CPX terminal

Manual

Electronics

CPX bus node

Type CPX-M-FB20

and CPX-M-FB21

Fieldbus protocol:

Interbus “Rugged

Line” fibre optic

cable remote bus

Manual

575 108

en 1202a

[8002868]

Contents and general safety instructions

Original de.......................................

Edition en 1202a..................................

Designation P.BE-CPX-FB20/21-EN....................

Order no. 575 108.................................

E (Festo AG & Co. KG, D-73726 Esslingen, 2012)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

The reproduction, distribution and utilization of this document

as well as the comunication of its contents to others without

express authorization is prohibited. Offenders will be held

liable for the payment of damages. All rights reserved in the

event of the grant of a patent, utility module or design.

Festo P.BE-CPX-FB20/21-EN en 1202a

I

Contents and general safety instructions

INTER BUS®, RUGGED LINE®,TORX®and VDE®are

registered trademarks of the respective trademark owners in

certain countries.

II

Festo P.BE-CPX-FB20/21-E N en 1202a

Contents and general safety instructions

Contents

Intended use III..........................................................

Target group III..........................................................

Service III...............................................................

Notesonthismanual IV...................................................

Important user instructions VI..............................................

1. Installation 1-1...................................................

1.1 Fibre optic cable (FOC) connection 1-3.................................

1.2 General instructions on installation 1-4................................

1.3 Settings of the DIL switches on the bus node 1-7.........................

1.4 Connecting the fieldbus 1-12..........................................

1.4.1 System structure on the remote bus 1-12........................

1.4.2 Fieldbus interface assignment 1-14.............................

1.4.3 Connecting the fibre optic cable 1-16............................

1.4.4 Fieldbus baud rate and fieldbus length 1-22......................

1.5 Pin assignment of power supply 1-23...................................

1.5.1 Connecting the power supply US1/US2 1-25......................

1.5.2 Sealing unused connections in the Rugged Line plug 1-28..........

2. Commissioning 2-1................................................

2.1 Configuration and addressing 2-3.....................................

2.1.1 Ascertaining the address range 2-3............................

2.1.2 Address assignment of the CPX terminal 2-8.....................

2.1.3 Address assignment after extension/conversion 2-16..............

2.1.4 Bus configuration and addressing 2-19..........................

2.1.5 Switching on the power supply 2-20............................

2.1.6 Bus configuration with the CMD software 2-21....................

2.1.7 Bus configuration without CMD software 2-29....................

2.1.8 Process data entry via the CMD software 2-30....................

2.2 Parameterisation 2-34...............................................

2.2.1 Parameterisation concepts 2-36................................

2.3 Commissioning the CPX terminal on the Interbus 2-38.....................

Festo P.BE-CPX-FB20/21-EN en 1202a

III

Contents and general safety instructions

2.3.1 Fail safe 2-39...............................................

3. Diagnostics and error handling 3-1...................................

3.1 Summary of diagnostics options 3-3...................................

3.2 Diagnostics via LEDs 3-4............................................

3.2.1 Normal operating status 3-6..................................

3.2.2 CPX-specific LEDs 3-7.......................................

3.2.3 Interbus-specific LEDs 3-10....................................

3.3 Diagnosis via Interbus 3-13...........................................

3.3.1 Diagnostics mode 2 … 4 (system diagnostics) 3-13.................

3.3.2 Peripheral fault (PF) 3-21......................................

3.4 Error handling 3-22..................................................

4. Technical appendix A-1.............................................

A.1 Technical data for fieldbus node type CPX-M-FB20/CPX-M-FB21 A-3.........

A.2 Phoenix Contact accessories A-6......................................

A.3 Accessories A-7....................................................

5. Index B-1.........................................................

IV

Festo P.BE-CPX-FB20/21-E N en 1202a

Contents and general safety instructions

Intended use

The CPX-M-FB20 or FB21 bus node documented in this description is intended exclusively for use as a participant on

the Interbus.

The CPX terminal must only be used as follows:

– As specified in industrial applications.

– In an original condition, without any modifications by the

user. Only the conversions or modifications described in

the documentati o n supplied with the product are permitted.

Target group

– In perfect technical condition.

The limit values specified for pressures, temperatures, electrical data, torques etc. should be observed.

