Page 1

F

esto Learning Systems

Getting Star

MecLab

ted

Page 2

By A. Huttner

R. Pittschellis

M. Klaus

M. Hubsch

M. Striegel

T. Lust

J. Schwarz

Graphics: D. Schwarzenberger

Layout: F. Ebel 05/2008

Editor: F. Ebel

F. Zierau

Copyright 2008

This document and its contents are the property of Festo Corporation. No part of this

document may be reproduced, utilized, transmitted or disclosed in any form or by any

means without prior written consent of Festo Corporation

Festo Corporation 395 Moreland Rd. Hauppauge, NY, USA 11788

© 2008 Festo Corporation 2 U

Page 3

Table of Contents

I

ntroduction

4

C

ourse Objectives

5

S

afety

6

raining Systems Operations 7

T

verview 9

O

ommissioning 14

C

Sample Programs 15

S

afety and Maintenance 16

Stac

k Magazine Station 18

onveyor Station 40

C

andling Station 56

H

esson Planning 77

L

P

rojects 86

© 2008 Festo Corporation 3 U

Page 4

Introduction

This workbook contains both information and exercises designed to introduce the student to

basic automated systems components commonly used in industry.

The information is intended for use in a mechatronics environment and is aimed at supporting

continued education in industrial automation. The topics cover basic components used in industrial automation. It also provides exercises for developing pneumatic and electrical schematics using FluidSim-P software. Overall the topics are intended to prepare the student to

study more advanced systems.

© 2008 Festo Corporation 4 U

Page 5

Course Objectives

Upon completion of the exercises in this workbook, the student will be able to:

• Identify machines and their function in a process.

• Familiarization with industrial components.

• Familiarization with industrial component symbols and designations.

• Understand the term “sequence of operations”.

• Become familiar with pneumatic and electrical schematics.

• Understand control of linear actuators.

• Understand principles of relays.

• Understand limit switches.

© 2008 Festo Corporation 5 U

Page 6

Safety *

Due to the potential hazards in any automated system, good safety practices are important in

the classroom, as well as on the production floor.

Students should never be allowed to place their hands on or near the system while operating.

Safety glasses should be worn around the equipment during operation.

All information in this workbook is intended for educational use only. It has

All information in this workbook is intended for educational use only. It has

been carefully compiled and checked, and we beli

been carefully compiled and checked, and we believe the material to be accu-

rately presented. However, Festo Corporation assumes no responsibility for

rately presented. However, Festo Corporation assumes no responsibility for

published technical errors. Additionally, Festo Corporation assumes no re-

published technical errors. Additionally, Festo Corporation assumes no re-

sponsibility for the safe and/or satisfactory operation of any machine.

sponsibility for the safe and/or satisfactory operation of any machine.

eve the material to be accu-

*See also page 7, “Operation of the Festo Training System,” for

additional safety considerations.

© 2008 Festo Corporation 6 U

Page 7

Operation of the Festo Training System

Festo training systems have been designed for ease of use by both the student and the instructor.

Compressed air should be handled with respect. Care should be taken to ensure that compressed air is not directed at open cuts or against the skin, since serious physical damage

and/or dangerous embolism may result.

Compressed air should be applied to the service unit at the port next to the regulator/filter.

Air service for the automated system is drawn from the right side of the service unit. The service unit is fitted with a normally closed 3/2 directional control valve with a red knob. The

valve is opened to provide air to the manifold by moving the knob in line with the direction of

airflow. All connections should be made with this switch turned off.

All pneumatic components are fitted with quick-connect air line fittings. Tubing to be connected to these fittings should be cut squarely. Tubing is pushed into the fitting until a resistance is felt; this is a metal ring. The tubing is pressed further until it stops. The tubing is

then checked by pulling gently back on the tubing. Leaks at the quick-connect fittings may

sometimes be traced to failure to fully set the tubing in the fitting. Another common cause of

air leaks may be a tubing end not cut at a shallow angle or tubing, which has become worn

and ragged through use. These tubing faults may be corrected by cutting a short section

from the end of the tubing to expose a fresh surface.

The instructor should check the connections on the circuits to ensure that the tubing is secured properly before the circuits are pressurized. Compressed air escaping to atmosphere

from a loose and uncontrolled tube will cause the tube to whip, therefore safety glasses

should be worn whenever students or instructors are working or observing any of the automated systems.

© 2008 Festo Corporation 7 U

Page 8

© 2008 Festo Corporation 8 U

Page 9

Getting Started with Festo MecLab

Overview

Automation technology has become increasingly important in engineering. It helps to improve both working and living conditions by ensuring high productivity and quality while at

the same time satisfying the ever-growing need for technological know-how.

Automation technology combines knowledge from virtually all other technical sciences. This

interdisciplinary field could not have developed without the fundamentals of electrical, mechanical and process engineering as well as information technology to name just a few.

We see and use automated technical systems every day. Escalators, automatic doors and

ATMs. At the supermarket, our groceries are move by conveyors which seem to “know” exactly when to stop. In this sense, automation technology is everywhere. Everyone is regularly

confronted by “something” that can be classified as an automated system. Thus technical

education must emphasize this technology in order to keep up with the demand for skilled

workers.

Training should include:

− Overview of automated systems.

− Developing skills in the use of automated systems.

− Developing skills in the commissioning and maintenance of automated technical

systems.

In addition, training must be designed so that students are given the opportunity to work with

technology, investigate its effects and discover their own capabilities.

Automation technology is one of the most challenging subjects because of its complexity. It

can not be taught through lectures alone. Students must be given hands-on practice with

automated technical systems in order to observe and understand how subsystems and components interact. They must be able to disassemble and assemble a system.

MecLab®, developed by Festo Learning Systems, includes a stack magazine, a conveyor

and a handling station. These simulate parts of an automated production line. It is designed

to familiarize students with automated technical systems.

© 2008 Festo Corporation 9 U

Page 10

Getting Started with Festo MecLab

Overview

MecLab® is a modular multimedia teaching and learning system. It is supplemented with:

− Computer software

− Video

− Technical drawings

− Diagrams

The combination of theory and practice is an essential aspect of MecLab® and its components. For every theory related to engineering sciences, there is a corresponding application.

The connection between theory and practice will encourage students to put in to practice

what they have learned. Additionally students can learn how to analyze practical applications

to prove a theory.

Individuals do not acquire a skill by simply listening to a description of the skills, rather they

learn by doing. It is in the “doing” where problem solving skills are developed.

Theory and practical applications of automation technology can be addressed with MecLab®, including:

− Types of control systems.

− Fundamentals of sensors.

− The link between sensors and drives in automated systems.

− Basic logic functions.

− Basics of programming automated systems.

MecLab® is intended for use in technically-oriented subjects. Basic knowledge of production

engineering, mechanical engineering, electrical engineering and information technology is

helpful, but not essential. Basic knowledge, such as physical fundamentals of drive and sensor technology, relays or logic operations can be learned with the help of the appropriate

theory section as well as the exercises. The focus, however, should be less on teaching fundamentals than on applying them.

© 2008 Festo Corporation 10 U

Page 11

Getting Started with Festo MecLab

Overview

The MecLab® learning system consists of three stations that carry out the following functions:

− Storage and separating

− Transporting (conveying)

− Handling.

These three processes are typical for all automated production.

Figure 2.1 shows a production line that manufactures formed sheet metal parts. The material

is transported by means of a roller conveyor (3) to the machining stations (1, 2, 7), where it is

shaped. The first robot (4) places the sheets from the conveyor into a magazine (5 storage),

the second robot (6) takes the sheets from the magazine and feeds them to the third machining station (7) (handling and separating functions).

Figure 2.1: Automated manufacture of bent sheet metal parts

© 2008 Festo Corporation 11 U

Page 12

Getting Started with Festo MecLab

Overview

The MecLab® stations perform the following functions:

Stack magazine station:

Stores and separates work pieces. An additional function, either “stamping” or “insertion”,

can be performed by the stamping unit.

Conveyor station:

Transports work pieces. An additional function, “sorting” or “rejection”, can be performed by

the ejecting solenoid.

Handling station:

Transfers work pieces between two points which can not be covered by conveyor.

The function of each station can be modified by adding or removing components. For example if the ejecting solenoid is removed from the conveyor station, it can still convey but no

longer sort. If the solenoid is moved from one side of the conveyor to the other, the deflector

becomes a stopper.

Stations are controlled using FluidSIM® simulation and control program in combination with a

modified EasyPort. This allows FluidSIM® to read sensor signals from the stations and to actuate the drives of each station. It is also used to connect the stations with the USB interface

of the PC.

The software contains sample programs designed to help the student “get started” with programming. Since the Meclab system is made of industrial components, it is also possible to

perform “manual override” operations.

Students are encouraged to use the provided tools to disassemble and reassemble the stations. The stations can be used independently or joined together to form a production line.

© 2008 Festo Corporation 12 U

Page 13

Getting Started with Festo MecLab

Overview

The Meclab system consists of the following:

− 1 compressor for supplying the stations with compressed air

− 6 licenses of FluidSIM for MECLAB® simulation and control program

− 3 modified EasyPorts for connecting the stations to a PC

− 3 power supply units for supplying power to the EasyPort

− 3 sets of workpieces

− 3 sets of tools and small parts

− All instruction material (e.g. this book) on CD-ROM

The following information can be found on the supplied CD-ROM:

− Introduction: Teaching with Meclab (this document)

− Instructions for commissioning the three stations

− Theory section: Explains key technologies, components and other relevant information

− Exercise sheets: Designed to assist the student in becoming familiar with automated sys-

tems , relevant technologies and project planning

− PowerPoint presentation

© 2008 Festo Corporation 13 U

Page 14

Getting Started with Festo MecLab

Commissioning

Install FluidSIM®

The FluidSIM® simulation and control program must be installed on a computer which has a

CD-ROM drive as well as a USB interface (version 1.1 or higher).

To install FluidSIM®, insert the enclosed CD-ROM, open the FluidSIM® directory, double-click

on the "setup.exe" file and follow the installation instructions.

Assemble the stations

MecLab® stations are delivered assembled. To commission a station, perform the following

steps:

− Insert the EasyPort interface module (1) to the Sub-D socket on the multi-pin plug distributor (2).

− Connect power supply unit to the EasyPort (3).

− Connect EasyPort to the PC using the USB cable (4) provided.

− Launch FluidSIM®:

− Click on "Open file"

− Open a sample program (see table below).

− Start operating the program sample program by clicking on the start arrow on the tool bar

at the top of the screen.

Figure 3.1: Connecting the EasyPort

© 2008 Festo Corporation 14 U

Page 15

Getting Started with Festo MecLab

Sample Programs

The FluidSim software contains sample programs to help the Instructor and the student get

started in programming the MecLab stations. These samples are located in the “ct

file\MecLab Samples. Use these files to become familiar with how the software and the hardware operate.

CAUTION: Any changes to the sample circuits, if saved, will change the sample program.

Save the file under a different name.

Program Station Function

1-4.ct

1-5.ct

1-7.ct

2-5a.ct

2-7.ct Conveyor Activate conveyor by means of a through-beam sensor.

2-8.ct

DC MOTOR

RELAY. ct

3-4.ct Handling Manually advance “z” axis

Stack

magazine

Manually activate single-acting cylinders

Stack

magazine

Manually activate double-acting cylinders

Stack

Separate and press lids onto containers (automatic)

magazine

Conveyor Activate conveyor by means of a through-beam sensor

Sort metal work pieces and de-activate the conveyor after 5

seconds.

