Universal bus node

CTEU-PB

Electronics

description

Bus nodes

Type CTEU-PB

Fieldbus protocol

PROFIBUS-DP

Description

575393

en 1208NH

[758863]

Contents and general safety instructions

Original de.......................................

Edition en 1208NH.................................

Designation P.BE-CTEU-PB-OP+MAINT-EN..............

Order no. 575393..................................

© (Festo AG & Co. KG, D-73726 Esslingen, 2012)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

Reproduction, distribution or sale of this document or communication of its contents to others without express authorization is prohibited. Offenders will be liable for damages.

All rights reserved in the event that a patent, utility model

or design patent is registered.

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

I

Contents and general safety instructions

PROFIBUS®,SIMATIC®,TORX®,TÜV®and VDE®are registered trademarks of the respective trademark owners in certain countries.

II

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Contents and general safety instructions

Ta b le o f c o n t e n t s

Intended use VII..........................................................

Range of application and certifications VII.....................................

Target group VIII..........................................................

Service VIII...............................................................

Instructions on this description VIII...........................................

Important user instructions IX..............................................

1. Installation 1-1...................................................

1.1 General instructions on installation 1-3................................

1.2 Mounting 1-5......................................................

1.2.1 Connection and display components 1-6........................

1.3 Power supply 1-7..................................................

1.3.1 Power supply connection 1-7.................................

1.4 Setting the DIL switches 1-9..........................................

1.4.1 Removal and mounting of the DIL switch cover 1-9................

1.4.2 Setting the DIL switches 1-10..................................

1.5 Connecting the fieldbus 1-13..........................................

1.5.1 Fieldbus cable 1-13..........................................

1.5.2 Cable specifications 1-13......................................

1.5.3 Fieldbus baud rate and fieldbus length 1-14......................

1.5.4 Fieldbus interface at the bus node 1-15..........................

1.5.5 Connection technology for fieldbus interface 1-16.................

1.5.6 Bus terminal 1-20............................................

1.5.7 Functional test 1-21..........................................

2. Commissioning 2-1................................................

2.1 General remarks on the fieldbus protocol PROFIBUS-DP 2-4...............

2.1.1 Components 2-4............................................

2.1.2 Data exchange with the PROFIBUS-DP fieldbus protocol 2-5........

2.1.3 Brief overview of the function range 2-5........................

2.1.4 Control commands 2-5......................................

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

III

Contents and general safety instructions

2.2 Preparing the bus node for configuration 2-7............................

2.2.1 Addressing the bus node 2-7.................................

2.2.2 Modules/devices at I-Port connection 1 and 2 2-7................

2.3 Installation on a higher-level controller 2-10.............................

2.3.1 Device master file (GSD) and symbol files 2-10....................

2.4 Configuration by using process data 2-12...............................

2.4.1 Configuration examples 2-12..................................

2.4.2 Configuration of a DP master 2-16..............................

2.4.3 Bus start-up 2-16............................................

2.4.4 Configuration using a DP master from Siemens as an example 2-17...

2.5 Identification and maintenance 2-26....................................

2.5.1 Overview of the I&M data structures 2-26........................

2.5.2 Load identification properties into the bus node using Step 7 2-27....

2.5.3 Check identification properties using Step 7 2-28..................

2.6 Parameterisation (DP) 2-31...........................................

2.6.1 Parameterisationwhen being switched on (start behaviour) 2-32.....

2.6.2 Equipment parameters 2-32...................................

2.6.3 Parameterisation of the bus node 2-33..........................

2.6.4 Bus node parameters too l change 2-34..........................

2.6.5 Application example for the parameterisation 2-37................

2.7 Communication 2-38................................................

2.7.1 Statuses when communication is established 2-38.................

2.7.2 Status transitions 2-38.......................................

2.8 Fail state behaviour 2-40.............................................

2.9 Switching on 2-42...................................................

2.9.1 Information concerning the switch-on behaviour of the bus node 2-42.

2.9.2 Checklist before switching on 2-43..............................

2.9.3 Switching on the power supply 2-44............................

2.9.4 Normal operating status 2-44..................................

IV

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Contents and general safety instructions

3. Diagnostics 3-1...................................................

3.1 Summary of diagnostics options 3-3...................................

3.2 Diagnostics via LED display 3-4.......................................

3.2.1 Normal operating status display 3-4...........................

3.2.2 PS-LED status display 3-5....................................

3.2.3 Status display X1-/X2-LEDs 3-6...............................

3.2.4 Status display BF-LED 3- 8....................................

3.3 Diagnostics via fieldbus 3-9..........................................

3.3.1 Diagnostic steps 3-9........................................

3.3.2 Overview of diagnostic bytes 3-11..............................

3.3.3 Details for standard diagnostic information 3-13..................

3.3.4 Details of the channel-related diagnostics 3-14....................

3.3.5 Channel-related and extended diagnostic data 3-17................

3.3.6 Event codes of connected equipment 3-17.......................

3.4 Diagnostics via controller or DP master 3-18.............................

3.4.1 Diagnostics for DP masters, general 3-18........................

3.4.2 Diagnostics with Siemens SIMATIC S7 3-18.......................

3.5 Online diagnostics with STEP 7 3-20....................................

3.5.1 Read out diagnostic buffer with STEP 7 (up to V 5.5) 3-20...........

3.5.2 Device-specific diagnostics with STEP 7 (up to V 5.5) 3-22...........

4. Error handling 4-1.................................................

4.1 Fault finding and error elimination 4-3.................................

4.1.1 Check installation 4-3.......................................

4.1.2 Check the power supply 4-3..................................

4.1.3 Restart communication between the bus node and the device 4-4...

4.1.4 Check fieldbus communication 4-5.............................

4.1.5 Check PROFIBUS-DP configuration 4-5.........................

4.1.6 Read out diagnostic messages via controller 4-6.................

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

V

Contents and general safety instructions

A. Technical appendix A-1.............................................

A.1 Technical data A-3..................................................

A.2 Access to the bus node via DPV1 A-7..................................

A.2.1 Reading and writing data records A-7..........................

A.2.2 Data records for DP-master controls, general A-10.................

A.3 Operation with the general DP master A-14..............................

A.3.1 Sending parameterisation data A-14............................

A.3.2 Checking the configuration data A-16............................

A.3.3 Transferring input and output data A-17.........................

A.3.4 Reading diagnostic information A-18............................

A.3.5 Implemented functions and service access points (SAP) A-18........

A.3.6 Transmission times at the master A-19...........................

B. Index B-1.........................................................

VI

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Contents and general safety instructions

Intended use

The bus node CTEU-PB documented in this description has

been designed exclusively for use as a station (slave) on the

PROFIBUS-DP fieldbus.

The bus node may only be used as follows:

–asintended

– in original condition, without unauthorised modifications.

Only the conversions or modifications describe d in the

document at i o n supplied with the product are permitt ed.

– in excellent technical condition.

The limit values specified for pressures, temperatures,

electrical data, torques etc. must be complied with.

Observe the regulations of the trade associations, German

T echnical Control Board (TÜV), VDE stipulations or corresponding national laws and regulations.

Range of application and certifications

The product fulfils the requirements of EU directives and is

marked with the CE marking.

Standards and test values which the product complies with

and fulfils can be found in the Technical appendix. The

product-relevant EC directives can be found in the declaration

of conformity.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

Certificates and declarations of conformity for this product

can be found at www.festo.com.

VII

Contents and general safety instructions

Targe t gro up

This description is intended exclusively for technicians

trained in control and automation technology who have

experience in installing, commissioning, programming and

diagnosing programmable lo gic controllers (PLCs) and

participants on the PROFIBUS-DP fieldbus.

Service

Please consult your local Festo Service if you have any technical problems.

Instructions on this description

This description includes specific information about the configuration, parameterisation, commissioning, programming

and diagnostics of the bus node with the PROFIBUS-DP fieldbus protocol.

Information for mounting the bus node on the CAPC-... electrical connection box can be found in the assembly instructions supplied with the electrical connection box.

Information about other bus nodes and components of the

CTEU… product family can be found in the product documentation for the respective product.

VIII

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Contents and general safety instructions

Important user instructions

Danger categories

This description includes instructions on the possible dangers

which can occur if the product is used incorrectly. These

instructions are marked with a signal word (Warning, Caution,

etc.), printed on a shaded background and marked

additionally with a pictogram.

A distinction is made between the following danger warnings:

Warning

... means that failure to observe this instruction may result

in serious personal injury or material damage.

Caution

... means that failure to observe this instruction may result

in personal injury or material damage.

Note

... means that failure to observe this instruction may result

in material damage.

In addition, the following pictogram marks passages in the

text which describe activities with electrostatically sensitive

devices:

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

Electrostatically sensitive devices: Incorrect handling may

cause damage to devices.

IX

Contents and general safety instructions

Marking special information

The following pictograms mark passages in the text which

contain special information.

Pictograms

Information:

Recommendations, tips and references to other information

sources.

Accessories:

Specifications on necessary or useful accessories for the

Festo product.

Environment:

Information on the environmentally friendly use of F esto

products.

Text designations

•

Bullet points denote activities that may be carried out in

any sequence.

1. Numerals denote activities that must be carried out in the

sequence specified.

– Arrowheads indicate general lists.

