Festo HSW-x-AP Series, HSW-x-AS Series, HSW-25-AP, HSW-12-AP, HSW-16-AP Operating Instructions Manual

...

Handling module

HSP-...-AP/AS

(en) Operating

instructions

8074323

2017-10b

[8074325]

HSP-...-AP/A S

Original instructions

Symbols: Installation and commissioning may only be per

Warning

Caution

formed in accordance with these instructions by

technicians with appropriate qualifications.

Note

Environment

Accessories

English 3.........................................................................

2

Festo HSP-...-AP/AS 2017-10b

HSP-...-AP/A S

Handling module type HSP-...-AP/ASEnglish

Documentation on the product

For all available product documentation è www.festo.com/pk

1 Operating parts and connections

5

4

3

2

1

1 Spring clamping element

2 End stop with

– groove for proximity switch SMx-8...

– shock absorber type YSRW (...-AP)

– fixed stop with rubber buffer (...-AS)

3 Adjusting screw for stroke setting

(y-direction)

aJaAaB

9

7 Centre piece for path guide

(only with HSP-16-... and HSP-25-...)

8 Sub-base with 4 through threaded holes

for fastening screws

9 Stop strip

aJ Swivel lever

6

7

8

4 Link with path guide

5 Adjusting screw for stroke setting

(z-direction)

6 Cable bearing with end caps

(1 or 2 depending on size)

Fig. 1 Operating parts and connections type HSP-... (front view)

Festo HSP-...-AP/AS 2017-10b English

aA Cable binder support for supply cables

(1 or 2 depending on size)

aB Cross guide (guide carriage)

3

HSP-...-AP/A S

2 Product overview

Basic design Variants

Types HSP-12-..., HSP-16-..., HSP-25-...

The handling module is supplied as stan

dard in sizes 12, 16, 25 ready fitted with

the following function elements:

– Sub-base with variable fitting and

fastening possibilities 8

– 2 adjustable guide links for path

control via roller bearing guide 4

– 2 linear guides arranged in cross-form

(cross guide) aB

– 2 stops in the end positions each with

a shock absorber (type ...-AS: with

rubber buffer) and a fastening rail for

proximity switches 2

Options

Type HSP-...-...-SD

Handling module with protective cover

and side plates.

The design “SD” is recommended for

stand alone mode.

Type HSP-...-AS

Handling module

without drive

Type HSP-...-AP

Handling module with

swivel module type

DSM-...

(double-acting,

pneumatic)

Type HSP-...-...-WR/WL

Handling module with cylinder

BWR-/BWL-HSP-... (see also the chapter

“Accessories”) for withdrawing the

swivel lever into a waiting position above

the

– right-hand end position: type ...-WR

– left-hand end position:type ...-WL

4

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Kits and accessories (see also the chapters “Fitting” and “Accessories”)

Fastening kit type HMB...

for fitting with angled pieces and sliding

blocks e.g. on profile columnns

Installation kit MKRP... (A)

– Flexible protective tube for moving tubing

– Cable support on the cross guide

– Adapter bracket for fastening e.g. on to a

sub-base or structure

– Cover profile for cable bearing in the

grooves of the sub-base or side plates

(A)

Proximity switch type SME/SMT-8-... (B)

for scanning end positions and waiting

positions (type HSP-...-...-WR/WL)

Adapter kit type HAPG-... (C) and in some

cases additional adapter plates (D)

for fastening add-on components (grippers,

swivel drive)

Instructions on fitting further accessories in

conjunction with Festo components are

summarized in the system manual “Handling

technology.”

For HSP-...-AP:

One-way flow control valves type GRLA-... (E)

for setting the positioning speed

(B)

(C)

(D)

(E)

Festo HSP-...-AP/AS 2017-10b English

5

HSP-...-AP/A S

z

3 Method of operation and use

By means of the path guide 4 and the cross

guide aB a movment in a vertical and horizon

tal direction is forced (y-z path). Spring

clamping elements fitted to the end stops 1

guarantee a high degree of repetition accu

racy in positioning.

Self-adjusting hydraulic shock absorbers 2

(only with type ...-AP) in the end positions

cushion the movement. The end positions can

be scanned with proximity switches of type

SME/SMT-8-.... The switching status of the

proximity switches can be observed through

the viewing window when the housing cover is

fitted on.

y

Fig. 2

The stroke range for both end positions (receive and release positions) is set

separately:

– in the y-direction: via the adjusting screws in the links 3

– in the z-direction: via the stop screws on the vertical guide rail 5

Handling module type HSP-...has been designed for use in automated component

assembly in handling and fitting systems.

