FG Modellsport 66000, 66001 Mounting Instruction

Mounting instruction for

Competition 4WD Off-Road 1:6 Baja Buggy

Item No 66000, 66001

E.66000-66001-271008

Please thoroughly keep this construction instruction for spare parts’ orders!

FG Modellsport-Vertriebs-GmbH

Spanningerstr. 2

73650 Winterbach-Germany

Phone: +49 7181 9677-0

Fax: +49 7181 9677-20

info@fg-modellsport.de

www.fg-modellsport.de

Weight of the individual bags/boxes:

Item No 66000, 66001

Bag A = 1 part

Bag B = 0.771 kg

Bag C = 0.931 kg

Bag D = 1.085 kg,

Bag E = 0.407 kg

Bag F = 0.900 kg

Bag G = 0.191 kg

Bag H = 0.383 kg

Bag I1 = 0.490 kg, only for 66000

Bag I2 = 0.499 kg, only for 66001

Bag J = 0.117 kg

Bag K = 0.343 kg

Bag L = 0.343 kg

Bag M = 0.285 kg

Bag N1 = 0.027 kg, only for 66000

Bag N2 = 0.038 kg, only for 66001

Bag O = 0.299 kg

Bag P = 0.239 kg

Bag Q = 0.604 kg

Bag R = 0.397 kg

The RCS accumulators and battery charger are not included in the

delivery volume.

We congratulate you on buying this FG Competition model. Please check the contents of

the construction set, respectively of the bags. The individual bags had been thoroughly

packed by us and their weight and content had been checked. When purchasing the individual bags, please check their weight and their closure by staples which must not have

been removed or opened and closed several times. It is possible that the weight of an individual bag deviates by 5 grams. In case of claims due to missing parts, you always need to

present the label indicating the weight at your specialized dealer. By checking the weight of

the bag, you may exclude that larger parts or several parts are missing.

Are you interested in receiving 4WD news?

For example information about meetings,

races, technical hints. Just send us an email

with your name and email address to

marketing@fg-modellsport.de. You will receive

the 4WD news automatically when available.

Comments regarding the construction manual:

Before starting the assembly please see through this construction

manual. This way you will get an overview of the whole execution.

Please check by means of the parts or bag list if the construction kit is

complete and also check the weight of the individual bags for the positions. Only this way you may be sure that all parts which you need for

the assembly are available. If a part is missing, please immediately contact your specialized dealer.

Contents

Position 1-2: Front and rear differential gear

Position 3-8: Belt drive, belt stretcher, chassis structure

Position 9-15: Rear axle

Position 16-17: Front and rear shock absorber

Position 19-25: Front axle, front bumper

Position 26-32: Engine, clutch, gear , air filter, tank

Position 33-40: RC-plate, receiver box, servo saver

Position 41-45: Roll cage, throttle rods, tuning pipe

Position 46-52: Front and rear tuning disk brake

Position 53-59: Front and rear FG Magura hydr. brake system

Position 60-61: Side guards, front roll cage

The handling with fuels requires circumspective and careful handling. Imperatively observe the security advices.

-Refuel only if the engine is switched off!

-Take off the body.

-Thoroughly clean the area around the fuels nipple.

-Remove the fuel filler cap and carefully fill in the fuel mixture.

-Smoking or any kind of open fire is not admitted.

-Fuels might contain solvent-like substances. Avoid contact with skin

and eyes. Wear gloves for refueling. Do not inhale fuel vapors.

-Do not spill any fuel. If you have spilled fuel immediately clean the

engine and the model.

-Make sure that no fuel will get into the soils (environmental protection).

Use an appropriate mat.

-Do not refuel in enclosed rooms. Fuel vapors accumulate at the soil

(risk of explosion).

-Transport and store fuels only in admitted and labeled canisters. Keep

fuel out of the range of children.

-The operator is responsible for any damages caused to third persons

in the operating range of the model, respectively of the engine, if they

are injured or in case of property damage.

-The model must only be passed on to persons who are familiar with

this model and its operation, always provide the operating manual.

-Persons with implanted heart pacemakers must not work on running

engines and on live parts of the ignition system when the engine is

being started.

