Page 1

ES 125 Q

ES 125 EQ

Instruction manual

Page 2 - 6

IMPORTANT: Read and understand all instructions

before using.

Guide dutilisation

Page 7 - 11

IMPORTANT: Lire et comprendre toutes les

instructions avant de démarrer les travaux.

Ponceuse excentrique

Manual de instrucciones

Página 12 - 16

IMPORTANTE: Lea y comprende todas las

457 984_002

instrucciones antes de usar.

1

Eccentric sander

Lijador excéntrica

Page 2

GENERAL SAFETY RULES

WARNING! Read and understand all

instructions. Failure to follow all instructions

listed below, may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work area

1 Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

2 Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or

fumes.

3 Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

4a Grounded tools must be plugged into an

outlet properly installed and grounded in

accordance with all codes and ordinances.

Never remove the grounding prong or

modify the plug in any way. Do not use any

adapter plugs. Check with a qualified

electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools

should electrically malfunction or break down,

grounding provides a low resistance path to carry

electricity away from the user.

4b Double insulated tools are equipped

with a polarized plug (one blade is wider

than the other.) This plug will fit in a

polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the

plug in any way. Double insulation eliminates

the need for the three wire grounded power cord

and grounded power supply system.

5 Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is grounded.

6 Dont expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

7 Do not abuse the cord. Never use the

cord to carry the tools or pull the plug from

an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords

increase the risk of electric shock.

8 When operating a power tool outside,

use an outdoor extension cord marked W-

A or W. These cords are rated for outdoor

use and reduce the risk of electric shock.

Personal safety

9 Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use while tired or under

the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

10 Dress properly. Do not wear loose

clothing or jewellery. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewellery,

or long hair can be caught in moving parts.

11 Avoid accidental starting. Be sure

switch is off before plugging in. Carrying

tools with your finger on the switch or plugging

in tools that have the switch on invites accidents.

12 Remove adjusting keys or switches

before turning the tool on. A wrench or key

that is left attached to a rotating part of the tool

may result in personal injury.

13 Do not overreach. Stand on both feet an

keep proper footing and balance at all

times. Proper footing and balance enables better

control of the tool in unexpected situations.

14 Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool use and care

15 Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

16 Do not force tool. Use the correct tool for

your application. The correct tool will do the job

better and safer at the rate for which it is designed.

17 Do not use tool if switch does not turn it

on or off. Any tool that cannot be controlled

with the switch is dangerous and must be

repaired.

18 Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the risk

of starting the tool accidentally.

19 Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

20 Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to

bind and are easier to control.

2

Page 3

21 Check for misalignment or binding of

Various dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and

other masonry products, and

arsenic and chromium from chemically-

treated lumber.

The risk from these exposures varies,

depending on how often you do this type of

work.

To reduce your exposure to these

chemicals: work in a well

ventilated area, and work with

approved safety equipment, such

as dust masks that are specially

designed to filter out microscopic

particles.

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools.

22 Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be suitable

for one tool, may become hazardous when used

on another tool.

Service

23 Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel

could result in a risk of injury.

24 When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorised parts or failure to follow

Maintenance instructions may create a risk of

electric shock or injury.

Technical data ES 125 Q ES 125 EQ

Wattage W 200 200

No load speed rpm 13 000 6 000 - 13 000

No. of strokes spm 26 000 12 000 - 26 000

Sanding stroke mm (in.) 2.0 (0.08) 2.0 (0.08)

Sanding base mm (in.) Ø 125 (4.9) Ø 125 (4.9)

Weight kg (lbs) 1.1 (2.4) 1.1 (2.4)

Safety llevel UL 745, CSA C22.2 No. 745

Symbols

V volts

A amperes

Hz hertz

W watt

alternating current

n

0

rpm revolutions per minute

spm strokes per minute

Intended use

The sanders are designed for sanding wood,

plastic, composite materials, paint / varnish,

filling material and similar materials. Metal and

materials with an asbestos content must not

be processed with these tools.

The machine is particularly suitable for

processing smaller surfaces and overhead work

because of its size, its weight and its output.

The machines must not be damp nor operated

in a damp environment for electrical safety

reasons. The machines may only be used for

dry sanding.

no load speed

Class II Construction

The user bears sole responsibility

for any damage or accidents resulting from

incorrect use.

Electrical connection and operation

The mains voltage must correspond with the

voltage on the rating plate!

See the following Fig. for connecting or

disconnecting the power cord of the tool.

Always switch the machine off

before connecting or disconnecting the power

cable!

