Page 1

Motor controller

SFC−DC

Manual

Function block S7

for motor controller

type SFC−DC

Manual

700 332

en 0604NH

Page 2

Page 3

Contents and general instructions

Original de. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edition en 0604NH. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Designation P.BE−SFC−DC−PB−S7−EN. . . . . . . . . . . . . . . . . . .

Order no. 700 332. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

© (Festo AG&Co. KG, D73726 Esslingen, 2006)

Internet: http://www.festo.com

E−Mail: service_international@festo.com

The reproduction, distribution and utilization of this docu

ment as well as the communicaton of its

contents to others

without express authorization is prohibited. Offenders will

be held liable for the payment of damages. All rights reser

ved in the event of the grant of a patent, utility module or

design.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

I

Page 4

Contents and general instructions

PROFIBUS

SIMATIC

®

®

is a registered trade name of PROFIBUS International (P.I.)

is a registered trade name of Siemens AG

II

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 5

Contents and general instructions

Contents

Designated use VII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic principles of programmed software VIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety instructions IX .

Target group X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important user instructions XI . . . . . . . . . . . . . . . . . . . . . . .

Manuals on motor controller type SFC−DC XIII . . . . . . . . . . . . . . . . . . . . .

Information on the versions XV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product−specific terms and abbreviations XVI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS−specific terms and abbreviations XVIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. .

1. Overview 1−1 . . . . . . . . . . .

1.1 General description 1−3 . . . . .

1.2 The blocks at a glance 1−4 . . . . . .

1.3 Festo Profile for Handling and Positioning (FHPP) 1−5 . . . . . .

2. Installation and overview of the projects 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Configuration 2−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Install device

2.1.2 I/O configuration 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Configuration with STEP 7 2−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Dearchivating

2.3 Overview of project 2−12 . . . . . . . . . . . .

2.3.1 Folder _CTRL" control functions 2−12 . . . . . . . . . . . .

2.3.2 Folder _PRM_FPC" parametrizing via FPC 2−13 . . . . . . . . . . . . . . . . . .

2.3.3 Folder PRM_DPV1_SFB" parametrizing via DPV1 2−14 . . . . . . .

2.3.4 Folder PRM_DPV1_SFC" parametrizing via DPV1 2−15 . . . . . . . . . . . .

2.3.5 Folder PRM_UP−DOWNLOAD" transmitting several

the example project 2−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

parameters 2−16 . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

master file (GSD file) and icon files 2−3 . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

III

Page 6

Contents and general instructions

3. Control block 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Function block SFC_DC_CTRL" 3−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Description of method of operation 3−4 . . . . . .

3.1.2 Input parameters 3−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

3.1.3 Output parameters 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Fault information 3−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Parametrizing blocks 4−1 . . . . . . .

4.1 Overview of parametrizing blocks 4−3 . . . . . . . . . .

4.1.1 Control and parametrizing methods 4−4 . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. .

4.1.2 Method of operation of the modules 4−4 . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Converting the measuring units 4−5 . . . . . . . . . . . . . .

4.2 Block PRM_FPC 4−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Input parameters 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . .

4.2.2 Output parameter 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Blocks PRM_DPV1_SFB / PRM_DPV1_SFC 4−8 .

4.3.1 Input parameters 4−9 . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Output parameters 4−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Block PRM_DB−FILE 4−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . .

. . .

4.4.1 Description of method of operation 4−11 . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Input parameters 4−13 . . . . . . . . . . . . . . . .

4.4.3 Output parameters 4−14 . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Implementation 4−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Restriction 4−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . .

.

4.5 Fault information 4−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Examples 5−1

5.1 Examples with the control block 5−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Enable controller 5−4 . . . . . .

5.1.2 Selecting the operating mode 5−5 . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

5.1.3 Starting a positioning task in direct mode 5−5 . . . . . . . . . . . . . . . . . . . .

5.1.4 Starting a positioning task in Record

5.2 Downloading a parameter list 5−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select mode 5−7 . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 7

Contents and general instructions

A. Technical appendix A−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Festo profile for handling

A.1.1 Supported operating modes A−3 . . . . . . . . . . . . . . . . . . . . . . .

A.2 Drive functions A−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and positioning (FHPP) A−3 . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . .

A.2.1 Reference system for electric drives A−5 . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 Reference travel A−7 . . . . . . . . . . .

A.2.3 Jogging A−9 . . . . . . . . . . . . . . . . . . . .

A.2.4 Teaching via field bus A−11 . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

A.2.5 Carry out record (Record Select) A−13 . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.6 Specifying

A.2.7 Standstill monitoring A−21 . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Fault messages A−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Diagnostic memory A−25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a position directly (Direct mode) A−18 . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . .

A.5 Diagnosis via PROFIBUS−DP A−27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5.1 Structure

B. Supplementary information B−1 . . . . . . . . . . . . . .

B.1 Parameters of the SFC−DC B−3 . . . . . . . . . . . . . . . . . . . . . . .

of the DP diagnosis A−27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

B.1.1 General parameter structure B−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.2 Overview of parameters B−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Index C−1 . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

V

Page 8

Contents and general instructions

VI

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 9

Contents and general instructions

Designated use

The function blocks (FB) described serve for controlling and

parametrizing motor controllers type SFC−DC−...−PB via PROFI

BUS−DP in a SIMATIC−S7 controller with integrated DP master

module (e.g. CPU315−2DP).

With the blocks the many functions of the motor controller

can be comfortably incorporated in the program.

The blocks can be parametrized and are capable of

many

instances. They are linked into the user program for each

motor controller (each axis) from where they can be accessed

cyclically with a separate instance data block or multi−in

stance block. Simultaneous use of other function blocks for

controlling the same controller is not permitted.

The motor controller (Single Field Controller, single

axis field

controller) type SFC−DC−... serves as a position controller and

position servo for the electric mini slide type SLTE−... with

control via the PROFIBUS field bus.

It is absolutely necessary to observe the Safety instructions"

as well as the designated use of the relevant components and

modules listed in the manual for the

SFC−DC. Please observe

also the safety instructions in the operating instructions for

the components used.

If additional commercially−available components such as sen

sors and actuators are connected, the specified limits for

pressures, temperatures, electrical data, torques, etc. must

not be exceeded.

Note also the Siemens specifications regarding the use of

their PLC Simatic S7.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

VII

Page 10

Contents and general instructions

Basic principles of programmed software

Please note that it is not possible with the present state of

technology to create programmed software which functions

without problems and is compatible with all applications and

combinations intended by the user.

As a rule the software must therefore be used in the desig

nated manner as specified in the program description

the user instructions.

At the moment when the software is transferred or made

available, it is in a state in which it will function under normal

operating and application conditions.

Festo does not guarantee that the software will suffice for all

applications and purposes intended by the user, or that it will

function without problems when used with other programs,

or that it is compatible with these programs. The responsibil

ity for the correct selection and the consequences of using

the software within the scope of use defined by the user, as

well as for the intended and achieved results therefore lies

with the user.

plied with the software.

The same applies to the written material sup

and in

VIII

The use of the programmed software does not exempt you as

customer from your duties and responsibility for observing

and adhering to technical machine and safety regulations as

well as for a comprehensive functional check.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 11

Contents and general instructions

Safety instructions

When commissioning and programming positioning systems,

you must observe the safety regulations in this manual as

well as those in the operating instructions for the other

components used.

The user must make sure that nobody is in the operating

range of the connected actuators or axis system. Access to

the possible danger area must

measures such as protective screens and warning signs.

Warning

Electric axes can move suddenly with high force and at

high speed. Collisions can lead to serious injury to human

beings and damage to components.

Make sure that nobody can gain access to the operating

range of the axes or other connected actuators and that no

objects lie in the positioning range while

connected to a power supply.

be prevented by suitable

the system is still

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Warning

Faults in parametrization can cause injury to people and

damage to property.

Enable the controller only if the axis system is correctly

installed and parametrized.

IX

Page 12

Contents and general instructions

Target group

This manual is intended exclusively for technicians trained in

control and automation technology, who have experience in

installing, commissioning, programming and diagnosing

positioning systems and PROFIBUS−DP slaves.

Service

Please consult your local Festo repair service or write to the

following e−mail address if you have any technical problems:

service_international@festo.com

The function blocks described here as well as software com

plementary to the product (e.g. GSD/GSG files) can be be

found on the Festo Internet pages under the address:

www.festo.com [Industrie−Automation/Service & Support/

Download Area/Software].

X

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 13

Contents and general instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which may occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc.), printed on a

shaded background and marked additionally with a picto

gram. A distinction is made between the following danger

warnings:

Warning

This means that failure to observe this instruction may

result in serious personal injury or damage to property.

Caution

This means that failure to observe this instruction may

result in personal injury or damage to property.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Please note

This means that failure to observe this instruction may

result in damage to proper ty.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive compo

nents.

Electrostatically sensitive components may be damaged if

they are not handled correctly.

XI

Page 14

Contents and general instructions

Marking special information

The following pictograms mark passages in the text

containing special information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Information on necessary or sensible accessories for the

Festo product.

Environment:

Information on environment−friendly use of Festo products.

XII

Text markings

· The bullet indicates activities which may be carried out in

any order.

1. Figures denote activities which must be carried out in the

numerical order specified.

Hyphens indicate general activities.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 15

Contents and general instructions

Manuals on motor controller type SFC−DC

This manual contains information on the S7 blocks for motor

controller type SFC−DC−...−PB with PROFIBUS field bus inter

face.

The following manual is also required for understanding the

function blocks:

Manual for motor controller type SFC−DC with PROFIBUS

interface, type P.BE−SFC−DC−PB−...

This manual on the S7 blocks contains all necessary informa

tion for commissioning the

portant extracts from the manual for motor controller type

SFC−DC are also reproduced.

However this does not replace in any way the manual for

motor controller type SFC−DC. The guidelines and safety re

gulations listed therein must be observed at all costs in order

to guarantee correct

section Designated use".

blocks. In addition, the most im

and reliable functioning. Note also the

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

Information on components, such as the electric slide type

SLTE−... or the reference switch can be found in the operating

instructions supplied with the relevant product.

Siemens

When reference is made in this manual to documents from

Siemens, this always means the Step 7 version 5.3 (service

pack 1). Other versions of Step 7 may differ from that de

scribed in this manual.