-The engine must neither be started nor operated in enclosed rooms

(without sufficient ventilation).

-When starting the engine, avoid inhaling the exhausts.

-The model must neither be started nor operated without air filter or

without exhaust system.

-Before every start perform a functional check of the safety-relevant

parts.

-The throttle rods must always return automatically to the idle position.

-Any cleaning, maintenance and repair works must only be performed

with the engine being switched off. The engine and silencers are getting very hot. In particular do not touch the silencer.

Our mentioned setting dimensions of steering linkage, wishbone thread

rods aso. are just guiding values which should be modified according

to the track conditions and surfaces.

Chassis adjustments and technical advices

Competition 4WD Off-Road 1:6 Baja Buggy

Our recommended chassis adjustments give you a basic setup. As the

surfaces in the Off-Road sector can be very different certain readjustments may be necessary. This depends on outdoor temperature, on

the roadbed and how strong the track is frequented.

Wheel camber:

Trailing effect:

Toe-in:

Damper springs:

Spring camber:

Damper position:

Damper piston:

Damper oil:

Stabilizer:

Driving height/ Chassis height:

Servo saver:

0° at chassis 90° rebounded

4-6mm clips

slightly open to the front

violet Item N°. 66305

5mm

Wishbone medium boring

5-hole aluminium ø1,9mm Item N°. 06484/05

2000-3000 FG damper oil

Sway bar 4mm

40mm with Baja wheels

Medium hole, outer hole position

0° at chassis 90° rebounded

3°

red Item N°. 66303

10mm

Lower wishbone outer boring

Rear alloy dampler plate outer boring

5-hole aluminium ø1,9mm Item N°. 06484/05

2000-3000 FG damper oil

Sway bar 5mm

45mm Baja wheels

Front axle Rear axle

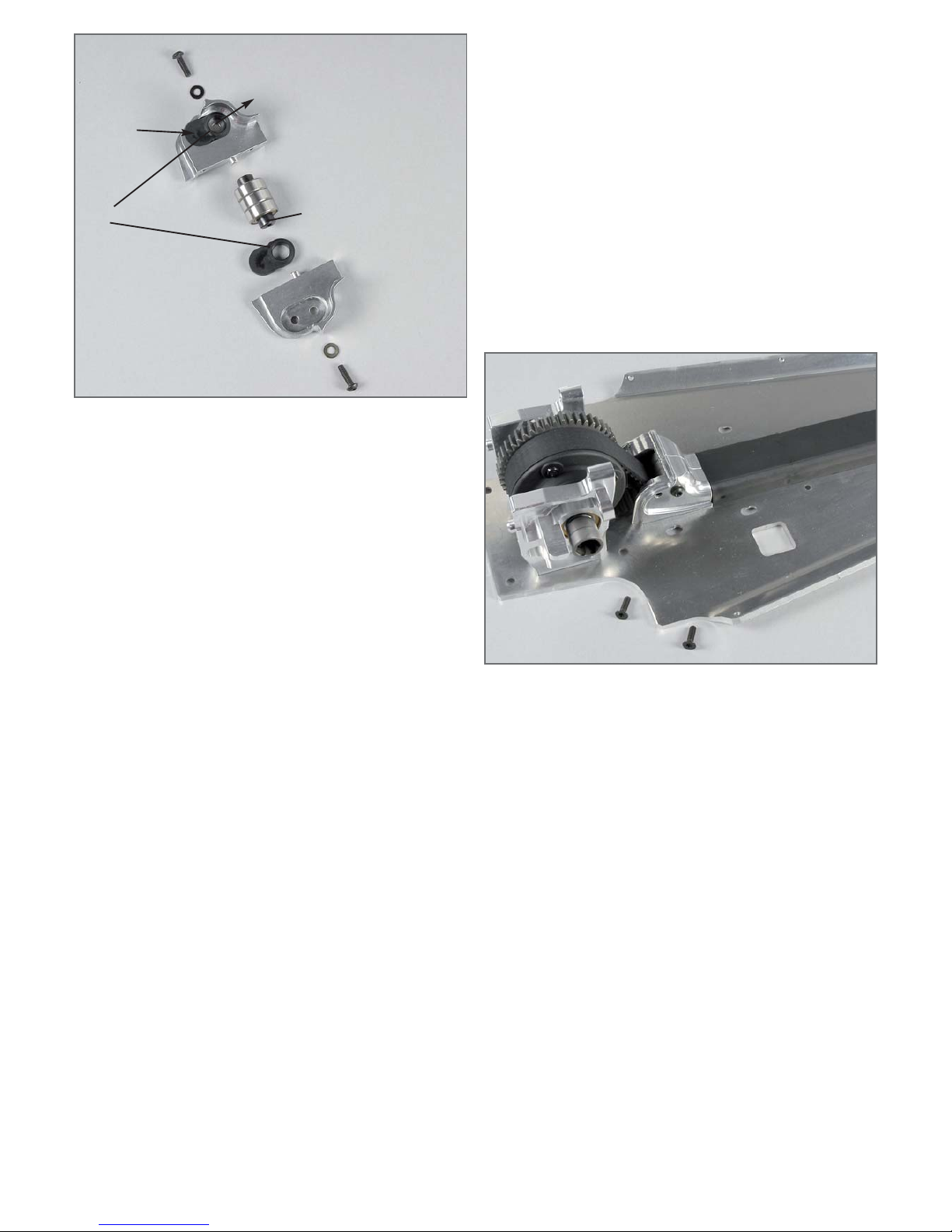

1. Insert the diff. gearwheels in the diff. housing as described in position 1. When using the FG mounting tool item No 08505, the inserting

of the bevel gearwheels will be eased considerably.

2. Lubricate the ball diff. driving axles slightly with grease and push it

in the diff. housing.

3. Mount the diff. bevel gear axle. If the bevel gear axle respectively the

driving axles can only be pushed in severely or if it cannot be pushed