X

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Contents and general safety instructions

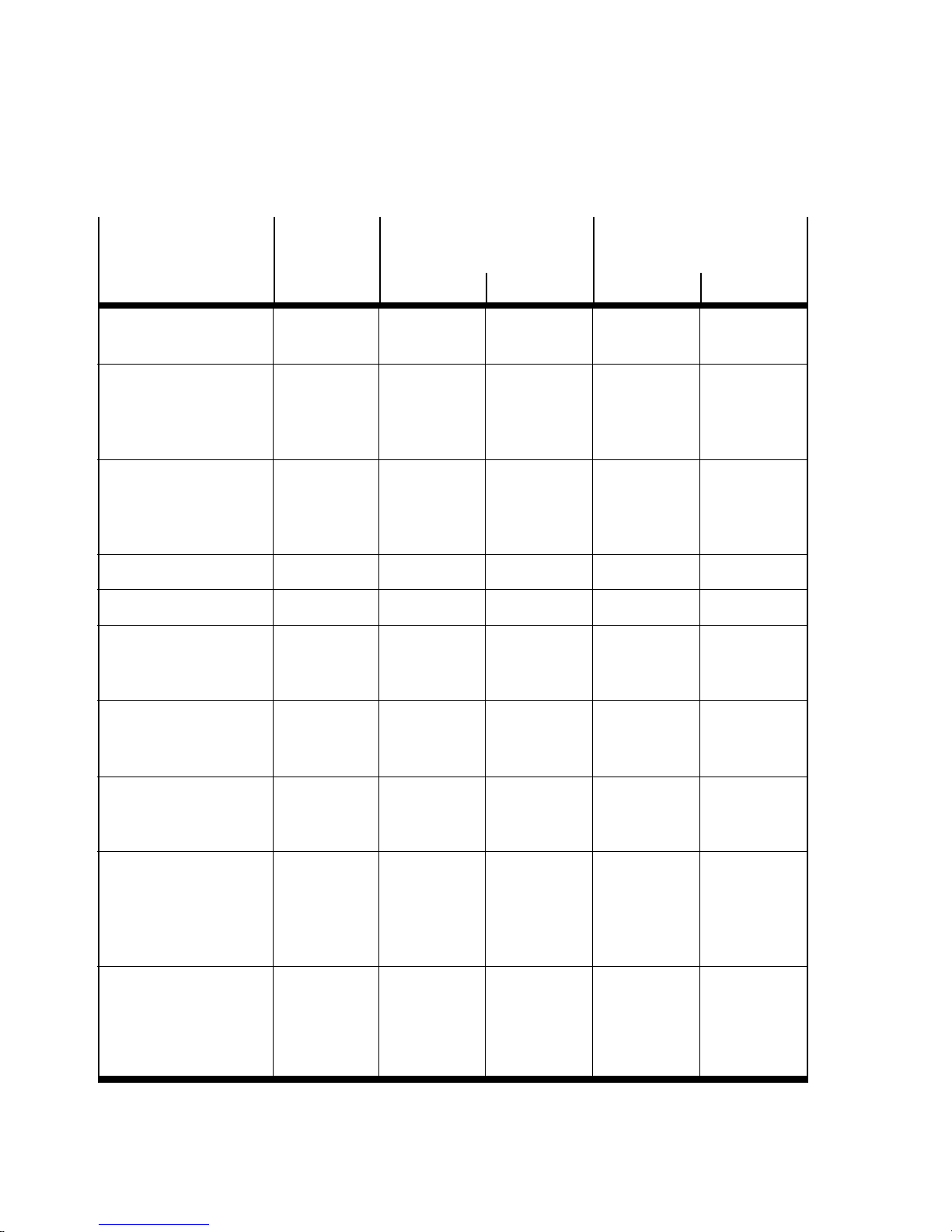

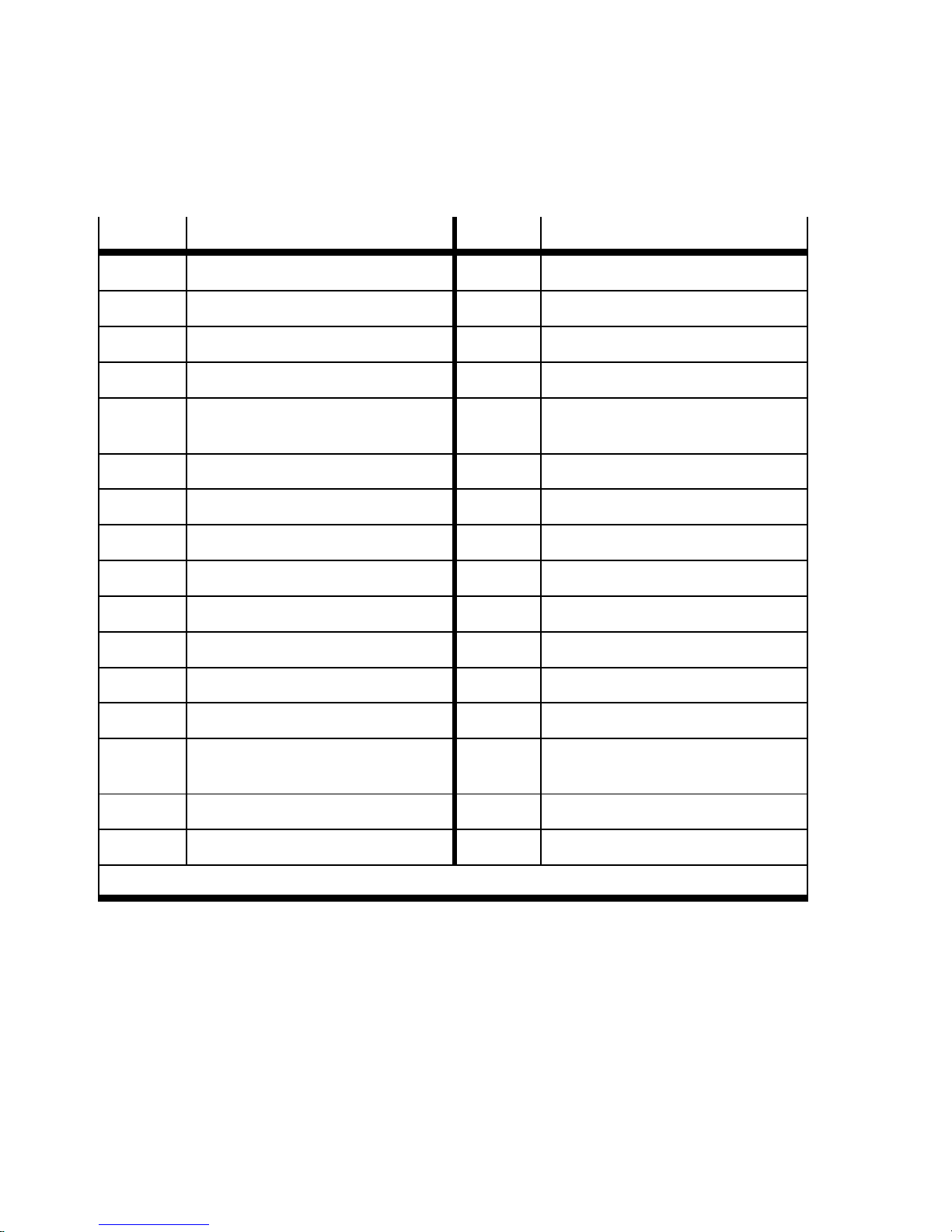

The following product and fieldbus-specific terms and abbreviations are used in this description:

T erm/abbreviation

Bus nodes create the connection to certain fieldbuses/networks, pass on control

CLEAR_DATA This command, sent by the master, resets all outputs of the addressed

DI, DO, DX Digital inputs (DI) or outputs (DO) or digital inputs and outputs (DX)

DIL switches Dual-In-Line switches usually comprise several switch elements that can

DP PROFIBUS protocol for decentralised peripheral equipment, such as

F0

h

Fail state This is a function which can automatically activate the “Hold last state” in

Significance

signals to the connected devices/modules and monitor their functioning.

slave.

be used to make hardware settings.

sensors and actuators, and their cyclical communication functions (data

exchange and diagnostic messages) through DPV0-protocol or acyclic,

need-dependent data exchange and alarm handling through DPV1-protocol.

Hexadecimal numbers are marked by a low-set “h”.

the event of connection errors (program abort or timeout of the fieldbus

connection) and is also designated “fail safe” in some cases.

FREEZE This command, sent by the master, freezes all inputs of the slave. The

GSD General Station Description (or Gerätestammdatei - device master file)

Hold last state defines the status which outputs/valves are to assume after fieldbus

I&M

Load voltage includes the power supply for connected devices and (digital) outputs,

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

slave now sends a constant image of all inputs, independent of their further change in status. The input image is updat ed with each further transmission of the FREEZE command.

A FREEZE command is cancelled with UNFREEZE.

stands for the individual electronic data sheet of the device type. It is

made available by the device manufacturer.

and/or communication errors

stands for ‘Identification and Maintenanc e’ and represents the electronic

name plate of the bus node.

e.g. solenoid coils of valves

XI

Contents and general safety instructions

T erm/abbreviation Significance

Master The master/DP master is an active device that determines the data traffic

in the fieldbus system PROFIBUS-DP and may send messages/commands

without external request if there is a transmission authorisation.

The DP master can be an individual device or part of a programmable logic

controller (PLC).

O, I Digital out put, digital input

OB Output byte

Operating voltage also designated signal voltage : includes the power supply for electronics

and sensors

PLC Programmable Logic Controller (German: Speicherprogrammierbare

Steuerung (SPS))

Power supply Heading term for operating and load voltage supplies

PROFIBUS DP is the PROFIBUS variant for speed-optimised, serial data exchange with

decentralised stations and is performed cyclically with the protocol DPV0.

Slave The slave/DP slave is a passive peripheral device that receives messages/

commands of the master, implements and acknowledges them or responds with a message on request of a master.

Station address Address of the fieldbus station, also designated PROFIBUS address or

station number

Status bits Internal inputs, which supply coded common diagnostic messages

PLC/IPC programmable logic controller/industrial PC, also designated system

controller or controller (German: SPS)

SYNC A SYNC command ca uses all slaves addressed by the master to freeze

their own output data and buffer the data transferre d from the master,

which will be switched through to the physical outputs at the next SYNC

command.

A SYNC command is cancelled with UNSYNC.

Tab. 0/1: Terms and abbreviations

XII

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Installation

Chapter 1

Installation

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

1-1

1. Installation

Ta b le o f c o n t e n t s

1. Installation 1-1...................................................

1.1 General instructions on installation 1-3................................

1.2 Mounting 1-5......................................................

1.2.1 Connection and display components 1-6........................

1.3 Power supply 1-7..................................................

1.3.1 Power supply connection 1-7.................................

1.4 Setting the DIL switches 1-9..........................................

1.4.1 Removal and mounting of the DIL switch cover 1-9................

1.4.2 Setting the DIL switches 1-10..................................

1.5 Connecting the fieldbus 1-13..........................................

1.5.1 Fieldbus cable 1-13..........................................

1.5.2 Cable specifications 1-13......................................

1.5.3 Fieldbus baud rate and fieldbus length 1-14......................

1.5.4 Fieldbus interface at the bus node 1-15..........................

1.5.5 Connection technology for fieldbus interface 1-16.................

1.5.6 Bus terminal 1-20............................................

1.5.7 Functional test 1-21..........................................

1-2

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.1 General instructions on installation

Warning

Danger of injury through uncontrolled movements of connected equipment.

