FG Wilson Generating set Installation Manual

GENERATING SET

INSTALLATION

MANUAL

ii

FOREWORD

This installation manual will guide you to the factors to be considered in the

installation of your diesel generator system. It discusses location and mounting

of the generating set; size of room; ventilation and air flow; engine cooling water

supply or radiator location; exhaust outlet; fuel tank and fuel transfer system.

By following the suggestions in this installation manual, you will be able to plan

an economical, efficient generating set installation with operating characteristics

suitable to each particular application.

You can make you work easier by enlisting the aid of an FG Wilson Distributor

when planning your generating set installation. Getting his advice early may save

cost and avoid problems. He knows engines, electrical equipment, local laws and

insurance regulations. With his help, you can be sure your generating set

installation will fulfil your needs without unnecessary cost.

TABLE OF CONTENTS

PAGE

1. INSTALLATION FACTORS

2. MOVING THE GENERATING SET

3. GENERATING SET LOCATION

4. GENERATING SET MOUNTING

5. VENTILATION

6. ENGINE EXHAUST

7. EXHAUST SILENCING

8. SOUND ATTENUATION

9. ENGINE COOLING

10. FUEL SUPPLY

11. SELECTING FUELS FOR STANDBY DEPENDABILITY

12. TABLES AND FORMULAS FOR ENGINEERING STANDBY

GENERATING SETS:

1

1

1

2

3

6

9

10

10

13

18

19

Table 1 Length Equivalents

Table 2 Area Equivalents

Table 3 Mass Equivalents

Table 4 Volume and Capacity Equivalents

Table 5 Conversions for Units of Speed

Table 6 Conversions of Units of Power

Table 7 Conversions for Measurements of Water

Table 8 Barometric Pressures and Boiling Points of Water at Various Altitudes

Table 9 Conversions of Units of Flow

Table 10 Conversions of Units of Pressure and Head

Table 11 Approximate Weights of Various Liquids

Table 12 Electrical Formulae

Table 13 kVA/kW Amperage at Various Voltages

Conversions of Centigrade and Fahrenheit

Fuel Consumption Formulas

Electrical Motor Hor sepower

Piston Travel

Break Mean Effective Pressure

19

19

19

20

20

20

21

21

22

22

22

23

24

25

25

25

25

25

13. GLOSSARY OF TERMS 26

Copyright 1997 by FG Wilson (Engineering) Ltd

All rights reserved. No part of the contents of this manual may be reproduced, photocopied or transmitted

in any form without the express prior written permission of FG Wilson (Engineering) Ltd.

1

1. INSTALLATION FACTORS

Once the size of the generating set and the required

associated control panel and switchgear have been

established, plans for installation can be prepared.

Proper attention to mechanical and electrical

engineering details will assure a satisfactory power

system installation.

Factors to be considered in the installation of a

generator are:

Access and maintenance location.

Floor loading.

Vibration transmitted to building and equipment.

Ventilation of room.

Engine exhaust piping and insulation.

Noise reduction.

Method of engine cooling.

Size and location of fuel tank.

Local, national or insurance regulations.

Smoke and emissions requirements.