3

Page 4

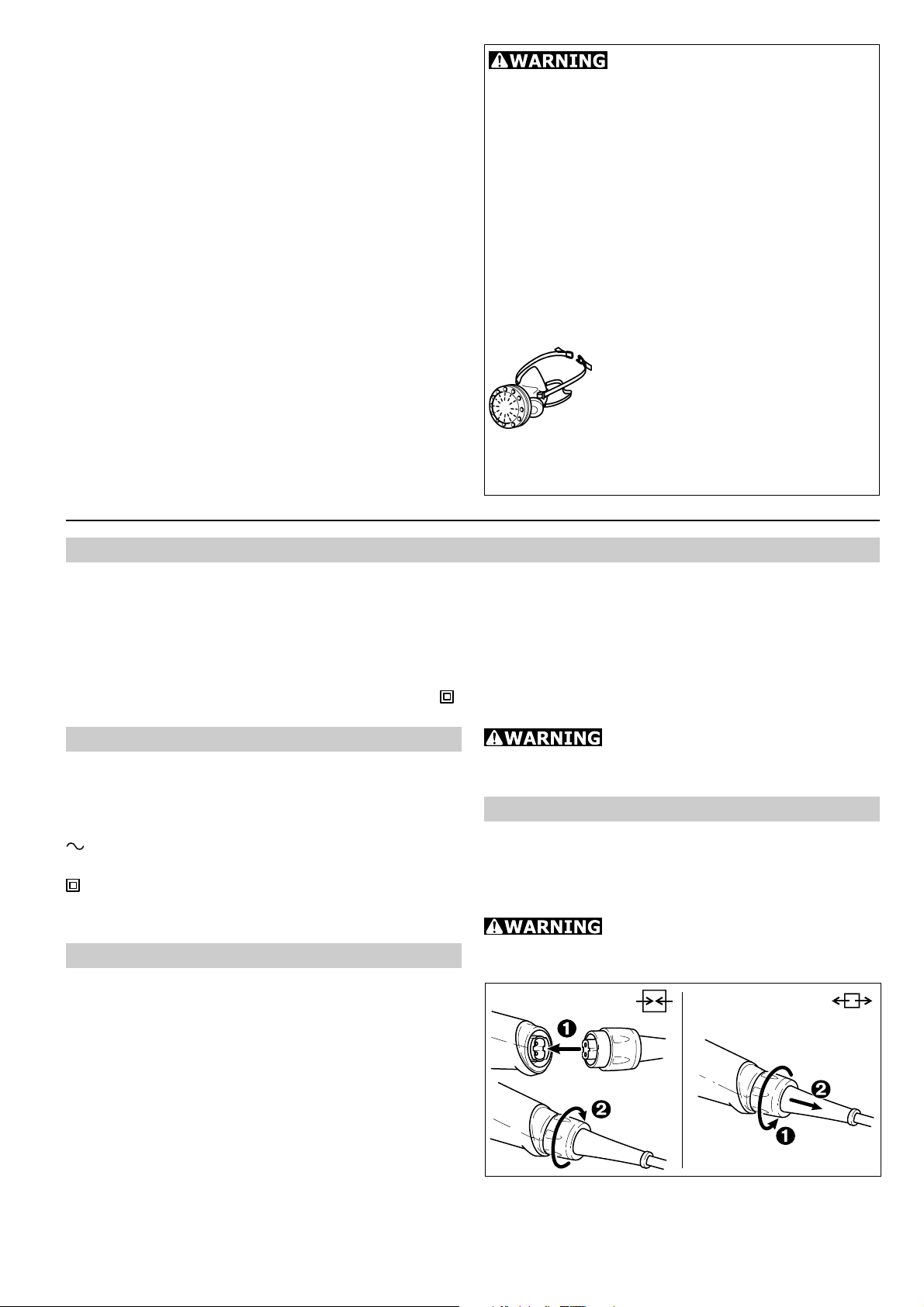

The switch (1.1) acts as an ON / OFF switch (I

ELECTRONIC

= ON / 0 = OFF).

Electronic control

The ES 125 EQ has an electronic control

with which the rotational speed can be

varied step-free.

This allows the sanding speed to be adapted to

the optimum level according to the material

concerned.

The speed is set using the rotary control button

(2.1).

Inserting a turbo-filter

- Push the filter holder with its opening (3.2)

as far as it will go onto the extraction nozzle

(3.1) of the machine and clamp tight by

turning rotary knob (3.3).

- Push the front cardboard section of the turbo-filter with the sealing lip (3.7) onto the

extraction nozzle (3.6) of the filter holder

- Insert rear cardboard section with slot (3.9)

onto the retaining strip (3.8) of the filter holder

The numbers on the rotary control button

represent approximately the following strokes

per minute:

Dust extraction

Dust extractors prevent large accumulations of

dust in the air in the working environment and

dirt collecting in the workplace.

Inboard extraction

The machines are fitted with inbuilt extraction

as standard. The sanding dust is extracted

through suction openings in the sanding base

(3.5) and trapped in the turbo-filter (3.4).

The turbo-filter has to be changed when it is so

full of dust that the extraction power diminishes.

External extraction by an extraction

unit

In order to avoid frequent changing of the turbo-filter when carrying longer sanding jobs, it

is possible to connect a Festool extractor to the

unit instead of using inbuilt extraction.

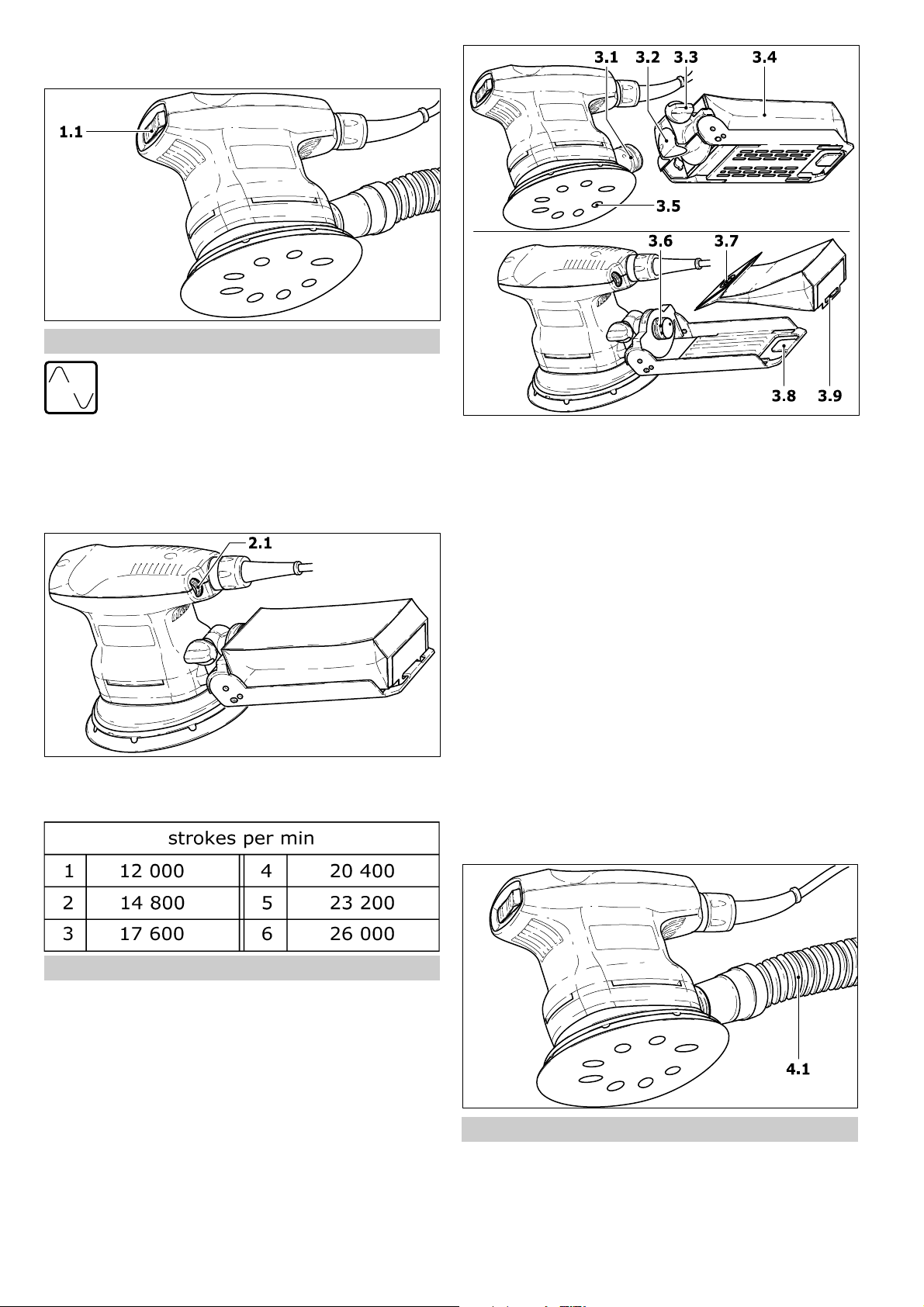

In this case, the extraction pipe (Æ 27 mm (4.1))

of the extraction unit is connected to the suction

nozzle.

Attaching sanding material

The appropriate Stickfix sanding paper and

Stickfix sanding felt can be fastened quickly and

easily onto the Stickfix sanding base.

4

Page 5

The self-adhesive sanding material (5.1) is

simply pressed onto the sanding base (5.2) and

held safely in place by the Stickfix sanding base

velcro surface.

Always use original Festool

sanding materials!

