FG Wilson DCP-10 User Manual

Manual

DCP

-

10

Genset Controller

DCP-10

I

The interpretation of the Symbol:

WARNING:

A WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death, serious personal injury or property

damage.

CAUTION:

A CAUTION indicates a potentially hazardous situation which, if not

avoided, could result in damage to equipment or property.

NOTE:

A NOTE provides other helpful information that does not fall under the

warning or caution categories.

DCP-10

II

WARNING:

Read this entire manual pertaining to the work to be performed before

installing, operating, or servicing this controller. Practice all plant and

safety instructions and precautions. Failure to follow instructions can

cause personal injury and/or property damage.

The engine or other type of prime mover should be equipped with an

overspeed shutdown device to protect against runaway or damage to

the prime mover with possible personal injury, loss of life, or property

damage.

The overspeed shutdown device must be totally independent of the

prime mover control system. An over temperature or low pressure

shutdown device may also be needed for safety, as appropriate.

CAUTION—BATTERY CHARGING

To prevent damage to a controller that uses an alternator or batterycharging device, make sure the charging device is turned off before

disconnecting the battery from the system.

Controllers contain static-sensitive parts. Observe the following

precautions to prevent damage to these parts:

Do not disassemble the rear back of controller or touch the

components and conductors on a printed circuit board.

DCP-10

III

Contents

1. Description……………………………………………………………………………………………………

2. Outline Dimension Drawings and Controller Wiring…………………………………………………

3. Panel Operation……………………………………………………………………………………………

4. Installation Guide…………………………………………………………………………………………

5. Control and Operation Instruction………………………………………………………………………

6. Measure and Display Data………………………………………………………………………………

7. Pre-alarm and Shutdown Alarm…………………………………………………………………………

8. Parameter Settings………………………………………………………………………………………

9. LCD Display and Menu System…………………………………………………………………………

10. Preparation before Starting the Controller……………………………………………………………

11. Technical Specification…………………………………………………………………………………

1

2

5

6

7

12

13

17

23

28

27

DCP-10

Page 1/27

1. Description

The DCP-10 is an Automatic Controller for generator. When running in “AUTO” mode, it starts the

Genset after receiving remote start signal and on failure automatically stops the Genset. The

generator’s controlling procedure and protection parameters can be modified, which fully meets the

Genset’s requirements of automatic start, stop control and basic protection.

The module displays fault conditions, operational status and related metering data on panel LCD.

LCD has a backlight function so that the operator can read running parameters clearly even in the

shadow.

The controller has 2 modes: AUTO and MANUAL. Either can be chosen through the panel push

button.

Measures and displays generator’s output voltage, current, oil pressure, coolant temperature,

frequency, DC source voltage, etc.

True RMS measure of voltage and current, which ensures the data more accurate.

Control the close/open of generator output switch.

Equipped with built-in communication interface to configure parameters by PC.

All connections of controller are by secure plug and socket, for ease and convenience to connect,

move, maintain and replace the device.

This manual is only suitable for DCP-10 Automatic control module, user must carefully read

this manual first.

DCP-10

Page 2/27

2. Outline Dimension Drawings and Controller Wiring

2.1 Following Details:

Module Dimensions W120mm×H102mm

Panel Cutout W110mm×H92mm

Thickness D48mm (without connection)

