CPX terminal

Electronics

Manual

CPX−I/O modules

sub−bases

pneumatic

interfaces and

MPA electronic

modules

Types:

CPX−...DE−...

CPX−...DA

CPX−8DE−8DA

CPX−AB−...

VMPA−FB−EPL−...

CPX−GP−...

VABA−10S6−X1

VMPA...−FB−EM...

Manual

526 440

en 05602d

[699 181]

Contents and general instructions

Original de. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edition en 05602d. .

DesignationP.BE−CPX−EA−EN. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

Order no. 526 440. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

(Festo AG & Co. KG, D73726 Esslingen, Federal Republic of

Germany, 2006)

Internet: http://www.festo.com

E−Mail: service_international@festo.com

The reproduction, distribution and utiliz

ation of this document

as well as the communicaton of its contents to others without

express authorization is prohibited. Offenders will be held

liable for the payment of damages. All rights reserved in the

event of the grant of a patent, utility module or design.

Festo P.BE−CPX−EA−EN en 05602d

I

Contents and general instructions

CAGE CLAMP® is a registered trade mark of WAGO Kontakttechnik GmbH,

32385 Minden, Germany

TORX® is a registered trade mark of CAMCAR TEXTRON IN

C.,

Rockford, Ill., USA

HARAX® is a registered trade mark of HARTING Deutschland GmbH,

32381 Minden, Germany

SPEEDCON® is a registered trade mark of

PHOENIX CONTACT GmbH &

Co.KG, 32825 Blomberg, Germany

II

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Contents

Designated use VII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Target group VIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service VIII . . . . . . . . . . . . . . . . . . . . . . . .

Important user instructionsIX .

Notes on the

Structure of a CPX terminal XII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPX pneumatic interfaces and MPA pneumatic modules XIII . . . . . . . . . . . . . . . . . . . . . . .

CPX I/O mo

Diagnosis via the field bus XIV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

use of this manual XI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

dules XIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

1. Pneumatic interfaces 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Function of the pneumatic interfaces 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Display and connecting elements1−5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Fitting 1−8 . . . . . .

1.3Settings for configuring the pneumatics 1−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Installation 1−1

1.5 Instructions on commissioning 1−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Diagnosis 1

1.6.1 Fault messages of the pneumatic interfaces 1−20 . . . . . . . . . . . . . . . . . .

1.6.2 LED display 1−21 . . . . . . .

1.6.3Fault treatment and parametrizing 1

2. MPA pneumatic modules 2−1 . . . . . . . . . . . . . . . .

2.1 Function of the MPA pneumatic modules 2−4 . . . . . . . . . . . . .

2.1.1 Display and connecting elements2−6 . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Fitting 2−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installation 2−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Instructions on commissioning 2−15 . . . . . . . . . . . . . . . . . .

2.5 Diagnosis 2−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Error messages of the MPA pneumatic modules 2−18 . . . . . . . . . . . .

2.5.2 LED display 2−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Error treatment and parametrizing 2−22 . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. .

. . . . . . . . . . . . . . .

. .

. . . . . . . . . . . .

. . .

. . .

4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−23 . . . . . . . . . . . . . . . . . . . . . . . . . .

Festo P.BE−CPX−EA−EN en 05602d

III

Contents and general instructions

3. Overview and connecting technology I/O modules 3−1 . . . . . . . . . . . . . . . . . . .

3.1 Components of an I/O module 3−3 . . . . . .

3.2 Connections 3−4 . . . . . . . . . . . . . . . .

3.2.1 Display and connecting elements 3−7 . . . . .

3.2.2 Combinations of I/O modules and sub−bases 3−8 . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . .

3.2.3 Connecting the cables and plugs to the sub−bases 3−10 . . . . . . . . . . . . .

3.3Fitting 3−20 . . . . . . . . . . .

3.3.1 Fitting

3.3.2 Fitting the screeni

4. Input modules 4−1 . . . . . . . . . . . .

4.1 Function of the input modules 4−3 . . .

4.2 Fitting 4−4 . . . . . . . . . . . .

4.3 Installation4−5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the sub−bases 3−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ng/shield plates 3−24 . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Input module CPX−4DE4−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Input module CPX−

4.3.3 Input module CPX−8DE−D with channel

4.3.4 Input module CPX−16DE4−21 . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Input module CPX−8NDE4−24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8DE4−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

diagnosis 4−16 . . . . . . . . . . . . . .

. . . . . . . . . .

. . .

4.4 Instructions on commissioning 4−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Parameters of the input modules type CPX−4DE, −8DE, −8DE−D, −16DE and

−8NDE4−29 . . . . . . . . . . . . . . . . . . . . . . .

4.5 Diagnosis 4−33 . . . . . . . . . . . . . . . . . . . . .

4.5.1 Fault messages of the input modules 4−33 . . . . . .

4.5.2 LED display 4−35 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3Fault treatment and parametrizing 4−38 . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . .

5. Output modules 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Function of the output modules 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Fitting 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Installation 5−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

5.3.1 Output module CPX−4DA 5−6 . . . . . . . . . . . . . . . . . . . . .

5.3.2 Output module CPX−8DA 5−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . .

5.4 Instructions on commissioning 5−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV

Festo P.BE−CPX−EA−E N en 05602d

.

Contents and general instructions

5.5 Diagnosis 5−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Error messages of the output modules 5−22 . . . . . . . . . . . . . . . . . . . . . .

5.5.2 LED display 5−23 . . . . .

5.5.3 Error treatment and parametrizi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ng 5−25 . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Multi I/O modules 6−1 . . . . . . . . . . . . . . .

6.1 Function of the multi I/O modules 6−4 . . . . . .

6.2 Fitting 6−4 . . . . . . . . . . . . . . . . . . .

6.3 Installation 6−5 . . . . . . .

6.3.1 Multi I/

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O module CPX−8DE−8DA 6−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Instructions on commissioning 6−10 . . . .

6.5 Diagnosis 6−16 . . . . . . . . . . . . . . . .

6.5.1 Error messages of the multi I/O modu

6.5.2 LED display 6−18 . . . . . . . . . . . . . . . . . . . . . .

6.5.3 Error treatment and parametrizing 6−20 . . . . . . . . . . . . . . .

A. Technical appendix A−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

les 6−16 . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . .

A.1 Technical specifications of the pneumatic interfaces A−3 . . . . . . . . . . . . . . . . . . .

A.2 Technical

A.3Technical specifications of the input modules A−7 . . . . . . .

A.4Technical specifications of the output modules A−9 . . . . . . . . . . . . . . . . . . . .

specifications of the MPA electronic modules A−5 . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . .

A.5 Technical specifications of the multi I/O modules A−10 . . . . . . . . . . . . . . . . . . . . .

A.6 Technical specifications of th

A.7 Internal structure of the CPX modules A−13 . . . .

A.8 Examples of circuitry A−18 . . . . . . . . . . . . . . . .

A.8.1 Circuitry examples of PNP inputsA−18 . . . . . . . . . . .

A.8.2 Circuitry examples of PNP outputsA−18 . . . . . . . . . . . . . . . . . . . . . . .

e sub−bases A−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . .

A.8.3 Circuitry examples of NPN inputsA−19 . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.8.4 Circuitry example

A.8.5 Circuitry example with DNCV A−21 . . . . . .

A.9 Accessories A−22 . . . . . . . . . . . . . . . . . . . . . . . .

with DUO cable A−20 . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Index B−1 . . . . . . . . . . . . . . . . . . .

Festo P.BE−CPX−EA−EN en 05602d

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

Contents and general instructions

Designated use

The CPX pneumatic interfaces, MPA pneumatic modules and

CPX I/O modules described in this manual have been de

signed exclusively for use in conjunction with CPX terminals

from Festo. The pneumatic interfaces and I/O modules are

only to be used as follows:

as specified in industrial applicatio

ns

without any modifications by the user

Only the conversions or modifications described in the

documentation supplied with product are permitt

ed.

in faultless technical condition.

If additional commercially−available components such as

sensors and actuators are connected, the specified limits for

pressures, temperatures, electrical data, torques, etc. must

not be exceeded.