XIII

Page 16

Contents and general instructions

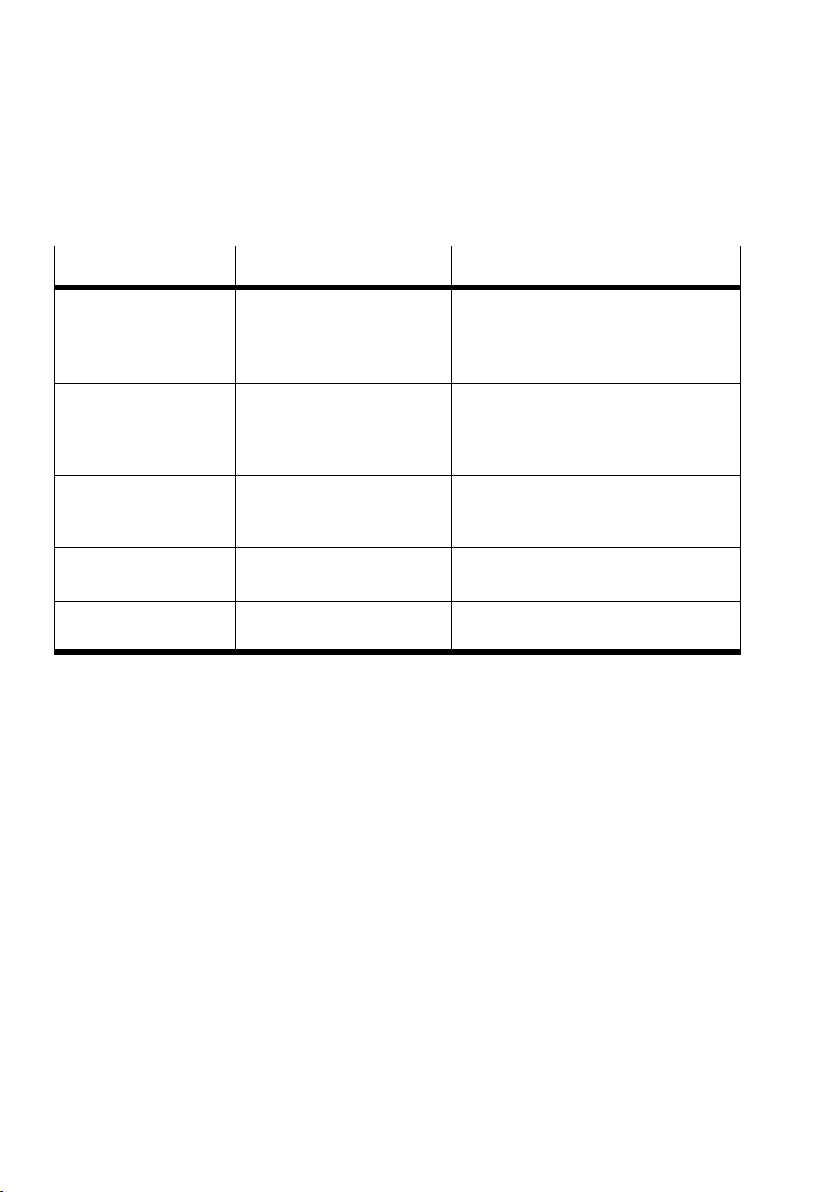

Overview of documentation on the SFC−DC

Design Designation Contents

Docu package with brief

description + manuals

on CD ROM

Manual Motor controller type SFC−DC

Help system for

software

Operating instructions Mini slide

Manual for S7 block S7 block for the SFC−DC

P.BE−SFC−DC−UDOK Brief description: Important instructions

with PROFIBUS interface

P.BE−SFC−DC−PB−...

Festo Configuration Tool help

(contained in FCT software)

type SLTE−...

P.BE−SFC−DC−PB−S7−...

Tab.0/1: Documentation on the SFC−DC

on commissioning and preliminary

information.

Manuals: Contents as described below.

Installation, commissioning and

diagnosis of electric axes with motor

controller type SFC−DC with

communication via PROFIBUS.

Function description of the Festo

Configuration Tool configuration

software.

Fitting and commissioning the electric

mini slide as a drive element.

Using the S7 block for motor controller

type SFC−DC with PROFIBUS interface.

XIV

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

Page 17

Contents and general instructions

Information on the versions

The function blocks for the SFC−DC require the following ver

sions:

motor controller type SFC−DC−...−PB with firmware version

GSD/GSG file as from revised version 14.12.2005

The firmware version specifies the version status of the

operating system of the SFC−DC.

You can find the specifications on the version status as

follows:

as from V1.10

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

in the

Festo Configuration Tool with active device

connection to the SFC−DC under Device data"

on the control panel under [Diagnostic] [Software

information].

XV

Page 18

Contents and general instructions

Product−specific terms and abbreviations

The following product−specific terms and abbreviations are

used in this manual:

Field bus specific abbreviations see following Tab.0/3.

Term/abbreviation

0−signal 0 V present at input or output (positive logic, corresponds to LOW).

1−signal 24 V present at input or output (positive logic, corresponds to HIGH).

Axis Complete actuator, consisting of motor, encoder and drive, optional with

Axis zero point (AZ) Measuring basis point for the project zero point and the software end

Controller Control electronics which evaluate the control signals and provide the

Drive Mechanical component of an axis which transfers the drive power for the

Encoder With the SLTE: magnetic pulse generator (rotor position transducer).

E

O

I/O

Festo Handling und

Positioning Profile (FHPP)

Meaning

gear, if applicable with controller.

positions. The basis point for the axis zero point is the reference point.

power supply for the motor via the power electronics

(power electronics + controller + position controller).

movement, defines the guide for the positioning movement, and enables

the work load and the reference switch to be fitted.

The electric mini slide type SLTE is an integrated unit consisting of a

motor, encoder, gear unit and drive.

The electric signals generated are sent to the controller, which then

calculates the position and speed on the basis of the signals received.

Input

Output

Input and/or output

Uniform field bus data profile for positioning controllers from Festo.

Festo Parameter Channel

(FPC)

Jog mode Manual positioning in positive or negative direction (only on field bus

XVI

FHPP−specific PKW design

(see PROFIBUS−specific terms and abbreviations", Tab.0/3).

variants of the SFC−DC via the field bus or only with FCT or control panel).

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 19

Contents and general instructions

Term/abbreviation Meaning

Operating mode Type of controller or internal operating mode of the controller.

PLC Programmable logic controller; in brief: controller

Positioning mode

(Profile position mode)

Position set Positioning command defined in the position set table, consisting of

Project zero point (PZ) Measuring reference point for all positions in positioning tasks (Project

Reference point (REF) Basis point for the incremental measuring system. The reference point

Reference switch External sensor (e.g. type SMT−10) which serves for ascer taining the

Reference travel The reference position and therefore the source of the measuring

Referencing

(Homing mode)

Type of control: Record Select, Direct mode

Operating mode of the controller: Position profile mode,

Homing mode, Demo mode, ...

(also IPC: industrial PC).

Operating mode for processing a position set or a direct positioning

task.

target position, positioning mode, positioning speed and accelerations.

zero point). The project zero point forms the basis for all absolute posi

tion specifications (e.g. in the position set table or with direct control via

the controller interface or diagnostic interface). The basis point for the

project zero point is the axis zero point.

defines a known orientation or position within the positioning path of

the drive.

reference position and is connected directly to the controller.

reference system of the axis will be defined by the reference travel.

Operating mode in which reference travel is carried out.

Referencing method Method for defining the reference position: against a fixed stop

(overcurrent/speed evaluation) or with reference switch.

SLTE... Type designation, electric slide.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

XVII

Page 20

Contents and general instructions

Term/abbreviation Meaning

Software end position Programmable stroke limitation (basis point = axis zero point)

Teach mode Operating mode for setting positions by moving to the target position

Software end position, positive:

max. limit position in positive direction (away from the motor);

must not be exceeded during positioning.

Software end position, negative:

min. limit position in negative direction (towards the motor);

must not be exceeded during positioning.

e.g. when creating position sets.

Tab.0/2: Index of terms and abbreviations for the SFC−DC

PROFIBUS−specific terms and abbreviations

Term/abbreviation Meaning

0x1234 or 1234h Hexadecimal numbers are marked by a prefixed 0x" or by a suffixed

AK See under response identifier or task identifier

BCD Binary coded decimal

Consistency A data range, which is defined as consistent, is transmitted complete,

GSD file Device master file in which all specific features of the slave are saved

h".

i.e. in a bus cycle.

(e.g. number of I/Os, number of diagnostic bytes etc.).

LSB Least significant bit (lower−value bit)

MSB Most significant bit (higher−value bit)

Octet Byte (8 bits); basis type for PROFIBUS telegrams

Parameter channel (PKW) Telegram part used for transmitting parameters (PKW = parameter

Parameter identifier (PKE) Integral part of the parameter channel (PKW) which contains the task

XVIII

identifier value) See also Festo Parameter Channel (FPC)" under

Product−specific abbreviations" (Tab.0/2).

and reply identifiers (AK) and the parameter number (PNU).

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 21

Contents and general instructions

Term/abbreviation Meaning

Parameter number (PNU) Parameters which can be transmitted via the parameter channel are

PKE See under parameter identifier

PKW See under parameter channel

PNU See under parameter number

Reply telegram Telegram sent from the slave to the master (slave reply)

Response identifier (AK) Integral part of the parameter channel in reply telegrams specifying

PROFIBUS PROcess FIeld BUS; German processing and field bus standard defined

PROFIBUS address Serves for clear identification of a bus slave on the PROFIBUS

Subindex (IND) Integral part of the parameter channel (PKW) which addresses an

Task identifier (AK) Integral part of the parameter channel in task telegrams specifying the

Task telegram Telegram sent from the master to the slave (task of master)

Terminating resistor Resistor for minimizing signal reflections. Terminating resistors must be

Work data Telegram data without protocol frame data The length of the work

addressed with the parameter number (PNU). The parameter number

is an integral part of the parameter identifier (PKE) and serves for

identifying or addressing the individual parameter.

the type of reply of a parameter processing.

in IEC 61158 type 3.

element of an array parameter (sub−parameter number)

type of task of a parameter processing.

installed or switched in at the end of bus segment cables.

data is defined in the configuration of the field bus slave.

Tab.0/3: Index of terms and abbreviations for PROFIBUS

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

XIX

Page 22

Contents and general instructions

XX

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 23

Overview

Chapter 1

1−1Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 24

1. Overview

Contents

1. Overview 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 General description 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 The blocks at a glance 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Festo Profile

for Handling and Positioning (FHPP) 1−5 . . . . . . . . . . . . . . . . . . . . .

.

1−2

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 25

1. Overview

1.1 General description

In order to facilitate commissioning of the motor controller

type SFC−DC, Festo has made available a SIMATIC STEP 7

Project. The STEP 7 Project contains function and data blocks

for controlling motor controller type SFC−DC via PROFIBUS−DP

with a SIMATIC−S7 controller.

The blocks for the SFC−DC will support you in programming

the PROFIBUS communication

SIMATIC S7 and motor controller type SFC−DC.

