Fgt TMFC30A, TMFC30V, TMFC50A, TMFC50V User Manual

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

Essential Instructions

Read this page before proceeding!

FGT designs, manufactures and tests its products to meet many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use and maintain them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered to and integrated into your safety program when installing, using and maintaining

Mass Flow Controller

TMFC Series

Installation and Operation Manual

FGT products.

z Read all instructions prior to installing, operating and servicing the products. If this instruction manual is not the correct manual,

telephone 886-6-2632460 and the requested manual will be provided. Save this instruction manual for future reference.

z If you do not understand any of the instructions, contact your FGT representative for clarification.

z Follow all warnings, cautions and instruction marked on and supplied with the products.

z Inform and educate your personnel in the proper installation, operation and maintenance of the product.

z Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local and

national codes. Connect all products to the proper electrical and pressure sources.

z To ensure proper performance, use qualified personnel to install, operate update, program and maintain the products.

z When replacement parts are required, ensure that qualified people use replacement parts specified by FGT. Unauthorized parts

and procedures can affect the product’s performance and place the safe operation of your process at risk. Look-alike substitutions

may result inn fire, electrical hazards or improper operation.

z Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

CAUTION

This Instrument contains electronic components that are susceptible to damage by static electricity. Proper handling

procedures must be observed during the removal, Installation or other handling or internal circuit boards or devices.,

www.fgttw.com

First General Technology Inc.

-1-

Handing Procedure

4. Power to unit must be removed.

5. Personnel must be grounded, via a wrist strap or other safe, suitable means before any printed circuit card or other internal

device is installed, removed or adjusted.

6. Printed circuit cards must be transported in a conductive bag or other conductive container. Boards must not be removed from

protective enclosure until immediately before installation. Removed boards must immediately be placed in protective container

for transport, storage or return to factory.

Comments

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronic designs contain

components that utilize metal oxide technology (NMOS, CMOS, etc,) Experience has proven that even small amounts of static electricity

can damage or destroy these devices. Damaged components even though they appear to function properly, exhibit early failure.

www.fgttw.co

-2-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

Part number:0912TWAD

U-TMFC--EN

October,2009

CONTENTS:

1.Specifications------------------------------------------------------------------------------- 4

1-1.Specifications------------------------------------------------------------------------- 4