Conveyor Activate conveyor by means of a through-beam sensor.

Sort metal work pieces and de-activate the conveyor after 5

seconds .

Manually reverse conveyor direction.

Conveyor Manually activate/deactivate conveyor. Reverse conveyor di-

rection.

3-6.ct Handling Automatically advance “z” axis in continuous operation.

3-7.ct

Handling Automatically reposition work piece from rear to the front

© 2008 Festo Corporation 15 U

storage plate.

Page 16

Getting Started with Festo MecLab

Safety and Maintenance

MecLab® has been designed in compliance with all relevant safety guidelines. As with all

technical systems, there is additional safety information that must be observed.

General

Students must be supervised at all times when working on the stations.

Read Data sheets and note individual station safety information.

Electrical components

Electrical power must be disconnected before making or breaking electrical connections.

Use only extra low voltages (max. 24 V DC).

Pneumatic components

− Do not exceed 60 psi (4 bar).

− Do not turn on compressed air until all tubing connections have been established and se-

cured.

− Do not uncouple tubing under pressure.

− Be alert for “pinch points” when switching on compressed air as cylinders can automati-

cally extend or retract.

− Loose tubing can “whip” rapidly causing serious eye injury. Ensure that “main air” is

turned off before disconnecting or connecting tubing.

− Always wear safety goggles when working on or near the system.

− Select tubing length that will provide the shortest connection between two ports.

Pneumatic circuit assembly:

− Connect devices using plastic tubing with an outside diameter of either 4 or 6 mm

(whichever is appropriate)

− Push the tubing as far as possible into the push-in connector.

© 2008 Festo Corporation 16 U

Page 17

Getting Started with Festo MecLab

Safety and Maintenance

Pneumatic circuit disassembly:

− Switch off the compressed air supply before disassembling the circuit.

− Press down on the blue release ring to pull out the tubing.

Compressor

Air pressure can be regulated at the compressor:

− Pull out the rotary knob on the pressure regulator and turn until pressure gauge shows

the required pressure.

− Push rotary knob back in (this locks the regulator).

− Do not touch the compressor once started as it can become extremely hot during opera-

tion.

− After switching off the compressor, release the pressure from the compressor tank.

− Do not leave the compressor running uninterrupted for more than one hour.

Mechanical components

− Install all components securely on the plate.

− Do not place your hand in the station while it is running.

Maintenance information

MecLab® is essentially maintenance-free. Wipe occasionally with a dry, lint free rag.

Water must be drained from the compressor tank or water separator (at the regulator) at

regular intervals.

Inspect compressor tank regularly for damage.

© 2008 Festo Corporation 17 U

Page 18

Getting Started with Festo MecLab

Stack Magazine Station

Virtually all automated production requires the temporary storage of raw material, semifinished product or finished product. Often the material is kept on pallets or in warehouses.

At some point the material (or parts) will be brought to the production line. It is here that the

work pieces must be organized in such a way that they can be fed into the production process as quickly and efficiently as possible.

Many small parts such as screws, nuts or springs are supplied in bulk and have to be arranged before they can be processed. Vibration feeders (Figure 4.1) are often used for this.

The high-speed vibrations move the small parts into either a “gate” or a vision system that

only let correctly aligned parts through and then on to the production process.

Figure 4.1: Vibration feeder for

storing and sorting screws

© 2008 Festo Corporation 18 U

Page 19

Getting Started with Festo MecLab

Stack Magazine Station

Delicate work pieces are generally supplied in an organized manner. Smaller work pieces

are often stored on tape while larger work pieces are stored on pallets (Figure 4.2 shows integrated circuits (ICs) on a pallet, normally called a tray in the electronics industry).

Figure 4.2: ICs on a pallet

The stack magazine is one of the simplest ways to store work pieces in an organized manner.

In production systems, the components are delivered in tube magazines. This means the

stack magazines can be filled quickly.

Besides storing and separating, the stack magazine station also contains a "pressing” function: when a container is placed on the deposit table, a lid can be pushed out from the stack

magazine and then pressed closed by the second pneumatic cylinder.

In addition to the electro mechanical content, the stack magazine station can also be used as

an introduction to "pneumatics".

As with the conveyor and the handling system, the FluidSIM® software is used to control the

stack magazine. Students can learn about the structure and function of programs used to

control automated production sequences.

© 2008 Festo Corporation 19 U

Page 20

Getting Started with Festo MecLab

Stack Magazine Station

Although not necessary, a basic knowledge of CAD/CAM programs is helpful when using the

FluidSIM software. The software, in turn, can be useful in learning:

− The function of simple electro-pneumatic circuits.

− The operation of common application programs.

− The sequence of production processes.

− The basics of pneumatics.

Stack Magazine Station Components

The stack magazine station consists of components that can be used on their own or combined, depending on the task. The system was designed for flexibility in order to meet varying

requirements. All necessary tools are provided with the system.

Figure 4.3: Complete structure of the Stack magazine station

© 2008 Festo Corporation 20 U

Page 21

Getting Started with Festo MecLab

Stack Magazine Station

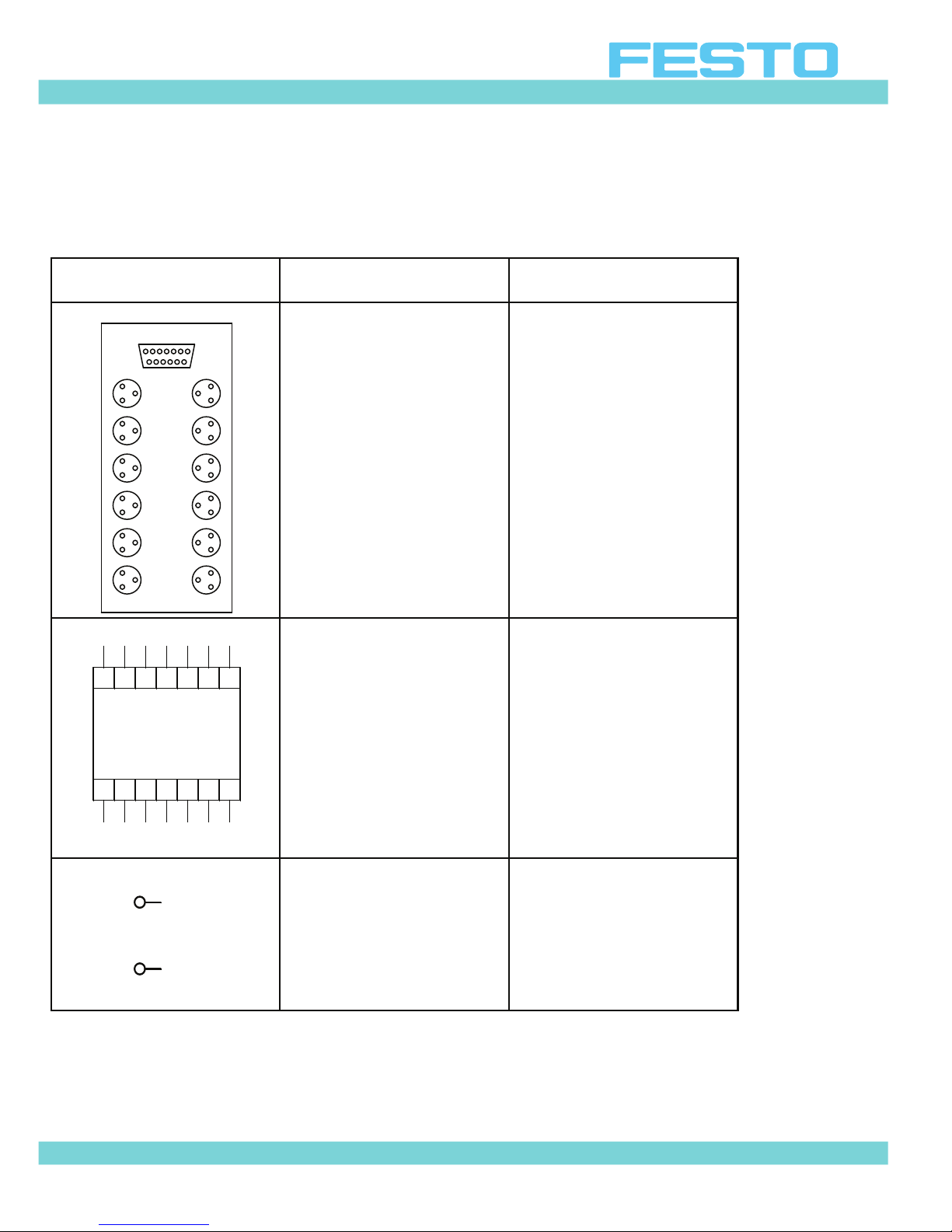

The following table lists the most important components of the Stack magazine station together with their circuit symbol.

Component Symbol Function

Mounting kit for proximity

sensors

Magnetic proximity sensor

for detecting the position of

the cylinder piston

3/2-way stop valve used for

shutting off the compressed

air and exhausting system.