Make sure that electrical and pneumatic equipment are in

a de-energised and pressureless status.

Before working on the pneumatics:

•

Switch off the compressed air supply

•

Vent the valve terminal

Before working on the electrical components, e.g. before

installation or maintenance work:

•

Switch off power supply

In this way, you can avoid:

– uncontrolled movements of loose tubing

– accidental and uncontrolled movements of the connec-

ted actuators

– undefined switching states of the electronics

Caution

The bus node includes electrostatically sensitive devices.

•

Do not touch any electronic components.

•

Observe the handling specifications for electrostatically

sensitive devices.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

They will help you avoid damage to the electronics.

1-3

1. Installation

Note

Use protective caps or blanking plugs to seal unused connections. You will then achieve protection class IP65.

1-4

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.2 Mounting

The bus node can be directly mounted on appropriate equipment (e.g. valve terminals with I-Port connection) from Festo

or decentralised on the electrical connection box.

Note

Information on mounting the bus node on the decentralised electrical connection box type CAPC-... can be found

in the assembly instructions that accompany the connection box.

Mo unting on valve terminal For mounting the bus node, a valve terminal from Festo with

I-port connection is required.

Proceed as follows:

1. Inspect the seals and sealing surfaces on bus node and

valve terminal.

2. Plug the bus node onto the valve terminal in the right

position and without tilting.

3. First, lightly screw in the three self-tapping screws with a

Torx screwdriver (size T10). Use existing threads, if available.

4. Tighten the screws with 1.0 Nm.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

1-5

1. Installation

1.2.1 Connection and display components

The following electrical connection and display components

can be found on the bus node (see Fig. 1/1):

4

1

2

3

1

Power supply connection for bus node

and connected devices, if applicable

(e.g. valve terminal)

2

Fieldbus connection (D-sub plug)

Fig. 1/1: Connection and display components on the bus node

3

DIL switch group 1 and 2

4

Status LEDs (status display/diagnostics chap. 3.2)

1-6

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.3 Power supply

The bus node has separate operating and load voltage

supplies. The bus node also supplies voltage to equipment

connected via the I-port interface.

Warning

•

For the electrical power supply, use only PELV circuits in

accordance with IEC/EN 60204-1 (Protective Extra-Low

Voltage, PELV).

Also take into account the general requirements for PELV

circuits in accordance with IEC/EN 60204-1.

•

Only use power sources which guarantee reliable electrical isolation of the operating voltage in accordance

with IEC/EN 60204-1.

Through the use of PELV circuits, protection from electric

shock (protection from direct and indirect contact) in accordance with IEC/EN 60204-1 is ensured (Electrical equipment of

machines. General requirements).

1.3.1 Power supply connection

Interface specifications The bus node is equipped with a power supply connection in

accordance with IEC 61076-2-101:

– Round plug connector M12

– Plug (male)

–Acoded

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

–5-pin

1-7

1. Installation

M12 connection, A-coded Pin Allocation Function

3

1 24 V

2

2 24 V

5

3 0V

4 0V

4

1

5 FU

EL/SEN

VAL/OUT

EL/SEN

VAL/OUT

1)

(PS) Operating voltage supply

(PL) Load voltage supply

(PS) Operating voltage supply

(PL) Load voltage supply

Functional earth

1) The connection to functional earth must also be ensured via the connected device or electrical

connection box CAPC-....

Tab. 1/1: Pin allocation of the power supply

For the connection to power supply units or the power supply,

use cables with M12 coupling (socket plug connector),

A-coded, in accordance with IEC 61076-2

( Accessories www.festo.com/catalogue).

1-8

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.4 Setting the DIL switches

Parameters With the DIL switches, you set the following parameters for

the bus node (incl./excl. connected equipment):

–Operatingmode

– PROFIBUS station address

–Diagnosticsmode

1.4.1 Removal and mounting of the DIL switch cover

T o set the bus node, the cover of the DIL switches must be

removed.

Caution

The bus node includes electrostatically sensitive devices.

•

Do not touch any electronic components.

•

Observe the handling specifications for electrostatically

sensitive devices.

They will help you avoid damage to the electronics.

Proceed as follows:

Dismounting 1. Switch off the power supply.

2. Unscrew the two mounting screws of the transparent cover.

3. Lift off the cover.

Mounting 1. Place the cover carefully on the bus node.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

Note

•

Make sure that the seal is seated correctly!

2. Tighten the two mounting screws at first hand-tight and

then with a max. torque of 0.4 Nm.

1-9

1. Installation

1.4.2 Setting the DIL switches

Proceed as follows:

1. Switch off the power supply.

2. Remove the DIL switch cover (chap. 1.4.1).

3. Assign a still unused station address to the bus node.

4. Activate/deactivate the diagnostics mode.

5. Set the Fail state characteristics.

6. Mount the DIL switch cover (chap. 1.4.1).

1

DIL switches

1…7:stationaddress

2

DIL switches

8 … 10: reserved

(standard setting:

OFF)

3

DILswitch11:

diagnostics mode

4

DILswitch12:

Fail state mode

Fig. 1/2: DIL switch groups in the bus node

1

23 4

1-10

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

Setting the station address with DIL switches

Set the station address of the bus node binary coded using

1

the switch elements 1 … 7 (Fig. 1/2, item

switch. The following station addresses are permissible:

)oftheDIL

Protocol

Address designation Permissible

station addresses

PROFIBUS DP PROFIBUS station

address

1 ... 125

Note

– Station addresses may only be assigned once per high-

er-level master.

– Assign the station addresses in ascending order.

– Assign the station addresses to suit the machine struc-

ture of your system.

Station address examples

Station address “5”

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

DIL switch setting

at the bus node

ON OFF ON OFF OFF OFF OFF

Binary notation 2

Binary number 1 0 1 0 0 0 0

Decimal number 1 0 4 0 0 0 0

0

20+22=1+4=5

1

2

2

2

3

2

4

2

5

2

Fig. 1/3: Station address coding, example 1

6

2

1-11

1. Installation

Station address “38”

DIL switch setting

at the bus node

OFF ON ON OFF OFF ON OFF

Binary notation 2

Binary number 0 1 1 0 0 1 0

Decimal number 0 2 4 0 0 32 0

0

21+22+25=2+4+32=38

1

2

2

2

3

2

4

2

5

2

6

2

Fig. 1/4: Station address coding, example 2

Reserved DIL switches

2

Leave the DIL switches 8 … 10 (Fig. 1/2, item

)onOFF

(standard setting) so that no undesired actions are triggered

in the case of a later extension of function.

Setting the diagnostics mode with DIL switches

You set the device-related diagnostics of the PROFIBUS-DP

with the switch element 11 (Fig. 1/2, item

3

)oftheDIL

switch groups.

If the device-specific diagnostics are activated (ON), devicespecific diagnostic information of the bus node will be sent to

the higher-order master, e.g. short circuit of the outputs or

undervoltage of the valves.

1-12

Setting the Fail state mode with DIL switches

You set the Fail state behaviour of the bus node with the

switch element 12 (Fig. 1/2, item

4

) of the DIL switch

groups. Constellations of Fail state behaviour can be found in

chap. 2.8.

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.5 Connecting the fieldbus

1.5.1 Fieldbus cable

Note

Faulty installation and high transmission rates may cause

data transmission errors as a result of signal reflections

and attenuations.

•

Always use a bus terminal on both ends of the fieldbus

segment (see chap. 1.5.6)

•

•

•

Note

If the bus node is installed on a movable mounting in a

machine, the fieldbus cable must be provided with strain

relief on the moving part of the machine. Also observe the

corresponding regulations in EN 60204 Part 1.

1.5.2 Cable specifications

Connect the screening continuously to all fieldbus cables

and earth the screening onl y once to avoid ground

loops.

Observe the specifications in the product documentation

of your control system regarding cable type, usable

T-adapters and max. length of branch lines.

In calculating the max. permissible length of the fieldbus

cable dependent on the baud rate used, also consider

the sum of the length of the branch lines.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

For fieldbus communication, use a twisted, screened two-wire

cable in accordance with the PROFIBUS specification

(EN 50170, cable type A):

1-13

1. Installation

Surge impedance: 135 ... 165 ohms (3 ... 20 MHz)

Capacity per unit length: < 30 nF/km

Loop resistance: < 110 ohms/km

Wire diameter: > 0.64 mm

Wire cross section: › 0.34 mm

2

Fieldbus segment length Precise specifications on the fieldbus segment length can be

found in chap. 1.5.3 and in the product documentation of

your control system.

1.5.3 Fieldbus baud rate and fieldbus length

Note

The maximum permissible fieldbus segment lengths (cable

length without repeater) are dependent on the baud rate

used.

•

Observe the maximum permissible segment length if

you connect the bus node to a fieldbus segment.

•

Avoid branch lines.

The baud rate is specified by the master. It limits the usable

cable lengths (see Tab. 1/2).

Cable length (approximate values) dependent on the data rate (baud rate)

Baud rate

9.6 kBaud Max. 1200 m Max. 500 m

19.2 kBaud Max. 1200 m Max. 500 m

93.75 kBaud Max. 1200 m Max. 100 m

1)

Segment length

2)

Branch line length3)(total)

187.5 kBaud Max. 1000 m Max. 33.3 m

500 kBaud Max. 400 m Max. 20 m

1-14

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

Cable length (approximate values) dependent on the data rate (baud rate)

Baud rate

1.5 MBaud Max. 200 m Max. 6.6 m

3…12MBaud Max. 100 m –

1)

The baud rates named here are approximate values and are not supported by all masters.

2)

Trunk line

3)

Drop line

1)

2)

Branch line length3)(total)Segment length

Tab. 1/2: Maximum cable lengths (approximate values)

1.5.4 Fieldbus interface at the bus node

There is a 9-pin sub-D socket on the bus node for connection

to the fieldbus.

