Page 1

Quarter turn actuator

DAPS..R..-F..-MW..

Festo AG & Co. KG

Postfach

D-73726 Esslingen

+49 711 347-0

www.festo.com

(en) Operatinginstructions 8024409

1309NH

[8030433]

Original: de

Quarter turn actuator DAPS..R..-F..-MW.. English...........................

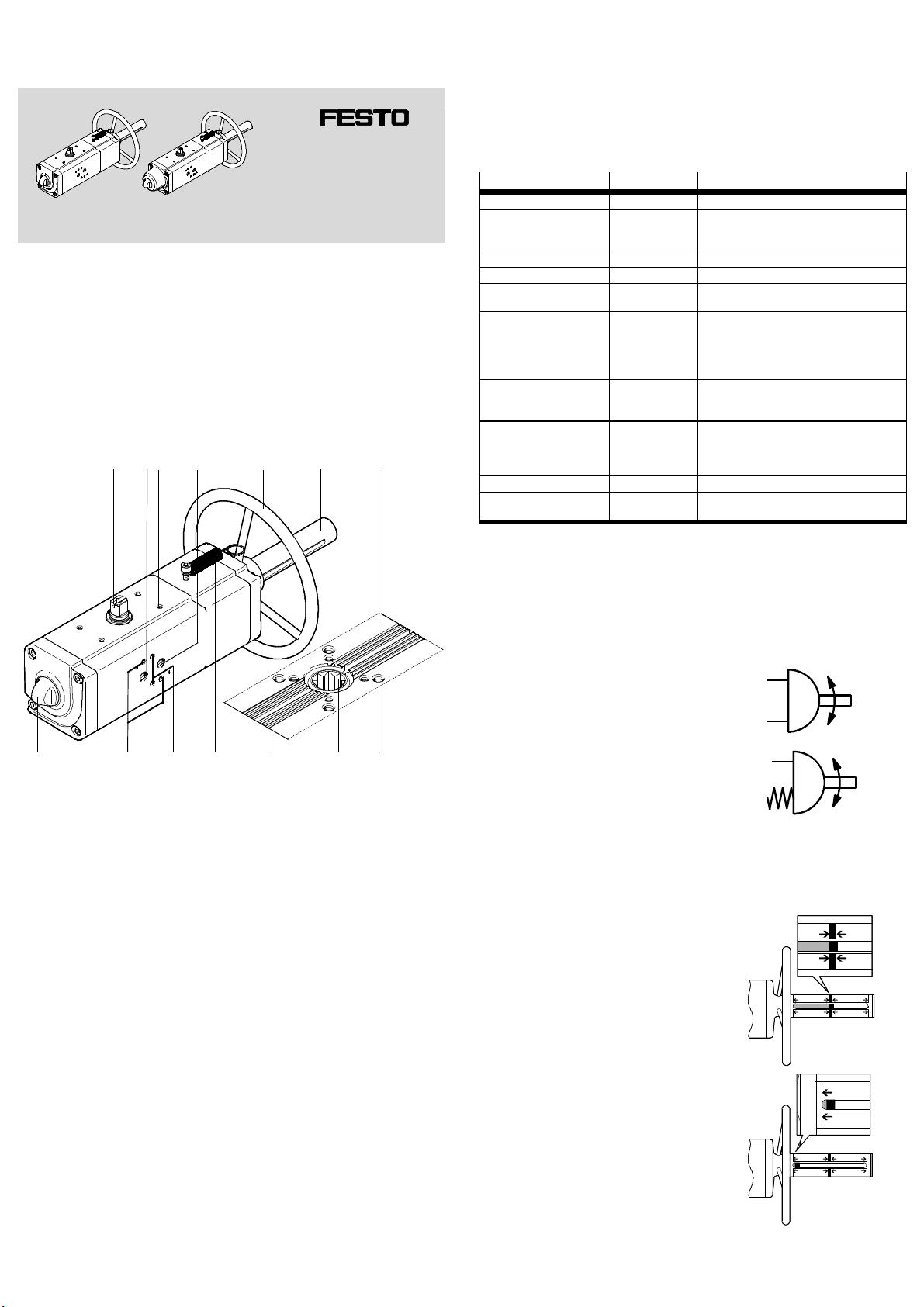

1 Control sections and connections

Example of c onnections on the double-acting quarter turn actuator DAPS:

12

34

5

6

7

The housing of some quarter turn actuators has, on the process valve port side, a

leakage groove ( Fig. 1, aJ ) through which the leakage of an untight process

valve can escape.

