Valveterminaltype03

Electronics

manual

Valve terminal with

field bus protocol:

INTERBUS optical

fibre waveguide

remote bus

“Rugged-Line”

type IFB21-03

Manual

191 085

en 0010a

Contents and general instructions

Author E. Klotz, M. Simons..........................

Editors H.–J. Drung, M.Holder........................

Oridinal de.......................................

Layout Festo AG & Co., Dept. KG-GD...................

Type setting DUCOM................................

Edition 0010a.....................................

Title MANUAL-EN..................................

Designation P.BE-VIFB21-03-EN......................

Order no. 191 085.................................

E (Festo AG & Co., D–73726 Esslingen,

Federal Republic of Germany, 2000)

Internet: http://www.festo.com

E-mail: service_international@festo.com

The copying, distribution and utilization of this document as

well as the communication of its contents to others without

expressed authorization is prohibited. Offenders will be held

liable for the payment of damages. All rights reserved, in

particular the right to carry out patent, utility model or

ornamental design registration.

Fest o P.BE-VIF B21-03-E N en 0010a

I

Contents and general instructions

II

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

Contents

Designated use VII........................................................

Target group VIII..........................................................

Service VIII...............................................................

Important user instructions IX..............................................

Abbreviations XI.........................................................

Manualsonthisvalveterminal XIII............................................

1. Summary of components 1-1........................................

1.1 Summary of multi-functional Festo valve terminals 1-3....................

1.2 Description of the components 1-4....................................

1.2.1 Elektric modules 1-4................................................

1.2.2 Pneumatic MIDI modules 1-5.........................................

1.2.3 Pneumatic MAXI modules 1-6........................................

1.3 Method of operation 1-7............................................

2. Fitting 2-1........................................................

2.1 Fitting the modules and components 2-3...............................

2.1.1 Earthing the end plates 2-4..........................................

2.2 Fitting the valve terminal onto a hat rail 2-6.............................

2.3 Fitting the valve terminal onto a wall 2-9...............................

3. Installation 3-1...................................................

3.1 Installation summary 3-3............................................

3.1.1 System structure on the remote bus 3-3................................

3.1.2 Installation instructions 3-5..........................................

3.2 Bus node 3-6......................................................

3.2.1 Configuration settings in the node 3-9.................................

3.3 Connecting the power supplies 3-11....................................

3.3.1 Calculating the current consumption 3-12...............................

3.3.2 Connecting the power supply 3-14.....................................

3.4 INTERBUS interface 3-22.............................................

3.4.1 Conecting the optical fibre waveguide Rugged-Line plug 3-23...............

Festo P.BE-VIFB21-03-EN en 0010a

III

Contents and general instructions

4. Commissioning 4-1................................................

4.1 Configuring and addressing the valve terminal 4-3.......................

4.1.1 Ascertaining the configuration data 4-3................................

4.1.2 Calculating the number of inputs/outputs 4-5...........................

4.1.3 Address assignment of the valve terminal 4-6...........................

4.1.4 Address assignments after extension/conversion 4-12.....................

4.2 INTERBUS – Configuring and addressing the bus 4-14.....................

4.2.1 General commissioning instructions 4-14................................

4.2.2 Configuring the bus with CMD software 4-16.............................

4.2.3 Configuring the bus without CMD software 4-25..........................

4.2.4 Addressing the inputs and outputs 4-27.................................

4.2.5 Entering process data via the CMD software 4-30.........................

4.2.6 Status bits 4-34.....................................................

4.2.7 Other instructions 4-36...............................................

5. Diagnosis and error treatment 5-1....................................

5.1 Summary of diagnostic possibilities 5-3................................

5.2 On-the-spot diagnosis 5-4...........................................

5.2.1 Bus node 5-4......................................................

5.2.2 LED modules 5-6...................................................

5.2.3 On-the-spot error treatment 5-9......................................

5.2.4 Status bits 5-10.....................................................

5.3 Diagnosis via INTER BUS 5-13.........................................

5.3.1 Reaction to faults in the control system 5-17.............................

A. Technical Appendix A-1.............................................

A.1 Technical specifications A-3..........................................

A.2 Cable length A-6...................................................

A.3 Examples of circuitry A-11............................................

A.3.1 Power supply connection A-11.........................................

IV

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

B. Accessories B-1...................................................

B.1 Connecting the cables to the plugs (sensors/outputs) B-3.................

B.2 Phoenix Contact accessories B-5......................................

B.2.1 Connecting the cables to the Rugged-Line plug B-6.......................

C. Index C-1.........................................................

C.1 Index C-3.........................................................

Festo P.BE-VIFB21-03-EN en 0010a

V

Contents and general instructions

VI

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

Designated use

The valve terminal described in this documentation is designed for use only as follows:

– for controlling pneumatic and electric actuators

– for interrogating electric sensor signals through

Please use the valve terminal only as follows:

–asdesignated

– in faultless technical condition

– without undertaking any modifications.

If the valve terminal is used in conjunction with additional

commercially-available components, such as sensors and

actuators, make sure that the maximum specified limits for

pressures, temperatures, electrical data, torques, etc. are

observed.

(valves and output modules)

the input modules.

Festo P.BE-VIFB21-03-EN en 0010a

Please observe the standards mentioned in the relevant

chapters and comply with national and local technical regulations.

VII

Contents and general instructions

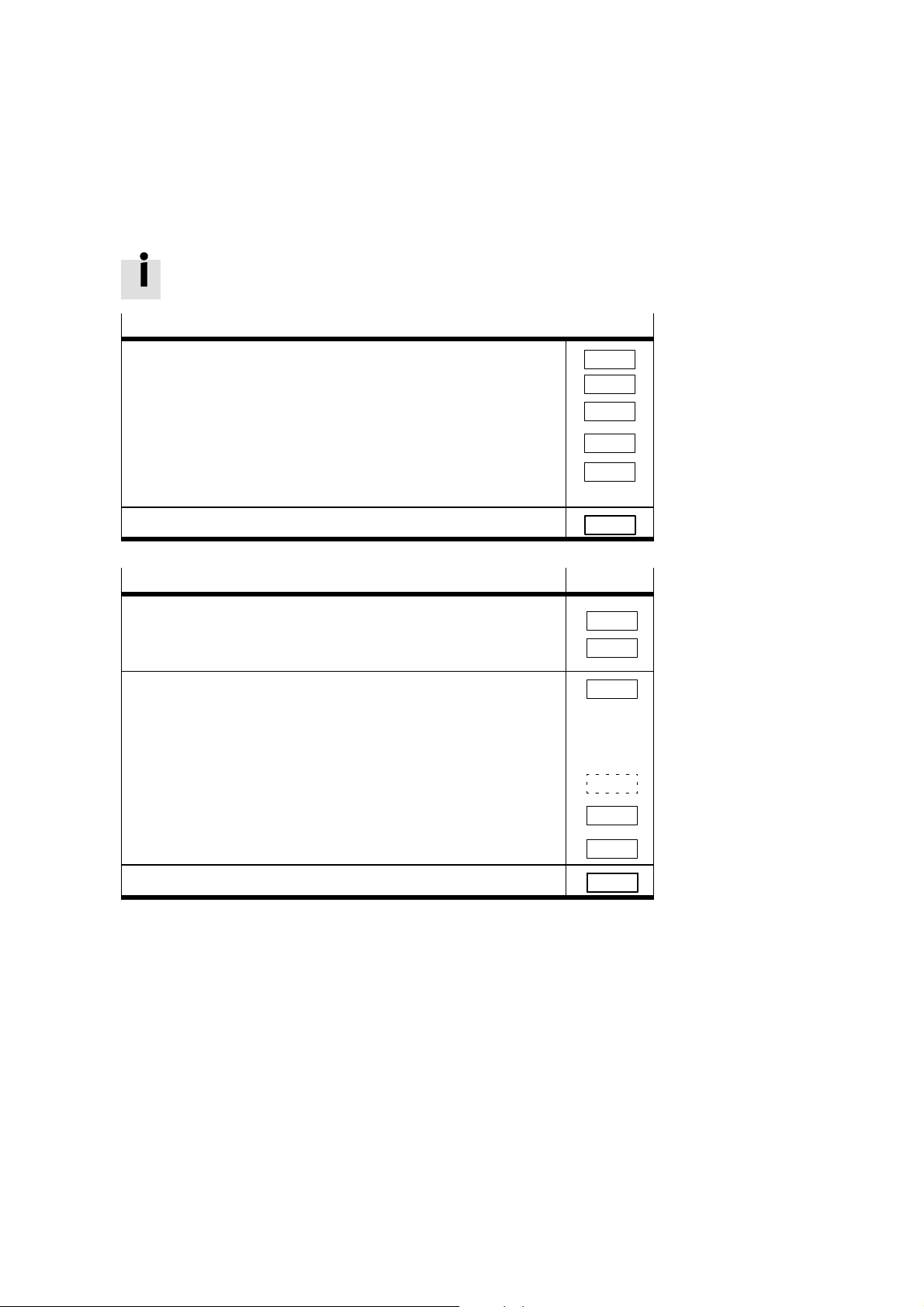

Additional modules for this valve terminal

The multifunctional valve terminal can be extended with the

following modules:

I/O modules

Type designation Name

VIGE-03-FB-... Input module with 4 or 8 inputs, PNP or NPN, 4-pin or 5-pin, with

VIGE-03-FB-16-SUBD-S Input module 16 inputs, PNP, 15-pin Sub-D connecting socket,

VIGA-03-FB-... Output module with 4 outputs, PNP or NPN, 4-pin or 5-pin

VIGV-03-FB-... Additional power supply module (24 V/25 A) for high-current out-

VIEA-03-FB-... Multi I/O module with 12 inputs and 8 outputs, PNP

VIA-03-FB-... Analogue I/O module with 3 inputs and 3 outputs

VIAP-03-FB Analogue I/O module with 1 input and 1 output

VIASI-03-M AS-interface master

or without electronic fuse.

with electronic fuse.

puts.

Target group

This manual is directed exclusively at personnel who are

trained in control and automation technology, and who have

experience in installing, commissioning, programming and

diagnosing programmable logic controllers (PLC) and field

bus systems.

Service

VIII

If you have any technical problems, please contact your local

Festo Service.

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

Important user instructions

Danger categories

This manual contains notes on possible dangers which may

occur if the product is not used correctly. These notes are

marked (warning, caution, etc.), printed on a shaded background and also accompanied by a pictogram. A distinction is

made between the following types of danger instructions:

Warning

This means that serious injury to persons or damage to

property can occur if these instructions are not observed.

Caution

This means that injury to persons or damage to property

can occur if these instructions are not observed.

Festo P.BE-VIFB21-03-EN en 0010a

Please note

This means that damage to property can occur if these

instructions are not observed.

In addition, the following pictogram indicates passages in the

text which describe activities with electrostatically vulnerable

components:

Electrostatically vulnerable components: incorrect handling

can cause damage to components.

IX

Contents and general instructions

Marking special information

The following pictograms mark passages in the text containing special information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Details about necessary or useful accessories for the Festo

product.

Environment:

Information on the environmental-friendly use of Festo

products.

Text markin gs

S The bullet marks activities which may be carried out in

any desired order.

1. Numbers indicate activities which must be carried out in

the sequence stated.

– Hyphens indicate general items.