This connection is used for the supply line and continuation

of the fieldbus cable. Connect the bus node with the fieldbus

plug from Festo type FBS-SUB-9-GS-DP-B.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

Note

Before connecting the sub-D plugs of other manufacturers:

•

Replace the two flat screws with bolts

(type UNC 4-40/M3x5) from Festo accessories

( Accessories www.festo.com/catalogue).

1-15

1. Installation

D-sub

socket

1)

Type FBS-SUB-9-GS-DP-B, part no. 532216, IP65

2)

The repeater control signal CNTR-P is a TTL signal.

Pin Fieldbus plug

1)

1

2

3

4

5

6

7

8

9

Housing

from Festo

-

B

-

-

-

A

Clamp strap

Signal

connection

Screening

n.c.

RxD/TxD-P

CNTR-P

DGND

VP

n.c.

RxD/TxD-N

n.c.

Screening

2)

Designation

Connection to functional earth

not connected

Reception/transmitted data P

Repeater control signal

Data reference potential (M5V)

Supply voltage plus (P5V)

not connected

Reception/transmitted data N

not connected

Connection to functional earth

Tab. 1/3: Pin allocation of the fieldbus interface of the bus node

1.5.5 Connection technology for fieldbus interface

2)

Note

Use protective caps or blanking plugs to seal unused connections. You will then achieve protection class IP65.

Connection with fieldbus plugs from Festo

With a fieldbus plug, you connect the bus node conveniently

to the fieldbus without the use of pre-made cable.

Use the fiel dbus plug, type FBS-SUB-9- GS - DP- B from the Fe st o

accesso ri e s ( Accessories www .festo.com/catalogue).

T-TAP function You can disconnect this fieldbus plug from the bus node

without interrupting the fieldbus cable (T-TAP function).

1-16

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

DIL switches With the DIL switch in the fieldbus plug, you can switch the

following:

1

Folding cover

with inspection

window

2

Blanking plug if

connection unused

DIL switch setting

OFF Disabled Enabled

ON Enabled Disabled

Note

The fieldbus plug, type FBS-SUB-9-GS-DP-B, switches the

continuing fieldbus line off if the bus terminal is activated.

Bus terminal Continuation

of the fieldbus line

213

Bus out

Bus in

3

Clamp strap for

screened connection

4

Fieldbus incoming (IN)

5

Switch for bus

terminal and continuing fieldbus

6

Fieldbus continued (OUT)

7

Only capacitively

connected

Fig. 1/5: Fieldbus plug from Festo, type FBS-SUB-9-GS-DP-B

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

AB AB

ON

567

4

1-17

1. Installation

Note

The clamp strap in the fieldbus plug from Festo is connected internally only capacitively with the metal housing of

the Sub-D plug. This is to prevent compensating currents

flowing through the screening of the fieldbus line.

Note

Observe the assembly instructions for the fieldbus plug.

Tighten the two mounting screws with max. torque of

0.4 Nm!

Connection with M12 adapter (reverse key coded)

With the M12 adapter, you connect the bus node conveniently

to the fieldbus with the use of pre-made cable. You can disconnect the M12 adapter from the bus node without interrupting the bus line (T-TAP function).

Connection to the fieldbus is made with a 5-pin M12 plug with

PG 9 fitting. Use the second socket for continuation of the

fieldbus.

Use M12 adapters, type FBA-2-M12-5POL-RK from the Festo

accessories ( Accessories www.festo.com/catalogue).

1-18

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

M12 adapter

Reverse key , B-coded

2

3

4

FBA-2-M12-5POL-RK

1

1

5

2

4

Bus OUT

Bus IN

Pin no.

Bus IN

1. n.c.

2. RxD/TxD-N

3. n.c.

3

4. RxD/TxD-P

5

5. FE

M12 thread:

functional earth FU, screening

Pin no.

Bus OUT

1. VP (P5V)

2. RxD/TxD-N

3. DGND (M5V)

4. RxD/TxD-P

5. FE

M12 thread:

functional earth FU, screening

Plug with bus terminal required if

connection remains unused.

Tab. 1/4: Pin allocation of the M12 adapters for the fieldbus interface

Connection with fibre-optic cables (FOC)

The PROFIB US-DP interface of the bus node corresponds to

the specification EN 50170-2 and supports the control of network components for fibre-optic cables.

Use fibre-optic cables for transmission in environments subject to heavy interference as well as for extending the working

range at high transmission rates.

Examples for fibre-optic cable network components:

– Siemens Optical Link Module (OLM) for PROFIBUS plus

– Siemens Optical Link Plug (OLP) for PROFIBUS (IP 20)

®

– Harting Han-InduNet

media converter IP 65 (optical data

transmission in the DESINA installati on concept)

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

1-19

1. Installation

1.5.6 Bus terminal

Note

Each fieldbus segment must be terminated at the start and

end to minimise data transmission errors due to signal

reflections and attenuations.

•

To terminate, use a bus terminal network on both ends

of the fieldbus segment (see Fig. 1/6).

•

Never use more than two activated bus terminals within

a fieldbus segment.

Pin 6: Supply voltage VP

390 Ω

Reception/transmitted data

RxD/TxD-P

Reception/transmitted data

RxD/TxD-N

Pin5: Data reference potential DGND

Pin 3

Pin 8

120 nH

220 Ω

120 nH

390 Ω

Fig. 1/6: Circuit diagram of a bus terminal network in

accordance with EN 50170

1-20

Recommendation:

Use the fieldbus plugs from Festo for the bus terminal (see

Fig. 1/5). A bus terminal network that can be connected and

disconnected is integrated in the housing of this plug.

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

1. Installation

1.5.7 Functional test

Check the operating status of the bus node using the status

LEDs:

–TheLEDPS is illuminated green when the power supply is

present at both circuits.

–TheLEDsX1 and/or X2 illuminate green when a device is

conne cte d.

Check for error-free communication between bus node and

master using the status LEDs:

–TheLEDBF is not illuminated in the normal operating

status.

See also chap. 2.9.4, Normal operating status.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

1-21

1. Installation

1-22

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Commissioning

Chapter 2

Commissioning

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-1

2. Commissioning

Ta b le o f c o n t e n t s

2. Commissioning 2-1................................................

2.1 General remarks on the fieldbus protocol PROFIBUS-DP 2-4...............

2.1.1 Components 2-4............................................

2.1.2 Data exchange with the PROFIBUS-DP fieldbus protocol 2-5........

2.1.3 Brief overview of the function range 2-5........................

2.1.4 Control commands 2-5......................................

2.2 Preparing the bus node for configuration 2-7............................

2.2.1 Addressing the bus node 2-7.................................

2.2.2 Modules/devices at I-Port connection 1 and 2 2-7................

2.3 Installation on a higher-level controller 2-10.............................

2.3.1 Device master file (GSD) and symbol files 2-10....................

2.4 Configuration by using process data 2-12...............................

2.4.1 Configuration examples 2-12..................................

2.4.2 Configuration of a DP master 2-16..............................

2.4.3 Bus start-up 2-16............................................

2.4.4 Configuration using a DP master from Siemens as an example 2-17...

2.5 Identification and maintenance 2-26....................................

2.5.1 Overview of the I&M data structures 2-26........................

2.5.2 Load identification properties into the bus node using Step 7 2-27....

2.5.3 Check identification properties using Step 7 2-28..................

2.6 Parameterisation (DP) 2-31...........................................

2.6.1 Parameterisationwhen being switched on (start behaviour) 2-32.....

2.6.2 Equipment parameters 2-32...................................

2.6.3 Parameterisation of the bus node 2-33..........................

2.6.4 Bus node parameters too l change 2-34..........................

2.6.5 Application example for the parameterisation 2-37................

2.7 Communication 2-38................................................

2.7.1 Statuses when communication is established 2-38.................

2.7.2 Status transitions 2-38.......................................

2.8 Fail state behaviour 2-40.............................................

2-2

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.9 Switching on 2-42...................................................

2.9.1 Information concerning the switch-on behaviour of the bus node 2-42.

2.9.2 Checklist before switching on 2-43..............................

2.9.3 Switching on the power supply 2-44............................

2.9.4 Normal operating status 2-44..................................

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-3

2. Commissioning

2.1 General remarks on the fieldbus protocol PROFIBUS-DP

The CTEU-… product family enables the creation of a decentralised automation system in a PROFIBUS-DP fieldbus network.