The blocks are available with full access rights. This offers

the possibility of adapting the blocks individually to the

project. However no guarantee can be given that open blocks

will function.

between the Siemens PLC

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

1−3

Page 26

1. Overview

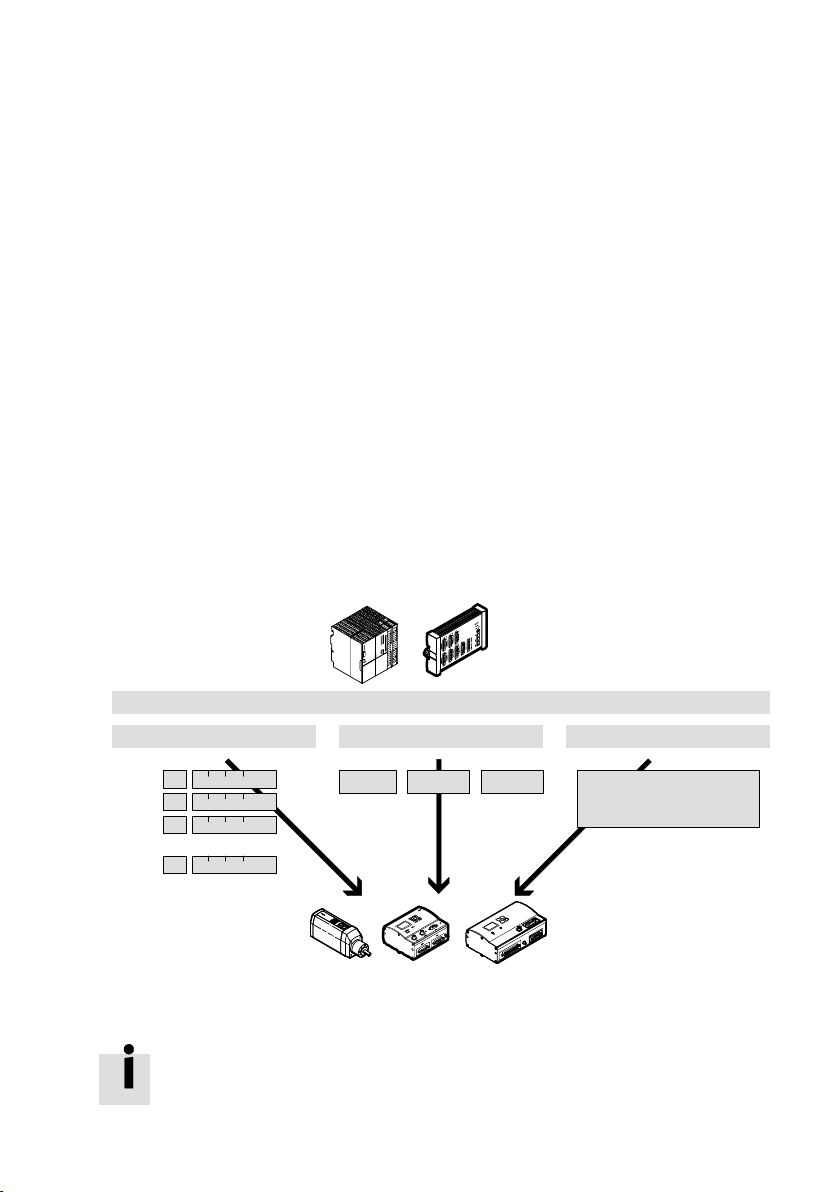

1.2 The blocks at a glance

With the blocks you can incorporate the functions of the

SFC−DC directly in your programs. Normally you would

require three blocks for the various functions.

The blocks have been purposely split into groups, so that you

can decide yourself which functions you require for your ap

plication. In this way, e.g. parametrizing functions

implemented in a separate project.

The example project contains the following special blocks:

SFC_DC_CTRL (example project: FB10)

PRM_FPC (example project: FB20)

PRM_DPV1_SFB (example project: FB21)

PRM_DPV1_SFC (example project: FB22)

can be

1−4

PRM_DB−FILE (example project: FB23)

A complete overview of the contents of the example project

can be found in chapter 2.3.

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

Page 27

1. Overview

1.3 Festo Profile for Handling and Positioning (FHPP)

Festo has developed an optimized data profile especially

tailored to the target applications for handling and position

ing tasks, the Festo Handling and Positioning Profile

(FHPP)".

The FHPP enables uniform control and programming for the

various field bus systems and controllers from Festo.

In addition it defines the following for the user:

the operating modes

the I/O data structure

the parameter objects

the sequence control.

. . .

Record Select

1

>

2

3

...

n

Fig.1/1: The FHPP principle

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

Field bus communication

Direct mode Parameter channel

Mode PositionSpeed

Free acces to all

parameters

reading and writing

. . .

Detailed information on the FHPP can be found in

appendixA.1.

1−5

Page 28

1. Overview

Control and status bytes

Control via the field bus is made via 8 bits of I/O data.

Functions and status messages required in operation can be

conntrolled directly mostly with single−bit operations.

Record Select

Saved position sets can be processed in the Record Select

mode.

For this purpose, up to 31 position sets

are parametrized with

the Festo Configuration Tool or taught via the control panel

during commissioning.

Direct mode

In the Direct operating mode the important positioning data

are transferred directly via the control bytes.

1−6

Target positions and speeds can be ascertained and

specified by the controller during running time, depend

ing on the operating status.

limitations due to the number of saved position sets.

No

In both operating modes values can be taught/parametrized

via the PLC.

Parameter channel

By means of the parameter channel, the controller can access

all parameter values of the controller via the field bus.

A further 8 bytes of I/O data are used for this

Festo P.BE−SFC−DC−PB−S7−E N en 0604NH

purpose.

Page 29

Installation and project overwiev

Chapter 2

2−1Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 30

2. Installation and project overwiev

Contents

2. Installation and project overview 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Configuration 2−3 . . . . . . . . . . . .

2.1.1 Install device master file (GSD file) and icon files 2−3 . . .

2.1.2 I/O configuration 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Configuration with STEP 7 2−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Dearchivating the example project 2−10 . . . . . . .

2.3 Overview of project 2−12 . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Folder _CTRL" control functions 2−12 . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Folder _PRM_FPC" parametrizing via FPC 2−13 . . . . . . . . . . . . . . . . . .

2.3.3 Folder PRM_DPV1_SFB" parametrizing via DPV1 2−14 . . . . . . . . . . . .

2.3.4 Folder PRM_DPV1_SFC" parametrizing via

2.3.5 Folder PRM_UP−DOWNLOAD"

transmitting several parameters 2−16 . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . . .

. . . .

DPV1 2−15 . . . . . . . . . . . .

2−2

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 31

2. Installation and project overwiev

2.1 Configuration

2.1.1 Install device master file (GSD file) and icon files

If a new hitherto unknown device is to be incorporated in a

configuration program when a PROFIBUS−DP system is to be

configured, an appropriate device master file (GSD file)

must be installed for this device. The device master file

contains all the necessary information for the configuration

program. You will require the appropriate

representing the device graphically.

Obtainable This documentation CD of the SFC−DC contains GSD files and

icon files for the SFC−DC in the folder PROFIBUS".

Current GSD files and icon files can be found on the Festo

Internet pages under:

www.festo.com/fieldbus

icon files for

GSD file You will require one of the following GSD files for the

SFC−DC:

SFC_0973.gsd English

SFC_0973.gsg German

(with support DPV0 and DPV1)

SFC00973.gsd English

SFC00973.gsg German

(only for older controllers/without DPV1)

Icon files In order to represent the SFC−DC in your configuration

software use the following icon files:

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

2−3

Page 32

2. Installation and project overwiev

2.1.2 I/O configuration

Normal operating

status

File: sfc−dc_n.dib or

sfc−dc_n.bmp

Diagnostic case Special operating

status

File: sfc−dc_d.dib or

sfc−dc_d.bmp

File: sfc−dc_s.dib or

sfc−dc_s.bmp

Tab.2/1: Icon files

Two configurations are supported by the GSD files:

Festo handling and positioning profile standard"

GSD entry as FHPP Standard",

8 bytes of I/O data, consistent transmission

Festo handling and positioning profile with parameter

channel"

GSD entry as FHPP Standard + FPC",

2 x 8 bytes of I/O data, consistent transmission

2−4

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 33

2. Installation and project overwiev

2.1.3 Configuration with STEP 7

General instructions

The software package SIMATIC Manager serves for project

planning and commissioning in conjunction with PROFIBUS

masters from Siemens or compatible masters. In order to

understand this chapter, you should be sure of how to handle

your configuration program. If necessary, refer to the docu

mentation for the SIMATIC Manager. This manual refers

software version V 5.3.

An appropriate device master file (GSD file) for the SFC−DC

must be installed for configuration.

With the STEP 7 Hardware Configurator you can load the files

via the menu command [Options] [Install GSD file] in the dia

logue window HWConfig".

to

Configuration program

STEP 7 Hardware Configurator 1)GSD file ...\STEP7\S7DATA\GSD

1)

If you copy the GSD files when the SIMATIC Manager has already been started, you can update the

hardware catalogue with the command [Options] [Update Catalog].

File type Directory

Bitmap files ...\STEP7\S7DATA\NSBMP

Tab.2/2: Folder for GSD and icon files STEP 7

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

2−5

Page 34

2. Installation and project overwiev

Insert SFC−DC as slave

The hardware configuration window represents graphically

the structure of the master system. When the GSD file has

been installed, the SFC−DC can be selected in the hardware

catalogue. It can be found in the group [PROFIBUS−DP]

[Additional Field Devices] [Drives] [Festo], (see Fig.2/1).

In order to insert the SFC−DC:

1. Drag

the station type Festo SFC−DC" or Festo SFC−DC

DP−V0" (3, see section 2.1.1) from the hardware

catalogue onto the PROFIBUS line (1) of the DP master

system (Drag & Drop).

2. Enter the PROFIBUS address, which you have set with the

Festo Configuration Tool or on the control panel in the

dialogue window

Properties PROFIBUS interface..." and

confirm with OK.

3. If necessary, enter other settings in the dialogue window

Properties DP slave" (e.g. the response monitoring or

the startup parametrizing) and confirm with OK.

The icon of the SFC−DC is displayed on the line of the DP

master system (2).

2−6

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 35

2. Installation and project overwiev

1 23

1 PROFIBUS line

2 Icon for SFC−DC

Fig.2/1: Station selection STEP 7

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3 Enter Festo SFC−DC from GSD file

2−7

Page 36

2. Installation and project overwiev

Configuring the slave features

After clicking the icon for the SFC−DC, you can configure the

Slave properties" in the lower part of the screen. Here you

can determine the number and size of the I/O ranges of the

slave and assign them with address ranges of the master.

In order to configure the

slave properties of the SFC−DC:

1. Open the available modules (configurations) in the hard

ware catalogue under [Festo SFC−DC ...].

2. Then drag the desired configuration (see section 2.1.2)

with the mouse into the appropriate line under Compo

nent/DP identifier.

With STEP 7 a Universal module" is also offered for

compatibility reasons. This must not be

used.

The SFC−DC is a modular slave, but with only one permitted

module. The configuration is defined only by the master.

2−8

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 37

2. Installation and project overwiev

123

1 DP identifiers

2 I/O address range

Fig.2/2: Configuring the slave features

When the configuration is concluded, transfer the data to the

master.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3 Modules (configurations)

2−9

Page 38

2. Installation and project overwiev

2.2 Dearchivating the example project

The example project will be made available as project

archive.

Procedure for dearchivating

1. Open the dialogue Retrieving Select an archive" with

the command [File] [Retrieve] ([File] [Dearchivate]).

2−10

Fig.2/3: Dearchivate project

2. Select the archive file of the example project

(e.g. SFC−DC.zip").

3. Select the desired destination path in the dialogue

Select destination directory".