Page

Installation and Operation Manual

Part number:0912TWAD

FGT® Model TMFC Mass Flow Controller/Mete

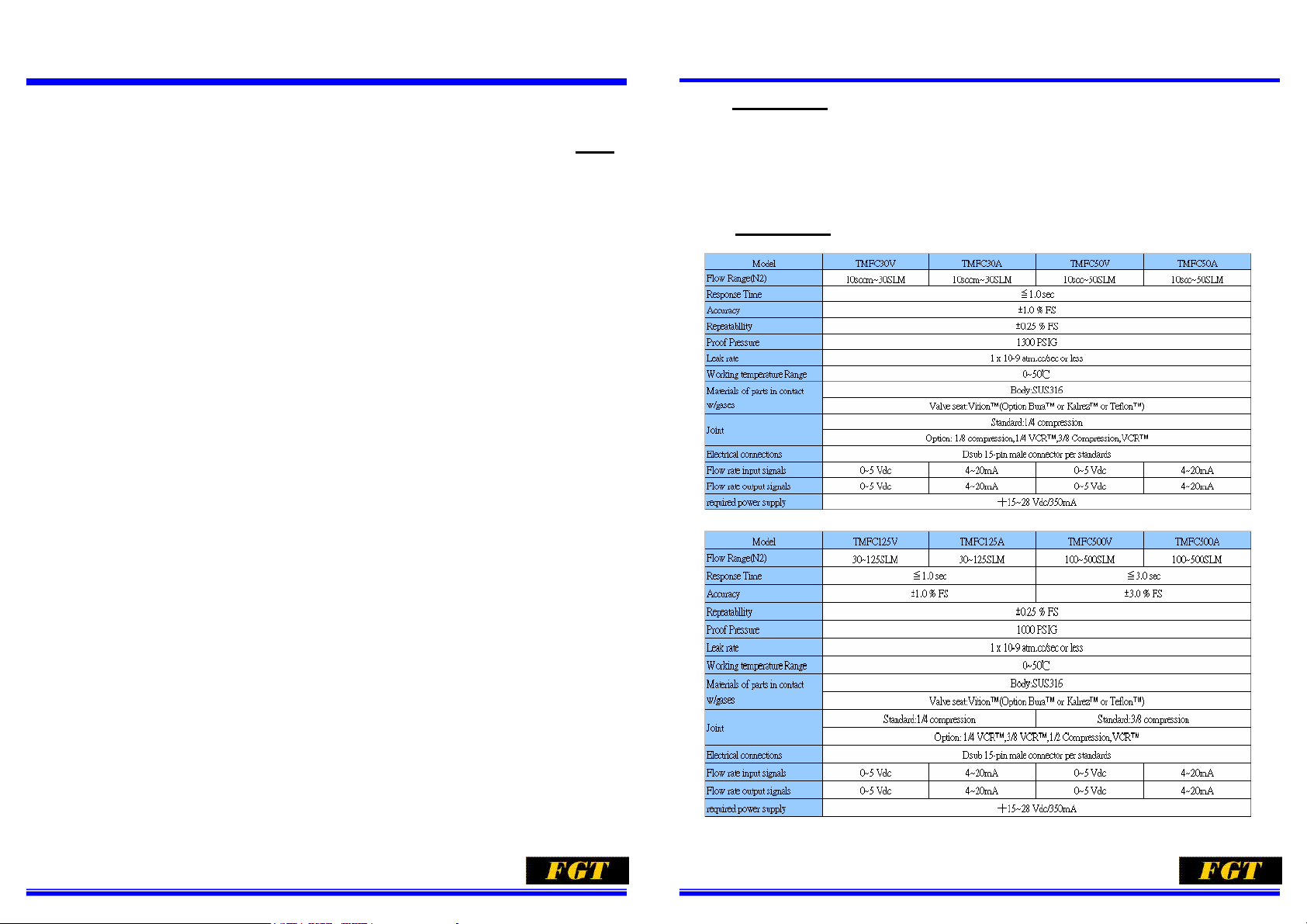

2. Specifications

Model TMFC series Mass Flow controller accurately measures and controls gas flow.

This instrument is used for flow control in a wide range of application including various

analyzers, combustion, and biotechnology.

U-TMFC--EN

October,2009

1-2.Unit of Flow--------------------------------------------------------------------------- 5

2.Principle of Operation-------------------------------------------------------------------- 6

3.Standard configuration and Wiring Connection------------------------------------ 7

3-1.Stadard Configuration-------------------------------------------------------------- 7

3-2.Electric connection Diagram and Wiring Connection------------------------ 8

4.Installation and Piping-------------------------------------------------------------------- 11

4-1.Storage and Application environment------------------------------------------ 11

4-2.Piping System Washing------------------------------------------------------------ 12

4-3.In-line Filter---------------------------------------------------------------------------- 12

4-4.Combined Use of The Set-point Valve------------------------------------------ 13

4-5.Use of The conversion Tables ---------------------------------------------------- 14

4-6 Gas Connection---------------------------------------------------------------------- 18

4-7.Installation----------------------------------------------------------------------------- 18

5.Operational Procedure------------------------------------------------------------------- 19

6.Troubleshooting----------------------------------------------------------------------------- 20

7.Dimensions---------------------------------------------------------------------------------- 22

1-1. Specifications

8.Product Warranty--------------------------------------------------------------------------- 23

www.fgttw.com

-3-

www.fgttw.co

-4-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

Part number:0912TWAD

U-TMFC--EN

October,2009

1-2. Unit of Flow

Our mass flow controller is based on the SEMIIE12-91(semi-standard).

The applied unit is SLM (Standard Liter per Minute) or SCCM (Standard Cubic per

Minute). The status of this gas is the same as the reference(normal) conditions of 0℃,

101.325kPa(abs). If the applied flow unit and definition thereon differ, inquire us of it or

give us your instructions. If the unit you require is a SI unit or unit approved by the current

measuring law, we will make a production on the basis of the unit you require.