Please observe the standards specified in the relevant

chapters and

comply with technical regulations, as well as

with national and local regulations.

Warning

· In order to provide the electric power supply, use only

PELV circuits as per IEC/DIN EN 60204−1 (Protective

Extra−Low Voltage, PELV ).

Take int

o account also the general requirements for

PELV circuits as per IEC/DIN EN 60204−1.

· Use only power packs which guarantee reliable electri

cal isolation of the operating voltage as per IEC/DIN

EN60204−1.

By the use of PELV power

units, protection against electric

shock (protection against direct and indirect contact) is

guaranteed in accordance with IEC/DIN EN 60204−1

(elec

trical equipment of machines, general requirements).

VI

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Target group

This manual is intended exclusively for technicians trained in

control and automation technology, who have experience in

installing, commissioning, programming and diagnosing

programmable logic controllers (PLC) and field bus systems.

Service

Please consult your local Festo repair service if you have any

technical problems.

Festo P.BE−CPX−EA−EN en 05602d

VII

Contents and general instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which may occur if the product is not used correctly. These

instructions are marked (W

shaded background and marked additionally with a picto

gram. A distinction is made between the following danger

warnings:

Warning

This means that failure to observe this instruction may

result in serious personal injury or damage to property.

Caution

This means that failure to observe this instruction may

result in personal injury or damage to property.

arning, Caution, etc.), printed on a

VIII

Please note

This means that failure to observe this instruction may

result in damage to property.

The following pictogram marks passages in the text

describe activities with electrostatically sensitive compo

nents.

Electrostatically sensitive components may be damaged if

they are not hand

led correctly.

Festo P.BE−CPX−EA−E N en 05602d

which

Contents and general instructions

Marking special information

The following pictograms mark passages in the text contain

ing special information.

Pictograms

Information:

Recommendations, tips and references to other sources

information.

Accessories:

Information on necessary or sensible accessories for the

Festo product.

Environment:

Information on environment−friendly use of Fes

of

to products.

Festo P.BE−CPX−EA−EN en 05602d

Text markings

· The bullet indicates activities which may be carried out in

any order.

1. Figures denote activities which must be carried out in the

numerical o

rder specified.

Hyphens indicate general activities.

IX

Contents and general instructions

Notes on the use of this manual

This manual contains general basic information on the

method of operation, on fitting and installing CPX pneumatic

interfaces, MPA pneumatic modules and CPX I/O modules.

General basic information on the method of operation, on

fitting, installing and commissioning CPX terminals can be

found in the C

Special information on commissioning, parametrizing and

diagnosing a CPX terminal with the field bus node you are

using can be found in

bus node.

Information on further CPX modules can be found in the

manual for the relevant module. An overview is

Tab.0/3.

PX system manual.

the appropriate manual for the field

provided in

Conventions

The special parameters of the modules are described in the

individual chapters. These appear in English on

the Handheld

type CPX−MMI−1.

[........]The data and parameters which appear in English on the

Handheld are shown in square brackets in this manual,

e.g. [Debounce time]. This is followed in the text by the

translation, e.g.:

Eingangsentprellzeit[Debounce time]

X

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Structure of a CPX terminal

CPX terminals consist of electric function modules, individual

modules and components. The diagram below shows an

example:

12 3 4

1 Field bus node

2 I/O modules

3 Pneumatic interface

4 Pneumatic modules

(example MPA)

Fig.0/1:Example of CPX terminal

Festo P.BE−CPX−EA−EN en 05602d

5

6

7

8

5 Manifold sub−base with additional power

supply

6 Manifold sub−base without supply

7 Manifold sub−base with system supply

8 End plate

XI

Contents and general instructions

CPX pneumatic interfaces and MPA pneumatic modules

An overview of the CPX pneumatic interfaces can be found in

Tab.1/1 and of the MPA pneumatic modules in Chap. 2.

CPX I/O modules

This manual contains information on the following modules:

I/O modules

Type

designation

CPX−4DE

CPX−8DE

CPX−16DE

CPX−8DE−D

CPX−8NDE

CPX−4DA

CPX−8DA

CPX−8DE−8DA Multi I/O module

Tab.0/1: Overview of I/O modules

Manual Sub−bases and

manifold sub−bases

Input modules

with 4, 8 or

16inputs, PNP

Input module with

8 inputs and

channel diagnosis,

PNP

Input module with

8 inputs, negative

logic, NPN

Output module

with 4 outputs,

PNP

Output module

with 8 outputs,

PNP

(input/output

module) with

8inputs and

8outputs, PNP

The I/O modules each

consist of the electronic

module as well as a

sub−base and a manifold

sub−base.

Sub−bases:

(Note the possible combina

tions in section 3.2.2).

CPX−AB−4−M12x2−5POL

CPX−AB−4−M12x2−5POL−R

CPX−AB−8−M8−3POL

CPX−AB−8−M8−4POL

CPX−AB−8−KL−4POL

CPX−AB−1−SUB−BU−25POL

CPX−AB−4−HARX2−4POL

CPX−AB−4−M12−8POL

Manifold sub−bases:

CPX−GE−EV

CPX−GE−EV−...

XII

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Diagnosis via the field bus

Depending on the parametrization, CPX pneumatic interfaces

and CPX I/O modules register specific faults via the field bus.

These can be evaluated

via the:

status bits (system status)

I/O diagnostic interface (system diagnosis)

module diagnosis

fault numbers.

Further information on diagn

osis can be found in the CPX

system manual or in the manual for the field bus node.

Festo P.BE−CPX−EA−EN en 05602d

XIII

Contents and general instructions

Type Title Description

Electronics

Manual

Software

package

System manual"

type P.BE−CPX−SYS−...

CPX field bus node"

type P.BE−CPX−FB...

CPX I/O modules"

type P.BE−CPX−EA−...

CPX analogue I/O

modules"

type P.BE−CPX−AX−...

CPX−CP interface"

type P.BE−CPX−CP−...

Handheld"

type P.BE−CPX−MMI−1−...

CPX−FEC"

type P.BE−CPX−FEC−...

FST" Programming in Statement List and Ladder

Overview of structure, components and method

of operation of CPX terminals;

installation and commissioning instructions as

well as basic principles of parametrizing

Instructions on fitting, installing, commissioning

and diagnosing the relevant field bus node

Notes on connection types and instructions on

fitting, installing and commissioning input and

output modules of type CPX−..., the MPA

pneumatic modules, as well as MPA, CPA and

Midi/Maxi pneumatic interfaces

Notes on connection types and instructions on

fitting, installing and commissioning CPX

analogue I/O modules

Instructions on fitting, installing, commissioning

and diagnosing CP systems with the CPinterface

type CPX−CP−4−FB

Instructions on commissioning and diagnosing

CPX terminals with the Handheld type

CPX−MMI−1

Instructions on fitting, installing, commissioning

and diagnosing the CPX Front End Controller

Diagram for the FEC

Tab.0/2:Manuals on the CPX terminal part 1

XIV

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Type Title Electronics

Electronics

Pneumatics

Val ve terminals with

MPApneumatics"

type P.BE−MPA−...

Val ve terminals with

CPApneumatics"

type P.BE−CPA−...

Val ve terminals with

Midi/Maxi pneumatics"

type P.BE−MIDI/MAXI−03−...

Val ve terminal with

VTSA/ISO pneumatics"

type P.BE−VTSA−44−...