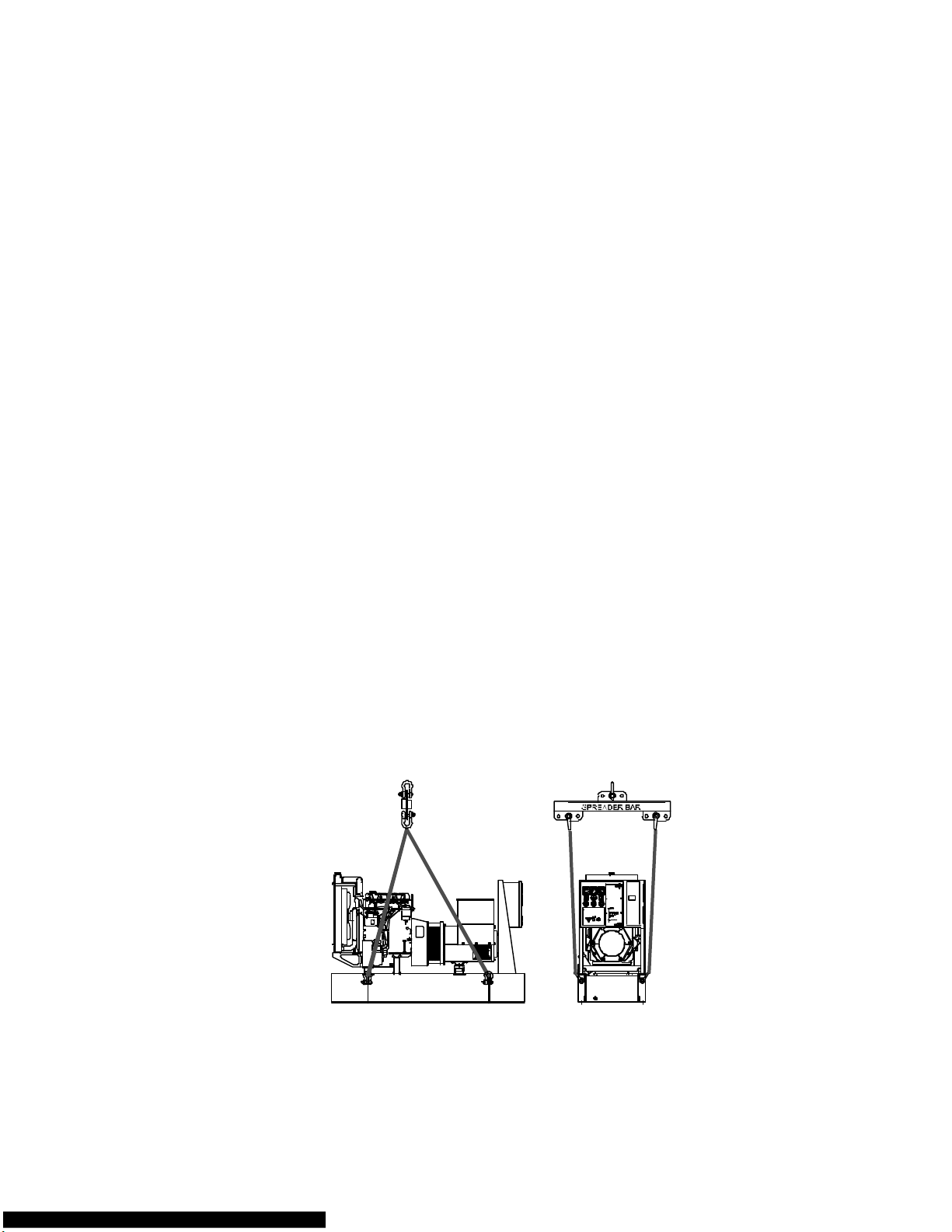

2. MOVING THE GENERATING

SET

The generating set baseframe is specifically

designed for ease of moving the set. Improper

handling can seriously damage the generator and

components.

Using a forklift,the generating set can be lifted or

pushed/pulled by the baseframe. An optional "Oil

Field Skid" provides fork lift pockets if the set will

be regularly moved.

Never lift the generating set by attaching to the

engine or alternator lifting lugs!

For lifting the generating set, lift points are

provided on the baseframe. Shackles and chains of

suitable length and lifting capacity must be used

and a spreader bar is required to prevent damaging

the set. See figure 2.1. An optional "single point

lifting bale" is available if the generating set will be

regularly moved by lifting.

3. GENERATING SET

LOCATION

The set may be located in the basement or on

another floor of the building, on a balcony, in a

penthouse on the roof or even in a separate

building. Usually it is located in the basement for

economics and for convenience of operating

personnel. The generator room should be large

enough to provide adequate air circulation and

plenty of working space around the engine and

alternator.

If it is necessary to locate the generating set

outside the building, it can be furnished enclosed in

a housing and mounted on a skid or trailer. This

type of assembly is also useful, whether located

inside or outside the building, if the installation is

temporary. For outside installation the housing is

normally "weatherproof". This is necessary to

prevent water from entering the alternator

compartment if the generating set is to be exposed

to rain accompanied by high winds.

FIG 2.1. PROPER LIFTING ARRANGEMENT

2

4. GENERATING SET

MOUNTING

The generating set will be shipped assembled on a

rigid base that precisely aligns the alternator and

engine and needs merely to be set in place (on

vibration isolation pads for larger sets) and levelled.

See figure 4.1

4.1 Vibration Isolation

It is recommended that the generating set be

mounted on vibration isolation pads to prevent the

set from receiving or transmitting injurious or

objectionable vibrations. Rubber isolation pads are

used when small amounts of vibration transmission

is acceptable. Steel springs in combination with

rubber pads are used to combat both light and

heavy vibrations. On smaller generating sets, these

isolation pads should be located between the

coupled engine/alternator feet and the baseframe.

The baseframe is then securely attached to the

floor. On larger sets the coupled engine/alternator

should be rigidly connected to the baseframe with

vibration isolation between the baseframe and floor.

Other effects of engine vibration can be minimised

by providing flexible connections between the

engine and fuel lines, exhaust system, radiator air

discharge duct, conduit for control and power

cables and other externally connected support

systems.

