Page 1

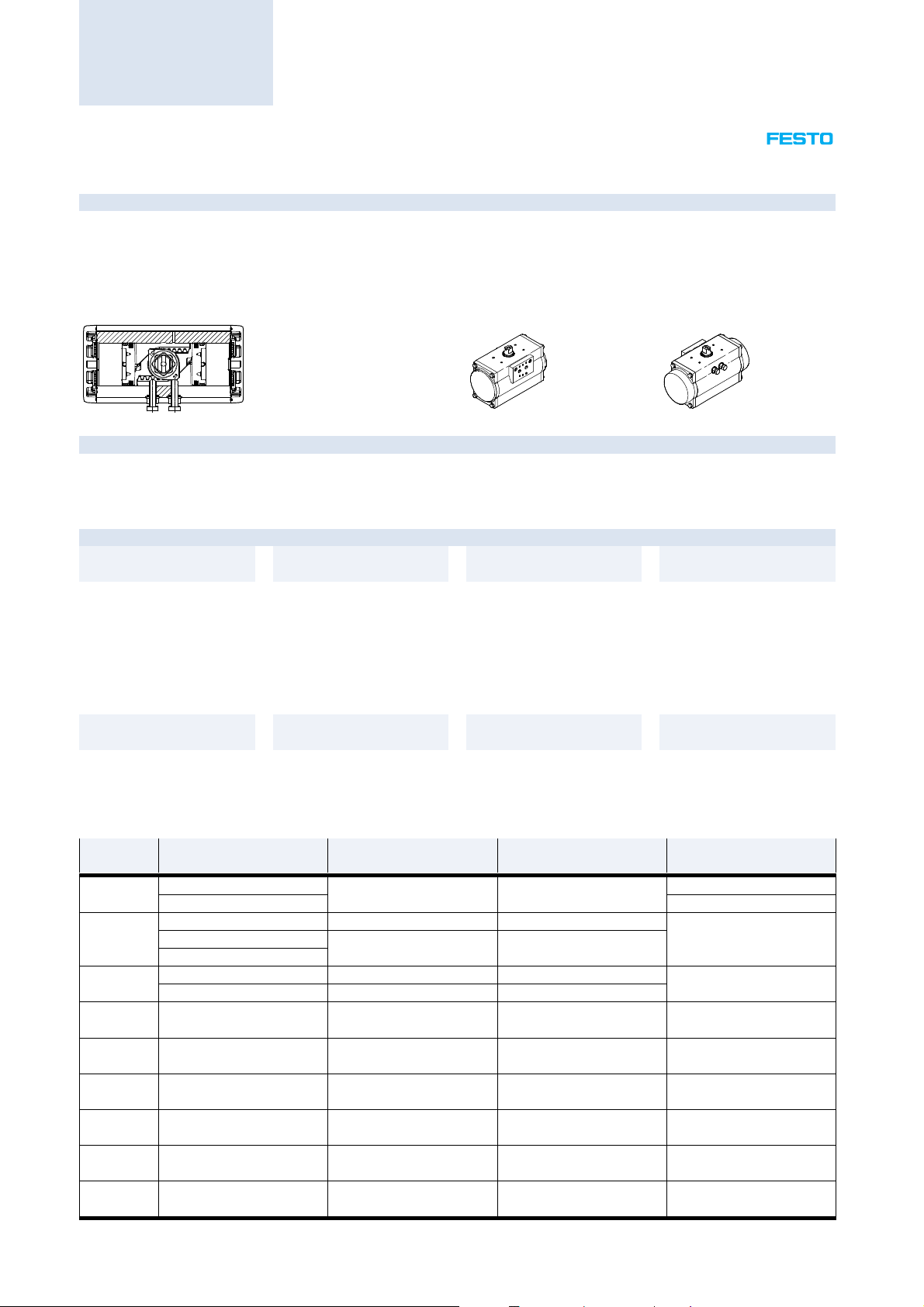

Quarter turn actuators DFPD

q/w Festo core product range

Covers 80% of your automation tasks

Worldwide: Always in stock

Superb: Festo quality at an attractive price

Easy: Reduces procurement and storing complexity

qReady for dispatch from the Festo factory in 24 hours

Held in stock in 13 service centres worldwide

More than 2200 products

wReady for dispatch in 5 days maximum from stock

Assembled for you in 4 service centres worldwide

Up to 6 x 1012 variants per product series

Look for the star!

Page 2

-V- New

Quarter turn actuators DFPD

Key features

Function

The DFPD series features a rack and pinion combination with a constant torque

characteristic across the entire swivel range. The torque range is from 10 to

480 Nm. Quarter turn actuators DFPD are suitable for automating butterfly

valves, ball valves and air dampers. They are also suitable for water/wastewater,

beverage, pharmaceutical and process automation. The modular and compact

design of the DFPD allows various spring configurations as a suitable solution

for different applications.

DFPD-…-D

double-acting

Types of connection

Port pattern to NAMUR VDI/VDE 3845 for mounting solenoid valves, position

sensors and positioners

Variants

High temperature

DFPD-…-T4

Seals made of FKM and plain

bearings made of PPS

For applications up to +150 °C

II 2G c T3 X

II 2D c 175°C X

0°C <= Ta <= +150°C

Epoxy coating

DFPD-…-EP

Drive with epoxy coating With stainless steel shaft Pneumatic connections with NPT

Low temperature

DFPD-…-T6

Seals made of FVMQ for

applications down to –50 °C

II 2G c T6 X

II 2D c 85°C X

–50°C <= Ta <= +60°C

Stainless steel shaft

DFPD-…-R3

Standard connection to the process valve to ISO 5211

Closes to the left and right

DFPD-…-R/L

The modular system offers the

option of closing to the left. This is

done by turning the pistons

NPT version

DFPD-…-N

threads

DFPD-…-S

single-acting

Spring configuration

DFPD-…-S

The spring index can be adapted to

the system's supply pressure in

increments of 0.5 bar through free

selection of the number of spring

cartridges (4 to 12)

180° version

DFPD-…-180

Sizes 40, 120, 240, 480 double-

acting also available with 180°

swivel angle

Size Flange pattern Shaft connection Shaft connection depth Pneumatic connection

[mm]

10 F03 V9 10.7 Gx

F04 NPTx

20 F03 V9 10.7 Gx

F04 V11 13.2 NPTx

F05

40 F04 V11 13.2 Gx

F05F07 V14 16.5 NPTx

80 F05F07 V17 19.3 Gx

NPTx

120 F05F07 V17 19.3 G¼

NPT¼

160 F07F10 V22 24.3 G¼

NPT¼

240 F07F10 V22 24.3 G¼

NPT¼

300 F07F10 V22 24.3 G¼

NPT¼

480 F10F12 V27 29.5 G¼

NPT¼

2

è

Subject to change – 2017/06

Page 3

Quarter turn actuators DFPD

Peripherals overview

1

2

-V- New

3

4

5

7

9

6

Mounting components and accessories

1 Positioner

CMSX

2 Limit switch attachment

DAPZ

3 Limit switch attachment

SRBC

4 Limit switch attachment

SRBG

5 Sensor box

SRAP

6 Ball valve

VAPB, VZBA

7 Solenoid valve

VSNC

8 Solenoid valve

VOFC

9 Solenoid valve

VOFD

8

Brief description è Page/Internet

For controlling the position of quarter turn actuators in process automation systems cmsx

Round design, variant AR, electrical, inductive or inductive and explosion-proof sensing dapz

For electrical position feedback and monitoring the position of process valves actuated using

quarter turn actuators

For electrical position feedback and monitoring the position of process valves actuated using

quarter turn actuators

Analogue sensor box continuously senses the entire swivel range and reports this back to the

controller

2-way brass or stainless steel, corrosion-resistant; 3-way stainless steel, corrosion-resistant vapb

For single- and double-acting quarter turn actuators with a port pattern to VDI/VDE 3845 vsnc