Tab.0/3: Manuals on the CPX terminal part 2

Instructions on fitting, installing, commission

ing, maintaining and converting the MPA pneu

matics (type 32)

Instructions on fitting, installing, commission

ing, maintaining and converting the CPA pneu

matics (type 12)

Instructions on fitting, installing, commission

ing, maintaining and converting the Midi/Maxi

pneumatics (type 03)

Instructions on fitting, installing, commission

ing, maintaining and converting the VTSA/ISO

pneumatics (type 44)

Festo P.BE−CPX−EA−EN en 05602d

XV

Contents and general instructions

The following product−specific terms and abbreviations are

used in this manual:

Term/abbreviation

CPX modules Common term for the various modules which can be incorporated in a

CPX terminal Modular, electric terminal type 50

Diagnosis D2 Additional diagnostic functions of MPA input modules

DIL switch Dual−in−line switches consist of several switch elements with which

Field bus node Provides the connection to specific field buses. Transmits control signals

I Digital input

I/O diagnostic interface The I/O diagnostic interface is a bus−independent diagnostic interface at

I/O modules Common term for the CPX modules which provide digital inputs and

I/Os Digital inputs and outputs

I module CPX input module

Manifold sub−base Lower part of the housing of a module or block for linking the module

MPA electronic module Electronic module which provides the electronic functionality including

MPA pneumatic module Pneumatic module which provides digital outputs for the valves fitted

Meaning

CPXterminal.

settings can be made.

to the connected modules and monitors their ability to function.

I/O level, permitting access to internal data of the CPX terminal.

outputs (CPX input modules and CPX output modules).

electrically with the terminal.

the diagnostic functions for the valve solenoid coils of the MPA

pneumatics.

(valve solenoid coils).

O Digital output

O module CPX output module

PLC/IPC Programmable logic controller/industrial PC

Pneumatic interface The pneumatic interface is the interface between the modular electrical

XVI

periphery and the pneumatics.

Festo P.BE−CPX−EA−E N en 05602d

Contents and general instructions

Term/abbreviation Meaning

Status bits Internal inputs which supply coded common diagnostic messages.

Sub−base Replaceable upper part of housing of modules with connections.

Tab.0/4: Product specific abbreviations

Festo P.BE−CPX−EA−EN en 05602d

XVII

Contents and general instructions

XVIII

Festo P.BE−CPX−EA−E N en 05602d

Pneumatic interfaces

Chapter 1

Type

VMPA−FB−EPL−...

CPX−GP−03−4.0

CPX−GP−CPA−10

CPX−GP−CPA−14

VABA−10S6−X1

1−1Festo P.BE−CPX−EA−EN en 05602d

1. Pneumatic interfaces

Contents

1. Pneumatic interfaces 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Function

1.1.1 Display and connecting elements1−5

1.2 Fitting 1−8 . . . . . . . . . . . . . . . . . .

1.3Settings for configuring the pneuma

1.4 Installation 1−14 . . . . . . . . . . . .

1.5 Instructions on commissioning 1−15

1.6 Diagnosis 1−19 . . . . . . . . . . .

1.6.1 Fault messages of the pn

1.6.2 LED display 1−21 . . . . . . . . . . . . . . . . . . .

1.6.3Fault treatment and parametrizing 1−23 . . . . . . . . . . .

of the pneumatic interfaces 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

tics 1−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eumatic interfaces 1−20 . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−2

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.1 Function of the pneumatic interfaces

The CPX pneumatic interfaces in a CPX valve terminal provide

the connection to the pneumatic modules.

The pneumatic modules enable pneumatic actu

controlled by means of the valves fitted.

ators to be

Pneumatic

interfaces

Type designation Description Connection to

Pneumatics

VMPA−FB−EPL−... CPX pneumatic interface

VABA−10S6−X1 CPX pneumatic interface

CPX−GP−03−4.0 CPX pneumatic interface

CPX−GP−CPA−10

CPX−GP−CPA−14

to MPA

for VTSA pneumatics

(ISO, type 44)

to Midi/Maxi

CPX pneumatic interface

to CPA10

CPX pneumatic interface

to CPA14

Pneumatic interface for

connecting the modular

electrical peripherals of

type 50 (CPX) to valve

terminals type 32 (MPA).

Pneumatic interface for

connecting the modular

electrical peripherals of

type 50 (CPX) to VTSA/ISO

valves (type44)

Pneumatic interface for

connecting the modular

electrical periphery type50

(CPX) to valve terminals

type 03 (Midi/Maxi).

Pneumatic interface for

connecting the modular

electrical periphery type50

(CPX) to valve terminals

type 12 (CPA).

Tab.1/1: Overview of pneumatic interfaces

Festo P.BE−CPX−EA−EN en 05602d

1−3

1. Pneumatic interfaces

MPA pneumatics From the technical point of view, the individual MPA pneu

matic modules each represent an electric module with e.g.

8digital outputs for controlling

the valves fitted

(seechapter 2).

Please note

The pneumatic interface for MPA pneumatics provides the

mechanical and electrical connection to the MPA pneu

matic modules.

As regards the CPX ter

minal, this pneumatic interface does

not therefore count as an electric module.

Midi/Maxi pneumatics,

CPA pneumatics or VTSA

pneumatics

From the technical poi

nt of view, the pneumatic interfaces

for Midi/Maxi pneumatics, CPA pneumatics or VTSA pneu

matics (ISO) each represent an electric module with a v

ari

able (configurable) number of digital outputs for controlling

the valves fitted (see following sections).

1−4

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.1.1 Display and connecting elements

MPA pneumatics The pneumatic interface for MPA pneumatics (type 32)

possesses the following display and connecting elements:

1 Connecting plug to

the MPA pneumatic

modules

1

2 Inscription field

3

3 Connecting plug to

the CPX manifold

sub−bases

Fig.1/1: Display and connecting elements of the pneumatic interface for MPA

pneumatics

2

Festo P.BE−CPX−EA−EN en 05602d

1−5

1. Pneumatic interfaces

VTSA pneumatics (ISO)The pneumatic interface for VTSA pneumatics (ISO, type 44)

possesses the following display and connecting elements:

1 Connecting plug to

the VTSA pneumatic

modules

5

2 Fault LED (red)

1

2

3 Inscription field

4

4 DIL switch under a

transparent cover

5 Connecting plug to

the CPX manifold

sub−bases

Fig.1/2: Display and connecting elements of the pneumatic interface for ISO

pneumatics

3

1−6

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

Midi/Maxi or

CPA pneumatics

1 Pneumatic interface

for Midi/Maxi

pneumatics (type03)

The pneumatic interfaces for Midi/Maxi or CPA pneumatics

possess the following display and connecting elements:

12

2 Pneumatic interface

for CPA pneumatics

(type 12 here

size10)

3

4

3 Connecting plug for

the valves

5

4 Fault LED (red)

5 DIL switch under a

transparent cover

6 Identification fields

7 Connecting plug to

the CPX manifold

sub−bases

Fig.1/3: Display and connecting elements of the pneumatic interface for Midi/Maxi or

CPA pneumatics

77

6

3

4

5

Festo P.BE−CPX−EA−EN en 05602d

Use identification labels type IBS 6x10 for marking

pneumatic interface for CPA pneumatics.

the

1−7

1. Pneumatic interfaces

1.2 Fitting

Warning

Sudden unexpected movement of the connected actuators

and uncontrolled movements of loose tubing can cause

injury to human beings or damage to property

.

Before carrying out installation and maintenance work,

switch off the following:

the compressed air supply

the operating and load voltage supplies.

The CPX

terminal must first be dismantled before it can be

extended or converted, or when a pneumatic interface must

be replaced. Instructions

on this can be found in the CPX

system manual.

Instructions on extending or converting the pneumatic

modules can be found in the appropriate pne

umatics manual.

For Midi/Maxi, CPA or ISO pneumatic interfaces:

The setting of the DIL switches for configuring the pneumatics

(valves used) can b

e set on the CPX terminal without the need

to disamantle the terminal.

1−8

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.3 Settings for configuring the pneumatics

Midi/Maxi, CPA or

VTSA pneumatics

Settings for configuring the pneumatics are only necessary

with the pneumatic interfaces for Midi/Maxi, CP

A and VTSA

pneumatics (ISO).

No settings are required for MPA pneumatics.

Caution

After conversion or extension of the Midi/Maxi, CPA or

VTSA pneumatics, the number of output addresses occu

pied by the pneumatics must be

set on a DIL switch on the

pneumatic interface.

CPX terminals can be fitted with various valves and electric

modules in accordance with the cus

tomer’s wishes.