4.2 Floor Loading

Floor loading depends on the total generating set

weight (including fuel and water) and the number

and size of isolator pads. With the baseframe

mounted directly on the floor, the floor loading is:

Floor Loading =

Total Gene rating Set Weight

Area of Skids

With vibration isolation between the baseframe and

the floor, if the load is equally distributed over all

isolators, the floor loading is:

Floor Loading =

Total Generating Set Weight

Pad Area x Number of Pads

Thus, floor loading can be reduced by increasing

the number of isolation pads.

If load is not equally distributed, the maximum floor

pressure occurs under the pad supporting the

greatest proportion of load (assuming all pads are

the same size):

Max Floor Pressure =

Load on Heaviest Loaded Pad

Pad Area

FIG 4.1 REDUCING VIBRATION TRANSMISSION

3

5. VENTILATION

Any internal combustion engine requires a liberal

supply of cool, clean air for combustion. If the air

entering the engine intake is too warm or too thin,

the engine may not produce its rated power.

Operation of the engine and alternator radiates heat

into the room and raises the temperature of the

room air. Therefore, ventilation of the generator

room is necessary to limit room temperature rise and

to make clean, cool intake air available to the

engine.

When the engine is cooled by a set mounted

radiator, the radiator fan must move large quantities

of air through the radiator core. There must be

enough temperature difference between the air and

the water in the radiator to cool the water

sufficiently before it re-circulates through the

engine. The air temperature at the radiator inlet

depends on the temperature rise of air flowing

through the room from the room inlet ventilator. By

drawing air into the room and expelling it outdoors

through a discharge duct, the radiator fan helps to

maintain room temperature in the desirable range.

In providing ventilation, the objective is to maintain

the room air at a comfortable temperature that is

cool enough for efficient operation and full

available power, but it should not be so cold in

winter that the room is uncomfortable or engine

starting is difficult. Though providing adequate

ventilation seldom poses serious problems, each

installation should be analysed by both the

distributor and the customer to make sure the

ventilation provisions are satisfactory.

