Festo YJKP Series, YJKP 12, YJKP 17, YJKP 0.8, YJKP 1.5 Instructions, Assembly, Installation

...

YJKP

Servo Press Kit

Instructions|

Assembly, Installation

8095980

8095980

2019-01e

[8095982]

Translation of the original instructions

CANopen®, EtherNet/IP®, MODBUS®, OPCUA®, PI PROFIBUS PROFINET® are registered trademarks of

the respective trademark owners in certain countries.

2 Festo — YJKP — 2019-01e

Table of contents

1 About this document................................................................................................... 4

1.1 Applicable documents.................................................................................................. 4

2 Safety........................................................................................................................... 5

2.1 Intended use................................................................................................................ 5

2.2 Foreseeable misuse...................................................................................................... 5

2.3 Training of qualified personnel..................................................................................... 5

3 Further information..................................................................................................... 5

4 Service..........................................................................................................................6

5 Product overview......................................................................................................... 7

6 Transport..................................................................................................................... 8

7 Mounting..................................................................................................................... 9

7.1 Preparation................................................................................................................... 9

7.2 Assembly...................................................................................................................... 9

8 Installation.................................................................................................................. 11

8.1 Safety............................................................................................................................ 11

8.2 Electrical installation - cables....................................................................................... 12

8.3 Electrical installation CECC-X-M1-YS............................................................................. 16

8.4 Electrical installation CMMP-AS.................................................................................... 23

8.5 I/O interface for STO [X40]............................................................................................ 26

9 Commissioning............................................................................................................ 27

10 Maintenance................................................................................................................ 29

10.1 Safety............................................................................................................................ 29

10.2 Maintenance work........................................................................................................ 29

10.3 Cleaning....................................................................................................................... 29

11 Repair........................................................................................................................... 29

12 Dismounting................................................................................................................ 30

13 Disposal........................................................................................................................30

14 Technical data............................................................................................................. 30

3Festo — YJKP — 2019-01e

About this document

1 About this document

1.1 Applicable documents

All available documents for the product èwww.festo.com/pk.

User documentation

Name, type Link, contents

Sensor SKDA-...-AB (operating instructions) èwww.festo.com/sp

Electric drive ESBF-BS (operating instructions) èwww.festo.com/sp

Axial kit EAMM-A (assembly instructions) èwww.festo.com/sp

Parallel kit EAMM-U (assembly instructions) èwww.festo.com/sp

Servo motor EMMS-AS-55 (operating instructions)

Servo motor EMMS-AS-70 (operating instructions)

Servo motor EMMS-AS-100 (operating instructions)

Servo motor EMMS-AS-140 (operating instructions)

Motor controller CMMP-AS-...-M0 (user documentation)

Controller CECC-X-M1 (user documentation) èwww.festo.com/sp

Encoder cable NEBM-M (assembly instructions) èwww.festo.com/sp

Encoder cable NEBM-T1G8 (assembly instructions)

Motor cable NEBM-M23G8 (assembly instructions)

Motor cable NEBM-T1G8 (assembly instructions) èwww.festo.com/sp

Connecting cable NEBS-M12G5-ES-...-LE5

(assembly instructions)

Connecting cable NEBC-S1WA9-P-1.5-N-BB-L2G4

(assembly instructions)

Connecting cable NEBC-S1G25-P-1.5-N-LE6

(assembly instructions)

Tab. 1 Further applicable documents on the Servo Press Kit

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

èwww.festo.com/sp

Festo — YJKP — 2019-01e4

Safety

Additional media

Name, type Contents

Web Help YJKP Operation of the software for Servo Press Kit

YJKP

Application note Application examples for connection and com-

missioning

èwww.festo.com/sp

Tab. 2 Additional media on the Servo Press Kit

The range of application and certifications of the individual components of the kit are described in

separate documents èwww.festo.com/sp.

2 Safety

2.1 Intended use

This product is a module for execution of joining tasks with monitoring of the joining process. The

module can be used within machines or automated systems with a higher-order controller.

Use the product only as follows:

– in perfect technical condition

– in its original condition, without unauthorised modifications

– Within the limits of the product defined by the technical data

– in an industrial environment

– permanently mounted

2.2 Foreseeable misuse

Construction of presses with manual loading or unloading in accordance with EC Machinery Directive

2006/42/EC Attachment IV Sec. 9 without further protective measures.

Never use the product as follows:

– With unauthorised modifications or alterations to the product

– With load limits exceeded

– In an invalid mounting position

2.3 Training of qualified personnel

Installation, commissioning, maintenance and disassembly should only be conducted by qualified personnel.

The personnel must be familiar with the installation of mechatronic control systems.

3 Further information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

5Festo — YJKP — 2019-01e

Service

4 Service

Contact your regional Festo contact person if you have technical questions èwww.festo.com.

6 Festo — YJKP — 2019-01e

Product overview

5 Product overview

1

Servo motor EMMS-AS

2

Axial/parallel kit EAMM-A/U

3

Electric drive ESBF-BS

4

Sensor SKDA-...-AB

5

Connecting cable NEBS-M12G5-ES-...-LE5

6

Encoder cable NEBM

7

Motor cable NEBM

8

LAN cable (not in scope of delivery)

Fig. 1 Product overview

9

Connecting cable NEBC-S1WA9-P-1.5-N-BBL2G4

10

Controller CECC-X-M1-YS

11

Memory card

12

Motor controller CMMP-AS

13

Connecting cable NEBC-S1G25-P-1.5-N-LE6

14

Higher-order controller (not in scope of

delivery)

15

Switch (not in scope of delivery)

16

Laptop (not in scope of delivery)

7Festo — YJKP — 2019-01e

Transport

6 Transport

Sequence of transport and unpackaging

NOTICE!