The size of the valve address range on Midi/Max, CPA or

VTSA pneumatics is not modified when the valves are ex

tended or

converted, providing sufficient address space has

already been reserved for the extension. The valve address

range must be set with a DIL switch. The DIL switch is situ

ated under the transparent cover on the pneumatic interface.

Festo P.BE−CPX−EA−EN en 05602d

Warning

Sudden unexpected movement of the connected actuators

and uncontrolled movements of loose tubing can cause

injury to human beings or damage to property

.

Before carrying out installation and maintenance work,

switch off the following:

the compressed air supply

the operating and load voltage supplies.

1−9

1. Pneumatic interfaces

Caution

Modules may be damaged if they are not handled

correctly.

· Do not touch the electrical contacts of the modules.

· Observe the regulations for handling electrostatically

sensitive components.

· Discharge yourself electrostatically before fitting or re

moving components in order to protect the components

against discharges of static electricity.

Please note

Handle all modules and components of the CPX terminal

with great care. Please note especially the following:

· Screws must be fitted accurately (otherwise threads will

be damaged).

Screws must be fastened at first only by hand. Place the

scre

ws so that the self−cutting threads are used.

· The specified torques must be observed.

· Screw connections must be fitted free of offset and

mechanical tension.

· Check the seals for damage (IP65).

· Connecting surfaces must be clean (to ensure sealing

effect, avoid leakage and contact faults).

The screw connection between the cover and the lower

part of the CPA pneumatic interface is designed for at least

10 fitting/removal cycles.

1−10

Removing the cover

1. Loosen the screws in the cover with a TORX screwdriver

size T10.

2. Lift the cover up carefully.

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

3. Set the DIL switch elements in accordance with the follow

ing table. Use a suitable tool, e.g. a small screwdriver, for

setting the DIL switches.

1 Printed circuit

board

2 Fault LED

3 DIL switches for

configuring the

pneumatics

Fig.1/4: DIL switches on the pneumatic interface (here for CPA pneumatics)

The DIL switch contains 8 switch elements. These switch

elements ar

VTSA/ISO) or ON (Midi/Maxi) are marked.

e numbered from 1...8. The positions OPEN (CPA,

1

2

3

Festo P.BE−CPX−EA−EN en 05602d

Rules for setting

If the number of valve solenoid coils fitted is less than the

number of output addresses set with the DIL switch, the

superfluous addresses will be reserved for later exten

sions (if the maximum number of valves is fitted, output

addresses will then remain unused).

Modifications to the configuration will not

effective until the operating voltage is switched on again.

8 further output addresses per switch element will be

assigned for valves in th

The setting of the highest−value DIL switch in the ON

(closed) position is decisive for the assigned address

range.

e address range.

become

1−11

1. Pneumatic interfaces

Setting the DIL switch

DIL switch setting Assigned addresses

Midi/Maxi CPA VTSA/ISO

Switches

8: reserved

8 outputs for valves

7: reserved

6: reserved

5: reserved

OPEN

1234 56 7 8

OPEN

1234567 8

4: OFF/OPEN

3: OFF/OPEN

2: OFF/OPEN

1234567 8

1: ON/CLOSED

8: reserved

16 outputs for valves

7: reserved

6: reserved

5: reserved

OPEN

1234 56 7 8

OPEN

1234567 8

4: OFF/OPEN

3: OFF/OPEN

2: ON/CLOSED

1234567 8

1: as desired

8: reserved

7: reserved

6: reserved

24 outputs for valves

(factory setting for CPA

1)

)

With CPA: only 22 can be used

5: reserved

4: OFF/OPEN

3: ON/CLOSED

2: as desired

1234567 8

1: as desired

8: reserved

7: reserved

6: reserved

32 outputs for valves (factory setting for

Midi/Maxi and VTSA/ISO

1)

With Midi/Maxi: only 26 can be used

1234 56 7 8

OPEN

Setting not

permitted

OPEN

1234567 8

5: reserved

OPEN

1234 56 7 8

1)

Depending on the equipment fitted on the CPX and the field bus node, see following note.

2)

Additionally occupied output addresses remain unused

4: ON/CLOSED

3: as desired

2: as desired

1234567 8

1: as desired

2)

)

2)

Tab.1/2: DIL switch setting

1−12

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

Please note

In the case of field bus protocols with which, due to the

limiting of the address range, the setting 32 outputs"

(VTSA/ISO or Midi/Maxi) o

r 24 outputs" (CPA) together

with the CPX equipment fittings would lead to an error, the

DIL switches have been set at the factory

according to the

actual number of valve solenoid coils.

Please note

DIL switch settings which are not represented are not

permitted.

Fitting the cover

1. Check the seal and the surface opposite it for damage or

dirt. If necessary, the seal must be replaced (only with

type CPX−GP−03−4.0) or the surfaces must be cleaned.

Festo P.BE−CPX−EA−EN en 05602d

2. Place the cover carefully into position so that the seal is

not damaged.

With type CPX−GP−CPA−...: Tighten the screws at first o

nly

by hand. Place the screws so that the self−cutting threads

can be used.

3. Tighten the screws in diagonally opposite sequence with

screwdriver size T10. Observe the tightening

a TORX

torques listed in the table below.

Pneumatic interface

Midi/Maxi (type CPX−GP−03−4.0) 1.0 ... 1.3 Nm

CPA (type CPX−GP−CPA−...) 0.9 ... 1.1 Nm

VTSA (type VABA−10S6−X1) 1.2 ... 1.8 Nm

Tightening torque

Tab.1/3: Tightening torques for the pneumatic interfaces

1−13

1. Pneumatic interfaces

1.4 Installation

Instructions on installing the pneumatic components can be

found in the relevant pneumatics manual.

Instructions on installing the electric components can be

found in the CPX system manual.

Instructions on addressing the valve solenoid coils as well as

further instructions on installing the electric

be found in the relevant field bus node manual.

components can

Power supply

The 24 V supply for the valves is provided via the load voltage

for the valves of the CPX terminal (V

The power supply for the electronics of the pneumatic inter

faces is provided via the operating voltage supply for the

V

electronics/sensors (

EL/SEN

).

VAL

).

1−14

Address assignment within the pneumatic modules

Instructions on assigning the addresses to the individual

valve solenoid coils with Midi/Maxi or CPA pneumatics can be

found in the appropriate pneumatics manual.

Instructions on assigning the addresses to the individual

valve solenoid coils with MPA pneumatic modules can be

found in chapter 2.

Protection class

When completely fitted, the pneumatic interfaces with the

valve terminal pneumatics comply with protection class IP65

(see appendix A.1).

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.5 Instructions on commissioning

Midi/Maxi, CPA or

VTSA pneumatics

The reaction of the pneumatic interface for Midi/Maxi, CPA

or VTSA pneumatics can be parametrized.

The table below

gives an overview of the parameters for the pneumatic

interfaces.

With the MPA pneumatics, parametrizing takes place via the

indi

vidual MPA pneumatic modules (module−orientated, see

chapter 2).

Further information on parametrizing can be found in the

system manual or in th

e manual for the field bus node.

Please note

Activate the wire−fracture monitoring only for outputs

which also have a valve solenoid coil.

If the wire−fracture monitoring is act

ivated for an output

which does not have a valve solenoid coil, the CPX terminal

will register the fault Wire fracture" when it is swi

tched

on, due to the valve solenoid coil being incorrectly regis

tered as defective.

Festo P.BE−CPX−EA−EN en 05602d

1−15

1. Pneumatic interfaces

Parameters of pneumatic interfaces types

CPX−GP−03−4.0, CPX−GP−CPA−... and VABA−10S6−X1

Module parameters: Monitoring the CPX module

Function no. 4828 + m * 64 + 0m = module number (0...47)

Description Monitoring of the possible faults can be activated or deactivated (suppressed)

Val ues 1 = active

Remark Monitoring can also be set for the complete CPX terminal

[...] = display in the Handheld

for each module separately. Active monitoring causes the following: The fault is:

sent to the CPX field bus node

displayed by the common module fault LED.