Solenoid valve with solenoid coil, port pattern to Namur vofc

Solenoid valve with solenoid coil, port pattern to Namur vofd

srbc

srbg

srap

2017/06 – Subject to change

è

3

Page 4

-V- New

Quarter turn actuators DFPD

Type codes

Type

DFPD Quarter turn actuator

System of units

– Metric

N Imperial

Version

– Standard

Torque

10 10 Nm

20 20 Nm

40 40 Nm

80 80 Nm

120 120 Nm

160 160 Nm

240 240 Nm

300 300 Nm

480 480 Nm

DFPD – – – – RP – – – – –

Design

RP Rack and pinion

Yoke type

– None

Swivel angle

90 90°

180 180°

Swivel direction

L To the left

R To the right

Function

D Double-acting

S Single-acting

Spring configuration

– None

20 For connection pressure 2 bar

25 For connection pressure 2.5 bar

30 For connection pressure 3 bar

35 For connection pressure 3.5 bar

40 For connection pressure 4 bar

45 For connection pressure 4.5 bar

50 For connection pressure 5 bar

55 For connection pressure 5.5 bar

60 For connection pressure 6 bar

4

è

Subject to change – 2017/06

Page 5

Quarter turn actuators DFPD

Type codes

Flange pattern 1

F03 Hole pattern F03

F04 Hole pattern F04

F05 Hole pattern F05

F07 Hole pattern F07

F10 Hole pattern F10

Flange pattern 2

– None

07 Hole pattern F07

10 Hole pattern F10

12 Hole pattern F12

Manual override

– None

-V- New

– – – – –

Temperature range

– Standard

T4 0 … +150

T6 –50 … +60

Corrosion protection

– Standard

R3 High corrosion protection

Housing surface treatment

– None

EP Epoxy-coated

2017/06 – Subject to change

è

5

Page 6

-V- New

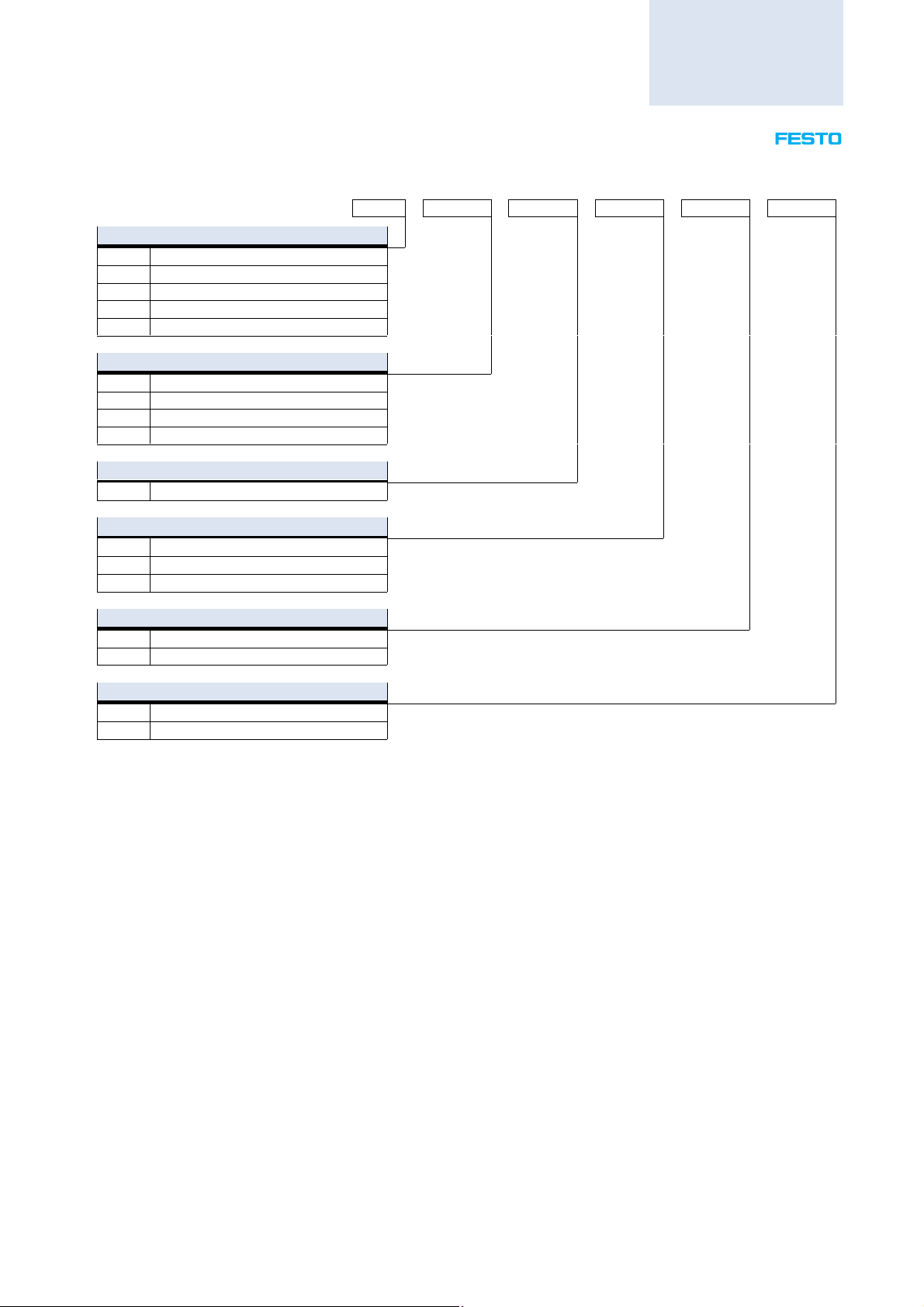

Quarter turn actuators DFPD, double-acting

Technical data

Function

-Y- Swivel angel

0 … 90°

-T- Size

10 … 480

-L- Torque

10 … 480 Nm

General technical data

Size 10 20 40 80 120 160 240 300 480

Mode of operation Double-acting

Design Rack and pinion

Cushioning No cushioning

Mounting position Any

Pneumatic connection Gx G¼

NPTx NPT¼

Connection to process valve as per

standard

Valve connection conforms to

standard

Connection for positioner and

position sensor conforms to

standard

Flange hole pattern F03 F04 F04 F05 F05F07 F07F10 F10F12

Swivel angle [°] 90

End-position adjusting range

at 0°

End-position adjusting range

at 90°

Position sensing Visual

Closing direction Closes to the right

ISO 5211

VDI/VDE 3845 (NAMUR)

VDI/VDE 3845 (NAMUR)

[°] –5 … +5

[°] –5 … +5

Operating and environmental conditions

Operating pressure [bar] 2 … 8

Nominal operating pressure [bar] 5.5

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Note on operating/pilot medium Pressure dew point 10°C below ambient temperature/temperature of medium

Lubricated operation possible (in which case lubricated operation will always be required)

Ambient temperature [°C] –20 … +80

CE marking (see declaration of

conformity)

è

ATEX category for gas II 2G

Explosion ignition protection type for

gas

ATEX category for dust II 2D

Explosion ignition protection type for

dust

Explosion-proof temperature

rating

6

To EC Machinery Directive

To EU Explosion Protection Directive (ATEX)

c T4 X

c 105°C X

[°C] –20 <= Ta <= +80

è

Subject to change – 2017/06

Page 7

-V- New

123 1

Quarter turn actuators DFPD, double-acting

Technical data

Theoretical torque [Nm] as a function of operating pressure

Operating pressure [bar]

Size 2 2.5 3 3.5 4 4.5 5 5.5 6 7 8

10 3.7 4.7 5.6 6.6 7.5 8.4 9.4 10.3 11.2 13.1 15.0

20 7.3 9.1 11.0 12.8 14.6 16.4 18.3 20.1 21.9 25.6 29.2

40 13.9 17.4 20.9 24.4 27.9 31.3 34.8 38.3 41. 8 48.7 55.7

80 30.0 37.5 44.9 52.4 59.9 67.4 74.9 82.4 89.9 104.9 119.9

120 42.7 53.4 64.0 74.7 85.4 96.1 106.7 117.4 128.1 149.4 170.8

160 58.5 73.2 87.8 102.5 117.1 131. 7 146.4 161.0 175.6 204.9 234.2

240 85.2 106.5 127.8 149.1 170.4 191. 7 213.0 234.3 255.6 298.2 340.8

300 109.8 137.2 164.7 192.1 219.6 247.0 274.5 301.9 329.3 384.2 439.1

480 172.4 215.5 258.5 301.6 344.7 387.8 430.9 474.0 517.1 603.3 689.5

-H- Note

The operating torque of the drive must not be higher than the maximum

permissible torque listed in ISO 5211, with reference to the size of the

mounting flange and of the coupling.