If the option Scan destination directory when dearchivat

ing" is switched off in the basic settings of the SIMATIC

Manager, the preset path will be used directly as the des

tination path during dearchivation.

4. The unpacking of the project will be shown in a DOS or

console window. The project will then be opened in the

SIMATIC Manager:

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 39

2. Installation and project overwiev

Fig.2/4: Folder S7 program" of the example project

The example project does not contain any hardware. You can

use this in your controller in one of the following ways:

Drag the modules required into your own control project.

Add the relevant hardware to the example project. Delete

non−required S7 program" folders.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

In each case adapt

the addresses to your controller.

2−11

Page 40

2. Installation and project overwiev

2.3 Overview of project

The following sections contain an overview of the

S7program" folders of the example project.

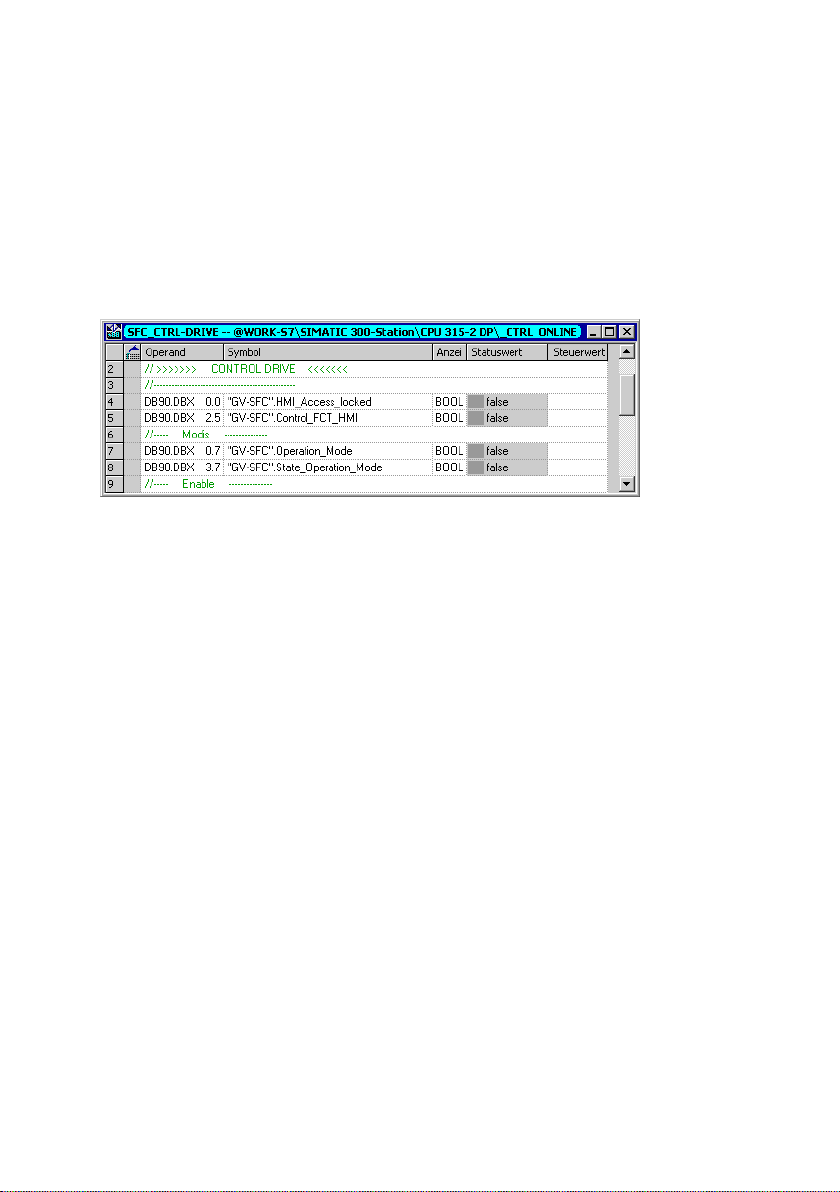

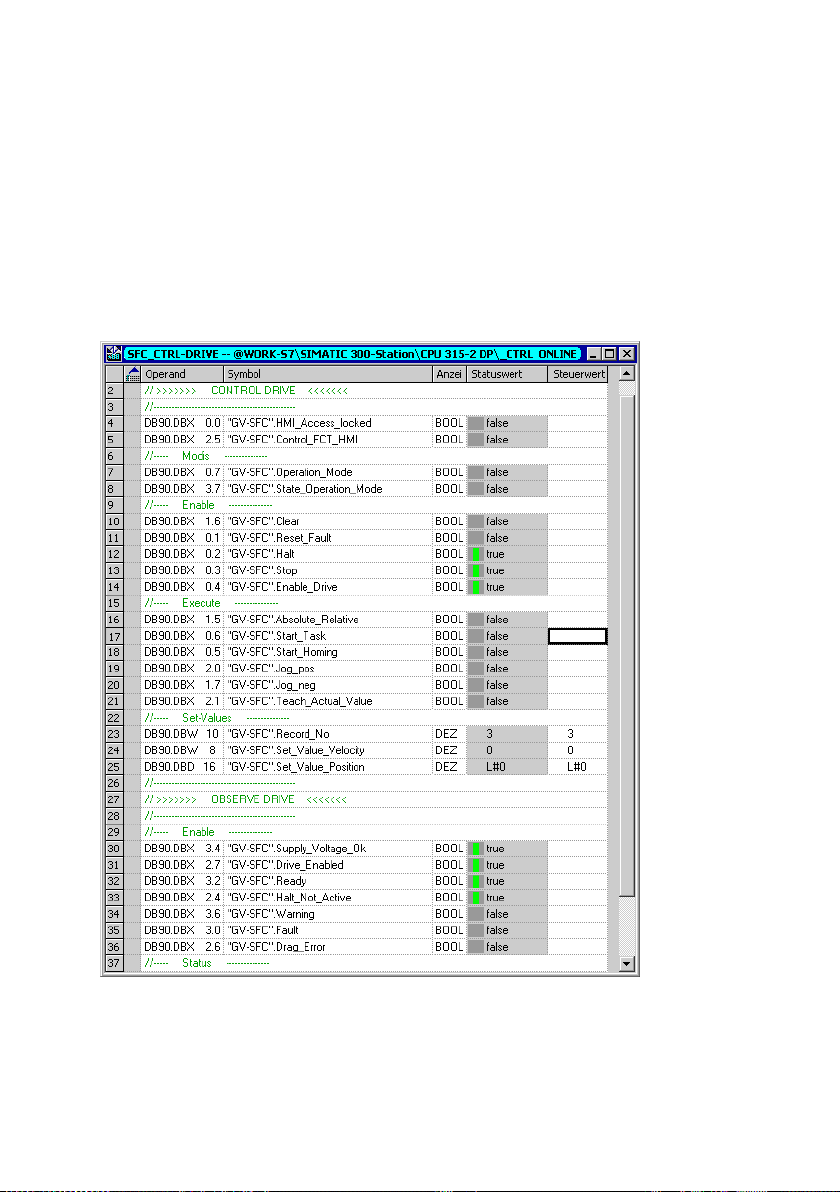

2.3.1 Folder _CTRL" control functions

The most important blocks in the folder _CTRL" for

controlling the controller are listed in Tab.2/3.

Additional blocks, e.g. for fault treatment or data blocks, etc.

are not listed.

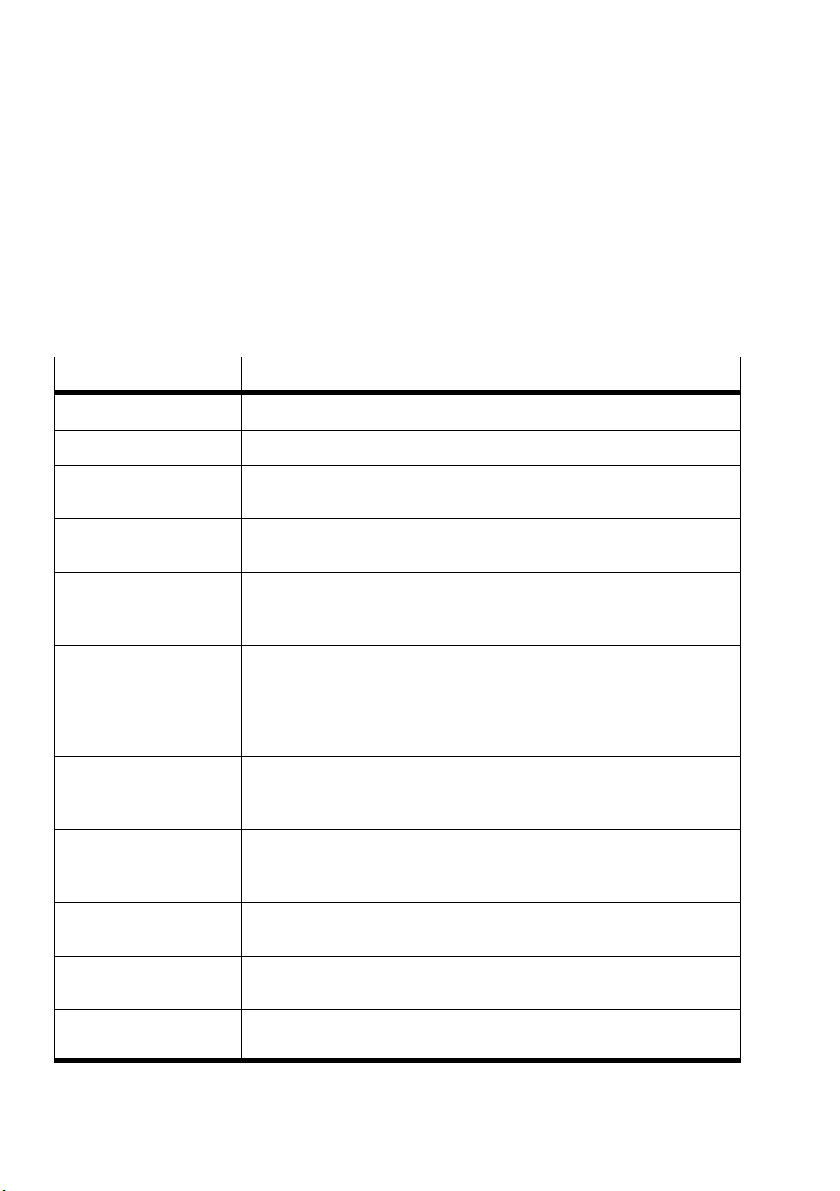

Block

OB1 Main Cyclic program

FB10 SFC_DC_CTRL Control FB for controlling the

DB90 GV−SFC Control Contains the global

SFC_CTRL−DRIVE Control Variable table for control Example

Name Purpose Description Access Function

access

Main program routine FB10 Example

SFC14/15 Festo control

drive

Example

control variables for FB10

project

block

project

project

Tab.2/3: Overview of the most important blocks of the folder _CTRL"

Block FB10 for controlling the SFC−DC is implemented in OB1.

The global variables for controlling the controller are saved in

DB90. With the aid of the variable table SFC_DC−CTRL the

drive can be positioned via PROFIBUS.