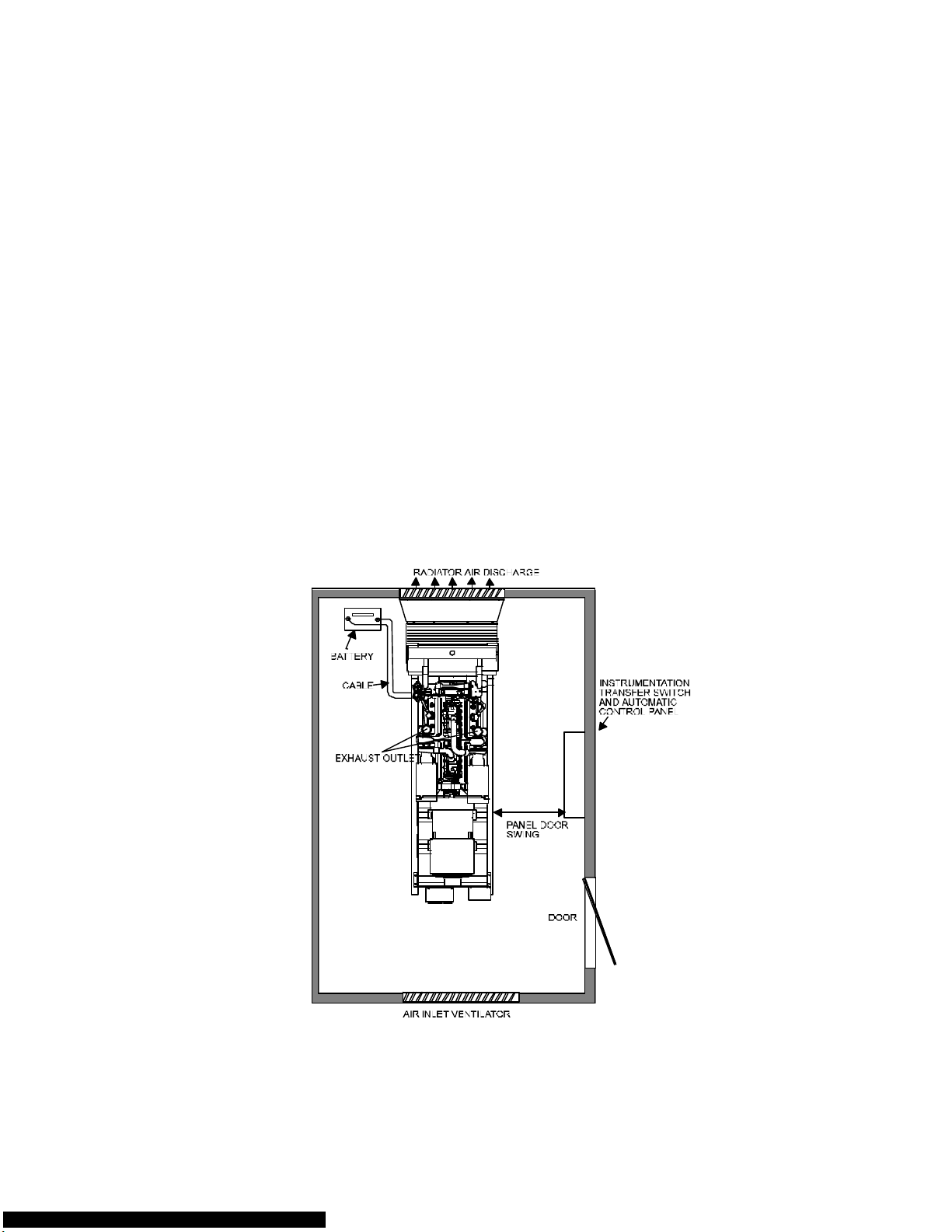

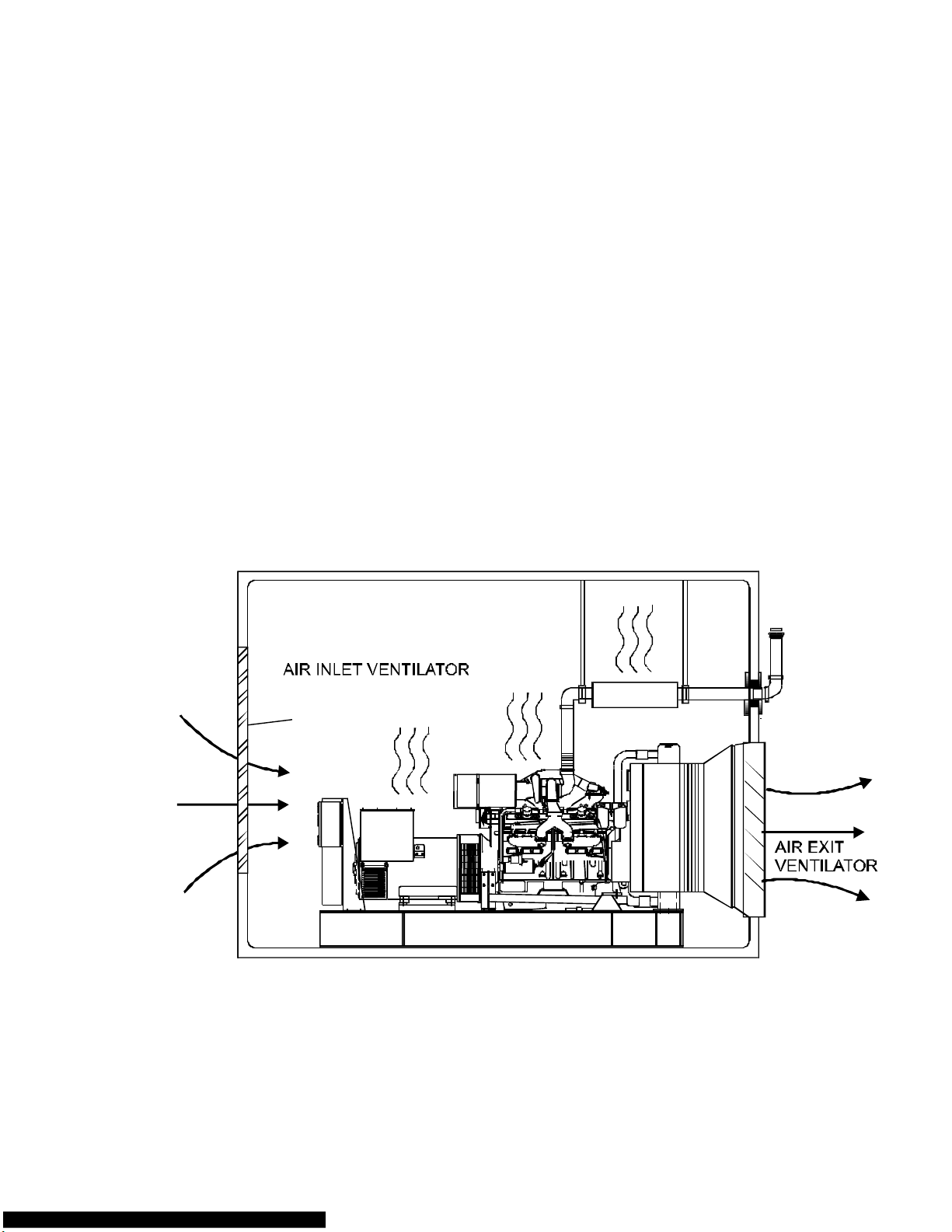

5.1 Circulation

Good ventilation requires adequate flow into and

out of the room and free circulation within the room.