Materials

Sectional view

Quarter turn actuators Basic material

1 Cap Coated die-cast aluminium EN AC-46100-D

2 Housing Anodised wrought aluminium alloy EN AW-6063-T6

3 Shaft Nickel-plated steel 1.0715

R3 High-alloy stainless steel 1.4305

– Mounting plate Anodised wrought aluminium alloy EN AW-6063-T6

Piston Die-cast aluminium EN AC-46100-D

Seals NBR –

Spring Spring steel –

Bearing POM –

Cam Stainless steel casting 1.4308

Steel 1.0765

Screws High-alloy stainless steel 1.4301

Note on materials RoHS-compliant –

Air consumption [l/cycle] at 6 bar

Type Type

DFPD-10-RP-90-D 0.54 DFPD-160-RP-90-D 10.80

DFPD-20-RP-90-D 1.21 DFPD-240-RP-90-D 15.60

DFPD-40-RP-90-D 2.47 DFPD-240-RP-180-D 28.20

DFPD-40-RP-180-D 4.80 DFPD-300-RP-90-D 26.40

DFPD-80-RP-90-D 5.3 DFPD-480-RP-90-D 40.20

DFPD-120-RP-90-D 7.80 DFPD-480-RP-1 80-D 66.60

DFPD-120-RP-180-D 14.40

number

2017/06 – Subject to change

è

7

Page 8

-V- New

Quarter turn actuators DFPD, double-acting

Technical data

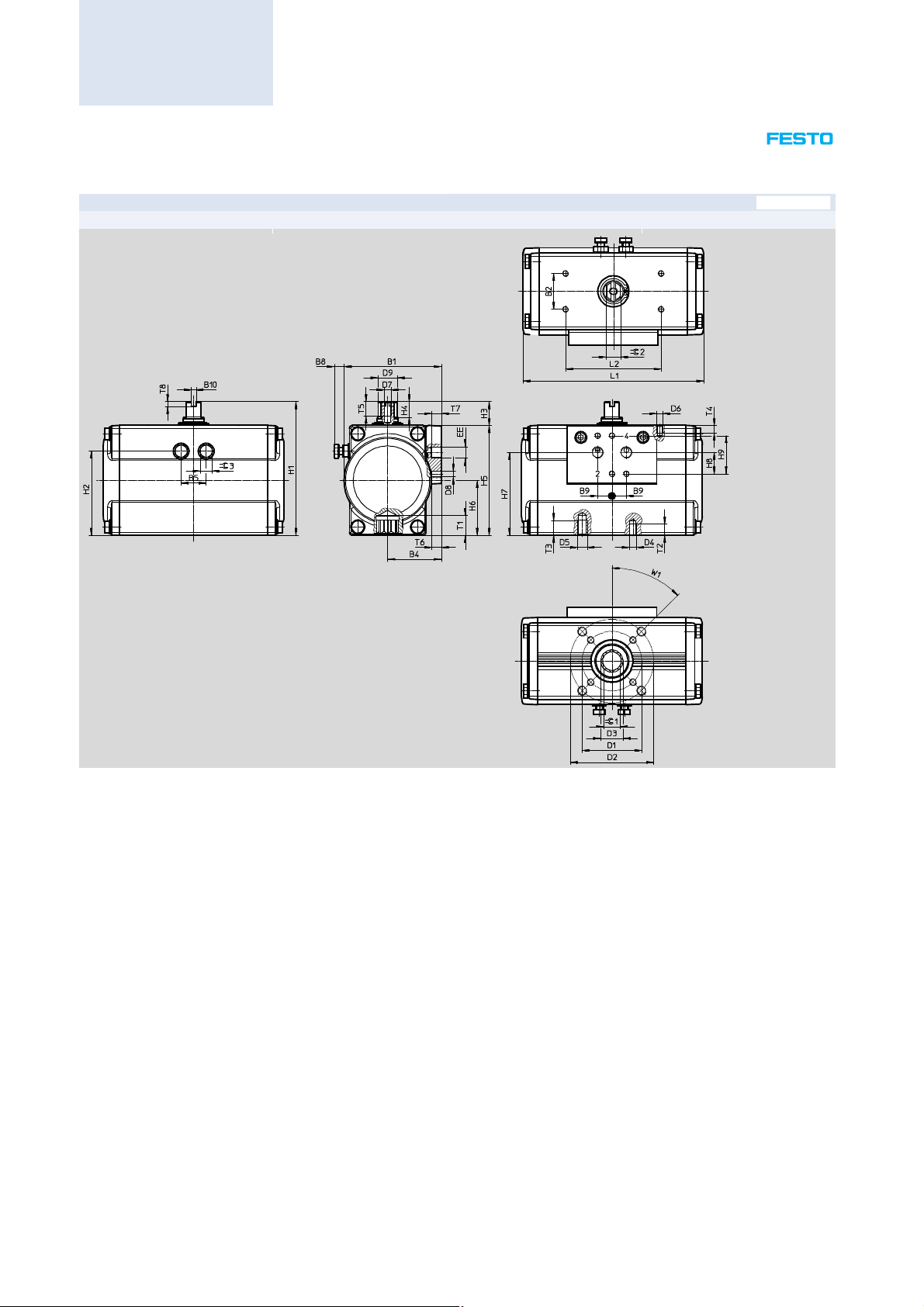

Dimensions Download CAD data è Size 10 … 80

8

è

Subject to change – 2017/06

Page 9

Quarter turn actuators DFPD, double-acting

Technical data

-V- New

Type B1 B2

±0.1

DFPD-10-F03

DFPD-10-F04

DFPD-20-F04

DFPD-20-F05

DFPD-40

DFPD-80

Type D7 D8 D9

DFPD-10-F03

DFPD-10-F04

DFPD-20-F04

DFPD-20-F05

DFPD-40

DFPD-40-180

DFPD-80

Type L1 L2

DFPD-10-F03

DFPD-10-F04

DFPD-20-F04

DFPD-20-F05

DFPD-40

DFPD-40-180

DFPD-80

59.5

68.5 38.5 19 9.2 – 14.6

81.5 45 21 8.2

124.7

133.3 13.2

151.4

227

189.3 19 .3 17 15 13

30

99 53 26 9 23.3

M6 M5

±0.1T1±0.4

80

B4 B5 B8

35 16 10.7

±0.1

10.9

12.7 100 59.75 10 80 40 57.5

16.2 112 70.5 13 92 46 67.5

20.2 130 86 13 110 55 86.5

10.7 8 –

16.5

B9 B10 D1

max.

12 4

EE H1 H2 H3

90 51

Gx or

NPTx

T2 T3 T4 T5 T6 T7 T8

8

– 11 9 10

9

9 12

8 12 8 8 4

±0.1

36

42

50

-0.5H4+0.1

10 70 35 47

20

D2

D3

D4 D5 D6

±0.1

– 12 M5 –

M5

M6

18.7

70

H5 H6

±0.2H7±0.3H8±0.1

+0.5

M6

ß 1

H11

9 9 10

14 12 10

–

M8DFPD-40-180

16 32

ß 2

ß 3 W1

h11

M5

H9

45°

2017/06 – Subject to change

è

9

Page 10

-V- New

Quarter turn actuators DFPD, double-acting

Technical data

Dimensions Download CAD data è

Size 120 … 480

10

è

Subject to change – 2017/06

Page 11

Quarter turn actuators DFPD, double-acting

Technical data

-V- New

Type B1 B2

±0.1

DFPD-120

DFPD-120-180

DFPD-160

DFPD-240

DFPD-240-180

DFPD-300

DFPD-480

DFPD-480-180

Type D7 D8 D9

DFPD-120

DFPD-120-180

DFPD-160

DFPD-240

DFPD-240-180

DFPD-300

DFPD-480

DFPD-480-180

Type L1 L2

111.5

120 63.5 36 13.4

135.5 71.5 41 18.5

144 74.5 46 17 30

163 83 52 19.3 102 125 37.4 M10 M12

M6 M5

B4 B5 B8

60.5 32 12.3

30

±0.1

22.5

25.5 154 106.25 134 67

31.8

38 214 149.5 184 92

B9 B10 D1

max.

12 4

EE H1 H2 H3

143 97.75

G¼ or

NPT¼

180 120.5

192 131 162 81

T2 T3 T4 T5 T6 T7 T8

±0.1

50 70

70 102

-0.5H4+0.1

20 13

30 19.5

D2

±0.1

H5 H6 H7

123 61.5

150 75

D3

23.3

23.2

23.2

30

30.3

±0.2

±0.2

±0.3

±0.4

±0.2

109.4

120.2

132.1

152.5

D4 D5 D6

M6 M8

M8 M10

±0.3H8±0.1

98.4

16 32

ß 1

ß 2

ß 3 W1

M5

H9

DFPD-120

DFPD-120/180

DFPD-160

DFPD-240

DFPD-300

DFPD-480

DFPD-480/180

213.7

326.8

230.9

257

395.5

334.4

374.2

550.3

±0.1T1±0.4

19.3 9 12

80

24.3 12 15 22

29.5 15 18 27 27 21

8 14 8 12 4

+0.5

H11

h11

17 15 13

19 16

22 18DFPD-240/180

45°

2017/06 – Subject to change

è

11

Page 12

-V- New

Quarter turn actuators DFPD, double-acting

Technical data

qCore product range

Ordering data

Type Size Product weight Part No. Type

[g]

10 965 q8047613 DFPD-10-RP-90-RD-F03

20 1275 q8047614 DFPD-20-RP-90-RD-F04

40 1882 q8047615 DFPD-40-RP-90-RD-F0507

80 3308 q8047616 DFPD-80-RP-90-RD-F0507

120 4872 q8048123 DFPD-120-RP-90-RD-F0507

wCore product range

Ordering data

Type Size Product weight Part No. Type

[g]

160 6082 w8048124 DFPD-160-RP-90-RD-F0710

240 8594 w8048125 DFPD-240-RP-90-RD-F0710

300 11224 w8048126 DFPD-300-RP-90-RD-F0710

480 16025 w8048127 DFPD-480-RP-90-RD-F1012

Ordering data

Type Size Product weight Part No. Type

[g]