X

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

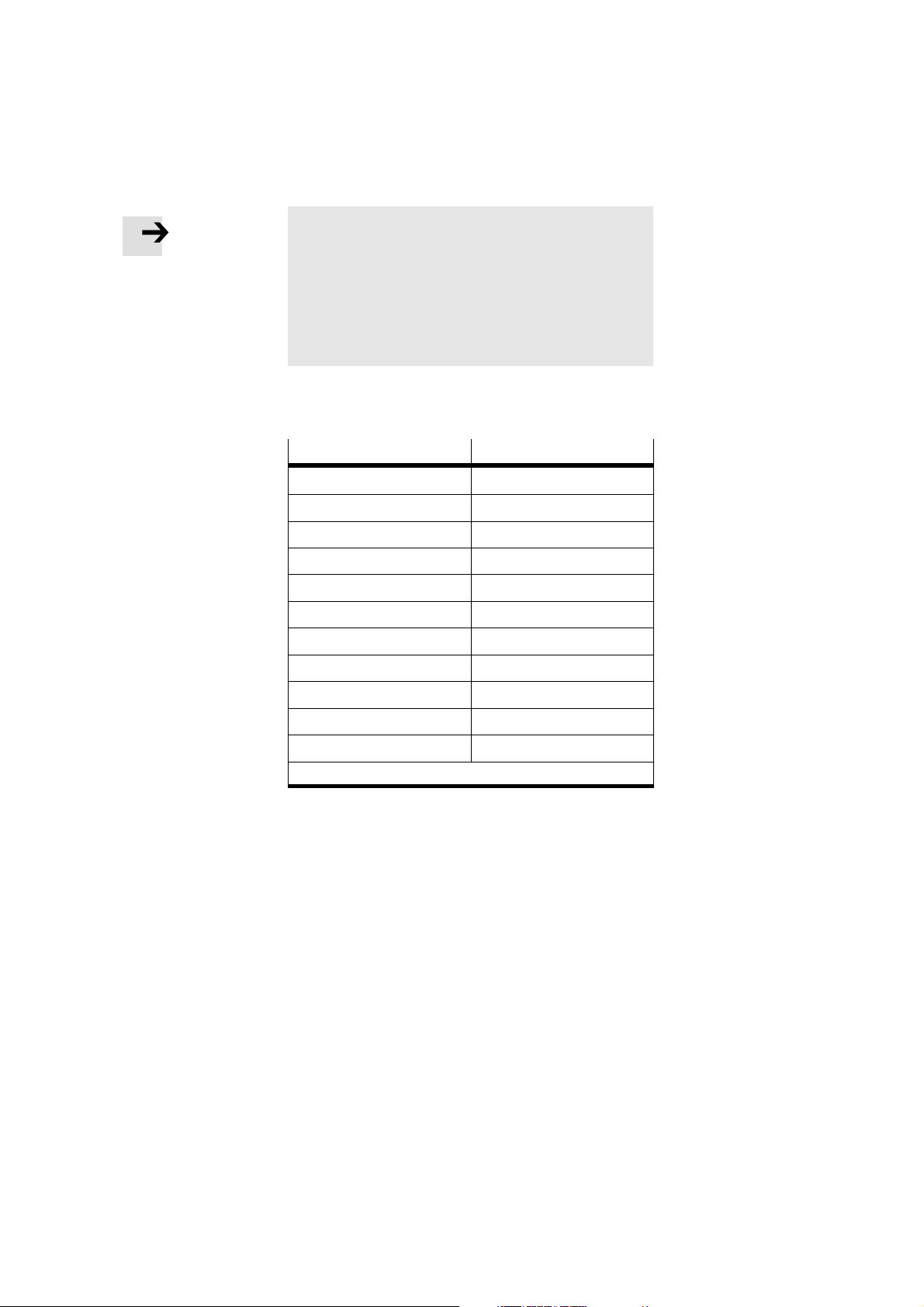

Abbreviations

The following product-specific abbreviations are used in this

manual:

Abbreviation Meaning

Terminal or valve terminal Valve terminal type 03 with/without electric I/Os

Node Field bus node

Manifold

Single manifold

Double manifold

I

O

I/O

P-module Pneumatic module in general

I/O module Module with digital inputs or outputs in general

PLC Programmable logic controller; in brief: controller

Waveguide Interbus optic al fibre waveguide

RL-connection Rugged-line connection

Pneumatic manifold for two valves

Manifold for two single-solenoid valves

Manifold for two double-solenoid or mid-position valves

Input

Output

Input/output

Fig. 0/1: List of abbreviations

Festo P.BE-VIFB21-03-EN en 0010a

XI

Contents and general instructions

Please note

A simplified representation of valve terminal type 03 with

four pneumatic manifolds and four input/output modules

(standard fitting) is used for most drawings in this manual.

1 Ein-/Aus-

gangsmodule

2 Feldbusknoten

3 Ventile

4 Ungenutzter Ven-

tilplatz

12 34

Fig. 0/2: Standard fitting for the drawings

XII

Festo P.BE-VIFB21-03-EN en 0010a

Contents and general instructions

Manuals on this valve terminal

The following Festo manuals will be required to complete the

documentation for the modular valve terminal, depending on

your order and on the equipment fitted on your system:

designation

P.BE-MIDI/MAXI-03-... Pneumatics manual

P.BE-VIEA-03...05-.. Supplementary manuals for I/O modules

P.BE-VIAX-03...05-... Analogue I/Os manual

P.BE-VIASI-03...05-... AS-i master manual

P.BE-VIFB21-03-... Electronics manual

Title/product

– Valve terminal type 03, MIDI/MAXI

(digital I/O modules 4 I, 8 I, 4 O, high-current output modules, multi-I/O modules)

S Field bus connection FB21 (this man-

ual)

Fig. 0/3: Manuals on this valve terminal

Festo P.BE-VIFB21-03-EN en 0010a

XIII

Contents and general instructions

XIV

Festo P.BE-VIFB21-03-EN en 0010a

Summary of components

Chapter 1

1-1Festo P.BE-VIFB21-03-EN en 0010a

1. Summary of components

Contents

1. Summary of components 1-1........................................

1.1 Summary of multi-functional Festo valve terminals 1-3....................

1.2 Description of the components 1-4....................................

1.2.1 Elektric modules 1-4................................................

1.2.2 Pneumatic MIDI modules 1-5.........................................

1.2.3 Pneumatic MAXI modules 1-6........................................

1.3 Method of operation 1-7............................................

1-2

Festo P.BE-VIFB21-03-EN en 0010a

1. Summary of components

1.1 Summary of multi-functional Festo valve terminals

The multi-functional valve terminal consists of the following

individual modules and components:

Valve termial Description of the modules

Typ e 0 3

MIDI/MAXI and electric

modules

Electric modules (PNP or NPN) fitted with:

– digital inputs (modules with 4 or 8 inputs)

– digital outputs (modules with 4 outputs) 0.5 A

– high-current outputs 2 A

– multi-I/Os (module with 12 I/8 O) 0.5 A

– analogue I/Os, AS-i master (not possible with every node

Pneumatic modules fitted with:

– manifolds (MIDI and MAXI) fitted with 5/2-way solenoid valves,

5/2-way double solenoid valves, 5/3-way mid-position valves

(with auxiliary pilot air) or blanking plat es

– Special modules for additional pressure supply, intermediate

pressure supply, end plates with/without regulator

Fig. 1/1: Summary of the modules of the multi-functional Festo valve terminals

)

Festo P.BE-VIFB21-03-EN en 0010a

1-3

1. Summary of components

1.2 Description of the components

1.2.1 Elektric modules

The following connecting and display elements can be found

on the electric modules:

2 3 4 56 78

1

9

1 Inputsocketfortwoelectricinputs

(PNP or NPN

)

5 Green LED (per input)

6 Output socket for electric output (PNP)

2 Red LED (error display of input module

with electronic fuse)

3 Two green LEDs (one LED per input)

4 Input socket for an electric input (PNP

or NPN)

Fig. 1/2: Connecting and display elements of the electric modules

1-4

7 Yellow LED (status display per output)

8 Red LED (error display per output)

9 Further modules (e.g. additional

supply, high-current PNP/NPN)

Festo P.BE-VIFB21-03-EN en 0010a

1. Summary of components

1.2.2 Pneumatic MIDI modules

The following display and operating elements can be found

on the pneumatic MIDI modules type 03:

123

4

Yellow LEDs (per valve solenoid coil)

1

3 Valve location inscription field

(identification labels)

2 Manual override (per valve solenoid

coil, either spring-return or locking)

Fig. 1/3: Operating, display and connecting elements of MIDI modules type 03

Festo P.BE-VIFB21-03-EN en 0010a

4 Unused valve location with blanking-

plate

1-5

1. Summary of components

1

2

1.2.3 Pneumatic MAXI modules

The following display and operating elements can be found

on the pneumatic MAXI modules type 03:

3

45

Yellow LED (per valve solenoid coil)

1

4 Valve location inscription field

(identification labels)

2 Manual override (per valve solenoid

coil, either spring-return or locking)

5 Regulator for limiting the auxiliary pilot

air pressure

3 Unused valve location with blanking

plate

Fig. 1/4: Operating, display and connecting elements of MAXI modules type 03

1-6

Festo P.BE-VIFB21-03-EN en 0010a

1. Summary of components

5

1.3 Method of operation

The node controls the following functions:

– It connects the valve terminal to the INTER BUS and

– It controls the system settings of the terminal as

– It controls data transfer to/from the field bus module

– It manages the internal control of the terminal.

1 Incoming field

bus

to the power supply.

well as an automatic valve test and (in conjunction

with G3 modules) the display and masking out of

error messages.

of your control system.

12

2 Continuing field

bus

3 Compressed air

4 Node

5 Workair (2, 4)

4

Fig. 1/5: Method of operation of a valve terminal

Festo P.BE-VIFB21-03-EN en 0010a

3

1-7

1. Summary of components

The input modules control the processing of input signals

(e.g. from sensors) and pass these signals onto the controller

via the field bus.

The output modules are universal electric outputs and control

low-current consuming devices, e.g. further valves, bulbs,

etc.

Additional I/O modules for special applications are also available.

Further information on the use of all the I/O modules can be

found in the ”Supplementary manual for the I/O modules” for

your valve terminal.

The pneumatic modules provide the following:

– the common channels for the supply and exhaust air

1-8

– electric signals from all valve solenoid coils

Work connections 2 and 4 have been provided for each valve

location on the individual pneumatic modules.

The valves are supplied with compressed air via the common

channels on the pneumatic end plate or via special supply

modules. The exhaust air and pilot exhaust air are also

vented via these channels or modules. Further modules for

supplying pressure are also available, e.g. to enable you to

work with different working pressures.

Detailed information on the use of these modules can be

found in the ”Pneumatics manual” foryourvalveterminal.

Festo P.BE-VIFB21-03-EN en 0010a

Fitting

Chapter 2

Festo P.BE-VIFB21-03-EN en 0010a

2-1

2. Fitting

Contents

2. Fitting 2-1........................................................

2.1 Fitting the modules and components 2-3...............................

2.1.1 Earthing the end plates 2-4..........................................

2.2 Fitting the valve terminal onto a hat rail 2-6.............................

2.3 Fitting the valve terminal onto a wall 2-9...............................

2-2

Festo P.BE-VIFB21-03-EN en 0010a

2. Fitting

2.1 Fitting the modules and components

The valve terminal is supplied from the factory ready

mounted. If you wish to add or replace individual modules

and/or components, please refer to the following manuals:

”Supplementary manual for the I/O modules” for fitting the

–

electric I/O modules

–”Pneumatics manual” for fitting the pneumatic modules

– The fitting instructions are included in the package in the

case of modules and components ordered at a later

stage.

Please note

Treat all the modules and components of the valve

terminal with care. Pay attention in particular to the

following:

– The screws must fit exactly (otherwise the threads will

be damaged). Tighten the screws without distortion or

mechanical stress.

– Observe the specified torques.

– Modules must not be offset (IP 65).

– Connecting surfaces must be clean (avoid leakage and

contact faults).

– The contacts of type 03 valve solenoid coils must not be

bent (they are not resistant to bending and will break off

if bent back).

– Electrostatically vulnerable components.

Do not touch any contact surfaces on the side plug connectors of the modules and components.

Festo P.BE-VIFB21-03-EN en 0010a

2-3

2. Fitting

2.1.1 Earthing the end plates

The valve terminal possesses a left-hand and a right-hand

end plate as a mechanical termination of the valve terminal.

These end plates fulfil the following functions:

– They comply with protection classs IP 65.

– They contain connections/contacts for earthing.

– They contain holes for fitting the terminal onto a wall

and for the hat rail clamping unit.

Please note

When supplied from the factory, the end plates of the valve

terminal are earthed internally. If you carry out any extensions/conversions to the type 03 valve terminal, you must

earth the end plates of the terminal as described below. In

this way you will avoid faults caused by electromagnetic

influences.

2-4

Earth the end plates as follows:

1. Right-hand end plate:

To earth the right-hand end plate connect the pre-fitted

cable on the inside to the appropriate contacts on the

pneumatic modules or the node (see diagram below).

2. Left-hand end plate:

The left-hand end plate must be connected conductively to

the other components by means of t he pre-fitted spring

contacts.

Please note:

Instructions on earthing the complete valve terminal can be

found in the chapter ”Installation.” The diagram below shows

how both end plates are fitted.