Monitoring

Bit

Description

2

Undervoltage of valves (V

3

Short circuit at the valve (SCV)

0 = inactive

Presetting: bit 2: active;

(see CPX system manual).

bit 3: inactive

VAL

)

[Monitor]

[Monitor Vval]

[Monitor SCV]

[Active]

[Inactive]

Tab.1/4: Monitoring the CPX module

1−16

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

Module parameters: Monitoring wire fracture channel x

(only CPA and VTSA pneumatics)

Function no.

channel 0...7:

channel 8...15:

channel 16...23:

channel 24...31:

4828 + m * 64 + 6m = module number (0...47)

4828 + m * 64 + 7

4828 + m * 64 + 8

4828 + m * 64 + 9

Description Determines whether Monitoring Wire Fracture for the relevant channel is active

Remark With Monitoring Wire Fracture, a missing valve or a wire fracture (connection

[...] = display in the Handheld

or inactive (CPA: channel 0...21, VTSA/ISO: channel 0...31).

Monitoring wire fracture output channel ...

0 = inactive (presetting)

1 = active

fault between the pneumatic interface and the valve coil) is recognized.

[Monitor open circuit Out Ch ...]

[Inactive]

[Active]

Tab.1/5:Monitoring wire fracture channel x (channel−specific)

Module parameters: Fail safe channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Fault mode channel x: Hold last state

Remark With the aid of the so−called Fail safe parametrizing, you can specify the signal

(see the manual for the field bus node).

Fault state (presetting)

Fault state channel x: Set output

Reset output (presetting)

status which the outputs are to assume in the event of field bus communication

faults (see also CPX system manual).

Tab.1/6:Fail safe channel x (channel−specific)

Festo P.BE−CPX−EA−EN en 05602d

1−17

1. Pneumatic interfaces

Module parameters: Idle mode channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Only relevant for certain field bus protocols.

Remark With the aid of the so−called Idle mode parametrizing, you can determine the

(see the manual for the field bus node).

Idle mode channel x: Hold last state

Idle state (presetting)

Idle state channel x: Set output

Reset output (presetting)

signal status which the outputs are to assume when switching is made to the

Idle state (see also CPX system manual).

This parameter is not available with all field bus protocols.

Tab.1/7: Idle mode channel x (channel−specific)

Module parameters: Force channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Force mode of outputs channel x: Blocked (presetting)

Remark The Force function enables the manipulation of signal states detached from

(see the manual for the field bus node).

Force state

Force state of outputs channel x: Set signal

Reset signal (presetting)

actual operating states (see also CPX system manual).

Tab.1/8:Force channel x (channel−specific)

1−18

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.6 Diagnosis

Midi/Maxi, CPA or

VTSA pneumatics

Specific faults of the pneumatic interfaces are registered or

suppressed depending on the module parametrizi

ng.

The faults are shown on−the−spot by means of the Fault LED

and, if necessary, can be evaluated with the Handheld (MMI).

Depending on th

e module parametrizing, the faults are sent

to the field bus node, where they can be evaluated according

to the field bus protocol used.

the MPA pneumatics, parametrizing takes place via the

With

individual MPA pneumatic modules (module−orientated, see

chapter 2).

Festo P.BE−CPX−EA−EN en 05602d

1−19

1. Pneumatic interfaces

1.6.1 Fault messages of the pneumatic interfaces

Midi/Maxi, CPA or

VTSA pneumatics

Fault number

5 Fault in load voltage for valves

11 Fault short circuit at valve

Description Fault treatment

Load voltage for the valves (V

missing or too low.

Short circuit/overload at the valve

A pneumatic interface can register the following standard

faults:

)

1)

VAL

2)

· Check the load voltage

· Check that the valves are fitted

correctly and check the electrical

connections,

· If necessary, replace the valve

13 Fault wire fracture

Monitoring the residual current of the

valve solenoid coils (open load, only

active with 0−signal).

Only relevant for CPA or VTSA pneu

matics.

2)

· Check that the valves are fitted

correctly and check the electrical

connections,

· If necessary, replace the valve

· Correct any faulty parametrizing (e.g.

with reserved valve locations/blank

ing plates, see section 1.3)

1)

Tolerance range of the load voltage supply V

2)

Number of the faulty channel: see module diagnostic data.

see Technical specifications" in the appendix.

VAL

Tab.1/9:Fault messages of the pneumatic interface for Midi/Maxi, CPA or VTSA

pneumatics

1−20

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.6.2 LED display

Midi/Maxi, CPA or

VTSA pneumatics

CPX−GP−03−4.0 CPX−GP−CPA−... VABA−10S6−X1

There is an LED under the transparent cover for diagnosing

these pneumatic interfaces.

111

1 Fault LED (red)

Fig.1/5: LED display of the pneumatic interfaces

Festo P.BE−CPX−EA−EN en 05602d

1−21

1. Pneumatic interfaces

LED lights up

Fault LED

Midi/Maxi, CPA or

VTSA pneumatics

The red fault LED of these pneumatic interfaces indicates

the faults of the pneumatic interface depending

on the

parametrization.

Fault LED

(red)

LED is out

LED lights up

Sequence Status Fault

number

ON

OFF

ON

OFF

Faultless operation None

Fault in load voltage for valves

Load voltage for the valves (V

missing or too low.

Fault short circuit at valve

Short circuit/overload at valve

Wire fracture fault

Monitoring the residual current of

the valve solenoid coils (open load,

only active with 0−signal).

Only relevant for CPA or VTSA pneu

matics.

5 See section

)

VAL

11

13

Fault

treatment

1.6.1, Tab.1/9.

Tab.1/10:Fault LED for pneumatic interfaces Midi/Maxi, CPA or VTSA pneumatics

The fault indicated by the red fault LED is transmitt

ed by the

pneumatic interface to the field bus node (unless parame

trized otherwise).

1−22

Status LEDs of the valve solenoid coils

The yellow status LEDs on the valve solenoid coils indicate

the status of the relevant output (see appropriate pneumatics

manual).

Festo P.BE−CPX−EA−E N en 05602d

1. Pneumatic interfaces

1.6.3Fault treatment and parametrizing

Midi/Maxi, CPA or

VTSA pneumatics

The following diagram shows the fault treatment of the pneu

matic interface for Midi/Maxi, CPA or VTSA

pneumatics.

Further registering and display of the faults can be sup

pressed as desired with the appropriate module parameters,

represented in th

e diagram as switches. The parameters are

described in section 1.5.

Fault message to

field bus node

Monitoring

01 01 01 01

V

VAL

Fault no. 5

Fault in load

voltage for

valves

Fault no. 11

Fault short

circuit at valve,

channel 0

Module

fault LED

Monitoring

SCV

Fault no. 11

...

Fault short

circuit at valve,

channel x

Monitoring

Wire fracture

Channel 0

Fault no. 13

Fault wire

fracture,

channel 0

...

...

Fault no. 13

Fault wire

fracture,

channel x

1

Monitoring

Wire fracture

channel x

2

3

1 Module parameters (switch position represented = default setting)

2 Module−specific fault

3 Channel−specific faults (fault no. 13 only with CPA or VTSA pneumatics)

Fig.1/6:Principle of fault treatment and parametrizing of the

Midi/Maxi, CPA or VTSA pneumatics

Festo P.BE−CPX−EA−EN en 05602d

pneumatic interface for

1−23

1. Pneumatic interfaces

1−24

Festo P.BE−CPX−EA−E N en 05602d

MPA pneumatic modules

Chapter 2

Electronik modules

type

VMPA1−FB−EMG−8

VMPA1−FB−EMS−8

VMPA2−FB−EMG−4

VMPA2−FB−EMS−4

2−1Festo P.BE−CPX−EA−EN en 05602d

2. MPA pneumatic modules

Contents

2. MPA pneumatic modules 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Function

2.1.1 Display and connecting elements2−6 . .

2.2 Fitting 2−7 . . . . . . . . . . . . . . . . . . . . .

2.3 Installation 2−11 . . . . . . . . .

2.4 Instructions on

2.5 Diagnosis 2−18 . . . . . . .

2.5.1 Error messages

2.5.2 LED display 2−19 . . . . . . . . . . . . . . . . . . .

2.5.3 Error treatment and parametrizing 2−22 . . . . . . . . . . . .

of the MPA pneumatic modules 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

commissioning 2−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the MPA pneumatic modules 2−18 . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

2−2

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

Contents of this chapterThis chapter describes the MPA pneumatic modules for CPX

terminals.