10 965 8048010 DFPD-10-RP-90-RD-F04

20 1275 8048011 DFPD-20-RP-90-RD-F05

Ordering data

Type Size Product weight Part No. Type

[g]

Version R3-EP, epoxy-coated

10 965 8047617 DFPD-10-RP-90-RD-F03-R3-EP

8048012 DFPD-10-RP-90-RD-F04-R3-EP

20 1275 8047618 DFPD-20-RP-90-RD-F04-R3-EP

8048013 DFPD-20-RP-90-RD-F05-R3-EP

40 1882 8047619 DFPD-40-RP-90-RD-F0507-R3-EP

80 3308 8047620 DFPD-80-RP-90-RD-F0507-R3-EP

120 4872 8048128 DFPD-120-RP-90-RD-F0507-R3-EP

160 6082 8048129 DFPD-160-RP-90-RD-F0710-R3-EP

240 8594 8048130 DFPD-240-RP-90-RD-F0710-R3-EP

300 11224 8048131 DFPD-300-RP-90-RD-F0710-R3-EP

480 16025 8048132 DFPD-480-RP-90-RD-F1012-R3-EP

Festo core product range qReady for dispatch from the Festo factory in 24 hours

wReady for dispatch in 5 days maximum from stock

12

è

Subject to change – 2017/06

Page 13

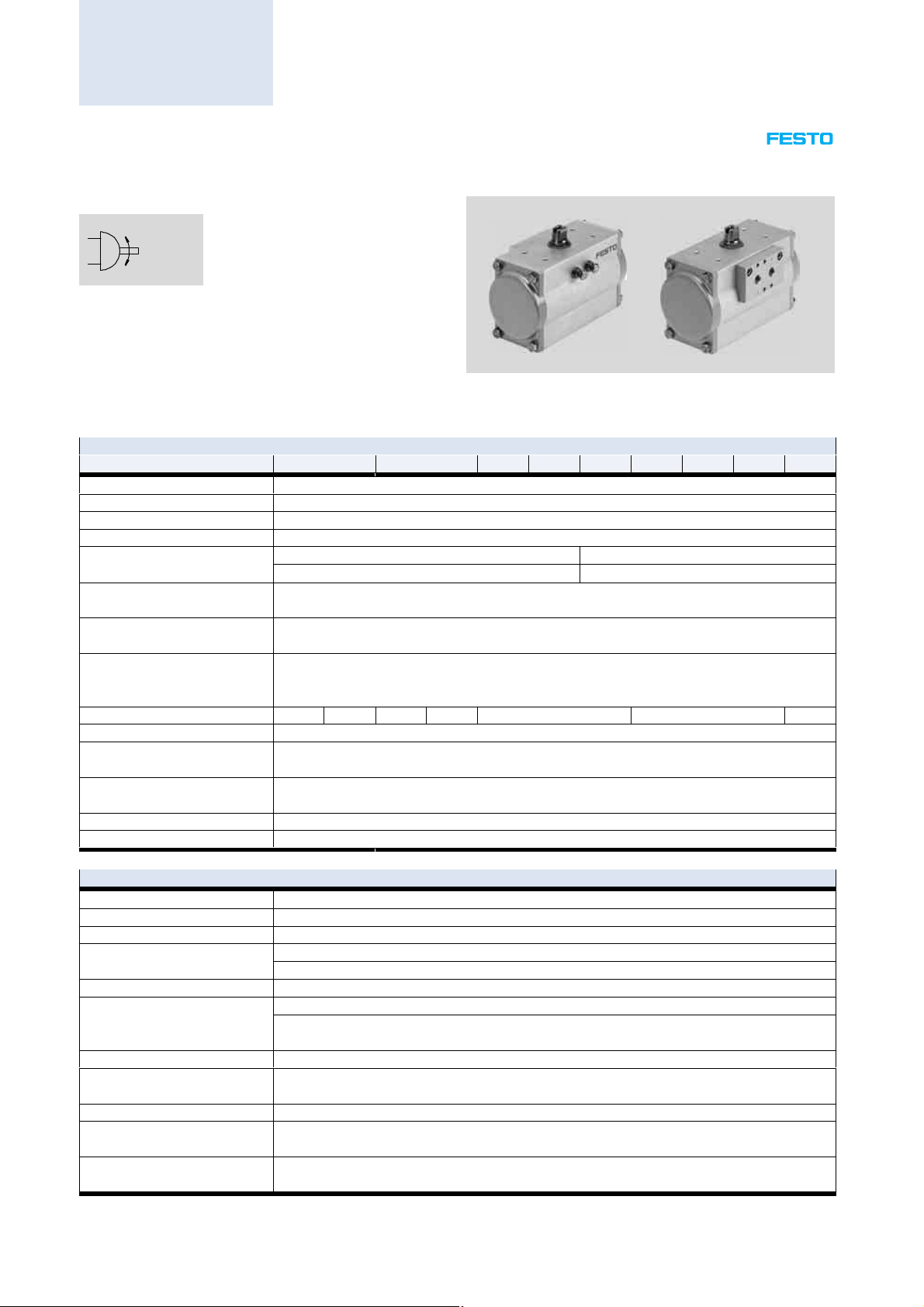

Quarter turn actuators DFPD, single-acting

Technical data

-V- New

Function

-Y- Swivel angel

0 … 90°

-T- Size

20 … 480

-L- Torque

7 … 156 Nm

General technical data

Size 20 40 80 120 160 240 300 480

Mode of operation Single-acting

Design Rack and pinion

Cushioning No cushioning

Mounting position Any

Pneumatic connection Gx G¼

NPTx NPT¼

Connection to process valve as per

standard

Valve connection conforms to

standard

Connection for positioner and

position sensor conforms to

standard

Flange hole pattern F03 F04 F05 F04 F05F07 F05F07 F07F10 F10F12

Swivel angle [°] 90

End-position adjusting range

at 0°

End-position adjusting range

at 90°

Position sensing Visual

Closing direction Closes to the right

ISO 5211

VDI/VDE 3845 (NAMUR)

VDI/VDE 3845 (NAMUR)

[°] –5 … +5

[°] –5 … +5

2017/06 – Subject to change

è

13

Page 14

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Operating and environmental conditions

Variant RS30 RS60

Operating pressure [bar] 2 … 8

Nominal operating pressure [bar] 3 6

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Note on operating/pilot medium Pressure dew point 10°C below ambient temperature/temperature of medium

Lubricated operation possible (in which case lubricated operation will always be required)

Ambient temperature [°C] –20 … +80

CE marking (see declaration of

conformity)

è

ATEX category for gas II 2G

Explosion ignition protection type for

gas

ATEX category for dust II 2D

Explosion ignition protection type for

dust

Explosion-proof temperature

rating

To EC Machinery Directive

To EU Explosion Protection Directive (ATEX)

