FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

Essential Instructions

Read this page before proceeding!

FGT designs, manufactures and tests its products to meet many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use and maintain them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered to and integrated into your safety program when installing, using and maintaining

Mass Flow Controller

TMFC Series

Installation and Operation Manual

FGT products.

z Read all instructions prior to installing, operating and servicing the products. If this instruction manual is not the correct manual,

telephone 886-6-2632460 and the requested manual will be provided. Save this instruction manual for future reference.

z If you do not understand any of the instructions, contact your FGT representative for clarification.

z Follow all warnings, cautions and instruction marked on and supplied with the products.

z Inform and educate your personnel in the proper installation, operation and maintenance of the product.

z Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local and

national codes. Connect all products to the proper electrical and pressure sources.

z To ensure proper performance, use qualified personnel to install, operate update, program and maintain the products.

z When replacement parts are required, ensure that qualified people use replacement parts specified by FGT. Unauthorized parts

and procedures can affect the product’s performance and place the safe operation of your process at risk. Look-alike substitutions

may result inn fire, electrical hazards or improper operation.

z Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

CAUTION

This Instrument contains electronic components that are susceptible to damage by static electricity. Proper handling

procedures must be observed during the removal, Installation or other handling or internal circuit boards or devices.,

www.fgttw.com

First General Technology Inc.

-1-

Handing Procedure

4. Power to unit must be removed.

5. Personnel must be grounded, via a wrist strap or other safe, suitable means before any printed circuit card or other internal

device is installed, removed or adjusted.

6. Printed circuit cards must be transported in a conductive bag or other conductive container. Boards must not be removed from

protective enclosure until immediately before installation. Removed boards must immediately be placed in protective container

for transport, storage or return to factory.

Comments

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronic designs contain

components that utilize metal oxide technology (NMOS, CMOS, etc,) Experience has proven that even small amounts of static electricity

can damage or destroy these devices. Damaged components even though they appear to function properly, exhibit early failure.

www.fgttw.co

-2-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

Part number:0912TWAD

U-TMFC--EN

October,2009

CONTENTS:

1.Specifications------------------------------------------------------------------------------- 4

1-1.Specifications------------------------------------------------------------------------- 4

Page

Installation and Operation Manual

Part number:0912TWAD

FGT® Model TMFC Mass Flow Controller/Mete

2. Specifications

Model TMFC series Mass Flow controller accurately measures and controls gas flow.

This instrument is used for flow control in a wide range of application including various

analyzers, combustion, and biotechnology.

U-TMFC--EN

October,2009

1-2.Unit of Flow--------------------------------------------------------------------------- 5

2.Principle of Operation-------------------------------------------------------------------- 6

3.Standard configuration and Wiring Connection------------------------------------ 7

3-1.Stadard Configuration-------------------------------------------------------------- 7

3-2.Electric connection Diagram and Wiring Connection------------------------ 8

4.Installation and Piping-------------------------------------------------------------------- 11

4-1.Storage and Application environment------------------------------------------ 11

4-2.Piping System Washing------------------------------------------------------------ 12

4-3.In-line Filter---------------------------------------------------------------------------- 12

4-4.Combined Use of The Set-point Valve------------------------------------------ 13

4-5.Use of The conversion Tables ---------------------------------------------------- 14

4-6 Gas Connection---------------------------------------------------------------------- 18

4-7.Installation----------------------------------------------------------------------------- 18

5.Operational Procedure------------------------------------------------------------------- 19

6.Troubleshooting----------------------------------------------------------------------------- 20

7.Dimensions---------------------------------------------------------------------------------- 22