T-connector for distributing

the compressed air

Single-acting cylinder with

50 mm stroke and 10 mm piston diameter

© 2008 Festo Corporation 21 U

Double-acting cylinder with

50 mm stroke and 10 mm piston diameter

One-way flow control valve,

used to regulate the speed of

pneumatic actuators

Page 22

Getting Started with Festo MecLab

Stack Magazine Station

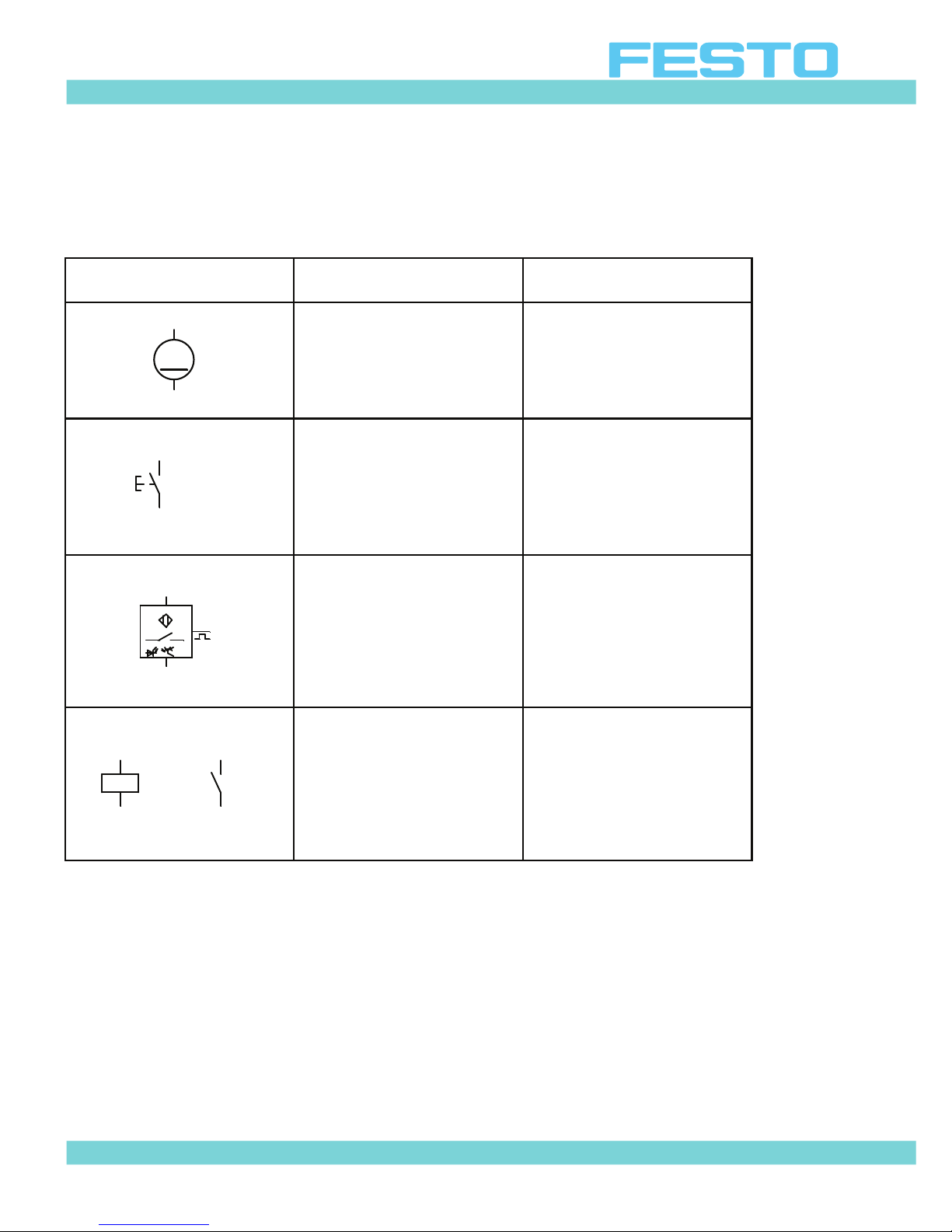

Component Symbol Function

4/2-way solenoid valve, with pneumatic spring

4/2-wa

Multi-pin plug distributor for connecting the

electrical components

return

y double solenoid valve

© 2008 Festo Corporation 22 U

Page 23

Getting Started with Festo MecLab

Stack Magazine Station

Assembly and Wiring

Several lessons require the student to disassemble and then reassemble the system. Follow

the instructions in this section.

An aluminum profile plate is used as a base in order to mount the components of the stack

magazine. T-nuts are used to secure the components to the plate. The tool used for assembling and disassembling are an adjustable wrench and a hex head, or Allen key.

Use the screwdriver to adjust the one-way flow control valves. Pneumatic tubing can be cut

to the correct length using the tubing cutter. Do not use scissors or knives to cut the tubing

as this can result in leaks.

The station contains a single-acting cylinder (press), a double-acting cylinder (ejector) and a

4/2-way single solenoid valve that are plumbed and wired. There is a second valve (double

solenoid) as well as a “reed” switch (magnetic proximity sensor) that must be plumbed and

wired. The instructions are listed on page 22.

Figure 4.4: Stack magazine station

© 2008 Festo Corporation 23 U

Page 24

Getting Started with Festo MecLab

Stack Magazine Station

Assembling the 4/2-way double solenoid valve

1. Shut off compressed air supply and electrical power.

2. Loosen the retaining screws that connect the valve to the valve retainer.

3. Remove the two short screws and replace with the longer screws.

4. Screw down the two valves using the longer screws.

5. Install tubing between outputs 2 and 4 of the valve and the corresponding ports on the

double-acting cylinder. Use the tube cutter to cut the tubing.

5a. Port 2 is connected to the front cylinder chamber.

5b. Port 4 is connected to the rear cylinder chamber.

6. Connect the valve to the multi-pin plug distributor.

6a. Connect valve solenoid 1M1 to slot # 3.

6b. Connect valve solenoid 1M2 to slot # 5.

Figure 4.5: Assembling the second valve

© 2008 Festo Corporation 24 U

Page 25

Getting Started with Festo MecLab

Stack Magazine Station

It is also possible to install a sensor for checking the end position of the double acting cylinder. This ensures that the overall sequence is monitored and enables the next step in the sequence.

The sensor is installed by placing the mounting kit for proximity sensors around the cylinder

body and securing it using the screw provided. The sensor is then inserted in the retainer

and carefully secured by turning the socket head screw half a rotation.

Figure 4.6: Proximity sensor on the cylinder

In order to establish a connection between the computer and the individual components, the

sensor must be connected to the multi-pin plug distributor.

The cables for the valves are connected to the row labeled with uneven numbers on the multipin distributor. These are “inputs” from the “control system” which is the FluidSIM software.

The cables for the sensors are connected to the row labeled with even numbers. These are

“outputs” to the “control system”.

© 2008 Festo Corporation 25 U

Page 26

Getting Started with Festo MecLab

Stack Magazine Station

Converting the 4/2-way solenoid valve

This shows normal use of a

4/2 directional control

to contr

cylinder. All

(1,2,3 and 4).

ol a double acting

ports are used

valve

This shows a 4/2 directional

control valve

to function a

tional contr

(normall

port 2 is plugged.

reconfigured

s a 3/2 direc-

ol valve

y closed). Note that

Figure 4.7: Converting a 4/2-way single solenoid valve

This shows a 4/2 directional

control valve

to function a

tional contr

(normall

port 4 is plugged.

reconfigured

s a 3/2 direc-

ol valve

y open). Note that

© 2008 Festo Corporation 26 U

Page 27

Getting Started with Festo MecLab

Stack Magazine Station

a) 4/2-way solenoid valve (normal use in combination with a double-acting cylinder)

b) 3/2-way solenoid valve normally closed (in combination with a single-acting cylinder;

port 2 is “plugged”)

c) 3/2-way solenoid valve, normally open (in combination with a single-acting cylinder;

port 4 is “plugged”, the cylinder is advanced in the switching position shown)

The station contains two valves they are both 4/2-way directional control valves. This means

that they each have 4 ports and 2 positions. The difference is in how the valves are actuated.

One valve is actuated by means of single solenoid the other is actuated by means of two solenoids.

The 4/2-way valve can be converted to a 3/2-way valve by sealing one of the two outputs.

The decision to seal one of the two output ports should be made after deciding which type of

valve is desired, normally closed or normally open.

The 4/2-way single solenoid valve is supplied with output 4 sealed, producing a 3/2-way normally closed valve. In this configuration the valve can be used to activate the single-acting

cylinder (stamping cylinder).

Opening output 4 produces a 4/2-way valve for actuating the double-acting cylinder.

Sealing output 2 produces a 3/2-way normally open valve. If this valve is used, the single acting cylinder will extend when the valve is not actuated and retract when the valve is actuated.

© 2008 Festo Corporation 27 U

Page 28

Getting Started with Festo MecLab

Stack Magazine Station

Sample exercise using the stack magazine

The purpose of this section is to explain the interaction of the FluidSIM® software and the

hardware components of the stack magazine station using a sample exercise.

Task

1. Build a stack magazine that pushes out one work piece when a button is momentarily

pressed.

2. When a second button is pressed, the stack magazine returns to its normal position.

Analysis of the task

1. The signal to advance must be “remembered” since the pushbutton is to be briefly or momentarily pressed.

2. The double-acting cylinder is actuated using a 4/2-way solenoid valve.

3. The 4/2-way double solenoid valve is used to store or remember the pushbutton signal.

Solution

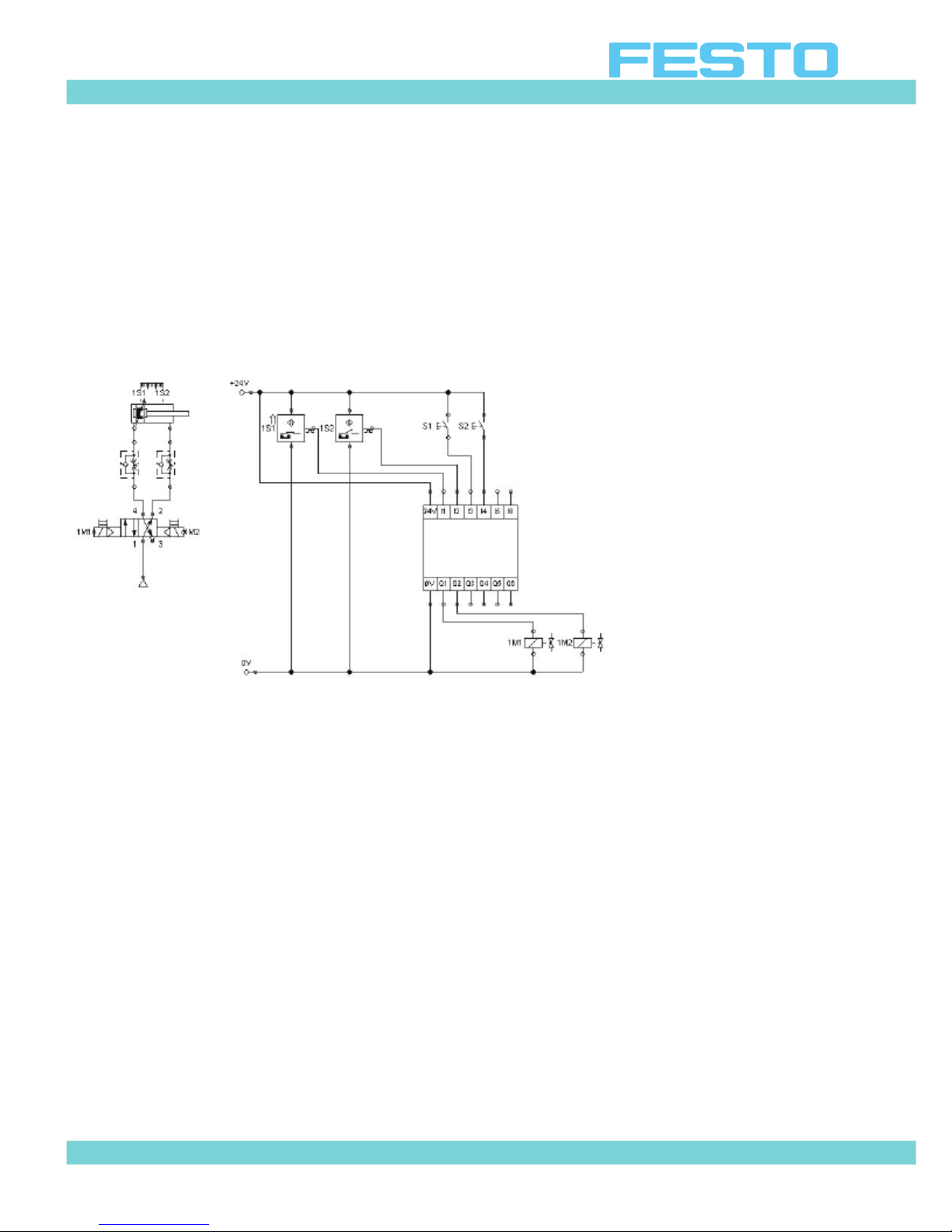

If not already done, the second valve as well as the magnetic proximity sensor must first be

assembled and connected (cf. Section 4.3). The circuit diagram in Figure 4.8 shows an example of how the components can be connected. Table 4.1 describes the connection of the sensor and the valve solenoids to the multi-pin plug distributor.