Operating instructions

Never overload the tool by using

too much pressure! The best sanding results

are achieved when applying moderate pressure.

The sanding performance and quality depend

mainly on the choice of the right sanding

material. Festool offers the appropriate sanding

material for all applications (see Festool

catalogue).

We recommend the following settings on the

rotary control (2.1) for electronic machines:

5 - 6

- sanding with max. drive

- sanding old paint

- sanding wood and veneer prior to painting

- interim sanding of paint on surfaces

1 - 2

- sanding stained edges

- sanding thermoplastic synthetics

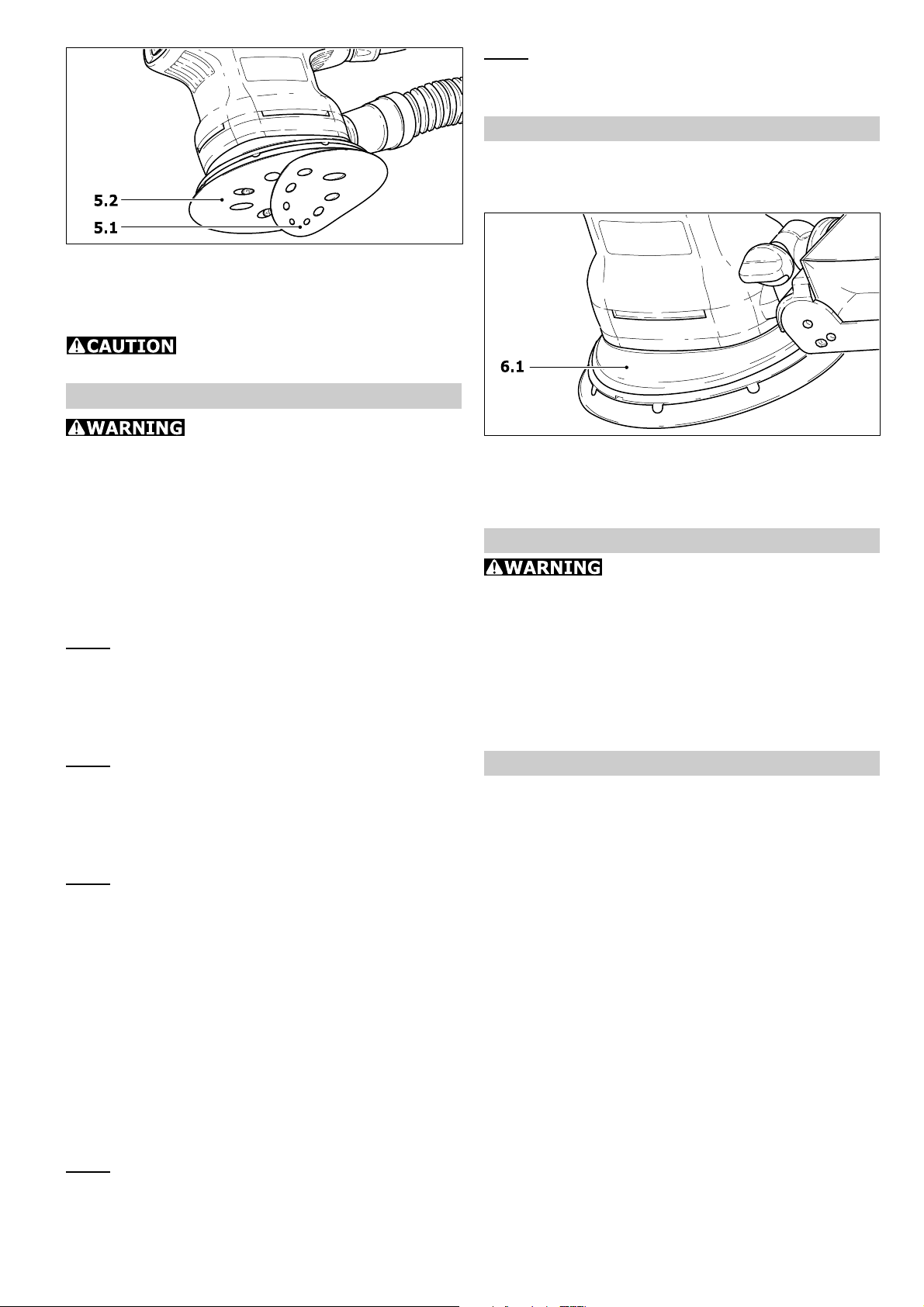

Sanding base brakes

The sanding base is braked by a collar (6.1) in

order to prevent any uncontrolled excessive

speed of the sanding base.

Because the collar wears down in the course of

time, it has to be replaced by a new one (order

no. 489 190) as soon as there is any reduction

in the braking effect.

Maintenance and care

Always remove the plug from the

mains supply socket before carrying out any

work on the machine!

The cooling air vents on the motor housing must

always be free of blockages and clean to ensure

air circulation. Any maintenance or repair work

requiring the motor housing to be opened may

only be carried out by an authorised service

workshop.

4 - 5

- sanding of thinly applied primer

- sanding of wood with sanding vlies

- sanding edges on wooden parts

- smoothing primed wooden surfaces.

3 - 4

- sanding full wooden and veneer edges

- sanding in the grooves/rebates of windows

and doors

- interim paint sanding on edges

- pre-sanding natural wood windows with

sanding vlies

- smoothing wood surfaces with sanding felt

prior to staining

- rubbing down stained surfaces with sanding

vlies

- rubbing down or removing excess lime paste

with sanding vlies

2 - 3

- interim paint sanding on stained surfaces

- cleaning natural wood window grooves with

sanding felt

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1

year + 2 years = 3 years) for your Festool power

tool. Festool shall be responsible for all shipping

costs during the first year of the warranty.

During the second and third year of the

warranty the customer is responsible for

shipping the tool to Festool. Festool will pay for

return shipping to the customer using UPS

Ground Service. All warranty service is valid 3

years from the date of purchase on your receipt

or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition that

the tool is used and operated in compliance

with the Festool operating instructions. Festool

warrants, only to the original consumer

purchaser, that the specified tool will be free

from defects in materials and workmanship for

a term of one year from the date of

procurement. Festool makes no other warranty,

5

Page 6

express or implied, for Festool portable power

tools. No agent, representative, distributor,

dealer or employee of Festool has the authority

to increase or otherwise change the obligations

or limitations of this warranty. The obligations

of Festool in its sole discretion under this

warranty shall be limited to the repair or

replacement of any Festool portable power tool

that is found to be defective as packaged with

the User Manual.

Excluded from coverage under this warranty

are: normal wear and tear; damages caused

by misuse, abuse or neglect; damage caused

by anything other than defects in material and

workmanship. This warranty does not apply to

accessory items such as circular saw blades,

drill bits, router bits, jigsaw blades, sanding

belts, and grinding wheels. Also excluded are

wearing parts, such as carbon brushes,

lamellas of air tools, rubber collars and seals,

sanding discs and pads, and batteries.

Festool portable power tools requiring

replacement or repair are to be returned with

the receipt of purchase to Festool (call 800554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE

FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH OF

THIS OR ANY OTHER WARRANTY,

EXPRESSED OR IMPLIED WHATSOEVER.

ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY LIMITED TO THE DURATION

OF THREE YEARS.

Some states in the U.S. and some Canadian

provinces do not allow the limitations on how

long an implied warranty lasts, so the above

limitation may not apply to you. With the

exception of any warranties implied by state or

province law as hereby limited, the foregoing

express limited warranty is exclusive and in lieu

of all other warranties, guarantees, agreements

and similar obligations of Festool.

This warranty gives you specific legal rights and

you may also have other rights which vary from

state to state in the U.S. and province to

province in Canada.

6

Page 7

RÉGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vour devez lire et

comprendre toutes les instructions. Le non-

respect, même partiel, des instructions ci-après

entraîne un risque de choc électrique, dincendie

et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

Aire de travail

1 Veillez à ce que laire de travail soit propre et bien éclairée. Le désordre et le manque

de lumière favorisent les accidents.

2 Nutilisez pas doutils électriques dans

une atmosphère explosive, par exemple en

présence de liquides, de gaz ou de

poussières inflammables. Les outils

électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

3 Tenez à distance les curieux, les enfants

et les visiteurs pendant que vous travaillez

avec un outil électrique. Ils pourraient vous

distraire et vous faire une fausse manoeuvre.

Sécurité électrique

4a Les outils mis à la terre doivent être

branchés dans une prise de courant

correctement installée et mise à terre

conformément à tous les codes et

règlements pertinents. Ne modifiez jamais

la fiche de quelque façon que ce soit, par

exemple en enlevant la broche de mise à la

terre. Nutilisez pas dadaptateur de fiche.

Si vous nêtes pas certain que la prise de

courant est correctement mise à la terre,

adressez-vous à un électricien qualifié. En

cas de défaillance ou de défectuosité électrique

de loutil, une mise à la terre offre un trajet de

faible résistance à lélectricité qui autrement

risquerait de traverser lutilisateur.

4b Les outils à double isolation sont

équipés dune fiche polarisée (une des

lames est plus large que lautre), qui ne

peut se brancher que dune seule façon

dans une prise polarisée. Si la fiche nentre

pas parfaitement dans la prise, inversez sa

position; si elle nentre toujours pas bien,

demandez à un èlectricien qualifié dinstaller une

prise de courant polarisée. Ne modifiez pas la

fiche de loutil. La double isolation élimine le

besoin dun cordon dalimentation à trois fils avec

mise à la terre ainsi que dune prise de courant

mise à la terre.

5 Évitez tout contact corporel avec des

surfaces mises à la terre (tuyauterie,

radiateurs, cuisinières, réfrigérateurs,

etc.). Le risque de choc électrique est plus grand

si votre corps est en contact avec la terre.

6 Nexposez pas les outils électriques à la

pluie ou à leau. La présence deau dans un

outil électrique augmente le risque de choc

électrique.

7 Ne maltraitez pas le cordon. Ne

transportez pas loutil par son cordon et ne

débranchez pas la fiche en tirant sur le

cordon. Nexposez pas le cordon à la

chaleur, à des huiles, à des arêtes vives ou

à des pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un

cordon endommagé augmente le risque de choc

électrique.

8 Lorsque vous utilisez un outil électrique

à lextérieur, employez un prolongateur

pour lextérieur marqué W.A. ou W. Ces

cordons sont faits pour être utilisés à lextérieur

et réduisent le risque de choc électrique.

Sécurité des personnes

9 Restez alerte, concentrez-vous sur

votre travail et faites preuve de jugement.

Nutilisez pas un outil électrique si vous

êtes fatigué ou sous linfluence de drogues,

dalcool ou de médicaments. Un instant

dinattention suffit pour entraîner des blessures

graves.

10 Habitiez-vous convenablement. Ne

portez ni vêtements flottants ni bijoux.

Confinez les cheveux longs. Napprochez

jamais les cheveux, les vêtements ou les

gants des pièces en mouvement. Des

vêtement flottants, des bijoux ou des cheveux

longs risquent dêtre happés par des pièces en

mouvement.

11 Méfiez-vous dun démarrage accidentel.

Avant de brancher loutil, assurez-vous que

son interrupteur est sur ARRÊT. Le fait de

transporter un outil avec le doigt sur la détente

ou de brancher un outil dont linterrupteur est

en position MARCHE peut mener tout droit à un

accident.

12 Enlevez les clés de réglage ou de

serrage avant de démarrer loutil. Une clé

laissée dans une pièce tournante de loutil peut

provoquer des blessures.

13 Ne vous penchez pas trop en avant.

Maintenez un bon appui et restez en équilibre

en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

14 Utilisez des accessoires de sécurité.

Portez toujours des lunettes ou une visière.

Selon les conditions, portez aussi un masque

antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur et/ou un

appareil antibruit.

Utilisation et entretien des outils

15 Immobilisez le matériau sur une surface

stable au moyen de brides ou de toute autre

façon adéquate. Le fait de tenir la pièce avec

7

Page 8

la main ou contre votre corps offre une stabilité

Certaines poussières

créées par le ponçage mécanique, le sciage, le

meulage, le perçage et autres activités reliées

à la construction contiennent des substances

chimiques connues (dans lÉtat de la Californie)

comme pouvant causer le cancer, des anomalies congénitales ou représenter dautres

dangers pour la reproduction. Voici quelques

exemples de telles substances:

Plomb provenant de peintures à base de

plomb,

Silice cristallisée utilisée dans les briques, le

ciment et autres matériaux de maçonnerie,

et

Arsenic et chrome du bois duvre traité avec

un produit chimique.

Le risque dexposition à de tels produits varie

selon la fréquence à laquelle vous faites ce

genre de travail.

Pour réduire les risques

dexposition à ces substances

chimiques : travaillez dans un

endroit adéquatement ventilé et

utilisez un équipement de sécurité

approuvé, tel que masques

antipoussières spécialement

conçus pour filtrer les particules

microscopiques.

insuffisante et peut amener un dérapage de loutil.

16 Ne forcez pas loutil. Utilisez loutil

appropríé à la tâche. Loutil correct fonctionne

mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

17 Nutlisez pas un outil si son interrupteur

est bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux

et doit être réparé.

Lentretien ou la réparation dun outil électrique

par un amateur peut avoir des conséquences

graves.

24 Pour la réparation dun outil,

nemployez que des pièces de rechange

dorigine. Suivez les directives données à

la section Réparation de ce manuel.

Lemploi de pièces non autorisées ou le nonrespect des instructions dentretien peut créer

un risque de choc électrique ou de blessures.

18 Débranchez la fiche de loutil avant

deffectuer un réglage, de changer

daccessoire ou de ranger loutil. De telles

mesures préventives de sécurité réduisent le

risque de démarrage accidental de loutil.

19 Rangez les outils hors de la portée des

enfants et dautres personnes inexpérimentées. Les outils sont dangereux dans

les mains dutilisateurs novices.

20 Prenez soin de bien entretenir les outils.

Les outils de coupe doivent être toujours

bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles de coincer

et plus faciles à diriger.

