

additions to, seat belt assemblies

and/or anchorages.

11

Page 14

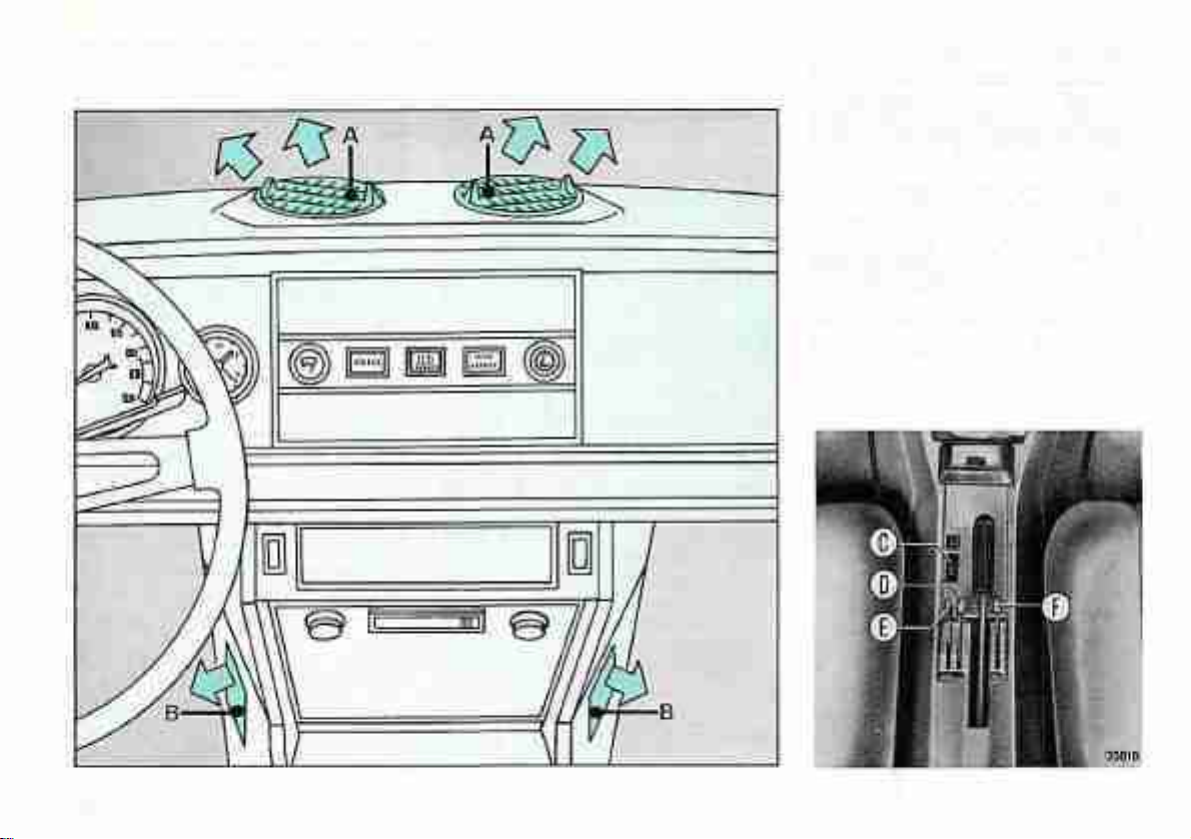

VENTILATION AND HEATING

Ventilation and heating are adjusta-

ble according to seasonal requirements.

To ensure best comfort to occupants it is important to become familiar

with system controls and operation.

Admission of Heated or Fresh Air

Heater fan switch C is ener-

gized only when ignition key is in

position MAR.

Pressed in forward = High speed

Intermediate position = Off

Pressed in backward = Low speed

12

390 68

Page 15

Lever D controls the air tempera- Defrosting end Demisting

ture.

Pulled all back - No heating of air

Pushed allforward - Maximum heating

of afr

For quick defrosting of windshield,

pull back completely lever F, push

forward lever D and set lever E in an

intermediate position. Turn on the

heater fan by switch C.

Lever E controls the air volume.

Frost Precautions

If during cold weather the car must

remain inactive for some time at freezing temperatures and the cooling

system is not protected with antifreeze

mixture, it will be necessary while

draining the radiator and Jackets

to empty also the heater core by

shifting lever D all forward.

Pulled all back - Maximum air flow

Pushed all forward - No admission

of air

Intermediate positions are used

especially when outdoor temperature

is low to limit the flow of cold air

around heater core.

Lever F controls the amount of air

flowing through windshield outlets A

and into front lower area through

console outlets B.

Pulled all back - Air flows through

outlets A only

Pushed all forward - Air flows through

outlets A and B

Door window ventilators are

opened by pulling lever G and tur-

ning upward lock H.

Note: If heating proves inadequate,

operation of the thermostat on the line

from cylinder block to radiator must be

checked.

Page 16

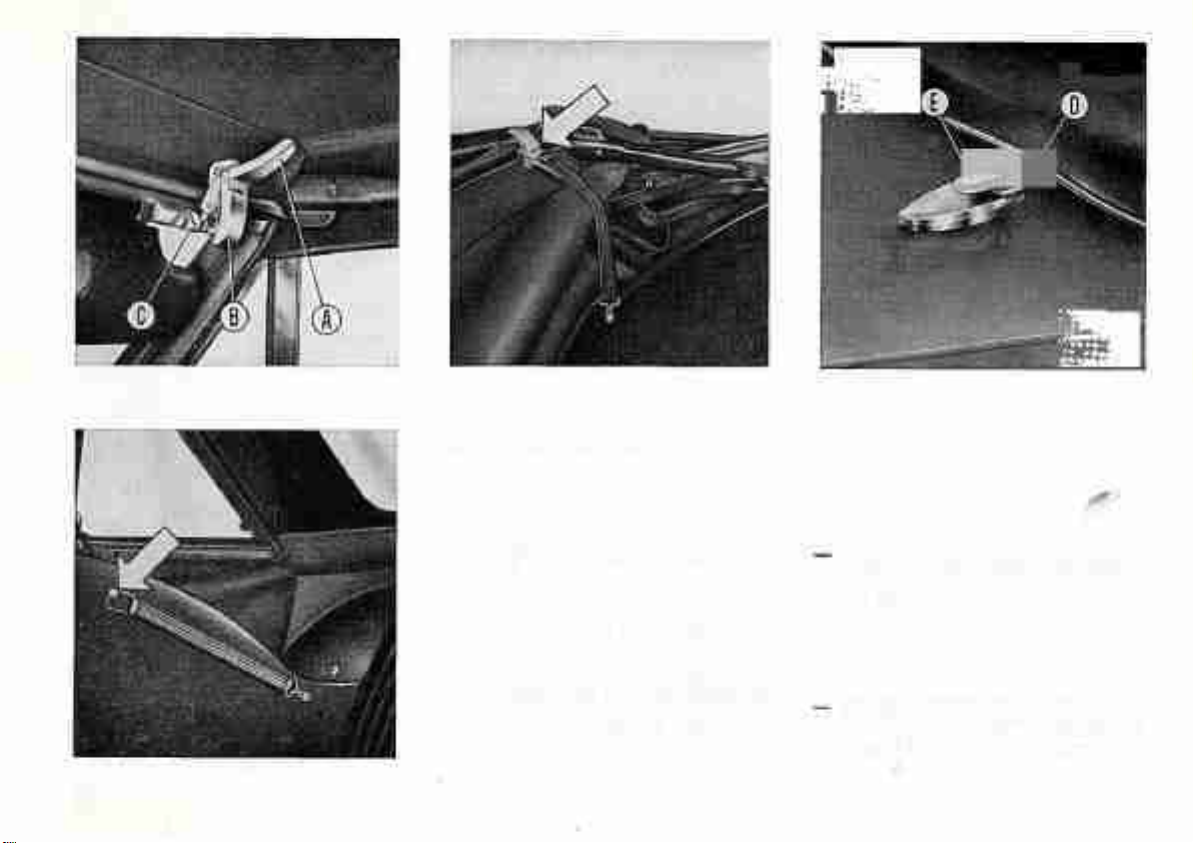

FOLD-AWAY TOP

: ti|ll

til* Bftl J.s,

*»^ *{ *rr^5^ ^^^

• ** •*&£& ^ ^JStH

1

-

-

* *

!l

r:.;

1*

> * I 1 " '" •'•' -

* *• - •

1

^^

• * * r ••

* " r "* ^ """ M * Itv

Wmgmm

^•:i •••••'•

! * i &?>*&!