Festo P.BE-VIFB21-03-EN en 0010a

2. Fitting

4

1 23

Seal

1

2 Contact for earth cable

Fig. 2/1: Fitting the end plates

Festo P.BE-VIFB21-03-EN en 0010a

3 Pre-fitted earth cable

4 Fastening screws max. 1 Nm

1

2-5

2. Fitting

2.2 Fitting the valve terminal onto a hat rail

The valve terminal is also suitable for fitting onto a hat rail

(support rail as per EN 50022). There is a guide groove on the

rear of all modules for hanging them on the hat rail (see Fig.

2/4).

Caution

– A hat rail fitting without a hat rail clamping unit is not

permitted.

– Iftheterminalisfittedinaslopingpositionorifitissub-

jected to vibration, secure the hat rail clamping unit

additionally against sliding down and unintentional

loosening/opening with the locking screws intended for

this purpose (item 3).

Please note

– If the terminal is fitted in a horizontal position and with a

permanent load, the hat rail clamping unit need not be

secured addititonally with locking screws (item 3).

– If the terminal does not have a hat rail clamping unit,

this can be ordered and fitted at a later date.

– WhetherMIDIorMAXIclampingunitsaretobeused,

dependsontheexistingendplates(MIDI/MAXI).

2-6

Hat-rail clamping unit

In order to fit the valve terminal onto a hat rail, you will require a hat-rail clamping unit. This must be fitted on the rear

of the end plates as shown in the diagram below.

Festo P.BE-VIFB21-03-EN en 0010a

2. Fitting

2

1

Pay attention to the following:

Before fitting

S The adhesive surfaces for the rubber feet must be clean

(clean with spirit).

S The flat-head screws must be tightened(item 3).

After fitting

S The levers must be secured with locking screws (item 7).

3

1

4

1 Lever

*)

2 O-ring

3 Flat-head screw

*)

different lever lengths for MIDI and MAXI

Fig. 2/2: Fitting the hat rail clamping unit

Festo P.BE-VIFB21-03-EN en 0010a

5

6

4 Rubber foot self adhesive

5 Clamping elements

6 Locking screw

2-7

2. Fitting

Please note

Observe the fitting space required due to the optical fibre

waveguide connections on the node.

Proceed as follows:

1. Ascertain the weight of your terminal as described in

chapter 2.2.

2. Make sure that the mounting surface can support this

weight.

3. Fit a hat rail (support rail as per EN 50022 - 35x15; width

35 mm, height 15 mm).

4. Fasten the hat rail to the fastening surface at least every

100 mm.

5. Hang the terminal onto the hat rail. Secure the terminal on

both sides with the hat rail clamping unit to prevent it

from tipping or sliding (see diagram below).

6. Iftheterminalisfittedinaslopingpositionorissubjected

to vibration, secure the hat rail clamping unit against

unintentional loosening/opening with two locking screws

(item 3).

1 Hat rail clamping

unit unlocked

2 Hat rail clamping

unit locked

3 Locking screw

12

Fig. 2/3: Fitting valve terminal type 03 onto a hat rail

2-8

33

Festo P.BE-VIFB21-03-EN en 0010a

2. Fitting

2.3 Fitting the valve terminal onto a wall

Caution

In the case of long terminals with several I/O modules, use

additiona l support bracket s (approxi m atel y every 200 mm).

You will then avoid:

– overloading the fastening eyes on the left-hand end

plate

– the terminal sagging (I/O side)

– natural resonances

Please note

Observe the fitting space required due to the optical fibre

waveguide connections on the node.

Proceed as follows:

1. Ascertain the weight of your terminal (weigh or calculate).

The following values are guidelines:

Modules of valve terminals

Typ e 0 3 *)

- per pneumatic module (incl. valves)

Node 1kg 1kg

I/O module 0.4 kg 0.4 kg

*) Components for height linking: weight see Pneumatics manual

Festo P.BE-VIFB21-03-EN en 0010a

MIDI

0.8 kg

MAXI

1.2 kg

2-9

2. Fitting

2. Make sure that the mounting surface can support this

weight and check to see if support brackets are required

for the I/O modules.

3. If necessary, use washers.

4. Fasten the valve terminal with four M6 screws on the left

and right-hand end plates. The terminal can be mounted

in any position.

2-10

Fig. 2/4: Fitting the terminal onto a wall

Festo P.BE-VIFB21-03-EN en 0010a

Installation

Chapter 3

3-1Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

Contents

3. Installation 3-1...................................................

3.1 Installation summary 3-3............................................

3.1.1 System structure on the remote bus 3-3................................

3.1.2 Installation instructions 3-5..........................................

3.2 Bus node 3-6......................................................

3.2.1 Configuration settings in the node 3-9.................................

3.3 Connecting the power supplies 3-11....................................

3.3.1 Calculating the current consumption 3-12...............................

3.3.2 Connecting the power supply 3-14.....................................

3.4 INTERBUS interface 3-22.............................................

3.4.1 Conecting the optical fibre waveguide Rugged-Line plug 3-23...............

3-2

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

3.1 Installation summary

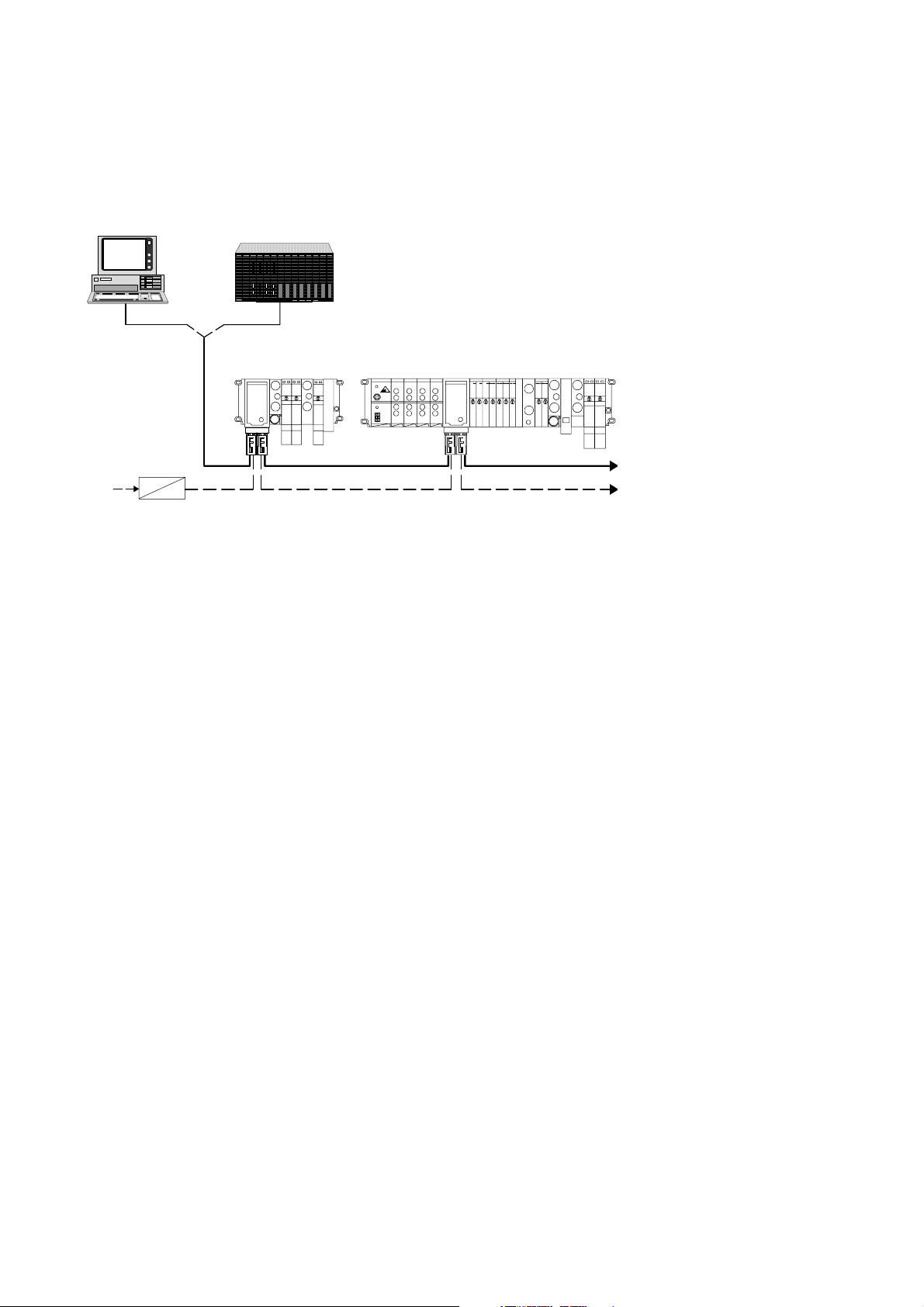

3.1.1 System structure on the remote bus

The multi-functional valve terminal type 03 with FB21 is an

optical fibre waveguide remote bus slave on the INTERBUS

with Rugged-Line connection technology. The terminal behaves on the remote bus like an optical fibre waveguide bus

terminal with integrated I/Os and must be addressed accordingly.

Please note

– Commissioning on the remote bus can only take place

when all the slaves have been fully connected.

– The valve terminal requires 24 V DC power supply. This

is supplied via the Rugged-Line plug. A separate supply

and separate switch off for the valve terminal outputs/

valves is possible.

Festo P.BE-VIFB21-03-EN en 0010a

3-3

3. Installation

1

1

23

230 VAC

24 VDC

1 INTERBUS master: PC or PLC with module

2 Valve terminal type 03: Only MA XI valves

3 Valve terminal type 03: M IDI/MAXI valves and electric modules

Fig. 3/1: Remote bus system structure with valve terminal

3-4

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

3.1.2 Installation instructions

The following sections and chapters contain information on

installation and on preparing commissioning.

– Settings in the relevant field bus node, if required.

– Calculating the current consumption of the valve terminal

and instructions on selecting suitable power units and

cables.

– Connecting the power supply and instructions on comply-

ing with EMC guidelines.

– Connecting the relevant bus system and instructions on

the bus cables.

The following supplementary information can be found in the

Appendix:

Festo P.BE-VIFB21-03-EN en 0010a

– Basic principles of cable length and cross sectional area

including calculation aids.

– Connecting the cables to the plug/socket.

– Accessories and sources of supply.

3-5

3. Installation

3.2 Bus node

Opening and closing the node

Warning

Before undertaking installation and/or maintenance work,

switch off the following:

S the compressed air supply

S the power supply for the electronics

S the load voltage supply for the outputs/valves

You can thereby avoid:

– uncontrolled movements of loose tubing

– undesired movements of the connected actuators

3-6

– undefined switching states of the electronics.

Caution

The node contains electrostatically vulnerable components.

S Do not therefore touch the contacts of these compo-

nents.

S Observe the regulations for handling electrostatically

vulnerable components.

You will then avoid damage to the electronics in the node.