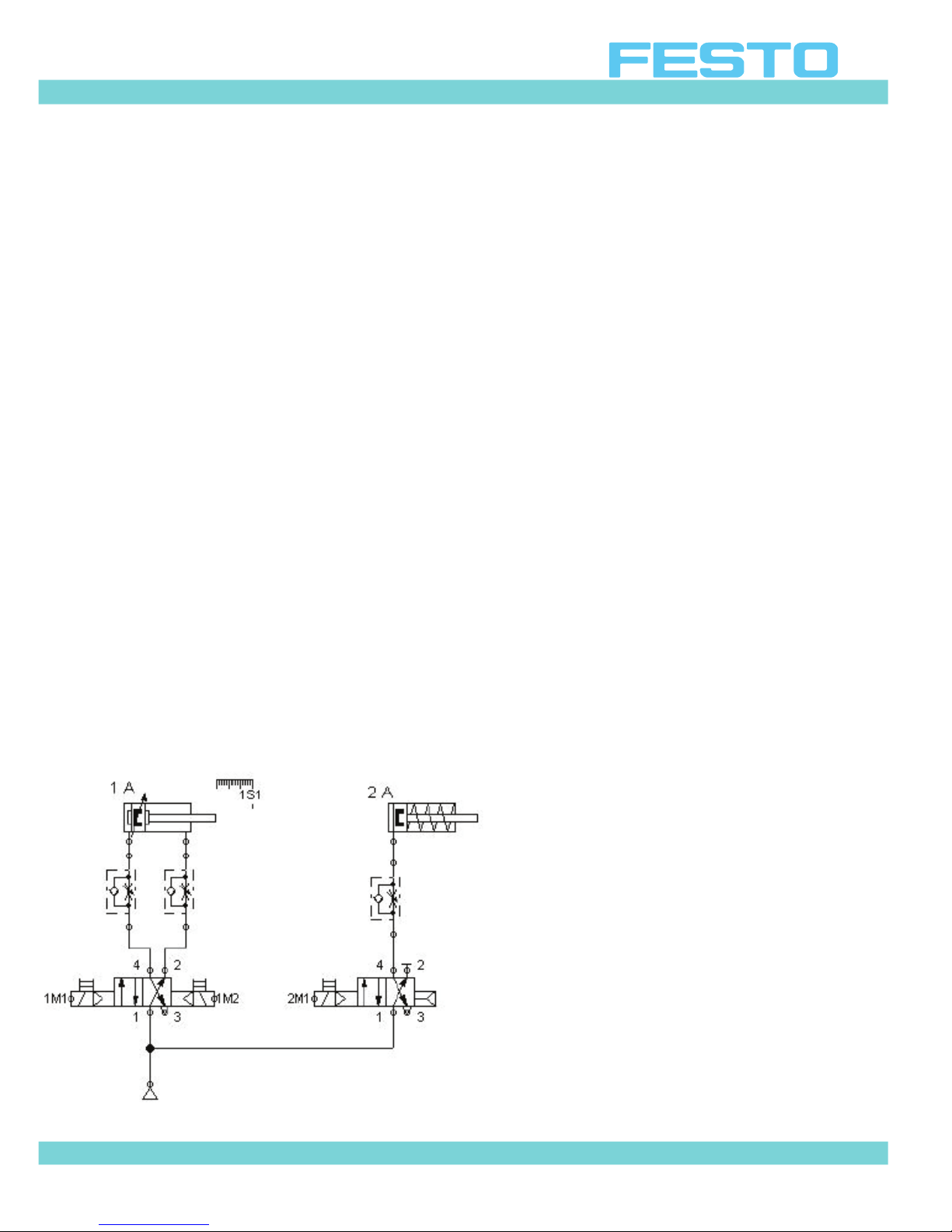

Figure 4.8: Pneumatic circuit diagram of

the stack magazine station

© 2008 Festo Corporation 28 U

Page 29

Getting Started with Festo MecLab

Stack Magazine Station

Slot Assignment Label

0 Sensor 1S1

1 Valve solenoid 2M1

3 Valve solenoid 1M1

5 Valve solenoid 1M2

Table 4.1: Pin allocation for the stack magazine station

The following are the steps necessary to launch and configure the control software:

Step 1: Launch the FluidSIM® program

Open the FluidSIM® program by double-clicking on the program icon.

Call up a new workspace. Click on the blank white page on the left in the second menu bar. A

new blank workspace appears. This will be the “controller”.

Save the new controller

To do this, select "File > Save As ..." in the menu bar and save the file to the desired location.

© 2008 Festo Corporation 29 U

Page 30

Getting Started with Festo MecLab

Stack Magazine Station

Step 2: Create the pneumatic circuit diagram

The components needed to create the pneumatic circuit diagram are located in the library on

the left side of the screen. Insert each component by:

− Left clicking and holding on the appropriate symbol.

− Dragging the symbol to the desired location in the circuit diagram.

− Releasing the left mouse button.

The pneumatic system consists of a double-acting cylinder, a 4/2-way double solenoid valve,

two one-way flow control valves and the compressed air supply. Figure 4.9 shows the component library.

Figure 4.9: Component library

© 2008 Festo Corporation 30 U

Page 31

Getting Started with Festo MecLab

Stack Magazine Station

The one-way flow control valves should be rotated to ensure straight flow paths. Right-click

on the symbol and select “Rotate” and then "270°" in the context menu.

Figure 4.10: Rotating the one-way flow control valves

Next “plumb” the components. Position the mouse over a “node point” (looks like a circle next

to one of the numbers) of the symbol until a crosshair is displayed. Left click, hold and drag to

the node point of the symbol that you want to connect to. Release the left mouse button as

soon as the crosshair symbol confirms the connection.

Figure 4.11: Tubing installed between the pneumatic components

© 2008 Festo Corporation 31 U

Page 32

Getting Started with Festo MecLab

Stack Magazine Station

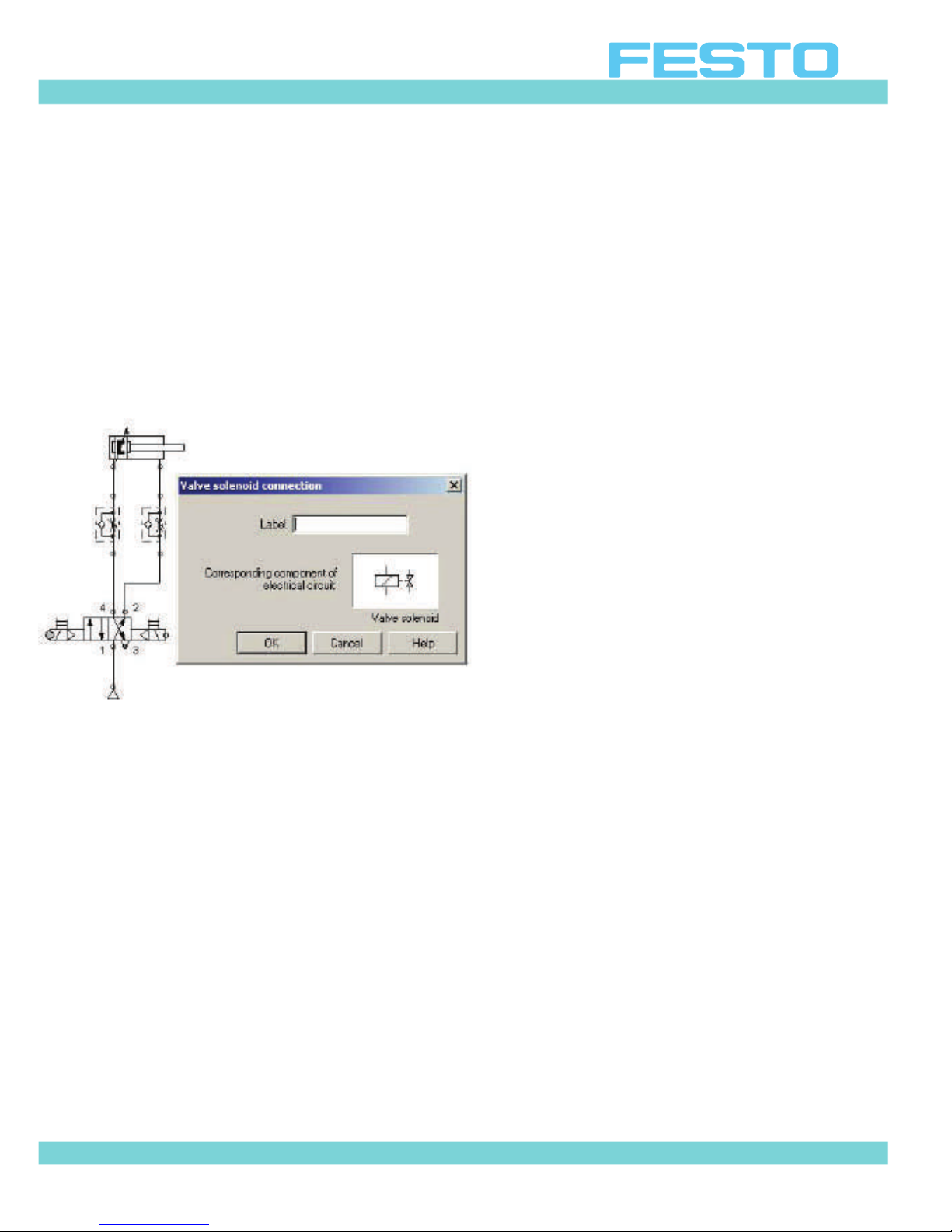

To link valve solenoids with the electrical circuit simply label the valve solenoid symbol (in the

pneumatic diagram) with the same label as the solenoid coil symbol (in the electrical diagram).

Right-click on the node of a valve solenoid (look for a small circle at the end of the solenoid

symbol). A menu will open. Select “properties". Then type in the designation in the “label”

field. The left-hand valve solenoid is normally called 1M1 and the right-hand 1M2 as per the

connection table.

Figure 4.12: Entering a label for the valve solenoid

© 2008 Festo Corporation 32 U

Page 33

Getting Started with Festo MecLab

Stack Magazine Station

Step 3: Simulate the pneumatic circuit diagram

Start the simulation by clicking on the “Start” button.

Left-clicking on the left or right manual override will extend or retract the cylinder.

Figure 4.13: Simulating the pneumatic circuit diagram

© 2008 Festo Corporation 33 U

Page 34

Getting Started with Festo MecLab

Stack Magazine Station

Step 4: Create an electrical circuit diagram

Select the symbols in the “component library” under the subcategory “Electrical

Controls” in the column on the left.

Left click, hold and drag each component to the right side of the program window (the white

area) release the left mouse button and component will appear on the white field.

Look for and drag out the following components:

− Power supply (24 V)

− Power supply ( 0 V)

− 2 pushbuttons (normally open)

− 2 valve solenoids.

Note:

The symbol for the valve solenoid is located in the library subcategory Pneumatic (see Figure

4.9).

Figure 4.14: Workspace with pneumatic circuit diagram and electrical components

All electrical components are wired in the same manner as the pneumatic components by

clicking on the “node points” and dragging the connecting cable to the next contact.

© 2008 Festo Corporation 34 U

Page 35

Getting Started with Festo MecLab

Stack Magazine Station

This produces a circuit diagram like that shown in Figure 4.15.