21 Soyez attentif à tout désalignement ou

coincement des pièces en mouvement, à

tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de

loutil. Si vous constatez quun outil est

endommagé, faites-le réparer avant de

vous en servir. De nombreux accidents sont

causés par des outils en mauvais état.

22 Nutilisez que des accessoires que le

fabricant recommande pour votre modèle

doutil. Certains accessoires peuvent convenir

à un outil, mais être dangereux avec un autre.

Réparation

23 La réparation des outils électriques doit

être confiée à un réparateur qualifié.

Caracteristiques techniques ES 125 Q ES 125 EQ

Puissance absorbée W 200 200

Vitesse à vite tr/min 13 000 6 000 13 000

Nombre d'oscillations tr/min 26 000 12 000 26 000

Amplitude mm (in.) 2.0 (0.08) 2.0 (0.08)

Patin de ponçage mm (in.) Ø 125 (4.9) Ø 125 (4.9)

Poids kg (lbs) 1.1 (2.4) 1.1 (2.4)

Sécurité UL 745, CSA C22.2 No. 745

Symbole

V Volt

A Ampère

Hz Hertz

W Watt

n

0

Tension alternative

Vitesse de rotation à vide

tr/min tours par minute

Utilisation conforme

Les ponceuses sont destinées au ponçage du

bois, des matières synthétiques, des matériaux

composites, de la peinture / du vernis, du mastic

et des matériaux similaires.

Classe II conception

8

Page 9

Les métaux et du matériau comportant de

ELECTRONIC

lamiante ne doivent pas être usinés.

En raison de sa taille, de son poids et de sa

puissance, la machine est adaptée notamment

au traitement de petites surfaces ainsi quaux

travaux au-dessus de la tête.

Pour des raisons de sécurité électrique, les

machines ne doivent pas être humides ni

fonctionner dans un environnement humide. Il

ne faut utiliser les machines que pour un

ponçage sec.

En cas dune utilisation

non conforme, la responsabilité des dommages

et accidents incombe à lutilisateur.

Raccordement électrique et mise en

service

La tension du réseau doit correspondre à la

tension indiquée sur la plaque signalétique!

Voir en figure suivante la connexion et la

déconnexion du câble de raccordement au

secteur.

La vitesse de rotation est réglée par la molette

(2.1).

Les chiffres de la molette correspondent

approximativement aux nombres de oscillations

ci-après :

Avant de brancher ou de

débrancher le câble de raccordement secteur,

il est absolument indispensable de toujours

mettre la machine hors marche!

Linterrupteur (1.1) sert dinterrupteur Marche

/ Arrêt (I = Marche / 0 = Arrêt).

Aspiration de la poussière

Laspiration de la poussière empêche des

lourdes charges de lair environnant par des

poussières et des fortes salissures du lieu de

travail.

Dispositif dauto-aspiration

Réglage électronique

La ponceuse ES 125 EQ possède un

réglage électronique permettant une

variation progressive de la vitesse de

rotation.

Ceci permet une adaptation optimale de la

vitesse du ponçage aux différents matériaux.

Les machines sont équipées en série dun

dispositif dauto-aspiration. La poussière de

ponçage est aspirée à travers les orifices

daspiration du patin de ponçage (3.5) puis

collectée dans le filtre turbo (3.3). Lorsque le

filtre turbo est rempli de poussières, la

performance daspiration baisse et il faut le

remplacer.

9

Page 10

Montage dun filtre turbo

- Placer le porte-filtre avec lorifice (3.2) jusquà

larrêt sur le manchon daspiration (3.1) de la

machine et serrer à laide du bouton tournant (3.3).

- faire glisser la partie avant du filtre avec la

lèvre détanchéité (3.7) sur le manchon

daspiration (3.6) du porte-filtre,

- placer la partie arrière du carton avec la fente

(3.9) sur la nervure de maintien (3.8) du

porte-filtre,

Aspiration extérieure à laide dun

aspirateur

Afin déviter davoir à remplacer souvent le filtre

turbo, on peut raccorder un aspirateur Festool

à la place du dispositif dauto-aspiration. Pour

ce faire, le flexible daspiration (Ø 27 mm (4.1))

de laspirateur est monté sur le manchon

daspiration.

Fixer labrasif

Le patin de ponçage Stickfix permet une fixation

rapide et aisée des papiers abrasifs Stickfix et

des non-tissés abrasifs Stickfix adaptés.

Le rendement et la qualité du ponçage

dépendent essentiellement de la sélection de

labrasif adéquat. Festool propose labrasif

approprié à chaque cas dutilisation (cf. le

catalogue Festool).

Pour des machines électroniques nous préconisons les réglages ci-après de la molette (2.1):

5 6

- Ponçage à entraînement max.

- Ponçage danciennes peintures

- Ponçage de bois et de contreplacage avant

application du vernis

- Ponçage intermédiaire du vernis de surfaces

4 5

- Ponçage dun enduit appliqué en fine couche

- Ponçage de bois à laide du non-tissé de

ponçage

- Réalisation de chants sur des pièces en bois

- Lissage de surfaces en bois à enduit

3 4

- Ponçage de bordures en bois massif et

contreplaquées

- Ponçage dans la rainure de fenêtres et de portes

- Ponçage intermédiaire du vernis de chants

- Ponçage de fenêtres en bois nature à laide

du non-tissé de ponçage

- Lissage de la surface en bois avant le

décapage à laide du non-tissé de ponçage

- Ponçage de surfaces décapées à laide du nontissé de ponçage

- Ponçage ou enlèvement de la pâte de chaux

superflue à laide du non-tissé de ponçage

2 3

- Ponçage intermédiaire de vernis de surfaces

décapées

- Nettoyage de rainures de fenêtres en bois à

laide du non-tissé de ponçage

Les abrasifs autoagrippant (5.1) sont facilement

placés sur le patin de ponçage (5.2) puis

maintenus en toute sécurité par le revêtement

autoagrippant du patin de ponçage Stickfix.

Nutilisez que des produits

abrasifs originaux Festool!

Conseils pour le travail

Ne surchargez pas la

machine en appuyant trop fort! Vous obtiendrez

le meilleur résultat de ponçage avec une

pression dapplication moyenne.

1 2

- Ponçage de chants décapés

- Ponçage de matières synthétiques thermoplastiques

Blocage du patin de ponçage

10

Page 11

Le patin de ponçage est bloqué par une

collerette (6.1) afin déviter quil ne monte de

façon incontrôlée.

La collerette étant soumise à lusure dans le

temps, leffet de blocage saffaiblit, et elle doit

être remplacée par une neuve (référence

489190).

Entretien et maintenance

Avant toute intervention

sur la machine il faut retirer la fiche de la prise

de courant!

Les orifices dair de refroidissement du carter

moteur doivent toujours être propres et libres

afin dassurer la circulation libre de lair.

Les travaux dentretien et de réparation

nécessitant une ouverture du carter moteur ne

doivent être effectués que par le personnel dun

atelier autorisé du service après-vente.