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

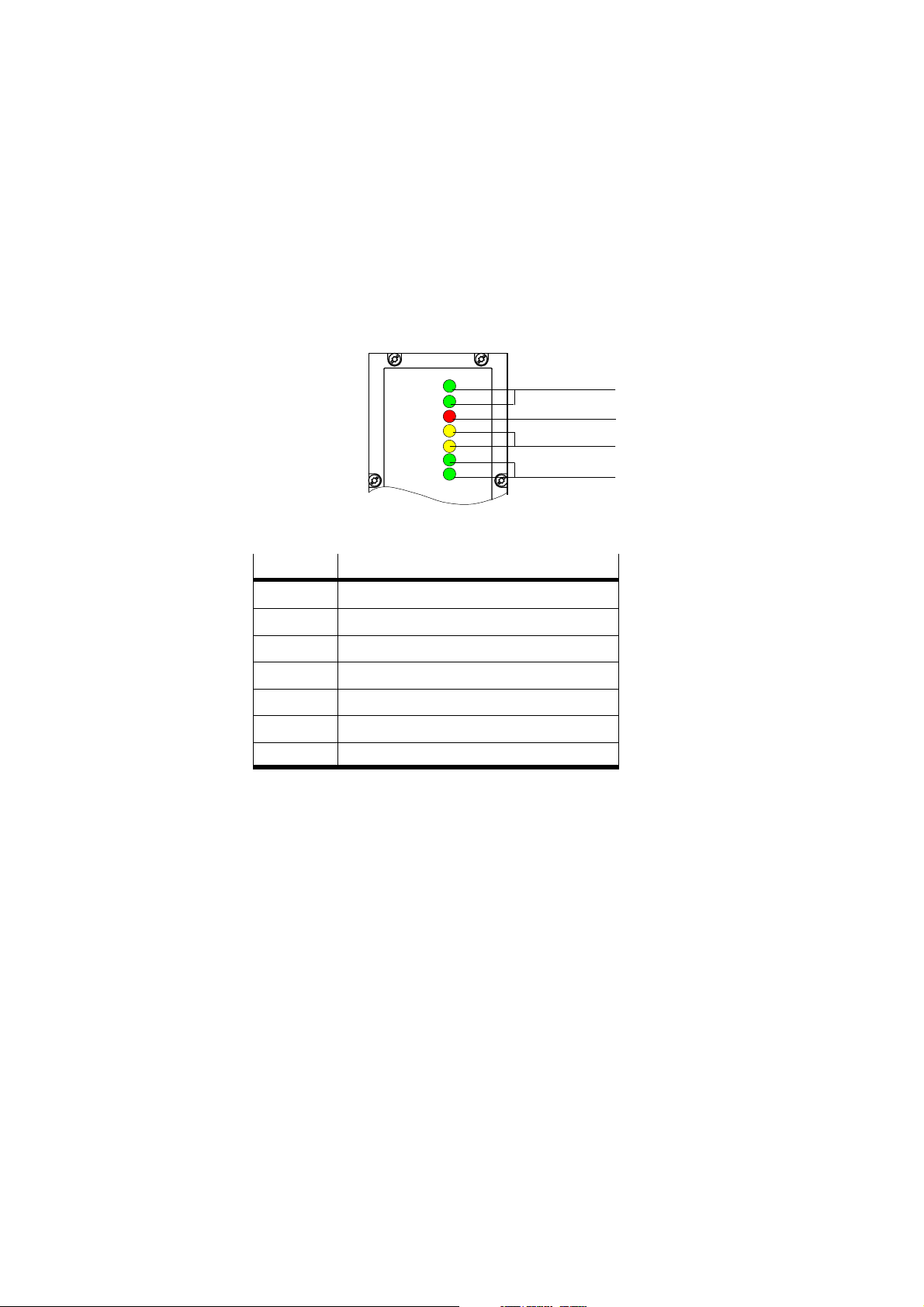

1 Green LED

2 Red LED

3 Yellow LED

4 Fuse for power

supply to inputs

5 INTERBUS op-

tical fibre waveguide interface,

continuing

6 Power supply

connection, continuing

The following connecting and display elements can be found

on the cover of the node:

1

IB DIAG

RC

RD

F01

F02

US1

US2

9

2

3

4

7 Power supply

connection, incoming

8 INTERBUS op-

tical fibre waveguide interface,

incoming

9 Philips screw

Fig. 3/2: Cover of the node

Festo P.BE-VIFB21-03-EN en 0010a

8

IN

OUT

IN

OUT

UB

UB

5

67

3-7

3. Installation

Please note

– The cover need not be opened for normal commission-

ing.

– The cover is connected to the internal printed circuit

boards by the cable with the fuse for the power supply

to the sensors and can, therefore, not be removed completely.

– In order to lift up the cover, unscrew the six Philips

screws in the cover.

Opening

S Unscrew and remove the six Philips screws in the cover.

Carefully lift up the cover. Do not damage the cable by

mechanical stress.

Closing

S Replace the cover. Place the cables with the fuse for the-

power supply to the sensors back into the housing so

that they are not clamped. Then tighten the Philips

screws in the cover in diagonally opposite sequence.

3-8

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

3.2.1 Configuration settings in the node

There are four printed circuit boards in the node. Board 3

contains LEDs and switches for setting the baud ratevalve

test function and the reaction to faults.

1 Board 3

2 DIL switch

1

Fig. 3/3: DIL switches in the node

Please note

Valve terminal typ 03 FB21 can be operated with 500

kBaud as from revised hardware version 6.6.2000. The

prerequisite for this is that all FB21 valve terminals in the

Interbus have this revised hardware status.

OFF ON

2

Festo P.BE-VIFB21-03-EN en 0010a

3-9

3. Installation

Setting the baud rate and the reaction to faults

The two DIL switches have the following functions:

– DIL switch 1: Setting the baud rate

– DIL switch 2: partial display/masking out of common

error messages/periphery error messages (only in conjunction with G3-module)

The switches are set at the factory as follows:

– DIL switch 1: ON

– DIL switch 2: OFF

Commissioning can therefore often be carried out without the

need to open the node. If conditions in your application

change or if faults occur, check the setting of the DIL switches

asshowninthetablebelow.

DIL switch

(factory setting)

500 KBd 2 MBd

(as from hardware

revision 6.6.2000)

*) Further information see chapter 4.2

DIL switch 1

baud rate

Fig. 3/4: Positions of the DIL switches

3-10

DIL switch 2

Error messages

ON OFF

Send part

*)

Festo P.BE-VIFB21-03-EN en 0010a

Send all

3. Installation

3.3 Connecting the power supplies

Warning

Use only power units which guarantee reliable isolation of

the power supply as per IEC 742 / EN 60742 / VDE 0551

with at least 4 kV isolation resistance (protected extra low

voltage, PELV). Switch power packs are permitted if they

guarantee reliable isolation in accordance with EN 60950 /

VDE 0805.

Remark:

By using PELV power units, protection against electric shock

(protection against direct and indirect contact) in accordance

with EN 60204-1 / IEC 204 is guaranteed on Festo valve terminals. Safety transformers with the adjacent designation

must be used for supplying PELV networks. The valve terminals

must be earthed in order to ensure their function (e.g. EMC).

Festo P.BE-VIFB21-03-EN en 0010a

Caution

The load voltage supply for the outputs/valves must be

protected with an external slow-blowing fuse maximum 10

A. With the external fuse, you can avoid functional damage

to the valve terminal in the event of a short circuit.

3-11

3. Installation

Before connecting the power supply, please observe the following:

S Avoid long distances between the power unit and the

valve terminal. If necessary, ascertain the maximum permitted distance as described in Appendix A.

S If necessary, ascertain the total current consumption in

accordance with the table below and then select a suitable power unit as well as a suitable cable cross-sectional

area.

3.3.1 Calculating the current consumption

The table below shows you how to calculate the total current

consumption for the terminal. The values specified have been

rounded up. If you wish to use other valves or modules, refer

to the appropriate technical specifications for their current

consumption.

3-12

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

Stromaufnahme Elektronik und Eingänge

(24V±25%)

Node

Number of simultaneously

actuated sensor inputs ____ x 0,010 A

Sensor supply

(see manufacturer specifications) ____ x _____ A

Current consumption of electronics and

inputs max. 2,2 A

Current consumption of valves and outputs

(24 V

± 10 %)

Number of valve coils (simultaneously energized):

Number of simultaneously activated

electric outputs: ____ x 0.010 A

Load current of simultaneously activated

electric outputs: ____ x _____ A

Current consumption of outputs max. 10 A

Current consumption at the node

Current consumption of high-current inputs

MIDI: ____ x 0.055 A

MAXI: ____ x 0.100 A

)

(pin 1 of additional supply 24 V/25 A)

Number of fitted

high-current output modules ____ x 0.100 A

Load current of simultaneously activated

high-current outputs ____ x _____ A

Current consumption of high-current outputs

*) per additional supply max. 25 A max. 25 A

*)

0,200 A

+

S A

+

S A

S A S A

S A

+

S A

+

S A

=

S A

+

=

S A

+

S A

=

S A S A

S A

S A

Fig. 3/5: Calculating the total current consumption

Festo P.BE-VIFB21-03-EN en 0010a

3-13

3. Installation

2

3.3.2 Connecting the power supply

The power supply connection and the INTERBUS optical fibre

waveguide connection are in the ”Rugged-Line” connection.

The following components on the valve termial are supplied

separately with + 24 V DC via the power supply connection:

– the power supply for the internal electronics and the in-

puts of the input modules (connection 1: +24 V DC, tolerance

±25 %, external fuse M3.15 A recommended)

– The load voltage for the valve outputs and the outputs of

the output modules (connection 3: +24 V DC, tolerance

±10 %, external fuse max. T10 A required)

1 Power supply

connection (incoming)

2 Power supply

connection (continuing)

1

Fig. 3/6: Position of the power supply connections in the Rugged-Line plug

3-14

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

1 24 V supply for

electronics and

inputs

Please note

Check within the framework of your EMERGENCY STOP

circuit, to ascertain the measures which are necessary for

placing your machine/system in a safe state in the event

of an EMERGENCY STOP (e.g. switching off the load voltage for the valves and output modules, switching off the

compressed air).

2 0 V (electronics

and inputs)

25

3 4 V supply for

valves and

outputs

4 0 V (valves and

outputs)

5 Earth connection

designed for 16 A

Fig. 3/7: Pin assignment of the power supply connection

Please note

– The method of connecting the cable to the power supply

connection in the Rugged-Line plug is described in Appendix B.2.

– 0 V of the electronics/inputs and 0 V of the valves/out-

puts are connected internally.

3

4

1

Festo P.BE-VIFB21-03-EN en 0010a

3-15

3. Installation

Power unit

Please note

If there is a common operating voltage and load voltage

supply for the electronics/inputs and outputs/valves:

S the lower tolerance of +/- 10 % for both circuits must be

observed.

Check the 24 V load voltage for the outputs while your system is operating. Make sure that the load voltage of the outputs lies within the permitted tolerance, even during full

operation.

Recommendation:

Use a closed-loop power unit.

3-16

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

Potential equalization

The valve terminal has two ear th connections for potential

equalization:

– on the load voltage connection

– on the left-hand end plate (M4-thread)

Please note

S Always connect the earth potential to pin 5 of the power

supply connection.

S Connect the earth connection of the left-hand end plate

to the earth potential with low impedance (short cable

with large cross-sectional area).

S By means of low-impedance connections, make sure

that the housing of the valve terminal and the earth

connection at pin 5 have the same potential and that

there are no equalization currents.

In this way you can avoid faults caused by electromagnetic

influences and comply with electromagnetic compatibility

in accordance with the EMC guidelines.