The single-acting design with spring return is equipped with different spring forces

for use with different supply pressures.

The DAPS...-MW product version described here is equipped with a handwheel for manual emergency override in a pressureless state.

The product is available in various designs. These operating instructions describe

the following product variants:

Features

Series DAPS- Quarter turn actuator

Size or nominal torque in Nm 0053-

Swivel angle in degrees 090- 90 °

Closing direction R Closes to right

Mode of operation - (without)

Spring strength (with mode

of operation S)

1st flange hole pattern F05

2nd flange hole pattern (without)

Manual emergency override -MW with handwheel

Design (without)

Type code Description

…

1920-

S

(without)

1234-

…

F14

07

…

16

-T6

Nominal torque 53 Nm

…

Nominal torque 1920 Nm

Double-acting

Single-acting

(Omitted for double-acting)

Spring strength for connection pressure 2.8 bar

Spring strength for connection pressure 3.5 bar

Spring strength for connection pressure 4.2 bar

Spring strength for connection pressure 5.6 bar

Flange hole pattern F05

…

Flange hole pattern F14

No second flange hole pattern

Flange hole pattern F07

…

Flange hole pattern F16

Standard design (-20 °C to + 80 °C)

Low temperature (-50 °C to 60°C)

Fig. 2 Type code (e.g. DAPS-0480-090-R-F1012-MW-T6)

aCaD

1 Transmission shaft (shaft groove

shows the process valve position–

open here)

2 Compressed air supply port 2 (A)

3 Four mounting threads – e.g. for

mounting the limit switch or

sensor box

4 Compressed air supply port 4 (B)

5 Handwheel

6 Shield tube with inspection win-

dow

aAaB

89aJ

8 Mountingthread

9 Star-shaped coupling for seating

of the square of a process valve

aJ Leakage groove

aA Locking spring

aB Mounting thread for threaded pin

for aligning the NAMUR valve

aC Mounting thread for pneumatic

NAMUR switching valve

aD Lock nut for retaining the set end

position.

7 View from below – flange to

ISO 5211

Fig. 1

2Design

Quarter turn ac tuators of the DAPS series are compact in design and have simple

and robust mechanics with little wear and tear. The design of the product is dependent on the product design and may differ from the representation shown in

Fig. 1 ( Fig. 1).

Through the housing, a shaft is guided outward on both sides. Through this, the

reaction torque is transmitted to a process valve ( Fig. 1, 9 ) and, if applicable,

a limit switch or sensor box ( Fig. 1, 1 ).

The flange to the process valve is designed in accordance with ISO 5211. Four

mounting threads on the top are used for mechanical attachment of a limit switch

or sensor box ( Fig. 1, 3 ). The housing side has a hole pattern for valve attachment in accordance with VDI/VDE 3845 (NAMUR).

Depending on the version, the DAPS is designed as a single-acting or double-acting

quarter turn ac tuator.

Select suitable accessories (e.g. adapter kits) from the c atalogue

(www.festo.com/catalogue).

3 Function

The piston movement of the DAPS is converted to a rotary movement by means of

yoke kinematics(Scotch yoke). These kinematics are only effective within an angle

of approx. 90°.

For double-acting quarter turn actuators:

Pressurising and venting of the cylinder chambers

cause the piston in the DAPS to move back and forth.

The linear motion of the piston is transformed into a

swivel motion of the transmission shaft.

Fig. 3

For single-acting quarter turn actuators:

Return is through spring force.

Product designs with different spring strengths are

available ( Fig. 2 ).

Fig. 4

The screwed-on processing valve records the moment of reaction of the quarter

turn actuator. The torques permitted in accordance with the technical specifications ( catalogue www.festo.com/catalogue) apply here.

The handwheel can be used to change the position of the actuator when the supply pressure is switched off (manual emergency override).