In a CPX terminal the MPA pneumatic modules provide d

outputs for the valves fitted (valve solenoid coils) and are

adapted to the specific application by means of different

valve plates.

You should

read this chapter if your CPX terminal is fitted with

MPA pneumatics.

Further information Information on fitting the complete CPX terminal, connec

the power supply as well as general instructions on configur

ation and parametrizing can be found in the CPX system man

ual.

Informatio

n on the pneumatics of the CPX terminal, especially

on the available valve plates, can be found in the appropriate

pneumatics manual.

Information on

the address assignment as well as on commis

sioning can be found in the appropriate field bus node man

ual or function module manual.

igital

ting

Festo P.BE−CPX−EA−EN en 05602d

2−3

2. MPA pneumatic modules

2.1 Function of the MPA pneumatic modules

In the CPX terminal the MPA pneumatic modules provide

digital outputs for controlling the valves and thus enable

pneumatic actuators to be controlle

From the technical point of view, the individual MPA pneu

matic modules each represent an electric module with digital

outputs.

d.

Maximum 8 MPA pneumatic mo

CPX terminal. Up to 64 valve solenoid coils (exclusively

MPA1) or 32 valve solenoid coils (exclusively MPA2) are

efore possible.

ther

MPA pneumatic

Type designation Description

modules

VMPA1−FB−EM..−8

VMPA1−FB−AP−4−1

VMPA1−M1H−...

VMPA1−RP

VMPA2−FB−EM..−4

VMPA2−FB−AP−2−1

VMPA2−M1H−...

VMPA2−RP

Tab.2/1:MPA pneumatic modules

dules are permitted for each

MPA1 pneumatic module:

Output module with MPA pneumatics, consisting of:

electronic module with 8 outputs (valve solenoid

coils)

sub−base for 4 valve plates,

valve plates (or corresponding pneumatic compo

nents) or

cover plates for reserve locations.

MPA2 pneumatic module:

Output module with MPA pneumatics, consisting of:

electronic module with 4 outputs (valve solenoid

coils)

sub−base for 2 valve plates,

valve plates (or corresponding pneumatic compo

nents) or

cover plates for reserve locations.

2−4

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

1 Val ve plates or

blanking plates

2 Electronic module

3 Sub−base

Fig.2/1: Components of the MPA pneumatic modules (example MPA1)

The electrical function of an MPA pneumatic module is deter

mined by the electronic

between the following types of MPA electronic modules:

module used. A distinction is made

1

2

3

Festo P.BE−CPX−EA−EN en 05602d

Type

VMPA1−FB−EMG−8 Electronic module with

VMPA1−FB−EMS−8 Electronic module with 8 out

VMPA2−FB−EMG−4 Electronic module with

VMPA2−FB−EMS−4 Electronic module with 4 out

Description

8 outputs (valve solenoid

coils), with electrical isolation

puts (valve solenoid coils),

without electrical isolation

4 outputs (valve solenoid

coils), with electrical isolation

puts (valve solenoid coils),

without electrical isolation

Tab.2/2: Overview of MPA electronic modules

2−5

2. MPA pneumatic modules

2.1.1 Display and connecting elements

The MPA pneumatic modules have the following display and

connecting elements:

1 LEDs:

outputs (yellow)

error (red)

2 Connecting plug to

further MPA

pneumatic modules

5

12

1357

0246

3 Manual override

4 Label supports with

inscription field

5 Connecting plug to

the CPX pneumatic

interface or to further

MPA pneumatic

modules

Fig.2/2: Display and connecting elements (example: MPA1)

Use sign supports type VMPA1−ST−1−4 for identification of the

MPA pneumatic modules.

3

4

2−6

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

2.2 Fitting

Warning

Sudden unexpected movement of the connected actuators

and uncontrolled movements of loose tubing can cause

injury to human beings or damage to property.

Befo

re carrying out installation and maintenance work,

switch off the following:

the compressed air supply

the operating and load voltage supplies.

The CPX te

rminal must first be dismantled before it can be

extended or converted, or when a pneumatic interface must

be replaced. Instructions o

n this can be found in the CPX sys

tem manual.

Instructions on extending or converting the MPA pneumatic

modules can be found in the appropriate

pneumatics manual.

Electronic modules or valve plates can be replaced on the

fitted CPX terminal.

Caution

Modules may be damaged if they are not handled

correctly.

· Do not therefore touch the contacts of the components.

· Observe the regulations for handling electrostatically

sensitive components.

· Discharge yourself electrostatically before fitting or re

moving components in order to protect the components

against discharges of static electricity.

Festo P.BE−CPX−EA−EN en 05602d

2−7

2. MPA pneumatic modules

Please note

Handle all modules and components of the CPX terminal

with great care. Please note especially the following:

· Screws must be fitted accurately (otherwise threads will

be damaged).

Screws must be fastened at first only by hand. Place the

screw

s so that the self−cutting threads are used.

· The specified torques must be observed.

· Screw connections must be fitted free of offset and

mechanical tension.

· Check the seals for damage (IP65).

· Connecting surfaces must be clean (sealing effect, avoid

leakage and contact faults).

Dismantling the electronic module

1. Use a screwdriver with a narrow blade to loosen the

fastening screws of all valve or blanking plates and re

move the plates from the

sub−bases.

2−8

2. Loosen the screws with which the electronic module is

fastened to the sub−base.

3. Pull the electronic module upwards out of the body of the

sub−base.

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

1 Fastening screws of

the valve plate or

blanking plate

1

2 Val ve plates or

blanking plates

3 Flat seals

9

8

4 Electronic module

5 Sub−base

6 Inscription label

holder

7

7 Sealing lip of the

electronic module

8 Fastening screws of

the electronic module

9 2 conical ring seals

per valve plate or

blanking plate

Fig.2/3: Dismantling and fitting the electronic module (example MPA1)

2

3

4

5

6

Festo P.BE−CPX−EA−EN en 05602d

2−9

2. MPA pneumatic modules

Sealing lip of the electronic module

Caution

Replace an electronic module only by an electronic module

of the same type (see section 2.3).

Please note

Before fitting, check the condition and position of the

following seals:

the sealing lip of the electronic module

the ring seal of the electrical contacts

the cord

1. Place the electronic module in the sub−base.

2. Tighten the screws of the electronic module with

0.2...0.25Nm.

seal of the valve plates or blanking plates.

2−10

n fit the valve plates or blanking plates. Check the

3. The

seals of the valve or blanking plates for damage. Replace

seals if they are damaged.

4. Make

sure that the seals are seated correctly.

The cord seal between the sub−base and the component

must be seated in the recess in the component. Th

seals between the electronic module and the component

are conical. The ring seals must be fitted on the guide pins

of the components so that

the cone slides easily into the

appropriate recess in the electronic module (see Fig.2/3).

5. Place the components on the sub−base.

6. Screw the components

at first only slightly and then

tighten with 0.2 Nm. 0.25 Nm.

Festo P.BE−CPX−EA−E N en 05602d

e ring

2. MPA pneumatic modules

2.3 Installation

Instructions on installing the pneumatic components can be

found in the pneumatics manual type P.BE−MPA−... .

Instructions on installing the electric components can be

found in the CPX system manual.

Instructions on addressing the valve solenoid coils as well as

further instructions on installing the

electric components can

be found in the relevant field bus node manual.

Power supply

The 24 V supply for the valves is provided via the load voltage

for the valves of the CPX terminal (V

The power supply for the electronic modules is provided via

the operating voltage supply for the electronics/sensors

EL/SEN

).

(V

VAL

).