2−12

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 41

2. Installation and project overwiev

2.3.2 Folder _PRM_FPC" parametrizing via FPC

The most important blocks in the folder _PRM_FPC" for

parametrizing the controller via the Festo Parameter Channel

(DPV0) are listed in Tab.2/4.

Additional blocks, e.g. for fault treatment or data blocks, etc.

are not listed.

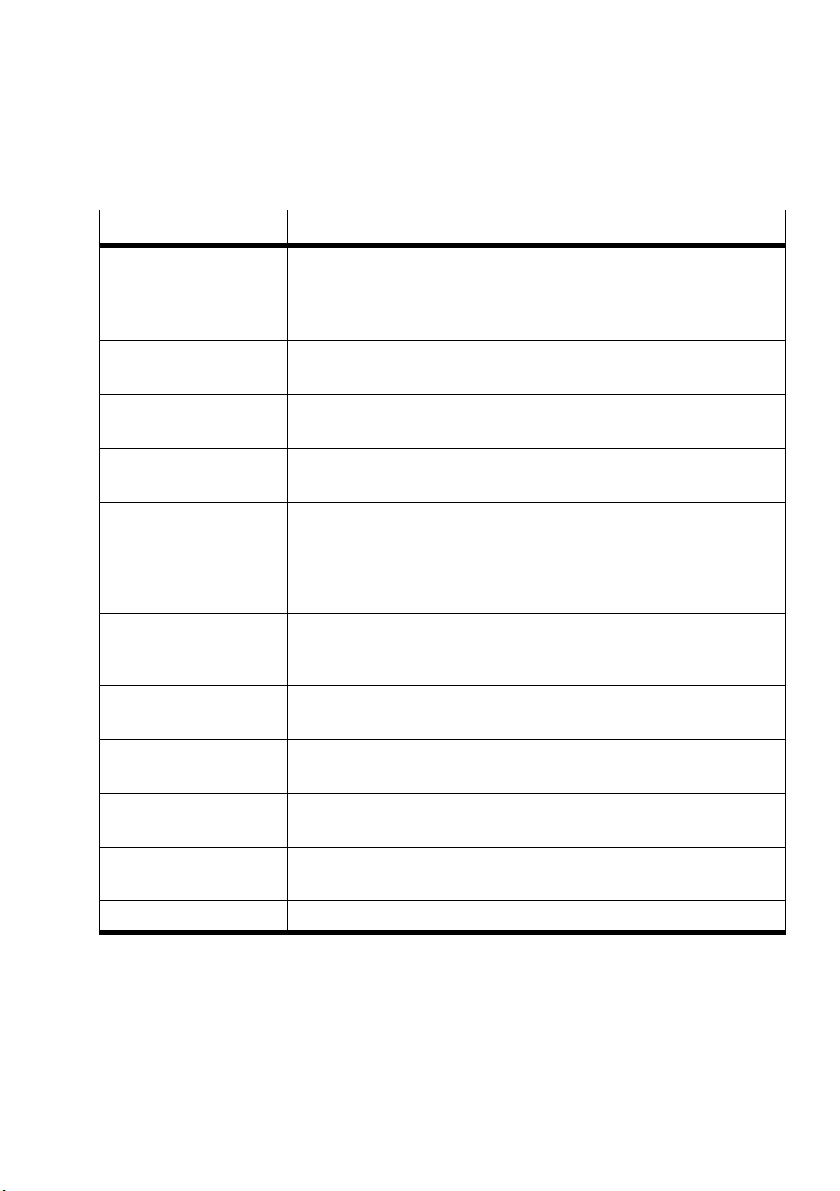

Block

OB1 Main Cyclic program

FB20 PRM_FPC Parametrizing

DB91 GV−PRM Parametrizing Contains the global control

PARAMETERIZE−DRIVE Parametrizing Variable table for

Name Purpose Description Access Function

access

(DPV0)

Main program routine FB20 Example

FB for parametrizing via

FPC

variables for parametrizing

parametrizing

SFC14/15 Festo control

Example

Example

Tab.2/4: Overview of the most important blocks of the folder _PRM_FPC"

Block FB20 for parametrizing the SFC−DC via DPV0 is implem

ented in OB1. The global variables for parametrizing are

saved in DB91. With the aid of the variable table PARAMETER

IZE−DRIVE the controller can be parametrized via PROFIBUS.

project

block

project

project

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

2−13

Page 42

2. Installation and project overwiev

2.3.3 Folder PRM_DPV1_SFB" parametrizing via DPV1

The most important blocks in the folder PRM_DPV1_SFB" for

parametrizing the controller via DPV1 are listed in Tab.2/5.

Additional blocks, e.g. for fault treatment or data blocks, etc.

are not listed.

Block

OB1 Main Cyclic program

FB21 PRM_DPV1_SFB Parametrizing

DB91 GV−PRM Parametrizing Contains the global

PARAMETERIZE−DRIVE Parametrizing Variable table for

Name Purpose Description Access Function

access

(DPV1)

Main program routine FB21 Example

FB for parametrizing

via DPV1 using

SFB52/53

control variables for

parametrizing

parametrizing

SFB52/53 Festo control

Example

Example

project

block

project

project

Tab.2/5: Overview of the most important blocks of the folder PRM_DPV1_SFB"

Block FB21 for parametrizing the SFC−DC via DPV1 is

implemented in OB1. The global variables for parametrizing

are saved in DB91. With the aid of the variable table

PARAMETERIZE−DRIVE the controller can be parametrized via

PROFIBUS.

2−14

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 43

2. Installation and project overwiev

2.3.4 Folder PRM_DPV1_SFC" parametrizing via DPV1

The most important blocks in the folder PRM_DPV1_SFC" for

parametrizing the controller via DPV1 are listed in Tab.2/6.

Additional blocks, e.g. for fault treatment or data blocks, etc.

are not listed.

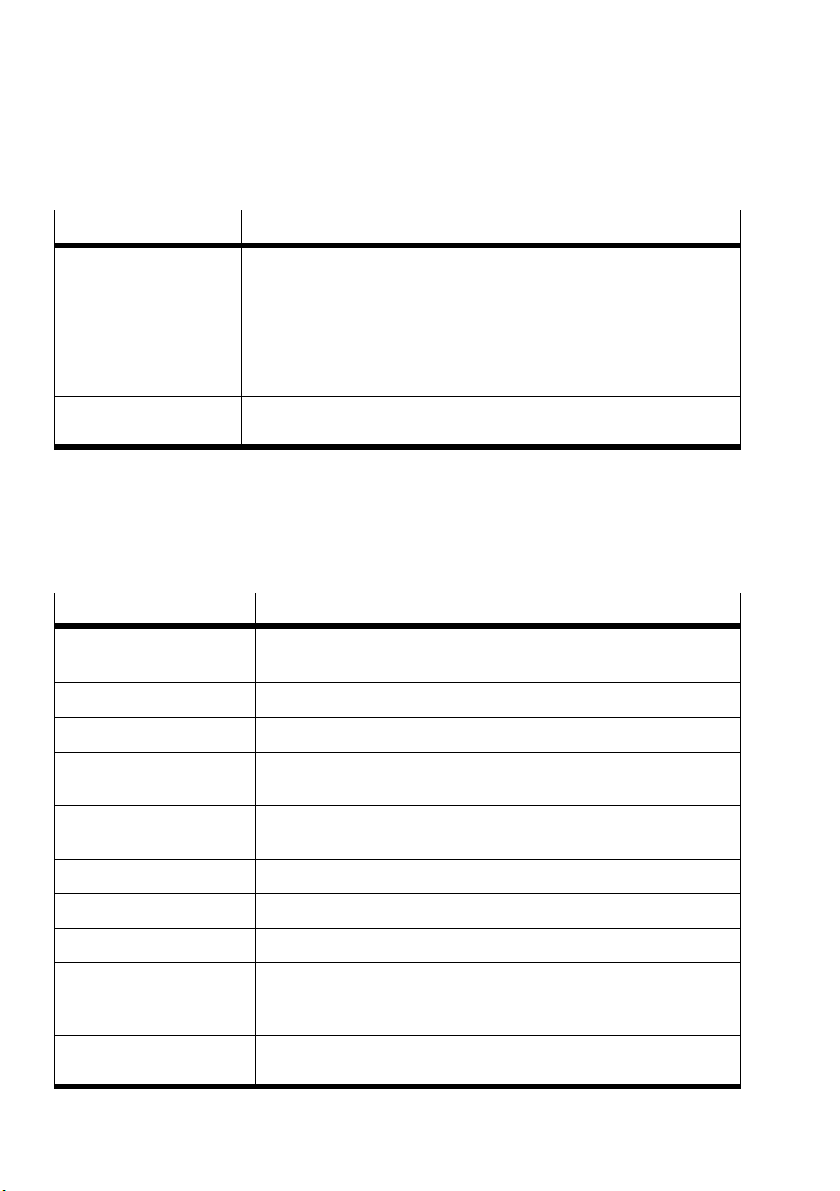

Block

OB1 Main Cyclic program

FB22 PRM_DPV1_SFB Parametrizing

DB91 GV−PRM Parametrizing Contains the global

PARAMETERIZE−DRIVE Parametrizing Variable table for

Name Purpose Description Access Function

access

(DPV1)

Main program routine FB22 Example

FB for parametrizing

via DPV1 using

SFC58/59

control variables for

parametrizing

parametrizing

SFC58/59 Festo control

Example

Example

project

block

project

project

Tab.2/6: Overview of the most important blocks of the folder PRM_DPV1_SFC"

Block FB22 for parametrizing the SFC−DC via DPV1 is

implemented in OB1. The global variables for parametrizing

are saved in DB91. With the aid of the variable table

PARAMETERIZE−DRIVE the controller can be parametrized via

PROFIBUS.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

2−15

Page 44

2. Installation and project overwiev

2.3.5 Folder PRM_UP−DOWNLOAD" transmitting several parameters

The most important blocks in the folder UP−DOWNLOAD" for

transmitting several parameters are listed in Tab.2/6.

Additional blocks, e.g. for fault treatment or data blocks, etc.

are not listed.

Block

OB1 Main Cyclic program

FB1 UP−DOWN Parametrizing Function block contains

FB20 PRM_FPC Parametrizing

FB23 PRM_DB−FILE Parametrizing

DB91 GV−PRM Parametrizing Contains the global control

DIAGNOSTIC BUFFER Parametrizing Variable table for reading

PARAMETERIZE−DRIVE Parametrizing Variable table for

Name Purpose Description Access Function

access

(DPV0)

(DPV0/DPV1)

Main program routine FB1 Example

examples of routines for

exchanging parameter sets

FB for parametrizing via

FPC

FB controls the upload/

download of parameter

sets from a global DB via

one of the three trans

mission paths

variables for parametrizing

out the diagn. memory

parametrizing

FB20,

FB23

SFC14/15 Festo control

SFC24 Festo control

Example

Example

Example

project

Example

project

block

block

project

project

project

Tab.2/7: Overview of the most important blocks of the folder PRM_DPV1_SFC"

Block FB1 is implemented in OB1. Block FB23 for transmitting

parameter sets as well as block FB20 for parametrizing the

SFC−DC via the Festo Parameter Channel (DPV0) are implem

ented in FB1. This is also possible via the blocks FB21 or

FB22.