Neutral position

If the indicator is located centrally , the

handwheel is in a neutral position.

– The piston can be moved freely.

– The actuator can be operated pneumatic-

ally.

Fig. 5

Indicator in left-hand position (inside)

A) Double-acting actuator:

Turning the handwheel anti-clockwise

moves the indicator inwards.

– The process valve opens.

B) Single-acting actuator:

Turning the handwheel clockwise moves the

indicator inwards.

– The process valve closes.

Fig. 6

Page 2

Indicator in right-hand position (outside)

A) Double-acting actuator:

Turning the handwheel clockwise moves the

indicator outwards.

– The process valve closes.

B) Single-acting actuator:

Turning the handwheel anti-clockwise

moves the indicator outwards.

– The process valve opens.

Fig. 7

4 Application

The DAPS quarter turn actuator is intended to activate right-closing process

valves, such as ball valves and butterfly valves with a rotation angle from 0° (valve

closed) to 90° (valve open).

It is completely tailored to the requirements of the processing industry and is suitable for control of media-flow process valves in fluid engineering systems.

5 Transport and storage

Ensure the following storage conditions: short storage times in cool, dry, shaded

and corrosion-resistant locations.

War n ing

Danger of c rushing! Danger of shearing!

The DAPS weighs up to about 50.6 kg, depending on the product version.

Body parts can be crushed or cut o ff if the product falls.

• For product versions weighing more than 12 kg, always use suitable load-carrying equipment in order to handle the product safely during transport and

assembly.

Note

• Use only unlubricated compressed air under normal conditions.

The DAPS quarter turn actuator possesses an initial lubrication which suffices

for the complete service life.

Note

Continuous operation at the limits of the specified ambient temperature and

work frequency can reduce the service life of the quarter turn actuator.

• Use lubricated compressed air for continuous operation under extreme conditions. The oil must be chemically inert and must not carbonise.

If lubricated compressed air is used:

The initial lubricationwill be washed out. The quarter turn actuator may then

only be operated with lubricated compressed air.

7 Installation

Note

The following instructions on fitting the DAPS quarter turn actuator onto a processing valve may only be used in the following circumstances:

– The quarter turn actuator is installed in the direction of the tubing.

– If a 2-way process valve is used:

The 2-way process valve is closed.

– If a 3-way process valve is used:

The switchingstatus of the 3-way process valve is known.

Note

Improper handing can cause damage to the product!

• Never use the handwheel to lift the actuator.

6 Requirements for productuse

Note

Improper handling can result in malfunctions.

• Make sure that all the instructions in this chapter are always observed. The

product will then function correctly and safely.

• Compare the maximum values specified in these operating instructions with

your actual application (e.g. pressures, forces, torques, masses, speeds, temperatures). The product can only be used in compliance with the relevant safety

guidelines if the maximum load limits are observed.

• Ensure that all applicable regulations for your location are adhered to, e.g. of

the trade association or national institutions.

• Take into consideration the ambient conditions at the location of use. Corrosive

environments reduce the service life of the product.

• Remove the packaging except for the adhesive labels on the compressed air

supply ports (danger of contamination). The material used in the packaging has

been specifically chosen for its recyclability (exception: oil paper = residual

waste).

• Use the product in its original status, without any unauthorised product modifications.

• Protect the device from pressure fluctuations. Use control valves for regulating

pressure and excess pressure.

• Make sure the c ompressed air is properlyprepared (Technical data

section 12).

• Before carrying out installation, dismantling and maintenance work, switch off

the compressed air supply and vent the actuator. Secure compressed air supply

against acc idental restarting.

• Never remove the end cap, shield tube or handwheel.

• Never use a wrench to operate t he transmission shaft by hand.

• Never use levering tools to operate the handwheel.

Danger

In the case of single-acting DAPS, high spring forces (mechanically stored energy) are at work inside the product.

Parts can be ejected and cause serious personal injuries if the end cap is dismounted.

• Never remove the end cap!

• Return the product to Festo if defective or for service.

Note

If a 3-way processing valve is used:

• Align the quar ter turn actuator so that the port openings for a NAMUR valve

facethesidewithouttubing.