Festo P.BE-VIFB21-03-EN en 0010a

3-17

3. Installation

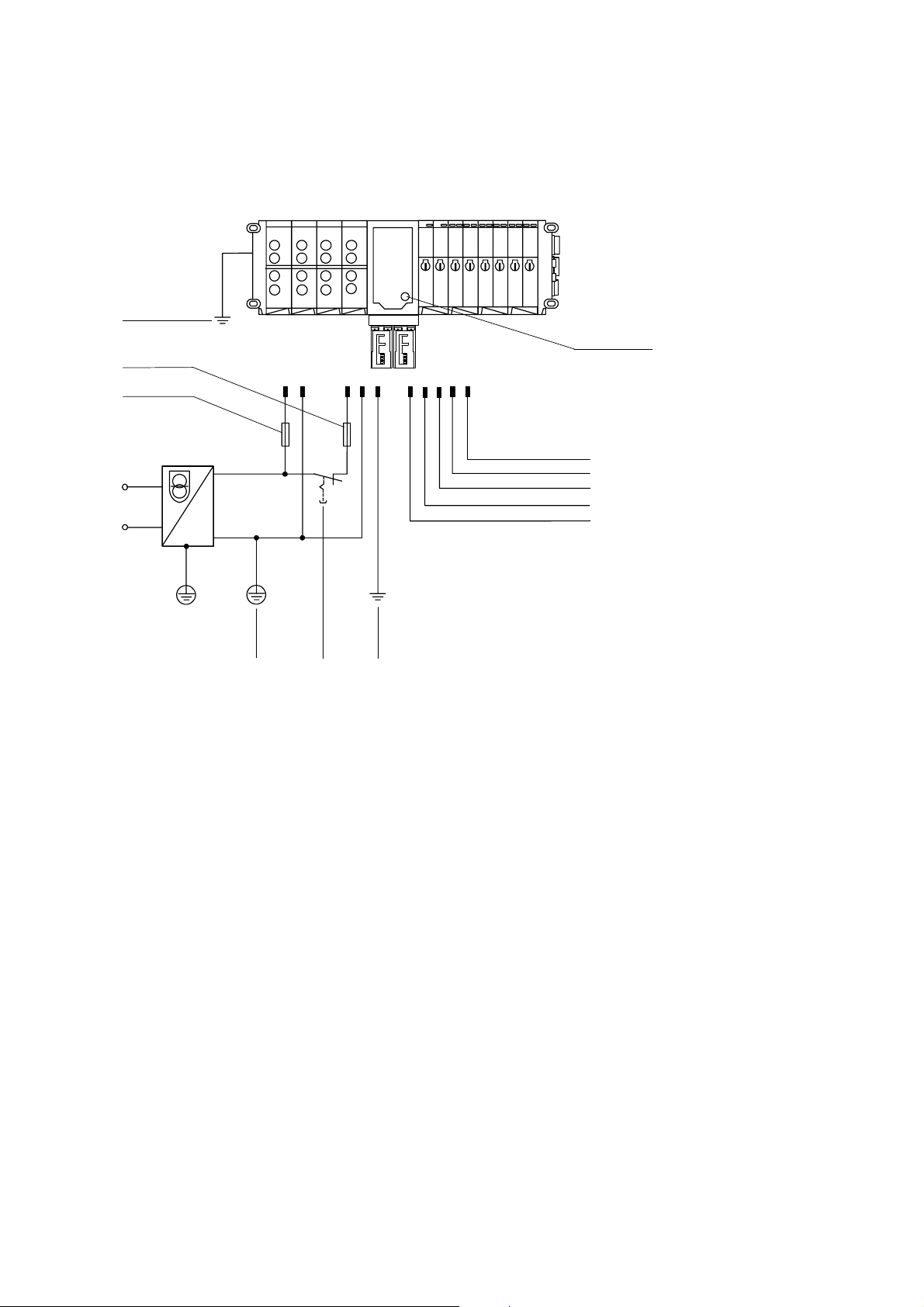

Example of connection

The diagram below shows as an example how to connect a

24 V power supply for pins 1 and 3. Please note that:

– the load voltage of the outputs/valves must be protected

with an external fuse maximum T10 A against short circuit/overload.

– the power supply for the electronics/inputs must be pro-

tected with an external fuse 3.15 A against short circuit/

overload (recommended).

– the power supply for the sensors is additionally protected

with the built-in fuse (2 A).

– the common tolerance of 24 V DC

¦ 10 % must be ob-

served.

– both connections for potential equalization are connected

and that equalizing currents are prevented.

– the load voltage at pin 3 (valves/electric outputs) can be

switched off separately.

3-18

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

2

5

12 3 5

4

24 V

AC

AC

DC

DC

0V

*)

PEPE

1

Fuse for inputs/sensors (2 A)

22

3

2 Potential equalization

3 Load voltage for outputs/valves can be

switched off separately

*)

0 V connected internally

4

123

54

to next

valve

terminal

4 External fuse (3.15 A) for electronics/

inputs

5 External fuses (10 A) for outputs/

valves

1

Fig. 3/8: Example – connecting a common 24 V supply and the potential equalization

Festo P.BE-VIFB21-03-EN en 0010a

3-19

3. Installation

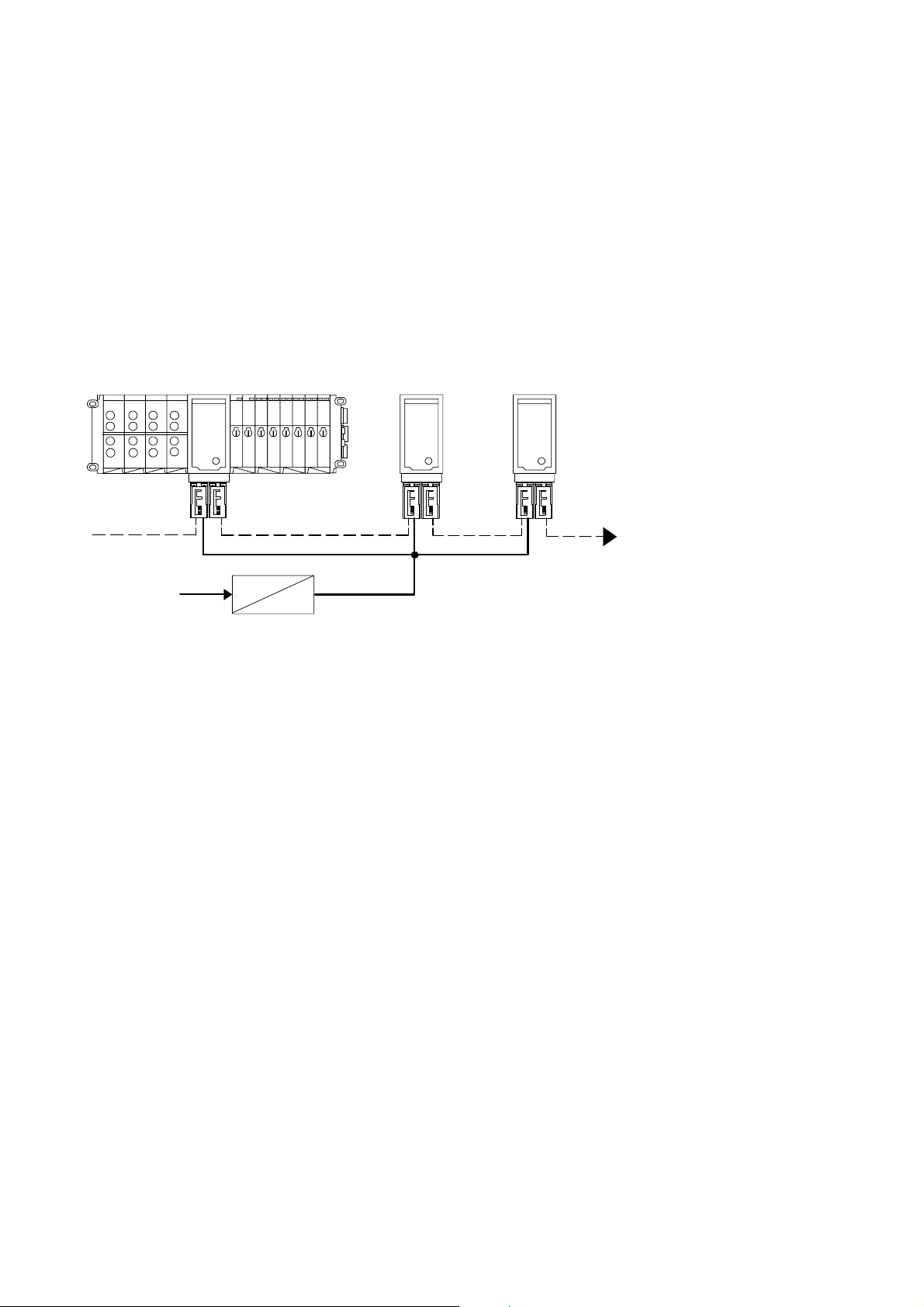

Power supply

You can arrange the power supply for several valve terminals

either:

– star-shaped or

– in series.

Connect the power supply star-shaped if you want short supply cables (this reduces voltag drop).

230 VAC

24 VDC

Fig. 3/9: Star-shaped 24 V power supply

3-20

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

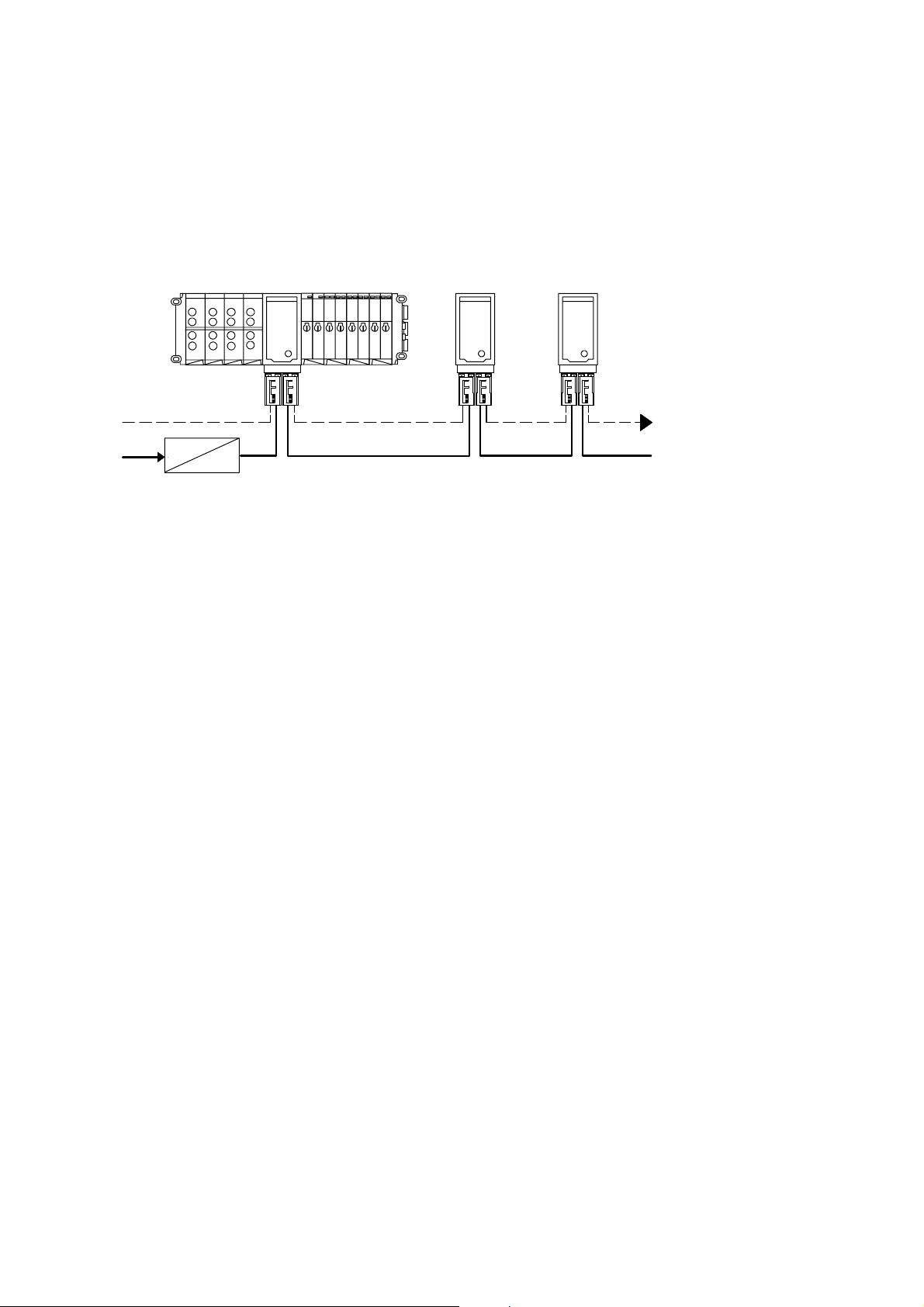

If you wish to connect the 24 V load voltage in series, note

that the sum current of the 24 V power supply must not exceed 16 A per contact of the power supply plug. If this value

is exceeded, a second 24 V power supply must be provided.

230 VAC

24 VDC

Fig. 3/10: Common 24 V power supply

Festo P.BE-VIFB21-03-EN en 0010a

3-21

3. Installation

3.4 INTERBUS interface

There are two connections on the node for connecting it to

the INTERBUS. One of these connections is for the incoming

cable; the other is for the continuing bus cable.

1 INTERBUS optical

fibre waveguide,

incoming

2 INTERBUS optical

fibre waveguide,

continuing

12

Fig. 3/11: Connecting the INTERBUS optical fibre waveguide interface

3-22

Festo P.BE-VIFB21-03-EN en 0010a

3. Installation

3.4.1 Conecting the optical fibre waveguide Rugged-Line plug

The method of connecting the optical fibre waveguide cable

to the optical fibre waveguide connection in the Rugged-Line

plug is described in Appendix B.2.

Please note

Connect the Rugged-Line plug only when the power supply

is switched off.

Proceed as follows:

1. Switch off the power supply.

2. Remove the existing protective cap.

3. Open the fuse clip and insert the Rugged-Line plug into

the interface of the incoming or continuing optical fibre

waveguide(seeFig.3/12).

Festo P.BE-VIFB21-03-EN en 0010a

4. Close the fuse clip.

3-23

3. Installation

2

1 Busorpower

supply connection, incoming

2 Busorpower

supply connection, continuing

1

Fig. 3/12: Bus or power supply connections

3-24

Please note

Unused connections must be sealed, see Appendix B

”Sealing unused connections in the Rugged-Line plug.”