Garantie

Conditions de la garantie (1+2 ans)

Vous avez droit à une prolongation de garantie

gratuite (1 an + 2 ans = 3 ans) sur votre outil

électrique Festool. Festool assumera tous les

coûts dexpédition pendant la première année

de la garantie alors que les deuxième et

troisième années, les coûts devront être

assumés par le client. Festool paiera les frais

de retour de loutil au client par service de

livraison terrestre UPS. La garantie est valable

pour une période de 3 ans à compter de la date

dachat indiquée sur votre reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition que loutil

soit utilisé conformément aux instructions de

Festool. Festool garantit, à lacheteur initial

seulement, que loutil indiqué sera exempt de

tout défaut de matériau et de fabrication

pendant un an à compter de la date dachat.

Festool ne donne aucune garantie

supplémentaire, implicite ou explicite, sur les

instruments portables électriques Festool.

Aucun agent, représentant commercial,

distributeur, vendeur ou employé de Festool

nest autorisé à prolonger ou à modifier les

obligations ou restrictions de la présente

garantie. Les obligations de Festool sont, à son

entière discrétion, limitées à la réparation ou à

léchange des outils portables électriques

Festool trouvés défectueux dans le présent

emballage, tels que fournis avec le présent

Guide dutilisation.

Cette garantie exclut lusure normale, les

dommages causés par un usage impropre, les

abus ou la négligence, ou tout dommage autre

que ceux attribuables à des défauts de matériau

et de fabrication. Cette garantie ne sapplique

pas aux accessoires tels que lames de scie

circulaire, mèches de perceuse et vilebrequin,

lames de scie sauteuse, bandes abrasives et

meules. Sont également exclues les pièces

dusure, telles que balais de charbon, lamelles

pour outils à air comprimé, joints et manchons

de caoutchouc, disques et patins ponceurs, ainsi

que les piles.

Les outils électriques portables Festool à

remplacer ou à réparer doivent être retournés

avec le reçu dachat à Festool (appelez au 800554-8741 pour connaître ladresse

dexpédition).

FESTOOL NEST EN AUCUN CAS

RESPONSABLE DES DOMMAGES DIRECTS

OU INDIRECTS, IMPLICITES OU

EXPLICITES, DÉCOULANT DE LA RUPTURE

DE CETTE GARANTIE OU DE TOUTE AUTRE

GARANTIE. TOUTES LES GARANTIES

IMPLICITES, Y COMPRIS LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE ET

DADÉQUATION À UN USAGE

PARTICULIER, SONT LIMITÉES À UNE

PÉRIODE DE TROIS ANS.

Certains états américains et certaines provinces

canadiennes ne permettent pas la limitation des

garanties implicites; il se pourrait donc que les

limites indiquées ci-dessus ne sappliquent pas

dans votre cas. À lexception de certaines

garanties implicites des provinces ou des états

indiquées ici, la présente garantie est exclusive

et remplace toute autre garantie, convention

et obligation similaire de Festool.

Cette garantie vous confère des droits légaux

spécifiques, et vous pouvez aussi avoir dautres

droits pouvant varier dun état à lautre, ou

dune province à lautre au Canada.

11

Page 12

NORMAS GENERALES DE SEGURIDAD

¡AVISO! Lea y entienda todas las

instrucciones. El incumplimiento de una sola

de las instrucciones aquí listadas, puede tener

como resultado una descarga eléctrica, fuego

y/o lesiones personales serias.

CONSERVE ESTAS INSTRUCCIONES

Espacio de trabajo

1 Mantenga su espacio de trabajo limpio y

bien iluminado. Bancos de trabajo desordenados

y areas oscuras facilitan accidentes.

2 No maneje herramientas mecánicas en

ambientes explosivos, como por ejemplo

en presencia de líquidos inflamables, gases,

o polvo. Las herramientas mecánicas generan

chispas que pueden encender el polvo o gases.

3 Mantenga espectadores, niños, y

visitantes fuera del alcance mientras maneje

herramientas mecánicas. Distracciones

pueden causarle la pérdida del control.

Seguridad eléctrica

4a Herramientas conectadas a tierra deben

estar enchufadas en una toma de corriente

apropiada que esté correctamente

instalada y conectada a tierra, de acuerdo

con la normativa vigente. Nunca quite el

diente de conexión a tierra o modifique el

enchufe de alguna manera. No utilice

ningún adaptador de enchufe. Compruebe

con un electricista cualificado si duda de la

conexión correcta a tierra de la toma de

corriente. Si las herramientas funcionaran

electricamente mal o se estropearan, la conexión

a tierra ofrece una vía de mínima resistencia para

desviar la corriente eléctrica del usuario.

4b Herramientas con doble aislamiento

están equipadas con un enchufe polarizado

(un filo es más ancho que el otro). Este

enchufe solo encaja de una manera en la

toma de corriente polarizada. Si el enchufe

no encaja, déle la vuelta. Si aún no encaja,

contacte un electricista cualificado para instalar

una toma de corriente polarizada. No modifique

el enchufe de ninguna manera. El doble

aislamiento

de corriente con conexión a tierra de tres hilos y

un sistema de suministro de corriente conectado

a tierra.

5 Evite el contacto con superficies

conectadas a tierra, como tubos,

radiadores, cableado y refrigeradores.

Existe un elevado riesgo de descarga eléctrica si

su cuerpo está conectado a tierra.

6 No exponga las herramientas

mecánicas a la lluvia o condiciones

húmedas. Agua que entra en una herramienta

elimina la necesidad de un cable

mecánica aumenta el riesgo de descarga

eléctrica.

7 No abuse del cable. Nunca use el cable

para transportar la herramienta o

desenchufarla de la toma de corriente.

Mantenga el cable fuera de calor, aceite,

filos agudos o partes movibles. Reemplace

cables dañados inmediatamente. Cables

dañados aumentan el riesgo de descarga

eléctrica.

8 Cuando utilice herramientas mecánicas

en el exterior, utilice un cable de exterior

señalizado con «W-A» o «W». Estos cables

están clasificados para uso exterior y reducen el

riesgo de descarga eléctrica.

Seguridad personal

9 Manténgase atento, observe lo que está

haciendo y use el sentido común cuando

use una herramienta mecánica. No trabaje

estando cansado o bajo influencia de

drogas, alcohol, o medicamentos. Un

momento sin prestar atención mientras maneja

una herramienta mecánica puede tener como

resultado serias lesiones personales.

10 Vístase apropiadamente. No lleve ropa

suelta o joyas. Sujete pelo largo. Mantenga

su pelo, ropa y guantes fuera del alcance

de partes movibles. Ropa, joyas y pelo suelto

pueden pillarse en partes movibles.

11 Evite accidentes al iniciar. Asegúrese

que el interruptor está apagado antes de

enchufar. Transportar herramientas con el dedo

en el interruptor o enchufar las herramientas con

el interruptor encendido puede provocar

accidentes.

12 Quite llaves de ajuste o conmutadores

antes de encender la herramienta. Una llave

inglesa u otra llave que se deja puesta en partes

rotatorias de la herramienta pueden causar

lesiones personales.