Figure 4.15: Wiring of the electrical circuit

Remember to assign the same label to the components that are located in both the electrical

schematic and the pneumatic diagram (for example the “valve” solenoid in the pneumatic diagram and the electrical solenoid “coil” in the electrical schematic) otherwise the circuit will

not operate correctly.

Figure 4.16: Inserting labels for the valve solenoids

© 2008 Festo Corporation 35 U

Page 36

Getting Started with Festo MecLab

Stack Magazine Station

Step 5: Simulate the entire circuit

Pressing the start button executes the simulation in FluidSIM®. This is an easy and safe way

of testing the operation of the electrical and pneumatic circuits.

To execute the individual program steps, the pushbuttons must be actuated in simulation

mode by clicking on them with the mouse. Actuating the left pushbutton closes the circuit,

the solenoid valve reverses, the valve opens the path for the compressed air and the pneumatic cylinder extends.

Actuating the right pushbutton retracts the cylinder piston to its initial position.

Note the following in FluidSIM®:

Pneumatic circuit:

Light blue lines represent lines that are not supplied with compressed air. Dark blue lines

represent lines that are pressurized.

Electrical circuit:

Red lines represent the path in the circuit that is conducting current

Figure 4.17: Simulating the

electro pneumatic circuit

.

© 2008 Festo Corporation 36 U

Page 37

Getting Started with Festo MecLab

Stack Magazine Station

Step 6: Perform test with the stack magazine station

Note:

Please observe all safety regulations when station is supplied with compressed air and electrical power.

The “real” cylinder will extend if the symbol for the multi-pin plug distributor is inserted in the

FluidSIM® program (provided the station is connected via the EasyPort). An error message

will appear if the EasyPort is not connected. Simulation is still possible if this happens (cf.

Figure 4.18).

Figure 4.18: Program with multi-pin plug distributor

© 2008 Festo Corporation 37 U

Page 38

Getting Started with Festo MecLab

Stack Magazine Station

Labels in the symbolic multi-pin plug distributor must be assigned. Open the symbol by double-clicking on it (Figure 4.19).

Labels are then assigned as per Table 4.1. The labels must match those used in the pneumatic and electrical circuit diagrams. The multi-pin plug symbol will then establish the connection to the stack magazine station.

It makes no difference what the labels are called (1M1 is a typical designation. It could also

be called "left valve solenoid" or “Joes solenoid” if you wish). The only important thing is that

the same labels are used for the same element in the pneumatic and electrical circuit diagrams and that this element is plugged into the correct slot on the multi-pin plug distributor.

Note:

The "Priority when hardware connected" box must be ticked. This ensures that the signals

for the actual sensors are used and not those simulated in the program.

If the simulation is started and pushbutton S1 is actuated, the cylinder in the station will extend. The status of the input and output channels is indicated in color in the multi-pin plug

symbol.

On the multi-pin plug distributor in the stack magazine station, the status of the input and output channels are indicated by LEDs. The program can now be extended step-by-step to incorporate the other actuators and sensors into the station.

© 2008 Festo Corporation 38 U

Page 39

Getting Started with Festo MecLab

Stack Magazine Station

Figure 4.19: Dialog box for the multi-pin Figure 4.20: Dialog box for the multi-pin

plug distributor (default settings) plug distributor with labels set

© 2008 Festo Corporation 39 U

Page 40

Getting Started with Festo MecLab

Conveyor Station

Conveyors are technical systems that are used in industry for the production (mainly transport) of material.

Conveyors are used in everyday life. Supermarkets use conveyors for groceries at cash registers and department stores use conveyors in the form of escalators for the convenience of

their customers. In airports “moving walkways” help passengers move faster between ever

expanding terminals.

Conveyors helped revolutionize industrial production. Henry Ford, in 1913, pioneered an entirely new method of production with the development of the assembly line and its use in

automobile production.

The technology of the assembly line has long since been transformed to become what it is today. These days computer-controlled systems have taking over the heavy manual labor role

of production lines.

The Conveyor station poses challenging electromechanical lessons because of it’s flexibility

in applications.

Figure 5.1: Conveyor station

© 2008 Festo Corporation 40 U

Page 41

Getting Started with Festo MecLab

Conveyor Station

The conveyor station can be used as one of three processes in a production assembly line or

as a stand-alone single unit. The following assumes that the conveyor is to be used as a

stand-alone unit.

The unit consists of modules that can be disassembled into individual components. This provides flexibility when conducting the lessons:

− The conveyor can be used as a complete technical system for one set of lessons.

− The conveyor module or each modules individual components can be used for another set

of lessons.

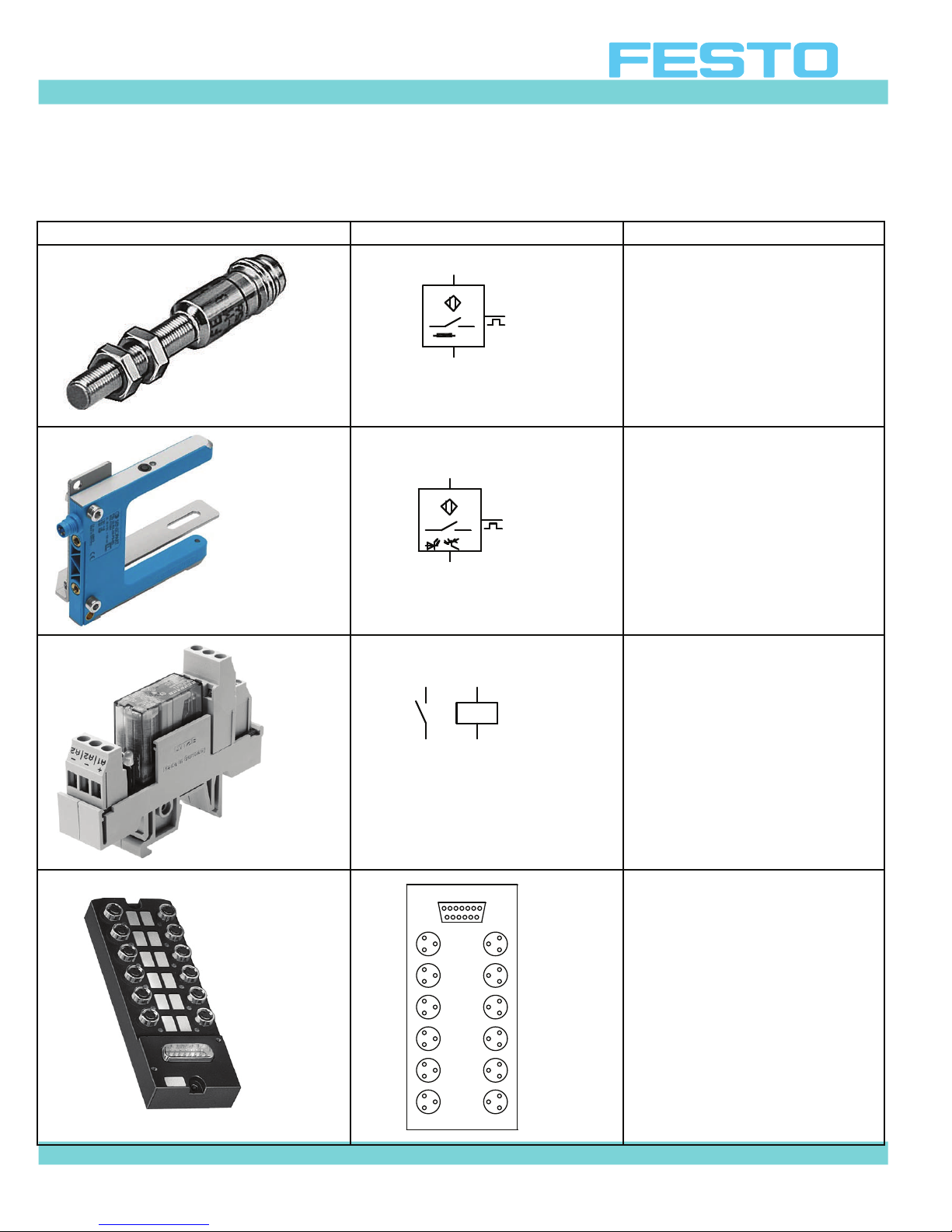

Components of the conveyor station

The following table lists the most important components and corresponding circuit symbols

of the conveyor station.

Illustration Symbol Description

DC geared motor. Moves

the belt of the

conveyor which, in turn,

M

transports the work

pieces. Can be made to

run forward and in reverse.

Solenoid. Acts as either a

deflector or stopper (can

eject or hold the work

piece)

depending on which side

the unit has been

attached.

© 2008 Festo Corporation 41 U

Page 42

Getting Started with Festo MecLab

Conveyor Station

Illustration Symbol Description

Inductive sensor. Senses

metal or

metal-coated work pieces.

Optical sensor. Detects

any work pieces that

breaks the beam of light

(any non-transparent

item).

Relay. Activates the motor. Can be used to reverse the polarity of the

motor (reverse direction).

Multi-pin plug distributor.

This is the interface for

0

1

connecting all actuators

and sensors of the con-

2

4

6

3

5

7

veyor station to the control PC.

© 2008 Festo Corporation 42 U

8

10

Priority active

9

11

Page 43

Getting Started with Festo MecLab

Conveyor Station

Assembly and wiring

The conveyor station is supplied assembled. In order to commission the system, the station

must be connected to the USB port of the PC using the EasyPort as well as to the power supply using the 24V power supply unit as described in Section 3.

The station can be reconfigured in order to accomplish different tasks. The function is primarily determined by the position of the sensors and the solenoid:

− Depending on which side of the conveyor it is mounted the solenoid can act as either a

stopper or deflector.

− The through-beam sensor reacts to all work pieces, while the inductive sensor only reacts

to metal work pieces. This can initiate actions such as starting or stopping the belt motor

and or triggering the solenoid.

Actuators and sensors must be wired properly in order for the supplied programs to operate. All pin assignments are described in the diagram in the sample program.

Sample conveyor exercise

The following sample exercise explains the step-by-step operation of the FluidSIM® software

as well as its interaction with the conveyor.

Task

1. Conveyor must start when a button is pressed.

2. The system must continue to run until a second button is pressed or until the work piece

has reached the end of the conveyor.

Analysis of the task

1. Only the conveyor motor is required for this task.

2. The solenoid and the slide can be removed.

3. A sensor that detects all work pieces must be mounted at the end of the conveyor. Only a

through-beam sensor can be used.

4. One pushbutton for starting the motor and a second pushbutton for switching it off must

be included in the control program.

© 2008 Festo Corporation 43 U

Page 44

Getting Started with Festo MecLab

Conveyor Station

Solution

The solution involves four steps:

1. Create the mechanical setup

2. Create the circuit diagrams and programming in FluidSIM®

3. Test the program via simulation

4. Test the program with the conveyor station

Step 1: Create the mechanical setup

Figure 5.2: Schematic diagram of the conveyor

Figure 5.2 is a schematic diagram of the conveyor as it is required for the task. It shows the

arrangements of the components. It is important to understand a systems layout in order to

plan and design the control program.

The optical sensor (through-beam sensor) must be mounted at the end of the conveyor using

the enclosed tool.

Since they will not be used, remove the stopper and the slide.

The following table provides an overview of the wiring at the multi-pin plug distributor:

Table 5.1: Pin assignment on the multi-pin plug distributor

© 2008 Festo Corporation 44 U

Page 45

Getting Started with Festo MecLab

Conveyor Station

Note:

In electrical circuit diagrams sensors are normally indicated with an "S" and relays with a

"K".