FGT® Model TMFC Mass Flow Controller/Mete

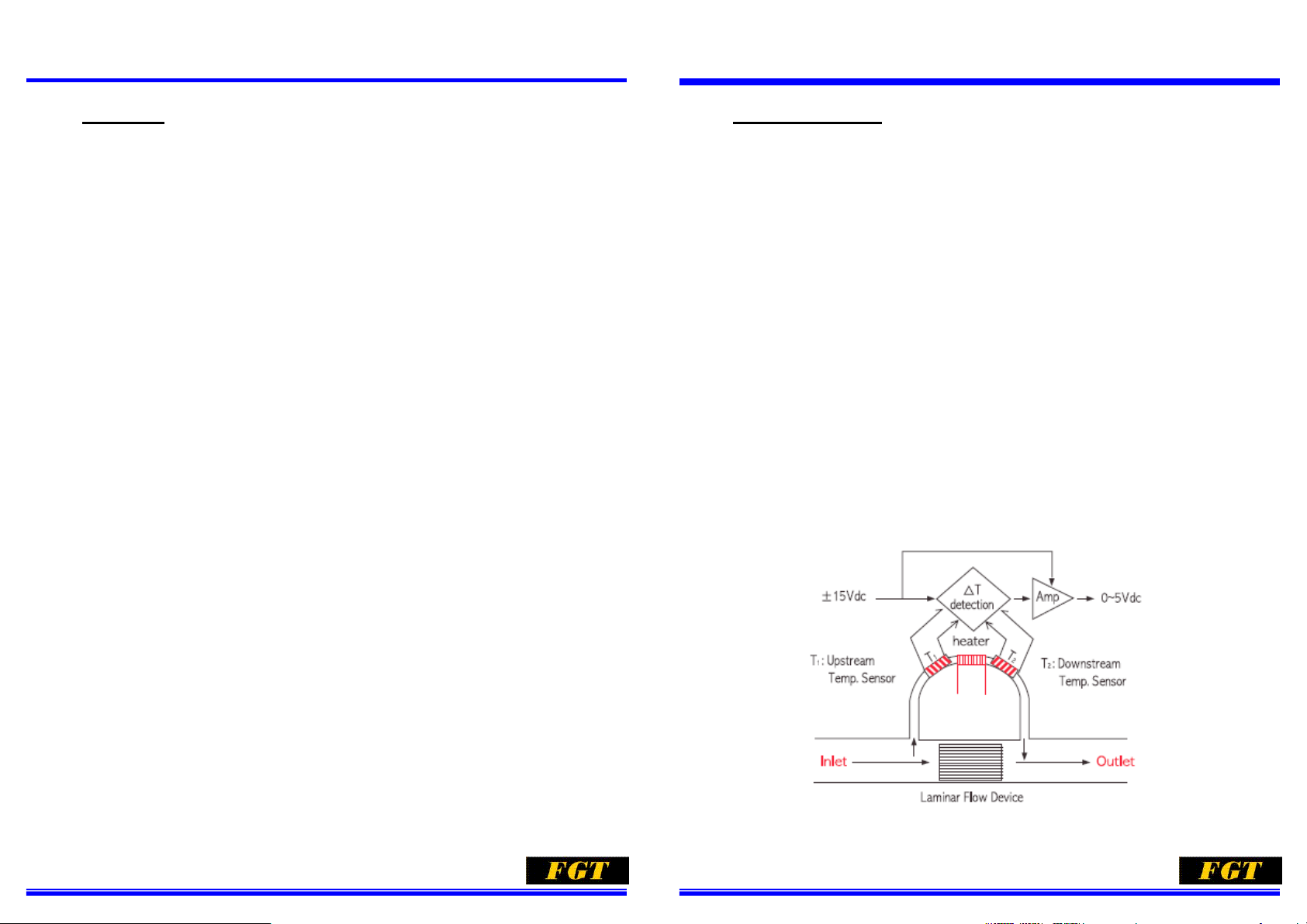

2. Principle of Operation

The detection sensor for Mass Flow is wound

thermo-resistance wires on the outsides of the

two positions (upstream and downstream) of the

metal tubing. Flowing a certain quantity of current

into its wires and self-heating them allow the

thermo-resistance wires on the two positions to

have a balance at the same temperature during

gas with no flow in the metal tubing. When gas

flows in this metal tubing, the thermo-resistance

wires on the up-per flow side is deprived of heat

by the gas, thereby lowering the temperature.