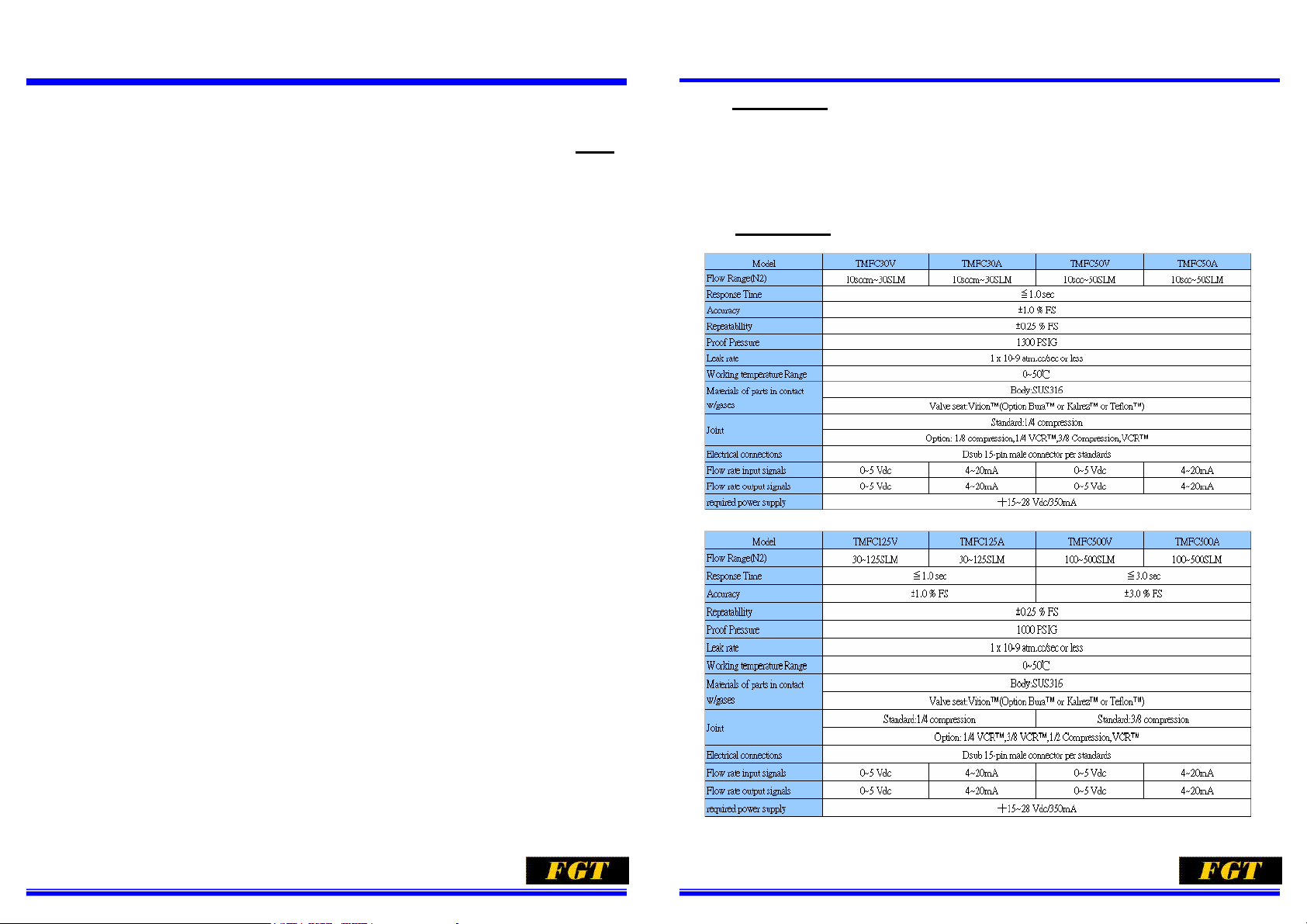

1-1. Specifications

8.Product Warranty--------------------------------------------------------------------------- 23

www.fgttw.com

-3-

www.fgttw.co

-4-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

Part number:0912TWAD

U-TMFC--EN

October,2009

1-2. Unit of Flow

Our mass flow controller is based on the SEMIIE12-91(semi-standard).

The applied unit is SLM (Standard Liter per Minute) or SCCM (Standard Cubic per

Minute). The status of this gas is the same as the reference(normal) conditions of 0℃,

101.325kPa(abs). If the applied flow unit and definition thereon differ, inquire us of it or

give us your instructions. If the unit you require is a SI unit or unit approved by the current

measuring law, we will make a production on the basis of the unit you require.