The global

variables for parametrizing are saved in DB91.

With the aid of the variable table PARAMETERIZE−DRIVE the

controller can be parametrized via PROFI BUS. The diagnostic

memory can be read out with the variable table DIAGNOSTIC

BUFFER.

2−16

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 45

Control block

Chapter 3

3−1Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 46

3. Control block

Contents

3. Control block 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Function block SFC_DC_CTRL" 3−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Description of method of operation 3−4 . . . . . .

3.1.2 Input parameters 3−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Output parameters 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Fault information 3−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

3−2

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 47

3. Control block

3.1 Function block SFC_DC_CTRL"

The SFC−DC is controlled with block SFC_DC_CTRL.

Fig.3/1: SFC−DC control block

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3−3

Page 48

3. Control block

3.1.1 Description of method of operation

The block enables the drive functions of the SFC−DC to be

controlled by the field bus. It enables comfortable access to

the control bits.

System functions used

For data exchange the block uses internally the system func

tions SFC14/SFC15.

The correct logical input and output addresses of the slave

projected in the Hardware Manager must be entered for the

data exchange.

Position factor

All position specifications are always saved internally in

increments in the SFC−DC.

In the control block the conversion between increments and

the desired measuring system takes place via a position fac

tor. The position factor is defined by a counter and a denomi

nator value.

Unit of length

Increments Pos_Faktor_nummerator:

m Pos_Faktor_nummerator:

Inch Pos_Faktor_nummerator:

Parameter SLTE−10 SLTE−16

Pos_Faktor_denummerator:

Pos_Faktor_denummerator:

Pos_Faktor_denummerator:

1000000

1000000

1795938 (default)

1000000

45616836

1000000

1000000

1000000

2338461

1000000

59396923

1000000

Tab.3/1: SFC−DC position factors with the electric mini−slide type SLTE

3−4

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 49

3. Control block

If both factors are 1, the current position and the nominal

value for the position will be specified in increments.

The values for specifying the positions in m are saved in

the SFC−DC and can be downloaded (PNU 1004, subindex 0

and 1).

Device control

In order that the drive can be controlled via the PLC, the

device control via the PROFIBUS interface must be active.

Control via the FCT or the control panel must be deactivated

(Reurn message−Bit Drive_Control_FCT_HMI = 0).

The drive is ready to operate when the bits Stop, Halt and

Enable_Drive = 1 and

bits Drive_Enabled and Ready = 1.

the Fault bit = 0. This is shown with the

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3−5

Page 50

3. Control block

3.1.2 Input parameters

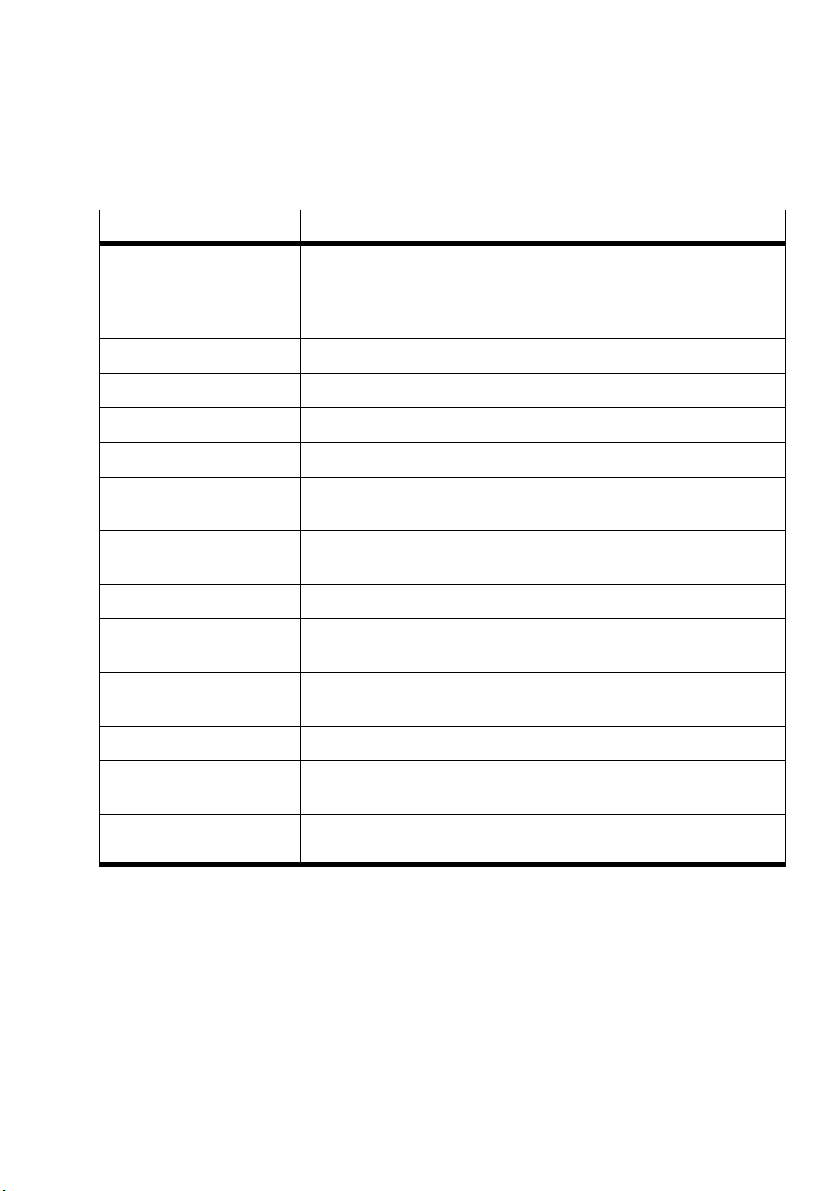

Parameter Declar

ation

I_ADDRESS INPUT WORD Address of the logical inputs of the slave.

O_ADDRESS INPUT WORD Address of the logical outputs of the slave.

Pos_Factor_

numerator

Pos_Factor_

denumerator

HMI_Access_

Locked

Reset_Fault INPUT BOOL With a rising edge a fault is quitted and the fault number is

Halt INPUT BOOL Halt drive.

INPUT INT Counter of the position factor (default 1)

INPUT INT Denominator of the position factor (default 1)

INPUT BOOL Controls access to the local (integrated) diagnostic

Data

type

Description

interface of the drive.

TRUE: MMI and FCT may only observe the drive, the

device control (HMI control) cannot be taken over

by MMI and FCT.

FALSE: MMI or FCT may take over the device control (in

order to modify parameters or to control inputs)

deleted.

TRUE: Halt is not active.

FALSE: Halt activated (do not cancel braking ramp +

positioning task). The axis stops with a defined

braking ramp, the positioning task remains active

(the remaining path can be deleted with

Clear_remaining_Position").

Stop INPUT BOOL Stop / enable operation.

TRUE: Enable operation.

FALSE: Stop active (cancel emergency ramp + positioning

task). The axis stops with maximum braking ramp,

the positioning task is reset.

Enable_Drive INPUT BOOL Enable drive.

TRUE: Enable drive (controller). Faults will be deleted.

FALSE: Drive (controller) blocked.

Start_Homing INPUT BOOL Start reference travel

With a rising edge reference travel with the set

parameters is started.

3−6

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 51

3. Control block

Parameter DescriptionData

Start_Task INPUT BOOL Start current task.

Operation_Mode INPUT BOOL Selecting the operating mode

Absolute_Relative INPUT BOOL Positioning mode

Clear_Remaining_

Position

Jog_pos INPUT BOOL Jogging positive

Jog_neg INPUT BOOL Jogging negative

Teach_Actual_

Value

Declar

ation

INPUT BOOL Deletes the unfinished positioning task after a stop.

INPUT BOOL Teach th ecurrent position, see appendix A.2.4.

type

With a rising edge the current nominal values will be

transferred and positioning started (record 0 = reference

travel).

FALSE: Record Select

TRUE: Direct mode

FALSE: Nominal value is absolute.

TRUE: Nominal value is relative to last nominal value

In the Halt" status, a positive signal edge causes the

positioning task to be deleted and transfer to the Ready"

status.

The drive moves at the specified speed in the direction of

larger actual values, providing the bit is set. The movement

begins with the rising edge and ends with the falling edge.

The drive moves at the specified speed in the direction of

smaller actual values, see Jog_neg".

The Teach target is defined with PNU 520.

Record_No INPUT INT Preselect of record number for Record Select

Set_Value_

Velocity

Set_Value_

Position

INPUT INT Preselect of speed for direct mode

INPUT DINT Preselect of position for direct mode:

(1 ... 31, 0 = reference travel).

(in % of the maximum speed)

position in measured unit, depends on position factor.

Tab.3/2: Input parameter SFC_DC_CTRL"

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3−7

Page 52

3. Control block

3.1.3 Output parameters

Parameter Declar

ation

Control_FCT_HMI OUTPUT BOOL Control sovereignty PLC or MMI/FCT.

Drive_enabled OUTPUT BOOL Drive enabled.

Supply_Voltage_OkOUTPUT BOOL Load voltage

Warning OUTPUT BOOL Warning.

Fault OUTPUT BOOL Fault

Ready OUTPUT BOOL Quit stop, if Drive_enable" = 1

State_Operation_

Mode

Ack_Start OUTPUT BOOL Quit Start

OUTPUT BOOL Reply message operating mode

Data

type

Description

FALSE: Control sovereignty PLC

TRUE: Control sovereignty MMI/FCT (PLC control is

Locked).

FALSE: Drive blocked, controller not active.

TRUE: Drive (controller) enabled.

FALSE: No load voltage

TRUE: Load voltage applied

FALSE: Warning not applied

TRUE: Warning applied

FALSE: No fault

TRUE: There is a fault or reaction to fault is active.

Fault number in diagnostic memory

FALSE: Record Select (standard)

TRUE: Direct mode

FALSE: Ready for start (reference, jog)

TRUE: Start carried out (reference, jog)

Ack_Teach OUTPUT BOOL Quit Teach

positive edge: Ready for teaching

negative edge: Teaching carried out

3−8

Actual value is transferred.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 53

3. Control block

Parameter DescriptionData

MC OUTPUT BOOL Motion Complete

Drive_is_moving OUTPUT BOOL Axis moves

Halt_Not_Active OUTPUT BOOL Reply message Halt

Drag_Error OUTPUT BOOL Drag error

Standstill_Control OUTPUT BOOL Standstill monitoring

Drive_is_

referenced

Declar

ation

OUTPUT BOOL Axis referenced.

type

FALSE: Positioning task active

TRUE: Positioning task completed, if applicable with

fault

Note: MC is set after device is switched on

(status Drive blocked")

FALSE: Speed of the axis < Limit value

TRUE: Speed of the axis > = limit value

FALSE: Halt is active, at start last positioning task will

be continued.

TRUE: Halt is not active, axis can be moved.

FALSE: No drag error.

TRUE: Drag error active.

FALSE: After MC axis remains in tolerance window.