in at any position, you have to dismantle the bevel gearwheels again.

Then insert it again.

4. If the gearwheels have too much clearance, correct it using the

enclosed shim rings. Please make sure that the gearwheel clearance

had not been set too close.

5. Lubricate the gearwheels slightly with multipurpose grease, e.g. item No

06501

6. Put the parts on the alloy diff. housing as described in position 1

and in the given sequence: O-ring large, O-ring small, steel gearwheel

48teeth., rear plastic gear disk 42 teeth, right alloy stop disk. Fasten

the complete unit using the M4x40 countersunk screws

(use the screw retention high-strength).

1. Mount the differential gear for the front axle as described in position

1 under the item 1-5.

2. Then put the parts on the alloy diff. housing as described in position

2 and in the given sequence: O-ring large, O-ring small, front plastic

stop disk left, plastic toothed belt wheel 42 teeth, right plastic stop

disk. Fasten the complete unit using the M4x40 countersunk screws

and the stop nuts M4.

3. Push the bearing shafts 6x50mm centrally in the deflection roller

16mm and in the 12-teeth toothed belt wheel.

Toothed belt

wheel

12 teeth

Bearing

shaft

6x50

Bearing shaft

6x50

Deflection roller

16mm

Front

plastic stop

disk left

Front plastic

toothed belt wheel

42 teeth

Front drive

Right plastic

stop disk

Position 1

Parts are in

bag B

Position 2

Parts are in

bag C

Differential rear

Rear drive

Ball diff.

driving axle

Ball bearing

15x28x7

Screw

M4x40

Needle

bearing f.

Diff

Bronze

bush

Alloy

differential

housing

Diff. bevel

gear axle

O-rings

Shim ring

5x17x0.1

Shim ring

8x20x0.1

Diff. gearwheel B

Diff. gearwheel A

Steel gearwheel

48 teeth

Rear plastic gear disk

42 teeth

Alloy stop disk

right

Chamfer

inbound

Ball diff.

driving axle

Ball bearing

15x28x7

Screw

M4x40

Alloy

differential

housing

Steel gearwheel

48 teeth

Rear plastic

gear disk

42 teeth

Alloy stop disk

right

Stop nut M4

Inserting of the diff.

bevel gearwheels or

of the complete

package is much

easier if you use the

FG mounting tool

8505.

Screw

M4x40

All metric screws need to be secured with thread lock fluid.