FGT® Model TMFC Mass Flow Controller/Mete

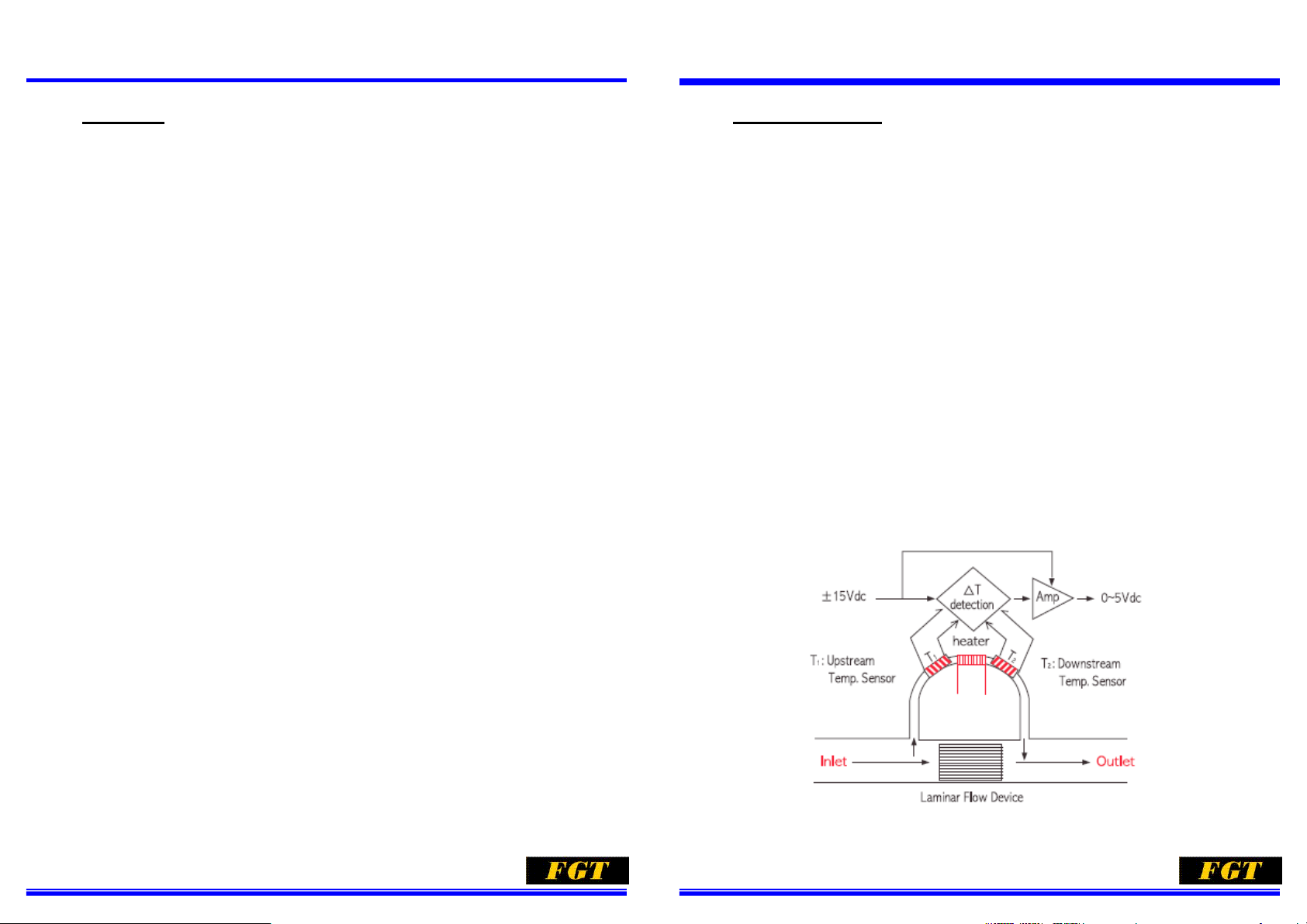

2. Principle of Operation

The detection sensor for Mass Flow is wound

thermo-resistance wires on the outsides of the

two positions (upstream and downstream) of the

metal tubing. Flowing a certain quantity of current

into its wires and self-heating them allow the

thermo-resistance wires on the two positions to

have a balance at the same temperature during

gas with no flow in the metal tubing. When gas

flows in this metal tubing, the thermo-resistance

wires on the up-per flow side is deprived of heat

by the gas, thereby lowering the temperature.