Note

Outflowing processing medium must not penetrate into the quarter turn actuator.

The housing of some quarter turn actuators has a leakage groove on the process

valve port side. If the processing valve leaks, the leakage can flow through the

open groove.

• For housings with a leakage groove, make sure the groove is not sealed. In

this way you can be sure that neither processing medium nor escaping air

from the processing valve can penetrate into the quarter turn actuator.

The DAPS quarter turn actuator can be mounted with or without an adapter bridge.

If there are high media temperature s in the tubing and in processing valve:

• Use an adapter bridge and also a heat-insulated coupling extension.

7.1 Mechanical installation

• In order to mount the DAPS quarter turn actuator, set the switching shaft of the

process valve so that the desired operating method for opening and closing the

process valve is implemented.

• Note that a processing valve with butterfly valve can only be opened in one direction and closed in the opposite direction.

• Observe the tightening torque:

Thread

Tightening torque [Nm] 5…610 …1120 …2345 ...5080 …85125 …

M5 M6 M8 M10 M12 M14 M16 M20

190 …

200

370 …

390

135

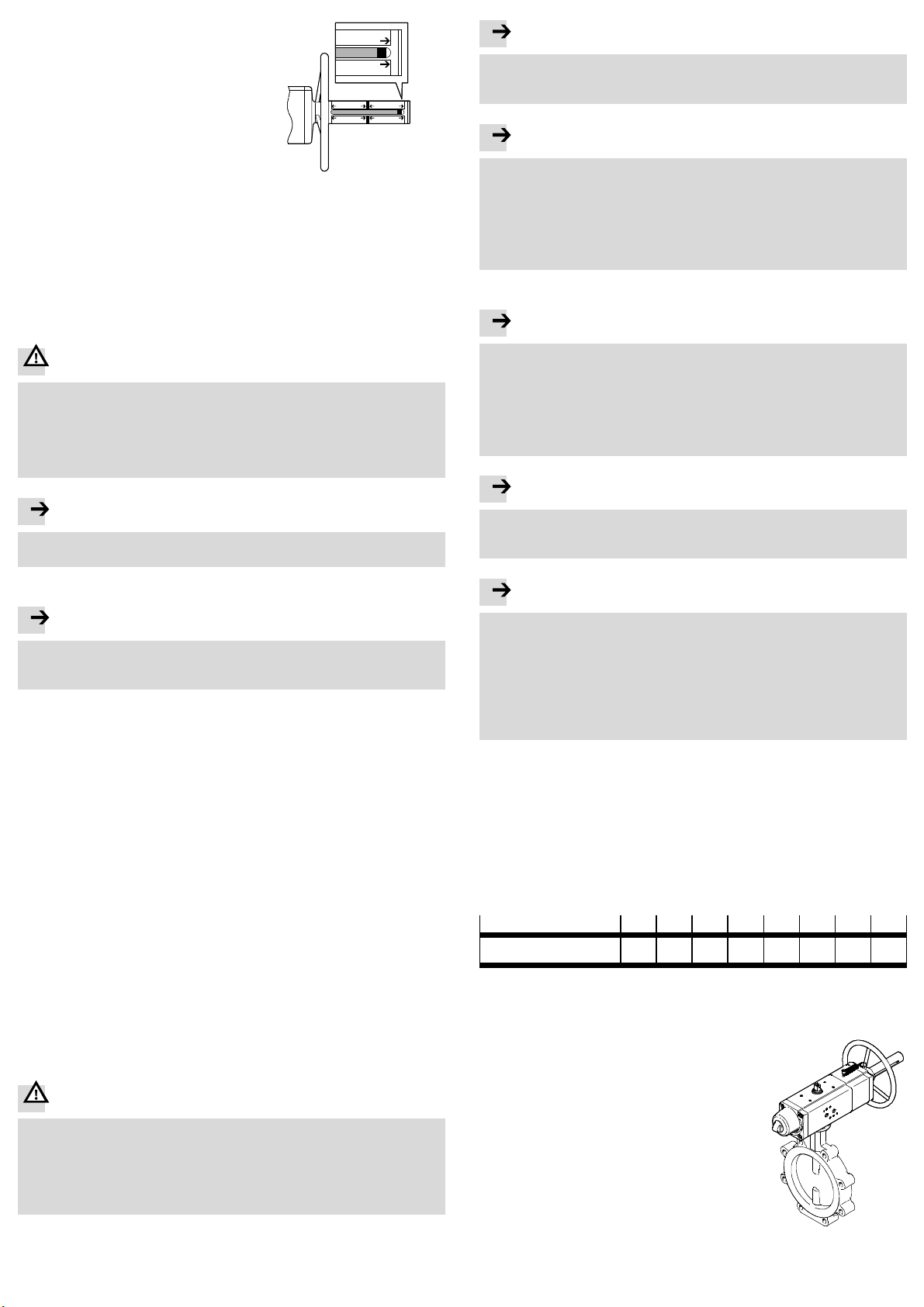

Fig. 8

To mount the quarter turn actuator without an adapter

bridge:

1. Place the quarter turn actuator on the switching

shaft of the processing valve. Make sure here that

the square of the processing valve sits in the starshaped coupling of the quarter turn actuator

without being tilted.

2. Fasten the quar ter turn actuator with 4 corrosionresistant screws and retaining rings (material: VA)

to the connection flange of the process valve.

3. Tighten all the screws in diagonally opposite sequence. Tightening torque Fig. 8.

4. Continued Point 6.

Fig. 9

Page 3

To mount the quarter turn actuator with an adapter

bridge, you need:

– an adapter bridge ( Fig. 10, 1 ),

– a shaft extension( Fig. 10, 2 ).

1. Align the adapter bridge so that its supports are

oriented in the direction of the longitudinal axis of

the quarter turn actuator and, if necessary, the

open side of the adapter bridge towards the pro-

1

2

cess valve.

2. Fasten the adapter bridge to the quarter turn actuator. Do not yet tighten the screws.

3. Guide the shaft extensionthrough the adapter

bridge into the star-shaped coupling on the bot-

Fig. 10