If conventional accessory components such as sensors and

actuators are connected, the specified limits for pressures,

temperatures, electrical data, torques etc. should be observed.

Comply with the legal rules and regulations and standards,

rules of the testing organisations and insurance companies

and national specifications applicable for the location.

This manual is intended exclusively for technicians trained in

control and automation technology who have experience in

installing, commissioning, programming and diagnosing programmable logic controllers (PLC) and the Interbus fieldbus

system.

Service

Festo P.BE-CPX-FB20/21-EN en 1202a

Please consult your local Festo Service if you have any technical problems.

V

Contents and general safety instructions

Notesonthismanual

This manual includes information about the following

modules:

CPX bus node

Type

Description Connection technology

designation

CPX-M-FB20 CPX bus node for INTERBUS

with fibre optic cable (FOC)

CPX-M-FB21 2 Rugged Line sockets:

Tab. 0/1: Overview of CPX bus node for INTERBUS FOC

1 Rugged Line socket:

– 1 x fieldbus, incoming

– 1 x fieldbus, incoming

– 1 x fieldbus, continuing

VI

Festo P.BE-CPX-FB20/21-E N en 1202a

Contents and general safety instructions

This manual includes information about installation and

configuration of the CPX bus node for INTERBUS with fibre

optic cable (FOC) as well as INTERBUS-specific information

regarding parameterisation, commissioning, programming

and diagnosis of a CPX terminal in an INTERBUS network.

General basic information about the method of operation,

fitting, installation and commissioning of CPX terminals can

be found in the CPX system manual.

Information about further CPX modules can be found in the

manual for the respective module.

An overview of the structure of the CPX terminal user documentation is contained in the CPX system manual.

Product specific information about the control system can

be found in the manufacturer's product documentation

accompanying the product.

Festo P.BE-CPX-FB20/21-EN en 1202a

VII

Contents and general safety instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which can occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc), printed on a

shaded background and marked additionally with a pictogram.

A distinction is made between the following danger warnings:

Warning

... means that failure to observe this instruction may result

in serious personal injury or damage to property .

Caution

... means that failure to observe this instruction may result

in personal injury or damage to property.

Note

... means that failure to observe this instruction may result

in damage to property.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive devices:

VIII

Electrostatic sensitive devices: inappropriate handling can

result in damage to components.

Festo P.BE-CPX-FB20/21-E N en 1202a

Contents and general safety instructions

Identification of specific information

The following pictograms designate texts that contain special

information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Information about necessary or useful accessories for the

Festo product.

Antipollution:

Information about the environmentally-friendly use of Festo

products.

Text designations

•

Bullet points indicate activities that may be carried out in

any order.

1. Numerals denote activities which must be carried out in

the numerical order specified.

– Arrowheads indicate general lists.

Festo P.BE-CPX-FB20/21-EN en 1202a

IX

Contents and general safety instructions

The following product-specific terms and abbreviations are

used in this manual:

T erm/abbreviation

CPX bus Data bus via which the CPX modules communicate with each other and

CPX modules Collective term for the various modules which can be integrated in a CPX

CPX terminal Modular electric terminal type 50

DIL switch Dual-in-line switches consist of several logic elements with which settings

Bus nodes Create the connection to certain networks or fieldbuses, conduct control

Handheld (MMI) Handheld terminal (handheld, CPX-MMI) for CPX modules for

I Digital input

I/O modules Collective term for the CPX modules which provide digital inputs and

I/Os Digital inputs and outputs

Meaning

are supplied with the necessary operating voltage.

terminal.

can be made.

signals to the connected modules and monitor their functioning.

commissioning and service purposes (Man-Machine Interface, MMI).

outputs (CPX input modules and CPX output modules).

O Digital output

PLC/IPC Programmable logic controller/industrial PC

Pneumatic interface The pneumatic interface is the interface between the modular elec trical

peripherals and the pneumatics.

VTSA… Pneumatic modules/valve terminal type 44/45

Tab. 0/2: CPX-specific terms and abbreviations

X

Festo P.BE-CPX-FB20/21-E N en 1202a

Contents and general safety instructions

The following Interbus-specific terms and abbreviations are

used in this manual:

T erm/abbreviation

CMD software Parameterisation, commissioning and diagnostic software for slaves on

FOC Fibre-optic cables

Ident. code By means of the Ident code (in brief: ID code), the module ascertains the

Module ThemoduleisthecentraldeviceforcheckingtheInterbusdataring.