The HSP-... is particularly suitable for handling small parts at high speed, e.g.

when inserting, turning over or joining.

4 Transport and storage

S Take the weight of the HSP-... into con

sideration. Depending on the size, the

basic design can weigh up to 8.2 kg.

S Consider the following recommendations

regarding storage:

Storage duration 48 months

Storage temperature + 20 °C

Fig. 3

6

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

5 Conditions of use

Please note

Incorrect handling can lead to malfunctioning.

S Make sure that the specifications in this chapter are always observed.

The product will then function correctly and safely.

S Please comply with national and local

safety laws and regulations.

S Please observe the prevailing ambient

[°C] [%] [mbar]

conditions.

S Compare the maximum values in these

operating instructions with your actual

application (e.g. pressures, forces,

torques, temperatures, masses, speeds).

Fig. 4

S Remove the packaging. The packaging is

intended for recycling. (exception: oiled

paper which must be disposed of).

S Please observe the warnings and instructions:

– on the product

– in these operating instructions and

– for the type HSP-...-...WR/WL: in the operating instruction for the

BWR-/BWL-HSP-...

S Use the product in its original state. Unauthorized modification is not per

mitted.

S Make sure there is a supply of correctly

prepared compressed air.

LF-... LR-...

S Maintain the selected medium for the

complete service life of the product.

Example: If non-lubricated compressed

air is used at the beginning, you should

always use non-lubricated compressed

air.

Festo HSP-...-AP/AS 2017-10b English

Fig. 5

7

HSP-...-AP/A S

S Slowly pressurize the complete system.

S Check to see if the following are

To do this use start-up valve type HEL-... /

HEM-....

Fig. 6

necessary:

a compensation reservoir type VZS-...

This will reduce fluctuations in the

pressure.

6 Fitting

Please note

Note especially the following when fitting all the components:

‒ Screw connections must be fitted free of offset and mechanical tension.

‒ Screws must be fitted accurately (otherwise threads will be damaged).

‒ The specified torques must be observed.

‒ Contact surfaces must be clean (avoid leakage and contact faults).

Observe also the installation instructions supplied with modules and compo

nents ordered at a later stage.

a non-return valve type HGL-...

In this way you can prevent the work load

from sliding down if there is a sudden drop

in pressure.

Please note

For the type HSP-...-...WR/WL: Please observe the warnings and instructions in

the operating instruction for the BWR-/BWL-HSP-...

8

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Fitting: Mechanical components

The HSP-... is supplied ready for fitting.

S If necessary, remove the protective cover before fitting.

S Fit first the add-on components and, in the case of the HSP-...-AS, the external

S Make sure that the fastening surface can support the weight of the HSP-....

S Fit the HSP-... only onto a flat fixed surface.

Select one of the following fastening methods:

– Direct fastening via 4 through holes in the sub-base

drive or after fastening make sure that there is sufficient free space for fitting

the components.

[mm]

H1

H2

@ D1

L1

HSP-12 HSP-16 HSP-24

40 20 40

40±0.2 100±0.2 100±0.2

6.3 6.3 6.3

200±0.6 280±0.6 370±0.6

– Fastening via the side plates

(user-specific hole pattern).

– Fastening on the rear of the sub-base with

– sliding blocks type HMBN-5-M5

(Fig. 8) or

– fastening kit type HMBK-ND and

connecting bracket type HMBV-ND

(example: Fig. 9).

L1

H1

H2

D1

Fig. 7

Fig. 8

Festo HSP-...-AP/AS 2017-10b English

9

HSP-...-AP/A S

Recommendation:

Fasten the HSP-... preferably in a vertical position with fastening kit type

HMBK-ND and connecting bracket type HMBV-ND on one or two profile columns.

Fig. 9

Please note

Note that two profile columns are necessary for stable fastening of the

HSP-25-....

S Place the HSP-... so that you can easily reach the operating parts.

S Make sure that the HSP-... is fitted free of mechanical stress. Tighten the

fastening screws to an equal extent.

S Make sure there is sufficient space for connecting the power cables and

compressed air tubing.

10

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Fitting the add-on components:

Use adapter kit type HAPG-... with:

– Universal adapter for the relevant size

– Two channels for the tubing bearing (B)

The standard hole pattern of the universal

adapter (D) forms the interface to selected

Festo products, e.g. micro grippers.