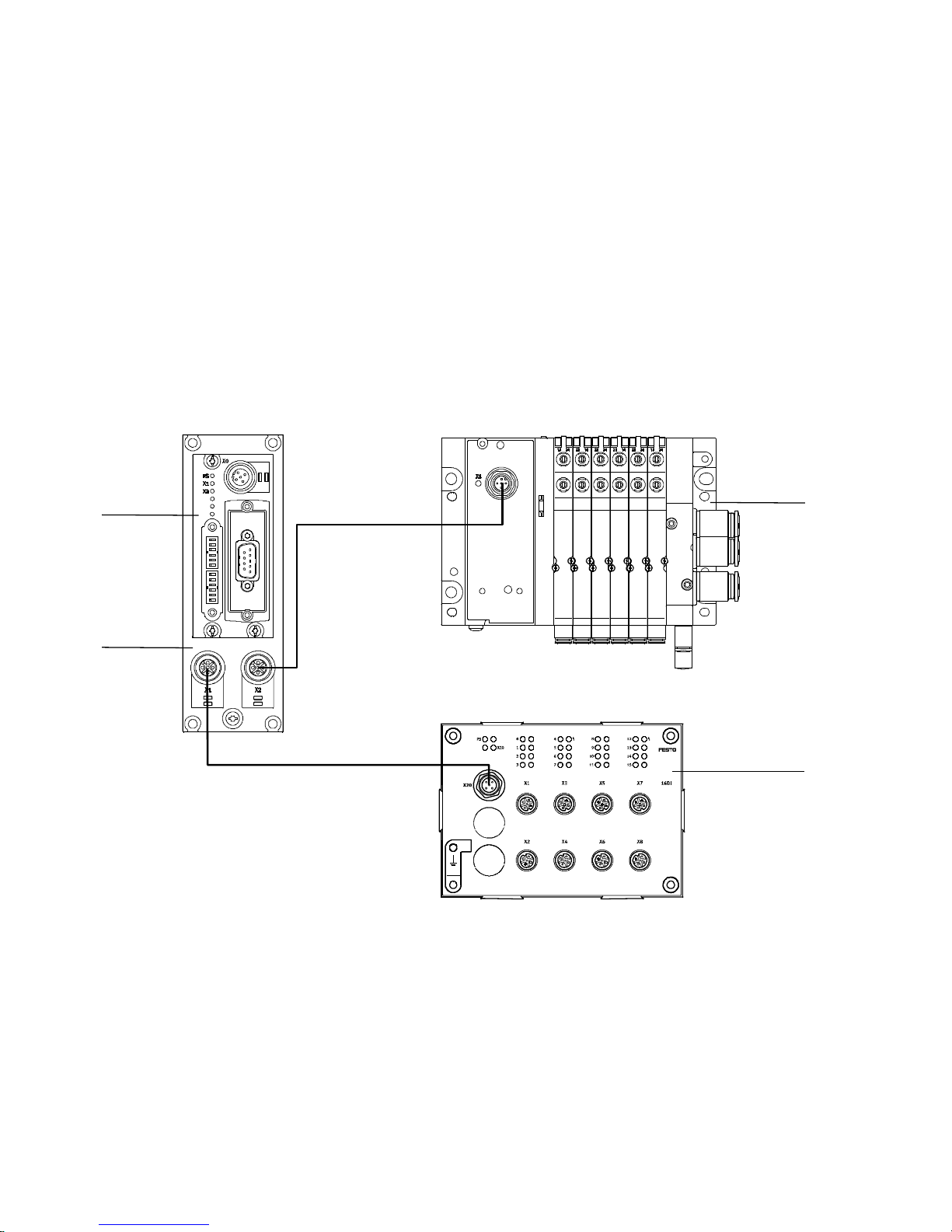

2.1.1 Components

1

Higher-order controller (DP master):

e.g. from

SIEMENS

1

2

Fieldbus level:

bus node CTEU

3

Device level:

e.g. valve terminal VTUB-12

4

Drive level:

e.g. Linear module HME

2

3

4

2-4

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.1.2 Data exchange with the PROFIBUS-DP fieldbus protocol

The fieldbus protocol PROFIBUS-DP uses a communication

profile to regulate how data is exchanged among the fieldbus

stations. Cyclical and acyclic data exchange are differentiated

thereby.

2.1.3 Brief overview of the function range

– General communication and diagnostic messages about

cyclical/synchronous data exchange (DPV0)

– Acyclic/asynchronous data exchange (DPV1)

–Diagnostics

–ProcessData

2.1.4 Control c ommands

The operating modes FRE E ZE, SYNC and CLEAR_DATA are

supported by the bus node in accordance with the PROFIBUS-DP standard.

The method of accessing these commands depends on the

controller used. Corresponding information can be found in

your controller’s documentation.

InformationonDPV1commandscanbefoundinchap.A.2in

Appendix A.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-5

2. Commissioning

Caution

The operating mode FREEZE or SYNC is reset automatically:

– when the bus node is switched on or off

– when the fieldbus interface stops

The operating mode FREEZE is also reset automatically

when:

– the bus connection to the bus node is interrupted (with

activated response monitoring in the controller)

FREEZE command

Set All input signals of the bus node are “frozen”. The bus node

now sends a constant image of all inputs to the master. With

each fur ther FR E E ZE command, the input image is updated

and sent again to the master.

Reset Return to normal operation: UNFREEZE command

SYNC command

Set All output signals of the bus node are “frozen”. The bus node

now no longer reacts to modifications to the output image in

the master. With each further SYNC command, the updated

output image is transmitted.

Reset Return to normal operation: UNSYNC command

CLEAR_DATA command

All output signals of the bus node are reset.

2-6

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.2 Preparing the bus node for configuration

A maximum of three modules can be configured: the bus

node itself as well as up to two connected I-Port devices

(e.g. valve terminals).

2.2.1 Addressing the bus node

The bus node has an address space of up to 16 bytes inputs

and 16 bytes outputs:

Max_Data_Len = 32 (20

)

h

The counting mode is module-oriented for inputs and outputs, starting with the device at I-Port connection 1, followed

bythedeviceatI-Portconnection2

2.2.2 Modules/devices at I-Port connection 1 and 2

Enter the identifiers corresponding to the physical sequence

of the modules in your configuration program, starting with

the device at I-Port connection 1, followed by the device at

I-Port connection 2.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-7

2. Commissioning

Electric modules Module

indicator

Designation EN50170 Siemens Inputs Outputs

Bus node CTEU for

PROFIBUS-DP

Valve terminal

CPV10-GE-PT-8 16

valves with I-Port connection

Valve terminal

CPV14-GE-PT-8 16

valves with I-Port connection

Input module CTSL M12 CTSL M12 0x11 16DI 2bytes/16I 0

Input module CTSL M8 CTSL M8 0x11 16DI 2bytes/16I 0

Valve terminal

VTUG-1-16 valves with

I-Port connection

CTEU-PB 0x00 0 – –

CPV10-8 0x21 16DO 0 2bytes/16O

CPV14-8 0x21 16DO 0 2bytes/16O

VAEM-L1-S8-PT

Identifier Allocated address

1)

0x21 16DO 0 2bytes/16O

space

Valve terminal

VTUG-17-32 valves

with I-Port connection

Valve terminal

VTUG-33-48 valves

with I-Port connection

Valve terminal

VTOC-Interlock /

VTUG-Interlock 1-16

valves with I-Port connection

Valve terminal

VTOC-Interlock /

VTUG-Interlock 17-32

valves with I-Port connection

VAEM-L1-S16-PT

VAEM-L1-S24-PT

VAEM-L2-S_

PTL-16

VAEM-L2-S_

PTL-32

0x23 32DO 0 4bytes/32O

0x25 37 0 6bytes/48O

0x13, 0x21 32DI 16DO 4bytes/

(18 used I)

0x33 32DX 4bytes/

(18 used I)

2 bytes/16 O

4 bytes/32 O

2-8

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

Electric modules Allocated address

Designation OutputsInputsSiemensEN50170

Valve terminal

VTOC-Interlock /

VTUG-Interlock 33-48

valves with I-Port connection

Valve terminal M PA-L

with I-Port connection

with 32 valves

Valve terminal VTUB

with I-Port connection

3-8 valves

Valve terminal VTUB

with I-Port connection

9-16 valves

Valve terminal VTUB

with I-Port connection

17-24 valves

Module

indicator

indicator

VAEM-L2-S_

PTL-48

VMPALEPL-IP032

VTUB-12-8 0x20 8DO 0 1byte/8O

VTUB-12-16 0x21 16DO 0 2 bytes/16 O

VTUB-12-24 0x23 32DO 0 4 bytes/32 O

IdentifierModule

1)

1)

0x13, 0x25 32DI 37 4bytes/(18

0x23 32DO 0 4bytes/32O

space

6bytes/48O

used I)

Valve terminal VTUB

with I-Port connection

24-35 valves

Universal module with

64 inputs and outputs

Universal module with

64 inputs

Universal module with

64 outputs

1)

Module identifier in the hardware configuration of the programming software

VTUB-12-35 0x25 37 0 6bytes/48O

Universal

module

64DIO

Universal

module 64DI

Universal

module

64DO

0x37 55 8bytes/64I 8bytes/64O

0x17 23 8bytes/64I 0

0x27 39 0 8bytes/64O

Tab. 2/1: Module overview and address allocation: bus nodes and examples for digital

input and output modules

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-9

2. Commissioning

2.3 Installation on a higher-level controller

2.3.1 Device master file (GSD) and symbol files

A device master file (GSD) is needed for configuration and

programming of the bus node with a programming unit or PC.

The GSD includes all required information for adjustment of

the bus node using configuration and programming software,

e.g. Siemens SIMATIC STEP 7.

Procurement source Current GSD and symbol files can be found on the Festo web-

site at www.festo .com Support/Downloads Search

“GSD”.

GSD files You will require one of the following files for the bus node:

– FEST0D67.GSD (German version)

– FEST0D67.GSE (International version)

For some older controllers, the GSD file can be too large for

the available memory capacity. In this case, contact Festo's

Technical Hotline.

Contact data can be found on the Festo website at

www.festo.c om Contact.

Symbol files Use the following symbol files to represent the bus node and

its statuses in your configuration software:

Normal operating status

Diagnostic case Special operating

status

2-10

File: CTEU_PB.dib File: CTEU_PBD.dib File: CTEU_PBS.dib

T ab. 2/2: Symbol files for configuration software

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

Publication date Supports

July 2012 Initial version

Tab. 2/3: History of the GSD fil es

Note

GSD files are downward compatible. Always use the latest

GSD file to ensure support of all functions of the bus node.

Installation Install the files by using the configuration software of your

master controller. Please refer to the product documentation

of your software for detailed procedures.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-11

2. Commissioning

2.4 Configuration by using process data

2.4.1 Configuration examples

Example 1: Bus node on adapter CAPC-… with valve

terminal MPA-L and input module CTSL-…

1

2

1

Bus node CTEU-PB

2

Electrical connection box CAPC-...

3

Valve terminal MPA-L with I-Port connection

4

Input module CTSL-…

3

4

Fig. 2/1: Configuration example 1:

Bus node with devices at I-Port connection 1 and 2

2-12

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

Modules Identifier Allocated address

space

Designation

No. Charac-

teristic

Bus node CTEU-PB for

PROFIBUS-DP

Valve terminal M PA-L 1 VMPAL-EPL-

Input module CTSL-… 2 CTSL-D-

1)

Module identifier in the hardware configuration of the programming software

0 CTEU-PB 00

IPO32

16E-M12-5

EN 50170 Siemens Inputs Outputs

1)

h

0x23 32DO 0 4bytes/32O

0x11 16DI 2bytes/16I 0

0 – –

Tab. 2/4: Configuration for example 1

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-13

2. Commissioning

1

2

Example 2: Bus node on adapter CAPC-… with valve

terminal VTUB-12

3

1

Bus node CTEU-PB

2

Electrical connection box CAPC-...