DCP-10

Page 3/27

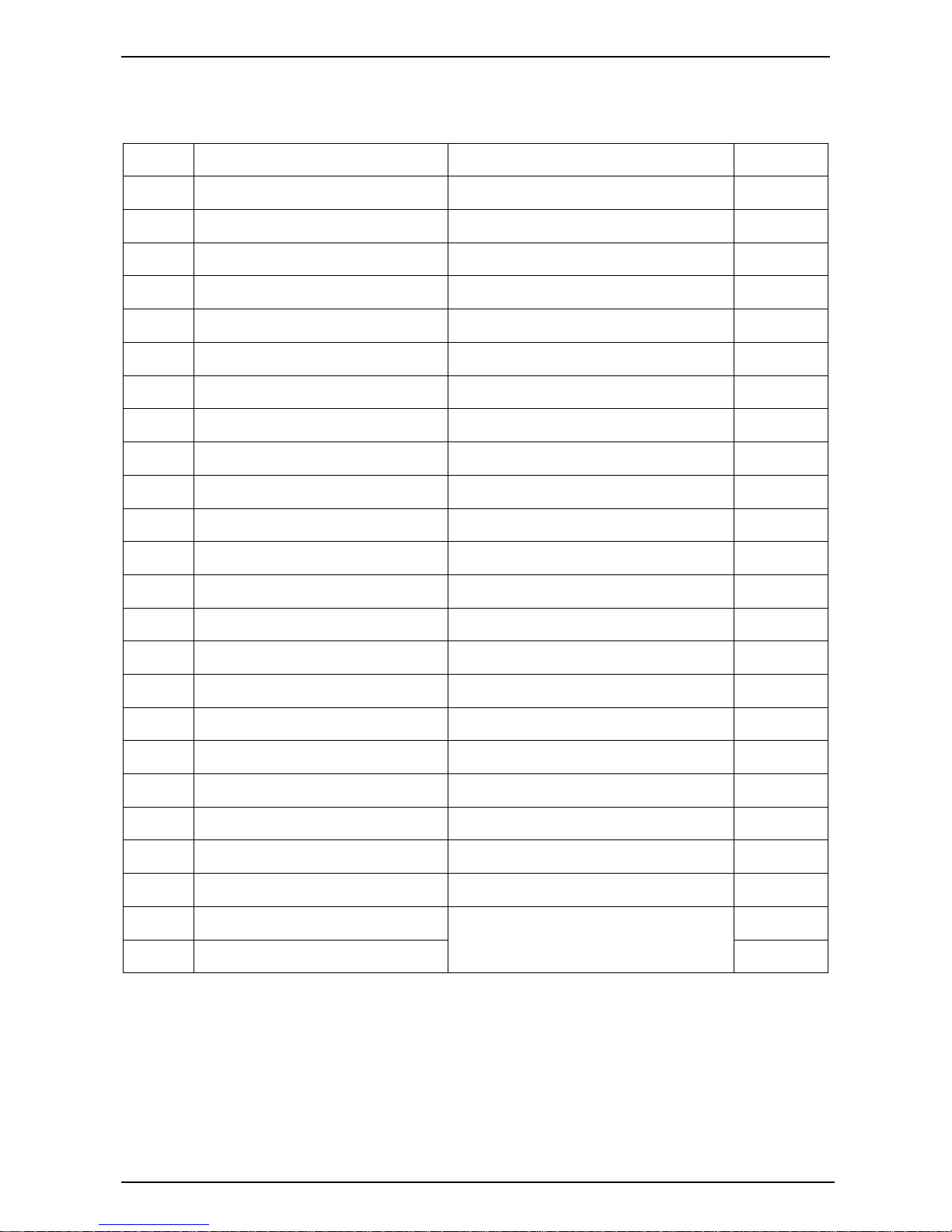

2.2 Terminal Connections:

Pin no.

Function Description Signal Dim

1

GEN. V

L1-N

input 0-300Vac

1mm²

2

GEN. V

L2-N

input 0-300Vac

1mm²

3

GEN. V

L3-N

input 0-300Vac

1mm²

4

GEN. Neutral

1mm²

5

Not used

6 Not used

7 I1 Gen current input 0-5A

2.5mm²

8 I2 Gen current input 0-5A

2.5mm²

9 I3 Gen current input 0-5A

2.5mm²

10 Common port for current input 0-5A

2.5mm²

11 LOP sensor or switch signal LOP sensor (<2KΩ)

1mm²

12 HET sensor or switch signal HET sensor (<2KΩ)

1mm²

13 Configurable digital input signal 1 low level is active

1mm²

14 Configurable digital input signal 2 low level is active

1mm²

15 Configurable digital input signal 3 low level is active

1mm²

16

Charge excitation power output if not used, do not connect to negative

1mm²

17

Configurable relay output 1 N.O. contact, 3A/30Vdc

1mm²

18

Configurable relay output 2 N.O. contact, 3A/30Vdc

1mm²

19

Configurable relay output 3 N.O. contact, 3A/30Vdc

1mm²

20

+5V supply Max 100mA,

1mm²

21

Start (Crank) relay output N.O. contact, 3A/30Vdc

1mm²

22

Fuel solenoid relay output N.O. contact, 3A/30Vdc

1mm²

23

Battery supply (+B)