13 No exceda límites. Mantenga

estabilidad y balance apropiado en todo

momento. Estabilidad y balance apropiado

posibilitan el mejor control de la herramienta en

situaciones inesperadas.

14 Use equipamiento de seguridad. Lleve

siempre gafas protectoras. Mascarilla de

polvo, zapatos de seguridad antirresbaladizos,

casco, o protección de los oídos deben ser

utilizados para condiciones adecuadas.

Uso y cuidado de la herramienta

15 Use abrazaderas u otras formas

prácticas de sujetar y asegurar la pieza de

trabajo en una plataforma estable. Sujetar

la pieza de trabajo con la mano o contra el cuerpo

es inestable y puede causar la pérdida de control.

12

Page 13

16 No fuerce la herramienta. Use la

Algunos polvos creados por

lijadoras mecánicas, aserraderos, trituradores,

perforadoras y otras actividades de

construcción contienen sustancias químicas que

se sabe (en el Estado de California) causan

cáncer, defectos de nacimiento u otros daños

al sistema reproductivo. Algunos ejemplos de

estas sustancias químicas son:

Plomo de las pinturas con base de plomo

Sílice cristalino de los ladrillos y cemento y

otros productos de mampostería, y

Arsénico y cromo de madera tratada con

sustancias químicas

El riesgo de exposición a estas sustancias varía,

dependiendo de cuantas veces se hace este tipo

de trabajo.

Para reducir el contacto con estas

sustancias químicas: trabaje en

un área con buena ventilación y

trabaje con equipo de seguridad

aprobado, como mascarillas para

el polvo diseñadas específicamente para filtrar partículas

microscópicas.

herramienta correcta para su aplicación. La

herramienta correcta hará su trabajo de manera

mejor y más segura al nivel para el cual está

diseñada.

17 No use la herramienta si el interruptor

no la enciende y apaga. Cualquier

herramienta que no se pueda controlar por el

interruptor es peligrosa y debe ser arreglada.

18 Desconecte el enchufe de la toma de

corriente antes de realizar cualquier ajuste,

cambiar accesorios, o guardar la

herramienta. Estas medidas preventivas de

seguridad reducen el riesgo de poner en

funcionamiento la herramienta accidentalmente.

19 Guarde herramientas desocupadas

fuera del alcance de niños u otras personas

sin experiencias. Las herramientas son

peligrosas en manos de personas inexpertas.

20 Mantenga las herramientas con

cuidado. Mantenga herramientas para

cortar afiladas y limpias. Herramientas

mantenidas correctamente, con filos afilados,

difícilmente se traban y se controlan con mayor

facilidad.

21 Compruebe si hay alineación incorrecta

o trabadura de partes movibles, rotura de

partes, o cualquier otra condición que

puedan afectar el funcionamiento de la

herramienta. En caso de daños, arregle la

herramienta antes de usarla. Muchos accidentes

son causados por herramientas con mal

mantenimiento.

22 Use solo accesorios que recomiende el

fabricante para su modelo. Accesorios que

funcionen en una herramienta pueden ser

peligrosos al usarlos en otra.

Datos técnicos ES 125 Q ES 125 EQ

Potencia absorbida W 200 200

Velocidad sin carga rpm 13 000 6 000 - 13 000

Orbitas por minuto opm 26 000 12 000 - 26 000

Orbita de lijado mm (in.) 2.0 (0.08) 2.0 (0.08)

Plato de lijado mm (in.) Ø 125 (4.9) Ø 125 (4.9)

Peso kg (lbs) 1.1 (2.4) 1.1 (2.4)

Seguridad UL 745, CSA C22.2 No. 745

Símbolos

V voltios

A amperios

Hz hertzios

W vatios

n

rensión alterna

0

revoluciones por minuto en vacío

Clase II Construcción

Mantenimiento

23 El mantenimiento de la herramienta

solo se podrá realizar por personal de

mantenimiento cualificado. Revisión o

mantenimiento realizado por personal no

cualificado puede resultar en el riesgo de lesión.

24 Cuando se revise una herramienta, use

solo repuestos idénticos. Siga las

instrucciones en la sección de mantenimiento de

este manual. El uso de repuestos no autorizados

o el incumplimiento de las instrucciones de

mantenimiento pueden conllevar el riesgo de

descarga eléctrica o lesión.

rpm revoluciones por minuto

opm orbitas por minuto

Uso conforme a lo determinado

En cuanto a su determinación de uso, las

lijadoras están previstas para el lijado de

madera, plástico, materiales compuestos,

pintura / barniz / nogalina, masilla de emplaste

y materiales similares. Con este útil no se deben

13

Page 14

trabajar metales ni materiales que contengan

ELECTRONIC

amianto.

Debido a su tamaño, su peso y su potencia, la

máquina es especialmente apropiada para el

trabajado de superficies pequeñas, así como

para realizar trabajos por encima de la cabeza.

A causa de la seguridad eléctrica, las máquinas

no deben ser operadas estando húmedas y

tampoco en un ambiente húmedo. Las

máquinas solamente se deben emplear para un

lijado en seco.

El usuario se responsabilizará en el caso de daños y accidentes durante un uso no conforme a lo predeterminado.

Conexión eléctrica y puesta en

servicio

¡La tensión de red tiene que coincidir con la

tensión indicada en la placa de características!

Ver la figura siguiente para enchufar y

desenchufar el cable de conexión a la red.

Apague siempre la máquina

antes de conectar o sacar el cable de conexión

a la red.

El número de revoluciones se ajusta en la rueda

de ajuste (2.1).

Al respecto, las cifras inscritas en la rueda de

ajuste corresponden aproximadamente a los

siguientes números de orbitas:

Dispositivo de aspiración de polvo

El interruptor (1.1) se utiliza como interruptor

de conexión / desconexión (I = conectado / 0

= desconectado).

El dispositivo de aspiración de polvo evita altas

cargas de polvo en el aire de trabajo y

ensuciamientos considerables en el puesto de

trabajo.

Dispositivo autoaspirador

Regulación electrónica

La lijadora ES 125 EQ dispone de una

posibilidad de regulación electrónica,

con la que se puede variar el número

de revoluciones en progresión continua.

De este modo es posible adaptar óptimamente

la velocidad de lijado al respectivo material.

Las máquinas están equipadas como equipo de

serie con un dispositivo autoaspirador. El polvo

de lijado es aspirado por las aberturas de

aspiración que se encuentran en el plato de

lijado (3.5) y es recogido en el turbofiltro (3.4).

Cuando el turbofiltro se ha llenado hasta el

punto de que se nota una merma de la

14

Page 15

capacidad de aspiración, se deberá proceder a

su cambio.

Montaje de un turbofiltro

- Meter el soporte del filtro con la abertura (3.2)

hasta el tope sobre la tubuladura de aspiración

(3.1) de la máquina y fijarlo con el botón

giratorio (3.3).