c T4 X

c 105°C X

[°C] –20 <= Ta <= +80

14

è

Subject to change – 2017/06

Page 15

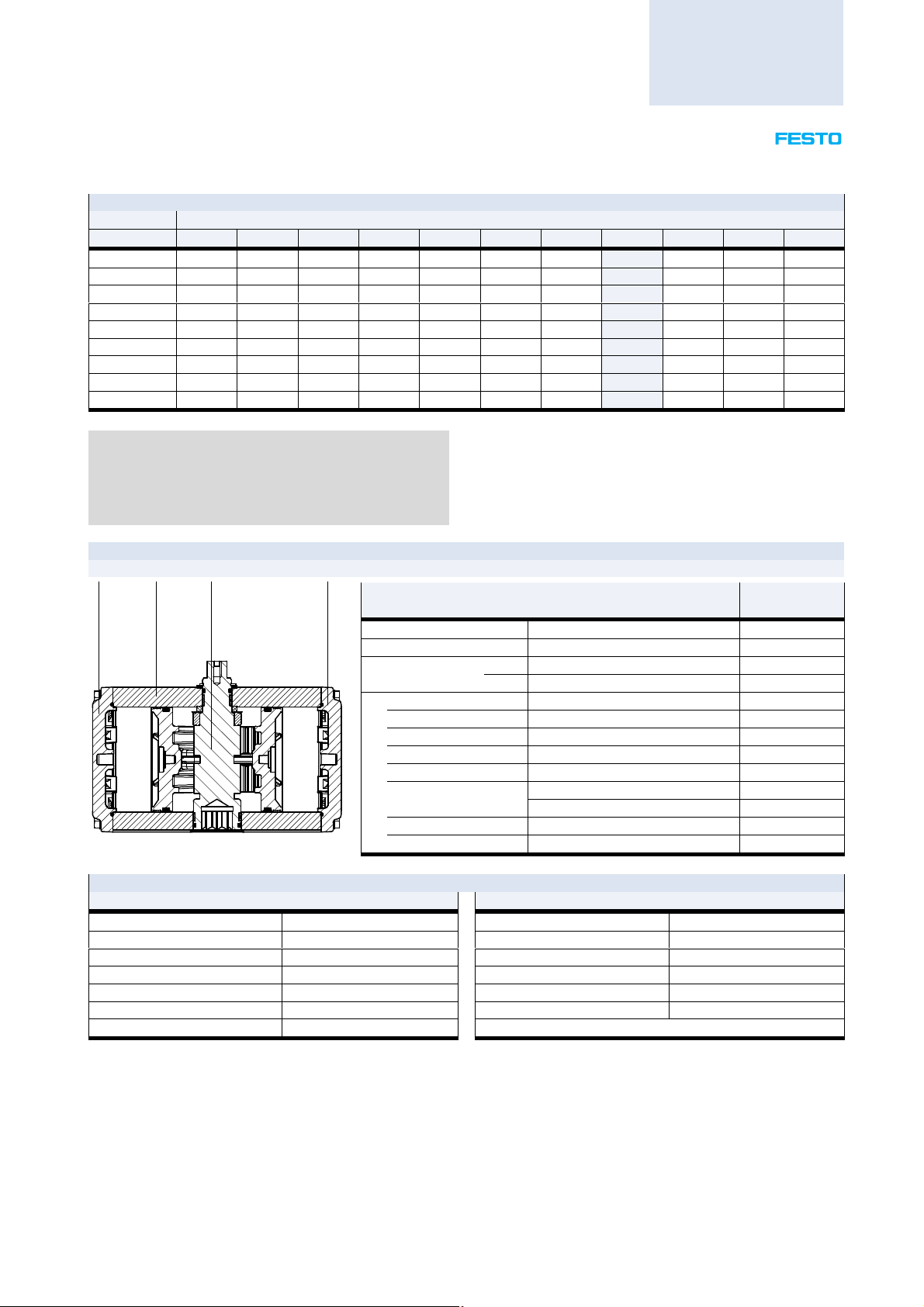

Quarter turn actuators DFPD, single-acting

12 3 1

Technical data

Materials

Sectional view

Quarter turn actuators Basic material

1 Cap Coated die-cast aluminium EN AC-46100-D

2 Housing Anodised wrought aluminium alloy EN AW-6063-T6

3 Shaft Nickel-plated steel 1.0715

– Mounting plate Anodised wrought aluminium alloy EN AW-6063-T6

Piston rod Die-cast aluminium EN AC-46100-D

Seals NBR –

Spring Spring steel –

Bearing POM –

Cam Stainless steel casting 1.4308

Screws High-alloy stainless steel 1.4301

Note on materials RoHS-compliant –

-V- New

number

R3 High-alloy stainless steel 1.4305

Air consumption [l/cycle] at 6 bar

Type Type

DFPD-20-RP-90-S 0.60 DFPD-160-RP-90-S 7.20

DFPD-40-RP-90-S 1.80 DFPD-240-RP-90-S 10.20

DFPD-80-RP-90-S 3.60 DFPD-300-RP-90-S 13.20

DFPD-120-RP-90-S 5.40 DFPD-480-RP-90-S 21.00

2017/06 – Subject to change

è

15

Page 16

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Theoretical torque [Nm] as a function of operating pressure [bar] and swivel angle [°]

Spring

configuration

Size DFPD-20

20 0 2.4 4.9 6.7 8.6 10.4 12.2 14.0 15.9 17.7 19.5 23.2 26.8

25 0 3.0 4.3 6.1 8.0 9.8 11.6 13.4 15.3 17.1 18.9 22.6 26.2

30 0 3.6 5.5 7.4 9.2 11.0 12.8 14.7 16.5 18.3 22.0 25.6

35 0 4.2 6.8 8.6 10.4 12.2 14.1 15.9 17.7 21.4 25.0

40 0 4.8 8.0 9.8 11.6 13.5 15.3 17.1 20.8 24.4

45 0 5.4 9.2 11.0 12.9 14.7 16.5 20.2 23.8

50 0 6.0 10.4 12.3 14.1 15.9 19.6 23.2

55 0 6.6 11.7 13.5 15.3 19.0 22.6

60 0 7.2 12.9 14.7 18.4 22.0

Nominal swivel

angle

[°] [Nm] 2 2.5 3 3.5 4 4.5 5 5.5 6 7 8

90 4.8 2.5 4.4 6.2 8.0 9.9 11.7 13.5 15.3 17.2 20.8 24.5

90 6.0 1.4 3.2 5.0 6.8 8.7 10.5 12.3 14. 2 16.0 19.6 23.3

90 7.1 2.0 3.8 5.7 7.5 9.3 11.1 13.0 14. 8 18.4 22.1

90 8.3 2.6 4. 5 6.3 8.1 9.9 11.8 13.6 17.3 20.9

90 9.5 3.3 5.1 6.9 8.8 10.6 12.4 16.1 19.7

90 10.7 3.9 5.7 7.6 9.4 11.2 14. 9 18.5

90 11.9 4.5 6.4 8.2 10.0 13.7 17.3

90 13.1 5.2 7.0 8.8 12.5 16.1

90 14.3 5.8 7.6 11.3 15.0

Spring

torque

Operating pressure [bar]

Size DFPD-40

20 0 4.6 9.3 12.8 16.3 19.8 23.3 26.7 30.2 33.7 37.2 44.1 51.1

90 9.1 4.8 8.3 11.8 15.3 18.8 22.3 25.7 29.2 32.7 39.7 46.6

25 0 5.8 8.2 11.7 15.1 18.6 22.1 25.6 29.1 32.6 36.0 43.0 50.0

90 11.4 2.6 6.1 9.5 13.0 16.5 20.0 23.5 27.0 30.4 37.4 44.4

30 0 6.9 10.5 14.0 17.5 21.0 24.4 27.9 31.4 34.9 41.8 48.8

90 13.6 3.8 7.3 10.8 14.2 17.7 21.2 24.7 28.2 35.1 42.1

35 0 8.1 12.8 16.3 19.8 23.3 26.8 30.3 33.7 40.7 47.7

90 15.9 5.0 8.5 12.0 15.4 18.9 22.4 25.9 32.9 39.8

40 0 9.2 15.2 18.7 22.1 25.6 29.1 32.6 39.5 46.5

90 18.2 6.2 9.7 13.2 16.7 20.1 23.6 30.6 37.5

45 0 10.4 17.5 21.0 24.5 28.0 31.4 38.4 45.4

90 20.4 7.4 10.9 14.4 17.9 21.4 28.3 35.3

50 0 11.5 19.8 23.3 26.8 30.3 37.2 44.2

90 22.7 8.6 12.1 15.6 19.1 26.0 33.0

55 0 12.7 22.2 25.7 29.1 36.1 43.1

90 25.0 9.8 13.3 16.8 23.8 30.7

60 0 13.8 24.5 28.0 34.9 41.9

90 27.2 11.1 14.5 21.5 28.5

-H- Note

The operating torque of the drive must not be higher than the maximum

permissible torque listed in ISO 5211, with reference to the size of the

mounting flange and of the coupling.

16

è

Subject to change – 2017/06

Page 17

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Theoretical torque [Nm] as a function of operating pressure [bar] and swivel angle [°]

Spring

configuration

Size DFPD-80

20 0 9.9 20.1 27.6 35.1 42.6 50.0 57.5 65.0 72.5 80.0 95.0 110.0

25 0 12.4 17.6 25.1 32.6 40.1 47.6 55.1 62.6 70.1 77.5 92.5 107.5

30 0 14.8 22.6 30.1 37.6 45.1 52.6 60.1 67.6 75.1 90.1 105.0

35 0 17.3 27.7 35.1 42.6 50.1 57.6 65.1 72.6 87.6 102.6

40 0 19.8 32.7 40.2 47.7 55.1 62.6 70.1 85.1 100.1

45 0 22.2 37.7 45.2 52.7 60.2 67.7 82.6 97.6

50 0 24.7 42.7 50.2 57.7 65.2 80.2 95.2

55 0 27.2 47.7 55.2 62.7 77.7 92.7

60 0 29.6 52.8 60.3 75.2 90.2

Nominal swivel

angle

[°] [Nm] 2 2.5 3 3.5 4 4.5 5 5.5 6 7 8

90 19.5 10.5 18.0 25.5 33.0 40.4 47.9 55.4 62.9 70.4 85.4 100.4

90 24.4 5.6 13.1 20.6 28.1 35.6 43 .1 50.6 58.1 65.5 80.5 95.5

90 29.2 8.2 15.7 23.2 30.7 38.2 45.7 53.2 60.7 75.5 90.6

90 34.1 10.9 18.3 25.8 33 .3 40.8 48.3 55.8 70.8 85.8

90 39.0 13.5 21.0 28.5 35.9 43.4 50.9 65.9 80.9

90 43.8 16.1 23.6 31.1 38.6 46.1 61.0 76.0

90 48.7 18.7 26.2 33.7 41.2 56.2 71.2

90 53.6 21.3 28.8 36.3 51.3 66.3

90 58.4 24.0 31.5 46.4 61.4

Spring

torque

Operating pressure [bar]