Peripheral fault (PF) Faults in the peripherals of Interbus slaves are shown by means of

Process data I/O data from the Interbus slaves transmitted cyclically via the Interbus,

Meaning

the Interbus (configuration, monitoring, diagnosis).

type and the process data length of all the slaves.

It exchanges the data transported serially in the data ring with the

higher-order controller or computer system and the lower-order Interbus

slaves in both directions acyclically or cyclically .

peripheral faults ( dependent on slave), e.g.

– load voltage failure

– short circuit at the outputs, etc.

The peripheral fault is a common fault message which does not contain

any module-specific information.

e.g. for:

– light barriers, sensors

– valves, fuses

– diagnostic I/Os

Remote bus The remote bus bridges long distances within an Interbus system

Tab. 0/3: Interbus-specific terms and abbreviations

Festo P.BE-CPX-FB20/21-EN en 1202a

(main string). With baud rates of 500 kBd and 2 MBd it can be up to

12.8 km long (from the module to the last connected remote bus slave).

Individual segments can be up to 400 m long.

XI

Contents and general safety instructions

XII

Festo P.BE-CPX-FB20/21-E N en 1202a

Installation

Chapter 1

Installation

Festo P.BE-CPX-FB20/21-EN en 1202a

1-1

1. Installation

Contents

1. Installation 1-1...................................................

1.1 Fibre optic cable (FOC) connection 1-2.................................

1.2 General instructions on installation 1-3................................

1.3 Settings of the DIL switches on the bus node 1-6.........................

1.4 Connecting the fieldbus 1-11..........................................

1.4.1 System structure on the remote bus 1-11........................

1.4.2 Fieldbus interface assignment 1-13.............................

1.4.3 Connecting the fibre optic cable 1-15............................

1.4.4 Fieldbus baud rate and fieldbus length 1-21......................

1.5 Pin assignment of power supply 1-22...................................

1.5.1 Connecting the power supply US1/US2 1-24......................

1.5.2 Sealing unused connections in the Rugged Line plug 1-27..........

1-2

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

1.1 Fibre optic cable (FOC) c onnection

We recommend fibre optic cable technology for transmission

in environments subjected to heavy interference, as well as

for extending the range when high transmission speeds are

used.

This has the added advantage of high electromagnetic resistance to interference due to the optical transmission of the

signals.

Festo P.BE-CPX-FB20/21-EN en 1202a

1-3

1. Installation

1.2 General instructions on installation

Warning

Before carrying out installation and maintenance work,

switch off the following:

•

Compressed air supply

•

the operating voltage supply for the electronics/sensors

•

the load voltage supply for the outputs and valves

In this way, you can avoid:

– uncontrolled movements of loose tubing

– uncontrolled movements of the connected actuators

– non-defined switching states of the electronic components.

Caution

The CPX bus node for Interbus includes electrostatically

sensitive devices.

•

Do not therefore touch any components

•

Observe the handling specifications for electrostatically

sensitive devices.

They will help you avoid damage to the electronics.