Step 2: Create the circuit diagrams and programming in FluidSIM®

− Launch FluidSIM®

− Double-click with the left mouse button on the FluidSIM® icon to access the start page of

the program.

− Click on "File > New" to open the actual workspace.

Select and place the required components. All required components are located in the component library. The library is divided into the following areas:

− Pneumatics

− Electrics

− Digital technology

− EasyPort

− Miscellaneous

In this exercise the required components will be selected from the "Electrics" and "Digital

technology" section of the component library.

Left-click on the appropriate section (this opens the folder) and then left-click and hold on the

desired component symbol. Drag the symbol to the workspace and release the left mouse

button.

The following table provides an overview of some of the components in FluidSIM®.

© 2008 Festo Corporation 45 U

Page 46

Getting Started with Festo MecLab

24V

Conveyor Station

Symbol

Multi-pin plug distribu-

tor

0

2

4

6

8

10

Priority active

1

3

5

7

9

11

Digital module (can

also be used as a PLC)

24V I1 I2 I3 I4 I5 I6

0V Q1 Q2 Q3 Q4 Q5 Q6

Voltage supply and 0

+

volts return

0V

Table 5.2: Important components in FluidSIM®

Designation

Function

Establishes the connection with the

Hardware. Labels

must match between

this device and the labels on the actuators

and

sensors in the FluidSIM® program.

Contains the logic program. Double click on

the device to open.

Supplies components

with power.

Attention: Without

power the components

will not work in the

simulation.

© 2008 Festo Corporation 46 U

Page 47

Getting Started with Festo MecLab

Conveyor Station

Symbol

Motor, DC Drives the conveyor.

M

Switch For manual interven-

34

Sensor (optical) The connections on

Relay coil with switch

A1

A2

Table 5.2: Important components in FluidSIM®

3

4

Designation

Function

Switched on and off

using relays.

tion in the program.

the top and bottom are

for the power supply.

The connection on

the side is the signal

output.

When current flows

through the coil, the

associated switch (the

switch with the same

label) will either close

or open.

© 2008 Festo Corporation 47 U

Page 48

Getting Started with Festo MecLab

Conveyor Station

Figure 5.3: Workspace of FluidSIM® with all the required components

Figure 5.4: Wiring of the components

© 2008 Festo Corporation 48 U

Page 49

Getting Started with Festo MecLab

Conveyor Station

Note:

Mistakes can be erased by simply clicking on the component, wiring etc., and pressing the

"Delete" button.

− Assign labels. Labels must be assigned in order for the FluidSIM® software to “link” the

components that belong together.

− Right-click on the component symbol. A context menu will appear.

− Select "properties".

− Enter the label in the dialog box (cf. Figures 5.5 and 5.6). Both parts of the relay (the sym-

bol for the coil and the symbol for the set of contacts) must have the same label, in this

case K1.

− Repeat the procedure for the sensor (labeled S1).

− Repeat for each of the two (PB1 and PB2), cf. Figure 5.7.

Figure 5.5: assigning labels (1)

© 2008 Festo Corporation 49 U

Page 50

Getting Started with Festo MecLab

Conveyor Station

Figure 5.6: Assigning labels (2)

Figure 5.7: Circuit with assigned labels

© 2008 Festo Corporation 50 U

Page 51

Getting Started with Festo MecLab

Conveyor Station

− Link the logic modules in the digital module. To enter the logic program in the digital mod

ule or the PLC (programmable logic controller):

− Open the digital module by double-clicking on it. A new window containing the digital module's input and output channels will be displayed.

Figure 5.8: Input and outputs channels of the digital module

On the left side are the inputs marked I1 to I6, on the right side the outputs marked Q1 to Q6.

Link the inputs and outputs by inserting logic modules. These are in the library on the left

side of the screen and are dragged to the workspace and connected in the same manner that

has been previously described.

The main purpose of the PLC (programmable logic controller) is to process the signals supplied by the sensors in such a way that the actuators can perform the required action.

© 2008 Festo Corporation 51 U

Page 52

Getting Started with Festo MecLab

Conveyor Station

As mentioned earlier the following functions are required:

− The motor is to start when a pushbutton is actuated (therefore a latching circuit is required to “store” or “remember” the pushbutton signal.

− The motor is to stop again when the second pushbutton or the through-beam sensor is actuated (requires an “OR” gate).

Figure 5.9 shows the digital module (or the PLC) with the connected logic gates. Closing the

input window stores the program in the digital module (or PLC).

Figure 5.9: Digital module with logic gates

Note:

The “lo level” module can be used to provide the third input of the OR gate. The program will

work without this module, but using it may avoid an “input undefined” flag when activating.

© 2008 Festo Corporation 52 U

Page 53

Getting Started with Festo MecLab

Conveyor Station

Step 3: Test the program

To start the simulation, the window of the digital module must be closed.

− Click on the arrow on the tool bar at the top of the window.

− Start the circuit by clicking on the main switch. Clicking on the pushbutton PB1 starts the

motor (indicated by a small arrow).

− To “simulate” a part arriving at the end of the conveyor, click on sensor S1. The motor

should stop.

Figure 5.10: Simulation mode, pushbutton PB1 actuated

© 2008 Festo Corporation 53 U

Page 54

Getting Started with Festo MecLab

Conveyor Station

Step 4: Test program via hardware

− Insert the symbol for the multi-pin plug distributor in the program (cf. Figure 5.11).

Figure 5.11: Program with multi-pin plug distributor

− Assign labels to the connection points on the distributor.

− Open the distributor symbol by double-clicking on it (Figure 5.12).

− Change the labels as per Table 5.1.

© 2008 Festo Corporation 54 U

Page 55

Getting Started with Festo MecLab

Conveyor Station

Figure 5.12: Multi-pin plug distributor dialog box before and after setting the labels

The labels must match those used in the electrical circuit diagram. The distributor can then

establish the connection to the station. Remember, it is not important what you call the components. It is however important that component listed in the dialog box has the same label

as the actual symbol in the electrical circuit diagram and that the actual (real) element is

plugged into the correct slot on the (real) multi-pin plug distributor.

Note:

There is a “check-off” box in the dialog box called "Priority for connected hardware". The box

must be checked to ensure that signals for the actual sensors are used and not those simulated in the program.

If the simulation is now started and pushbutton PB1 is actuated, the conveyor motor should

start. The status of the input and output channels are indicated in color on the multi-pin plug

symbol. On the station's multi-pin plug distributor, the status of the input and output channels

are indicated by LEDs.

The program can now be modified as needed to incorporate the other actuators in the station.

© 2008 Festo Corporation 55 U

Page 56

Getting Started with Festo MecLab

Handling Station

Movement, orientation and assembly of work pieces are a common function of automated assembly systems. These tasks are often performed by automated handling machines. The

most powerful are industrial robots (cf. Figure 6.1).

Industrial robots have at least four axes (also called joints), making them extremely flexible.

They are also fast (over 1 meter per second) and accurate.

Robots are also expensive therefore simpler, less expensive handling devices are normally

used for many assembly tasks.

Figure 6.1: Industrial robot (picture by Festo Didactic)

The following data is important and normally provided by manufacturers of handling devices:

− Number of axes

− Speed

− Accuracy (normally called “repeatability)

− Working space (normally called “window” or “envelope”)

© 2008 Festo Corporation 56 U

Page 57

Getting Started with Festo MecLab

Handling Station

The most important component in a handling device is the gripper. It is this device that

makes contact and manipulates the work piece. The two most common grippers are mechanical and Vacuum:

− Mechanical grippers. These normally have two or three gripper jaws which “grip” the

work piece like a hand. Since the jaws are not very flexible they must be adapted to the

work piece. Mechanical grippers can be operated by either fluid power (hydraulics or

pneumatics) or electricity.

− Vacuum grippers. These hold work pieces by means of vacuum. They are especially suit

able for flat, non-porous work pieces. The vacuum is generated by either a vacuum pump

or by a simple venture valve.

Two-axis automated handling machines are most frequently used to remove (pick) work

pieces from a magazine and then deposit (place) them somewhere else. These are called

“pick and place” devices.

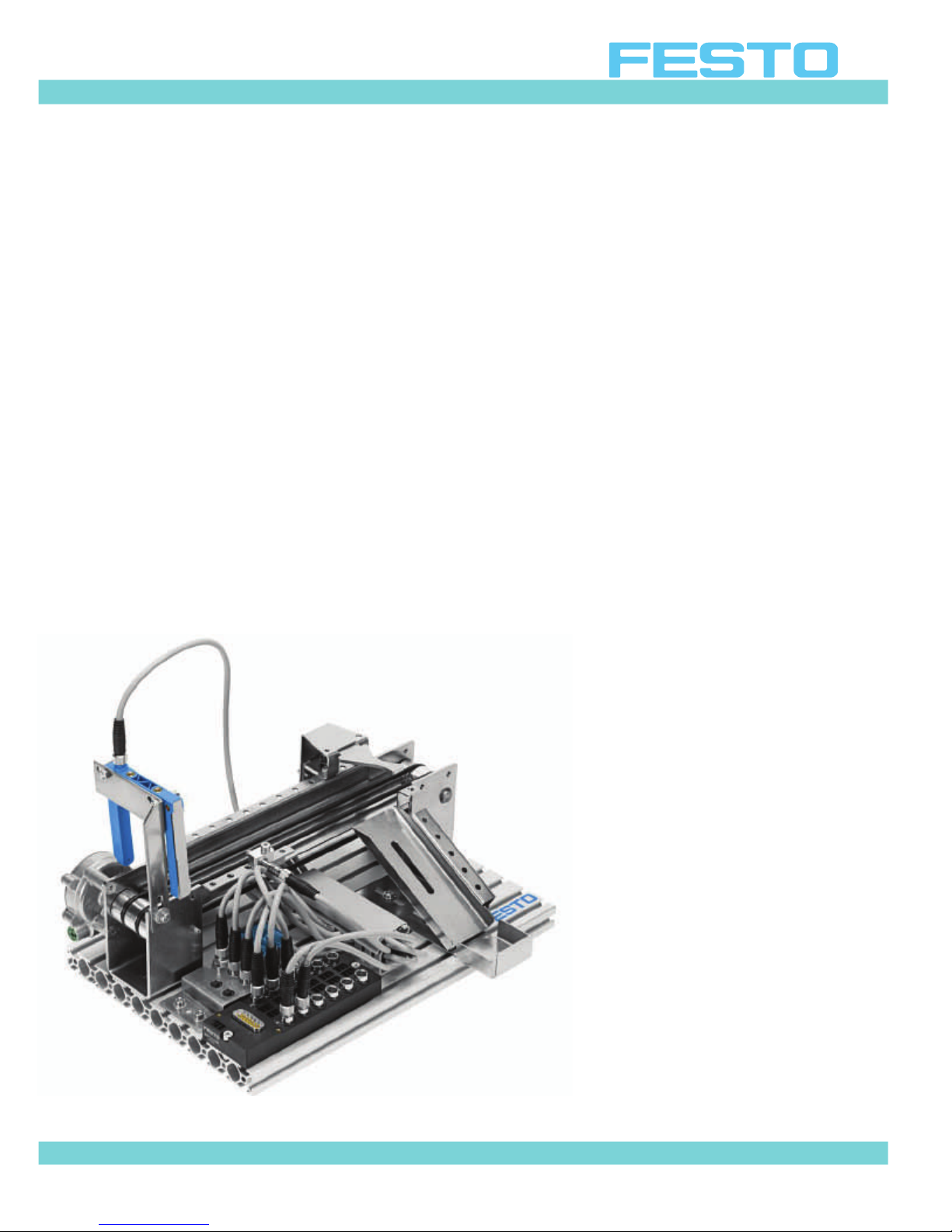

Figure 6.2: Handling station

© 2008 Festo Corporation 57 U

Page 58

Getting Started with Festo MecLab

Handling Station

Components of the handling station

The handling station consists of :

1. Two pneumatic linear axes

2. One pneumatic gripper

3. Three valves for controlling the pneumatic actuators

4. Four magnetic proximity sensors for detecting the position of the axes and other components.

The following table provides an overview of the components, their function and the corresponding circuit symbol.