Size DFPD-120

20 0 14.0 28.7 39.3 50.0 60.7 71.3 82.0 92.7 103.4 114.0 135.4 156.7

90 27.8 14.9 25.6 36.3 46.9 57.6 68.3 79.0 89.6 100.3 121.7 143.0

25 0 17.6 25.1 35.8 46.5 57.2 67.8 78.5 89.2 99.9 110.5 131.9 153.2

90 34.7 8.0 18.7 29.3 40.0 50.7 61.4 72.0 82.7 93.4 114.7 136 .1

30 0 21.1 32.3 43.0 53.6 64.3 75.0 85.7 96.3 107.0 128.4 149.7

90 41.6 11.7 22.4 33.1 43.7 54.4 65.1 75.8 86.4 107.8 129.1

35 0 24.6 39.5 50.1 60.8 71.5 82.2 92.8 103.5 124.8 146.2

90 48.6 15.5 26.1 36.8 47.5 58 .1 68.8 79.5 100.8 122.2

40 0 28.1 46.6 57.3 68.0 78.6 89.3 100.0 121.3 142.7

90 55.5 19.2 29.9 40.5 51.2 61.9 72.6 93.9 115.2

45 0 31.6 53.8 64.5 75.1 85.8 96.5 117.8 139.2

90 62.5 22.9 33.6 44.3 54.9 65.6 87.0 108.3

50 0 35.1 61.0 71.6 82.3 93.0 114.3 135.7

90 69.4 26.7 37.3 48.0 58.7 80.0 101.4

55 0 38.6 68.1 78.8 89.5 110.8 132.2

90 76.3 30.4 41.1 51.7 73.1 94.4

60 0 42.1 75.3 86.0 107.3 128.6

90 83.3 34.1 44.8 66.1 87.5

-H- Note

The operating torque of the drive must not be higher than the maximum

permissible torque listed in ISO 5211, with reference to the size of the

mounting flange and of the coupling.

2017/06 – Subject to change

è

17

Page 18

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Theoretical torque [Nm] as a function of operating pressure [bar] and swivel angle [°]

Spring

configuration

Size DFPD-160

20 0 19.2 39.3 53.9 68.6 83.2 97.9 112.5 127.1 141.8 156.4 185.7 214.9

25 0 24.1 34.5 49.1 63.8 78.4 93.0 107.7 122.3 137.0 151.6 180.9 210.1

30 0 28.9 44.3 59.0 73.6 88.2 102.9 117.5 132.1 146.8 176.0 205.3

35 0 33.7 54.1 68.8 83.4 98.1 112.7 127.3 142.0 171.2 200.5

40 0 38.5 64.0 78.6 93.2 107.9 122.5 137.2 166.4 195.7

45 0 43.3 73.8 88.4 103.1 117.7 132.3 161.6 190.9

50 0 48.1 83.6 98.3 112.9 127.5 156.8 186.1

55 0 52.9 93.5 108.1 122.7 152.0 181.3

60 0 57.7 103.3 117.9 147.2 176.5

Nominal swivel

angle

[°] [Nm] 2 2.5 3 3.5 4 4.5 5 5.5 6 7 8

90 38.1 20.5 35.1 49.7 64.4 79.0 93.6 108.3 122.9 137.6 166.8 196.1

90 47.6 37.6 25.6 40.2 54.9 69.5 84.1 98.8 113.4 128.0 157.3 186.6

90 57.1 16.1 30.7 45.3 60.0 74.6 89.2 103.9 118.5 147.8 177.1

90 66.6 21.2 35.8 50.4 65.1 79.7 94.4 109.0 138.3 167.5

90 76.2 26.3 40.9 55.6 70.2 84.8 99.5 128.7 158.0

90 85.7 31.4 46.0 60.7 75.3 90.0 119.2 148.5

90 95.2 36.5 51.2 65.8 80.4 109.7 139.0

90 104.7 41.6 56.3 70.9 100.2 129.5

90 114.2 46.8 61.4 90.7 119.9

Spring

torque

Operating pressure [bar]

Size DFPD-240

20 0 28.0 57.2 78.5 99.8 121.1 142.4 163.7 185.0 206.3 227.6 270.2 312.8

90 55.4 29.8 51.1 72.4 93.7 115.0 136.3 157.6 178.9 200.2 242.8 285.4

25 0 35.0 50.2 71.5 92.8 114.1 135.4 156.7 178.0 199.3 220.6 263.2 305.8

90 69.2 16.0 37.3 58.6 79.9 101.2 122.5 143.8 165.1 186.4 229.0 271.6

30 0 42.0 64.5 85.8 107.1 128.4 149.7 171.0 192.3 213.6 256.2 298.8

90 83.0 23.5 44.8 66.1 87.4 108.7 130.0 151.3 172.6 215.2 257.8

35 0 49.0 78.8 100.1 121.4 142.7 164.0 185 .3 206.6 249.2 291.8

90 96.9 30.9 52.2 73.5 94.8 116.1 137.5 158.7 201.3 243.9

40 0 56.0 93.1 114.4 135.7 157.0 178.3 199.6 242.2 284.8

90 110.7 38.4 59.7 81.0 102.3 123.6 14 4.9 187.5 230.1

45 0 63.0 107.4 128.7 150.0 171.3 192.6 235.2 277.8

90 124.6 45.8 67.1 88.4 109.7 131.0 173.6 216.2

50 0 70.0 121.7 143.0 164.3 185.6 228.2 270.8

90 138.4 53.3 74.6 95.9 117.2 159.8 202.4

55 0 77.0 136.0 157.3 178.6 221.2 263.8

90 152.2 60.8 82.1 103.4 146.0 188.6

60 0 84.0 150.3 171.6 214.2 256.8

90 166.1 68.2 89.5 132.1 174.7

-H- Note

The operating torque of the drive must not be higher than the maximum

permissible torque listed in ISO 5211, with reference to the size of the

mounting flange and of the coupling.

18

è

Subject to change – 2017/06

Page 19

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Theoretical torque [Nm] as a function of operating pressure [bar] and swivel angle [°]

Spring

configuration

Size DFPD-300

20 0 36.1 73.7 101.1 128.6 156.0 183.4 210.9 238.3 265.8 293.2 348.1 403.0

25 0 45.2 64.6 92.1 119.5 147.0 174.4 201.9 229.3 256.8 284.2 339.1 394.0

30 0 54.2 83.0 110.5 137.9 165.4 192.8 220.3 247.7 275.2 330.1 384.9

35 0 63.2 101.5 128.9 156.4 183.8 211.2 238.7 266.1 321.0 375.9

40 0 72.2 119.9 147.3 174.8 202.2 229.7 257.1 312.0 366.9

45 0 81.3 138 .3 165.7 193.2 220.6 248.1 303.0 357.9

50 0 90.3 156.7 184.2 211.6 239.0 293.9 348.8

55 0 99.3 175.1 202.6 230.0 284.9 339.8

60 0 108.4 193.5 221.0 275.9 330.8

Nominal swivel

angle

[°] [Nm] 2 2.5 3 3.5 4 4.5 5 5.5 6 7 8

90 71.4 38.4 65.9 93.3 120.8 148.2 175.6 203.1 230.5 258.0 312.9 367.8

90 89.2 20.6 48.0 75.5 102.9 130.4 157.8 185.3 212.7 240.1 295.0 349.9

90 107.0 30.2 57.6 85.1 112.5 14 0.0 167.4 194.9 222.3 277.2 332.1

90 124.9 39.8 67.2 94.7 122.1 149.6 177.0 204.5 259.4 314.2

90 142.7 49.4 76.8 104.3 131.7 159.2 186.6 241.5 296.4

90 160.6 59.0 86.4 113.9 141.3 168.8 223.7 278.6

90 178.4 68.6 96.1 123.5 150.9 205.8 26 0.7

90 196.2 78.2 105.7 133.1 188.0 242.9

90 214.1 87.8 115.3 170.2 225.0

Spring

torque

Operating pressure [bar]

Size DFPD-480

20 0 56.7 115.7 158.8 201.9 245.0 288.0 331.1 374.2 417.3 460.4 546.6 632.8

90 112.0 60.3 103.4 146.5 189.6 232.7 275.8 318.9 362.0 405.1 491.2 577.4

25 0 70.9 101.5 14 4.6 187.7 230.8 273.9 317.0 360.1 403.2 446.2 532.4 618.6

90 140.1 32.3 75.4 118.5 161.6 204.7 247.8 290.9 334.0 377.0 463.2 549.4

30 0 85.0 130.4 173.5 216.6 259.7 302.8 345.9 389.0 432.1 518.3 604.4

90 168.1 47.4 90.5 133.6 176.7 219.8 262.8 305.9 349.0 435.2 521.4

35 0 99.2 159.4 202.4 245.5 288.6 331.7 374.8 417.9 504.1 590.3

90 196.1 62.5 105.6 148.7 191.7 234.8 277.9 321.0 407.2 493.4

40 0 113.4 188.3 231.4 274.5 317.5 360.6 403.7 489.9 576.1

90 224.1 77.6 120.6 163.7 206.8 249.9 293.0 379.2 465.4

45 0 127.5 217.2 260.3 303.4 346.5 389.6 475.7 561.9

90 252.1 92.6 135.7 178.8 221.9 265.0 351.2 437.4

50 0 141.7 246.1 289.2 332.3 375.4 461.6 547.8

90 280.1 107.1 150.8 193.9 237.0 323.2 409.4

55 0 155.9 275.0 318.1 361.2 447.4 533.6

90 308.1 122.8 165.9 209.0 295.2 381.3

60 0 170.0 304.0 347.1 433.2 519.4

90 336.1 137.9 181.0 267.2 353.3

-H- Note

The operating torque of the drive must not be higher than the maximum

permissible torque listed in ISO 5211, with reference to the size of the

mounting flange and of the coupling.