J^ 1^" ^-.H

Si

14

To lower the folding top, proceed as

follows:

— Wind down the door windows.

— Pull down the two latch levers A

and release clamps B from latches C

securing the top to windshield

frame.

Push the top to the rear, making

sure the back window is not pinched by the metal frame.

Free the rubber strap from the peg

on body side and strap the folded

top as shown in the figure.

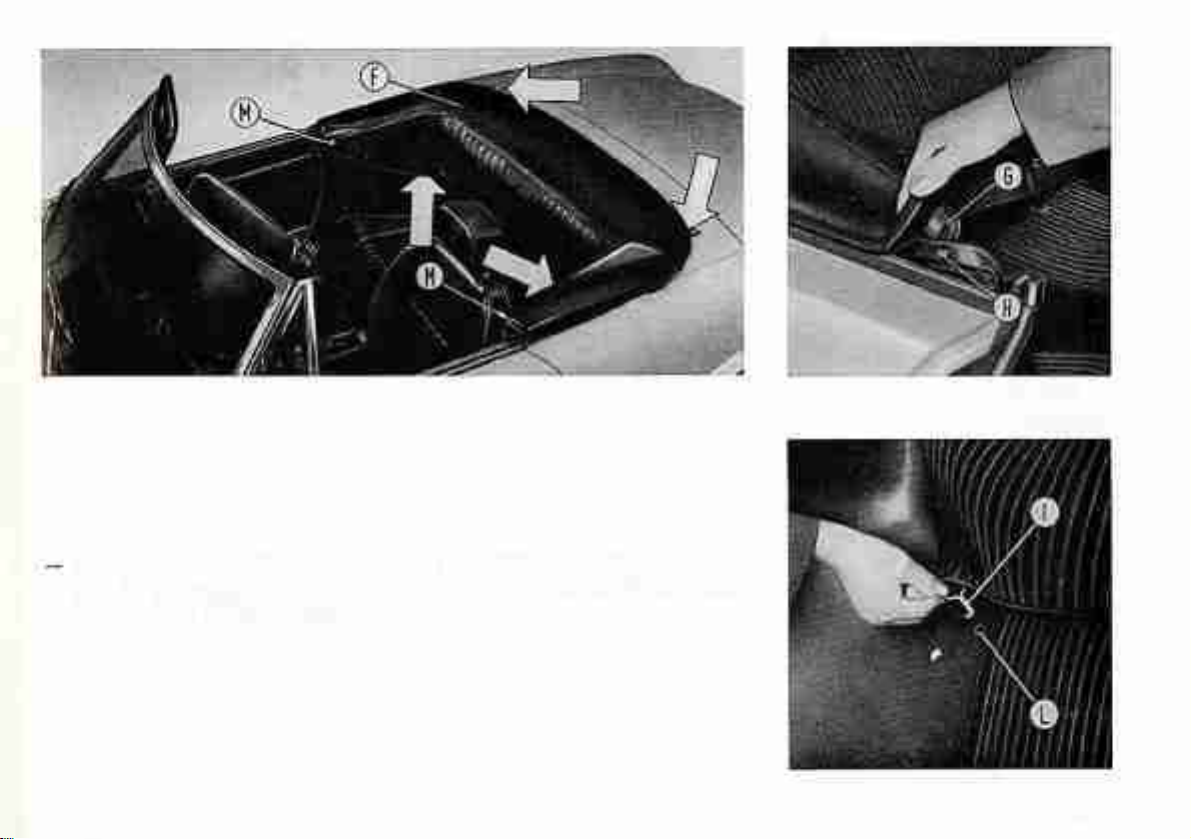

Page 17

Place cover F on the folded top

well by fitting rear eyelets D on

hooks E (page 14) then catches G

in detents H, spring hooks I in

holes L and snap on the button

fasteners M.

15

Page 18

38000

STARTING THE ENGINE

Cold Starts With Manual

Transmission

— Move gearshift lever to neutral.

— Depress clutch pedal, especially in

cold climates.

— Insert and turn ignition key clock-

wise to the stop, that is position

AW. As soon as engine is started

release key which will snap back to

position MAR.

16

Should the engine fail to start

return ignition key back to ST position and repeat starting attempt.

— Do not step on accelerator pedal

until the engine is running smoothly.

— Avoid sudden acceleration when

engine is cold.

Do not continue with repeated starting attempts. If the engine fails to

start or stalls at idling have the fuel

injection and ignition systems checked

as soon as possible.

Cold Starts With Automatic

Transmission

Move the selector lever to HI or P

Engine starting is not possible with

the selector lever in any other position.

Then proceed according to manual

transmission instructions.

Hot Starts

For vehicles with manual and automatic

transmission turn ignition key without

touching accelerator pedal.

Page 19

DRIVING THE CAR

Never maintain nor exceed the

maximum allowed speeds and do

not drive with tachometer pointer

steadily on the yellow sector.

Do not travel steadily for long

intervals at top speed in any gear.

All red indicator lights should be

out while driving.

Do not coast downhill with the

clutch pedal depressed, the transmission in neutral or the engine off, as the

marginal saving in fuel consumption

which may be derived from such

practice does not compensate for the

resulting loss in brake lining life and

driving safety which is provided by the

braking effect of the engine.

Remember that upon switching off

the engine, the brake servo is

deactivated and, therefore, braking

requires more effort.

Do not allow the engine to lug,

particularly when driving up steep

hills, but shift down in good time to

benefit from maximum engine pulling

power.

Do not ride the clutch, otherwise

slippage and damage will result.

Ensure that both the foot and

hand brakes are efficient at all times.

After a car wash apply the foot-brake

a few times so as to restore full

brake effectiveness.

Always apply the foot brake progressively. Remember that wheel locking, especially with an unladen car,

will result in dangerous skidding. In

case of emergency the hand brake may

be used to stop the car.

On wet or slippery roads hard

braking will increase the likelihood of

wheel locking and consequent inevitable loss of handling control. Instead,

use the engine braking effect by

engaging a gear lower than would

normally be required. Braking, if absolutely unavoidable, should be gentle

and progressive and, in any case,

simultaneous with engine braking.

On icy roads drive slowly, turn

the steering wheel very gently, avoid

using the brakes, change gear smoothly

and do not drive with the clutch

pedal depressed. If the car starts

skidding release the accelerator pedal,

do not brake, but steer smoothly in

the direction of skid; as the car re-

gains its course straighten the wheels

and accelerate gently.

Always use tire chains or snow

tires before starting a journey on ice

or snow covered roads and remember

that while snow chains can be fitted

to the driving wheels only, studded

tires should be fitted to all wheels.

When driving in mist or fog during

daylight switch on the parking and

tail lights: do not use the high beams.

17

Page 20

Before turning or changing lanes,

in addition to giving the correct signals

glance in the mirrors to ascertain the

intentions of the drivers behind you.

Before cutting back into your lane

after overtaking a vehicle wait until

it appears in your inner mirror.

At night when meeting oncom-

ing traffic, keep your eyes on the

right side of the road rather than

looking straight into the approaching

headlights or other light sources: you

will avoid being blinded.

PARKING

Always apply the hand brake when

parking and if on a grade, for added

safety also shift into first or reverse

depending on whether the car is

heading up- or downhill.