Toothed belt wheel

12 teeth

Left

front axle

housing

Left alloy

front axle

housing

Right alloy

front axle

housing

Ball bearing

6x16x6

Toothed belt

Toothed belt

Toothed belt

Alloy chassis

Alloy chassis

Deflection roller

16mm

Rear

differential

gear

Alloy rear axle mount

left

Alloy rear axle

mount left

Upper part

belt channel

Lower part

belt channel

Front differential

mounted

Front

differential gear

Screw

M4x14

Screw

M4x14

Position 3

Parts are in

bag C

Position 4

Parts are in

the bags A,C

Position 5

Parts are in

bag B

1. Push the front differential gear, deflection roller 16mm, toothed belt

wheel 12 teeth in the left alloy front axle housing as described in

position 3.

2. Put the toothed belt on the front differential gear, deflection roller

16mm and the toothed belt wheel with 12 teeth as described in position 3.

3. Press the right alloy front axle housing on the front differential gear,

deflection roller 16mm and the toothed belt wheel with 12 teeth

(position 4).

4. Put the complete alloy front axle housing on the alloy chassis and

fasten it using the M4x14 countersunk screws.

1. Put the toothed belt on the rear differential gear as described in

position 5.

2. Press the left and right rear axle mounts on the ball bearings of the

rear differential gear as described in position 5.

3. Put the left and right alloy rear axle mounts on the alloy chassis and

mount it using the M4x14 countersunk screws.

Alloy chassis

Upper part

belt channel

Lower part

belt channel

Screw

M4x14

Screw

4.2x16

Position 6

Parts are in

bag C

Toothed belt

Left alloy

front rear

axle

housing

Right alloy

front rear

axle

housing

1. Put the lower part of the belt channel on the lower part of the too-

thed belt as described in position 6. Then push the upper part of the

belt channel in the lower part of the belt channel. Then insert the complete belt channel in the opening of the alloy front axle housing. Make

sure that the toothed belt is running smoothly.

2. Mount the belt channel to the alloy chassis using the 4.2x16

countersunk screws.

Screw

M4x14

Disk

Ø4.3

Left stretching pulley

housing

Toothed belt

wheel 42 teeth

Toothed belt wheel

40 teeth

Right stretching

pulley housing

Collar

Plastic bearing

seat

Ball bearing

10x19x7

Bearing shaft f.

housing for

stretching pulley

Position 7

Parts are in

bag B

Alloy chassis

Screw

M4x14

Stretching

pulley

housing

Belt channel

mounted

Position 8

Parts are in

bag B

1. Push the bearing shaft for the stretching pulley housing centrically in

the 3 ball bearings 10x19x7.

2. Push the plastic bearing seat with inbound collar in the left and right

stretching pulley housing as described in position 7.

3. Push the bearing shaft which is equipped with ball bearings in the left

and right stretching pulley housings which are equipped with plastic

bearings seats and mount it using M4x14 pan-head screws and disks

Ø4.3.

4. Put the complete stretching pulley housing on the belt and belt

channel as described in position 8 and mount it on the alloy chassis

using the M4x14 countersunk screws. For this purpose, slightly move

the belt.

5. When the assembly is performed, turn the belt in running

direction. The belt has to rotate easily.

Hint: The position of the front bearing seat is made for the front plastic

toothed belt wheel with 42 teeth. The position of the rear bearing seat

is made for the rear plastic toothed belt wheel with 40 teeth.

All metric screws need to be secured with thread lock fluid.