2017/06 – Subject to change

è

19

Page 20

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Dimensions Download CAD data è Size 20 … 80

20

è

Subject to change – 2017/06

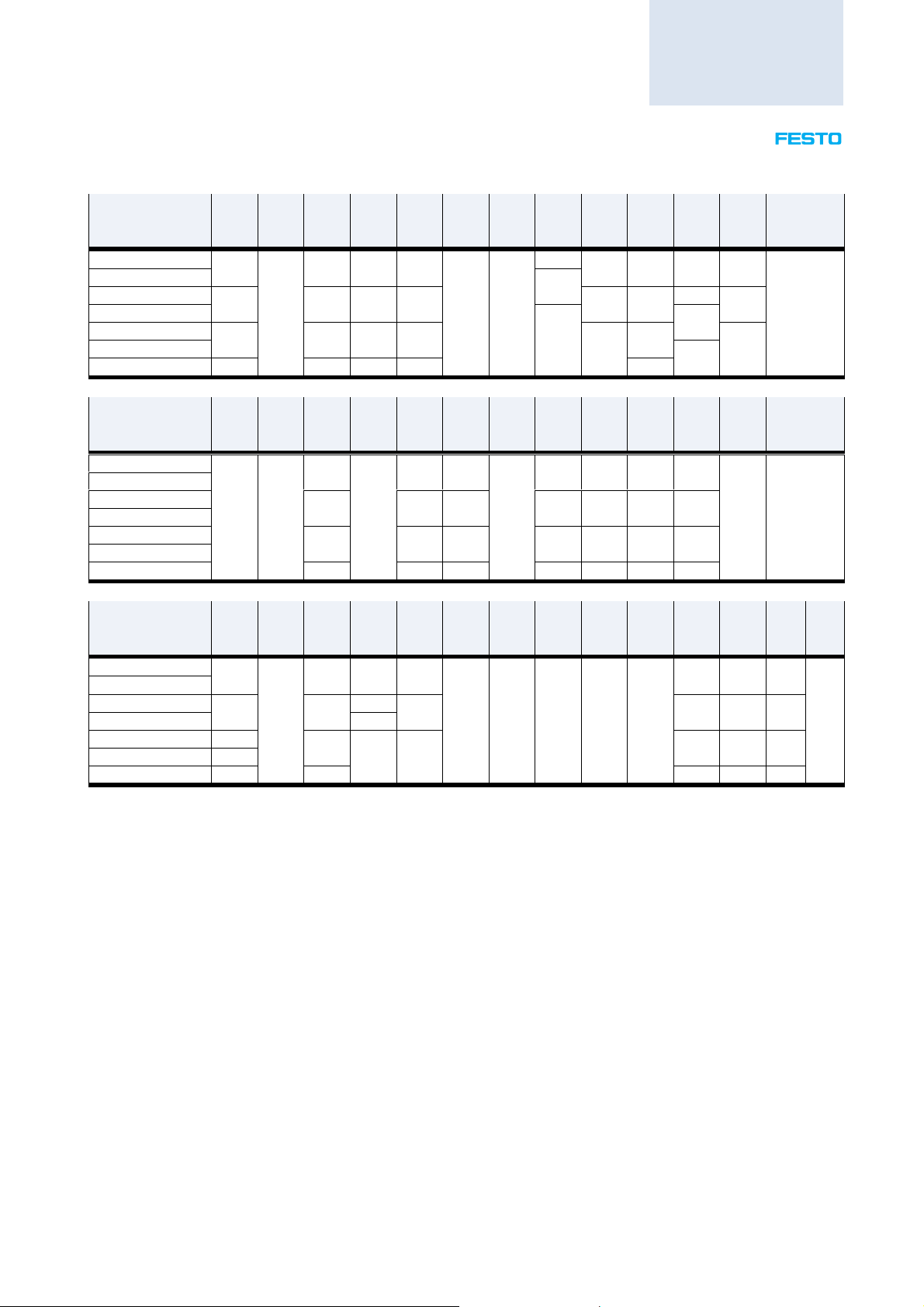

Page 21

Quarter turn actuators DFPD, single-acting

Technical data

-V- New

Type

[mm]

DFPD-20-F03

DFPD-20-F04

DFPD-40-F04

DFPD-40-F0507

DFPD-80-F0507

Type

[mm]

DFPD-20-F03

DFPD-20-F04

DFPD-20-F05

DFPD-40-F04

DFPD-40-180-F0507

DFPD-80-F0507

Type

[mm]

DFPD-20-F03

DFPD-20-F04

DFPD-40-F04

DFPD-40-180-F0507

DFPD-80-F0507

B1 B2

±0.1

68.5

30

81.5 45 21 8.2

99 53 26 9 23.3

D7 D8 D9

M6 M5

L1 L2

±0.1T1±0.4

145.7

170.4

–

223.1 19.3 17 15 13

B4 B5 B8

max.

38.5 19 9.2

EE H1 H2 H3

±0.1

12.7

Gx or

NPTx

16.2 112 70.5

20.2 130 86 110 55 86.5

10 min.

13.2

80

12 min. 8

16.5

100 59.8

T2 T3 T4 T5 T6 T7 T8

8

9

9 12

–

B9 B10

+0.1

12 4

–0.5H4+0.1

8 12 8 8 4 45°

D1

D2

±0.1

±0.1

36

42

50 M6

42

50

10 80 40 57.5

20

13

–

70

H5 H6

92 46 67.5DFPD-40-F0507

D3

D4 D5 D6

12

M5

14.6DFPD-20-F05

M5

18.7

±0.2H7±0.3H8±0.1

+0.5

M6 M8DFPD-40-180-F0507

W1 ß 1

H11

11DFPD-20-F05

14

–

M5

16 32

ß 2

h11

9

9

12DFPD-40-F0507

H9

ß 3

10

2017/06 – Subject to change

è

21

Page 22

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Dimensions Download CAD data è

Size 120 … 480

22

è

Subject to change – 2017/06

Page 23

Quarter turn actuators DFPD, single-acting

Technical data

-V- New

Type

[mm]

DFPD-120-F0507

DFPD-120-180-F0507

DFPD-160-F0710

DFPD-240-F0710

DFPD-240-180-F0710

DFPD-300-F0710

DFPD-480-F1012

DFPD-480-180-F1012

Type

[mm]

DFPD-120-F0507

DFPD-120-180-F0507

DFPD-160-F0710

DFPD-240-F0710

DFPD-240-180-F0710

DFPD-300-F0710

DFPD-480-F1012

DFPD-480-180-F1012

Type

B1 B2

±0.1

111.5

120 63.5 36 13.4

135.5 71.5 41 18.5 30.3

144 74.5 46 17 30

163 83 52 19.3 102 125 37.4 M10 M12

D7 D8 D9

M6 M5

L1 L2

B4 B5 B8

max.