RECOMMENDED

SHIFTING SPEEDS

1st-2nd 2nd-3rd 3rd-4th 4th-5th

15 mph 25 mph 40 mph 45 mph

Note: In any case the maximum speed

listed on page 62 should never be exceeded.

When the car is left in dark areas

always turn on the parking lights:

lighting switch pressed halfway in

at bottom.

18

Page 21

AUTOMATIC

TRANSMISSION

(Optional Extra)

OPERATION

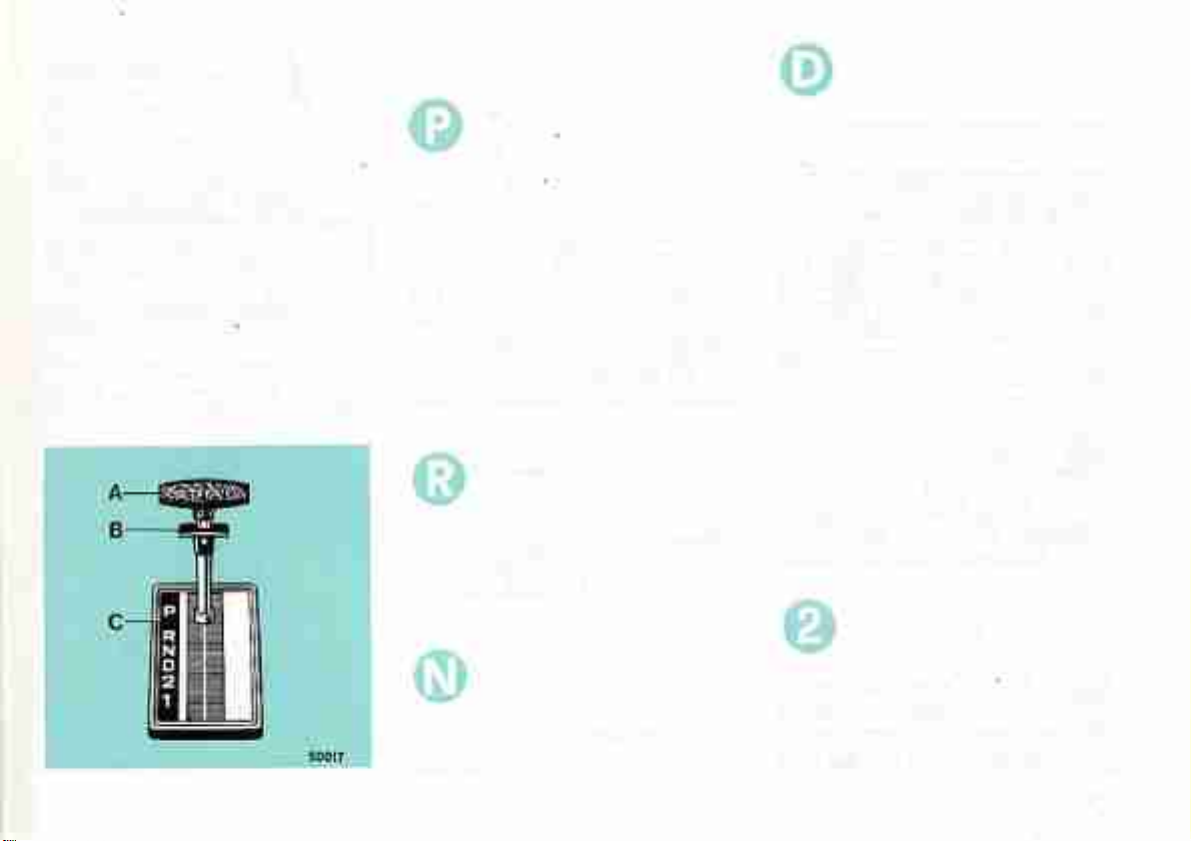

To obtain any ratio move selector

lever A to the desired position.

When shifting from P to R, R to P,

N to R, D to N or 2 to 1 lift trigger B

simultaneoulsy. When shifting from D

to 2 and viceversa do not operate

trigger B, Light C indicates the selected

position.

Selector Lever Positions

P. Park - R. Reverse - M. Neutral D. Drive - 2. Intermediate - 1. Low.

Selector Lever Positions

Park

In this position the transmission is

mechanically locked but engine starting

is possible. Park should not be selected

when the car is in motion or stationary

in busy car parks where shunting is

likely to occur.

Use of the Park position is recommended when parking on flat and

sloping ground and before servicing.

Reverse

To select Reverse bring the car to Q

dead stop and release the accelerator

pedal (engine idling).

Drive

This position is used for normal

driving.

The transmission starts in low gear

and automatically changes up or down

at suitable road speeds according to

the position of the accelerator pedal

and the demands made by the driver.

For quick down-shifting depress the

accelerator pedal through its hard spot

(kickdown position).

Kickdown permits down-shifting

from third to second below 59 to 64

mph or into first below 31 to 34 mph.

Normal change-down from D to 2

and D to 1 can be obtained by means

of the selector lever below 70 mph

and 43 mph respectively, without de-

pressing the accelerator pedal.

Intermediate

Neutral

In this position the engine can be

started.

Operation is as described under D

but no up-shift into third is possible.

This may be advantageous when driving

over hilly or difficult roads requiring

19

Page 22

consistent pull and moderate engine

braking.

Low (Lock-up in First)

o

To be selected when driving up and

down very steep hills, especially with

a trailer on tow, and when maximum

engine braking is desired.

When the selector lever is moved to

1 the transmission changes to, and

remains in first, regardless of engine

speed.

Note: With the engine idling and D,

2, 1 or R selected the car may tend to

creep forwards or backwards. This

tendency can be obviated by lightly

applying the foot brake and may well

be advantageous for difficult parking

maneuvers.

Starting

Before starting the engine move the

selector lever to l\l or P.

Engine starting is not possible with

the selector lever in any other position.

Starting instructions not described

here are as given on page 19.

Depress the brake pedal without

accelerating at all, and move the

seSector lever to 1, 2, D or R as

desired.

Release the hand brake and the foot

brake.

Depress the accelerator pedal progressively. In D the car will move off

in first gear and automatically change

up as speed is increased,

For maximum acceleration depress

the pedal through its hard spot. This

causes up-changes to occur at higher

road speeds than under part-throttle

driving {approximately 40 to 43 mph

from first to second and approximately

65 to 70 mph from second to third).

Exceptionally, when maneuvering

in confined areas or for hill-holding

the driver will find it convenient to

use the left foot on the brake pedal

and, using this pedal in conjunction

with or without the accelerator pedal,

a high degree of control is obtained.

During normal driving both the

accelerator and the brake pedals should

be operated with the right foot only.

Towing by Another Vehicle

Proving the transmission is

operating satisfactorily, the car may

be towed in N over distances up to

30 miles and at road speeds not

exceeding 30 mph, otherwise gearbox

damage may result. If the car is to

be towed over long distances, or if

the transmission is defective, the car

must be towed with the rear wheels

raised from the ground or propeller

shaft disconnected.

Warning

To prevent dangerous over-revving

do not exceed the prescribed shifting

speeds.

Stopping

To stop the car release the accele-

rator pedal and apply the brakes.

No further action is needed for

short stops, as first gear will be automatically re-engaged when moving

off again. On upgrades, hold the car

exclusively by pressing the brake pedal.

For long stops, move the selector

lever to hi and apply the handbrake.

When leaving the car unattended

shift the selector lever to P after

coming to rest. Thus, the transmission

will be locked.

20

Page 23

WHEEL CHANGING

If possible, place the car on level

ground and lock rear wheels by the

hand brake.

Release strap B and take out jack A

and spare wheel C in trunk.

38821

The jack is completed by hand

lever D and extension E,

Extension E has two drives: a hex.

shank for the jack hand lever and a

hex. socket to manipulate both the jack

and wheel bolts.

To Remove the Wheel

— Slacken about one turn the four

wheel fixing bolls using extension

E and lever D.

— Place the jack under the car at the

bracket nearest the wheel to be

removed.