Damage to the product due to incorrect transport.

• Observe the transport labelling and information on the packaging.

1. Transport the product to the installation/storage location in its packaging and set it down on a

firm and flat base.

2. When storing: Pay attention to the storage conditions è 14 Technical data.

NOTICE!

Damage to the product due to incorrect unpacking.

• Observe the labelling and information on unpacking shown on the packaging.

• Unpack the product with at least 2 persons present.

• Use appropriate tools.

• Parts of the packaging are large and heavy:

– Do not let any parts fall onto the product.

– Use suitable aids to raise and lower the product (e.g. crane).

3. Remove the packaging in accordance with the printed sequence.

Restraints in the packaging

Transport restraints prevent uncontrolled movement of the product in the packaging during transport

and installation. The product is provided with the following designated transport restraints:

Fig. 2 Transport screws

8 Festo — YJKP — 2019-01e

Mounting

Fig. 3 Cable ties

7 Mounting

7.1 Preparation

Fitting space

The fitting space required for the product depends on the selected size of the Servo Press Kit and the

following factors:

– Stroke of the electric cylinder èwww.festo.com/catalogue

– Attachment position and type of motor

Unintentional lowering of the piston rod is possible at any time. The axis cannot be pushed back

manually. If necessary, the electric cylinder may need to be dismantled.

Mounting surface

The mounting surface must exhibit the following characteristics:

– torsionally rigid

– free of stress

– sufficient strength to absorb the maximum forces

– sufficient evenness

7.2 Assembly

WARNING!

Risk of injury due to lowering piston rod.

• Before working on the product: Secure the piston rod to prevent it from lowering.

CAUTION!

Risk of injury due to falling product.

• Make sure the mounting surface is sufficiently strong to absorb the maximum forces.

• Only use the supplied mounting components.

• Secure the screw connections.

9Festo — YJKP — 2019-01e

Mounting

In the Servo Press Kit, the electric drive, axial or parallel kit and servo motor can be pre-assembled.

With individual components, the following assembly steps are required.

Assemble the motor mounting kit

Depending on the configuration, an axial or parallel kit can be assembled.

Assemble the axial kit EAMM-A

Fig. 4 Axial kit EAMM-A

èPay attention to the accompanying documentation: Axial kit EAMM-A (assembly instructions)

èwww.festo.com/sp

• Assemble the axial kit EAMM-A

Assemble the parallel kit EAMM-U

Fig. 5 Parallel kit EAMM-U

èPay attention to the accompanying documentation for EAMM-U.

èwww.festo.com/sp

• Assemble the parallel kit EAMM-U.

Mount the drive unit on the frame

èPay attention to the accompanying documentation for ESBF.

èwww.festo.com/sp

• Mount the complete unit consisting of axis, axial/parallel kit and motor on the customer-provided

frame so that it is tension-free.

10 Festo — YJKP — 2019-01e

Installation

Assemble the sensor SKDA

Fig. 6 Sensor SKDA

èPay attention to the accompanying documentation for SKDA.

èwww.festo.com/sp

1. Do not screw the lock nut up to the stop on the ESBF-BS.

2. Screw the sensor on the ESBF-BS.

3. Apply the lock nut to secure the sensor.

Additional steps

1. Insert the memory card (microSD card) into the CECC-X-M1-YS.

2. Assemble the CECC-X-M1-YS.

èPay attention to the accompanying documentation for the CECC-X-M1-YS.

èwww.festo.com/sp

3. Assemble the CMMP-AS.

èAccompanying documentation for the CMMP-AS.

èwww.festo.com/sp

Up-to-date information on the accessories èwww.festo.com/catalogue.

8 Installation

8.1 Safety

WARNING!

Risk of injury due to lowering piston rod.

• Before working on the product: Secure the piston rod to prevent it from lowering.

WARNING!

Risk of injury due to unexpected movement of the product.

Electrical energy can cause unexpected movement of the product.

• Before working on the product: Switch off the power supply, ensure that it is off and secure it

against being switched on again.

11Festo — YJKP — 2019-01e

Installation

NOTICE!

Material damage as a result of using the wrong connections.

In accordance with intended use, all unnamed connections must not be used.

Details on handling the individual components of the kit are described in separate documents

èwww.festo.com/sp.

8.2 Electrical installation - cables

Connecting cable NEBS-M12G5-ES-...-LE5

The connecting cable connects the sensor on the electric drive with the analogue input [X19] on the

controller.

The accompanying plug must be assembled on the open cable ends.

Sensor SKDA Controller CECC-X-M1-YS

Connection Pin Wire colour

1)

Use Pin Connection [X19]

1 BN 24VDC

X19.0.1

Power supply for

sensor

2 WH Not used

3 BU Input 4…20mA

X19.0.2

Evaluation of the

sensor signal

through servo

press software

4 BK Not used

5 GY Not used

Braided screen Apply braided

screen in direct

proximity of controller and sensor

with a large surface area

1) Colour code in accordance with IEC 60757:1983-01

Tab. 3 Sensor connecting cable - analogue inputs [X19]

1. Connect connecting cable to the sensor.

2. Place the open cable ends in the plug provided in accordance with the table.

12 Festo — YJKP — 2019-01e

Installation

Fig. 7 Screening clamp, controller side

Fig. 8 Screening clamp, sensor side

3. Partially remove the cable sheath on both sides and apply the braided screen across a large sur-

face area with screening clamps 1. Provide strain relief with cable binders 2 over the cable outer

sheath.