1-4

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

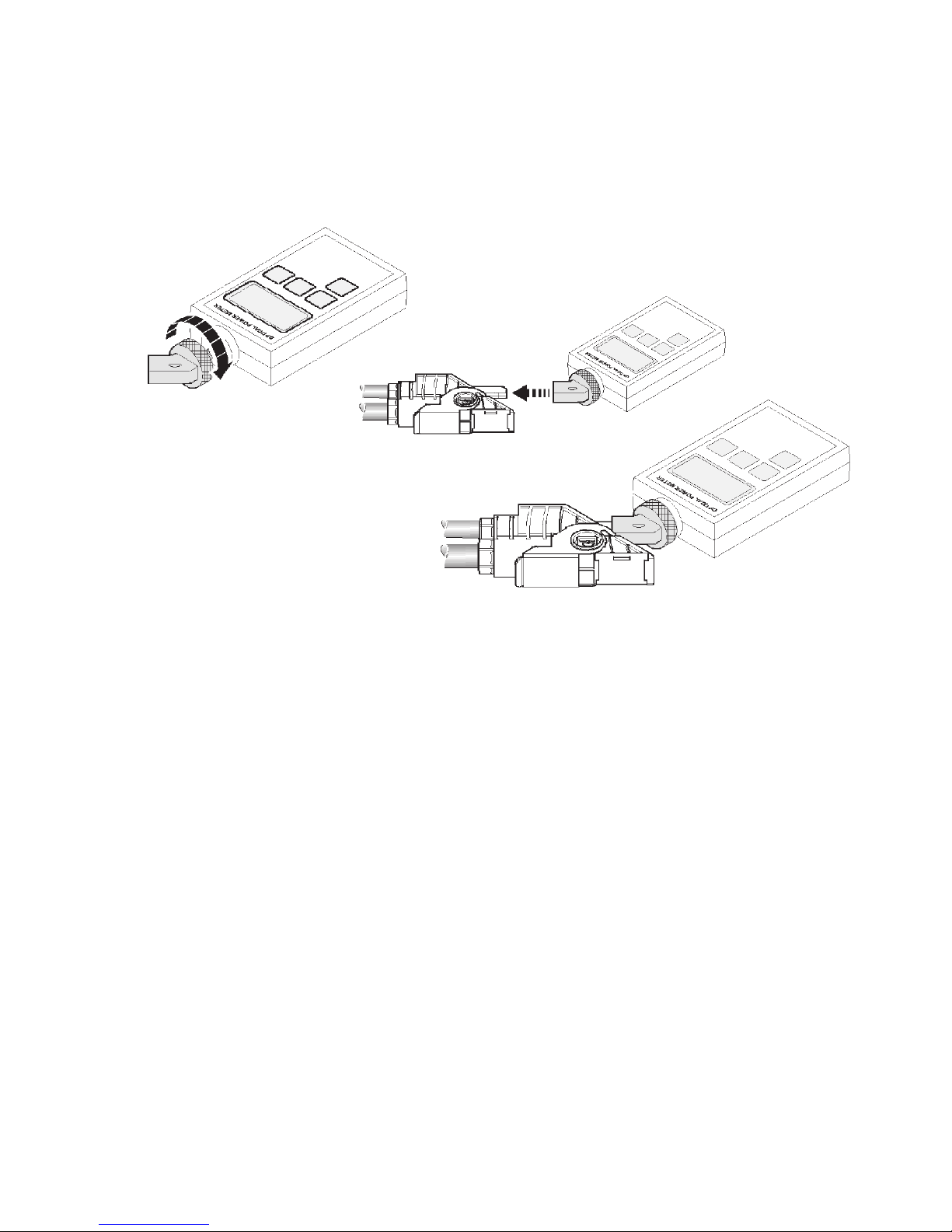

1

Fieldbus

connection IN

(incoming,

Rugged Line

plug)

Electrical connection and display components

The following connection and display components can be

found on the CPX bus node F B20 for the Interbus fibre-optic

cable:

2

Bus-statusspecific and

CPX-specific LEDs

3

Service interface

for handheld, etc.

4

DIL switch under

cover

4

3

2

Fig. 1/1: Connection and display components on the CPX bus node FB20

1

Festo P.BE-CPX-FB20/21-EN en 1202a

1-5

1. Installation

1

Fieldbus

connection OUT

(continuing,

Rugged Line

plug)

2

Fieldbus

connection IN

(incoming,

Rugged Line

plug)

3

Bus-statusspecific and

CPX-specific LEDs

4

Service interface

for handheld, etc.

5

DILswitchunder

cover

Fig. 1/2: Connection and display components on the CPX bus node FB21

5

4

3

12

1-6

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

1.3 Settings of the DIL switches on the bus node

There are 8 DIL switches available for configuring the bus

node. These are located under a cover to the left above the

Rugged Line connection (see Fig. 1/1 and Fig. 1/2).

1

DIL switch 1:

Baud rate

2

DIL switches

2, 7 and 8:

Reserved

1

2

3

2

3

DIL switches 5 and 6:

Diagnostic mode

4

DIL switch 4:

Error message

5

DIL switch 3:

Data format

Fig. 1/3: DIL switches on the bus node

(Additional information on 1 ... 5 see following pages)

Procedure:

1. Switch off the power supply.

2. Remove either the fitted fieldbus plugs or the cover, as

required.