Screw

M5x25

Taper disk

4x Screw Ø5.3 and 1x

screw M5x30

Taper disk

Stop nut M5

Push in guide

bushes

Position 10

Parts are in

bag D

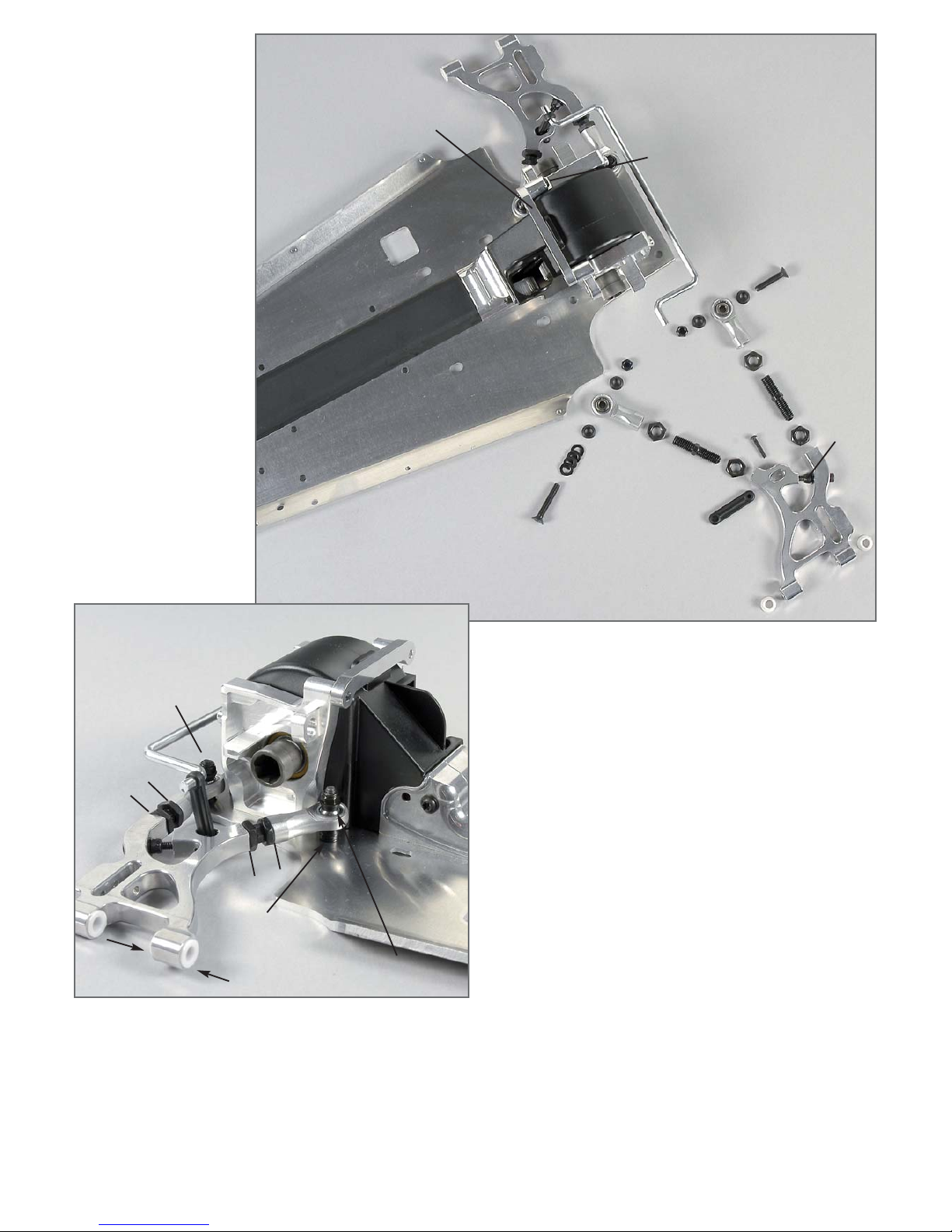

1. Push the rear axle cover between the alloy rear axle mounts and

mount it using an alloy connection brace, a M4x20 pan-head screw

and a disk Ø4.3.

2. Push the guide bushes with collar in the rear lower alloy wishbones

from inside and outside.

3. Mount the M4x25 cylinder screws with stop nuts M4 and disks Ø4.3 in

the rear lower alloy wishbones.

4. Screw the hexagon nuts with M8 left-handed thread on the adjusting

screws 32mm and screw it in the rear lower alloy wishbones, then screw

the hexagon nuts with M8 right-handed thread and alloy ball bearings on

the adjusting screws 32mm.

5. Mount the plastic brace for the stabilizer to the rear lower alloy

wishbone using M3x16 pan-head screws, then push the stabilizer 5mm

in the plastic brace for the stabilizer.