Fig. 2/2: Configuration example 2:

Bus node with device at I-Port connection 2

Modules

Designation

Bus node CTEU for

PROFIBUS-DP

Valve terminal

VTUB-12

1)

Module identifier in the hardware configuration of the programming software

No. Charac-

0 CTEU-PB 00

1 VTUB-12-8 0x20 8DO 0 1byte/8O

Identifier Allocated address

teristic

1)

3

Valve terminal VTUB-12 with I-Port

connection

EN 50170 Siemens Inputs Outputs

h

0 – –

space

Tab. 2/5: Configuration for example 2

2-14

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

1

2

Example 3: Bus node on adapter CAPC-… with valve

terminal CPV

3

1

Bus node CTEU-PB

2

Electrical connection box CAPC-...

Fig. 2/3: Configuration example 3:

Bus node with device at I-Port connection 2

Modules

Designation

Bus node CTEU-PB for

PROFIBUS-DP

valve terminal CPV 1 CPV10-8 0x21 16DO 0 2bytes/16O

1)

Module identifier in the hardware configuration of the programming software

No. Charac-

0 CTEU-PB 00

Identifier Allocated address

teristic

1)

3

Valve terminal CPV with I-Port connection

space

EN 50170 Siemens Inputs Outputs

h

0 – –

Tab. 2/6: Configuration for example 3

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-15

2. Commissioning

2.4.2 Configuration of a DP master

The bus node can be controlled by commercially available

programmable logic controllers (PLC) aw well as PCs and industrial PCs with a PROFIBUS-DP interface in accordance with

EN 50170. The corresponding programming and commissioning software of your PLC manufacturer is required for commissioning.

Configuration of the bus node with a PLC from Siemens is

described in chap. 2.4.4.

2.4.3 Bus start-up

In order to commission the mounted and connected bus

node, the master must carry out the following functions in the

corresponding sequence:

1. Request diagnostic information

2. Send parameterisation data (Set_Prm)

For the start parameterisation, the parameter set is

loaded by the master into the bus node. The bus node

distributes the parameters to the connected equipment.

3. Check configuration data (Chk_Cfg)

4. Transfer input and output data (cyclical data exchange,

Data_Exchange)

5. Read diagnostic information (Slave_Diag)

The structure and contents of the individual telegrams are

described in the appendix.

2-16

Note

After each interruption of fieldbus communication, the

parameter set is resent to the bus node by the master.

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.4.4 Configuration using a DP master from Siemens as an example

The configuration examples shown in this chapter are based

ontheuseofaprogrammablelogiccontroller(PLC)Siemens

SIMATIC S7-300 and the configuration and programming software Siemens Step 7, Version 5.5 + SP2. Operation of the

STEP 7 software is assumed to be known in the following.

Note

These instructions refer to the German language version of

the Siemens SIMATIC controller and STEP 7 configuration

and programming software.

Other language versions usually use other designations for

the program and function calls and menu items mentioned

here.

Preparations

Caution

Danger of malfunctions, damage or injuries to people

•

Before commissioning, ensure that the connected elements (e.g. actuators) do not perform any accidental or

uncontrollable movements.

•

If necessary, disconnect the load voltage supply and

compressed air supply.

See also chap. 2.9.2, Checklist before switching on.

Setting up automation project

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

1. Start the Siemens SIMATIC Manager of your Siemens

SIMATIC controller.

2. Create a new project in the SIMATIC Manager: [File] [New…].

2-17

2. Commissioning

3. Enter a project name (e.g. “CTEU-PB”) in the input field

“Name” of the “New” dialogue window and confirm the

input with “OK”.

The new automation project is now set up.

Setting up the controller system (PLC/Master)

4. Select the newly set-up automation project in the left

part of the dialogue window and click on [Insert] - [Station] to select the hardware type of your controller

(e.g. “SIMATIC 300 Station”).

The selected hardware now appears in the right part of

the dialogue window.

5. Open the automation project by clicking on the Plus

symbol in the left part of the dialogue window.

Equip control system (PLC/DP Master)

6. Click on the Station symbol (which is located to the left

of the station name) and double-click on the Hardware

symbol under “Object name” in the right part of the dialogue window.

The “HW Config” hardware configuration window opens.

7. Open the Hardware Catalogue ( 1 ) via the toolbar .

1

2-18

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

132

4

1

Select control system

2

Insert rack rail

Fig. 2/4: Set up control system (PLC/DP Master) - insert rack rail (Rail)

8. Select your control system (PLC/DP Master) in the Hard-

ware Catalogue (e.g. “SIMATIC 300”, 1 in Fig. 2/4):

Click on the Plus symbol to expand the selection.

9. Open the rack folder (e.g. “RACK-300”, 2 in Fig. 2/4) for

selection of a rack rail.

10. Double click on the rack rail symbol (e.g. “Rail”, 2 in

Fig. 2/4).

A sub-window (with rack rail symbol in the header) opens

in the left area of the HW Config window ( 3 and 4 in

Fig. 2/4).

3

Set up control system in the rack rail

window

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

The sub-window symbolises the rack rail (profile rail) of

your control system. You compile the individual elements

in this sub-window and thus form the basis for your

PROFIBUS automation system.

2-19

2. Commissioning

11. Select your CPU from the Hardware Catalogue (precise

comparison with your hardware required!) and drag the

corresponding element (symbol) into a line of the rack rail

window ( 3 or 4 in Fig. 2/4).

Note: Slot 1 is reserved and cannot be used for the configuration.

The dialogue window “Properties - PROFIBUS interface

DP” opens automatically (see Fig. 2/5).

2-20

Fig. 2/5: Edit the sub-network properties

12. Select the tab “Parameters” or “Network Settings” and

there the station address that you set at the bus node

using DIL switches (see chap. 1.4.2)

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

Set up sub-network

13. Click on “New...” in the “Properties” dialogue windowto

set up a PROFIB US sub-network (see Fig. 2/5).

14. Edit, if necessary, the “Transmission rate” und “Profile”

entries in the “Parameters” tab (see Fig. 2/5).

15. Click on “OK” in the two “Properties” dialogue windows in

succession to complete the setting of the PROFIBUS subnetwork.

Install GSD and symbol files

Install the GSD and symbol files in the next steps: These must

be reachable via your PC. Source and notes for the selection,

see chap. 2.3.1.

1. Start the installation function via the HW Config menu:

[Options] - [Install GSD File ...].

2. Update the hardware catalogue through the menu commands [Options] - [Update Catalog].

The slaves installed through the GSD file are read into the

hardware catalogue.

3. Open in the hardware catalogue the path PROFIBUS-DP >

Additional Field Devices > Valves > Festo AG und Co. KG >

CTEU-PB.

All modules that can be connected to the CTEU-PB bus

node now appear.

Install bus node as slave

1. Mark the line view of the PROFIBUS sub-network in the

main window (2, see Fig. 2/6).

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2. Open in the hardware catalogue the path PROFIBUS-DP >

Additional Field Devices > Valves > Festo AG und Co. KG >

CTEU-PB.

2-21

2. Commissioning

3. Selectthemodule“CTEU-PB”.

The dialogue window “Properties - PROFIBUS interface”

opens automatically (3, see Fig. 2/6).

4. Select the tab “Parameters” and there the station address

that you set at the bus node using DIL switches (see

chap. 1.4.2)

5. Click on “OK” in the “Properties” dialogue window to

complete the setting of the PROFIBUS sub-network.

A graphic symbol of the bus node is linked in the main

window with the line view of the PROFIBUS sub-network

(5, see Fig. 2/6).

2-22

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2

1

5

3

1

Hardware catalogue call

2

Line view of the PROFIBUS sub-network

3

Module selection in the hardware catalogue

Fig. 2/6: Station selection with STEP 7 - HW Config

4

“Properties” dialogue window

5

With the bus node linked to the

PROFIBUS sub-network

4

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-23

2. Commissioning

Configuration of the modular part with STEP 7

Create configuration Fill the configuration table with the device or devices connec-

ted to your bus node (see Fig. 2/7):

1. Click on the symbol of the valve terminal to be configured

in HW Config 1. The configuration table 2 will be displayed under the rack.

2. Open in the hardware catalogue 3 themodule“CTEU-PB”

via the path PROFIBUS-DP > Additional Field Devices > Valves

>FestoAGundCo.KG>CTEU-PB.

3. Pull a bus node into slot 1 of the configuration table.

4. Pull the device connected to I-Port connection 1 into

slot 2 of the configuration table and assign the start address of the inputs or outputs in the “Pro perti es - PR O FIBUS

interface” dialogue window 4.

5. Repeat this step, if necessary , with the second I-Port

device connected to the bus node.

Note

Always pull the device connected to I-Port connection 1 as

a module without gaps into the configuration table first

and only after that do the same with the device connected

to I-Port connection 2.

Modifying the address 1. Double-click on the corresponding line in the configura-

tion table 2.

2. Modify the starting address of the inputs/outputs in the

“Properties - DP Slave” dialogue window 4.

2-24

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

1

Note

SIEMENS S7-400 controllers reserve up to 4 bytes of addresses for each DP identifier, depending on the version

status.

2

4

1

HW Config

2

Configuration table

Fig. 2/7: Configuration with STEP7 – Hardware catalogue

3

Hardware catalogue

4

“Properties – DP-Slave” dialogue

window

3

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

This concludes the station selection and configuration.

2-25

2. Commissioning

2.5 Identification and maintenance

The I&M function (Identification and Maintenance function)

serves as an electronic name plate of the bus node and offers

uniform, non-proprietary access to device-specific online information via the internet.

2.5.1 Overview of the I&M data structures

Address/

Designation, size Description Use

structure,

I&M0 (65000) Device-specific basic informa-

tion

I&M1 (65001) Informationonthesystem

(32 bytes)

Informationonthelocation(22

bytes)

I&M2 (65002) Informationonthetime

(16 bytes)

I&M3 (65003) Additional information

(54 bytes)

I&M4 (65004) Reserved Support through CTEU-PB:

The manufacturer and the

device with its hardware and

software versions is uniquely

identified.

The user can specify system

identifiers here

The user can specify the installation site here

The user can, for example, specify the installation/mounting

date here

Here the user can specify additional information

no

obligatory/

optional

Obligatory in

all DP-V1

slaves

Optional

Optional

Optional

Optional

Optional

I&M5 …

I&M017

(65005 …

65017)

Reserved for futher I&M Functions

2-26

Support through CTEU-PB:

no

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

Optional

2. Commissioning

Address/

structure,

I&M18 …

I&M098

(65018 …

65098)

I&M100 …

I&M199

(65100 …

65199)

Profile-specific I&M functions Support through CTEU-PB: no Optional

Manufacturer-specific I&M

functions

Tab. 2/7: I&M data structures (data records)

– Module-related I&M data are not supported.