The downstream is conveyed the heat of the

upstream. This raises the temperature and

breaks the initial balance, thus also causing a

difference between the resistances. The

temperature difference of theses position grows

in proportion to the gas flow amount and a

volume of the heat capacity specified with the

specific gravity and specific heat determines the

ratio of the temperature difference change. The

change of the gas flow amount is caught of the

resistance value. Thus detecting the Mass Flow.

(=Principal of the thermal flow sensor).

Installation and Operation Manual

Part number:0912TWAD

The change of the Mass Flow is represented as

a change of the voltage signal by the electronic

circuit, through utilization of this principal.

Selecting-mounting a bypass capillary for

making the flow detecting sensor bypass the

flow limits the gas flow in this section, thus

enabling the flow rating to be determined. In

addition, mount a comparative control circuit

onto the combination of the flow detection

sensor and control valve for this Mass Flow,

thereby providing it with signals for setting the

flow detection sensor and flow. The

comparative control circuit compares these two

signals. Then if the output signal is smaller than

the setting signal, turn the opening of the control

valve greater, thus changing the current added

to the solenoid valve, the standard valve is of

normal closing type, with the power not-being

On, the flow route is closed.

U-TMFC--EN

October,2009

www.fgttw.com

-5-

www.fgttw.co

-6-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

3.. Standard configuration and Wiring Connection

3-1. Standard Configuration

WARNING

Do not operate this instrument in excess of the specifications. Failure to heed this

warning may result in serious personal injury and / or damage to the equipment

Standard Ranges Output Signal(Fig-4)

z 10 sccm to 500 slpm (nitrogen equivalent) z 0~5 Vdc into 2kΩor greater. Maximum

ripple 3 mV. Jumper selectable 4~20 mA.

Refer to Fig-4 for maximum total loop

resistance.

Accuracy 5 Volt reference Output

z ±1.0% scale including linearity at calibration

conditions. ±1.50% full scale including

linearity for floe ranges greater than 20 slpm

z 5 V ±0.2%.Maximum load 1KΩ

Repeatability Command Input(Fig-2/Fig-3)

z 0.25% of rate z Jumper Selectable: 0~5 Vdc, Input resistance

200KΩ or 4~20 mA, Input resistance 75Ω

Response Time Leak Integrity

z Less than 3 seconds response to within 2%

full scale final value with 0 to 100%

command step.