6. Mount the pre-assembled rear lower alloy wishbones to the front

alloy ball-and-socket joints with M5x30 countersunk screws, 4 disks

Ø5.3 and one taper disk each between the alloy ball-and-socket joints

and mount

it to the alloy chassis using M5 stop nuts. Then mount the rear alloy

ball-and-socket joints with M5x25 countersunk screws and one taper disk

each between the alloy ball-and-socket joints and mount it to the alloy

chassis using M5 stop nuts. The mounted wishbones should move easily

up and down.

Hint: Mount taper disks always with the thinner side towards the alloy

ball-and-socket joint.

Alloy chassis

Screw

M4x20

Disk Ø4.3

Screw

M5x25

Screw

M5x30

Screw

M3x16

Screw

M4x25

Stop nut

M4

Disk Ø4.3

Disk Ø5.3

Rear lower alloy

wishbone

Alloy

connection

brace

Stabilizer

5mm

Rear axle

cover

Taper disk

Taper disk

Plastic brace for

stabilizer

Alloy balland- socket

joint

Hexagon nut M8

left-handed thread

Hexagon nut M8

right-handed thread

Adjusting screw

r/l 32mm

Stop nut

M5

Guide bush

with collar

Position 9

Parts are in

bag D

All metric screws need to be secured with thread lock fluid.

ca. 15,5mm

ca. 13-14mm

Square

wheel driver

14mm

Balls for driving shaft

Adjusting clips

Retaining

washer

Wishbone pin

Ball driving

axle

Ball driving

shaft

Protection

bellow

Distance

disk

Hexagon

nut

Headless

pin M6x6

Thread

pin M3x3

Alloy

upright

left

Disk Ø4.3

Screw

M4x8

Screw

M4x8

Use screw retention

high-strength

Screw

M4x20

Screw

M4x20

Guide bush

with collar

Guide bush

with collar

Guide bush

decentered

Guide bush

decentered,

boring

towards bottom

Rear alloy

shock mount

Alloy rear axle

mount right

Rear lower alloy

wishbone

Bearing

8x22x7

1. Mount the rear alloy shock mount to the left and right alloy rear axle

mount using the M4x20 pan-head screws.

2. Push the stabilizer in the rear alloy shock mount and fasten it using

M4x8 pan-head screws and disks Ø4.3.

3. Push the guide bushes with collar from the interior side into the left

and right alloy rear axle mounts. Push the decentered guide bushes with

boring showing to the bottom from the interior side in the rear alloy shock

mount.