S Check to see if additional fastening el

ofHSP-...(A).

and the support for the cable binder (C).

ements and adapter plates (E) are neces

sary. An overview of this can be found in

the sales documentation for the HSP-... .

(B)

(A)

(C)

(D)

(E)

Please note

Natural resonance when the work load

vibrates can cause damage.

S Place the mass centre of gravity of the

work load, therefore, as near as possible

to the axes of symmetry of the cross

guide.

Please note

Excessive forces and torques can damage

the drive and the mechanical components.

S Make sure that you observe the maxi

mum permitted values of the following

variables:

– force F

– torques Mx, My and M

, Fy, F

x

z

z

The reference point for forces and

torques is the centre of the cross guide

on the guide slide.

Fig. 10

See chapter “Technical specifications.”

Festo HSP-...-AP/AS 2017-10b English

Fig. 11

11

HSP-...-AP/A S

Fitting an external drive for type HSP-...-AS:

Please note

S Use a drive with constant drive speed

without impact loading.

S Make sure that you observe the maxi

(A)

mum permitted values of the following

variables:

– axial radial force F

– drive speed M

y

and F

y

z

(B)

(C)

The reference point for forces and

torques is the centre of the shaft.

See chapter “Technical specifications.”

Fig. 12

The drive speed is transmitted via a drive shaft with ball bearings. The external

drive can be fastened to the rear of the sub-base.

Fastening the drive

(A) Fastening holes (4x) M4 M4 M5

(B) Shaft with feather key

as per DIN 6885

(C) Centring fit @ 45

HSP-12-AS HSP-16-AS HSP-25-AS

A2x2x12 A2x3x18 A2x4x25

f8

@ 60

f8

@ 70

f8

12

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Static adjustment of the end positions:

S Remove the protective cover of the

S Exhaust the drive.

Setting the Z-stroke:

1. Loosen the locking nut of the stop

2. Use a hexagon socket screw key to turn

3. Tighten the locking screw (tightening

4. Repeat the procedure for setting the

handling module.

screw (A).

the stop screw at the same time with

counter force against the locking screw

unti the receive position (B) is reached.

torque: 1 Nm).

release position.

(B)

(A)

Fig. 13

Setting the Y-stroke:

Warning

Sudden movements of the actuators when they are under pressure during the

setting of the y-stroke can cause injuries and loose link parts can damage the

HSP-... .

S Exhaust the drive before you loosen the fastening screws of the link parts.

S After setting the Y-stroke: Make sure that the fastening screws of the link

parts are screwed tight.

In this way you will avoid injury to human beings and damage to the device.

Please note

Loosen only the fastening screws of both link parts.

The fastening screws of the centre piece 7 between the link parts on HSP-16-...

and HSP-25-... must not be loosened.

Festo HSP-...-AP/AS 2017-10b English

13

HSP-...-AP/A S

5. Loosen the fastening screws (C) of the

6. Turn the adjusting screws (D) until the link

Alignment free of offset:

7. Press the link parts down vertically

right-hand and left-hand link parts just

enough to enable the link parts to be

shifted.

parts have reached the desired receive or

release position.

If side plates are fitted, you can set the

adjusting screws with a hexagon socket

screw key through the holes in the side

plates.

against the aluminium stop strip (E) of the

horizontal guide rail, while you tighten the

fastening screw of the link parts (tighten

ing torque: 6 Nm).

(D)

(C)

Fig. 14

S Carry out a manual check of the following

after each adjustment (without pressuriz

ing the drive):

– Has the desired end position been

reached?

– Are the link parts aligned without

offset?

S In order to do this, swing the moveable

mass into the end positions.

– by hand or

– with a hexagon socket screw key on

the drive (Fig. 16).

S When doing this, check that the double

rollers run smoothly in the path guide.

S If necessary, correct the alignment of the

link parts.

Fig. 15

Fig. 16

(E)

14

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Fitting: Pneumatic components

Connecting the drive for type HSP-...-AP:

S Use one-way flow control valves of type

S Screw in both one-way flow control valves

S Connect the tubing of the drive.

Connecting the add-on components:

Installation kit MKRP-.. (see chapter “Accessories”) enables the tubing and cables

to be grouped together in a flexible installation tube. The installation tube is fas

tened to the cross guide with the support, and e.g. to the sub-base or the struc

ture with the adapter bracket. The installation tube may be filled to max. 70 %.

GRLA-... for setting the swivel speed. The

speed will be reduced by the throttling of

the exhaust air.