Festo P.BE-VIFB21-03-EN en 0010a

Commissioning

Chapter 4

4-1Festo P.BE-VI FB21-03-E N en 0010a

4. Commissioning

Contents

4. Commissioning 4-1................................................

4.1 Configuring and addressing the valve terminal 4-3.......................

4.1.1 Ascertaining the configuration data 4-3................................

4.1.2 Calculating the number of inputs/outputs 4-5...........................

4.1.3 Address assignment of the valve terminal 4-6...........................

4.1.4 Address assignments after extension/conversion 4-12.....................

4.2 INTERBUS – Configuring and addressing the bus 4-14.....................

4.2.1 General commissioning instructions 4-14................................

4.2.2 Configuring the bus with CMD software 4-16.............................

4.2.3 Configuring the bus without CMD software 4-25..........................

4.2.4 Addressing the inputs and outputs 4-27.................................

4.2.5 Entering process data via the CMD software 4-30.........................

4.2.6 Status bits 4-34.....................................................

4.2.7 Other instructions 4-36...............................................

4-2

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

4.1 Configuring and addressing the valve terminal

4.1.1 Ascertaining the configuration data

Before configuring, you must ascertain the exact number of

inputs/outputs available. A multi-functional valve terminal

consists of a different number of I/Os, depending on what

you have ordered.

Please note

S A valve terminal with field bus node provides four status

bits for diagnosis. These bits are always assigned automatically within the terminal when there are input

modules.

S The s tatus bits must be treated like inputs and occupy

four input addresses.

S The maximum possible extent to which the valve ter-

minal can be equipped, is limited by the addressing limits of the field bus protocol and the mechanical limits

of the terminal.

Festo P.BE-VIFB21-03-EN en 0010a

4-3

4. Commissioning

The table below indicates the I/Os required per module for

configuration.

Modulart

MIDI/MAXI-manifold (type 03)

– single-solenoid manifold

– Double-solenoid manifold

4-output module (4 digital outputs)

4-input module ( 4 digital inputs)

8-input module ( 8 digital inputs)

16-input module (16 digital inputs)

Multi-I/O module

*) The I/Os are assigned automatically within the terminal,

irrespecitve of whether an input/output is actually used.

**) The status bits are assigned automatically within the terminal

as soon as there are input modules.

Anzahl belegter

*)

EAs

2 outputs4 outputs

4 outputs

4 inputs

8 inputs

16 inputs

12 inputs + 8 o utputs

4 inputs

Fig. 4/1: Number of assigned I/Os per module

4-4

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

4.1.2 Calculating the number of inputs/outputs

Copy this table for further calculations.

Eingänge

1. Number of 4-input module ________ · 4

2. Number of 8-input modules ________

3. Number of 16-input modules ________

4. Number of other inputs, e.g. multi-I/O module

5. .The 4 status bits are assigned internally automatically

by the terminal.

Total number of inputs to be configured

· 8

· 16

Outputs

6. Number of single manifolds ________ · 2

7. Number of double manifolds ________

Intermediate sum 6. + 7.

8. .Check whether the sum of 6. + 7.

Is divisible by four without remainder.

This check must be carried out because of the

4-bit orientated addressing of the terminal.

Case distinction:

a) If divisible by four without remainder, continue with 9.

b) If not divisible without remainder, round up to next half byte (+1...3).

· 4

+

+

+

+

=

+

=

+

S E

S E

S E

S E

4E

S E

S O

S O

S O

S 2O

9. Number of electric 4-output modules ________

10.Number of other outputs, e.g. multi-I/O module

Total number of outputs to be configured

Festo P.BE-VIFB21-03-EN en 0010a

· 4

+

+

=

S O

S O

S O

4-5

4. Commissioning

4.1.3 Address assignment of the valve terminal

The address assignment of the outputs of a multi-functional

valve terminal depends on the modules/valves fitted on the

terminal. A distinction must be made between the following

fitting variants:

– valves and digital I/O modules

– only valves

– only digital I/O modules

The basic rules described below apply to the address assignment of these fitting variants. A detailed example is given

after these basic rules.

Please note

If two addresses are assigned for one valve location, the

following assignment applies:

lower-value address > pilot solenoid 14

higher-value address > pilot solenoid 12

4-6

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Basic rule for addressing

With mixed fitting, consideration is given to the address assignment of the valves, the digital I/O modules and the

status bits.

Outputs

1. The address assignment of the outputs does not depend

on the inputs.

2. Address assignment of the valves:

– Addresses are assigned in ascending order

without gaps

– Counting begins on the node from left to right.

– Maximum 26 valve solenoid coils can be addressed

– Single manifolds always occupy 2 addresses.

– Double manifolds always occupy 4 addresses.

3. Rounding up to 4 bits: case distinction:

a) If the number of valve addresses is divisible by 4

without remainder, continue with point 4.

b) If the number of valve addresses is not divisible by

4 without remainder, you must round the addresses

up to 4 because of the 4-bit orientated addressing.

The bit thus rounded up in the address range cannot

be used.

Festo P.BE-VIFB21-03-EN en 0010a

4. Address assignment of the outputs:

The digital outputs are addressed after the (rounded up

4-bit) addresses of the valves.

– Addresses are assigned in ascending order without

gaps.

– Counting begins on the node from right to left.

– Counting on the individual modules is from the top to

the bottom.

– Digital output modules occupy 4 or 8 addresses.

4-7

4. Commissioning

Inputs

1. The address assignment of the inputs does not depend

on the outputs.

2. Address assignment of the inputs:

– Addresses are assigned in ascending order without

gaps.

– Counting begins on the node from right to left.

– Counting on the individual modules is from the top to

the bottom.

– Input modules occupy 4, 8, 12 or 16 addresses.

3. Status bits:

The address assignment of the status bits depends on

the fitting variants of the inputs and on the configuration.

The following basic rule applies:

– The status bits are only available if input modules are

connected to the terminal and configured.

– Addressing:

The status bits are transferred to the four highestvalue positions in the configured address range.

4-8

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

1

When the power supply is switched on, the valve terminal

recognizes all available pneumatic modules and digital input/

output modules automatically and assigns the appropriate

addresses. If a valve location remains unused (blanking

plate) or if an input/output is not connected, the relevant

address will still be assigned. The diagram below shows an

example of address assignment.

2 3456

0

8

1

2

9

3

4

10

5

6

11

7

1 4-input module

2 8-input module

3 4-output module

20

16

21

17

22

18

23

19

0

12345678910111213

4 SINGLE manifold

5 DOUBLE manifold

6 Round up (not used)

Fig. 4/2: Address assignment of a terminal with digital I/Os

Remarks on the diagram:

– If single-solenoid valves are fitted onto double manifolds,

four addresses will be occupied for valve solenoid coils;

the higher address will in each case remain unused (see

address 3).

1514

Festo P.BE-VIFB21-03-EN en 0010a

4-9

4. Commissioning

– If unused valve locations are sealed with blanking plates,

the addresses will still be assigned (see addresses 12,

13).

– Due to the 4-bit orientated addressing of the modular

valve terminal, the last valve location will always be

rounded up to a full 4 bits (providing the fittings do not

already use the full four bits). Two addresses cannot,

therefore, always be used (see addresses 14, 15).

Additional instructions for valve terminal without I/O modules

If only valves are used, the address assignment will always

be as described in basic rule for addressing.

Please note

– Maximum 26 valve solenoid coils can be addressed.

– There is no rounding of the last two positions on the

valve side.

– Valve terminals without input modules do not require a

configuration for inputs. The status bits are not therefore available.

4-10

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Additional instructions for valve terminal without valves

If only electric I/Os are used, the address assignment will

always be as described in basic rule for addressing.

Please note

– Counting begins immediately to the left of the node.

– There is no rounding of the last two positions on the

valve side.

– The maximum possible extent to which equipment can

be fitted on the valve terminal is limited by the addressing limits of the relevant field bus protocol and by the

mechanical limits of the valve terminal (92inputs or 48

outputs).

Festo P.BE-VIFB21-03-EN en 0010a

4-11

4. Commissioning

4.1.4 Address assignments after extension/conversion

A speciality of the multi-functional valve terminal is its flexibility. If the demands placed on the machine change, different equipment can be fitted onto the valve terminal.

Caution

If the terminal is extended or converted at a later date, the

input/output addresses may be shifted. This applies in the

following cases:

– When one or more pneumatic modules are added or

removed at a later date.

– When a pneumatic module with single-solenoid valves is

replaced by a new module with double-solenoid valves

or vice versa.

– When additional input/output modules are added be-

tween the node and exsting input/output modules.

– Existing input/output modules are removed or replaced

by input/output modules which occopy more fewer

input/output addresses.

4-12

If the configuration of the inputs is modified, the addresses

of the status bits will be shifted.

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Using the standard fitting shown in the previous diagram, the

diagram below shows as an example the modifications which

can occur to the address assignment when extra equipment

is added to the valve terminal. Two double-solenoid manifolds and two single-solenoid manifolds have been added to

the valves. An 8-input module and a 4-output module have

been removed from the electric I/Os.

1 2 34 5 436

0

0

20

21

1

2

22

3

23

12345678910111213

1514171618

19

1 4-input module

2 4-output module

3 Single-solenoid manifold

4 Double-solenoid manifold

5 Power supply

6 No rounding

Fig. 4/3: Address assignment of a terminal with digital IOs after extension/conversion

Please note:

Pressure supply modules and intermediate pressure supply

modules do not occupy any addresses.

Festo P.BE-VIFB21-03-EN en 0010a

4-13

4. Commissioning

4.2 INTERBUS – Configuring and addressing the bus

4.2.1 General commissioning instructions

Before commissioning or programming you must compile a

configuration list of all the connected field bus slaves. On the

basis of this list you can:

– carry out a comparison between the nominal and the

actual configurations in order to detect any connection

faults;

– access these specifications during the syntax check of a

program in order to avoid addressing faults.

Configuration of the valve terminal requires an exact procedure, as different configuration specifications are sometimes required for each terminal due to the modular structure. Please read carefully the information contained in the

sections which follow.

4-14

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Switching on the power supplies

Please note

Observe here also the instructions in the manual

for your controller.

When the controller is switched on, it automatically carries

out a comparison bewteen the nominal and the actual configurations. For this configuration comparison it is important

that:

– the specifications on the configuration are complete and

correct;

– the field bus slaves are supplied with power, in order that

they can be recognized when the ACTUAL configuration is

ascertained.

Switch on the power supply for all the slaves simultaneously

if there is a central switch or, switch the power supplies on in

the following sequence:

Festo P.BE-VIFB21-03-EN en 0010a

1. first the power supply for the field bus slaves,

2. then the power supply for the controller.

4-15

4. Commissioning

4.2.2 Configuring the bus with CMD software

This chapter describes as an example the main steps required in the CMD software, before you can insert a Festo

valve terminal into your project. A general and comprehensive description can be found in the relevant manual for the

CMD software. In the following, it is assumed that the user is

familiar with the information contained in the CMD manual.

Please note

The software packages are subject to modifications which

are not taken into consideration in this manual.

The examples used here for the screen displays have been

taken from CMD software version 4.

Further and current information can be found in the manual for your CMD software.

4-16

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Inserting with the Ident code

Proceed as follows:

S Open the dialogue window of the INTERBUS module.

S Select the option ”Insert with Ident code... .”

Fig. 4/4: Inserting bus slaves with Ident code

Festo P.BE-VIFB21-03-EN en 0010a

4-17

4. Commissioning

The following dialogue window will then appear:

Fig. 4/5: Dialogue window ”Insert slave”

Enter the following in the dialogue fields:

4-18

S Ident code:

Enter the appropriate Ident code according to the table.

Valve terminal equipment

Only outputs

Only inputs 2

Inputs and outputs

1

Valve coils and/or electric outputs

1

1

Ident-Code

1

3

S Process data channel:

Enter here the number of inputs and/or outputs on your

valve terminal. Note the following:

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Please note

– The number of inputs and/or outputs must be rounded

up to the next word limit.

– If the number of input bits differs from the number of

output bits, the larger number is decisive in each case

for entering the process data channel bits.

– The status bits of a valve terminal with inputs occupy

four additional inputs.