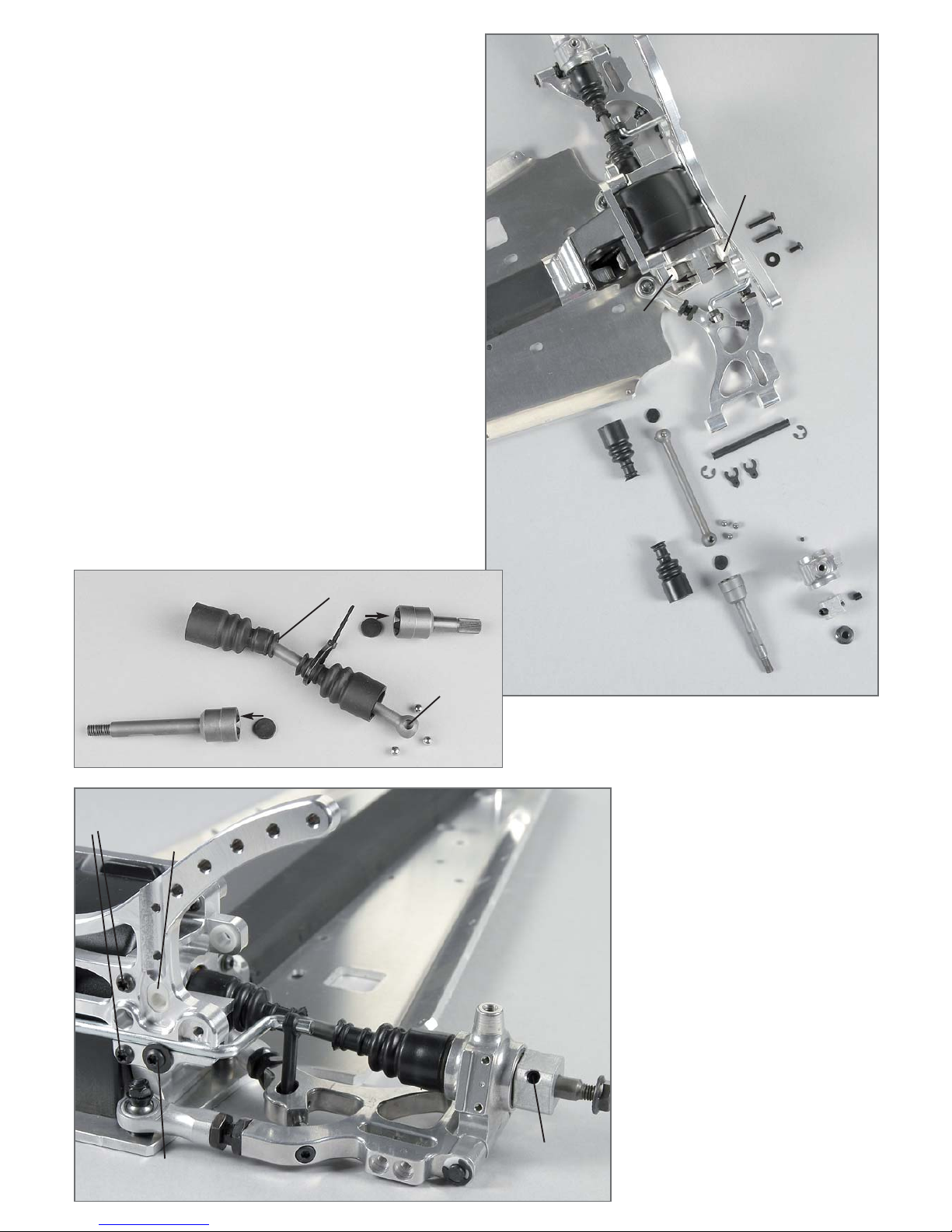

4. Mount the ball driving set as described in position 12.

5. Push the ball driving axles in the alloy uprights which are equipped

with ball bearings and mount the square wheel driver 14mm with

recess towards the ball bearing to the surfaces of the ball driving axles

using M6x6 headless pins (use a high-strength screw retention).

6. Push the alloy uprights and headless pins in the rear lower alloy

wishbones as described in position 13. Secure the headless pins using

Ø5 retaining washers.

7. Put two adjusting clips each on the headless pins between the front

alloy uprights and between the rear lower alloy wishbones. Secure the

alloy uprights using M3x3 headless pins. Check if the alloy uprights are

running smoothly.

Position 11

Parts are in

bag D

Position 13

Parts are in

bag D

Apply

lubricating

grease

Slightly lubricate the

ball driving shaft

Protection bellow

Ball diff. axle

Ball driving

axle

Distance disks

Balls for

driving shaft

Mounting of the ball driving shafts.

Stick the distance disks in the round relief of the ball drive axle as well

as in the ball diff. axle using some multipurpose grease. Mount the

protection bellows to the ball driving shafts according to the illustration. When putting on the protection bellow, slightly grease the ball

area. Apply some lubricating grease on the ball holes and push in the

balls. The balls will be held by the lubricating grease and this way the

driving shaft can be mounted more easily. Then push the complete ball

driving shaft in the differential axle and the driving axle. Put the protection bellows on the ball diff. axles and the driving axles.

Position 12

Parts are in bag B

1. Push the guide bushes with collar in the rear

upper alloy wishbones.

2. Screw the hexagon nuts with M10 left-handed thread

on the rear wishbone thread rods M10/M8 and screw it

in the rear upper alloy wishbones, then screw the hexagon nuts with M8 right-handed thread and alloy

ball-and-socket joints on the rear wishbone thread rods

M10/M8. Use medium screw retention.

3. Push the wishbone pins throughout the alloy rear

axle mounts, rear alloy shock mount and the preassembled rear upper alloy wishbones according to

the illustration. Secure the wishbone pins using Ø5

retaining washers.

4. Push two adjusting clips each in the wishbone

pins at the front between the alloy rear axle mounts

and the rear upper alloy wishbones and push one

adjusting clip each in the wishbone pins at the rear

between the rear alloy shock mount the rear upper

alloy wishbones.