3. Set the DIL switches as described on the following pages.

The following applies:

5

4

Festo P.BE-CPX-FB20/21-EN en 1202a

– DI L switch in upper position = ON

– DIL switch in lower position = OFF

4. Refit either the fieldbus plugs or the cover, as required.

Tighten the fastening screws at first by hand and then

with 0.3 Nm.

1-7

1. Installation

ThesettingoftheDILswitchhasprecedenceovertheparameterisation of defined settings.

Baud rate

Set the operating mode of the CPX-terminal with DIL switch 1:

Baud rate

500 kBd 1: OFF

2MBd 1: ON

DIL switch 1

(default)

Tab. 1/1: DIL switch 1

Data format

Set the data format with DIL switch 3:

Data format

Standard 3: OFF

DIL switch element 3

(default)

1-8

Siemens (Byte swap) 3: ON

Tab. 1/2: DIL switch 3

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

Error message

Use DIL switch 4 to determine whether the undervoltage error

message should be registered:

Error message

Register undervoltage V

as peripheral fault

Do not register

undervoltage V

load

load

Tab. 1/3: DIL switch 4

DIL switch 4

4: OFF

(default)

4: ON

Festo P.BE-CPX-FB20/21-EN en 1202a

1-9

1. Installation

Diagnostic mode

Set the diagnostic mode with DIL switches 5 and 6:

Peripheral fault mode

Diagnostic mode 1 (M1):

– No diagnosis

– No assignment in the

image table for inputs

Diagnostic mode 2 (M2):

– With diagnosis

– Diagnosis occupies 4 bytes

at the start of the image

table for inputs

Diagnostic mode 3 (M3):

– With diagnosis

– Diagnosis occupies 2 bytes

at the end of the image

table for inputs

Diagnostic mode 4 (M4):

– With diagnosis

– Diagnosis occupies 4 bytes

at the end of the image

table for inputs

DIL switches 5 and 6

5: OFF

6: OFF

(default)

5: OFF

6: ON

5: ON

6: OFF

5: ON

6: ON

1-10

T ab. 1/4: DIL switches 5 and 6

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

Reserved DIL switches

DIL switches 2, 7 and 8 are reserved for future expansion.

Reserved DIL switches

--- 2OFF

DIL switches 2, 7 and 8

7: OFF

8: OFF

(default)

Tab. 1/5: DIL switches 2, 7 and 8

Festo P.BE-CPX-FB20/21-EN en 1202a

1-11

1. Installation

1.4 Connecting the fieldbus

There are one (FB20) or two (FB21) connections on the node

for connecting the Interbus. One connection is for the incoming line; the other is intended for the continuing bus cable.

Observe the differences in the remote bus, which are listed

below.

Note

Faulty installation and high transmission rates may cause

data transmission errors as a result of signal attenuations.

Transmission errors can be caused by:

– transmission over distances which are too long

– inappropriate cables.

Observe the cable specifications! Obtain information about

the cable type to be used from the manual for the interface

module or from the Interbus installation manual.

1.4.1 System structure on the remote bus

The CPX terminal with bus node FB20/21 is a fibre-optic

remote bus par ticipant on the Interbus with Rugged Line

connection technology. Dependent on the modules used, it

reacts to the remote bus like a fibre-optic bus terminal with

integrated I/Os and it must be addressed accordingly.

Note

– Commissioning on the remote bus can only take place if

all slaves are completely connected, or if they are

bridged by means of a software setting.

1-12

– The CPX terminal requires a 24 V DC power supply.

This is supplied via the Rugged Line plug. It is possible

to supply and switch off separately the valve terminal

outputs/valves.

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

24 V DC

1

230 V AC

1

23

4

1

Interbus master: PC or PLC with module

2

CPX terminal: Onl y electric I/O modules

3

CPX terminal: VTSA valves and electric I/O modules

4

Further Interbus slaves

Fig. 1/4: Remote bus system structure with CPX terminals

Festo P.BE-CPX-FB20/21-EN en 1202a

1-13

1. Installation

Remote bus

The bus node has been prepared for operation on the remote

bus.

Further information on installing an Interbus system can be

found in the Interbus installation manual.

Installation manual

IBS SYS INST UM 27 54 28 6

Obtainable from:

Phoenix Contact Deutschland GmbH

Postfach 1341

32825 Blomberg, Germany

1.4.2 Fieldbus interface assignment

Required accessories from Phoenix Contact for connecting

the bus node FB20 and FN21 can be found in Appendix A.