4. Insert the plug into the connection [X19.0] of the controller.

Connecting cable NEBC-S1WA9-P-1.5-N-BB-L2G4

The connecting cable connects the CANopen interface [X4] of the motor controller with the CANopen

interface [X18] of the controller.

The cable is readily assembled.

1. Insert the plug into the connection [X4] of the motor controller.

2. Insert the plug into the connection [X18] of the controller.

Connecting cable NEBC-S1G25-P-1.5-N-LE6

The connecting cable is used to provide power to the digital controller interface [X1] of the motor controller.

The circuitry should be carried out in accordance with the following table.

13Festo — YJKP — 2019-01e

Installation

Motor controller

Provided by the customer

CMMP-AS-...-M0

Connection [X1] Pin Wire colour

1)

Use Type

YJKP

0.8/

node number bit1

1.5/4

7/ 12/ 1-7+24VDC

8 YE Fieldbus: offset

All GND

node number bit3

9 GY Controller enable All +24VDC

0.8/ 1.5-

node number bit 0

/ 7/ 12

4/ 17 +24VDC

20 GN Fieldbus: offset

All GND

node number bit 2

21 PK Output stage

All +24VDC

enable

1) Colour code in accordance with IEC 60757:1983-01

Tab. 4 Connecting cable wiring, digital control interface [X1]

1. Insert plug into the connection [X1] of the motor controller.

2. Place the open cable ends in accordance with the table.

If a customer-specific connecting cable is used, the following PIN must also be laid:

Connection

GND7 BN Fieldbus: offset

GND19 WH Fieldbus: offset

Motor controller

CMMP-AS-...-M0

Connection [X1] Pin Wire colour

1)

Use Connection

Provided by the customer

3, 11,14- - GND

16, 23 - - +24VDC

1) Colour code in accordance with IEC 60757:1983-01

Tab. 5 Connecting cable wiring, digital control interface [X1] - customer-specific

1. Insert plug into the connection [X1] of the motor controller.

2. Place the additional open cable ends in accordance with the table also.

Motor cable NEBM-M23G8-E-...-Q9N-LE8; NEBM-T1G8-E-...-Q7N-LE8

The motor cable connects the connection [X6] on the servo motor with the connection [X6] on the

motor controller. The circuitry should be carried out in accordance with the following table.

The circuitry should be carried out in accordance with the following table.

14 Festo — YJKP — 2019-01e

Installation

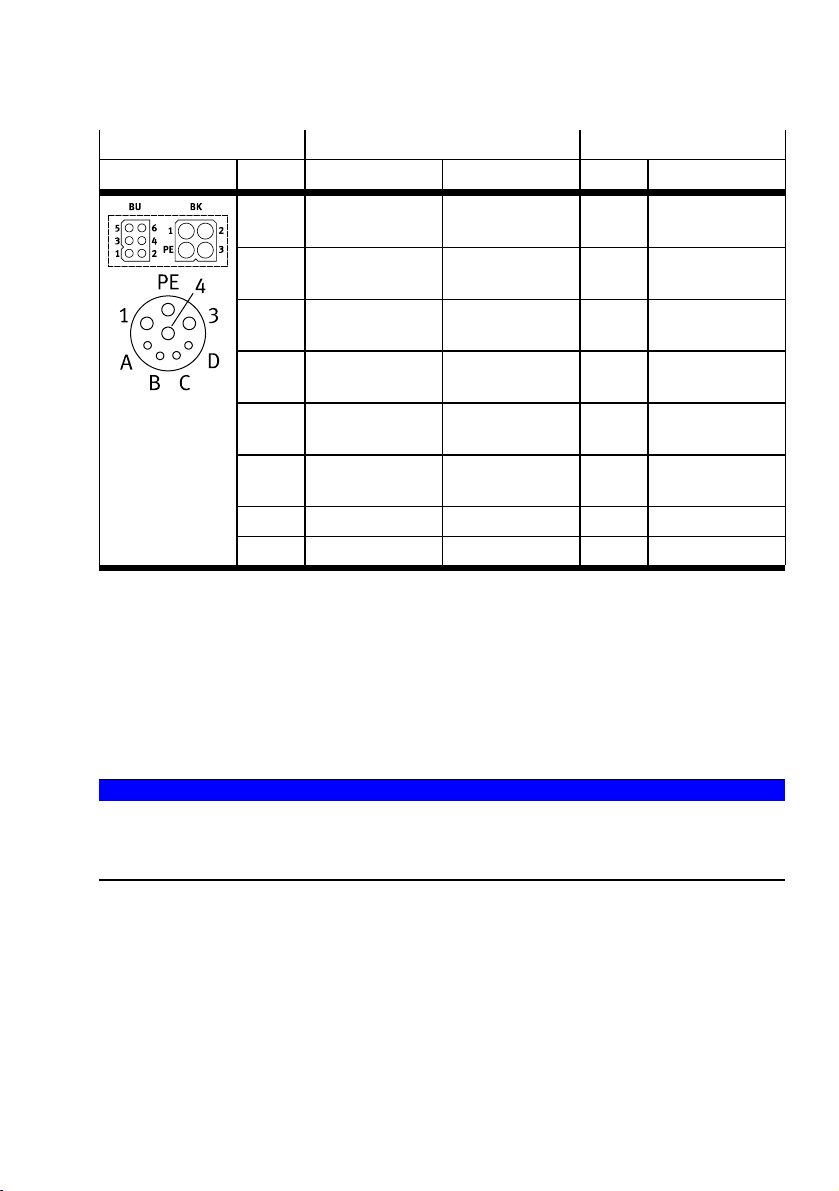

Servo motor EMMS-AS Motor controller CMMP-AS

Connection [X6] Pin Wire colour

1)