Fig. 17

on the drive.

Make sure that the moving pneumatic tubing

and electric cables are laid correctly (example

Fig. 18):

S Lay the cables and tubing upwards along

the vertical guide rail.

S Fasten the cables and tubing with cable

binders

– on the support of the universal adapter

(A) or pass them through the two cable

channels of the universal adapter (B).

– on the cable binder support (C) on the

cross guide.

S Pass the cables and tubing through the

holes in the sub-base (E) or use protective

tubing (D).

(D)

(E)

(C)

(B)

(A)

Fig. 18

Festo HSP-...-AP/AS 2017-10b English

15

HSP-...-AP/A S

Fitting: Electric components

Use proximity switches SME/SMT-8 for

(E)

scanning the end positions:

1. Remove the protective cover of the

handling module.

2. Make sure that the shock absorbers are

screwed in completely (only type ...-AP; as

supplied from the factory).

3. Push the proximity switch into the groove

of the sensor rail (A).

The electric proximity switches are trig

gered by magnets in the stop screws (B).

(A)

4. Fasten the proximity switches in the end

positions. Subsequent adjustment of the

shock absorbers is not necessary.

Fig. 19

Please note

The cables of the proximity switches must not lie in the working range of the

handling module.

(D)

(C)

(B)

S Clamp the cables in the groove of the side plates (D) and the sub-base.

S Secure the cables with the aid of the cover profile (C) of the installation kit

(cut to size).

S Paass the cables back through the through hole in the sub-base (E).

16

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

7 Commissioning

Complete system

S Slowly pressurize the complete system. This will prevent uncontrolled

movements from occurring. For slow start-up pressurization, use start-up valve

type HEL-... orHEM-....

S Make sure that the conditions of use for the setting procedure are identical

with those in continuous operation. Otherwise there is a danger of the

handling module becoming overloaded.

Individual unit

Warning

S Make sure that:

‒ nobody can place his/her hand in the positioning range of the handling

module

‒ there are no objects in the path of the moveable mass

‒ there is no tubing in the path.

Protect the area e.g. by means of a cover or screen.

Please note

HSP-...-AP:

S Handle the shock absorbers with care so that the thread, the piston rod and

the outer cylinder are not damaged.

S Make sure that the shock absorbers are screwed in completely and locked

(assupplied from the factory). If the shock absorbers are not screwed in

completely, the cushioning effect will be considerably reduced (reduced

cushioning stroke).

Please note

HSP-...-AS with an electromotor:

Moving to the fixed stop (2 in fig. 1) generates sudden loadings in the drive

chain. This can lead e.g. to gear damage.

S Carry out reference travel against the fixed stops only with low energy. The

rubber buffers in the fixed stops are only to reduce noise.

Festo HSP-...-AP/AS 2017-10b English

17

HSP-...-AP/A S

S Pressurize the add-on components. If necessary, carry out a separate test run

Please note

For the type HSP-...-...WR/WL: Please observe the warnings and instructions in

the operating instruction for the BWR-/BWL-HSP-...

to check that the add-on components are functioning correctly.

Add-on components

Without work load – Correct assignment of the compressed air

With work load – Reliable holding of the work load

Tests

connections

– Gripping speed

– Function of the proximity switches

S Pressurize the drive in one of the following ways as desired:

– slow pressurization of one side

– simultaneous pressurization of both sides with subsequent exhausting of

one side.

Please note

Swivel module DSM-... for HSP-...-AP may only be commissioned in unmodified

state as at delivery and with protective cap.

Please note

S Start first of all a test run at reduced operating speed.

S Accelerate in steps until the operating speed is reached. For this speed,

please refer to the calculations for your application.

S Interrupt the test run if:

‒ there is a metallic knocking of the stop screws

‒ the double rollers do not run smoothly in the path guide

‒ the end positions are not reached

‒ the work load falls down.

For eliminating faults, please refer to the information in chapter 12.

18

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Test run

1. Tighten the two upstream one-way flow

2. Make sure that the operating conditions

control valves

– at first completely

– then loosen approximately one turn.

lie within the permitted ranges.

Fig. 20

Please note

The permitted kinetic impact force at the

end stop applies for certain mass-speed

combinations. It must not be exceeded.

S Make sure that the permitted values for

the positioning time as a factor of the

work load are observed (chapter

“Characteristic curves”).

Fig. 21

3. During the test run check:

– that the proximity switches are functioning correctly

– that the work load is held safely

– the positioning time as a factor of the work load

– the adjustment of the end positions.