tom of the quarter turn actuator. Make sure that

the shaft extension sits in the coupling without

being tilted.

4. Fasten the quarter turn actuator with adapter bridge and shaft extensionto the

connection flange of the process valve. Make sure here that the square of the

processing valve sits in the shaft extension without being tilted.

5. Tighten all the screws in diagonally opposite sequence.

Tightening torque Fig. 8.

After fitting the quarter turn actuator:

6. Check that the quarter turn actuator turns in the required direction of rotation

and whether the processing valve assumes the required position.

7. If the quarter turn actuator does not turn in the required direction of rotation:

Carry out the following modification:

8.1 Adjustment of the end positions

Some product variants offer the possibility to adjust one or even both end positions of the DAPS within narrow limits in order to influence the closing or opening

angle of the mounted process valve. During adjustment of the end positions, observe the permissible adjustment range of the DAPS used ( section 12, end

position adjustment range).

Note

Product variants without specification of an adjustment range have no possibility

for setting end positions, e.g. all product variants made of stainless steel

(DAPS-...-CR).

The now following description for end position setting refers to the following sizes

in the designs “Standard” and “Low temperature” (-T6):

– DAPS-…-R-…(double-acting); size 0015 up to 1920 ( section 8.2)

– DAPS-…-RS.. (single-acting); size 0015 up to 0960 ( section 8.3)

Information on adjustment of the end position for other sizes can be found, if applicable, in the appendix to the operating instructions supplied with the product

( www.festo.com).

8.2 Adjustment for the DAPS-…-R-… (double-acting) – size 0015 … 1920

For these product variants, the end position that the actuator takes during venting

through port 4 (B) can be adjusted (turn to the right - close process valve).

DAPS..R-… (double-acting)

1. Remove the pneumatic solenoid valve.

2. Turn the solenoid valve 180°.

3. Note the position of the th readed pin for

orientation of a NAMUR valve.

4. Fasten the solenoid valve again.

DAPS..RS-… (single-acting)

1. Remove the screws on the actuator side.

2. Turnthe actuator 90° while it is still connected through the shaft extension or directly to

the processing valve.