Use Pin Connection [X6]

BK 2 Motor power sup-

8 V

ply

BK 3 Motor power sup-

7 W

ply

BK 1 Motor power sup-

9 U

ply

GNYE Motor power sup-

6 PE

ply

BN Temperature

5 +MTdig

sensor

WH Temperature

4 -MTdig

sensor

GN Brake (optional) 2 BR+

YE Brake (optional) 1 BR-

1) Colour code in accordance with IEC 60757:1983-01

Tab. 6 Motor cable

1. Insert the plug into the connection [X6] of the servo motor.

2. Place the open cable ends in accordance with the table in the connection [X6] of the motor controller.

Encoder cable NEBM-M12W8-E-...-N-S1G15; NEBM-T1G8-E-...-N-G1G15

The encoder cable connects the connection [X2] on the servo motor with the connection [X2B] on the

motor controller.

The cable is readily assembled.

NOTICE!

Restart single-turn encoder.

Loss of the reference position.

• Homing is required at the restart of the encoder.

1. Insert the plug into the connection [X2] of the servo motor.

2. Insert the plug into the connection [X2B] of the motor controller.

15Festo — YJKP — 2019-01e

Installation

8.3 Electrical installation CECC-X-M1-YS

Overview of interfaces

1

Ethernet interface [X8]

2

USB interface [X9]

3

Functional earth connection

4

I/O interfaces [X2, X3, X4]

5

Power supply [X1]

Fig. 9 Interfaces, front

6

Status LEDs

7

Memory card

8

Power supply [X5] for digital outputs

9

CANopen interface [X18]

10

Digital outputs [X20]

11

Digital inputs [X17]

12

Analogue inputs [X19]

Fig. 10 Interfaces, lower

NOTICE!

Material damage as a result of using the wrong connections.

In accordance with intended use, all unnamed connections must not be used.

The status LEDs show the operating status of the controller.

Status LED Meaning

[Run] Application status

[Error] Error

[Net] Device detected

16 Festo — YJKP — 2019-01e

Installation

Status LED Meaning

[Mod] Reserved

Tab. 7 Status LEDs

Overview of connection and plug/cable: CECC-X-M1-YS

Connection Plug/cable Purpose

[X1] NECC-L2G4-C1

[X5] NECC-L2G2-C1

[X2] NECC-L2G8-C1

[X3] NECC-L2G6-C1

[X4] NECC-L2G4-C1

[X8] Standard LAN patch cable

1)

1)

1)

1)

1)

Power supply for device

Power supply for digital outputs

I/O interface

2)

Ethernet interface

[X9] USB port

[X17] 2x NECC-L2G6-C1

1)

Digital inputs

[X18] NECC-L2G4-C1 CANopen interface

[X20] NECC-L2G2-C1

1) Plug for customer-provided cable

2) not included in the scope of delivery of the kit

1)

Digital outputs

Tab. 8 Connection and plug

Power supply [X1]

WARNING!

Risk of injury due to electric shock.

• For the electric power supply, use only PELV circuits that ensure a reliable electric disconnection

from the mains network.

• Observe IEC60204-1/EN60204-1.

– Power supply for device, digital and analogue inputs

Resultant current for all supplied ports: £750mA

–

Of which intrinsic current consumption: £200mA

–

– Use an external overload protection for the power supply of the device.

Terminal Connection Use

X1.1 24 24 V DC

X1.2 0 0 V DC

X1.3 Functional earth

X1.4 Not assigned

–

Tab. 9 Power supply connection for device, digital and analogue inputs

17Festo — YJKP — 2019-01e

Installation

1. Supply the device with power.

2. Place the open cable ends in the plug provided in accordance with the table.

3. Insert the plug into the connection [X1] of the controller.

Power supply [X5]

– Power supply for digital outputs.

Resultant current for all supplied ports: £5A

–

Terminal Connection Use

X5.1 24 24VDC

X5.2 0 0VDC

Tab. 10 Connection, power supply for digital outputs

1. Supply the device with power.

2. Place the open cable ends in the plug provided in accordance with the table.

3. Insert the plug into the connection [X5] of the controller.

I/O interface [X2, X3, X4]

Terminal Connection Use

X2.0…X2.7 8 digital inputs Configurable as step enabling

condition in the sequencer of

the press process: DI1…DI8

X3.0 Start the press process

6 digital inputs

1)

Manual operating mode: plot

the reference curve

Automatic operating mode:

start the press process

X3.1 "Manual" operating mode

X3.2 "Automatic B" operating

1)

mode

X3.3 Start homing

X3.4 Acknowledge errors

X3.5

Terminate press process

1)

1)

1)

2)

X4.0…X4.3 4 digital outputs Configurable as output signals

in the sequencer of the press

process: DO1…DO4

1)

24VDC output set by the software as soon as certain event

occurs (position reached, force

reached).

1)

1)

18 Festo — YJKP — 2019-01e

Installation

Terminal Connection Use

X4.4…X4.7 Not assigned

1) For details, see online help

2) Process termination if input = FALSE.

–

Tab. 11 I/O interface connection

Ethernet interface [X8]

The Ethernet interface is designed as an RJ45 socket and supports gigabit LAN.