— Fit extension E to jack shank, and

turn handwheel F until the jack

contacts the lift bracket under floor.

— Make sure the ground is sufficiently

hard (that is, jack base does not

sink during the lift action).

3BS24

Fit the hand lever to extension E

and actuate the lever to and fro until

the wheel is clear of the ground.

Back out completely the bolts and

remove trim and wheel.

Keep the bolts in a clean place to

prevent the threads from getting

fouled with dirt, a frequent cause

of difficulties at reassembly.

Page 24

To Fit the Wheel

— Fit the spare wheel seeing that the

location dowel fits into the location

hole in wheel disk.

— Remove the jack hand lever and

actuate handwheel F of extension

E and lower the car.

— Fully tighten the wheel bolts in

criss-cross sequence.

— Refit trim and refit and tighten

uniformly the wheel fixing bolts in

criss-cross sequence.

— Check that the newly fitted tire is

inflated to the correct pressure.

When repositioning the jack in the

trunk make sure extension E is properly

housed and Jack, bag and hand lever D

are correctly fastened by strap B.

34975

JACKING UP AND

TOWING

When either the front or rear end

of car must be raised with a garage

jack, it is necessary to fit jack head

under front suspension cross rail, in-

terposing a suitably thick (abt. 3 cm

- I'A in.) wooden block, or rear

axle bulge.

If car needs towing with a rope

this must be attached to the specially provided front brackets.

22

Page 25

MAINTENANCE

This section includes all periodical

maintenance operations essential for

continued effectiveness of the car.

The lubrication, cleaning, inspection and adjustment operations recommended in relation to given mileages

are listed on a General Maintenance

Schedule. Reference is made to the

pages where each operation is described.

The Owners Warranty and Service

Book contains a free service coupon.

This service should be performed at

1 500 miles.

Failures, other than those resulting

from defects in material or workmanship, which arise solely as a result of

owner abuse and/or lack of proper

maintenance are not covered by war-

ranty.

Particular stress is laid on

importance of reporting to a

FIAT Dealer for all the main- "

tenance operations so marked :

For oil grades not mentioned here,

seethe Fill-up Data Table.

EMISSION CONTROL

SYSTEMS

The maintenance operations necessary to ensure the proper functioning of the vehicle emission control

systems are printed in red for im-

mediate identification both in the

General Maintenance Schedule and

in the paragraphs of this section.

The engine tuneup and adjustment

specifications are also listed on the

E.P.A. and California Regulations Conformity Tag. located in the engine

compartment (see page 3).

For oil these operations it is also

recommended to refer to the instructions specified in the Owners Warranty

and Service Book,

NOTICE

Besides the routine maintenance

operations listed in the Schedule,

this section describes other operations

which must be performed only in

special cases of defective operation of

mechanical units.

23

Page 26

MAINTENANCE

GENERAL MAINTENANCE SCHEDULE

We recommend that all operations so marked be entrusted to the Fiat service network

OPERATIONS

Valve clearance: Check and adjust if necessary

Air cleaner: Renew filtering element ....

Spark plugs : Changs

See page

26

27

27

Every

15 000

miles

• *

Every

30 000

miles

0

Every

45 000

miles

Alternator and water pump drive belt; C/ieck tension and state of wear; Adjust andjor

renew as necessary

Oxygen sensor (Lambda probe): Renew , ,

28

32

o •

o

o

Brakes; Check state of wear of seals, lines and check hand brake efficiency, renew or adjust

as necessary ,

Transmission (manual and automatic) and differential: Change oil

Clutch: Check pedal height and adjust if necessary

Suspensions, steering and drive line: Check components

Wheel bearings: Check lubrication

Body: Lubricate door locks and hinges

1

These operations are not obligatory but only recommended when the car is used frequently in abnormal traffic conditions or on sandy

38

39

39

41

41

43

•

and dusty roads.

24

Page 27

SPECIAL MAINTENANCE

OPERATIONS

Engine oil -.Check level , , 26

Engine oil and filter; Change 26

Cooling system : Check coo/ant level 37

Brakes: Check brake pads and front discs 38

Automatic transmission (where fitted): Check oil level 40

Tires: Check pressure 41

Battery: Check electrolyte level, terminals and clamps 44

See page

Lubricant Designations

FIAT

VS

+

INTERNATIONAL

Single-grade low-ash content detergent oils - API Service SE, to

MIL-L.46152 and above :he CCMC

European Sequence

FIAT

Gl/A

W90/M

INTERNATIONAL

A.T.F. - DEXRON II Type

for automatic transmission

SAE 30 W/90 EP Oil to MIL-L-2105 B

Every

500

miles

(or

weekly)

0

Every

3 000

miles

•

Every

7 500

miles

ZC90

SAE SOW/90 Oil with anti-wear

additives, for manual transmission

Jotai

MR 3

Lithium-base Grease N.L.C.I. Mo. 1

Lithium-base Grease N.L.G.I. No. 3

25

Page 28

ENGINE

Engine Oil

Every 500 miles or weekly -

With engine cold, check oil level which

mus1 always be between the Min

and Max marks on dipstick, and top

up if required.

Every 7 500 miles or every six

months at most - Replace

oil with engine well warmed up.

Drain all used oil through plug B.

Oil should of course be changed

also in relation to the grade used and

outdoor temperature (Singiegrade or

Multigrade) as shown in the Fill-up

Data Table,

Engine Oil Filter

Every 7 500 miles or at every en-

gine oil renewal - Unscrew

filter A from its support on

crankcase, and replace.

Before fitting a new filter on the

support, wet its seal with engine oil.

Screw on the filler: once the seal

contacts the support, tighten 3/4 turn

more.

Tappet Clearance

Every 15 000 miles or whenever

valve operation becomes noisy.

Check clearance between tap-

pets and cams. Specified

clearance, with cold engine, is .41 10

.49 mm (.016 to .019 in) for intake

and .46 to .54 mm (.018 to .021 in)

for exhaust valves.

.

Page 29

37995

Spark P/ugs

Every 30 000 miles (*): Change

spark plugs. To disassemble

spark plugs, withdraw terminals

A and back off using a suita-

ble wrench.

New spark plugs must be of the type

specified (see page 62}; if their thermal

rating is incorrect engine malfunction

and/or failure may occur.

(*) It is recommended thai air cleaner and

spark plugs be replaced every 15 000 miles

if the vehicle is frequently driven in heavy

traffic conditions or sandy or dusty areas.

Air Cleaner

Every 30 000 miles (*) : Change fil-

tering element. To gain access

to filtering element A undo

fasteners C using a screwdriver

and remove cover B.

Change the filtering element, refit cover

and secure with fasteners C.

Reinstall fasteners by pressing on

curved section.

27

Page 30

Alternator and Water Pump

Drive Beit

Every 30 000 miles (*); Check belt

for wear and if necessary renew,

Also check belt tension and

adjust if necessary,

Belt sag should he 1 to 1.5 cm (1/3

to 1/2 in.) when firm thumb pressure

is applied. To adjust tension of belt

driving water pump A and alternator

B, slacken nuts C and D and move

alternator outwards and then retighten

the nuts.

Do not exceed the tension since this

would result in abnormal stress on the

bearings.

(') It is recommended that [hese operations

be carried out every 15,000 miles if the

vehicle is frequently driven in heavy traffic

conditions or In sandy and dusty areas.

Ignition Timing

Spark advance is set in the factory

and no further adjustment is required

during the life of the vehicle.

— For vehicles fitted with manual

transmission, engage top gear and

move vehicle until cylinder no. 1 is

in compression phase and the mark

on the crankshaft pulley is aligned

with the fixed timing mark A indicating 10u B.T.D.C.

Ignition timing:

v.);B = 5°(Adv.);C-0°(TDC)

37991 |

Ignition timing must be checked only if

the ignition distributor is removed.

To adjust proceed as follows:

Page 31

For vehicles fitted with automatic transmission use a suitable wrench to adjust

the nut D securing crankshaft pulley

until above conditions are obtained.