The downstream is conveyed the heat of the

upstream. This raises the temperature and

breaks the initial balance, thus also causing a

difference between the resistances. The

temperature difference of theses position grows

in proportion to the gas flow amount and a

volume of the heat capacity specified with the

specific gravity and specific heat determines the

ratio of the temperature difference change. The

change of the gas flow amount is caught of the

resistance value. Thus detecting the Mass Flow.

(=Principal of the thermal flow sensor).

Installation and Operation Manual

Part number:0912TWAD

The change of the Mass Flow is represented as

a change of the voltage signal by the electronic

circuit, through utilization of this principal.

Selecting-mounting a bypass capillary for

making the flow detecting sensor bypass the

flow limits the gas flow in this section, thus

enabling the flow rating to be determined. In

addition, mount a comparative control circuit

onto the combination of the flow detection

sensor and control valve for this Mass Flow,

thereby providing it with signals for setting the

flow detection sensor and flow. The

comparative control circuit compares these two

signals. Then if the output signal is smaller than

the setting signal, turn the opening of the control

valve greater, thus changing the current added

to the solenoid valve, the standard valve is of

normal closing type, with the power not-being

On, the flow route is closed.

U-TMFC--EN

October,2009

www.fgttw.com

-5-

www.fgttw.co

-6-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

3.. Standard configuration and Wiring Connection

3-1. Standard Configuration

WARNING

Do not operate this instrument in excess of the specifications. Failure to heed this

warning may result in serious personal injury and / or damage to the equipment

Standard Ranges Output Signal(Fig-4)

z 10 sccm to 500 slpm (nitrogen equivalent) z 0~5 Vdc into 2kΩor greater. Maximum

ripple 3 mV. Jumper selectable 4~20 mA.

Refer to Fig-4 for maximum total loop

resistance.

Accuracy 5 Volt reference Output

z ±1.0% scale including linearity at calibration

conditions. ±1.50% full scale including

linearity for floe ranges greater than 20 slpm

z 5 V ±0.2%.Maximum load 1KΩ

Repeatability Command Input(Fig-2/Fig-3)

z 0.25% of rate z Jumper Selectable: 0~5 Vdc, Input resistance

200KΩ or 4~20 mA, Input resistance 75Ω

Response Time Leak Integrity

z Less than 3 seconds response to within 2%

full scale final value with 0 to 100%

command step.