Festo P.BE−CPX−EA−EN en 05602d

Caution

Damage to components and functional damage

It is not permitted to supply voltage to MPA pneumatic

modules with electronic modules without

electrical isola

tion via a manifold sub−base type CPX−GE−EV−V.

· If your MPA pneumatics are fitted with electronic mod

ules type VMPA1−FB−EMS−8 or VMPA2−FB−EMS−4, you

must supply the MPA pneumatics only by means of the

system supply module type CPX−G E−EV−S.

2−11

2. MPA pneumatic modules

Note that MPA electronic modules may only be supplied with

power via the following supply modules:

MPA electronic

Permitted supply modules (type)

module

VMPA1−FB−EMS−8

VMPA2−FB−EMS−4

(in each case without

electrical isolation)

VMPA1−FB−EMG−8

VMPA2−FB−EMG−4

(in each case with

electrical isolation)

1)

The electrical isolation does not function if the system supply is

used.

System supply (CPX−GE−EV−S)

Va lve supply module (CPX−GE−EV−V)

or

System supply module (CPX−GE−EV−S)

1)

In the cae of electronic modules with electrical isolation type

VMPA1−FB−EMG−8 or VMPA2−FB−EMG−4, V

EL/SEN

and V

VAL

are

completely electrically isolated. In conjunction with a mani

fold sub−base with valve supply type CPX−GE−EV−V, it is there

fore possible to switch

off the valve supply voltage at all

poles.

2−12

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

12345 6

7

8

9

0 V

24 V

0 V

24 V

0 V

24 V

FE

VAL

VAL

OUT

OUT

EL/SEN

EL/SEN

0 V

24 V

VAL

VAL

aJ

12 34

24V0V FE24V

Manifold sub−base with system supply

1

2 Manifold sub−base without supply

3 Manifold sub−base with valve supply

4 MPA pneumatic interface

5 MPA pneumatic module with electrical

isolation

Only useful with separate load supply

via manifold sub−base with valve

supply

Fig.2/4: Diagram of voltage supply of MPA pneumatic modules

n.c.

1

2 34

0V FE24V

6 MPA pneumatic module without

electrical isolation

Not permitted with load supply via

manifold sub−base with valve supply

7 Load voltage for valves (V

8 Load voltage for digital outputs (V

9 Operating voltage for electronics and

sensors (V

EL/SEN

aJ 5 further rails

)

VAL

)

OUT

)

Festo P.BE−CPX−EA−EN en 05602d

Protection class

When completely fitted, the MPA pneumatic modules comply

with protection class IP65 (see appendix A.1).

2−13

2. MPA pneumatic modules

Address assignment within the pneumatic modules

An MPA1 pneumatic module always occupies 8 output

addresses, an MPA2 pneumatic modul always occupies

4output addresses.

Each valve location occupies 2 addresses, irrespecti

ve of

whether a valve plate or blanking plate is fitted.

The following assignment applies:

solenoid coil 14 occupies the lower−value address,

solenoid coil 12 occ

upies the higher−value address.

12

12

14

12 14 12 14 14 12 14 12 14

Oy+1

Oy+0

Ox+1

Ox+0

Ox+3

Ox+2

Ox+5

Ox+4

Ox+7

Ox+6

Oy+3

Oy+2

3

4

3

4

6

7

5

5 Val ve plates with two solenoid coils

6 Val ve plates with one solenoid coil

(addresses Ox+5 unused)

MPA1 pneumatic module

1

2 MPA2 pneumatic module

534

3 Addresses of coil 14 (channel 0, 2, 4, 6)

7 Blanking plate

4 Addresses of coil 12 (channel 1, 3, 5, 7)

Fig.2/5:Example: Address assignment of MPA pneumatic modules (viewed from above)

2−14

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

2.4 Instructions on commissioning

The reaction of the MPA pneumatic modules can be parame

trized. The table below gives an overview of the parameters

for the MPA pneumatic

modules.

Further information on parametrizing can be found in the

system manual or in the manual for the field bus node.

Parameters for the MPA pneumatic modules with

electronic module type VMPA..−FB−EM..−...

Module parameters: Monitoring the CPX module

Function no. 4828 + m * 64 + 0m = module number (0 ... 47)

Description Monitoring of the possible faults can be activated or deactivated (suppressed)

Val ues 1 = active (presetting)

Remark Monitoring can also be set for the complete CPX terminal

for each module independently. Active monitoring causes the following:

The fault is:

sent to the CPX field bus node

displayed on the error LEDs

Monitoring

Bit

Description

2

Undervoltage of valves (V

0 = inactive

(see CPX system manual).

VAL

)

[Monitor]

[Monitor Vval]

[Active]

[Inactive]

Tab.2/3: Monitoring the CPX module

Festo P.BE−CPX−EA−EN en 05602d

2−15

2. MPA pneumatic modules

Module parameters: Fail safe channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Fault mode channel x: Hold last state

Remark With the aid of the so−called Fail safe parametrizing, you can specify the signal

(seethe manual for the field bus node).

Fault state (presetting)

Fault state channel x: Set output

Reset output (presetting)

status which the outputs are to assume in the event of field bus communication

faults (see also CPX system manual).

Tab.2/4: Fail Safe channel x (channel−specific)

Module parameters: Idle mode channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Only relevant for certain field bus protocols.

Remark With the aid of the so−called Idle mode parametrizing, you can determine the

(seethe manual for the field bus node).

Idle mode channel x: Hold last state

Idle state (presetting)

Idle state channel x: Set output

Reset output (presetting)

signal status which the outputs are to assume when switching is made to the

Idlestate (see also CPX system manual).

This parameter is not available with all field bus protocols.

Tab.2/5: Idle mode channel x (channel−specific)

2−16

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

Module parameters: Force channel x

Function no. Access to these module parameters is made via protocol−specific functions

Description Force mode of outputs chanel x: Blocked (presetting)

Remark The Force function enables the manipulation of signal states detached from

(seethe manual for the field bus node).

Force state

Force state of outputs channel x: Set signal

Reset signal (presetting)

actual operating states (see also CPX system manual).

Tab.2/6:Force channel x (channel−specific)

Festo P.BE−CPX−EA−EN en 05602d

2−17

2. MPA pneumatic modules

2.5 Diagnosis

Specific faults of the MPA pneumatic modules are registered

or suppressed depending on the module parametrizing.

The faults are shown on−the−sp

ot by means of the Error LED

and, if necessary, can be evaluated with the handheld.

Depending on the module parametrizing, the faults are sent

t

o the field bus node, where they can be evaluated according

to the field bus protocol used.

2.5.1 Error messages of the MPA pneumatic modules

An MPA pneumatic module can register the following

standard faults:

Fault number

5 Fault in load voltage for valves

1)

Tolerance range of the load voltage supply V

Tab.2/7: Error messages of the MPA pneumatic modules

Description Fault treatment

Load voltage for valves (V

or too low.

1)

) missing

VAL

see Technical specifications" in the appendix.

VAL

· Check the load voltage

Please note

The fault Load voltage for valves" is registered for the

complete module as module fault with channel number 1.

2−18

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

2.5.2 LED display

For diagnosing the MPA pneumatic modules there is a

two−colour LED for each channel on the electronic modules.

1 LED of the valve

solenoid coils 12

(here channel 1)

1 23

2 LED of the valve

solenoid coils 14

(here channel 0)

3 Addresses and LED

assignment of the

valve solenoid

coils12

4 Addresses and LED

assignment of the

valve solenoid

coils14

Fig.2/6: LED display of the MPA1 pneumatic modules

1357

0246

121412141214121

1357

4

0246

4

3

4

Festo P.BE−CPX−EA−EN en 05602d

2−19

2. MPA pneumatic modules

1 LED of the valve

solenoid coils 12

(here channel 1)

1 23

2 LED of the valve

solenoid coils 14

(here channel 0)

3 Addresses and LED

assignment of the

valve solenoid coils12

4 Addresses and LED

assignment of the

valve solenoid coils14

Fig.2/7: LED display of the MPA2 pneumatic modules

13

02

12 14 12

1032

14

4

3

4

3

4

2−20

Festo P.BE−CPX−EA−E N en 05602d

2. MPA pneumatic modules

Status and error LEDs

The yellow LEDs indicate the status of the relevant output

(see also appropriate pneumatics manual).