1mm²

24

Battery supply (-B)

12V/24V (8-35Vdc continuous)

1mm²

DCP-10

Page 4/27

2.3 Typical Wiring Diagram

(12/24V)

DC POWER

CRANKFUEL

CONFIG.OUTPUT

LOAD

M

CONFIG. INPUT

REMOTE START

COOLANT TEMP.

(OR TEM P. SWIT CH)

OIL PRE SSURE

(OR OIL SWITCH )

DCP-10

Fuse protection with a rating of 0.5A must be provided externally to the Controller.

DCP-10

Page 5/27

3. Panel Operation

The operation panel consists of 3 sections: LCD display indicating measurement parameters, LED

indicator for common failure, and push buttons for Genset and selection of control modes.

The LCD circularly displays different measuring parameters. When failure occurs, LCD displays the

corresponding fault icon. LCD also has a backlight so that the operator can clearly read information day

or night. After pressing any button the backlight will automatically turn off in a certain time.

The LCD display and its control push buttons provide a friendly operation interface for the operator to

conveniently read information and parameter setting.

3.1 Control buttons and LEDs

Function Description

Tag

Scroll Button

Enter into submenu / Modify / confirm modification / scroll menu to

display.

MUTE / LAMP TEST Button

When failure occurs, alarm buzzer sounds. Pressing mute button will

mute the sound. LCD displays mute icon. Press and hold mute button

for 2sec, all LEDs illuminate simultaneously.

AUTO Mode Button / LED

The push button is used for selecting “AUTO mode”. When the

controller is running in AUTO mode, the LED above the push button

illuminated. The activation and deactivation of the “remote start signal

input” controls the starting and stopping of the Genset.

MAN Mode Button / LED

The push button is used for selecting “manual mode”. When the

controller is running in MANUAL mode, the LED above the push button

illuminated. The Start and Stop push buttons control the starting and

stopping of the Genset..

START / VALUE INCREASE “+” Push Button

The push button is used for manually start the Genset .When the

controller is in MANUAL mode, press this push button to start the

generator.

When in parameter setting mode, this push button is used to increase

values.

STOP / RESET / VALUE DECREASE “-” Push Button

The push button is used for MANUALLY stops the Genset. When the

controller is in MAN mode, press and hold this button more than 2sec

to stop the Genset.

If failure occurs, press this button, the shutdown alarm lockout can be

cleared.

When in parameter setting mode, this push button is used to decrease

values.

COMMEN FAILURE LED

LED will flash when pre-alarm (Warning) occurs.

LED will illuminate permanently when shutdown alarm occurs.

DCP-10

Page 6/27

4. Installation Guide

4.1 The cutout dimensional drawing installed on panel as above attached.

The controller is fixed by 2 special fittings. The shock-proof equipment must be mounted if the

enclosure is mounted on Genset or other heavy vibrant device. A readily accessible disconnect

device shall be incorporated external to the equipment.

4.2 Please refer to the above Typical Wiring Diagram 2.3 for connection.

4.3 Installation of engine LOP and HET sensors:

1211

Terminal

12

Battery negative (Genset enclosure)

11

Description

Sensor Com. Port

HET sensor/ temp switch

LOP sensor/ LOP switch

DCP-10

C O N T R O L L E R

CAUTION:

Pin no. “11” and “12” is for “LOP sensor or switch signal” and “HET

sensor or switch signal” input respectively. Either switch or sensor can be

chosen. When sensor is used, according to the actual situation, increase

the cross section area of cable to reduce the cable resistance from

controller to engine, which ensures the accuracy of measured values for

both oil pressure and engine temperature.

If both switches and sensors are required for oil pressure and engine

temperature, connect Pin no. “11” and “12” as above, and connect 2

configurable inputs to the switches of oil pressure and temperature, then

configure parameters by setting.

Loading...

Loading...