5. Mount the alloy ball-and-socket joints between the

alloy uprights and alloy ball-and-socket joints to the

alloy uprights using M5x30 countersunk screws and

taper disks. Position 15.

6. Screw M5 nuts on M5x25 headless pins and

screw it from the top in the rear upper alloy wishbones (Rebound stop travel).

Hint: The upper wishbone needs to be shimmed

according to the adjustment of the toe-in using the

adjusting clips. Always mount taper disks with the

thinner side towards the alloy ball-and-socket joint.

Adjusting clips

Adjusting clips

The upper wishbone needs to be shimmed

according to the adjustment of the toe-in

using the adjusting clips.

Retaining

washer Ø5

Wishbone pin

Headless pin

M5x25

Left alloy

uprights

Guide bush

with collar

Rear alloy

shock mount

Hexagon nut M8

right-handed thread

Hexagon nut M10

left-handed thread

Rear wishbone

thread rod

M10/M8

Rear upper

alloy wishbone

Alloy ball and sokket joint

Taper disk

Taper disk

Nut

M5

M10

M8

Screw

M5x30

Screw

M5x30

Rebound stop

travel

Position 15

Parts are in

bag D

Position 14

Parts are in

bag D

All metric screws need to be secured with thread lock fluid.

Make sure the driving shaft has not moe than 2-3mm clearance in

horizontal position. Mount enclosed disks Ø8,5/18x1,5 between

rear respectively diff.axle and ball bearing.

ca. 52mm

Screw

M4x20

Screw

M5x25

Nut

M5

Rear shock

absorber

mounted

Stop

nut

M5

Internal

silicone

tube Ø5

Shock absorber locking

Internal silicone

tube Ø4

Disk Ø3.2

Stop

nut M3

O-ring

O-ring

O-ring

Damper spring

red at the rear

violet at the front

Alloy

shock absorber

piston

Spring plate

Shock retaining

short

Threaded

piston rod long

Silicone

O-rings

Alloy

shock absorber

housing

Adjustable

ring

Sheet

gasket

Volume

compensation

Position 17

Parts are in

bag E

Position 18

Parts are in

bag E

Position 16

Parts are in

bag E

1. Insert 2 red silicone O-rings each in the alloy shock absorber housing as described in position 17.

2. Insert the black O-rings in adjustable rings and screw the adjustable

rings on the alloy shock absorber housing.

3. Mount the O-rings with the smaller groove towards the threaded

piston rod to the alloy shock absorber pistons using a disk Ø3.2 and a

stop nut M3.

4. Carefully insert the threaded piston rods throughout the alloy shock

absorber housings, without damaging the silicone O-rings. Screw the

short shock retaining in the thread of the threaded piston rod until

there is no thread visible anymore.

5. Mount the O-rings to the sheet gaskets and push it in the alloy

shock absorber housing.

6. Fill the alloy shock absorber housing with oil up to about 3mm

below the sheet gasket. Carefully slide the threaded piston rod several

times in and out of the alloy shock absorber housing, so that the air

bubbles in the oil will come up. If no longer air bubbles are coming up,

push the threaded piston rod slowly in the alloy shock absorber housing until there is only visible about 5mm of the piston rod. Then insert

the volume compensation with cambering towards the oil and screw it

down with the shock absorber locking. If too much oil is filled in it

might leak through the thread.

7. Mount the red damper springs for the rear axle to the shock

absorbers with the larger boring in the shock absorber locking and

secure it using spring plates. Proceed in the same way for the front

shock absorbers with the smaller borings in the shock absorber lokking and the violet damper springs.

8.Mount the rear lower mounted shock absorbers to the rear lower

alloy wishbones using M4x20 cylinder screws. Screw M5x25 pan-head

screws in the rear alloy shock mount and counter it using M5 nuts,

then mount the upper shock absorber with internal silicone tube Ø5

and M5 stop nuts.

Hint: Slightly lubricate the silicone O-rings and the threaded piston

rods when mounting. If the FG mounting tool item No 06853 is used,

the mounting of the shock absorbers will be eased considerably.

Rear alloy

damper plate

Loading...

Loading...