The following protocols are supported:

– EtherNet/IP (Server)

– ModbusTCP (Server)

– Ethernet TCP/IP

– PROFINET IO

– OPCUA (Only possible with the optional software extension package.)

The interface [X10] of the controller is not supported. The controller cannot be used as a switch.

The Ethernet interface is used to configure and parameterise the system through a PC/tablet connected to the network. After the mechanical and electrical installation, the servo press kit can be commissioned with a web browser. Control and process data can be exchanged with a higher-order controller

through this interface during the run-time of the system.

A requirement for this is integration of the CECC-X-M1-YS in the local network.

Minimum requirements for a PC/tablet

– Web browser with Java Script and support of HTML5 Canvas, e.g. Firefox, Chrome, Internet

Explorer ³ Version9

– Screen resolution 1024 x 768 pixels

Access is through entry in the address line: http://<<IP address>>:8080/servo_press_kit.htm

Example: http://192.168.4.2:8080/servo_press_kit.htm

NOTICE!

Unauthorised access to the device can cause damage or malfunctions.

When connecting the device to a network, protect the network from unauthorised access.

Measures to protect the network include:

• Firewall

• Intrusion Prevention System (IPS)

• Network segmentation

• Virtual LAN (VLAN)

• Virtual Private Network (VPN)

• Security at physical access level (Port Security)

USB interface [X9]

The controller offers the option of connecting the USB memory stick up to 32GB to the USB interface

[X9] and saving the press results.

19Festo — YJKP — 2019-01e

Installation

The USB interface is compatible with the USB 3.0 and USB 2.0 standards. It is suitable for USB plug

type A.

Digital inputs [X17]

The digital inputs, configured in 3-wire connection technology, are not galvanically separated. The

ground potential for all inputs relates to GND of the power supply [X1].

For connecting additional sensors (e.g. external cylinder limit switches, workpiece inspection) with

3-wire connection technology: Use 3 adjacent terminals each.

NOTICE!

Material damage or loss of function due to incorrect I/O circuitry.

• All digital inputs/outputs are designed as PNP. Use only corresponding circuitry.

Terminal Connection Use

X17.0.1 24VDC Power supply 24VDC for pro-

gram selection bit 0

1)

X17.0.2 Input DI9 Program selection bit 0

X17.0.3 GND logic Power supply GND sensor for

program selection bit 0

X17.1.1 24VDC Power supply 24VDC sensor

for program selection bit 1

X17.1.2 Input DI10 Program selection bit 1

X17.1.3 GND logic Power supply GND sensor for

program selection bit 1

X17.2.1 24VDC Power supply 24VDC sensor

for program selection bit 2

X17.2.2 Input DI11 Program selection bit 2

X17.2.3 GND logic Power supply GND sensor for

program selection bit 2

X17.3.1 24VDC Power supply 24VDC sensor

for program selection bit 3

X17.3.2 Input DI12 Program selection bit 3

X17.3.3 GND logic Power supply GND sensor for

program selection bit 3

X17.4.1 24VDC Power supply 24VDC

2)

X17.4.2 Servo press activation Release of motor controller out-

put stage via controller

CECC-X-M1-YS

X17.4.3 GND logic Power supply GND

2)

20 Festo — YJKP — 2019-01e

Installation

Terminal Connection Use

X17.5.1 24VDC Power supply 24VDC

2)

X17.5.2 Activation of step operation Press process in step operation

X17.5.3 GND logic Power supply GND

X17.6.1…X17.6.3 Not assigned

X17.7.1…X17.7.3 Not assigned

1) optional

2) reserve

–

–

2)

Tab. 12 Connection of digital inputs

Digital outputs [X20]

The digital outputs, configured in 2-wire connection technology, are galvanically separated. The current load for each output is 0.5 A.

The ground potential for all outputs relates to GND of the power supply [X5]. All outputs are protected

against short circuit and thermal overload.

NOTICE!

Material damage or loss of function due to incorrect I/O circuitry.

• All digital inputs/outputs are designed as PNP. Use only corresponding circuitry.

Fig. 11 PNP circuit

Use 2 adjacent terminals when connecting a consumer.

Terminal Connection Allocation Comments

X20.0.1 Signal P Error 0.5 A per channel, SSR

X20.0.2 Not assigned

– –

X20.1.1 Signal P Servo press ready for

operation

X20.1.2 Not assigned

– –

1)2)

0.5A per channel, SSR

1)2)

X20.2.1 Signal P Homing requirement 0.5A per channel, SSR

1)2)

X20.2.2 Not assigned

– –

21Festo — YJKP — 2019-01e

Installation

Terminal Connection Allocation Comments

X20.3.1 Signal P Press result OK 0.5A per channel, SSR

1)2)

X20.3.2 Not assigned

– –

X20.4.1 Signal P Press result not OK 0.5A per channel, SSR

1)2)

X.20.4.2 Not assigned

X20.5.1 Signal P Servo press activated

X20.5.2 Not assigned

X20.6.1 Signal P Program step com-

– –

–

– –

–

pleted

X20.6.2 Not assigned

X20.7.1…X20.7.2 Not assigned

1) SSR: Solid State Relay

2) For details, see online help

– –

– –

Tab. 13 Terminal allocation of digital outputs

Card slot for memory card

• Plug the memory card laterally into the device so the system can run.

Configurations, programs and results of press processes can be stored.