— Remove distributor cap and turn

shaft manually until rotor is posi-

tioned against contact for firing of

cylinder no. 1.

Without moving distributor shaft, insert

distributor1 in its seat and secure.

Connect leads going to coit, install

cap and check that the leads are

correctly connected to spark plugs,

Connect the rev counter and the stroboscopic lamp to the engine using

spark plug lead for cylinder no. 1.

EMISSION CONTROL

SYSTEMS

Vehicle emissions are controlled by

various devices that make up the crankcase emission control system, the

exhaust emission control system and

the fuel evaporative emission control

system.

38113

— Start engine and check ignition

timing with the stroboscopic lamp.

Ignition timing should be 10"

B.T.D.C. at 800 to 850 rpm for

vehicles with manual transmission

and 10" B.T.D.C. at 700 to 750 rpm

for vehicles with automatic transmission,

— If distributor calibration is not cor-

rect, slacken and rotate manually

until correct calibration is obtained,

then tighten it.

If distributor removal is not required,

proceed from this point.

Any modification of the emission control systems is subject to federal laws

and regulations and may incur penalties.

29

Page 32

Crankcase Emission Control

System

This is a closed system designed to

prevent any emission of blow-by gases

and oil vapours into the atmosphere.

These gases and vapours are piped

to an orifice downstream of the throt-

tle and are then drawn into the engine

In any rpm condition.

1. Emission feedback port

2. Throttle valve

3. Flame trap

4. Intake manifold

5. Sump-to-air cleaner line

6. Cyclone liquid/vapor separator

7. Oil drain line into sump

38004

30

Page 33

Fuel Evaporative Emission

Control System

The fuel evaporative emission control

system is designed to prevent air pol-

lution caused by evaporative tosses

from the fuel system.

This is accomplished by a proper sys-

tem which prevents the release into the

atmosphere of fuel vapors from the

fuel tank.

The fuel vapors from the fuel lank ftow

into the activated charcoal carbon canister where they are absorbed and

stored when the engine is not opera-

ting.

When the engine is running, the fuel

vapors retained in carbon canister are

purged through a line which conveys

them to intake manifold.

The system consists essentially of:

— Sealed filler cap.

— Limited-filling tank,

— Vapor-liquid separator.

— Two-way valve.

— Vapor vent line.

— Carbon canister.

— Purge line.

39069

1. Fuel pressure regulator - 2. Cold start solenoid injector - 3. Solenoid injectors -

4. Activated carbon canister - S. Two-way valve - 6. Fuel tank vapor vent fine - 7. Fuel

return line - 8. Fuel delivery line - 3. Fuel filter - 10. Electric fuel pump - 11. Sealed filler

cap - 12. Vapor-liquid separator.

31

Page 34

Ftief Injection System

General

This is an electronically controlled

intermittent low pressure injection

system.

The fuel is injected upstream of the

intake vaives by means of solenoid

injectors supplied at constant pressure.

Flow is controlled by means of varia-

tion in the opening time of the injectors.

The main factor controlling flow is

the direct measurement of drawn air

by a special sending unit which trans-

mits the most important information

for fuel metering to the electronic

control unit.

The system is also provided with a

certain number of measuring sensors

which provide the electronic control

unit with the information required to

optimize the composition of the mixture in all engine operating conditions.

Exhaust Gas Emission Control

System

For the control of exhaust gas emissions, the injection system is fitted with

an oxygen sensor {Lambda probe)

which measures the oxygen content of

the exhaust gases and transmits any

adjustment of the air-fuel mixture to

the control unit. It is thus possible

with the aid of a catalytic converter

fitted to the exhaust pipe, to reduce to

a minimum the harmful residues con-

tained in the exhaust gases.

Oxygen Sensor {Lambda probe)

Every 30,000 miles: Renew oxygen

sensor. An indicator on the

instrument panel lights up on

completion of 30,000 miles

(see page 7) signifying that the sen-

sor must be replaced.

To renew sensor proceed as follows:

— Disconnect probe cable A.

— Back off probe B from its seat C

on exhaust manifold.

— Fi 1 new probe lubricating threaded

part with anti-seize, ami-rust grease.

— Reconnect cable A.

— Press button to zero indicator.

I79H9

32

Page 35

ELECTRONIC FUEL

INJECTION DIAGRAM

1. Battery

2. Relay set - Operates electronic

control unit 3 and motor driven fuel

pump 1 7.

3. Electronic control unit

Receives information about oil quantity, coolant temperature and temperature of cylinder head, position of

throttle valve, starting phase as well

as engine rpm and injection point.

it processes this information and trans-

mits electric pulses to the solenoid

injector.

It is connGcted with the individual

components by means of a multiple

connection plug and associated con-

necting cables.

18

Vacuum

Components con rlHttiO nS

•Systam components

3800S

4. Coil

In addition to its normal function, it

transmits the number of engine rpm or

the injection point to the control unit.

33

Page 36

5. Air measuring instrument

This supplies information to electronic

control unit of quantity of air drawn

and activates fuel supply pump,

12. Fuel pressure regulator

Keeps fuel pressure constant in fuel

lines.

20. Catalytic converter

Reduces harmful residues contained

in exhaust gases to a minimum.

6. Supplementary air valve

Supplies extra air during engine heating stage, depending on temperature

level.

7. Throttle switch

Signals idle and full load to electronic

control unit.

8. Temperature sensor

Signals coolant temperature at the cy-

linder head outlet

9. Cold starting solenoid injector

During starting in low temperatures,

injects extra fuel into intake line.

10. Solenoid injectors

Inject fuel in intake port of cylinders.

11. Delay thermal switch

This automatically controls injection

of cold starting solenoid injector.

13. Fuel delivery line

14. Excess fuel exhaust line

15. Ignition switch

16. Fuel filter

Is fitted on fuel supply line for fuel

filtering.

17. Motor driven fuel supply

pump

Delivers a constant supply of fuel to

solenoid injector.

18. Fuel tank

19. Oxygen sensor {Lambda probe).

Measures the oxygen content of exhaust gases and transmits any adjustment of air-fuel mixture to control unit.

Note: You are advised to take the

following precautions:

— Never start the engine if the battery

is not properly connected.

— Do not use charger with battery

leads disconnected.

— Never disconnect battery leads with

the engine running.

— When charging battery, disconnect

clamps.

— If temperature is above 80° C

(special body work) disconnect

electronic control unit from vehicle.

— Never remove or insert control unit

harness connector with ignition

switched on.

— Jf car is to remain out of service for

some time, add 10% of engine oil to

the fuel tank.

Page 37

Idling Speed

Any adjustment to idling speed must

be carried out with a warm engine

and with gearshift lever in neutral

position for mechanical versions and

in D (drive) position for automatic

versions.

idling speed is S50 _L 50 rpm for

manual transmission and 750 ± 50 rpm

for automatic transmission.

WARNING

Fuel Refilling

Strictly adhere to the label on instrument panel and on filler cap.

The engine is warm when the radiator

electric cooling fan has been activated

at least twice.

To adjust idle the electric fan must be

off.

To adjust, turn bypass screw A.

Idle CO Setting

The idle co setting is factory adjusted

and sealed. No additional adjustment

is required when tuning up engine

during the useful life of the vehicle.

UNLEADED FUEL ONLY

Leaded fuel will damage the catalytic

converter beyond repair, Alwais refill

at Service Stations which carry unleaded fuel (small pump nozzle).

35

Page 38

COOLING SYSTEM

Coolant Circuit

Every 500 miles or weekly - Check

the coolant level in system expansion

tank, with cold engine: the level must

3lways be abt. 7 cm (2y.F in) above the

M!N mark on tank.

When engine is very hot the level

might rise noticeably: this could afso

happen immediately after stopping the

engine.

Should the coolant level drop below

the tank MIN mark, top up by removing

expansion tank cap and pouring in

coolant, seeing that its level is as

specified.