z 1x 10

-9

Atm. CC/sec helium

Power Requirements Control Range

z +15 ~ + 28 Vdc 350mA z 50 to 1

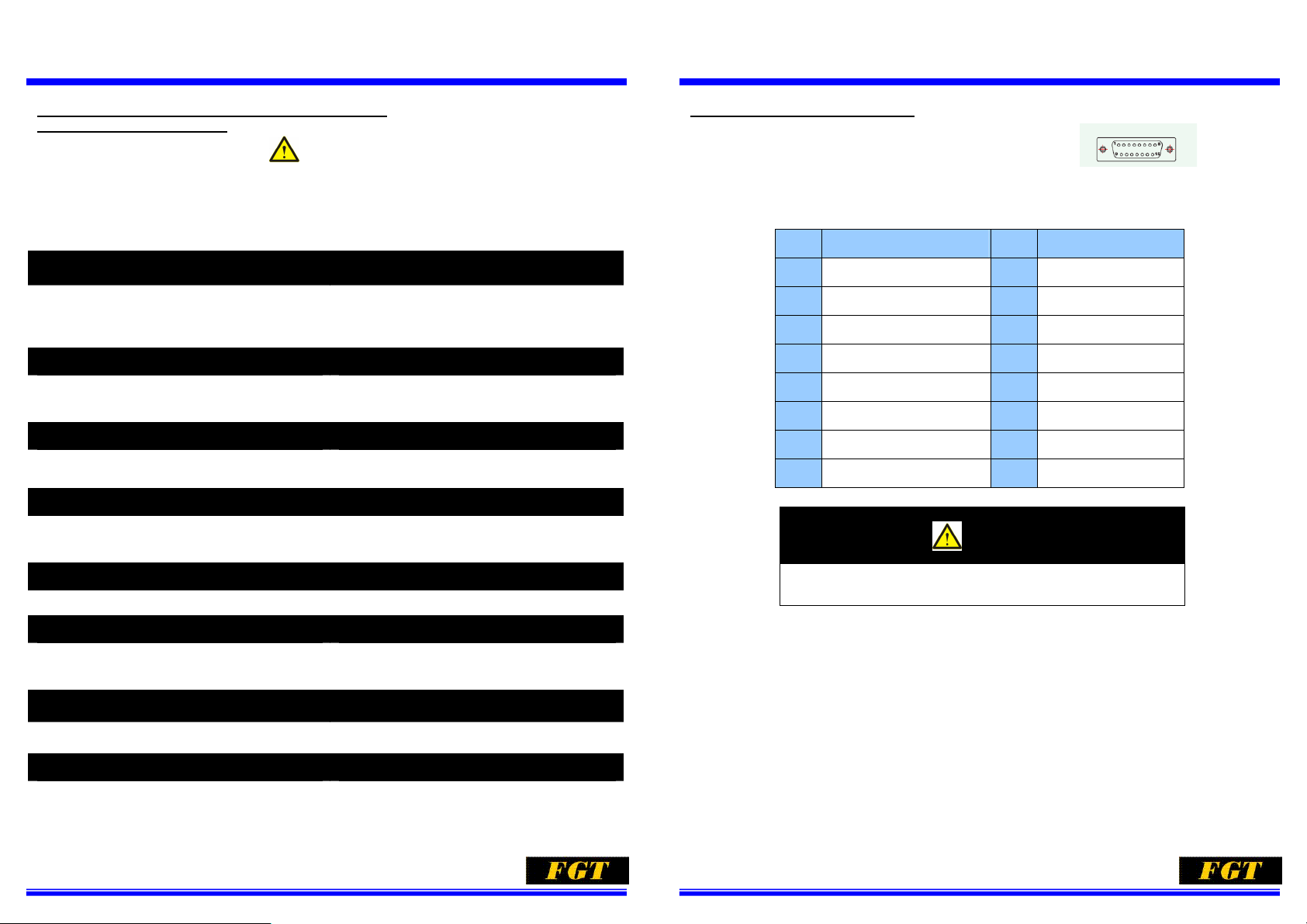

3-2. Electric connection Diagram

Electrical Connection(Fig-1)

D-type Connections Pin out

Pin Assignment of Dsub 15-Pin Connector per Standards

Pin No. Signal Pin No. Signal

1 COM ground 9 Power Source COM

2 Flow output 0~5VDC 10 Flow output Ground

3 No used 11 +5 Vdc reference output

4 Flow output 4~20mA 12 Valve Override

5 +15~28 VDC Power Source 13 No used

6 -15 VDC Power source 14 Chassis ground

7 Current flow input COM 15 No used

8 Voltage flow Input COM

*Because a differential input system is used for the products, pin 2&8 for TMFC30V and pin

4&7 for TMFC30A choice one kind of signal input/output to use.

Fig-1

CAUTION

Ambient temperature Limits Mechanical Connection (Fig-5)

z Operating:5 ~ 65 (40 to 150℃ ℉)

z No-Operating:-25 to 100 (℃ -13 to 212℉)

z Range. Consult factory for details.

z Interchangeable with most popular mass

flow controller .Fig-5

Working Pressure Electrical Connection(Fig-1)

z 1300/1000 psi maximum z D-type:Dsub 15-pin connector, Mating

connector supplier.

Allowable Differential Pressure Mounting Attitude Sensitivity

z 5 psi minimum,50 psi maximum. Higher

differential pressures are allowable

z ±0..5% maximum full scale deviation after

re-zeroing.

www.fgttw.com

-7-

www.fgttw.co

-8-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

Command Input(Fig-2/Fig-3)

For Signal I/O:0~5Vdc in sub-code of “V” Type

Fig-2

For Signal I/O:4~20mAdc in sub-code of “A” Type

Output Signal(Fig-4)

TMFC-Series PCB board Jumper Location & Function

www.fgttw.com

Fig-3

Fig-4

-9-

www.fgttw.co

-10-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

4.Installation and Piping

For design and piping construction of the instrument and piping of the system including the

mass flow controller, fully read the following matter and perform job with particular attention

being parid.