Ä

22 Festo — YJKP — 2019-01e

Installation

8.4 Electrical installation CMMP-AS

Overview of interfaces

1

2

3

4

5

6

7

8

Activation of firmware download

Activation of CANopen terminating resistor

CANopen interface [X4]

Ethernet interface [X18]

7-segments display

Reset button

Status LEDs

Digital I/O interface for control of the STO function

[X40]

Fig. 12 Interfaces, front

23Festo — YJKP — 2019-01e

Installation

Fig. 13 Interfaces, upper

1

Digital control interface [X1]

2

Power supply [X9]

3

PE connection

24 Festo — YJKP — 2019-01e

Installation

1

Motor connection [X6]

2

Encoder connection [X2B]

Fig. 14 Interfaces, lower

NOTICE!

Material damage as a result of using the wrong connections.

In accordance with intended use, all unnamed connections must not be used.

The status LEDs show the operating status of the motor controller.

Status LED Meaning

Ready/Error Status

Enable Enable

CAN CAN bus status indication

Tab. 14 Status LEDs

Overview of connection and plug/cable: CMMP-AS

Connection Plug/cable Purpose

[X1] Connecting cable

NEBC-S1G25-P-1.5-N-LE6

Digital control interface for customer connection

[X2B] Encoder cable Connection for servo motor

encoder connection

25Festo — YJKP — 2019-01e

Installation

Connection Plug/cable Purpose

[X4] Connecting cable

NEBC-S1WA9-P-1.5-N-BB-L2G4

Connection for controller

CECC-X-M1-YS

[X6] Motor cable Connection for servo motor con-

nection

[X9] Plug

[X18] Standard LAN patch cable

1)

2)

Power supply

Ethernet interface

[X40] Plug Interface for STO function

1) Plug for customer-provided cable

2) not included in the scope of delivery of the kit

Tab. 15 Connection and plug

Basic setting of DIP switch

The two DIP switches on the motor controller CMMP-AS must be set to a defined basic setting in this

application.

1. Set switch [S2] to the position [0].

2. Set switch [S3] to the position [0].

Power supply [X9]

• Connect the power supply in accordance with the table è 1.1 Applicable documents.

Force range Power supply

Up to 4kN 100…230V AC (1 phase)

From 7kN 230…480VAC (3 phases)

Tab. 16 Power supply

Ethernet interface [X18]

The Ethernet interface is used to for the connection with the higher-order controller.

8.5 I/O interface for STO [X40]

The STO function is described in the additional documents è 1.1 Applicable documents.

Motor controller Design on the device Counterplug

CMMP-AS PHOENIX MINICOMBICON MC

1.5/8-GF-3.81 BK

Tab. 17 Plug design [X40]