Warning: Do not remove radiator or

expansion tank caps on a hot engine

to avoid possibly scorching your hands;

wait until engine has cooled down.

Do not top up a hot engine with

cold water.

Should more than 2 consecutive top-ups be required at

short intervals, or after limited

mileages (500 miles), the system needs

checking, This applies also when

water temperature gage pointer stays

on the red sector (see page 6).

To drain cooling system, move

lever D to the left {see page 12),

open the cocks on radiator lower side

and on cylinder block, and disconnect

expansion tank hose.

To fill the system:

— Connect expansion tank hose, close

radiator cock and remove plug A.

— Pour in water siowly through radia-

tor filler port until water overflows,

then refill the expansion tank.

— Refit radiator and expansion tank

caps and plug A then run the

engfne so as to favor a thorough

mixing of the fluid in the system.

— Stop the engine, slacken plug A,

wait for a proper system bleeding

and refit the plug.

— With engine cold check the level

in expansion tank and, if nee. top up.

Antifreeze Mixture

The cooling system is filled with an

antifreeze mixture effective down to

— 35 "C (—32

(1

F). In case of coolant

change or topping-up FIAT recommends the use of a 50-50 mixture of

water and Paraflu 11 fluid {or equi-

valent), which allows the use of hard

or chlorinated water and incorporates

Page 39

oxidation, corrosion, foam and scale

inhibiting properties and is effective

down to — 35"C (—32° F). See Fill-up

Data Table.

This mixture shall subsequently be

replaced after 45 000 miles or every

two years, whichever occurs first

thus reducing the need for any servicing action on the cooling system.

Fluid Reservoir

The « Low Brake Fluid Level » indicator (see page 7), controlled by

a float and switch assembly on brake

fluid reservoir, warns the driver of a

sudden drop in brake fluid.

Every 15 000 miles - Top up brake

fluid reservoir. Use exclusively DOT 3

MotorVehicle Brake Fluid (conforming

to F.M.V.S.S. No. 116). Avoid using

any other type of fluid which would

damage the special rubber parts in the

system.

When this mixture is used, plain

water may be added only in emergencies (sudden heavy coolant losses).

As soon as possible repair the

fault and refill the system

with the recommended coolant.

BRAKES

Brake system with front and rear

independent circuits.

If pedal free travel has become

excessive, if braking unbalance

on one wheel is appreciable

or if pedal sponginess is felt with

consequent reduced brake effectiveness, a complete inspection of the

system is needed.

A - Front brake fluid section

B - Rear brake fluid section

Front Brakes

Every 7 500 miles - Check that brake

linings are not worn down to less than

1.5 mm (.06 in). Replace if required.

Lines and Fittings

Every 15 000 miles - Check hoses

and fittings for leakages and tightness.

Bleeding

Bleeding is a delicate operation

requiring the necessary know-

how and should only be needed

when air has entered either one or

both brake circuits (line disconnection,

37

Page 40

fluid drainage, etc.). This is indicated

through pedal sponginess and reduced

braking effectiveness.

POWER TRAIN

Clutch

Manual Transmission OH

Every 30 000 miles

Hand Brake

Every 15 000 miles or sooner if

hand lever stroke is excessively

long, pull up the lever three

notches and adjust through

the appropriate tensioner (see fi-

gure below).

Then release the lever and check

that the wheels are not locked.

The clutch is mechanically controlled,

with automatic wear take up and no

pedal free travel.

Every 15 000 miles

Check pedal height and adjust

if necessary.

After repeated adjustments, check

clutch facings for excessive wear:

replace if required.

Renew oil. Let drip thoroughly

from plug B before refilling. The correct

level is up to the opening of filter

plug A.

sk is

38

Page 41

Automatic Transmission

(Where fitted)

If defective transmission operation is detected contact your

nearest FIAT Dealer.

Every 3 000 miles

Check the fluid level. Correct level

is between the MIN and MAX marks

on dipstick A.

Before checking the fluid level

drive about 6 miles to reach normal

operating temperature, stop the car

on level ground but keep the engine

running at idling speed, and move the

gear selector lever to P or N.

If necessary, top up to the MAX

mark through filler B using Fiat GI/A

or equivalent grade of automatic trans-

mission fluid. Do not overfill.

The utmost care should be taken

to ensure that both the containers and

the funnel used for topping up are

absolutely clean.

Following emergency topping-up

after a sudden leak, owners are

recommended to contact the nearest

FIAT Dealer for a general inspection

of the transmission.

mm

m

Every 30 000 miles or two years -

Renew the fluid with a warm transmission. If the fluid is found to be

heavily soiled, also renew the filter in

the valve assembly, together with the

associated seal.

To renew the fuild remove plug A.

To renew the filter remove sump B.

Axle Oil

Every 30 000 miles

Renew oil after thorough draining

through plug B. The correct level is

up to the opening of filler plug A.

MIIS Hii

Page 42

SUSPENSIONS

AND STEERING

Front Suspension [Steering

Articulation Boots and Caps

Every 15 000 miles or whenever

underbody inspections are carried out,

check the condition of ball joint rubber

caps and steering gear rack rubber

boots.

If they are damaged, replace.

The new caps should be packed

with grassofiat MR 3 prior

to their installation.

At the same time inspect ball joints

for excessive play. If evidence of

looseness exists, replace the bail joint.

Proper joint maintenance is essen-

tial for car safety.

Front and Rear Suspensions

Check rubber mounts for proper

efficiency.

Front Wheel Bearings

Every 30 000 miles - Check bearings

for play and adequate lubrication. Adjust and lubricate

with grassofiat MR 3, if nee-

ded.

TIRES

Every 500 miles or weekly - Check

pressure with a gage not forgetting

the spare wheel (see page 56 for

pressures}.

Make sure pressure is exactly the

same in each pair of tires. In hot climates, do not reduce pressure as this

would only increase tire temperature.

MISCELLANEA

Windshield Washer

Every 7 500 miles approximately

Check level in the bottle located

in left headlamp compartment.

In case of incorrect jet aiming:

Clean the jet squirt hole accurately (by

a needle).

Page 43

Check also electric pump terminals.

To re-aim jets: Turn the complete

body with a screwdriver and then the

lateral pin so as to direct the water

squirt to top of wiper sweep arc.

Windshield Wiper

Every 7 500 miles approximately

Check for proper efficiency.

To remove a wiper blade, tilt out

the arm, free blade mount A from its

lock dowel B on arm and extract the

blade upwards.

2546Q

Note - When adjusting wiper arms

position on windshield ensure that

the distance from windshield base to

wiper arm fulcrum is:

driver's side = 55 to 75 mm

passenger's side = 70 to 90 mm

BODY

Every 15 000 miles

Lubricate the following items as

required using the recommended products:

Door lock cylinders with gfaphite

powder.

Door locks through the specially

provided hole (near lock) blanked

by a plastic plug, door hinges and

limiter, and front seat reclinable

backrest control with engine oil.

Window venti-pane joints and hinges with glycerine (2-door version).

Trunk lids and engine hood catches

and hinges with petroleum jelly.

Seat guide rails with grassofiat

Jotai.

Tool Kit

The tool box contains:

Wrench, socket, spark plugs

Wrench, double end, 8x10 mm

Wrench, double end, 13x17 mm

Screwdriver, double-tipped

Punch, straight

Wrench, wheel bolts

The jack is stored in trunk, on righthand side.

41

Page 44

Exterior Body Care

the paintwork extra protection. Also

remove any stain promptly.

interior Body Care

Wash the bodywork frequently with

cold or lukewarm water. Sponge down

using a good quality car shampoo -

Deterlux or equivalent. Never use

household soap or detergent, otherwise

the paintwork may be adversely affected.

If a hose is used avoid directing it

at full force against the body. Rinse

thoroughly and dry off with a clean

chamois leather.

Do not wash your car in the

sunshine, especially in hot climates or

when the hood is still hot.

When cleaning the windshield raise

the wipers clear, and do not force them

sideways.