4. When adjusting the end positions, observe the instructions in the chapter

“Fitting.”

Warning

Sudden movements of the actuators when they are under pressure during the

setting of the y-stroke can cause injuries and loose link parts can damage the

HSP-....

S Exhaust the drive before you loosen the fastening screws of the link parts.

S After setting the y-stroke: Make sure that the fastening screws of the link

parts are screwed tight.

In this way you will avoid injury to human beings and damage to the device.

Festo HSP-...-AP/AS 2017-10b English

19

HSP-...-AP/A S

5. Open up the one-way flow control valves slowly again until the desired

6. Make sure that the pulse time does not drop below the minimum permitted

positioning speed is reached.

time.

Definition

Pulse time t

= positioning time t + dwell time t

t

e

t: Time which the HSP-... requires in order to move from the receive position to

the release position and back. (permitted values see chapter “Characteristic

curves”).

: Time during which the HSP-... remains in the receive position and release

t

e

position.

Type

Minimum permitted pulse time tt [s] 0.6 0.8 1

HSP-12-... HSP-16-... HSP-25-...

The HSP-... should reach the end position safely, but not strike hard against it.

Striking too hard causes the device to bounce back out of the end stop.

Please note

The tendency to vibrate increases if the speed at the start of cushioning is high.

The complete cycle time increases due to the reverberation time.

S Set the drive below the max. permitted speed at the start of cushioning. You

can then increase the end position accuracy.

When all corrections have been undertaken:

Please note

Before exhausting:

S Make sure that the gripper is not holding a work load.

In this way you can prevent a mass from sliding down when the device is

exhausted.

7. Conclude the test run. Exhaust the drive and the add-on components.

20

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

8 Operation

Warning

S Make sure that:

– nobody can place his/her hand in the

positioning range of the moveable mass

– there are no objects in the positioning range.

S Make sure that the handling module is set into

motion only with the protective cover or screen.

Please note

HSP-...-AP:

If the shock absorber is not used to its full extent, there will be an increase in

the oil leakage.

m

Make sure that the shock absorber is operated with an energy utilization of at

least 25 % to max. 100 %.

The recommended range lies between 50 and 80 %.

AB C BD

A = unfavourable

Fig. 22

B = permitted C = optimum

D = not permitted

S Note that during operation the viscosity of the hydraulic oil diminishes due to

the frictional heat produced.

The shock absorber can therefore break through after a long period of

operation.

At temperatures of approx. 0 °C:

S Note that the reset times of the shock absorber are longer.

Low temperatures cause an increase in the viscosity of the hydraulic oil.

The HSP-... should reach the end position safely, but not strike hard against it.

Festo HSP-...-AP/AS 2017-10b English

21

HSP-...-AP/A S

S Check the cushioning elements and spring clamping elements (type designa

tion see “Accessories”) for the following signs of wear:

Test

Test cycle Every 2 million strokes (approx.every 2 months)

Sign of wear Play of the vertical

Replacement cycle After 5 million cycles Every 10 million strokes (approx 1 year)

1)

At 0.5 Hz in dual operation mode.

2

) The rubber buffers in the fixed stops are only to reduce noise.

Spring clamping

element 1

guide rail in the end

positions in a

horizontal direction

Shock absorber 2

(...-AP)

Oil leakage; hard

knocking; stop plunger

remains in the

retracted end position

or moves away from it

only hesitantly.

Rubber buffer 2

(...-AS)

1)

Hard knocking

S Check to see if more frequent tests are required. This may be the case with:

– higher temperatures

– excessive dirt

– solvent liquids or fumes.

Please note

If the load changes, repeat the test taking the modified work load into

consideration.

2)

1)

‒ End position adjustment (chapter “Fitting”)

‒ Setting the positioning speed (chapter “Commissioning”)

Please note

HSP-...-AS with an electromotor:

Moving to the fixed stop (2 in fig. 1) generates sudden loadings in the drive

chain. This can lead e.g. to gear damage.

S Move to the fixed stops only with low energy or use a drive chain which can

withstand sudden loadings. The rubber buffers in the fixed stops are only to

reduce noise.

22

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

9 Care and maintenance

S Check regularly the shock absorbers (or the rubber buffers in the fixed stops)

and the spring clamping elements.

S If the HSP-... is dirty, clean the exterior with a soft cloth.

If the HSP-... is defective or if the drive on the HSP-...-AP is defective:

S Send the HSP-... to Festo for repairs.