Thus, the room should be of sufficient size to allow

free circulation of air, so that temperatures are

equalised and there are no pockets of stagnant air.

See figure 5.1. The generating set should be

located so that the engine intake draws air from the

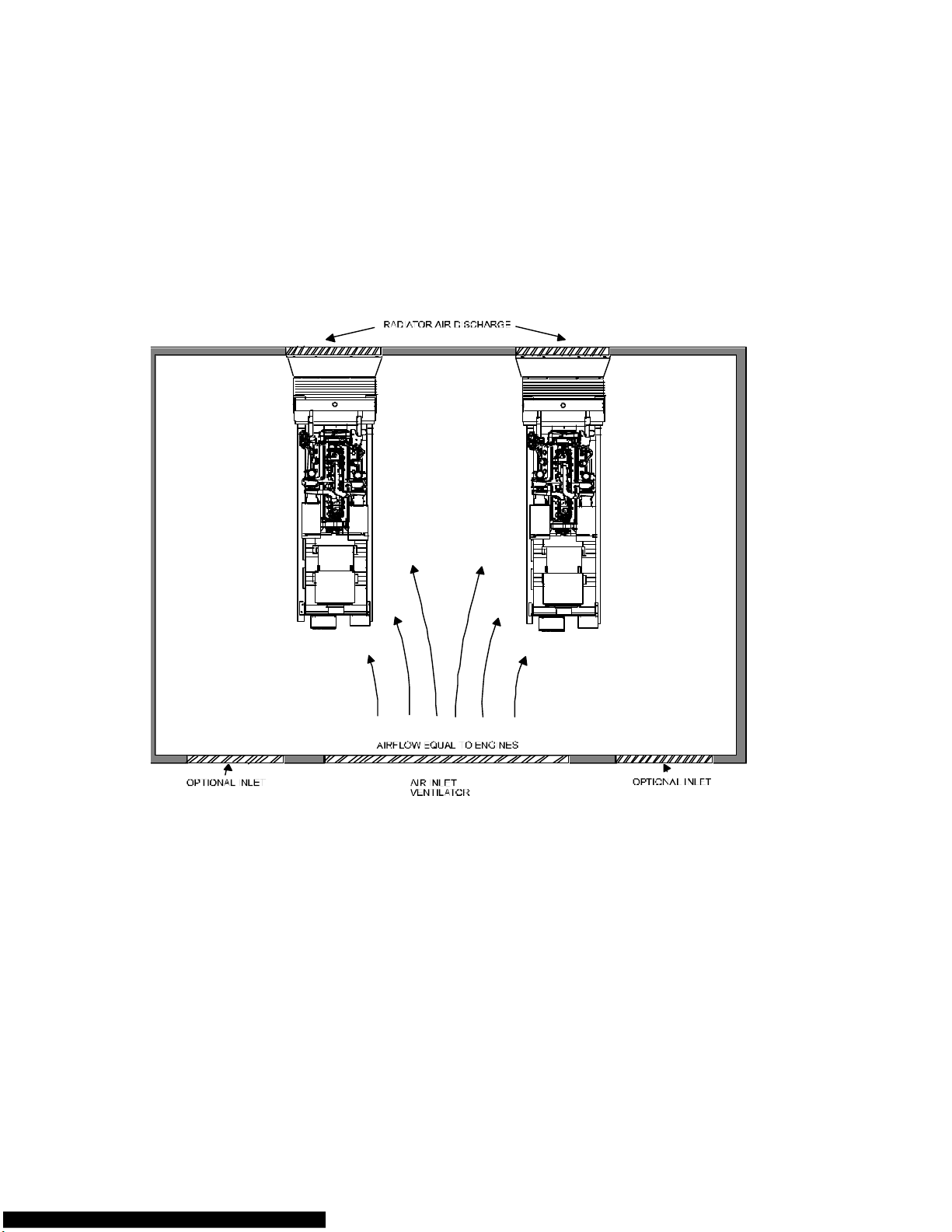

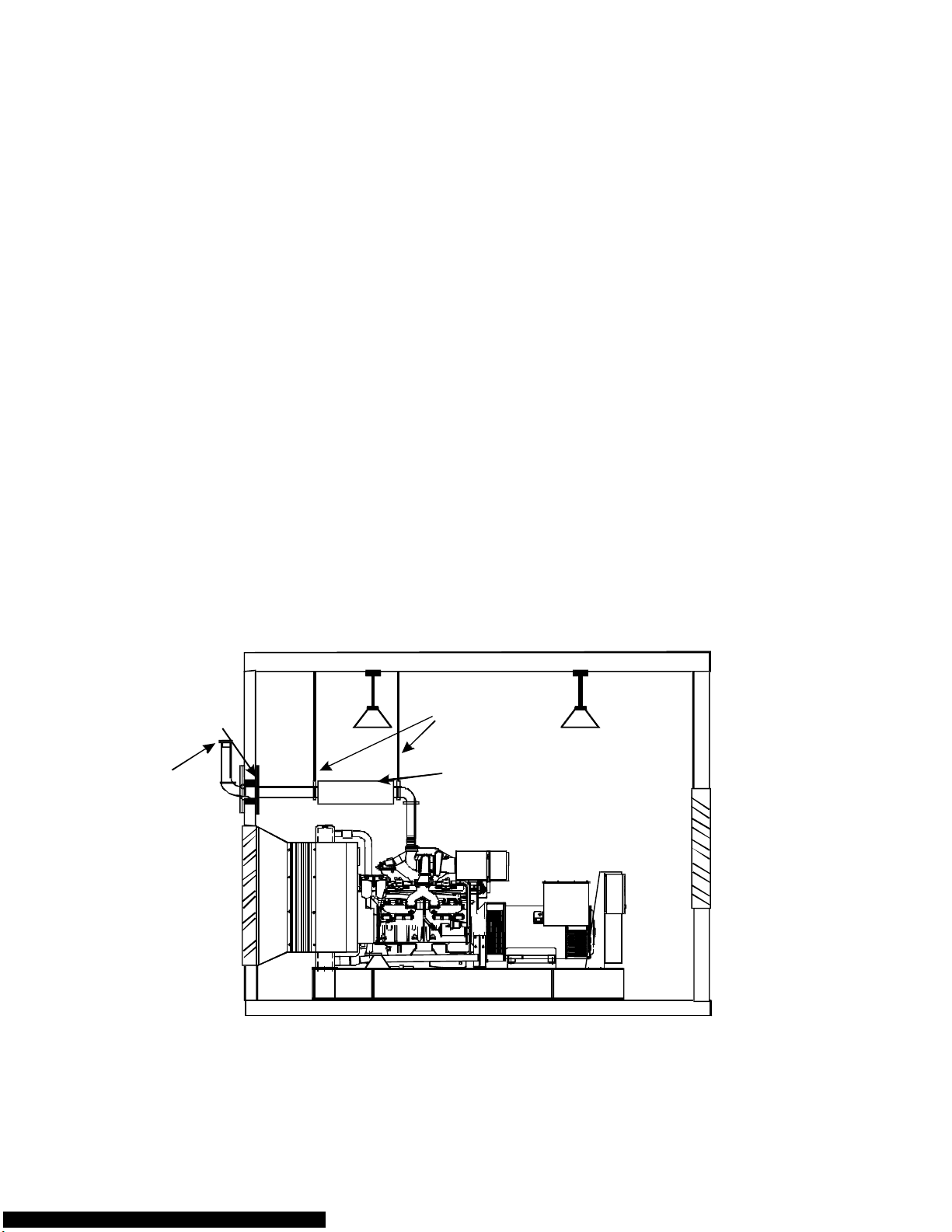

cooler part of the room. If there are two or more

generating sets, avoid locating them so that air

heated by the radiator of one set flows toward the

engine intake or radiator fan of an adjacent set. See

figure 5.2.

FIG 5.1 TYPICAL ARRANGEMENT FOR ADEQUATE AIR CIRCULATION AND VENTILATION

4

5.2 Ventilators

To bring in fresh air, there should be an inlet

ventilator opening to the outside or at least an

opening to another part of the building through

which the required amount of air can enter. In

smaller rooms, ducting may be used to bring air to

the room or directly to the engine's air intake. In

addition, an exit ventilator opening should be

located on the opposite outside wall to exhaust

warm air. See Figure 5.3.

Both the inlet and exit ventilators should have

louvres for weather protection. These may be fixed

but preferably should be movable in cold climates.

For automatic starting generating sets, if the

louvres are movable, they should be automatically

operated and should be programmed to open

immediately upon starting the engine.

FIG 5.2 TYPICAL ARRANGEMENT FOR PROPER VENTILATION WITH MULTIPLE GENERATING SETS

5

5.3 Inlet Ventilator Size

Before calculating the inlet ventilator size, it is

necessary to take into account the radiator cooling

air flow requirements and the fan static pressure

available when the generating set is operating at its

rated load. In standard room installations, the

radiated heat is already taken into account in the

radiator air flow.