26 Festo — YJKP — 2019-01e

PHOENIX MINICOMBICON MC

1.5/8-STF-3.81 BK

Commissioning

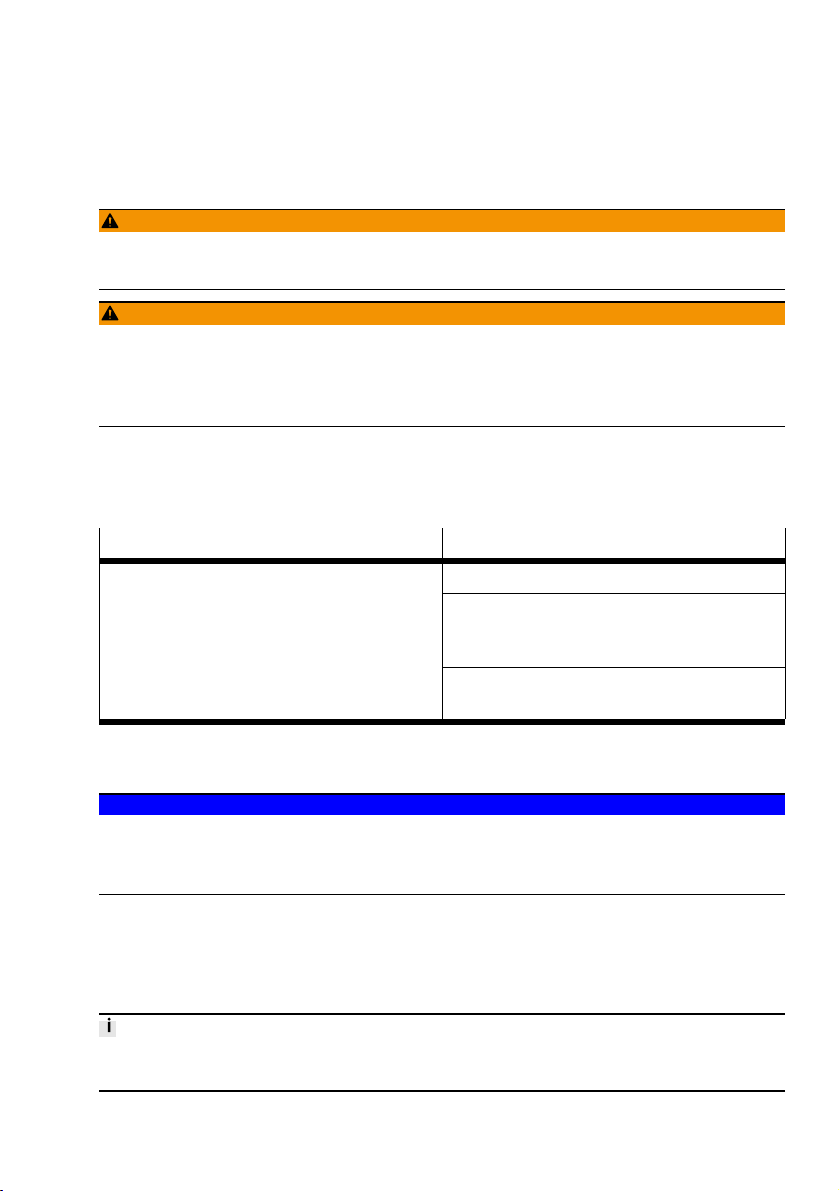

[X40] Pin Designation Value Specification

1 STO-A 0V / +24VDC Control input A for

the function STO

2 0V-A 0V Reference potential

for STO-A

3 STO-B 0V / +24VDC Control input B for

the function STO

4 0V-B 0V Reference potential

for STO-B

5 C1

–

Acknowledgment

contact for the STO

status on an external

controller

6 C2

–

Acknowledgment

contact for the STO

status on an external

controller

7 24V +24VDC Output for auxiliary

power supply

(24VDC logic supply of the motor controller brought out)

8 0V 0V Reference potential

for auxiliary power

supply

Tab. 18 Assignment [X40]: I/O interface for STO

Circuitry with use of the STO safety function [X40]

• To work safely with the STO safety function (safe torque off), please observe the additional

information in the further applicable documents è 1.1 Applicable documents.

9 Commissioning

WARNING!

Risk of injury due to unexpected movement of the product.

Electrical energy can cause unexpected movement of the product.

• Before working on the product: Switch off the power supply, ensure that it is off and secure it

against being switched on again.

The first steps for commissioning the servo press kit are made with the help of the Festo Field Device

Tool (FFT èwww.festo.com/sp).

27Festo — YJKP — 2019-01e

Commissioning

Requirements

– PC with FFT as well as control and motor controller are connected over the same network.

– Participants (control, motor controller) are connected directly over a switch.

Port Description TCP/UDP

161 PROFINET (use of SNMP)

80, 8080 HTTP. Access to the servo press

TCP

software

20, 21 FTP TCP

1024 - 65535 FTP logging

TCP

Depending on the FTP server

configuration, ports in this area

have to be released.

4444 Control of servo press via

TCP

TCP/IP

502 Modbus TCP

44818 EtherNet/IP TCP

2222 EtherNet/IP UDP

10002 Festo Field Device Tool UDP/TCP

445 SMB TCP

4840, 443 OPCUA TCP

Tab. 19 Ports for servo press controller

Preparation with the FFT

1. Preparation with the FFT: set network parameters of the controller CECC-X-M1-YS.

2. Set network parameters of the motor controller CMMP-AS.

3. Optional: update firmware and software.

– Firmware update for controller CECC-X-M1-YS

– Firmware update for motor controller CMMP-AS

– Software update for servo press software on the controller CECC-X-M1-YS

Examples with explanations in the application notes from Festo èwww.festo.com/sp.

NOTICE!

Increased wear in case of operation with too little stroke.

• Observe the minimum stroke.

• If undercut: minimum stroke of 12.5mm must be traversed 10 times in every 100 movement

cycles.

28 Festo — YJKP — 2019-01e

Maintenance

10 Maintenance

10.1 Safety

WARNING!

Risk of injury due to lowering piston rod.

• Before working on the product: Secure the piston rod to prevent it from lowering.

WARNING!

Risk of injury due to unexpected movement of the product.

Electrical energy can cause unexpected movement of the product.

• Before working on the product: Switch off the power supply, ensure that it is off and secure it

against being switched on again.

10.2 Maintenance work

The maintenance work required for the individual components of the kit is described in the further

applicable documents è 1.1 Applicable documents.

Interval Maintenance work

At least once a year - depending on the number

of movements and load

Tab. 20 Maintenance work

Check the mounting of the force sensor.

With the parallel kit: check the toothed belt for

wear and pretension. If the toothed belt breaks,

the axis can fall down in an uncontrolled manner.

With the axial kit: check the mounting (locking

screw) of the coupling on a regular basis.

10.3 Cleaning

NOTICE!

Material damage due to incorrect cleaning.

• Do not clean the guide elements.

• Clean product only with non-abrasive cleaning agents and a soft cloth.

The procedure for cleaning the individual components of the kit is described in the further applicable

documents è 1.1 Applicable documents.

11 Repair

Repair is described in separate documents èwww.festo.com/sp.

For additional support for repairs: Consult your regional Festo contact.

29Festo — YJKP — 2019-01e

Dismounting

12 Dismounting

WARNING!

Risk of injury due to unexpected movement of the product.

Electrical energy can cause unexpected movement of the product.

• Before working on the product: Switch off the power supply, ensure that it is off and secure it

against being switched on again.

WARNING!

Risk of injury due to unexpected movement of the product when lifting it.

• Secure movable components with transport locks to prevent unexpected movement.

• Use all of the transport lugs.

• Observe the position of the centre of gravity.

Details on handling the individual components of the kit are described in separate documents

èwww.festo.com/sp.

13 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accordance with the current

regulations èwww.festo.com/sp.

14 Technical data

General features

Servo Press Kit YJKP 0.8 1.5 4 7 12 17

Max. pressing force [kN] 0.8 1.5 4 7 12 17

Max. payload [kg] 19.5 19.5 48 48 95 95

PLC interface Ethernet (EtherNet/IP, ModbusTCP, Ethernet TCP/IP,

PROFINETIO, OPCUA

Duty cycle [%] 100

Mounting position Any

Control CECC-X-M1-YS

Motor controller

CMMP-AS-...-M0

30 Festo — YJKP — 2019-01e

1)

C2-3A C5-3A C5-11A-P3 C10-11A-

P3

Technical data

Servo Press Kit YJKP 0.8 1.5 4 7 12 17

Servo motor

55-M 70-S 100-S 100-M 140-L

EMMS-AS-...-HS

Electric drive

Electric drive

32-...2)40-...2)50-...2)63-...2)80-...