– Every data structure always comprises 64 bytes.

– The I&M data structures are read with the “ call service”

from the bus node or written into the device.

DescriptionDesignation, size

Support through CTEU-PB: no Optional

Use

obligatory/

optional

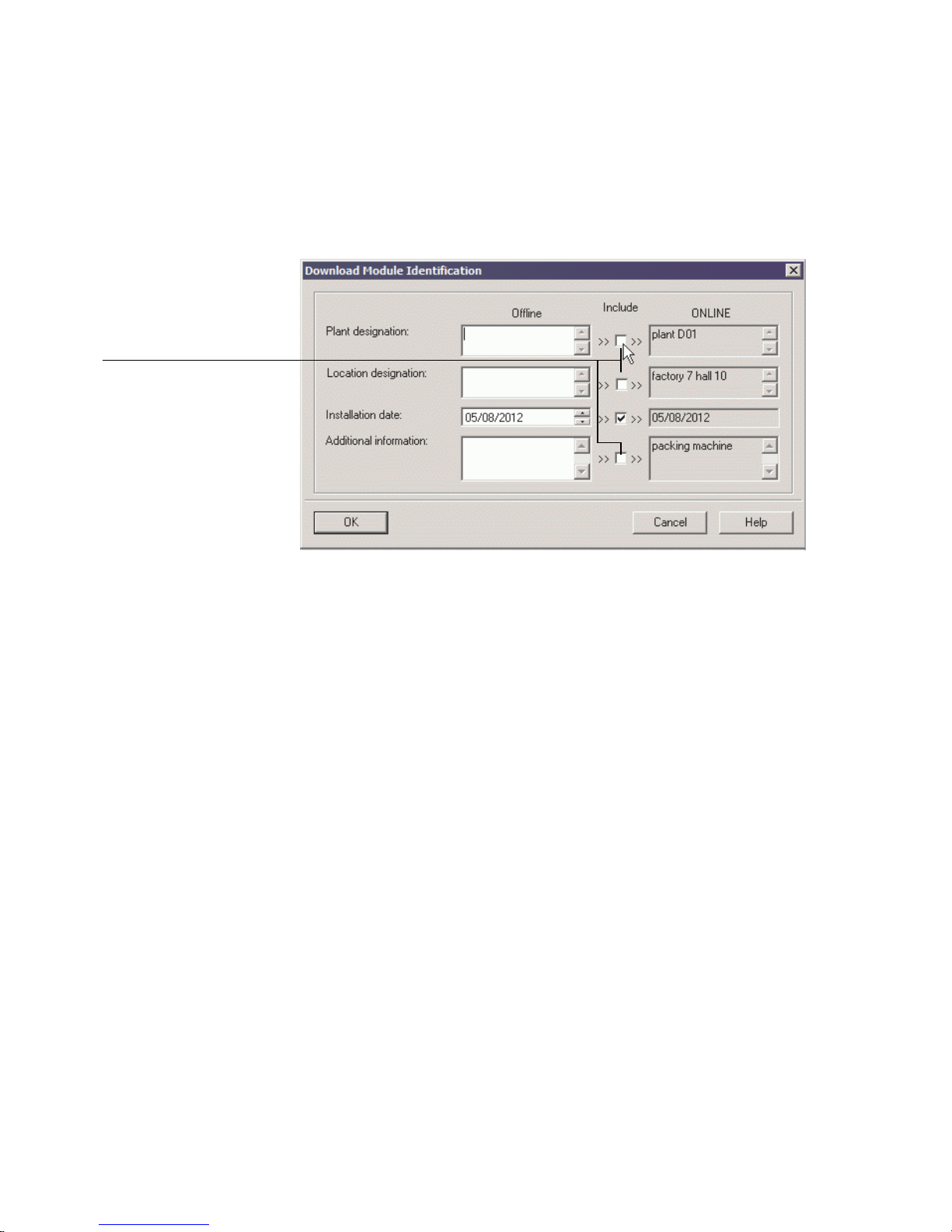

2.5.2 Load identification properties into the bus node using Step 7

1. Mark the bus node in HW Config.

2. Click on [Download Module Identification...] in the [PLC]

menu.

The corresponding dialogue window is displayed (see

Fig. 2/8).

3. Enter your identification properties into the data fields

under “Offline” (example, see Fig. 2/8).

4. Activate the checks under “Include” only for the data

fields for which you wish to load data into the bus node.

Deactivate checks for the already correctly filled-out data

fields in the “ONLINE” field, or they will be overwritten!

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-27

2. Commissioning

1

5. Confirm with “OK”.

1

Deactivate checks so that ONLINE fields that have already been filled out are

not overwritten.

Fig. 2/8: Load identification data into the bus node

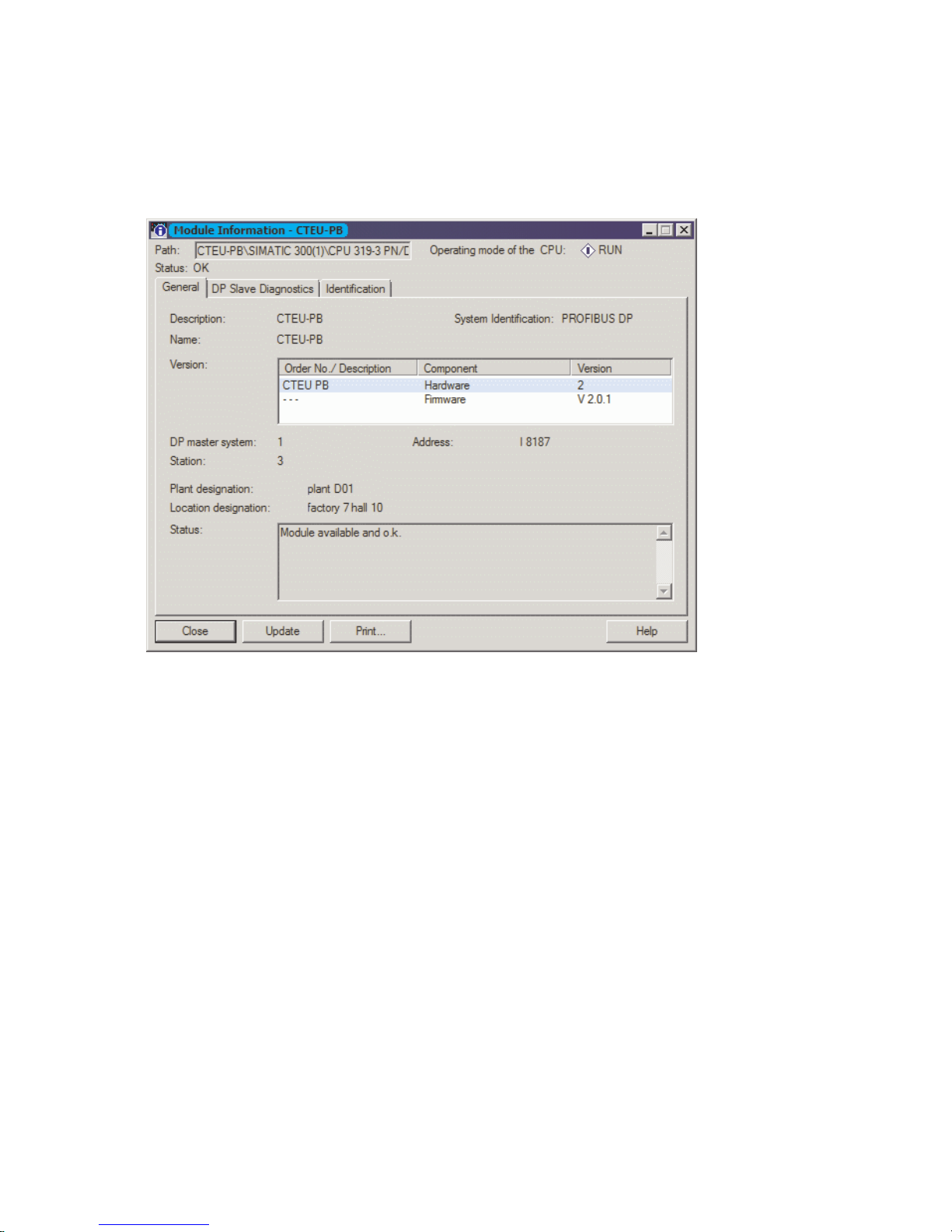

2.5.3 Check identification properties using Step 7

1. Mark the bus node in HW Config.

2. Click on [Module Information...] in the [PLC] menu.

The corresponding dialogue window is displayed

(see Fig. 2/9).

“General” In the “General” tab, you will find the hardware and software/

firmware status of the bus node (see Fig. 2/9) as well as the

specifications entered in the fields “Plant designation” and

“Location designation” (Fig. 2/8).

“DP-Slave Diagnostics” In the “DP-Slave Diagnostics” tab, you will find, if applicable,

diagnostic information about the bus node (see Fig. 2/10,

status: error).

“Identification” In the “Identification” tab, you will find further information,

2-28

such as manufacturer's specifications (see Fig. 2/10) as well

as the specifications entered in the fields “Installation date”

and “Additional information” (Fig. 2/8).