For generator room installation with remote

radiators, the room cooling airflow is calculated

using the total heat radiation to the ambient air of

the engine and alternator and any part of the

exhaust system.

Engine and alternator cooling air requirements for

FG Wilson generating sets when operating at rated

power are shown on specification sheets. Exhaust

system radiation depends on the length of pipe

within the room, the type of insulation used and

whether the silencer is located within the room or

outside. It it usual to insulate the exhaust piping

and silencer so that heat radiation from this source

may be neglected in calculating air flow required for

room cooling.

After determining the required air flow into the

room, calculate the size of inlet ventilator opening

to be installed in the outside wall. The inlet

ventilator must be large enough so that the

negative flow restriction will not exceed a maximum

of

10 mm (0.4 in) H2O. Restriction values of air filters,

screens and louvres should be obtained from

manufacturers of these items.

5.4 Exit Ventilator Size

Where the engine and room are cooled by a set

mounted radiator, the exit ventilator must be large

enough to exhaust all of the air flowing through the

room, except the relatively small amount that enters

the engine intake.

FIG 5.3 INLET AND EXIT VENTILATORS

6

6. ENGINE EXHAUST

Engine exhaust must be directed to the outside

through a properly designed exhaust system that

does not create excessive back pressure on the

engine. A suitable exhaust silencer should be

connected into the exhaust piping. Exhaust system

components located within the engine room should

be insulated to reduce heat radiation. The outer

end of the pipe should be equipped with a rain cap

or cut at 60° to the horizontal to prevent rain or

snow from entering the exhaust system. If the

building is equipped with a smoke detection

system, the exhaust outlet should be positioned so

it cannot set off the smoke detection alarm.

6.1 Exhaust Piping

For both installation economy and operating

efficiency, engine location should make the exhaust

piping as short as possible with minimum bends

and restrictions. Usually the exhaust pipe extends

through an outside wall of the building and

continues up the outside of the wall to the roof.

There should be a sleeve in the wall opening to

absorb vibration and an expansion joint in the pipe

to compensate for lengthways thermal expansion or

contraction. See figure 6.1.

It is not normally recommended that the engine

exhaust share a flue with a furnace or other

equipment since there is danger that back pressure

caused by one will adversely affect operation of the

others. Such multiple use of a flue should be

attempted only if it is not detrimental to

performance of the engine or any other equipment

sharing the common flue.