The table below gives a summary of the possible number of

bits for the process data channel.

Valve terminal equipment

Up to 12 + 4 inputs 16

Up to 28 + 4 inputs 32

Up to 44 + 4 inputs 48

Up to 60 + 4 inputs 64

Up to 76 + 4 inputs 80

Up to 92 + 4 inputs 96

Up to 16 outputs

Up to 32 outputs

Up to 48 outputs

Up to 64 outputs

Up to 80 outputs

1

Valve coils and/or electric outputs

1

1

1

1

1

Process data channel bits

S Slave type:

The default entry ”Remote bus slave” can be used.

S Save these entries with OK.

16

32

48

64

80

Festo P.BE-VIFB21-03-EN en 0010a

4-19

4. Commissioning

Insert slave description

In the following dialogue window you can describe the slave

and enter specific information on the valve terminal, e.g. station name and slave image.

4-20

Fig. 4/6: Dialogue window ”Insert slave description”

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Possible entries:

– Profile number:

The Festo valve terminal conforms to the INTERBUS I/O

profile 12. Enter this value in the field ”Profile number.”

– Interface type:

The default entry ”Universal interface type” can be used.

Alternately, you can select the type ”Remote bus.”

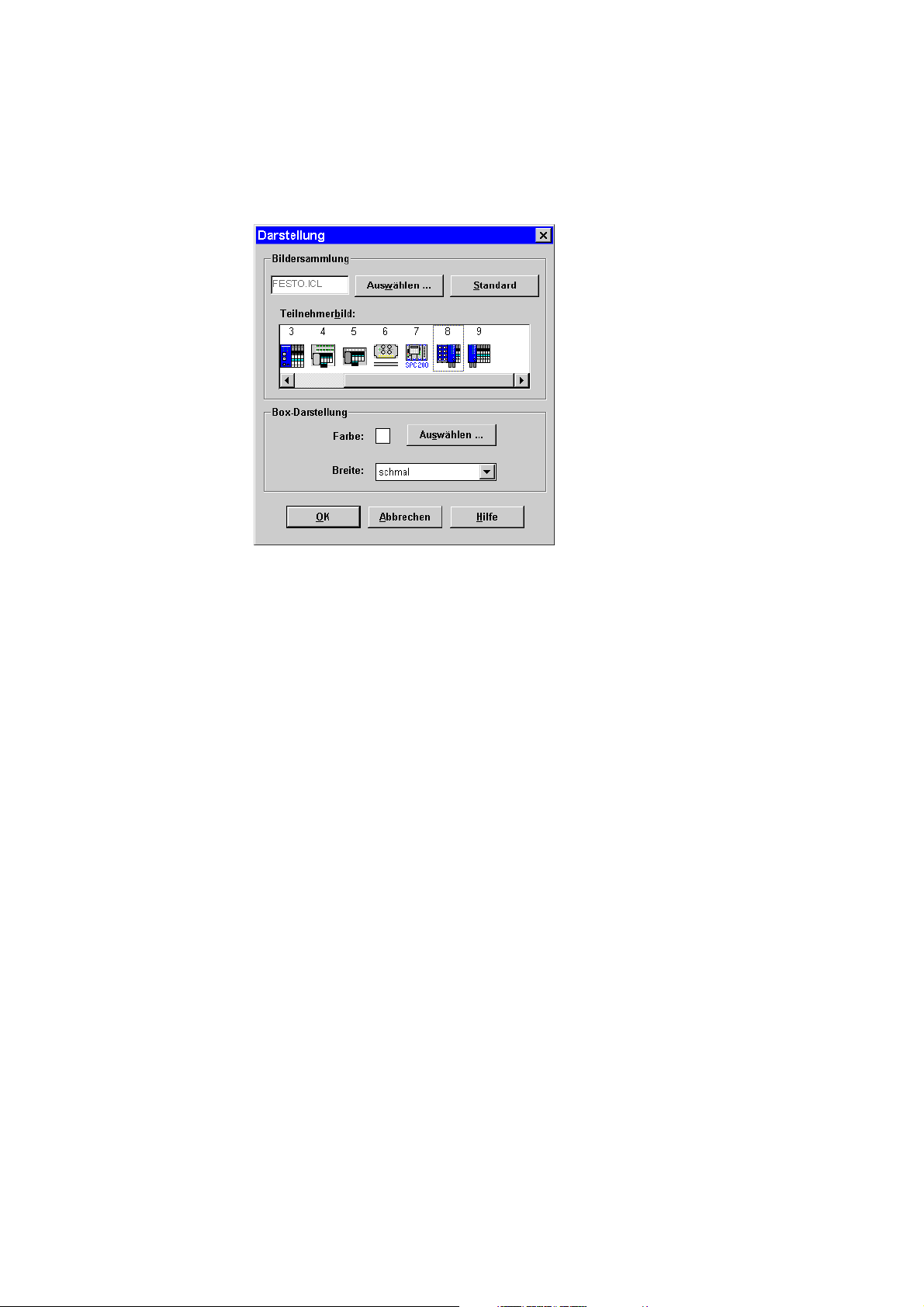

– Picture:

Open the dialogue window ”Picture ...” if you wish to use

specific icons for the Festo valve terminal.

The specific icons of the Festo valve terminals can be found

on the accompanying CD ROM.

S If If necessary, read the file ”Readme.txt” on on the CD

ROM for a quick summary of the contents of the CD ROM.

Festo P.BE-VIFB21-03-EN en 0010a

S Copy the file ”Festo.ICL” into the CM D directory

Directory \PICTURE\.

4-21

4. Commissioning

The following dialogue window will then appear:

4-22

Fig. 4/7: Dialogue window ”Slave picture” for selecting an

icon

S Use the button ”Select ...” to select the file Festo.ICL.

S Mark icon which corresponds to your valve terminal (no. 8

or no. 9 in Fig. 4/7).

S Save the icon with OK.

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

The icons are numbered. The following table shows the relationship between the number of the icon and the valve terminal type.

Icon no.

3 Types 03-05 only with valves

4 Type 02 with inputs and outputs

5 Type 02 only with valves

6 Type 10 with INTERBUS-Loop

7 SPC200 positioning system

8 Type 03 with inputs and outputs,

9 Type 03 only with outputs,

Valve terminal type

INTERBUS optical fibre waveguide Rugged-Line

INTERBUS optical fibre waveguide Rugged-Line

Festo P.BE-VIFB21-03-EN en 0010a

4-23

4. Commissioning

When all the entries have been made, the valve terminal is

inserted into your bus structure as follows (example):

Fig. 4/8: Example of valve terminal inserted into bus structure

4-24

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

4.2.3 Configuring the bus without CMD software

Logical addressing

Please note

S ID CODE

Configure a valve terminal as follows:

– terminal only with outputs

– terminal only with inputs with Ident code 2

– terminal with inputs and outputs with Ident code 3

S Process data channel

The number of inputs and/or outputs must be rounded

up to the next word limit.

If the number of input bits differs from the number of

output bits, the larger number is always decisive for

entering the process data channel bits.

S The s tatus bits of a valve terminal with inputs occupy

four additional inputs.

1)

with Ident code 1

Festo P.BE-VIFB21-03-EN en 0010a

1)

Valve coils and/or electric outputs

4-25

4. Commissioning

These specifications must be known by or ascertained for

each bus slave. Proceed as follows with the valve terminals:

Ascertain the number of I/Os per valve terminal (see chapter

4.1.2, section ”Ascertaining the number of I/Os”).

S Take into consideration the four status bits in the case of

valve terminals with inputs.

S Ascertain the Ident code and the number of bits in the

process data channel according to the table below.

S Assign logical IN and OUT addresses to each slave.

Valve terminal

equipment

Inputs

max

0

0

0

0

0

12+4

28+4

44+4

60+4

76+4

92+4

12+4

28+4

44+4

60+4

76+4

92+4

Outputs

max.

16

32

48

64

74

0

0

0

0

0

0

16

32

48

64

80

96

IDCode

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

3

3

Process

data channel bits

16

32

48

64

80

16

32

48

64

80

96

16

32

48

64

80

96

Meaning

Up to

16 outputs

32 outputs

48 outputs

64 outputs

80 outputs

Up to

12 inputs + 4 status bits

28 inputs + 4 status bits

44 inputs + 4 status bits

60 inputs + 4 status bits

76 inputs + 4 status bits

92 inputs + 4 status bits

16 outputs and up 12 inputs + 4 status bits

32 outputs and up 28 inputs + 4 status bits

64 outputs and up 44 inputs + 4 status bits

64 outputs and up 60 inputs + 4 status bits

80 outputs and up 74 inputs + 4 status bits

92 outputs and up 92 inputs + 4 status bits

4-26

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

4.2.4 Addressing the inputs and outputs

Further information on addressing can be found in the manuals for your controller and the INTERBUS module.

The address assignment (process data assignment) of the

inputs and outputs of a valve terminal on the INTERBUS or a

compatible system depends primarily on the INTERBUS module and on the control system used.

Caution

There are different address assignments on the INTERBUS.

The reason for this is the assignment of the process data

within the INTERBUS module and not within the Festo

valve terminal.

S When assigning the addresses, note the position of the

high and low bytes, because in conjunction with some

control systems the position of these bytes can be

swapped.

Festo P.BE-VIFB21-03-EN en 0010a

In this way you will avoid faults when addressing the inputs/

outputs.

4-27

4. Commissioning

The following examples explain the different address assignments and the position of the low bytes (n) and the high

bytes (n+1). A distinction is made between the:

– Siemens mode and the

– standard mode.

Example:

– In Siemens mode, the lower-value output byte (byte n) is

mapped on valve coils 0 - 7 of the valve terminal; byte

n+1 on the next coils (8 -15) etc.

– In standard mode, the lower-value output byte (byte n) is

mapped on valve coils 8 -15 of the valve terminal; byte

n+1 on valve coils 0 -7.

In the chapter after the following examples, you will find instructions on addressing with the CMD software (process

data assignment) and on modifying the position of the low

and high bytes (”Byte swap”).

4-28

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Example: address assignment of the outputs

1

2

Standard mode 2 Siemens mode

1

Fig. 4/9: Address assignment of the outputs with Siemens controllers and other con-

trollers on the INTERBUS

Please note

If two addresses are assigned for one valve location, the

following assignment applies:

– lower-value address: pilot solenoid 14

– higher-value address : pilot solenoid 12

Festo P.BE-VIFB21-03-EN en 0010a

4-29

4. Commissioning

1

Standard mode

Example: address assignment of the inputs

2 Siemens mode

1

3 8-input module

4 4-input module

2

34

Fig. 4/10: Address assignment of the inputs with Siemens controllers and other con-