10 Replacement and repairs

Replacing the spring clamping elements:

Please note

Use only original parts when replacing the

spring clamping elements.

1. Exhaust the drive.

2. Remove the protective cover and the side

plates.

3. Move the cross guide into the

mid-position.

4. Use a hexagon socket screw key to

unscrew the defective clamping element.

5. Move the cross guide into the end position.

6. Screw in the new clamping element until it

just touches the guide carriage.

7. Then tighten the clamping element with

another 1/2 turn (pre-tension 0.5 mm).

The vertical guide rail is then free of play.

Fig. 23

Please note

The specified pre-tension of the spring clamping element is sufficient for

play-free guidance. Avoid unnecessary wear on the cross guide and links due to

excessive pressing force.

8. Fasten the side plates and protective cover.

Festo HSP-...-AP/AS 2017-10b English

23

HSP-...-AP/A S

Replacing the shock absorbers (HSP-...-AP):

1. Exhaust the drive.

2. Remove the protective cover.

3. Remove the proximity switch and the

4. Loosen the locking screws (A).

5. Unscrew the stop sleeve from the shock

6. Unscrew the shock absorber from the

7. Screw the stop sleeve completely onto

sensor rail on the shock absorber support.

absorber (B).

support (surface for wrench on the thread

of the shock absorber).

the new shock absorber.

(B)

(A)

Fig. 24

8. Screw the new shock absorber with stop sleeve from above into the support

(tightening torque see table).

9. Tighten the locking screw (tightening torque see table).

10. Fasten the sensor rail.

11. Push the proximity switch into the groove of the sensor rail. Fasten the

proximity switch in the end positions.

12. Fasten the protective cover.

Permitted tightening torque

[Nm]

– Shock absorber with stop sleeve

– Locking nut

HSP-12-...

YSRW-5-8

2 3 5

HSP-16-...

YSRW-7-10

HSP-25-...

YSRW-8-14

Reduce the amount of waste by using the materials in the shock absorber for other

purposes (material recycling). The shock absorber is filled with hydraulic oil. Due

to the design refilling is not possible.