3. Tighten th e mounting screws.

7.2 Pneumatic installation

Connections for the compressed air supply

• DAPS quarter turn actuator, double-acting – standard design

– Air supply at port 2 (A) – see Fig. 1 2

Rotation of the switching shaft in an anti-clockwise direction.

– Air supply at port 4 (B) – see Fig. 1 4

Rotation of the switching shaft in a clockwise direction.

• DAPS quarter turn actuator, single-acting with spring return – standard design

– Air supply at port 4 (B): rotational movement anti-clockwise.

– Spring return: rotation clockwise.

Note

For DAPS..RS-… (single-acting):

• Fasten a filter element to the exhaust port 2 (A) to prevent ingress of dirt

particles.

7.3 Installing circuitry

Using the pneumatic switching valves:

• Please note the instructions and explanations in the relevant operating instructions for the pneumatic valves.

8 Commissioning

Note

• Make sure that the operating conditions section 12 lie within the permissible ranges.

The product is ready for operation as soon as it is installed and connected.

• Make sure that a process valve attac hed to the quarter turn actuator can be

switched without hindrance.

• When the supply pressure is switched off, set the handwheel to the neutral

position ( Fig. 5) so that the actuator can be operated pneumatically.

• Slowly pressurize the quarter turn actuator.

123 54

1 Lock nut with sealing ring

2 Threaded rod

4 Port 2 (A)

5 Port 4 (B)

3 Piston

Fig. 11

1. Supply compressed air and close the process valve. The pistons move to the

outer end position. This fixes the threaded rod – dependent on the current setting. Loosening of the lock nut will then not accidentally change the current

setting.

2. Screw down the lock nut with sealing ring. If the threaded rod has loosened,

retighten it by hand until a light resistance is felt.

3. Supply compressed air and open the process valve. The pistons move to the

inner end position.

4. Adjust the end position:

Observe that a complete turn of the threaded rod can change the swivel angle

approx. 1.5° to 3.5° – dependent on the product design.

– Turning the threaded rod clockwise reduces the swivel angle.

– Turning the threaded rod anti-clockwise increasesthe swivel angle.

5. Supply compressed air and close the process valve. The pistons run against the

threaded rod into the outer end position.

6. Check the position of the process valve. To change the swivel angle, repeat

step 3 and 4.

7. Retighten the lock nut on the threaded rod – tightening torque 5 Nm.

8. Check the mode of operationof the quarter turn actuator ( section 8.4)

8.3 Adjustment with the DAPS-…-RS.. (single-acting) – size 0015 to 0960

For these product variants, one of the two end positions of the DAPS can be adjusted – either the end position for right turning or the end position for left turning.

End position for right turning – closing process valve

Note

For the single-acting DAPS, the end position setting for right turning (closing

process valve) does not have a mechanical stop, since the spring disc is not

mechanically connected to the piston. The threaded rod therefore limits only the

path of the return spring so that the piston comes to rest without spring force.

But the piston movement or turning of the shaft is not mechanically limited and

can be continued through external forces.

Page 4

12 34 5

1 Lock nut with sealing ring

2 Threaded rod

3 Piston

Fig. 12

4 Port 2 (A)

5 Port 4 (B)

8.4 Check the mode of operation of the quarter turn actuator

• Check in cyclical tests, through alter nating pressurisation and, if necessary,

venting, whether the quarter turn actuator takes the required positions.

• If necessary, adjust the end positions to the extent the quar ter turn actuator

offers this possibility ( sec tion 8.1).

8.5 Emergency handwheel operation

Before operating the handwheel:

1. Make sure the actua tor is free of pressure.

2. Unhook the locking spring.

3. For the DAPS..R..-F..-MW-T6 “low temperature” version: Remove the protective

cover from the display.

Opening the process valve with the handwheel

DAPS..R-… (double-acting) DAPS..RS-… (single-acting)

• Turn the handwheel anti-clockwise

until the indicator moves inwards

( Fig. 6).

• Turn the handwheel anti-clockwise

until the indicator moves outwards

( Fig. 7).

1. Vent the DAPS and close the process valve. The pistons run to the inside end

position, as a result of spring return, until t he spring disc is held, if necessary, by

the threaded rod. This fixes the threaded rod – dependent on the c urrent setting. Loosening of the lock nut will then not accidentally change the current

setting.