60.5 32 12.3

30

EE H1 H2 H3

±0.1

22.5

25.5 154 106.25 134 67 109.4

G¼ or

NPT¼

31.8

38 214 149.5 184 92 152.5

143 97.75

180 120.5

192 131 162 81 132.1

T2 T3 T4 T5 T6 T7 T8

B9 B10 D1

±0.1

12 4

0. 5H4+0.1

20 13

30 19.5

D2

±0.1

50 70 23.2 M6 M8

70 102

H5 H6 H7

123 61.5 98.4

150 75 120.2

D3

30

D4 D5 D6

M8 M10

±0.3H8±0.1

W1 ß 1

M5

16 32

ß 2

H9

ß 3

[mm]

DFPD-120-F0507

DFPD-120-180-F0507

DFPD-160-F0710

DFPD-240-F0710

DFPD-300-F0710

DFPD-480-F1012

DFPD-480-180-F1012

252.3

270.9

301.4

334.4

374.2

–

–

–

±0.1T1±0.4

19.3 9 12

80

24.3 12 15 22

29.5 15 18 27 27 21

8 14 8 12 4 45°

wCore product range

Ordering data

Type Size Product weight Part No. Type

[g]

20 1419 w8047622 DFPD-20-RP-90-RS60-F04

40 2180 w8047624 DFPD-40-RP-90-RS60-F0507

80 3960 w8047626 DFPD-80-RP-90-RS60-F0507

120 5736 w8048134 DFPD-120-RP-90-RS60-F0507

160 7179 w8048136 DFPD-160-RP-90-RS60-F0710

240 10036 w8048138 DFPD-240-RP-90-RS60-F0710

300 12880 w8048140 DFPD-300-RP-90-RS60-F0710

480 18485 w8048142 DFPD-480-RP-90-RS60-F1012

+0.5

H11

h11

17 15 13

19 16

22 18DFPD-240-180-F0710

Festo core product range qReady for dispatch from the Festo factory in 24 hours

wReady for dispatch in 5 days maximum from stock

2017/06 – Subject to change

è

23

Page 24

-V- New

Quarter turn actuators DFPD, single-acting

Technical data

Ordering data

Type Size Product weight Part No. Type

[g]

20 1371 8047644 DFPD-20-RP-90-RS30-F03

1419 8047645 DFPD-20-RP-90-RS60-F03

1371 8047621 DFPD-20-RP-90-RS30-F04

1371 8048014 DFPD-20-RP-90-RS30-F05

1419 8048015 DFPD-20-RP-90-RS60-F05

40 2087 8047635 DFPD-40-RP-90-RS30-F04

2180 8047636 DFPD-40-RP-90-RS60-F04

2087 8047623 DFPD-40-RP-90-RS30-F0507

80 3746 8047625 DFPD-80-RP-90-RS30-F0507

120 5422 8048133 DFPD-120-RP-90-RS30-F0507

160 6767 8048135 DFPD-160-RP-90-RS30-F0710

240 9442 8048137 DFPD-240-RP-90-RS30-F0710

300 12052 8048139 DFPD-300-RP-90-RS30-F0710

480 17261 8048141 DFPD-480-RP-90-RS30-F1012

Ordering data

Type Size Product weight Part No. Type

[g]

Version EP, epoxy-coated

20 1371 8047646 DFPD-20-RP-90-RS30-F03-R3-EP

1419 8047647 DFPD-20-RP-90-RS60-F03-R3-EP

1371 8047627 DFPD-20-RP-90-RS30-F04-R3-EP

1419 8047628 DFPD-20-RP-90-RS60-F04-R3-EP

1371 8048016 DFPD-20-RP-90-RS30-F05-R3-EP

1419 8048017 DFPD-20-RP-90-RS60-F05-R3-EP

40 2087 8047642 DFPD-40-RP-90-RS30-F04-R3-EP

2180 8047643 DFPD-40-RP-90-RS60-F04-R3-EP

2087 8047629 DFPD-40-RP-90-RS30-F0507-R3-EP

2180 8047630 DFPD-40-RP-90-RS60-F0507-R3-EP

80 3746 8047631 DFPD-80-RP-90-RS30-F0507-R3-EP

3960 8047632 DFPD-80-RP-90-RS60-F0507-R3-EP

120 5422 8048143 DFPD-120-RP-90-RS30-F0507-R3-EP

5736 8048144 DFPD-120-RP-90-RS60-F0507-R3-EP

160 6767 8048145 DFPD-160-RP-90-RS30-F0710-R3-EP

7179 8048146 DFPD-160-RP-90-RS60-F0710-R3-EP

240 9442 8048147 DFPD-240-RP-90-RS30-F0710-R3-EP

10036 8048148 DFPD-240-RP-90-RS60-F0710-R3-EP

300 12052 8048149 DFPD-300-RP-90-RS30-F0710-R3-EP

12880 8048150 DFPD-300-RP-90-RS60-F0710-R3-EP

480 17261 8048151 DFPD-480-RP-90-RS30-F1012-R3-EP

18485 8048152 DFPD-480-RP-90-RS60-F1012-R3-EP

24

è

Subject to change – 2017/06

Page 25

-V- New

Quarter turn actuators DFPD

Ordering data – Modular product system, size 10 … 80

Ordering table

Size 10 20 40 80 Condi

tions

0M Module No. 8042184 8042185 8042186 8042187

Function Quarter turn actuator, based on ISO 5211 DFPD DFPD

0O System of units Metric

Imperial -N

Version Standard

0M Torque 10 Nm – – – -10

20 Nm – – – -20

40 Nm – – – -40

80 Nm – – – -80

0M Design Rack and pinion -RP -RP

0O Yoke type None

0M Swivel angle 90° -90

180° – – – -180

Swivel direction To the left -L

To the right -R

Function Double-acting D

Single-acting – 1 wS

0O Spring configuration None

Connection

pressure

2 bar 5 20

2.5 bar 5 25

3 bar 5 30

3.5 bar 5 35

4 bar 5 40

4.5 bar 5 45

5 bar 5 50

5.5 bar 5 55

6 bar 5 w60

0M Flange pattern 1 Hole pattern F03 – – -F03

F04 – -F04

F05 – -F05

0O Flange pattern 2 None

Hole pattern 07 – – 6 07

Manual override None

Temperature range Standard

0 … +150 °C – – -T4

–50 … +60 °C – – -T6

Corrosion protection Standard

High 8 -R3

Housing surface

treatment

None

Epoxy-coated 4 -EP

Code Enter

code

1 S Not in combination with swivel angle 180°

4 EP Only in combination with high corrosion protection -R3

Mandatory data

M

Options

O

5 20, 25, 30, 35, 40, 45, 50, 55, 60 Not in combination with double-acting function, with 2

6 07 Mandatory specification in combination with (torque) 40 Nm, 80 Nm, 120 Nm

8 R3 Mandatory specification in combination with (housing surface treatment)

Order code

DFPD – – – – – – – – – – –

Festo core product range qReady for dispatch from the Festo factory in 24 hours

wReady for dispatch in 5 days maximum from stock

2017/06 – Subject to change

è

cylinders (DD), mandatory specification in combination with (function) single-acting (S)

epoxy-coated -EP

25

Page 26

-V- New

Quarter turn actuators DFPD

Ordering data – Modular product system, size 120 … 480

Ordering table

Size 120 160 240 300 480 Condi

tions

0M Module No. 8042188 8042189 8042190 8042191 8042192

Function Quarter turn actuator, based on ISO 5211 DFPD DFPD

0O System of units Metric

Imperial -N

Version Standard

0M Torque 120 Nm – – – – -120

160 Nm – – – – w-160

240 Nm – – – – w-240

300 Nm – – – – w-300

480 Nm – – – – w-480

0M Design Rack and pinion -RP -RP

0O Yoke type None

0M Swivel angle 90° -90

180° – – -180

Swivel direction To the left -L

To the right -R

Function Double-acting D

Single-acting 1 wS

0O Spring configuration None

Connection

pressure

ê 6 bar 5 w60

2 bar 5 20

2.5 bar 5 25

3 bar 5 30

3.5 bar 5 35

4 bar 5 40

4.5 bar 5 45

5 bar 5 50

5.5 bar 5 55

Code Enter

code

1 S Not in combination with swivel angle 180° 5 20, 25, 30, 35, 40, 45, 50, 55, 60 Not in combination with double-acting function, with 2

Mandatory data

M

Options

O

Transfer order code

DFPD – – – – – – –

Festo core product range qReady for dispatch from the Festo factory in 24 hours

wReady for dispatch in 5 days maximum from stock

cylinders (DD), mandatory specification in combination with (function) single-acting (S)

26

è

Subject to change – 2017/06

Page 27

-V- New

Quarter turn actuators DFPD

Ordering data – Modular product system, size 120 … 480

Ordering table

Size 120 160 240 300 480 Condi

tions

0M Flange pattern 1 Hole pattern F05 – – – – -F05

F07 – – w-F07

F010 – – – – w-F10

0O Flange pattern 2 Standard – – – – –

Hole pattern F07 – – – – 6 07

F10 – – w10

F12 – – – – w12

0O Manual override None

Temperature range Standard

0 … +150 °C -T4

–50 … +60 °C -T6

Corrosion protection Standard

High 8 -R3

Housing surface

treatment

None

Epoxy-coated 4 -EP

Code Enter

code

4 EP Only in combination with high corrosion protection -R3 6 07 Mandatory specification in combination with (torque) 40 Nm, 80 Nm, 120 Nm

8 R3 Mandatory specification in combination with (housing surface treatment)

epoxy-coated -EP

Mandatory data

M

Options

O

Transfer order code

– – – – –

Festo core product range qReady for dispatch from the Festo factory in 24 hours

wReady for dispatch in 5 days maximum from stock

2017/06 – Subject to change

è

27

Loading...

Loading...