24

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

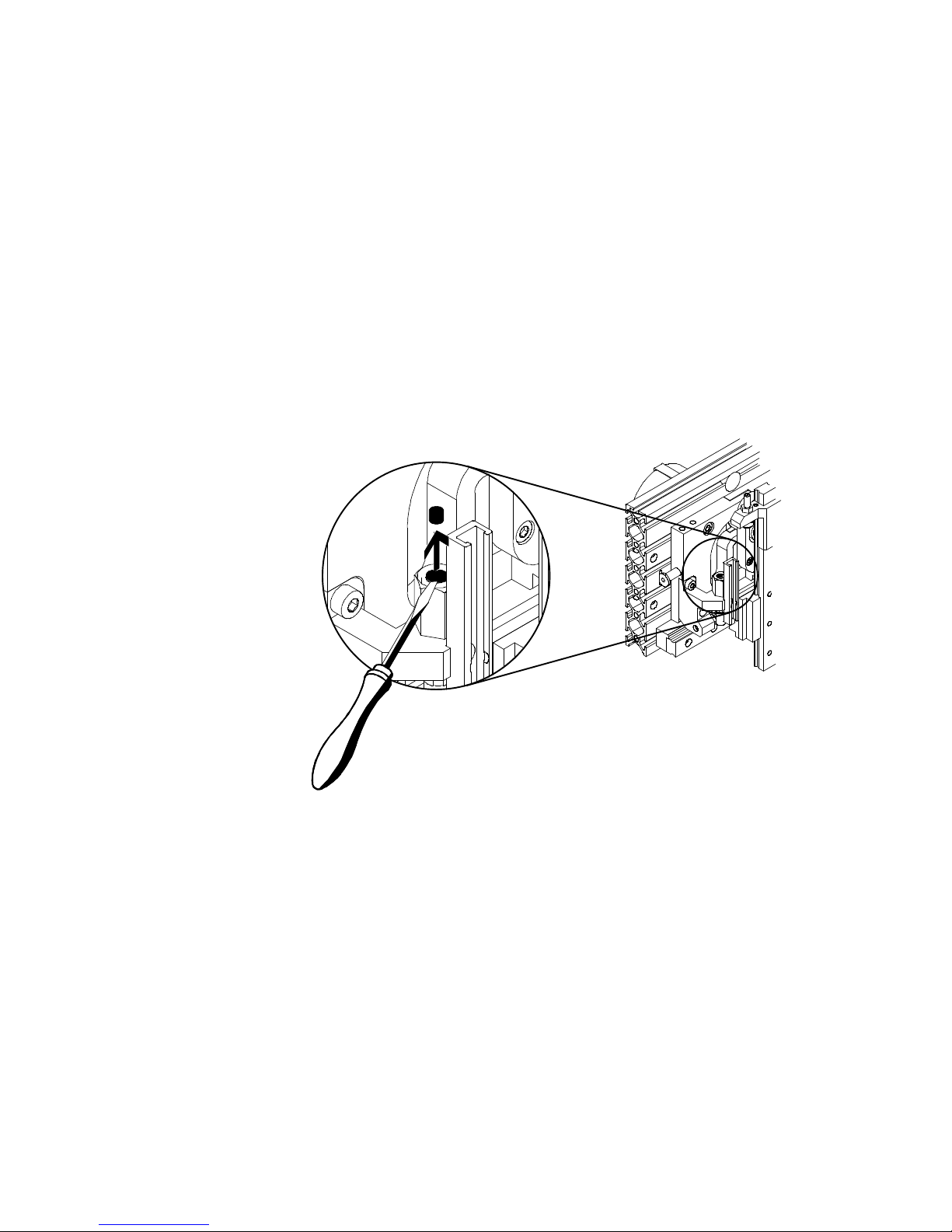

Replacing the rubber buffers in the fixed stops (HSP-...-AS):

1. Switch off the power supply of the drive.

2. Remove the protective cover.

3. Use a suitable tool to remove the rubber buffer of the fixed stop (e.g. screwdri

4. Press the new rubber buffer into the fixed stop.

5. Fasten the protective cover.

ver, pliers).

Fig. 25

Festo HSP-...-AP/AS 2017-10b English

25

HSP-...-AP/A S

11 Accessories

Designation Type

Protective cover kit BSD-HSP-12 BSD-HSP-16 BSD-HSP-25

Installation kit MKRP-1 MKRP-2 MKRP-3

Adapter kit HAPG-70 HAPG-71 HAPG-72

HSP-12-... HSP-16-... HSP-25-...

Waiting position, right BWR-HSP-12 BWR-HSP-16 BWR-HSP-25

Waiting position, left BWL-HSP-12 BWL-HSP-16 BWL-HSP-25

Shock absorber YSRW-5-8 YSRW-7-10 YSRW-8-14

Spring clamping element Original spare part for HSP

Connecting kit

Connecting bracket

Sliding block HMBN-5-M5

Proximity switch SME-8-K(S)-LED-24

Start-up valve HEL-... or HEM-...

One-way flow control valve

(restricted exhaust)

HMBK-ND

HMBV-ND

SMT-8-PS(NS)-K(S)-LED-24-B

GRLA-...

Instructions on fitting further accessories in conjunction with Festo components

are summarized in the system manual “Handling technology.”

26

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

12 Eliminating faults

Fault Possible cause Remedy

Hard knocking in

stroke end position

Faults in position

scanning

End positions not

reached

The double rollers

do not run smoothly

in the path guide

Shock absorber defective Replace shock absorber

Stop element overloaded

Reduce speed

– Work load too heavy

– Speed of moveable mass

too high

Position of proximity switch

incorrect

Incorrect type of proximity

switched used

Correct position of proximity

switch

Use only proximity switches of

type SME/SMT-8-...

Proximity switch defective Replace proximity switch

Ferritic parts in vicinity of

proximity switch

Setting of the y-stroke and the

z-stroke not correct

Use parts made of

non-magnetic materials

Adjust end positions

(seechapter “Fitting”)

Link parts offset Align link parts free of offset

(see chapter Fitting, “Setting

the y-stroke”)

Play of the vertical

guide rail in the end

positions

Festo HSP-...-AP/AS 2017-10b English

Spring clamping element

defective

Replace spring clamping

elements

27

HSP-...-AP/A S

13 Technical specifications

Type HSP-12-... HSP-16-... HSP-25-...

Part no. -AP 533 599 533 607 533 615

-AP-SD 533 600 533 608 533 616

-AS 533 605 533 613 533 621

-AS-SD 533 606 533 614 533 622

Design -AP Handling module with pneumatic swivel drive

(double-acting swivel vane)

-AP-SD With pneumatic swivel drive and protective cover

-AS Without drive

-AS-SD Without drive, with protective cover

Weight [kg]

-AP 1.9 3.3 6.4

Basic design

-AP-SD 2.6 4.6 7.6

Increases in weight due to

accessories can be found in the

relevant documentation.