The red LEDs indicate the faults of the MPA pneu

module depending on the parametrizing.

If the module fault Load voltage for valves missing or too

low", all LEDs will light up red.

LED

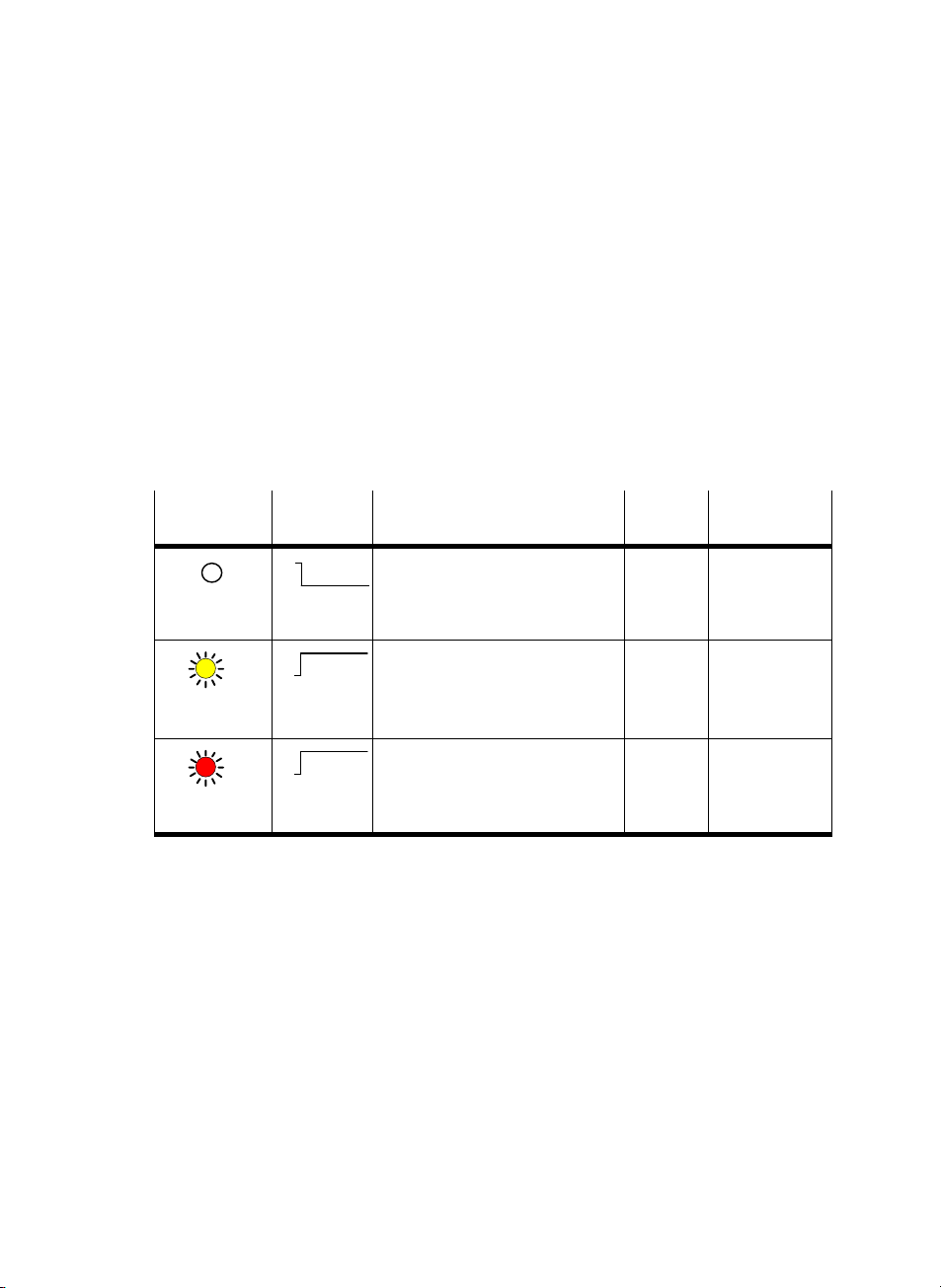

Sequence Status Fault

(yellow/red)

ON

OFF

LED is out

ON

OFF

LED lights up

yellow

ON

OFF

LED lights up

red

Faultless operation

Status of assigned channel logical 0

(output supplies 0−signal)

Faultless operation

Status of assigned channel logical 1

(output supplies 1−signal)

Fault in load voltage for valves

Load voltage for valves (V

missing or too low.

Tab.2/8: LEDs of the MPA pneumatic module

The fault indicated by red LEDs is transferred to the field bus

node by the MPA pneumatic module

otherwise).

VAL

matic

Fault

number

None

None

5 See section

)

treatment

2.5.1, Tab.2/7

(unless parametrized

Festo P.BE−CPX−EA−EN en 05602d

2−21

2. MPA pneumatic modules

2.5.3 Error treatment and parametrizing

The following diagram shows the error treatment for the MPA

pneumatic modules. Further registering and display of the

fault can be suppressed as desire

module parameter, represented in the diagram as a switch. A

description of the parameter can be found in section 2.4.

d with the appropriate

Fault message to

field bus node

01

Fault no. 5

Fault in load

voltage for

valves

Error LEDs

Monitoring

V

VAL

1 Module parameters

(switch position represented = default setting)

2 Module−specific faults

Fig.2/8:Principle of error treatment and parametrizing in

the MPA pneumatic module

1

2

2−22

Festo P.BE−CPX−EA−E N en 05602d

Overview and connecting technology I/O modules

Chapter 3

Type

CPX−AB−4−M12x2−5POL

CPX−AB−4−M12x2−5POL−R

CPX−AB−8−M8−3POL

CPX−AB−8−M8−4POL

CPX−AB−8−KL−4POL

CPX−AB−1−SUB−BU−25POL

CPX−AB−4−HARX2−4POL

CPX−AB−4−M12−8POL

3−1Festo P.BE−CPX−EA−EN en 05602d

3. Overview and connecting technology I/O modules

Contents

3. Overview and connecting technology I/O modules 3−1 . . . . . . . . . . . . . . . . . . .

3.1 Components of an I/O module 3−3 . . . .

3.2 Connections 3−4 . . . . . . . . . . . . .

3.2.1 Display and connecting elements 3−7 . .

3.2.2 Combinations of I/O modules and sub−bases 3−8 . . . . . . . . . . .

3.2.3 Connecting the cables and plugs to the sub−bases 3−10 . . . . . . . . . . . . .

3.3Fitting 3−20 . . . . . . . .

3.3.1 F

3.3.2 Fitting the

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

itting the sub−bases 3−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

screening/shield plates 3−24 . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

3−2

Festo P.BE−CPX−EA−E N en 05602d

3. Overview and connecting technology I/O modules

3.1 Components of an I/O module

All I/O modules consist of three parts:

The sub−base provides the electrical connections in the

form of different sockets or terminal strips.

1 Sub−base with

specific

connections

2 Electronic

module

3 Manifold

sub−base

The electronic

with the electronics and the LED display of the I/O mod

ule. The electronic module is fitted into the sub−b

is connected to this and to the manifold sub−base by

means of electric plug connectors.

The manifold sub−base as the lower part of the housing

provides

module and the valve terminal.

module contains the printed circuit board

ase and

the mechanical and electrical link between the

1

2

3

Fig.3/1: Components of an I/O module

Festo P.BE−CPX−EA−EN en 05602d

3−3

3. Overview and connecting technology I/O modules

3.2 Connections

Individual connection requirements can be fulfilled with

different sub−bases. These sub−bases provide the required

sockets or terminal strips for connect

actuators, irrespective of the I/O module used.

ing the sensors and

Sub−base

Type Description

CPX−AB−4−M12x2−5POL 4 M12 sockets, 5−pin

Protection class IP65/IP67

One functional earth connection per

socket

Screening/shielding possibility via