4-1.Storage and Application environment

Applying this instrument near the equipment such as high frequency induction

furnace or in the place in which various power systems are concentrated may easily

intrude noise in to Mass Flow Controller, thereby interfering normal operation.

Avoid storage or application outdoor in direct contact with wind-rain or dusts. Avoid

application under the environment in which drops of water directly fall, or dusts have

been accumulated, or in the atmosphere having a high temperature or corrosive

gases. The application in there places may deteriorate or corrode the electronic parts

or cause a connection fault of the cable connection unit.

Avoid storage or application in a place in which the ambient temperature exceeds

65℃ or vibrations occur. When using the controller with gas being actually flowed,

the gas temperature and ambient temperature must be within 5~65 ℃.

Application out of this range may cause damages of the performance. So pay

particular attention to it.

CAUTION: When installing this instrument, avoid the environment in which an

ambient noise generating source exists, and drops of water or dusts

have accumulated, or the atmosphere in which a high temperature

4-2.Washing of The Piping System

Fully internally wash the pipes and applications ( such as the pressure regulator,

pressure gauge and stop valve) used for piping system before the application thereof. Mixing of dusts, rusts, oil and water makes and intrusion of their substances into

the mass flow controller, thus causing and internal clogging, deterioration in

performance and erroneous operation..

CAUTION: Never wash the piping system after incorporation of this instrument.

Ignoring it may cause a critical malfunction.

4-3.In-line Filter

It is recommend that an In-Line be installed upstream from the controller to prevent

the possibility of any foreign material entering the flow sensor or control valve. The

filtering element should be replaced periodically or ultrasonically cleaned.

When applying the air fed out of the compressor or fan, a large quantity of oil mist or

drops of water may intrude. So mount an oil filter or water-eliminating filter on the

front stage.

Recommended filter size

Maximum flow Filter size

10~30SLM

Up to 500SLM

.

15μ

30μ

www.fgttw.com

and corrosive gas exist. Ignoring it may cause a critical malfunction.

-11-

www.fgttw.co

-12-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

4-4.Combined Use of The Set-point Valve

z Valve Override:

z Set-point(Command):

z Low Command Valve Inhibit:

z Removable Cleanable Sensor:

z Output Limiting:

Permits the user to fully open and

close the control valve independent of

the Set-point(Command) setting.

Permits the user to program the mass

flow controller with an external

0~5Vdc or 4~20mAdc signal.

(Auto Shutoff) prevents the valve

from opening whenever the set-point

is less than 2% of full scale.

Permits the user to clean or replace

the sensor

Prevents possible damage to delicate

data acquisition devices by limiting

the output to -0.7~+6.8 Vdc on the

voltage signal output and 0~26 mAdc

on the current output

4-5.Use of The conversion Tables

When operating Model TMFC-Series Mass Flow controller correctly, design the

piping system so that the pressure difference between the inlet and outlet. If a mass

flow controller is operated on a gas other than the gas it was calibrated with, a scale

shift will occur in the relationship between the output signal and the mass flow rate.

This is due to the difference in heat capacities between the two gases. This scale

shift can be approximated by using the ratio of the molar specific heat of the two

gases. Or sensor conversion factor. A list of sensor conversion factors is given in

Table 4-1 to change to a new gas. Multiply the output reading by the ratio of the gas

factor for the desired gas to the gas factor for the calibration gas.

It is generally accepted that the mass flow rate derived form this equation is only

accurate to ± 5%. The sensor conversion factors given in Table 4-1 are calculated

based on a gas temperature of 21℃ and pressure of one Atmosphere. The specific

heat of most gases are not strongly pressure and temperature dependent, however

gas conditions that vary widely from these reference conditions may cause an

additional error due to the change in specific heat due to temperature or pressure.