-AS 1.8 3.1 6.2

-AS-SD 2.5 4.3 7.4

Medium -AP-... Filtered, lubricated or non-lubricated

compressed air (filter fineness min. 40 ìm)

Permitted operating pressure -AP-... Min. 4 ... max. 8 bar

Pneumatic connection -AP-... M5

Permitted temperature range 0 ... + 60 C

Vibration

tested as per DIN/IEC 68/EN 60068 part 2-6

Severity class 2

– 0.35 mm path at 10...60 Hz

– 5 g acceleration at 60...150 Hz

Shock

tested as per DIN/IEC 68/EN 60068 part 2-27

Mounting position As desired (vertical operation preferred)

28

Severity class 2

– ± 30 g at 11 ms duration

– 5 shocks in each direction

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Type HSP-25-...HSP-16-...HSP-12-...

Lubrication Cross guide with service life lubrication,

re-lubrication recommended after 10 million

strokes.

End position adjustment Adjusting screws in the y-direction

Stop screws in the z-direction

End position cushioning with shock absorber YSRW-5-8 YSRW-7-10 YSRW-8-14

Permitted shock absorber energy

E

max

E

hmax

[Nm]

[kNm]

1

10

2

15

3

21

Min. permitted pulse time [s]

Pulse time t

= positioning time t + dwell time t

t

0.6 0.8 1

e

(definition see chapter 7)

Stroke ranges

y-stroke [mm] 52...68 90...110 130...170

z-stroke [mm] 20...30 35...50 50...70

Max. permitted loading values of the cross

guide

Dynamic torque M

per

[Nm]

*)

1.1 2.4 3.2

with vertical operation and observation of the

maximum work load

Static torque M

0per

[Nm]

M

M

per

*)

5 10 15

M

x

)

M

per

M

y

)

M

per

z

v 1

with vertical operation

for press-fit and joining procedures without

dynamic loading

M

M

0x

0per

)

M

M

0y

0per

)

M

M

0z

0per

v 1

*)

The torques refer to the centre of the cross guide.

Festo HSP-...-AP/AS 2017-10b English

29

HSP-...-AP/A S

Type HSP-12-... HSP-16-... HSP-25-...

Max. permitted loading with external drive

Axial force on drive shaft F

Radial force on drive shaft F

Drive torque M

[Nm] 1.25 2.5 5

Yper

Noise emission as per DIN 45635

LpAeq [dBA]

[N] 18 30 50

Yper

[N] 45 75 120

Zper

*)

64 67 73

Sound pressure level as per aural reception,

(corresponds to continuous sound level DIN IEC 804)

LpAIm [dBA]

75 78 84

Pulse holding of positioning sounds, (corresponds to

pulse continuous sound level DIN IEC 804)

*)

Measured at maximum stroke 6 bar; pulse frequency 1/s; additional mass 0.3 kg;

frequence assessment A

30

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

14 Materials

Component Materials

– Sub-base

Al wrought alloy, anodized

– Shock absorber support

– Segment (between the stop screws)

– Sensor rail

– Housing

– Link

Hardened steel, burnished

– Swivel lever

– Stop screw

Steel, high alloy

– Stop sleeve

– Clamping element

Cross guide Tempered steel

Additional materials for HSP-AS-...

Shaft Steel

Storage Al wrought alloy

Ball bearing Roller bearing steel

Festo HSP-...-AP/AS 2017-10b English

31

HSP-...-AP/A S

15 Characteristic curves

a) Positioning time t as a factor of the work load m

Definition

Work load m = additional mass on the vertical guide rail

e.g. adapter, swivel drive, gripper and work item

Positioning time t = time which the HSP-... requires in order to move from the

receive position to the release position and back.

m [kg]

a) Mass moment of inertia J as a factor of the work load m

(for drive design)

J [kgcm2]

32

t [ms]

m [g]

Festo HSP-...-AP/AS 2017-10b English

HSP-...-AP/A S

Festo HSP-...-AP/AS 2017-10b

33

Copyright:

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

Phone:

+49 711 347-0

Fax:

+49 711 347-2144

Reproduction, distribution or sale of this document or communica

tion of its contents to others without express authorization is

prohibited. Offenders will be liable for damages. All rights re

served in the event that a patent, utility model or design patent is

registered.

E-mail:

service_international@festo.com

Internet:

www.festo.com

Loading...

Loading...