trollers on the INTERBUS

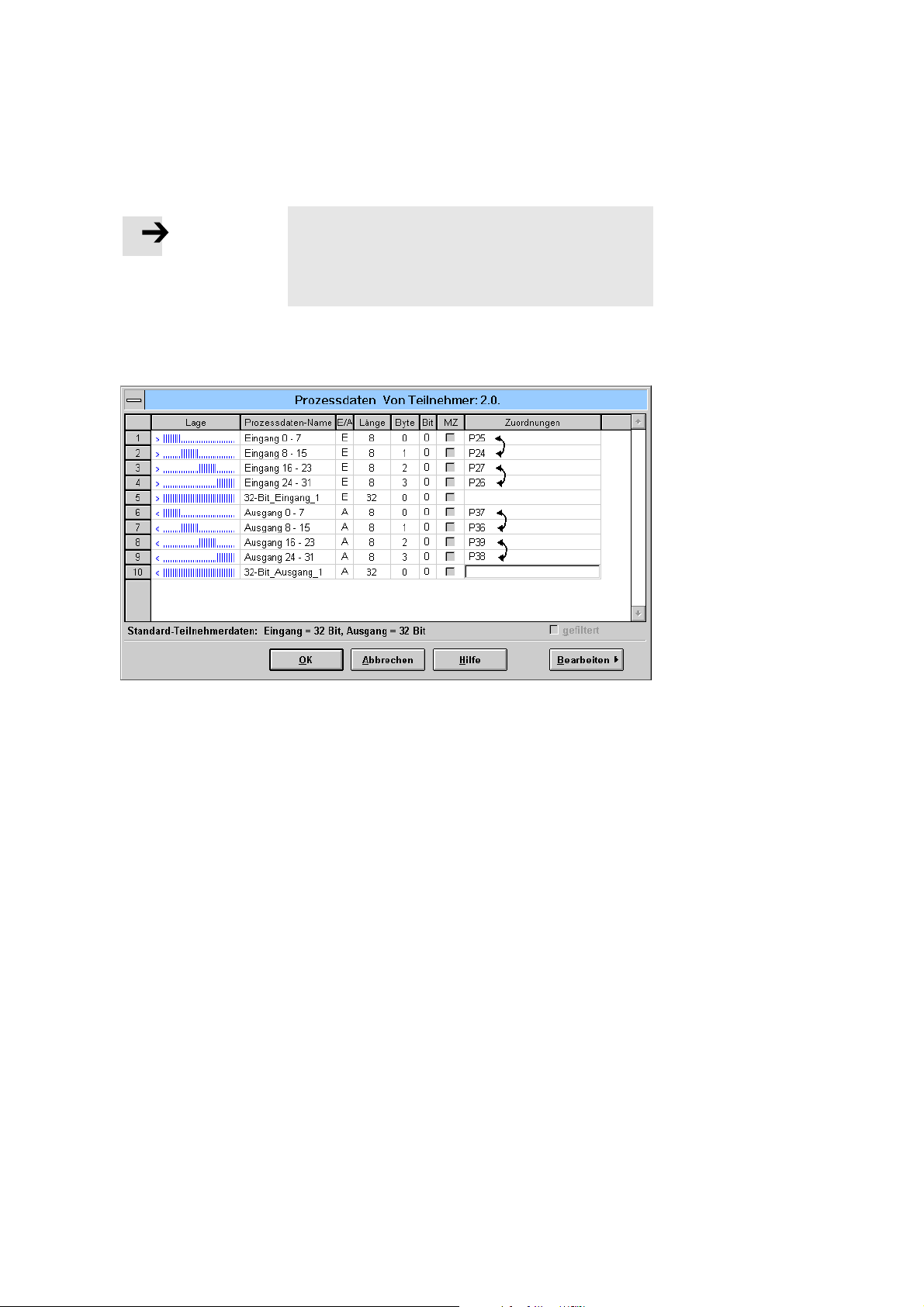

4.2.5 Entering process data via the CMD software

The CMD software offers, as from version 4, the possibility of

assigning each input/output of a valve terminal within the

configured address range to any input/output in the PLC/IPC.

To do this, proceed as follows:

S Add a valve terminal to your bus structure (necessary

steps see section 4.2.2 ”Configuring the bus with CMD

software”).

4-30

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

S Use the right-hand mouse button to open the dialogue

window of the inserted valve terminal.

S Select the option ”Process data.”

Fig. 4/11: Selecting the option for entering the process data

Festo P.BE-VIFB21-03-EN en 0010a

4-31

4. Commissioning

In the following dialogue window you can determine the I/O

addresses. In this way you can adapt the I/Os of your valve

terminal to the PLC used. If necessary, swap the high byte

and low byte (byte swap). The following mapping shows the

byte-by-byte assignment for a Siemens S5.

Fig. 4/12: Entering process data ? Example for ”Siemens mode”

4-32

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Please note

In order to correct the byte swap, it will suffice if you assign the appropriate I/O address to each byte.

An individual I/O assignment at bit level is only necessary

in very few cases.

The following dialogue window shows you the entries which

are necessary for swapping the assignment of the high byte

and the low byte (example: byte swap for ”standard mode”).

Fig. 4/13: Modifying the I/O assignment ? Example for ”standard mode”

Festo P.BE-VIFB21-03-EN en 0010a

4-33

4. Commissioning

4.2.6 Status bits

The status bits of a valve terminal serve for displaying internal valve terminal faults, e.g.:

– voltage below tolerance

– voltage switched off

– short circuit or overload

These error messages are treated like inputs and transmitted

with the rest of the inputs of a valve terminal to the INTERBUS master. There they can be interrogated, linked and processed as ”normal” inputs.

Further information on the function of the status bits can be

found in the secton ”Diagnosis via the INTERBUS” in chapter

5.3.

The status bits always occupy four addresses of the configured address range. If the inputs of the input addresses

thereunder are not used, the valve terminal will set them to

”logical zero.” The addresses of the status bits in the address

range of a valve terminal depend, like all inputs/outputs, on

the INTERBUS modue and on the control system used.

4-34

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

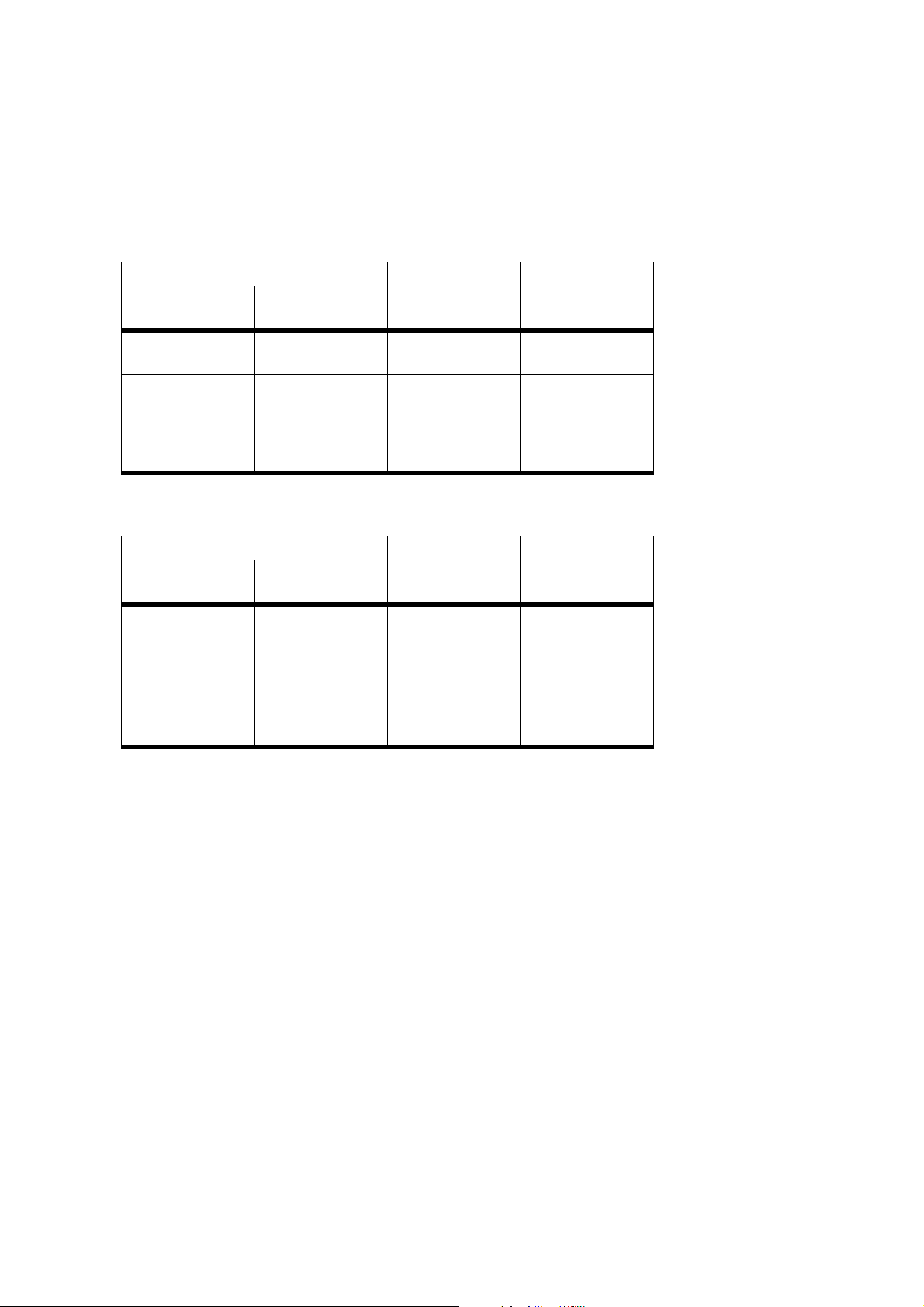

The following tables indicate the different positions of the

four status bits.

Valve terminal equipment

Ident code Process data chan-

Available address Addresses of the

range status bits

nel

1 No address range for

2or3

2or3

2or3

2or3

2or3

2or3

16

32

48

64

80

96

inputs

0 ... 15

0 ... 31

0 ... 47

0 ... 63

0 ... 79

0 ... 95

Fig. 4/14: Position of the status bits in ”Siemens mode”

Valve terminal equipment

Ident-Code Process data chan-

Available address Addresses of the

range status bits

nel

1 No address range for

2oder3

2oder3

2oder3

2oder3

2oder3

2oder3

16

32

48

64

80

96

inputs

0 ... 15

0 ... 31

0 ... 47

0 ... 63

0 ... 79

0 ... 95

No status bits available

12, 13, 14, 15

28, 29, 30, 31

44, 45, 46, 47

60, 61, 62, 63

76, 77, 78, 79

92, 93, 94, 95

No status bits available

4, 5, 6, 7

20, 21, 22, 23

36, 37, 38, 39

52, 53, 54, 55

68, 69, 70, 71

84, 85, 86, 87

Fig. 4/15: Position of the status bits in ”Standard mode”

Festo P.BE-VIFB21-03-EN en 0010a

4-35

4. Commissioning

4.2.7 Other instructions

Preprocessing

Under preprocessing on the INTERBUS, we understand the

logical linking of process data within the INTERBUS module.

Please note

All inputs/outputs of a module can be preprocessed (see

manual for CMD software from Phoenix Contact).

Periphery faults (PF)

If a fault is detected by the valve terminal and entered in the

statusbits,aaperipheryfaultwillalsobetriggered and

transmitted to the INTERBUS module, where it will be displayed.

The reasons for periphery faults can be:

4-36

1. The voltage of the valves and electric outputs is below

the tolerance (21.6 V).

2. The voltage for the valves and electric outputs is switched

off (e.g. EMERGERNCY STOP).

3. The power supply for the inputs/sensors is switched off

(e.g. internal fuse triggered).

4. There is a short circuit or overload at the digital outputs.

Festo P.BE-VIFB21-03-EN en 0010a

4. Commissioning

Masking out an error message (up till INTERBUS

G3 module)

When delivered from the factory, the periphery fault of a valve

terminal can be triggered by all four causes (summary of periphery faults see chapter 5.3 ”Diagnosis via INTERBUS”).

However, the fault can be partially suppressed if DIL switch 2

inside the node is switched on (compare the section ”Setting

the DIL switch elements” in chapter 3.2.2):

– DILswitchelement2toON:

error causes 1 and 2. (tolerance of valve/output voltage

and EMERGENCY STOP) are not transmitted, but suppressed. Only causes 3 and 4 are transmitted.

Please note

Error causes 1 and 2 a re entered in the status bits irrespective of the setting of DIL switch 2.

Festo P.BE-VIFB21-03-EN en 0010a

– DILswitchelement2toOFF(factorysetting):

All error causes will be transmitted as periphery faults to

the INTERBUS.

The system is not stopped by periphery faults. You can determine the reaction to periphery faults by parametrizing the

INTERBUS module. You can also quit the periphery fault by

parametrizing the INTERBUS module.

4-37

4. Commissioning

Masking out an error message (as from INTERBUS

G4 module)

As from the INTERBUS G4 module, error messages can be

displayed or masked out by means of the CM D software

(SRC services) (summary of the periphery faults see the section ”Diagnosis via INTERBUS” in chapter 5.3).

Proceed as follows:

1. Open the dialogue window ”Activity/service editor” in the

CMD software

2. Select the entry ”Set valve request” in the list field

”Name.”

3. Enter the appropriate code in the 4-th field in the table.

Code 046C: error message US2 1 is masked out

Code 047C: All errors are shown

Code 0404: No error is shown

Code 0004: G4-compatible mode

4-38

Please note

The setting applies to the complete bus with all bus slaves.

Festo P.BE-VIFB21-03-EN en 0010a

Diagnosis and error treatment

Chapter 5

5-1Fest o P.BE-VIF B21-03-E N en 0010a

5. Diagnosis and error treatment

Contents

5. Diagnosis and error treatment 5-1....................................

5.1 Summary of diagnostic possibilities 5-3................................

5.2 On-the-spot diagnosis 5-4...........................................

5.2.1 Bus node 5-4......................................................