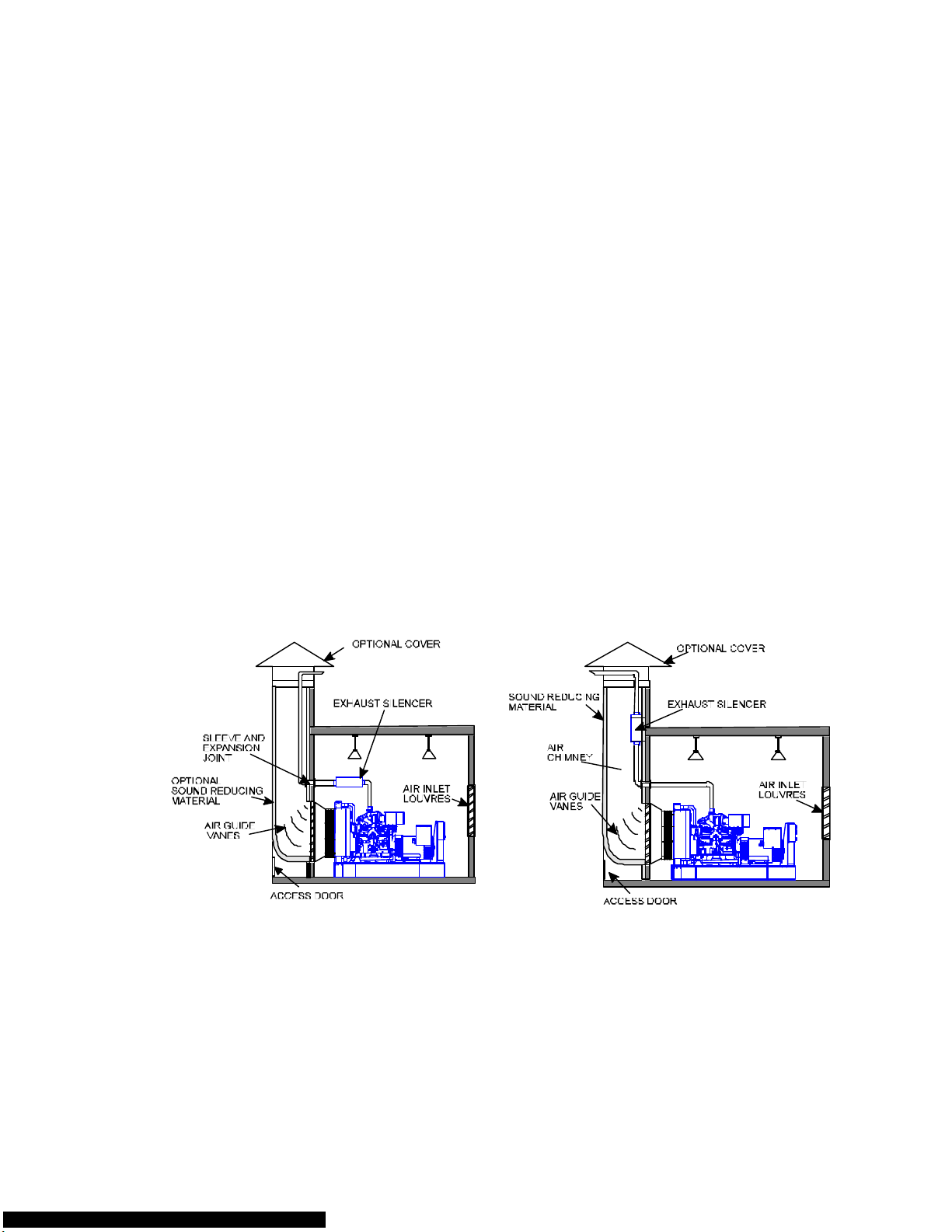

The exhaust can be directed into a special stack that

also serves as the outlet for radiator discharge air

and may be sound-insulated. The radiator

discharge air enters below the exhaust gas inlet so

that the rising radiator air mixes with the exhaust

gas. See figures 6.2 and 6.3. The silencer may be

located within the stack or in the room with its tail

pipe extending through the stack and then outward.

Air guide vanes should be installed in the stack to

turn radiator discharge air flow upward and to

reduce radiator fan air flow restriction, or the sound

insulation lining may have a curved contour to

direct air flow upward. For a generating set

enclosed in a penthouse on the roof or in a separate

outdoor enclosure or trailer, the exhaust and

radiator discharges can flow together above the

enclosure without a stack. Sometimes for this

purpose the radiator is mounted horizontally and

the fan is driven by an electric motor to discharge

air vertically.

FIG 6.1 TYPICAL EXHAUST SYSTEM INSTALLATION

EXHAUST

SILENCER

WALL SLEEVE

AND EXPANSION

JOINT

SILENCER/PIPEWORK

SUPPORTS

RAIN CAP

7

6.2 Exhaust Pipe Flexible Section

A flexible connection between the manifold and the

exhaust piping system should be used to prevent

transmitting engine vibration to the piping and the

building, and to isolate the engine and piping from

forces due to thermal expansion, motion or weight

of piping. A well designed flex section will permit

operation with ± 13 mm (0.5 in) permanent

displacement in any direction of either end of the

section without damage. Not only must the section

have the flexibility to compensate for a nominal

amount of permanent mismatch between piping and

manifold, but it must also yield readily to

intermittent motion of the Generating Set on its

vibration isolators in response to load changes.

The flexible connector should be specified with the

Generating Set.

6.3 Exhaust Pipe Insulation

No exposed parts of the exhaust system should be

near wood or other inflammable material. Exhaust

piping inside the building (and the silencer if

mounted inside) should be covered with suitable

insulation materials to protect personnel and to

reduce room temperature. A sufficient layer of

suitable insulating material surrounding the piping

and silencer and retained by a stainless steel or

aluminium sheath may substantially reduce heat

radiation to the room from the exhaust system.

An additional benefit of the insulation is that it

provides sound attenuation to reduce noise in the

room.

6.4 Minimising Exhaust Flow

Restriction

Free flow of exhaust gases through the pipe is

essential to minimise exhaust back pressure.

Excessive exhaust back pressure seriously affects

engine horsepower output, durability and fuel

consumption. Restricting the discharge of gases

from the cylinder causes poor combustion and

higher operating temperatures. The major design

factors that may cause high back pressure are:

• Exhaust pipe diameter too small

• Exhaust pipe too long

• Too many sharp bends in exhaust system

• Exhaust silencer restriction too high

• At certain critical lengths, standing pressure

waves may cause high back pressure

FIG 6.2 HORIZONTALLY MOUNTED EXHAUST SILENCER FIG 6.3 RADIATOR AIR DISCHARGING INTO

WITH EXHAUST PIPE AND RADIATOR AIR SOUND-INSULATED STACK CONTAINING

UTILISING COMMON STACK EXHAUST SILENCER

Loading...

Loading...