An occasional light polish with an

approved silicone car polish will give

Grease and tar should be removed

using a clean and soft kerosene- or

gasoline-moistened cloth. Subsequently, apply a fresh coat of polish.

To clean the windows use a good

quality spray type window polish DP 1 or equivalent - and wipe dry with

water-absorbing paper.

Chromium-plate and any other

bright decorative metal parts are best

cleaned with either cold or tepid water,

or any reputable make of car chrome

cleaner.

To preserve the rubber seals of

doors, hood and trunks use silicone

grease. This will also prevent squeaking,

particularly during the cold season.

Dust the interior, preferably using a

vacuum cleaner.

To remove grease spots from cloth

lining use a good brand of stain

remover (petroleum ether or light gasoline) apply talc liberally, allow to soak

and brush off.

To remove dirt from the seats or any

other imitation leather-lined part use a

damp sponge and a neutral or bland

soap. Subsequently, rinse with a ciean

damp sponge and dry off using

chamois leather.

Textile fiber mats should be cleaned

using a moistened cloth with good

quality detergent.

Rubber mats or floor lining should

be washed with a damp sponge and

neutral detergent or water and soap.

42

Page 45

PROLONGED INACTIVITY

If the car is to remain inactive over

long periods it is advisable to carry

out the following operations:

— Store the car in a covered, dry and

ventilated place.

— Ensure that the handbrake is re-

leased.

— Do not empty the cooling system:

in cold climates, if necessary,

replace the coolant with a reliable

high grade anti-freeze mixture.

— Remove the wiper blades to pre-

vent the rubber from distorting.

— Protect the car using a non-plastics

car cover.

If the car is to be left in the open

spray the underside and the entire

engine compartment with an approved

engine preservant, PROT V or equivalent. Do not spray a hot engine.

Before starting a sprayed engine

open the hood and wait for at least

ten minutes.

ELECTRICAL SYSTEM

Battery

Located in trunk.

Every 3 000 miles or monthly With battery at rest and cold, check

the electrolyte level.

In hot climates, check the level

more often.

When liquid additions are needed,

add distilled water (battery cold), never

electrolyte fluid (which contains sulphuric acid) as only water evaporates

from the battery in service, never

the acid.

— Check the tire inflation pressures

periodically.

— Re-charge the battery about every

six weeks.

— Switch off any electrical loads and

remove the ignition key.

— Protect the finish with a coat of

good silicone wax.

— Coat all bright metal parts with a

reputable make of car chrome

preservant.

Prior to using the car following a

prolonged period of inactivity perform

the following operations:

— Remove the chrome preservant from

all bright metal parts.

— Wash the car.

— Renew the engine oil.

— Recharge the battery,

— Refit the wiper blades.

— Check the tire inflation pressures

(including that of the spare wheel).

43

Page 46

WARNING - The battery contains

sulphuric acid. Avoid contactwithskrn,

eyes or clothing.

Externalantidote: Flush with water.

Internal antidote: Drink large quan-

tities of water or milk.

Follow with milk of magnesia,

beaten egg or veg. oil.

Call physician immediately.

Eyes: Flush with water for 15

minutes and get prompt medical atten-

tion.

Batteries produce explosive gases.

Keep sparks, flame, cigarettes away.

Ventilate when charging or using

in enclosed space.

Always shield eyes when working

near batteries.

Every 3 000 miles

Check posts and clamps for tight-

ness and cleanliness.

Except in particular service condi-

tions the battery does not require any

periodical recharge.

As your car is fitted with electronic devices

never run the engine - even for a very

short while - with battery disconnected

from the alternator or wrongly connected

(positive ground) otherwise serious da-

mage will result.

Fuses

Nine 8-Amp. and three 16-Amp.

fuses in a box under dash, driver's

side, and two 8-Amp. and 16-Amp.

fuses in separate holders.

Before replacing a blown fuse trace

the cause and remedy accordingly.

Unprotected Circuits

Alternator, starting and starter refay,

ignition high beams relay coilr battery

charge indicator, radio set {where

fitted), electronic fuel injection system.

Keep out of reach of children.

44

Page 47

Protected Circuits

•

A (8 Amps)

Turn signal lamps and indicator

Stop lamps

OH pressure gage and insufficient pres-

sure Indicator

Engine coolant temperature gage

Fuel gage, with reserve indicator

Engine tachometer

Low brake fluid level and hand brake

ON indicator

Back-up lamps

Fast idle electrovalve

Fasten belts indicator and relay for

buzzer

Delay circuit for fasten seat belts indi-

cator and buzzer

Selected gear indicator light (autom.

transmission)

30 000 miles pick-up and indicator

B (8 Amps)

Windshield wiper motor

Heater fan motor

Windshield washer pump

Windshield wiper sweep rate rheostat

C (8 Amps)

Left headlight high beams

High beam indicator

D (8 Amps)

Right headlight high beams

E (8 Amps)

Left headlight low beam

F (8 Amps)

Right headlight iow beam

G (8 Amps)

Front right parking lamp

Rear left tail lamp

Front right/rear left side marker lamps

License plate lamp (right)

H {8 Amps)

Front left parking lamp

Parking and tail lamps indicator

Rear right tail lamp

Front left/rear right side marker lamps

License plate lamp (left)

Cigar lighter housing indicator

Trunk light

Instrument cluster light

Ideogram illumination optical fibers

light source

Vehicular hazard warning signal switch

light

I (8 Amps)

Quartz crystal clock

Courtesy light

Hazard warning flasher and indicator

Inspection lamp receptacle

Remove key and fasten belts buzzer

L (16 Amps)

Horns

Engine fan motor

Wl (16 Amps)

Power window motor {Left-if fitted)

N (16 Amps)

Power window motor (Right - if fitted)

In separate holder (8 Amps)

Cigar lighter

In separate holder (16 Amps}

Fuel pump

Supplementary air valve

45

Page 48

Lights

Headlights

Alignment

For aiming the headlights,

screw 6 (vertically) and C

(horizontally) are readily acces-

sible after removing retaining

ring G.

Removal

Turn off screw E and remove

retaining ring 6. Slacken 4

screws Dand,byturning counterclockwise remove headlight unit

L. Then pull off terminal socket I.

Caution: Replace blown bulbs

exclusively with bulbs of the same

type and wattage. Weaker bulbs

will diminish visibility whereas

stronger bulbs will draw a greater

amount of current and overwork

the alternator, resulting in progressi-

ve battery discharge. For bulb specifications see page 63.

Installation

Center headlight unit L on body

by aligning locating dowel H with its

seat. Turn the unit clockwise and tighten screws D. Refit retaining ring G

by tightening screw E in hole F.

Front Parking and Turn Signal

Lamps

A Lens mounting screws

B Lens

C Bayonet-coupled bulb, double fila-

ment

D Positioning tabs

46

Page 49

Rear Turn Signal, Stop

and Back-up Lamps

The bulbs are accessible from inside

trunk after removing panel A.

To remove the panel free it from

the arrowed lugs.

The bulbs are of the bayonet type. Side Marker Lamps

B Turn signal light

C Stop light

D Tail light

E Back up light

The rear bulb holders are accessible

from inside the trunk.

To remove the bulb, disconnect bulb

holder A from seat B by turning coun-

terclockwise.

Bulb C is of the plug-in type.

822

47

Page 50

Front bulbs are accessible from in-

side fenders.

Courtesy Lamp

License Plate Lamps

To remove or refit follow the proce-

dure given for the rear bulbs.

A Spring plates (two) unit mounting

B Switch

C Bulb, pressure mounted

D Lens and body unit

To withdraw bulb holder remove retaining nuts from inside the trunk.

A Body retaining screws

B Body and lens

C Bulb holder

D Bayonet-coupled bulb

E Gasket

43

1^824

Page 51

Advice

for bodywork

maintenance

Page 52

Protection from Atmospheric Agents

FIAT has introduced a series of measures to protect the automobile from the various factors that can cause damage and

corrosion.