2. Screw down the lock nut with sealing ring. If the threaded rod has loosened,

retighten it by hand until a light resistance is felt.

3. Supply compressed air and open the process valve. The pistons move to the

outer end position.

4. Adjust the end position:

Observe that a complete turn of the threaded rod can change the swivel angle

approx. 1.5° to 3.5° – dependent on the product design.

– Turning the threaded rod clockwise increases the spring travel.

– Turning the threaded rod anti-clockwise reduces the spring travel.

5. Vent the DAPS and close the process valve. The pistons are moved to the inside

end position, as a result of spring force, untilthe threaded rod and the spring

disc delimit the spring travel.

6. Check the position of the process valve. To change the swivel angle, repeat

steps 3 to 6

7. Retighten the lock nut on the threaded rod – tightening torque 5 Nm.

8. Check the mode of operationof the quarter turn actuator ( section 8.4)

End position for left turning – opening process valve

5

12 34

Fig. 14

Closing the process valve with the handwheel

DAPS..R-… (double-acting) DAPS..RS-… (single-acting)

• Turn the handwheel clockwise until

the indicator moves outwards

( Fig. 6).

Fig. 15

Before pneumatically actuating the actuator again:

4. Turn back the handwheel until the indicator is located centrally once again

(neutral position, Fig. 5).

5. Hook in the locking spring again.

6. For the DAPS..R..-F..-MW-T6 “low temperature” version: Replace the protective

cover on the display.

9 Maintenance and care

If used as intended in the operating instructions, the device will be maintenancefree.

10 Disassembly

War n ing

Danger of injury due to uncontrolled movements.

• Switch the tubing system pressureless before dismantling.

1. If necessary, remove any existing limit switches.

2. Remove the pneumatic switching valve.

3. Loosen the screws on the flange of the process valve.

4. Remove the quarter turn actuator (if necessary including mounting adapter and

coupling extension) from the process valve.

11 Troubleshooting

• Please contact Festo.

• Turn the handwheel clockwise until

the indicator moves inwards

( Fig. 6).

1 Lock nut with sealing ring

2 Threaded rod

3 Spring disc

Fig. 13

1. Supply compressed air and open the process valve. The pistons move to the

outer end position. This fixes the threaded rod – dependent on the current setting. Loosening of the lock nut will then not accidentally change the current

setting.

2. Screw down the lock nut with sealing ring. If the threaded rod has loosened,

retighten it by hand until a light resistance is felt.

3. Vent the DAPS and close the process valve. The pistons move to the inner end

position.

4. Adjust the end position:

Observe that a complete turn of the threaded rod can change the swivel angle

approx. 1.5° to 3.5° – dependent on the product design.

– Turning the threaded rod clockwise reduces the swivel angle.

– Turning the threaded rod anti-clockwise increasesthe swivel angle.

5. Supply compressed air and open the process valve. The pistons run against the

threaded rods into the outer end position.

6. Check the position of the process valve. To change the swivel angle, repeat

steps 3 to 6.

7. Retighten the lock nut on the threaded rod – tightening torque 5 Nm.

8. Check the mode of operationof the quarter turn actuator ( section 8.4)

4 Piston

5 Adjustment range of the outer end

position (see technical data)

Page 5

12 Technical data

General technical data

Operating medium Compressed air according to ISO8573-1:2010 [7:4:4]

Note about the

operating medium

Ambient temperature [°C] –20 … +80 –50 … +60

Swivel angle [°] 90

Mounting position Any

Valve connection

corresponding to

standard

Pneumatic connection

– DAPS-0053..RS to

DAPS-0180..RS..

– DAPS-0106..R- to

DAPS-0360..R-..

– DAPS-0240..RS to

DAPS-0960..RS..

– DAPS-0480..R- to

DAPS-1920..R-..

Standard connection

to the process valve

CE marking

(see declaration of

conformity

www.festo.com)

1) Certification-specific special documentation and the documentation of the se nsors must be considered

www.festo.com

Operating conditions DAPS..RS-…-MW..

Nominal operating

pressure

Operating pressure

– DAPS..R– DAPS..RS1-...