z 1x 10

-9

Atm. CC/sec helium

Power Requirements Control Range

z +15 ~ + 28 Vdc 350mA z 50 to 1

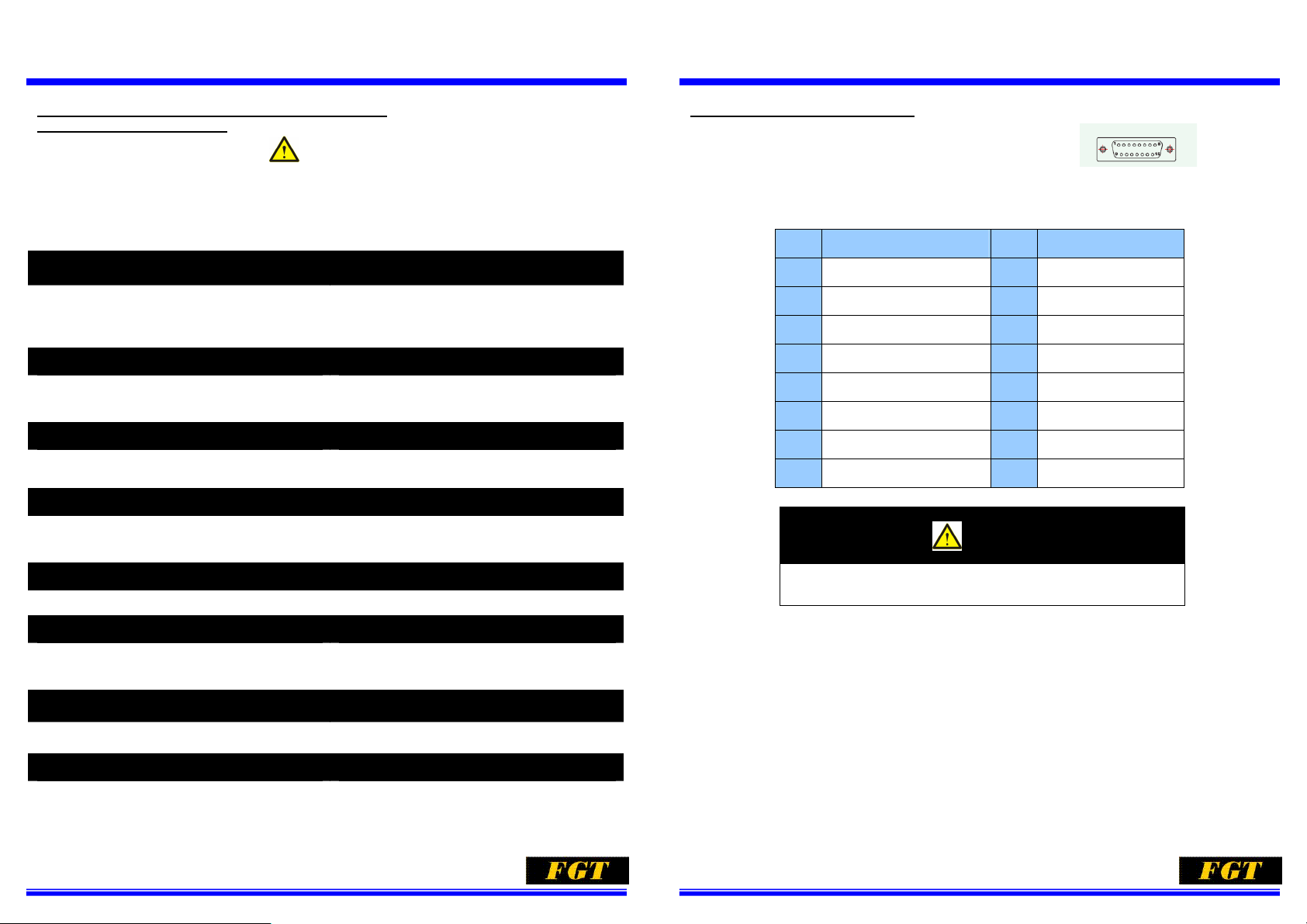

3-2. Electric connection Diagram

Electrical Connection(Fig-1)

D-type Connections Pin out

Pin Assignment of Dsub 15-Pin Connector per Standards

Pin No. Signal Pin No. Signal

1 COM ground 9 Power Source COM

2 Flow output 0~5VDC 10 Flow output Ground

3 No used 11 +5 Vdc reference output

4 Flow output 4~20mA 12 Valve Override

5 +15~28 VDC Power Source 13 No used

6 -15 VDC Power source 14 Chassis ground

7 Current flow input COM 15 No used

8 Voltage flow Input COM

*Because a differential input system is used for the products, pin 2&8 for TMFC30V and pin

4&7 for TMFC30A choice one kind of signal input/output to use.

Fig-1

CAUTION

Ambient temperature Limits Mechanical Connection (Fig-5)

z Operating:5 ~ 65 (40 to 150℃ ℉)

z No-Operating:-25 to 100 (℃ -13 to 212℉)

z Range. Consult factory for details.

z Interchangeable with most popular mass

flow controller .Fig-5

Working Pressure Electrical Connection(Fig-1)

z 1300/1000 psi maximum z D-type:Dsub 15-pin connector, Mating

connector supplier.

Allowable Differential Pressure Mounting Attitude Sensitivity

z 5 psi minimum,50 psi maximum. Higher

differential pressures are allowable

z ±0..5% maximum full scale deviation after

re-zeroing.

www.fgttw.com

-7-

www.fgttw.co

-8-

Loading...

Loading...