TRUE: Achse steht nach MC außerhalb Toleranzfenster.

FALSE: Referencing must be carried out.

TRUE: Reference information exists, reference travel

must not be carried out.

Actual_Record_No OUTPUT INT Reply message of record number for Record Select

(1...31, 0 = reference travel).

Actual_Velocity OUTPUT BYTE Reply message of speed for Direct mode

(in % of the maximum speed)

Actual_Position OUTPUT DINT Reply message of the position.

Position, depends on position factor (see Tab.3/1).

RET_VAL OUTPUT INT Reply value of the function block.

Tab.3/3: Output parameter SFC_DC_CTRL"

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

3−9

Page 54

3. Control block

3.1.4 Fault information

The fault output of the block distinguishes between faults in

the SFC−DC and faults in the block. Faults in the SFC−DC are

shown with the Fault bit, more precise details of the fault

must be downloaded in the diagnostic buffer of the SFC−DC.

Block faults are output at the output RET_VAL. If the

block is

processed incorrectly, the ENO bit will be set to 0.

Block−internal faults are triggered by a position factor

denummerator with value 0, or by system functions

(e.g.SFC14/SFC15, ...).

The fault codes are defined by the transmission blocks, seeh

elp for STEP 7.

The evaluation of the fault can take place with the

value

RET_VAL and the help for the relevant transmission blocks

(SFC14/SFC15, SFB52/SFB53, SFC58/SFC59).

3−10

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 55

Parametrizing blocks

Chapter 4

4−1Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 56

4. Parametrizing blocks

Contents

4. Parametrizing blocks 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Overview of parametrizing blocks 4−3 . .

4.1.1 Control and parametrizing methods 4−4 . . . . . . . . . . . . . .

4.1.2 Method of operation of the blocks 4−4 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Converting the measuring units 4−5 . . . .

4.2 Block PRM_FPC 4−6 . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Input parameters 4−7 . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Output parameter 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Blocks PRM_DPV1_SFB / PRM_DPV1_SFC 4−8 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Input parameters 4−9 . . . . . . . . . . . . .

4.3.2 Output parameters 4−9 . . . . . . . . . . . . . . . . . . . . .

4.4 Block PRM_DB−FILE 4−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Description of method of operation 4−11 . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Input parameters 4−13 . . . . .

4.4.3 Output parameters 4−14 . . . . . . . . . . . . . .

4.4.4 Implementation 4−15 . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Restriction 4−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Fault information 4−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . .

4−2

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 57

4. Parametrizing blocks

4.1 Overview of parametrizing blocks

For parametrizing the SFC−DC, different methods can be used

depending on the blocks:

parametrizing with the block PRM_FPC via the cyclic data

(DPV0)

parametrizing with the block PRM_DPV1_SFB using the

system function blocks SFB52/SFB53 (DPV1)

parametrizing with the block PRM_DPV1_SFC using the

system functions SFC58/SFC59 (DPV1)

automatic transfer of several parameters with the block

PRM_DB−FILE"

The choice of transfer method depends primarily on the con

troller used. Transfer via the cyclic data is possible with any

DP controller, but requires memory space in the logical ad

dress range, which can cause problems under certain circum

stances with many slaves on the bus.

and one of the parametrizing blocks.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

the case of transfer via DPV1 with the system function

In

moules SFB52/SFB53 from Siemens, you must make sure

that this transfer procedure is supported by the controller.

With the system functions SFC58/SFC59 for older controllers,

Siemens therefore offers the possibility of transferring para

meters DV1−conform to the controller.

For compatibility reasons the block

interfaces of all transfer

types are identical.

Please note

All blocks address parameters with subindices as per

DPV1. This means that the subindices must be transferred

from 0 ... n−1.

4−3

Page 58

4. Parametrizing blocks

4.1.1 Control and parametrizing methods

DPV0 Parametrizing with the DPV0 is carried out via the Festo para

meter channel (FPC, further 8 I/O bytes), see manual for the

SFC−DC−...−PB.

DPV1 Die Parametrizing with the DPV1 is carried out via the para

meter channel as per PROFIdrive V3.1. This protocol is a com

patible extension of the PKW protocol within the

data. This means that the parameters can be addressed with

PNU, subindex etc.

DPV1 work

4.1.2 Method of operation of the blocks

With all blocks a parameter is clearly defined by the PNU

(parameter number), the subindex and the length in bytes.

4−4

With the blocks named under 4.1 only one parameter can be

transferred in each case. With the bit RD_WR you can define

whether the parameter is to be read or written. When the

parameters are transferred, a distinction is made between

three data types: Byte, Word, Double word or length 1, 2, 4.

How the parameter is to be interpreted can be found in the

description of the relevant parameter, see manual for the

controller used.

An overview of the parameters can be found in appendix

It is not necessary to specify the length of the parameter in

order that it can be read.

A positive edge at the start input triggers the transfer. When

the transfer is completed, this will be shown at the output

Done. The result of the transfer is shown all the time the

bit is set to 1.

The reply to an incorrect parameter entry depends on the

transmission method.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

B.1.

start

Page 59

4. Parametrizing blocks

4.1.3 Converting the measuring units

In the SFC−DC all parameters are always saved in increment

specifications (inc, inc/s, inc/s

2

). Conversion is carried out via

the parameters:

Feed constant, depending on the drive

Gear reduction

Encoder resolution = physical measuring steps per motor

revolution. With the SFC−DC: pulse quadruplication by

digital interpolation.

Parameters

feed Feed constant

gear Gear ratio

enc Encoder resolution

1) D

epending on drive, here type SLTE−...

2)

Specification in 2 natural numbers for counter or denominator of the fraction

3)

With the SFC−DC: pulse quadruplication by digital interpolation

1)

2)

3)

SLTE−10 SLTE−16

SLTE−...−BS5.0: 5000 [m/rev] SLTE−...−LS7.5: 7500 [m/rev]

SLTE−...−G04 (57:13)

512 x 4 = 2048 [incr/rev] 1000 x 4 = 4000 [incr/rev]

Tab.4/1: Basis parameter for the measuring system

The values for specifying the positions in m are saved in the

SFC−DC and can be downloaded (PNU 1004, subindex 0 and 1).

Special conversion factors for the SFC−DC

Length unit SLTE−10 SLTE−16

Increments > millimetres Increments / 1795.938 Increments / 2338.461

Millimetre > increments Millimetres * 1795.938 Millimetres * 2338.461

Increments > inch Increments / 45616.836 Increments / 59396.923

Inch > increments Inch * 45616.836 Inch * 59396.923

Tab.4/2: Conversion factors for SLTE measuring system

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

4−5

Page 60

4. Parametrizing blocks

4.2 Block PRM_FPC

The block transfers the parameters internally to the FPC

(Festo Parameter Channel).

Fig.4/1: Parametrizing via the cyclic data

4−6

Fault treatment

Transmission faults are displayed with the Fault bit, the para

meter Length_RD then contains value 2.

The cause of the fault will be output at Value_RD.

Information on faults can be found in section 4.5.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 61

4. Parametrizing blocks

4.2.1 Input parameters

Parameters Decla

ration

I_ADDRESS INPUT WO RD Logical input address of the FPC (PKW) specifications

O_ADDRESS INPUT WO RD Logical output address of the FPC (PKW) specifications

RD_WR INPUT BOOL FALSE: Read

Start INPUT BOOL Starts write or read procedure

PNU INPUT WORD Parameter number of the current parameter

Subindex INPUT BYTE Subindex of the current parameter

Length INPUT INT Length of the parameter to be written in bytes

Param_

Value_WR

INPUT DWORD Parameter value when writing a parameter

Data

type

Description

TRUE: Write

Tab.4/3: Input parameter PRM_FPC

4.2.2 Output parameter

Parameters Decla

ration

Data

type

Description

Done OUTPUT BOOL FALSE: Transfer completed

TRUE: Write

Value_RD OUTPUT DWORD Value of parameter to be read

Length_RD OUTPUT INT Length of parameter to be transferred

Fault OUTPUT BOOL FALSE: No fault

TRUE: Fault

RET_VAL OUTPUT INT Return value after incorrect processing of the block

Tab.4/4: Output parameter PRM_FPC

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

4−7

Page 62

4. Parametrizing blocks

4.3 Blocks PRM_DPV1_SFB / PRM_DPV1_SFC

The blocks PRM_DPV1_SFC and PRM_DPV1_SFB enable

transfer of parameters via DPV1.

The differences with the transfer via DPV1 are not recogniz

able externally or functionally. However, block

PRM_DPV1_SFC offers older controllers the possibility of

transferring parameters acyclically.

Fig.4/2: Parametrizing block with SFB52 / SFB53

Fig.4/3: Parametrizing block with SFC58 / SFC59

Fault treatment

Transmission faults are displayed with the Fault bit, the

parameter Length_RD then contains value 0x44 (68).

The fault number can be read at Value_RD.

Information on faults can be found in section 4.5.

4−8

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 63

4. Parametrizing blocks

4.3.1 Input parameters

Parameters Decla

ration

I_O_ADDRESS INPUT WO RD Logical address of the DP slave module

RD_WR INPUT BOOL 0 = read

Start INPUT BOOL Starts write or read procedure

PNU INPUT WORD Parameter number of the current parameter

Subindex INPUT BYTE Subindex of the current parameter

Length_WR INPUT INT Length of the parameter to be written in bytes

Value_WR INPUT DWORD Parameter value when writing

Data

type

Description

Example: I−address 256, O−address 264

−−> W#16#100

The smaller of the two addresses must be specified.