– DAPS..RS2-...

– DAPS..RS3-...

– DAPS..RS4-...

End-position adjusting

range at 0°

End-position adjusting

range at 90°

1) Minimum operating pressures vary for single-acting quarter turn actuators depending on spring quantity

2) Exceptions for devices with special marking

1)2)

DAPS-...-MW DAPS-...-MW-T6

Operation with lubricated medium possible (in which case

lubricated o peration will always be required)

Ester oil < 0.1 mg/m³, corresponds to ISO 8573:2010 class [-:-:2]

VDI/VDE 3845 (NAMUR)

G1/8

G1/4

ISO 5211

in accordance with EU Explosion Protection Directive (ATEX)

DAPS..R-…-MW..

(single-acting)

0053 … 1920

[bar] 5.6

[bar]

2.8 ... 8.4

3.5 ... 8.4

4.2 ... 8.4

5.6 ... 8.4

[°] One end position adjustable;

-1 … +9

[°] One end position adjustable;

81 … 91

(double-acting)

0053 … 1920

1 ... 8.4

-1 … +9

-

1)

Required manual force

1)

[N]

DAPS-0053-… 13.9 –

DAPS-0090-... 22.2 –

DAPS-0106-... – 13.9

DAPS-0120-... 27.3 –

DAPS-0180-... 33.7 22.2

DAPS-0240-... 41.7 27.3

DAPS-0360-... 54.4 33.7

DAPS-0480-... 64.3 41.7

DAPS-0720-... 68.5 54.4

DAPS-0960-... 81.3 64.3

DAPS-1440-... – 68.5

DAPS-1920-... – 81.3

1) Required force to overcome the nominal torque during operation of the handwheel

Number of revolutions1)DAPS..RS-…-MW..

DAPS-0053-… 13 –

DAPS-0090-... 16 –

DAPS-0106-... – 13

DAPS-0120-... 18 –

DAPS-0180-... 15 16

DAPS-0240-... 16 18

DAPS-0360-... 19 15

DAPS-0480-... 20 16

DAPS-0720-... 25 19

DAPS-0960-... 26 20

DAPS-1440-... – 25

DAPS-1920-... – 26

1) Number of revolutions re quired for opening and closing with the handwheel, starting from the ne utral

position

DAPS..RS-…-MW..

(single-acting)

(single-acting)

DAPS..R-…-MW..

(double-acting)

DAPS..R-…-MW..

(double-acting)

Information on materials DAPS-...-MW DAPS-...-MW-T6

Seals Nitrile rubber

Polyurethane (PUR)

Fluoro elastomer

Shaft High-alloy ste el (1.4305)

Cover Wrought aluminium alloy

Housing

Screws High-alloy steel

FVMQ

PTFE-reinforced

Switching time [s] per

1)

cycle

DAPS-0053-... 0.89 –

DAPS-0090-... 1.3 –

DAPS-0106-... – 0.41

DAPS-0120-… 1.71 –

DAPS-0180-... 2.70 0.63

DAPS-0240-… 2.2 0.81

DAPS-0360-... 3.6 1.18

DAPS-0480-… 3.8 1.54

DAPS-0720-... 4.7 2.1

DAPS-0960-... 6.3 3.1

DAPS-1440-... – 4.7

DAPS-1920-... – 6.3

1) Average values under idling conditions

Product weight [kg] DAPS..RS-…-MW..

DAPS-0053-… 4.5 –

DAPS-0090-... 6.8 –

DAPS-0106-... – 4

DAPS-0120-... 9 –

DAPS-0180-... 11.7 6

DAPS-0240-... 15.2 8

DAPS-0360-... 19.5 10.2

DAPS-0480-... 28.1 13.2

DAPS-0720-... 38.8 17.8

DAPS-0960-... 50.6 23.8

DAPS-1440-... – 33.6

DAPS-1920-... – 43

1) Product weight is dependent on the spring strength ( www.festo.com/catalogue).

DAPS..RS-…-MW..

(single-acting)

(single-acting)

1)

DAPS..R-...-MW..

(double-acting)

DAPS..R-…-MW..

(double-acting)

Loading...

Loading...