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

Fig. 2/9: Identification data, “General” tab

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-29

2. Commissioning

Fig. 2/10: Identification data, “DP-Slave Diagnostics” and “Identification” tabs

2-30

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.6 Parameterisation (DP)

You can set the characteristics of the bus node individually by

parameterisation. A distinction is made between the following

types of parameters:

Types of parameters

System parameters Fail state Defines the status which digital output sig-

Bus node parameters Tool change See chap. 2.6.4

Equipment parameters Device-specific Influence the characteristics of a specific

Diagnostic memory parameters Influence the operating method of the in-

Parameters Description

nals (outputs and valves) are to assume in

the event of fieldbus communication errors.

module, e.g. monitoring, settings in the case

of error

Channel-specific Influence the behaviour of a specific input or

output channel, e.g. settings of the inputs'

debounce times

ternal diagnostic memory

Tab. 2/8: Types of parameters

Parameter descriptions for I-Port devices can be found in the

product documentation for the respective product if it supports parameterisation.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-31

2. Commissioning

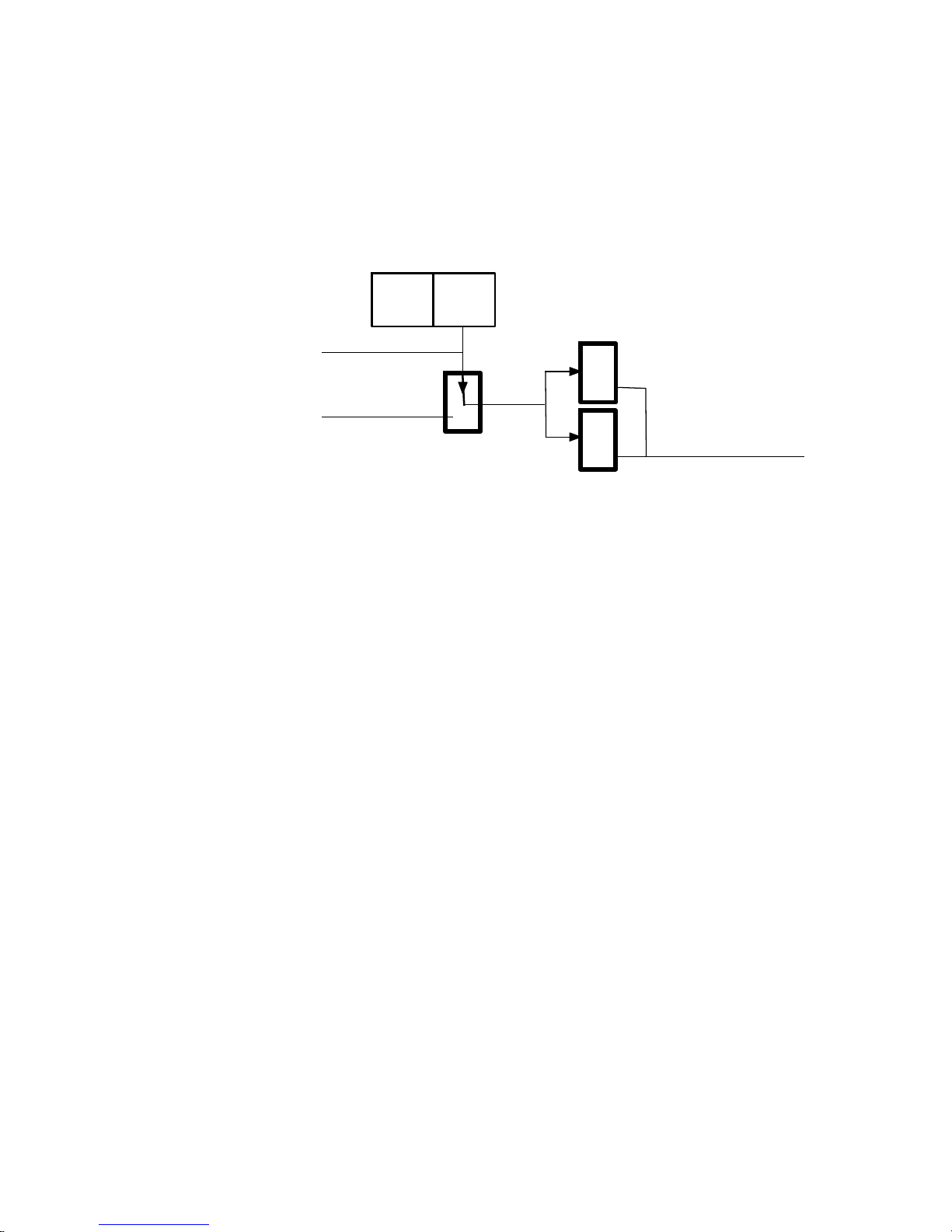

3

2.6.1 Parameterisationwhen being switched on (start behaviour)

1

Master loads

parameter set into the bus node

2

Bus node distributes parameter

set

3

I-Port devices 1

and 2 receive

parameter set

1

2

PLC/

IPC

DP

master

Fig. 2/11: Sequence of the start parameterisation

When the fieldbus system is switched on, the bus node is

parameterised as “Start parameterisation” through the parameter set stored in the DP master. The bus node then distributes the parameters in a module-oriented manner to the connected equipment.

2.6.2 Equipment parameters

Proceed as follows:

1. Double click in the configuration table on the line of the

module which you wish to parameterise 1.

The corresponding dialogue window is displayed (see

Fig. 2/12).

2. Click on the parameter value which you wish to modify.

A list field with the possible values is opened 4.

2-32

3. Modify the value by clicking on and selecting it and confirm the entry with “OK”.

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2

1

1

Connected device

Fig. 2/12: Parameterisation of bus nodes and connected I-Port devices

Note

Module parameters can refer to:

– properties of a complete I-Port device

– properties of an individual channel of an I-Port device.

2

List field with available values

2.6.3 Parameterisation of the bus node

– Diagnostics (DIL swi tch element 11, see chap. 1.4.2)

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

– Fail state (DIL switch element 12, see chap. 1.4.2)

– Tool change mode (software parameters, see chap. 2.6.4)

2-33

2. Commissioning

2.6.4 Bus node parameters tool change

The tool change mode (GSD: “T ool Change Mode”) offers the

option to integrate or replace I-Port devices flexibly. Merely a

universal data range is created, which a device can occupy.

Which equipment is then actually connected is not defined.

As a result, a flexible replacement of different equipment is

possible. In this case, any I-Port devices are recognised

without an error message as long as their real process data

size does not exceed the configured size.

Through a universal module (see Tab. 2/1), a fixed maximum

I/O data length is assigned to each I-Port connection on the

respective module or slot position (Siemens). This ensures

that the right module configuration, i.e. sufficient data length,

is also queried after every switch-on.

In the parameters of the bus node, the tool change mode can

be activated for each I-Port connection individually.

2-34

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

The following cases of the tool change mode can be differentiated:

Case

Connect/remove or link/separate device in ongoing operation

Tool change mode off Tool change mode on

If a device is separated from the

I-Port connection during operation, the “Device disconnected”

diagnosis becomes active.

This error is automatically reset

as soon as the connection to the

device is restored.

If a device is connected to an

I-Port connection during operation, th e bus node issues an error (“Device wrongly connected”).

This error is automatically reset

as soon as the connection to the

device is separated again.

If a device was already found at

the I-Port connection during

switch-on, the “Device disconnected” diagnosis is active as

long as the connection to the

device is/becomes separated

during operation.

This error is automatically reset

(diagnosis “Device reconnected”) as soon as the connection

to the device is restored.

A fixed address space is reserved in the image table for

both I-Port devices. As soon as a

device is detected at one of the

I-Port connections, its I/O data

are mapped into the image

table.

Diagnostic messages are not

generated when there is no connection to the device nor in case

of configuration errors (e.g. I/O

length of the device is larger

than I/O length of the tool

change mode).

If a device is connected to an

I-Port connection during operation, the device is recognised

but no error message is generated.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-35

2. Commissioning

Case Tool change mode onTool change mode off

Switching on without a connected I-Port device and subsequent connection.

The I-Port connection is not

configured at the DP master

The I-port connection is deactivated und cannot be used.

If no device is connected to the

relevant I-Port connection at

switch-on, no I/O data are

mapped into the image table. As

a result, the “Device configuration failed” diagnosis is output.

The second I-Port connection

then is/becomes inactive as well

and can no longer be used.

This error can only be eliminated

by adjusting the configuration or

connecting an I-Port device to

the bus node and restarting the

system.

Ifadeviceisrecognisedatthe

I-Port connection when the system is switched on, the diagnosis “Device wrongly connected” is

reported. The second I-Port connectionistheninactiveaswell

and can no longer be used.

This error can only be eliminated

by adjusting the configuration or

connecting an I-Port device to

the bus node and restarting the

system.

A fixed address space is reserved in the image table for

each I-Port device. As soon as a

device is detected at an I-Port

connection, its I/O data are

mapped into the image table.

The “Device disconnected” diagnosis is active as long as the

connection to the device is separated during operation. This error is automatically reset as

soon as the connection to the

device is restored.

If a device is detected at this unconfigured I-Port connection, the

second I-Port connection remains active and effective.

2-36

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

2.6.5 Application example for the parameterisation

In the application example (Fig. 2/13), packages are transported on a fast-moving conveyor belt.

1

Input for 1st

sensor

2

Parameterised input for 2nd

sensor

1

2

1st sensor

2nd sensor

Fig. 2/13: Application example for parameterisation of input debounce time and signal

extension time on the 2nd sensor

For improvement of the signal detection and processing, the

input for the 2nd sensor is parameterised as follows:

– Reduction of the input debounce time from 3 ms (factory

setting) to 0.1 ms: detection of shorter signals is possible.

This parameter is set for the total module.

– Signal extension time set for 50 ms: Secure detection of

the signals through the controller.

The value of this parameter is set for the complete module, but must be activated / deactivated separately for

each input channel.

Festo P.BE-CTE U-PB-OP+MAI NT-E N en 1208NH English

2-37

2. Commissioning

2.7 Communication

After the fieldbus stations are switched on, they all assume

the “waitParam” status and wait for instructions from the

higher-level DP master.

2.7.1 Statuses when communication is established

waitParam In this status, the bus node waits for parameters of the DP

master.

waitConfig In this status, the bus node waits for the set configuration of

the DP master.

DataEx In this status, the bus node is exchanging data (DataEx-

change) with the DP master. User data and diagnostic information can be transmitted thereby.

2.7.2 Status transitions

Power On

4

Application initialization (init)

0

0

3

Waiting for parameters (waitParam)

1

Waiting for configuration (waitConfig)

2

Data exchange (DataEx)

Fig. 2/14: Status transitions (for description see Tab. 2/9)

2-38

Festo P.BE-CTEU-PB-OP+MAINT-EN en 1208NH English

2. Commissioning

0

Description of the status transitions

Status Designation Function

0

1 Check Param OK Checking of the parameters was successful.

2 Check Config OK Checking of the configuration was successful (comparison of the con-

3 Reset communica-

4 Hardware reset After the bus node isrestarted, initialization of the bus node is started

– Initialisation was successful.

figuration set at the DP master with the actually existing configuration

in the bus node).