2)

100-...

ESBF-BS-...-5P

Spindle pitch [mm] 5

Repetition accuracy [mm] ± 0.01 ± 0.015 ± 0.01

Feed speed [mm/s] £250 £160

Acceleration

Deceleration

Quick-stop decelera-

3)

4)

[m/s2] 2

[m/s2] 2

[m/s2] 5

tion

Motor attachment posi-

Axial, parallel

tion

Force sensor

Force sensor

0.8 1.5 4 7 12 17

SKDA-...-AB

Max. overload [kN] ± 1.5 ± 3.75 ± 11.25 ± 15 ± 30 ± 37.5

Scanning frequency [Hz] 1000

Accuracy of measure-

[%FS] £± 0.25

ment

1) The system can permanently press with nominal force against a component/load (with v less than 50 mm/s).

2) Working stroke [mm]: 100, 200, 300, 400

3) Acceleration for positioning procedures

4) Deceleration when force is reached

Tab. 21 Technical data YJKP

Technical data of the main components

2)

Controller

CECC-X-M1-YS

Operating voltage [X1,

[VDC] 19.2…30

X5]

Operating voltage [X21] [VDC] 19.2…50

Nominal current con-

[mA] 200

sumption at 24VDC

31Festo — YJKP — 2019-01e

Technical data

Controller

CECC-X-M1-YS

Reverse polarity pro-

No

tection

Fan noise LpAeq (1m

[dB(A)] 35.7

distance)

Memory card

Supported type microSD

Capacity [GByte] 32

File system FAT32

Analogue input [X19]

Input signal [mA] 0…20

Resolution 14 bit

Hardware

Processor (CPU) Dual core, 2 x 866 MHz

Total main memory [MByte] 512

Tab. 22 Technical data CECC-X-M1-YS

Motor controller

C2-3A-M0 C5-3A-M0 C5-11A-P3-M0 C10-11A-

CMMP-AS

Nominal voltage [VDC] 24 ± 20 %

Nominal current

Max. current for hold-

1)

[A] 0.55 0.65 1

[A] 1 2

ing brake

Type of mounting Screwed onto sub-base

Display 7-segment display

Device profile CANopen DS402

Dimensions (HxWxD) 2)[mm] 202x66x207 227x66x207 252x79x247

Mounting plate dimen-

[mm] 248x61 297x75

sions

1) Plus current consumption from an existing holding brake and I/Os

2) Without plug, shield screw and screw heads

Tab. 23 Technical data CMMP-AS

P3-M0

32 Festo — YJKP — 2019-01e

Technical data

Product weight

Servo Press Kit YJKP 0.8 1.5 4 7 12 17

CECC-X-M1-YS [kg] 0.41

CMMP-AS-...-M0 [kg] 2.1 2.2 3.5

Servo motor

Servo motor

55-M 70-S 100-S 100-M 140-L

EMMS-AS-...-HS

Basic weight [kg] 1.6 2.1 4.8 6.9 16.2 16.2

Additional weight of

[kg] 0.1 0.2 0.5 0.6 0.8 0.8

brake

Electric drive

Electric drive

32-a 40-a 50-a 63-a 80-a 100-a

ESBF-BS-...-5P

Basic weight with

[kg] 0.781 1.237 1.982 3.163 7.393 11.123

0mm stroke

Additional weight per

[kg] 0.33 0.47 0.65 0.87 1.55 1.93

100mm stroke

Force sensor

Force sensor

0.8 1.5 4 7 12 17

SKDA-..-AB

Basic weight [kg] 0.2 0.2 0.3 0.3 0.7 0.7

Connecting kit

Parallel kit [kg] 1.05 2.45 4.99 4.95 11.9 11.8

Axial kit [kg] 0.26 0.41 1.14 1.17 2.92 3.46

Tab. 24 Technical data, product weight

Operating and storage conditions

Feature

Storage temperature [°C] –10…+60

Storage location Dry, solid and flat base (in original packaging)

Max. storage time 48 months

Ambient temperature [°C] 0…+40

Air humidity [%] 0…90 (non-condensing)

33Festo — YJKP — 2019-01e

Technical data

Feature

Corrosion resistance

1)

0

class CRC

Permissible installation altitude above sea level

At nominal power [m] 1000

With performance

reduction

1) No corrosion stress. Applies to small, optically irrelevant standard parts such as threaded pins, circlips and clamping sleeves which

are usually only available on the market in a phosphated or burnished version (and possibly oiled) as well as to ball bearings (for components < CRC 3) and plain bearings.

2) Above 1000 m above sea level, performance reduction of 1 % per 100 m

2)

[m] 1000…2000

Tab. 25 Technical data, operating and storage conditions

34 Festo — YJKP — 2019-01e

Reproduction, distribution or sale of this document or communication of its contents to others without express authorization is

prohibited. Offenders will be liable for damages. All rights

reserved in the event that a patent, utility model or design patent

is registered.

Copyright:

Festo AG & Co. KG

73734 Esslingen

Ruiter Straße 82

Germany

Phone:

+49 711 347-0

Fax:

+49 711 347-2144

e-mail:

service_international@festo.com

Internet:

www.festo.com

Loading...

Loading...