Actual Gas Flow and Operational Pressure Calculated

www.fgttw.com

-13-

www.fgttw.co

-14-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

Table 4-1 Conversion Factors(Nitrogen Base)

Table 4-1 Conversion Factors(Nitrogen Base) Continued

www.fgttw.com

-15-

www.fgttw.co

-16-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

Table 4-1 Conversion Factors(Nitrogen Base) Continued

4-6.Gas Connection

The standard joints of the TMFC30/50/125-Series Mass Flow Controller are 1/4"

Compression (Swagelok™) or the equivalent on both of the inlet and outlet.

The standard joints of the TMFC50-Series Mass Flow Controller are 3/8" Compression

(Swagelok™) or the equivalent on both of the inlet and outlet

.

4-7.Installation

When designing the piping system employing the Mass Flow Controller, pay

particular attention to that this instrument may have to be removed for maintenance

jobs such as inspection and disassembling washing. Take into full consideration the

arrangement having a space enabling easy removing and reinstallation piping jobs.

During installing this instrument, pay particular attention so that no foreign matters

intrude from the inlet or outlet. Hold attaching the protective caps on the both ends

until the installation.

【Installation procedure】

E. Install Model TMFC-Series Mass Flow Controller in a clean-dried place in which

no impacts and vibration occur.

F. Secure a sufficient space allowing span or zero-point adjustments.

G. Perform piping so that it can be easily removed for request for maintenance

service to us.

CAUTION: Applying toxic gas may cause a contamination or corrosion in

the Mass Flow Controller due to a piping leak or improper

purging. Before the application, fully check to ensure that no

www.fgttw.com

leaks exist in the piping, and perform purging with dried N

gas.

2

H. There exist no limits for instillation posture. However, apply Model

TMFC-Series Mass Flow Controller at the physically no forcible status. Install it

levelly. In the case of other installation postures, perform zero-point adjustment

after the warming-up. When installing Model TMFC-Series Controller, existence

of an angle piping just in front of the controller worsens the accuracy a little.

-17-

www.fgttw.co

-18-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

5.Operation Procedure

z Check to ensure that the piping system connection, cable connection and

wirings are correct.

z Securely close the mass flow controller with the solenoid valve and manual

stop valve so that gas will not flow into there.

z Turn ON the power switch and perform warming-up at least for 15 minutes.

This is intended to make thermal and electric balances of the sensor, thus

creating the stable status.

z When no gas flow, the warming-up is sufficiently conducted and the flow

instruction output gets stable, once clockwise turn the knob on the upper

portion of the mass flow controller with a small female driver so that the

indicated valve changes by around 20% full scale and the output changes by

around 1 V or 4 mAdc. Next, counterclockwise turn it so that the indicated value

gets 0% or 0 V(4 mAdc) . For the adjustment mentioned-above, be sure to

make a zero-point adjustment from the plus side so that the indicated value or

output gets a minus value.

z If a compensation for errors between our reference calibrator and reference

flow meter or a span periodical calibration is required, perform calibration in the

following procedure. Ordinarily the calibration is not required. If you don’t have

a reference flow meter, never move the span pot.

【Span calibration procedure】

Connect a reference flow meter to the gas outlet side of the main machine.

Add a gas pressure within the range of the applied pressure to the inlet side

and set the flow at 100% (5 Vdc or 20 mAdc) full scale. After the indicated

value gets stable at its status, measure the flow. Turn the span pot so that the

indication of the flow meter gets a full-scale flow.

It may take times until the flow gets completely stable. So if the span pot was

operated intentionally, waiting for about 5 minutes until measurement of the

flow leads to a calibration with a higher accuracy.

6.Troubleshooting

6.1 Troubleshooting and actions

for quality assurance, and cautions for maintenance

Trouble Possible Cause Check/corrective Actions

Actual flow overshoots set-point by

more than 5% full scale.

Output stays at 0 Volts regardless

of command and there is no flow

through the controller

Output signal stays at +6.8V

regardless of command and there

is flow through the controller.

Output signal follows set-point at

higher commands but will not go to

zero.

Output signal follows set-point at

lower commands but does not

reach full scale

Partially clogged valve Disassemble and repair control valve.

Anticipate potentiometer out of adjustment. Adjust anticipate potentiometer.

Clogged Sensor.