Illustration Symbol Description

Gripper. Holds work

pieces.

Magnetic proximity sensor.

Detects the position of the

cylinder.

3/2 directional control

valve. Used as on/off for

regulator. Turns main air off

and exhausts system.

“T” connector. Used for es-

tablishing a 3-way connection of tubing.

Double acting cylinder with

guides.

© 2008 Festo Corporation 58 U

Page 59

Getting Started with Festo MecLab

Handling Station

Illustration Symbol Description

One way flow control valve.

Used to regulate the speed

of pneumatic drives.

4/2 directional control

valve, solenoid operated

with air spring return.

4/2 directional control

valve, double solenoid.

Multi pin plug distributor.

Used to interface all actuators and sensors with the

control PC.

© 2008 Festo Corporation 59 U

Page 60

Getting Started with Festo MecLab

Handling Station

Commissioning the handling station

The handling station consists of a two-axis handling device that can perform simple assembly

tasks.

The handling station can perform several tasks:

1. Transferring a work piece

2. Joining the base and lid

3. Sorting or assembly functions in conjunction with other MecLab® stations.

The handling station uses a mechanical two-jaw gripper that has been adapted to

the cylindrical work piece. This gripper can be exchanged for a vacuum gripper that is available as an accessory.

The handling station is supplied fully assembled. It may be necessary to readjust the place

holders of the work piece so that the gripper is aligned properly.

An aluminum profile plate is used as the base on which modules are mounted. T-head nuts

are used to secure the modules to the plate.

All modules and components can be disassembled and assembled using the supplied tools.

Flow control valves can be adjusted with the supplied screwdriver. There is also a tubing cutter used to cut the pneumatic tubing at a square angle (do not use scissors or knives).

The handling system must be connected to the USB port of the PC using the EasyPort and the

24V power supply should be connected as described in Section 3.

Correct wiring of the actuators and sensors must be ensured in order for the supplied sample

programs to operate the system. Pin assignments are described in a schematic diagram in

the sample program.

© 2008 Festo Corporation 60 U

Page 61

Getting Started with Festo MecLab

Handling Station

Executing a simple task using the handling station

In a production line, the handling station often carries work pieces between two stations.

The following sample exercise explains the step by-step operation of the FluidSIM® software

as well as its interaction with the handling station:

Task:

1. Develop a computer-aided manual control with the following functions:

a. Advance the x-axis when a pushbutton is actuated, but only if the cylinder is in the

retracted position.

b. Retract the x-axis when a pushbutton is actuated, but only if the cylinder is in the ex-

tended position.

Procedure for solving the task:

The solution to this task can be broken down into five phases:

1. Initial considerations and schematic diagram

2. Assignment tables for the components

3. Circuit diagram creation and programming using FluidSIM®

4. Testing with FluidSIM® via simulation

5. Testing the program on the actual handling station

© 2008 Festo Corporation 61 U

Page 62

Getting Started with Festo MecLab

Handling Station

Initial considerations:

1. Schematic diagram or drawing of the handling system. Always have a drawing or diagram

of the mechanical setup in order to identify the position of sensors valves and actuators.

One possible diagram of the components involved in the task could look something like

Figure 6.3. The drawing can be drawn by hand or created using a computer.

Figure 6.3: Schematic diagram of the handling station

2. Pneumatic circuit diagram (figure 6.4). It is also a good idea to produce a pneumatic circuit diagram as well as an assignment table for the input and output signals. This circuit

diagram can be created using FluidSIM® or drawn by hand.

Figure 6.4: Pneumatic circuit diagram (x-axis only)

© 2008 Festo Corporation 62 U

Page 63

Getting Started with Festo MecLab

Handling Station

Slot Assignment Description

0 1S2 Sensor for cylinder extended position

2 1S1 Sensor for cylinder retracted position

1 1M1 Valve solenoid (extend cylinder)

3 1M2 Valve solenoid (retract cylinder)

Table 6.1: Assignment table for the handling station

Analysis of the task

Before programming, you should be clear about the task. Normally, it is a good idea to

describe the task in your own words or to create a flow chart.

The piston of the horizontal, double-acting cylinder is to advance from its normal position

(retracted).

The command for this is issued via a pushbutton in FluidSIM®.

The cylinder may advance only if it is in the retracted position. This can be verified by the

proximity sensor (labeled 1S1) in the schematic and in the circuit diagram.

The return stroke is to be executed by means of a second pushbutton. The cylinder

may retract only if it has been verified that it is in the fully extended position.

The sensor for the forward end position is labeled 1S2 in the schematic diagram.

Two pushbuttons for operation are needed in the FluidSIM® program.

The horizontal cylinder is activated using a 4/2-way double solenoid valve. Switching on valve

solenoid 1M1 will cause the cylinder to extend. Switching on valve solenoid 1M2 will cause

the cylinder to retract (as long as no current is being applied to valve solenoid 1M1).

Since the valve is a double solenoid valve, a short current pulse is sufficient to keep the valve

(and the cylinder) in the respective position.

© 2008 Festo Corporation 63 U

Page 64

Getting Started with Festo MecLab

Handling Station

Circuit diagram creation and programming using FluidSIM®

The supplied FluidSIM® software is used for programming. This enables the circuit to be

simulated on the computer. If the simulation does not reveal any errors, then the station can

be directly activated and operated with the program.

Since the test setup consists of electrical and pneumatic components, a circuit plan must be

created in FluidSIM® for both system components. We recommended that you create the

pneumatic circuit diagram first and then the electrical circuit diagram.

Step 1: Opening FluidSIM®

Opened by double-clicking on the program icon:

– Call up a new workspace

Click on the blank white page on the left in the second menu bar (or on "File > New").

A new empty workspace for a controller appears.

– Save the new controller

To do this select "File > Save As ..." in the menu bar and save the file to the desired location

on a data storage medium under a user-defined name.

Step 2: Insert components

The components needed to create the pneumatic circuit diagram are located in the library

located on the left side of the screen. They are inserted into the diagram by:

Left clicking and holding on the appropriate symbol

Dragging the symbol to the blank sheet and releasing the mouse button.

© 2008 Festo Corporation 64 U

Page 65

Getting Started with Festo MecLab

Handling Station

The pneumatic system consists of :

1. One double-acting cylinder

2. One 4/2-way double-solenoid valve

3. Two one-way flow control valves

4. One compressed air supply

Figure 6.5 shows the components in the workspace.

Figure 6.5: Components of the pneumatic circuit diagram

© 2008 Festo Corporation 65 U

Page 66

Getting Started with Festo MecLab

Handling Station

Step 3: Rotate the one-way flow control valves

The one-way flow control valves should be rotated to produce straight flow paths. Right-click

on the symbol. In the context menu that opens, select menu item "Rotate" followed by "270°".

Figure 6.6: Rotating the one-way flow control valves

© 2008 Festo Corporation 66 U

Page 67

Getting Started with Festo MecLab

Handling Station

Step 4: Install tubing between components

Drag the mouse over a the node point of a symbol until a crosshair is displayed. With the left

mouse button pressed, move to the node point of the next symbol. Release the left mouse button as soon as the crosshair symbol appears.

The pneumatic circuit diagram should look as follows:

Figure 6.7: Installing the tubing for components

© 2008 Festo Corporation 67 U

Page 68

Getting Started with Festo MecLab

Handling Station

Step 5: Set labels and insert proximity sensors

Labels need to be assigned in order for the software to link the symbols. This will also ensure

the operation of external hardware via the software program. All components that are used in

both the electrical and pneumatic circuit drawing must be labeled.

To label the valve solenoids, right-click on the valve solenoid and select the menu item

"Properties". Enter the valve solenoid designation in the "Label" field, in this case 1M1 and

1M2 (for the first or second valve solenoid).

Figure 6.8: Entering a label for the valve solenoid

To mount proximity sensors right-click on the cylinder. A window opens where you can

enter the proximity sensors mounted on the cylinder and their position.

There are two proximity sensors on the cylinder; one in the retracted position and one in the

extended position. The position of one of the proximity sensors is 0 mm (this is the default setting. It can be changed to either inches or feet by using the drag down window at the far

right). The position of the other proximity sensor is 100mm. The proximity sensors should be

labeled 1S1 (retracted) and 1S2 (extended).

Clicking on "OK" closes the input window.

© 2008 Festo Corporation 68 U

Page 69

Getting Started with Festo MecLab

Handling Station

Figure 6.9: Labeling proximity sensors

Step 6: Test the pneumatic circuit

Start the simulation by clicking on the Start button (this is the arrow button at the top tool

bar). If one of the two manual overrides is clicked on, the valve switches position and the cylinder will either extend or retract.

Figure 6.10: Simulating the pneumatic circuit diagram

© 2008 Festo Corporation 69 U

Page 70

Getting Started with Festo MecLab

Handling Station

Step 7: Components and wiring of the electrical circuit

Electrical components are inserted and connected in the same manner as the pneumatic

components.

The workspace should look something like figure 6.11 upon completion:

Figure 6.11: Inserting and wiring the electrical components

© 2008 Festo Corporation 70 U

Page 71

Getting Started with Festo MecLab

Handling Station

Step 8: Assign labels

To link electrical and pneumatic components, the electrical components must be labeled.

This is done the same way as the pneumatic components, i.e. by right-clicking on the component and entering the labels in an input window. Labels are necessary for the valve solenoids

and the sensors.

Figure 6.12: Assigning labels for the electrical components

Remember to insert and label two pushbuttons as S1 and S2.

© 2008 Festo Corporation 71 U

Page 72

Getting Started with Festo MecLab

Handling Station

Step 9: Create the control program

The figure below is a control module. It is called a “Logic Module” in the FluidSim library.

24V I1 I2 I3 I4 I5 I6

0V Q1 Q2 Q3 Q4 Q5 Q6

Q3 Q4 Q5 Q6

In order to “write” a program in this module you must first “enter” the module by double

clicking on it. A new window containing the digital module's input and output channel will be

displayed.

Figure 6.13: Input and output channel inside the logic module

Inputs marked I1 to I6 are located on the left side. Outputs marked Q1 to Q6 are located on

the right. Inputs and outputs are linked using logic devices (these are located in the same

part of the library as the logic module).

The devices are inserted in the program like all other components. Left click, hold and drag

the component to the program, then release.