1 = write

Tab.4/5: Input parameters PRM_DPV1_SFB / PRM_DPV1_SFC

4.3.2 Output parameters

Parameters Decla

ration

Data

type

Description

Done OUTPUT BOOL Transfer completed

Value_RD OUTPUT DWORD Value of parameter to be read

Length_RD OUTPUT INT Length of parameter to be transferred

Fault OUTPUT BOOL Fault bit

RET_VAL OUTPUT INT Return value after incorrect processing of the block

Tab.4/6: Output parameters PRM_DPV1_SFB / PRM_DPV1_SFC

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

4−9

Page 64

4. Parametrizing blocks

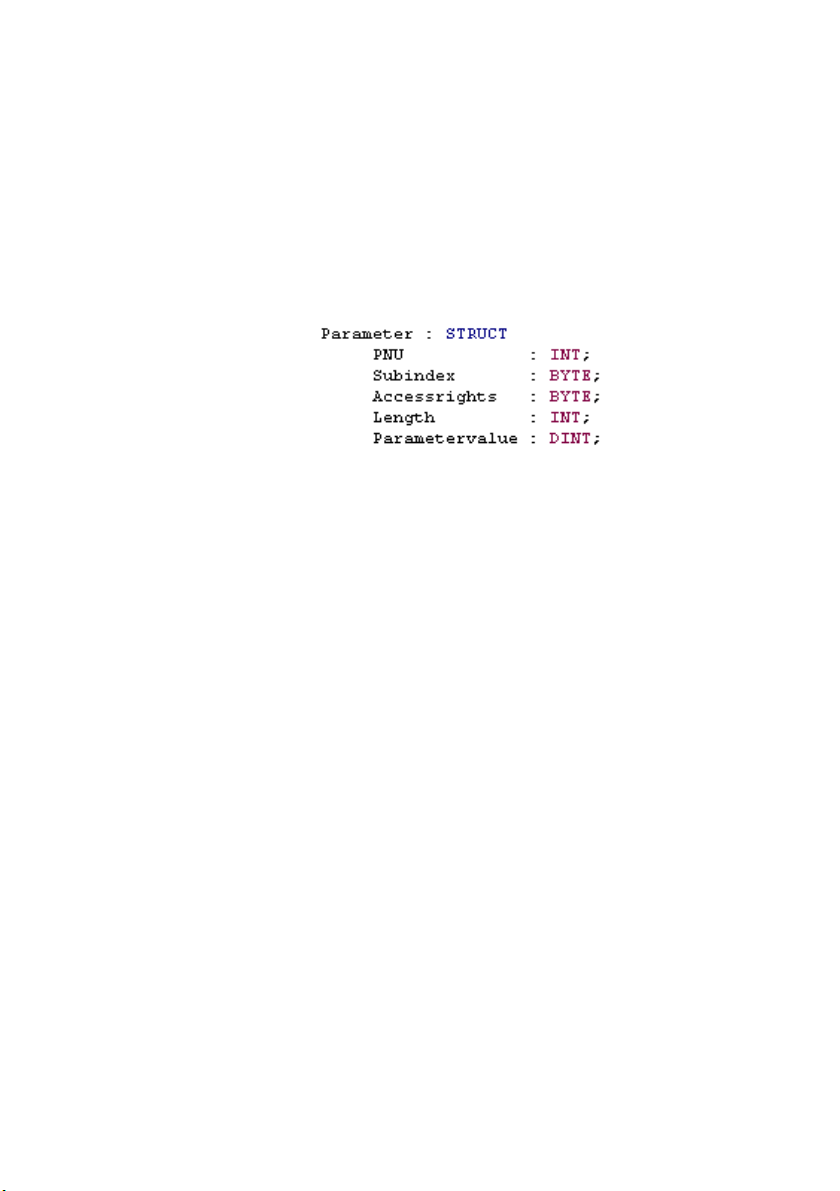

4.4 Block PRM_DB−FILE

In order to automate the transfer of several parameters, block

PRM_DB−FILE offers the possibility of transferring parameter

sets from a global DB to the controller or of receiving para

meter sets. The block uses one of the three transfer blocks

FB20, FB21 or FB22 for the transfer.

Block

PRM_FPC,

PRM_DPV1_SFC,

PRM_DPV1_SFB

List of the parameters for reading / writing

Individual parameter

DB Source

Block

PRM_DB−FILE

While i < n

PROFIBUS

Fig.4/4: System overview upload/download

4−10

Saving the parameters read

DB Target

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 65

4. Parametrizing blocks

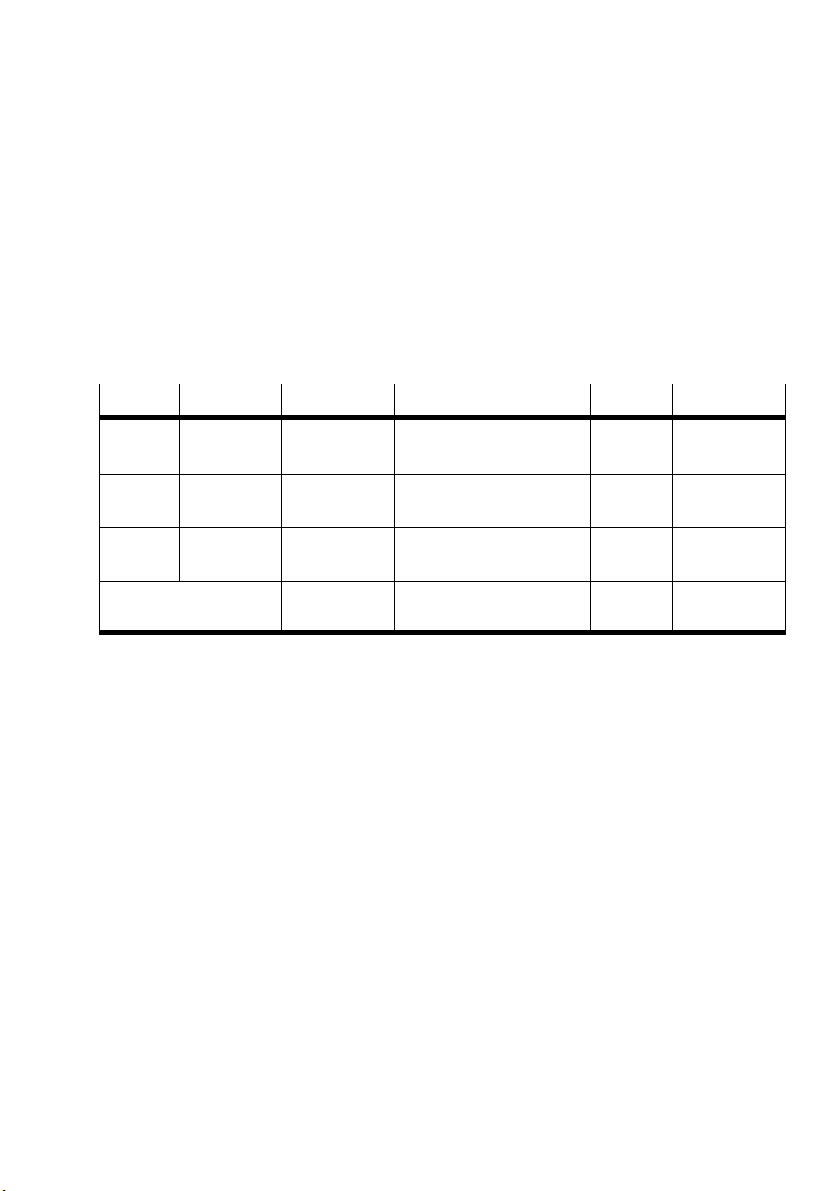

4.4.1 Description of method of operation

A list of the desired parameters must be saved in a global DB,

a parameter must be composed as follows:

Fig.4/5: Composition of a parameter

The byte Accessrights" is a reserve byte for additional

implementations, e.g. parameters with a certain identification

could be omitted from write−read authorization during

parametrizing.

The data block must correspond to an array of this structure

(n*10BYTE). A source and a target DB, which must be of the

ame length (n*10BYTE),

From the source DB you can read the parameters which are to

be read or written. In the case of reading, the read para

meters will then be transferred to the target DB. The same DB

can be specified for source and target. Only the parameter

values

will be transferred.

must be specifed for the transfer.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

The data type for the parameter value always has the length

of a double word. It is therefore independent of the para

meter to be transferred. It occupies memory space but re

duces the problem in handling. If a parameter with length 1 is

transferred, the above−named three bytes will

be ignored.

Vice−versa when reading the above−named three byted will be

assigned with zeros. How the parameter value is to be inter

preted can be found in the description of the parameter.

The transmission is started with the bit Start_RxTx.

The progress of the transmission will be shown in % at the

Progress"

output. The transmission is completed when the

bit Done_RxTx supplies TRUE.

4−11

Page 66

4. Parametrizing blocks

If the parameter is faulty, the transmission will be aborted.

The fault can be identified by means of the incorrect

parameter values which are still present in the block.

Fig.4/6: Block for transferring a parameter list

4−12

Fault treatment

Transmission faults are shown with the Fault bit. The para

meter which caused the fault can be read with the last trans

ferred parameter values.

Information on faults can be found in section 4.5.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 67

4. Parametrizing blocks

4.4.2 Input parameters

Parameters Decla

ration

Start_RxTx INPUT BOOL Start transmission

Rx_Tx INPUT BOOL Read DB / write DB

DB_Source INPUT INT Source DB

DB_Target INPUT INT Target DB

_Done_RD_WR INPUT BOOL Transmission of individual parameters is concluded

_Fault_RD_WR INPUT BOOL Faults in the transmission of individual parameters

_Length_RD INPUT INT Length of the read parameter in BYTE

_Value_RD INPUT DWORD Parameter value of the current parameter when reading

Data

type

Description

Tab.4/7: Input parameter PRM_DB−FILE

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

4−13

Page 68

4. Parametrizing blocks

4.4.3 Output parameters

Parameters Decla

ration

_Start_R_WR OUTPUT BOOL Start transfer of individual parameters

_RD_WR OUTPUT BOOL Read/write individual parameter

_PNU OUTPUT INT PNU of the current parameter

_Subindex OUTPUT BOOL Subindex of the current parameter

_Length_WR OUTPUT INT Length of the current parameter in BYTE

_Value_WR OUTPUT DWORD Current parameter value to be written

Done_RxTx OUTPUT BOOL Read DB / write DB completed

Progress OUTPUT INT Progress of transmission in %

Fault_RxTx OUTPUT BOOL Fault with Read DB / write DB

RET_VALUE OUTPUT INT Return value after incorrect processing of the block

Data

type

Description

Tab.4/8: Output parameter PRM_DB−FILE

The block is ready to operate when the Done bit supplies

TRUE and there are no faults. Transmission is started with a

positive edge; the progress of the transmission is shown in

percent at the Progress" output. During transmission the

Done bit is set to FALSE.

4−14

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

Page 69

4. Parametrizing blocks

4.4.4 Implementation

The block PRM_DB−FILE cannot function on its own, only in

combination with one of the transfer blocks can it transfer a

list of parameters. Some of the inputs or outputs must there

fore be linked directly with each other.

4.4.5 Restriction

RD_WR_DB−FILE

_PNU OUTPUT −−> _PNU INPUT

_Subindex OUTPUT −−> _Subindex INPUT

_Length_RD OUTPUT −−> _Length INPUT

_Value_WR OUTPUT −−> _Value_WR INPUT

_Done_RD_WR INPUT <−− _Done_RD_WR OUTPUT

_Fault_RD_WR INPUT <−− _Fault_RD_WR OUTPUT

_Value_RD INPUT <−− _Value_RD OUTPUT

<−>

PRM_...

Tab.4/9: Wiring table

Function block RD_WR_DB−File uses internally the system

function SFC24. With this function the source and target DB

can be tested and their length defined. However, this function

is not implemented in controllers of an earlier date. The block

cannot therefrore be used there in this form.

Festo P.BE−SFC−DC−PB−S7−EN en 0604NH

4−15

Page 70

4. Parametrizing blocks

4.5 Fault information

A distinction is always made between two types of faults:

block faults and transmission faults.

Block faults (e.g. incorrect logic address, incorrect hardware

configuration, etc.) are caused by the relevant system func

tion blocks used SFC14/SFC15, SFC58/SFC59, SFB52/SFB53

or SFC24 and shown at the output R ET_VALUE. The fault code

can be found in the

STEP 7 help. If a block fault occurs, the

block will be exited with the ENO bit = 0.

Transmission faults arise as a result of incorrect parameter

data (e.g. non−existent PNU, incorrect parameter length when

writing, non−existent subindex, etc.).