Clogged Controller Valve

- 15 Volts applied to the valve override input

Defective printed circuit board Replace printed circuit board.

Valve stuck open or leaky Clean and /or adjust valve.

+15 V applied to the valve override input.

Detective printed circuit board Replace printed circuit board.

Command input floating

Leaky control valve Disassemble and repair valve.

Excessive resistance in valve voltage

Insufficient inlet pressure or pressure drop.

Clean sensor. Refer to Fig-1&Fig-2&Fig-3

to cleaning.

Check TP3 with the command valve at

100%. If the voltage is more negative than

-11V for NC Valve or +11V for NO Valve,

disassemble and repair the controller

valve.

Check valve override input. For terminal

assignments.

Check the valve override terminal. Refer to

Fig-1&Fig-2&Fig-3 for terminals

assignments.

Connect command signal. Refer to

Fig-1&Fig-2&-Fig-3 for terminal

assignments.

Reduce wiring resistance or re-configure

controller for “External Valve Return”.

Refer to Fig-1&Fig-2&Fig-3

Adjust pressure, inspect the filters and

clear/replace as necessary.

www.fgttw.com

Valve out of adjustment Adjust valve.

Valve guide spring failure Controller oscillates(see bellow) Clean sensor, Contact to us

Controller grossly out of calibration.

Flow is higher than desired

Controller oscillates

Partially clogged restrictor. Replace restrictor

Pressure drop or inlet pressure excessive

Valve out of adjustment Adjust valve. Or contact to us.

Faulty pressure regulator Check regulator output.

Defective printed circuit board Replace printed circuit board. Contact to

Adjust pressures.

us

-19-

www.fgttw.co

-20-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

6.2 Cautions for maintenance

6-2-1.Zero-point and span calibrations

I

f you have a reference flow meter, perform both adjustment and calibration of the

zero-point and span. If you do not have the meter, adjust only the zero-point. Or

contact to us

6-2-2.Joint washing of the inlet and outlet

Remove the joints for washing thereof in an environment as clean as possible so that

no dusts will enter the main machine. Never disassemble the sensor and valve.

( With regard to the disassembling, it is difficult to warrant the initial performance.)

7. Dimensions

TMFC30/50-Series

TMFC125/500-Series

Connections "A" Dimensions(mm)

1/8"Compression 126.7

1/4" Compression 131.3

3/8" Compression 134.3

1/4" MVCR 127.8

Connections "A" Dimensions(mm)

1/4"Compression 148.3

www.fgttw.com

3/8" Compression 151.3

1/2" Compression 165.0

1/4" MVCR 144.8

1/2" MVCR 154.0

-21-

www.fgttw.co

-22-

FGT® Model TMFC Mass Flow Controller/Meter

r

m

Installation and Operation Manual

Part number:0912TWAD

U-TMFC--EN

October,2009

8.Product Warranty

The warrant period shall be one (1) year after the shipment.

If a malfunction of the products you purchased occurs because of our responsible

reasons, it will be charge-free repaired in our factory. The range of the warrant shall

be limited to the main machine. Any damages caused by the malfunction of the main

machine can not be compensated by us.

If a malfunction of the main machine occurs due to the following reasons, even within

the warrant period, it will be onerously repaired by us.

A. Malfunctions due to erroneous applications, repairs or remodeling

B. (Including the case in which the manufacturing specifications differs from the

application conditions.)

C. Malfunctions due to the falling after the purchase.

D. Malfunctions caused by natural disasters such as fire, earthquake, water

disaster and lightning stoke, or riots or wars.

E. Malfunctions caused by mixinging-in of foreign matters out of the piping.

F. Malfunctions caused by the peculiar problems due to combinations with other

built-in equipment.

FGT® Model TMFC Mass Flow Controller/Mete

Installation and Operation Manual

U-TMFC--EN

Part number:0912TWAD

October,2009

www.fgttw.com

First General Technology Inc.( FGT® )

Head Office

Overseas Division

No.6,Shin-Ai Rd.,South District, Tainan,702,Taiwan

Tel:+886-6-2632460(Key number)

Fax:+886-6-2650141

URL:www.fgttw.com

-23-

www.fgttw.co

-24-

Loading...

Loading...