Briefly summarized, these factors are:

— Atmospheric pollution (urban environments and industrial

zones)

— Airborne salts (marine areas, particularly those with warm

and humid climates)

— Seasonal and ambiental humidity conditions (use of salt on

roads during the winter).

The paintwork and body shell underside can be subjected not

only to the chemical action caused by the factors mentioned

above, but also to the abrasive actron of airborne dust and

sand, mud, and loose gravel thrown up by passing cars as well

as the damaging action of salt spread on the roads in winter.

FIAT's answer to this problem can be summarized as follows:

— Corrosion and abrasion resistant paints and painting

systems.

— Widespread use of pre-treated and highly corrosion resistant

sheet metal.

— Spraying of the underside of the floor plan, engine compart-

ment, wheel boxes, and the various box sections with highly

adhesive protective waxes.

— Adequate covering or protective spraying with setting plastic

of such particularly exposed parts as the door sill panels,

wing interiors, borders, and so on.

— Use of enamels with greater resistance to polluted and

industrial atmospheres.

50

Page 53

Obviously the factors we have described act in different ways

in different cases, according to the environmental conditions

and the use of the car. Equally obvious is the fact that the

owner who cares about hfs car and maintains it properly can

make it last longer. We would like to list a few useful hints and

pieces of advice which, though obvious, often pass unobserved

for that very reason. The FIAT Service Network will be happy

to supply more details on request.

Body Paintwork

Needless to say, the paintwork does not serve only an aesthetic

function, but also covers and protects the metal on which it is

deposited.

Therefore, any abrasion or deep scratches that expose the

sheet metal should be retouched immediately to avoid pitting

by rust.

This retouching should always be done with original products

(see paint indentification plate).

Washing the car is the greater part of normal paint maintenance.

The frequency or washing depends not only on the frequency

of use, but also on the nature of the car's surroundings: washing

should be more frequent in more polluted areas, or if the car

is often parked under trees which produce harmful resins.

A correct wash should be done as follows: First the car should

be wet down with water at low pressure and sponged down

with a light (2 - 4%) detergent solution. Rinse the sponge frequently. Rinse the car with a spray of water to carry away the

loosened dirt, then dry with an air jet or chamois leather.

51

Page 54

Be particularly careful to dry the less visible areas, such as the

door frames, hood and headlight housings, where standing

water can collect more easily. Similarly, avoid putting the car

in a closed space immediately after washing, so that air circulation can help evaporate any trapped water.

Do not wash the car after it has been parked in the sun, or if

the hood is still hot, as this could adversely affect the brilliancy

of the paint.

The occasional use of a silicone car wax wilt give the paintwork extra protection and keep it shiny. If the paintwork beco-

mes cloudy due to smog accumulation, a slightly abrasive light

wax polish can be used.

Body Underside

The less accessible areas of the underside and frame box

sections have already been treated to ensure longer duration.

Regular check-ups should be made on the car. The aim of these

is to survey the soundness of the body and mechanical components, as well as to repair any damage. Particular attention

should be paid during check-ups to the drainage holes in the

underbody box frames and door frame undersides. These holes

serve to drain any water that may accumulate while driving the

car in the rain or while washing it, and so should be kept clear.

52

Page 55

In harsh environmental conditions, periodic supplementary pro-

tective treatments to the box sections and door interiors are

recommended.

These treatments must be done with special products and

techniques, and so should be left to experts. It should be done

at least every two years, and, in more severe cases, annually,

preferably at the beginning of winter.

Car Interior

The maintenance of the passenger compartment is no less important than that of the exterior. The same care should be

devoted to it.

Check to see that there is no standing water under the mats or

floor lining, as this could cause rusting. Dust the seats and

cloth parts with a brush or vacuum cleaner.

To remove grease spots use petroleum ether or light gasoline,

apply talc and brush off.

To clean seats in imitation leather, use a damp sponge and a

neutral or bland soap. Rinse several times with a clean damp

sponge.

While cleaning perforated seat covers, be particularly careful

that water does not seep through the holes to the padding.

53

Page 56

Windows

To ensure perfect visibility, windows should be cleaned with a

good quality glass cleaner and then wiped dry. Always use a

clean cloth to avoid scratching the glass.

To clean the inside of the windshield, where more obstinate

grease deposits are to be found, use sulphur ether as a solvent.

The inside of the rear window can be cleaned in the same way,

but particular care should be used to avoid damaging the demister wires embedded in the glass.

Engine Compartment

The engine compartment should be well washed at the end of

every winter to avoid damage caused by salt on the roads.

54

Chromium Trim

Chromium parts should be coated occasionally with car chrome

preservant to protect them from atmospheric agents.

Page 57

Cleaning Plastic Parts

Exterior plastic parts should be washed in the same way as the

car itself. If traces of dirt remain, use special plastic cleaners,

following the manufacturer's instructions. Interior plastic parts

can be cleaned in the same way. Do not use paint cleaners.

Cleaning the Convertible Top

To properly clean the convertible top, use the following procedure:

• Do not perform cleaning procedure in direct sunlight.

• Thoroughly wet down the entire vehicle with water.

— Keep vehicle wet through entire cleaning operation.

Caution: Make sure soap and cleansers do not run onto a dry

body finish since it may cause streaks or stains if allowed to dry.

• Apply a mild foaming cleanser to the entire top.

— Use a Lestoil and Fantastic mixture with clean warm water

in a 2 to 1 ratio.

For example:

— 1 pint Lestoil

— Vs pint Fantastic

— y2 gallon clean water

55

Page 58

• Scrub the top with a small medium-soft bristle brush adding

water, as necessary, until the cleanser forms a soapy consistency.

• Remove the first accumulated dirt from the top with a cloth

(towel} or sponge before it can be rubbed back into the fabric

top.

• Apply a fresh mixture of cleanser and clean water to top.

Scrub top with brush until the top is clean.

• Thoroughly rinse the top with clean water to remove all

traces of cleanser.

If any dirt spots are still on the top, apply Lestoil directly to the

wet top, utilizing the same scrub brush and a final rinsing with

clean water.

Leaving the Car in the Garage

A car left in the garage is subject to damage by humidity, which

is generally greater in a closed space than in the open air.

Parking the car in the garage while wet or covered with snow

will increase humidity through slow evaporation. In such cases

the car should be dried. Do not store large quantities of water

in the garage. Make sure that the garage has windows or other

openings to ensure adequate ventilation.

Page 59

Prolonged Inactivity

If the car is to remain inactive over long periods, It is advisable

to carry out the following operations:

• Clean and protect the painted areas with silicone wax, Coat

the bright metal parts with a standard chrome preservant.

• Store the car in a covered, dry and ventilated place.

• Ensure that the parking brake is released.

• Disconnect the battery terminals.

• Remove the wiper, blades and coat with talc.

• Open the door windows slightly.

• Protect the car using a non-plastic car cover. This should

not be waterproof.

• Check the tire inflation pressure periodically.

• Check the battery charge every iy2 month. When necessary,

use a slow 24 hr. charge.

• Do not empty the cooling system.

57

Page 60

Page 61

SPECIFICATIONS

ENGINE

Type 132 C3.031

Number of cylinders, in line 4

Bore and Stroke .... 84x90 mm

(3.31

x 3.54 in.)

Total piston displacement. 1995 cc

(121.74cu. in.)

Compression ratio . . . 8.2 to 1

Maximum power (SAE net) 102 HP

at 5500 rpm

Value Gear

0, H.V.

Twin O. H. camshafts driven by toothed

timing belt with tensioner.

Intake

Exhaust

Tappet clearance adjust-

ment, for valve timing .80 mm (.031 in.)

Final tappet operation clearance adjust-

ment, cold engine:

Intake .41 to .49 mm (.016 to .019 in.)

Exhaust .46 to .54 mm (.018 to .021 in.)

Opens; B.T.D.C.

Closes: A.B.D.C.

Opens: B.B.D.C.

Closes: A.T.D.C.

53°