- desplazar la parte delantera de cartón del

turbofiltro con labio de hermetización (3.7)

sobre la tubuladura de aspiración (3.6) del

soporte del filtro,

- meter la parte trasera de cartón con ranura

(3.9) sobre la aleta de retención (3.8) del

soporte del filtro,

Dispositivo de aspiración externa, con

aspirador

A fin de evitar un frecuente cambio del

turbofiltro durante trabajos de lijado

relativamente largos, en lugar del dispositivo

autoaspirador se puede conectar un aspirador

Festool. Para ello se cala el tubo flexible de

aspiración (Ø 27 mm (4.1)) del aspirador sobre

la tubuladura de aspiración.

¡Emplee únicamente material

abrasivo original de Festool!

Indicaciones para el trabajo

No sobrecargue la máquina

presionándola demasiado sobre el objeto a lijar.

Un resultado óptimo de lijado lo conseguirá

trabajando con una presión de apriete

moderada.

La capacidad y calidad de lijado dependen

esencialmente de la elección del material

abraviso correcto. Festool ofrece material

adhesivo apropiado para todo caso de aplicación

(ver el catálogo Festool).

Para máquinas con sistema electrónico

recomendamos realizar los siguientes ajustes

de la rueda de ajuste (2.1):

5 - 6

- Lijado con accionamiento máximo

- Lijado de pinturas viejas

- Lijado de madera y de enchapados antes del

barnizado

- Lijado intermedio de barniz sobre superficies

4 - 5

- Lijado de barnizado previo de aplicación fina

- Lijado de madera con velo de lijar

- Redondeado de cantos en piezas de madera

- Alisado de superficies de madera con pintura

de imprimación

Fijación del material abrasivo

Sobre el plato de lijado Stickfix se pueden fijar

con rapidez y facilidad los papeles de lija Stickfix

y velos de lijado Stickfix apropiados para ello.

Los materiales abrasivos autoadheribles (5.1)

se presionan simplemente sobre el plato de

lijado (5.2) y son retenidos con seguridad por

el recubrimiento adherente del plato de lijado

Stickfix.

3 - 4

- Lijado de cantos de madera maciza y de

madera enchapada

- Lijado de encajes de ventanas y puertas

- Lijado intermedio de barniz en cantos

- Lijado inicial de ventanas de madera natural

con velo de lijado

- Alisado de la superficie de madera antes del

barnizado, empleando velo de lijado

- Frotado de superficies barnizadas empleando

velo de lijado

- Abrasión o desprendimiento de pasta de cal

sobrante empleando el velo de lijado

2 - 3

- Lijado intermedio de pinturas sobre superficies

barnizadas (coloreadas con nogalina)

- Limpieza de encajes de ventanas de madera

natural con velo de lijado

1 - 2

- Lijado de cantos pintados/coloreados con

nogalina

- Esmerilado de termoplásticos.

15

Page 16

Freno del plato de lijado

A fin de evitar una aceleración incontrolada del

plato de lijado, ésta es frenada por medio de

una guarnición (6.1).

Debido a que esta guarnición se desgasta con

el tiempo, ésta tiene que ser renovada cuando

se registre una merma en el efecto de frenado

(núm. de pedido 489 190).

Mantenimiento y conservación

Desenchufar el enchufe de

la toma de corriente antes de realizar trabajos

en la máquina!

Para asegurar la circulación de aire, las

aberturas para el aire de refrigeración en la

carcasa del motor tienen que mantenerse

siempre libres y limpias.

Todos los trabajos de mantenimiento y de

reparación, para los que se tiene que abrir la

carcasa del motor, sólo deben ser llevados a

cabo por un taller de servicio de asistencia

técnica autorizado.

Garantiá

Condiciones de la Garantía 1 + 2

Usted tiene derecho a una garantía extendida

gratuita (1 año + 2 años = 3 años) para su

herramienta mecánica Festool. Festool se hará

responsable por los gastos de envío durante el

primer año de garantía. Durante el segundo y

tercer año de garantía el cliente es responsable

por el costo del envío de la herramienta a

Festool. Festool pagará el embarque de regreso

al cliente usando UPS Ground Service. Todo el

servicio de garantía es válido por 3 años desde

la fecha de la compra de acuerdo a la fecha de

su recibo o factura de compra.

Garantía limitada de Festool

Esta garantía es válida con la condición previa

de que la herramienta se usa y opera de

conformidad con las instrucciones de operación

de Festool. Festool garantiza, sólo al comprador

original, que la herramienta especificada estará

libre de defectos de fabricación y materiales

durante un periodo de un año a partir de la

fecha de compra. Festool no otorga otras

garantías, ni explícitas ni implícitas para

ninguna de las herramientas mecánicas

portátiles Festool. Ningún agente, representante,

distribuidor, comerciante o empleado de Festool

está autorizado para extender o modificar de

cualquier manera las obligaciones o limitaciones

de esta garantía. Las obligaciones de Festool,

a su propia entera discreción, están limitadas

a la reparación o sustitución de cualquier

herramienta portátil Festool que se encuentre

estar defectuosa en el momento de ser

embalada junto con el manual de usuario.

Quedan excluidos de la cobertura en esta

garantía: el desgaste normal; los daños

causados por uso indebido, el abuso o

negligencia; los daños causados por cualquier

otra causa que no sean defectos del material o

de la fabricación. Esta garantía no aplica a

accesorios como cuchillas de sierras circulares,

brocas de taladro, barrenas de buriladora,

cuchillas de sierra, cuchillas para sierras de

calado, correas de lijadoras y ruedas de esmeril.

También se excluyen las partes que se

desgastan como cepillos de carbón, laminillas

de herramientas de aire, collarines de hule y

sellos, discos y cojines de lijado, y baterías.

Las herramientas mecánicas portátiles Festool

que requieran de reemplazo o reparación deben

devolverse con el recibo de compra a Festool

(llame al 800-554-8741 para los detalles de la

dirección).

EN NINGÚN CASO FESTOOL SE HARÁ

RESPONSABLE POR LOS DAÑOS

SECUNDARIOS O CONSECUENTES

OCASIONADOS POR LA VIOLACIÓN DE

ESTA O CUALUQUIER OTRA GARANTÍA,

SEA EXPLÍCITA O IMPLÍCITA. TODAS LAS

GARANTÍAS IMPLICADAS POR LEYES

ESTATALES, INCLUYENDO LAS

GARANTÍAS IMPLICADAS DE

COMERCIALIZACIÓN Y ADECUACIÓN A UN

PROPÓSITO PARTICULAR, QUEDAN

LIMITADAS A TRES AÑOS DE DURACIÓN.

Algunos estados de EE.UU. y algunas provincias

de Canadá no permiten las limitaciones en

cuanto a la duración de las garantías implícitas,

de modo que la limitación arriba indicada puede

que no le afecte. A excepción de algunas garantías

implicadas por leyes estatales o provinciales,

limitadas por la presente, la anteriormente

citada garantía, expresamente limitada, es

exclusiva y sustituye a cualquier otra garantía,

acuerdo u obligación similar de Festool.

Esta garantía le concede derechos legales

específicos y usted podría tener otros derechos

legales que varían de estado a estado en EE.UU.

y de provincia a provincia en Canadá.

16

Loading...

Loading...