© 2008 Festo Corporation 72 U

Page 73

Getting Started with Festo MecLab

Handling Station

The task requires that the cylinder retract or extend when the respective pushbutton is

pressed and

1. Valve solenoid 1M1 is switched on when pushbutton S1 and proximity sensor 1S1 are actuated.

Valve solenoid 1M2 is switched on when pushbutton S2 and proximity sensor 1S2 are actuated.

This means that two AND gates are needed in the program. Since the AND gate in FluidSIM®

has three inputs, two high gates are used so that the third, redundant one can always be set

to high. Otherwise FluidSIM® would issue an error message that there is one unassigned input.

Figure 6.14: Digital module with logic gates

Note

Unused AND gate inputs must be provided with a signal. Use a “Hi” symbol and connect to

the unused input.

The logic gates are now connected and the logic program is completed (cf. Figure 6.15).

Closing the input window stores the program in the digital module (or PLC). The simulation

can be started after the window closes.

the cylinder has reached the relevant end position:

© 2008 Festo Corporation 73 U

Page 74

Getting Started with Festo MecLab

Handling Station

Figure 6.15: Complete logic program

Testing the solution via simulation

Start the simulation by clicking on the Start button (the arrow button on the toolbar).

Press pushbutton S1 . The cylinder should extend. Press pushbutton S2. The cylinder should

retract.

Note

The cylinder cannot retract until it has reached the fully extended position.

Figure 6.16: Simulating the circuit

© 2008 Festo Corporation 74 U

Page 75

Getting Started with Festo MecLab

Handling Station

Testing the solution on the handling station

To connect the handling station to FluidSIM®, the EasyPort must be plugged into the multi-pin

plug distributor on the station, to the pc (using the USB cable) and to the power

supply.

The symbol for the multi-pin plug distributor is then dragged into the workspace in the FluidSIM® program.

Figure 6.17: Multi-pin plug distributor symbol for

connecting the station

Labels must be assigned in the multi-pin plug distributor. Open the symbol by double-clicking

on it (Figure 6.18).

Assign labels as per Table 6.1. Remember the labels must match those used in the pneumatic and electrical circuit diagrams. The distributor establishes the connection to the station.

It is not important what the labels are called (1M1 is the normal designation. However, the label could also be "left valve solenoid"). It is important that the same labels are used for each

component that is located in both the pneumatic and electrical circuits.

Note

The "Priority for connected hardware" box must be checked. This ensures that the signals

for the actual sensors are used and not those simulated in the program.

Once the simulation is started and pushbutton S1 is pressed, the cylinder will extend.

The status of the input and output channels will be indicated in color on the distributor symbol. On the actual distributor, the status of the input and output channels will be indicated by

LEDs.

© 2008 Festo Corporation 75 U

Page 76

Getting Started with Festo MecLab

Handling Station

The program can then be built upon to include the other actuators and sensors that are on

the station.

The schematic diagram, the circuit diagram and the logic program form the technical documentation for the project. They can be supplemented with operating instructions and data

sheets if necessary.

Figure 6.18: Dialog box of the Figure 6.19: Dialog box of the multi-pin plug

multi-pin plug distributor distributor with the labels changed

before the labels are changed

© 2008 Festo Corporation 76 U

Page 77

Getting Started with Festo MecLab

Lesson Planning

Overview of the supplied media

The MecLab® learning system consists of three components:

1. Hardware,

2. FluidSIM® programming and simulation software,

Learning materials.

The learning materials consist of the following:

Fundamentals of Automation Technology (Theory section)

The theory section covers the fundamentals of automation technology and mechatronics. It

contains information on sensors, pneumatic and electric drives, relay controllers and programmable logic controllers. It also includes a section on the history of automation technology and on how engineers work.

This document is stored as a pdf file. You may print and distribute it to the students. You may

not modify the content.

Teaching with Meclab (Commissioning instructions) (this manual)

The commissioning instructions consist of an introduction and detailed step-by-step instructions on how to assemble and commission the three MecLab® stations. We recommend that

you follow the instructions contained in this document.

This document is stored as a pdf file. You may print and distribute it to the students. You may

not modify the content.

© 2008 Festo Corporation 77 U

Page 78

Getting Started with Festo MecLab

Lesson Planning

Set of Exercises

Each station has a set of exercises that begin as simple tasks. Each subsequent task (or exercise) builds on the previous and is a little more difficult. It starts out by learning about components, their function and symbols and ends with complex programming.

The exercise workbooks are to be used by the students as worksheets. The worksheets

are available as Word files. You may copy, distribute and modify these as needed.

Presentation

This contains the illustrations from the theory section and can be used during a lecture or to

create your own documents.

Hardware

The hardware consists of the three stations, the EasyPorts, the necessary cables, work

pieces and tools.

Some of the exercises call for the conversion of the stations. For example changing, adjusting or relocating sensors, attaching or removing actuators.

The system was designed so that components can be swapped between stations. For example:

Sensors from the conveyor station can be used in the stack magazine or handling station.

The stamping unit from the stack magazine station can be attached to the conveyor.

It is also possible to form an assembly line with all three stations, however this calls for

more advanced conversion and/or relocation and adjustment of the components.

FluidSIM® Programming and Simulation Software

The FluidSIM® programming and simulation software on the supplied CD-ROM is tailored to

the functions of MecLab®. The software is easily installed on the PC from the CD-ROM.

© 2008 Festo Corporation 78 U

Page 79

Getting Started with Festo MecLab

Lesson Planning

Lesson Design

MecLab® should be used to teach programming as well as mechanical makeup, setup and

conversion of automated systems.

Lessons can be divided into three phases:

1. Preparation

2. Project

3. Follow-up and Assessment.

Preparation

Normally, students do not have access to industrial production and therefore no relationship

with the topic. If at all possible it is advised that the students are taken on a field trip to see an

automated production facility before starting to work with MecLab®.

The emphasis of the visit should be to recognize that an automated assembly system always

includes functions for:

1. Conveying

2. Handling

3. Storing and feeding work pieces

Preparation

Normally, students do not have access to industrial production and therefore no relationship

with the topic. If at all possible it is advised that the students are taken on a field trip to see an

automated production facility before starting to work with MecLab®.

The emphasis of the visit should be to recognize that an automated assembly system always

includes functions for:

1. Conveying

2. Handling

Storing and feeding work pieces

These, of course, are the basic functions of the MecLab®.

© 2008 Festo Corporation 79 U

Page 80

Getting Started with Festo MecLab

Lesson Planning

If a visit to an actual production facility is not possible, the videos supplied on the

CD-ROM can be used.

In the follow-up phase, the results should be summarized and a connection should be made

with the learning system:

Which functions are found in the stations in our classroom?

Which components were also present in the actual production facility?

Group work

MecLab® is designed for project-based teaching in small groups. The recommended group

size is 2 students for each station (they will also need a PC with the supplied FluidSIM® software).

Before starting the group work, it is a good idea to give a general introduction on using FluidSIM®, connecting the stations to the PC and also the function of the components.

Students must also be made familiar with the safety information.

Project work can be introduced with an explanation about certain topics, for example sensors, pneumatics, circuit or programming technology. Instructor resources include the information in the theory section, the supplied PowerPoint presentation and the animations on

CD-ROM and in FluidSIM® .

The Instructor can allow the students to acquire the information they need to complete the

exercises on their own (within the window of the project work). In this case, it is useful to allow the students to present their results once the exercises have been completed. This is important given the fact that the subject matter is similar, but not completely identical between

the three stations. The presentations will help to ensure that all students have the same level

of knowledge.

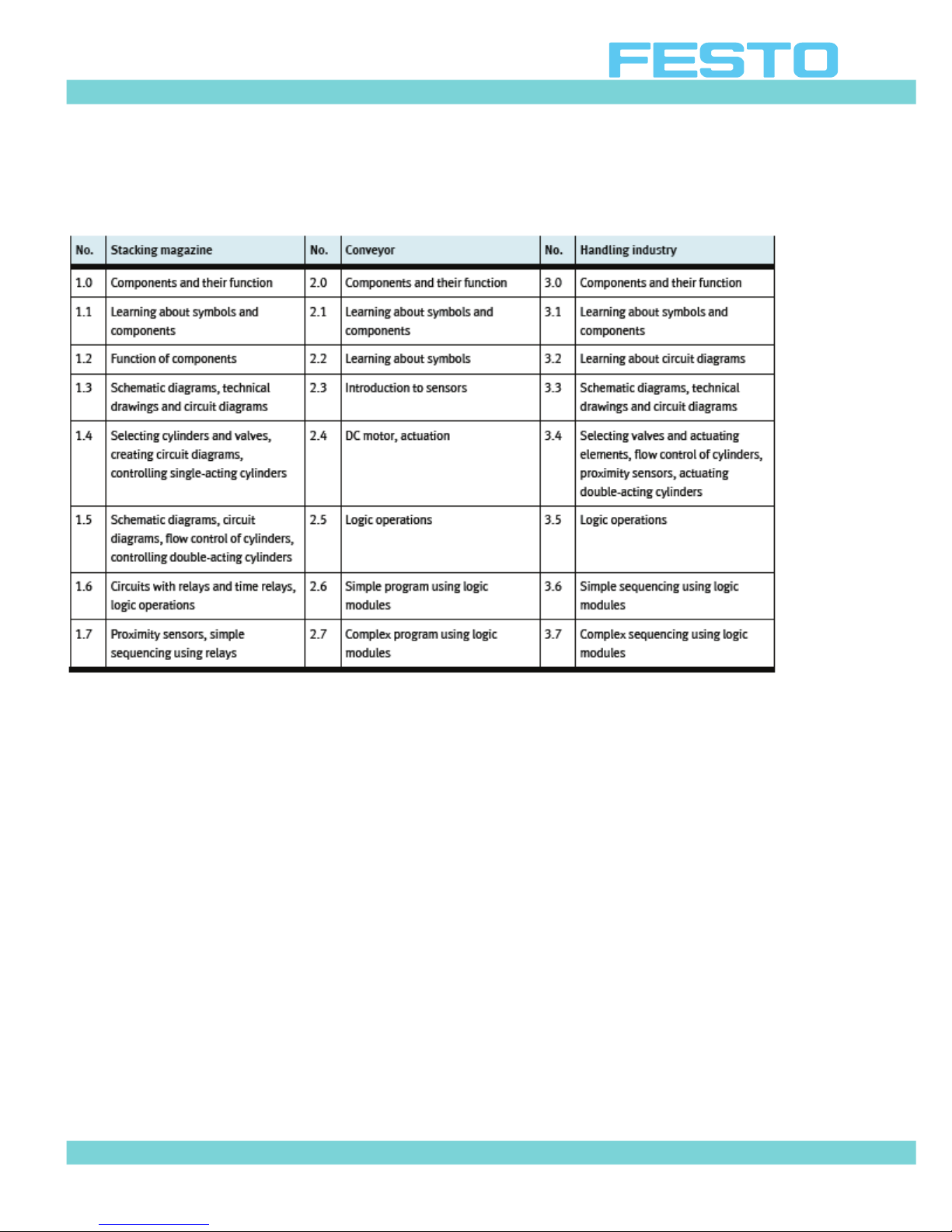

The exercises become increasingly challenging. Table 7.1 provides an overview of the objectives of the exercises. The stack magazine station has the easier exercises and the handling

station has the more complex exercises. That leaves the exercises for the conveyor station

somewhere in the middle.