A Rugged Line IN connection (remote bus), as well as a

Rugged Line OUT connection (remote bus) in the case of the

FB21, can be found on the bus node for connecting the CPX

terminal to the fieldbus.

Order no. Phoenix

1-14

These connections serve for the incoming (IN) and continuing

(OUT) fieldbus cable.

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

Plugs Pin Bus connection (fibre optic cable) in first Rugged Line plug,

incoming

OUTINTransmitted data, wire colour = black

Received data, wire colour = orange

OUT

IN

Plugs Pin Bus connection (fibre optic cable) in se cond Rugged Line plug,

continuing (FB21 only)

OUTINTransmitted data, wire colour = orange

Received data, wire colour = black

OUT

IN

Tab. 1/6: Connection assignment of bus connection (remote bus)

Festo P.BE-CPX-FB20/21-EN en 1202a

1-15

1. Installation

1.4.3 Connecting the fibre optic cable

Preparing

Note

– Only use the fibre optic cable from Phoenix Contact

(see Appendix A, Tab. A/5).

– Only the following procedure is suitable for removing the

outer red insulation coating:

– The fibre optic cable must be at least 12 cm longer than

required, as the cable must be shortened by this length

when the insulation is removed (see following pos. 7).

Proceed as follows:

1. The cable must be cut in a longitudinal direction.

The cable cross-section must be turned so that the

longitudinal cut is on the side facing the aramide yarn.

2. Place the cable cutter (KAMES LWL) on the cable coating

approx. 10 cm from the end of the cable and pull it in a

longitudinal direction (see Fig. 1/5, diagram A). If necessary, repeat the step until the cable coating has been cut.

3. Loosen the strain relief (aramide yarn) from the cable

coating which has been cut open (see Fig. 1/5, diagram B).

4. Wind the aramide yarn onto a mandril (e.g. screwdriver,

pliers) and protect it against rolling off (see Fig. 1/5,

diagram C).

5. Tear open the outer red cable coating approx. a further

15 cm with the aramide yarn without bending the cable

(see Fig. 1/5, diagram C).

1-16

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

Note

The two individual cores must not be damaged.

6. Use a sharp diagonal cutter to cut off the outer red cable

coating and the strain relief at the start of the cut area,

without damaging the two individual cores (see Fig. 1/5,

diagram D).

7. Shorten the individual cores by 12 cm, as this part may

have been damaged when the insulation was removed

with the cable cutter (see Fig. 1/5, diagram D).

1

A

B

D

Cable stripper “Kames 1” from Phoenix Contact

1

C

Fig. 1/5: Removing the outer cable insulation

Festo P.BE-CPX-FB20/21-EN en 1202a

1-17

1. Installation

Connecting

Proceed as follows:

1. Break through the sealing rubber with a screwdriver.

2. Place the Quickon screw, the clamping box and the sealing rubber on the polymer fibre cable. The sealing rubber

must be flush with the edge of the insulation (see Fig. 1/6,

diagram A).

3. Push both black cores through the splice ring. The

smooth side of the splice ring must face towards the

cable.

Note

– Note the marking IN/OUT on the splice ring.

– Cross the individual cores on the opposite splice ring

(see Fig. 1/6, Pos. 5 ).

– If you have inserted the individual cores incorrectly in

the splice ring, you must not turn the cores, as they will

then be damaged.

4. Push both black cores through the appropriate opening in

the Rugged Line plug until they project at the other end

(see Fig. 1/6, diagram B).

1-18

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

5. Tighten the Quickon screw with the fibre cutter (Phoenix

Contact, type IBS RL FOC). This provides strain relief

(see Fig. 1/6, diagram C).

6. Push the fibre cutter as far as possible onto the projecting

cores on the Rugged Line plug (see Fig. 1/6, diagram D).

7. Cut off the individual cores.

12

A

C

1

Quickon screw

2

Clamping box

3

Sealing rubber

3 4 5

D

B

4

Splice ring

5

Crossing the fibre optic cable with

remote IN and OUT

6

Fibre cutter

6

Fig. 1/6: Connecting the fibre optic cable

Festo P.BE-CPX-FB20/21-EN en 1202a

1-19

1. Installation

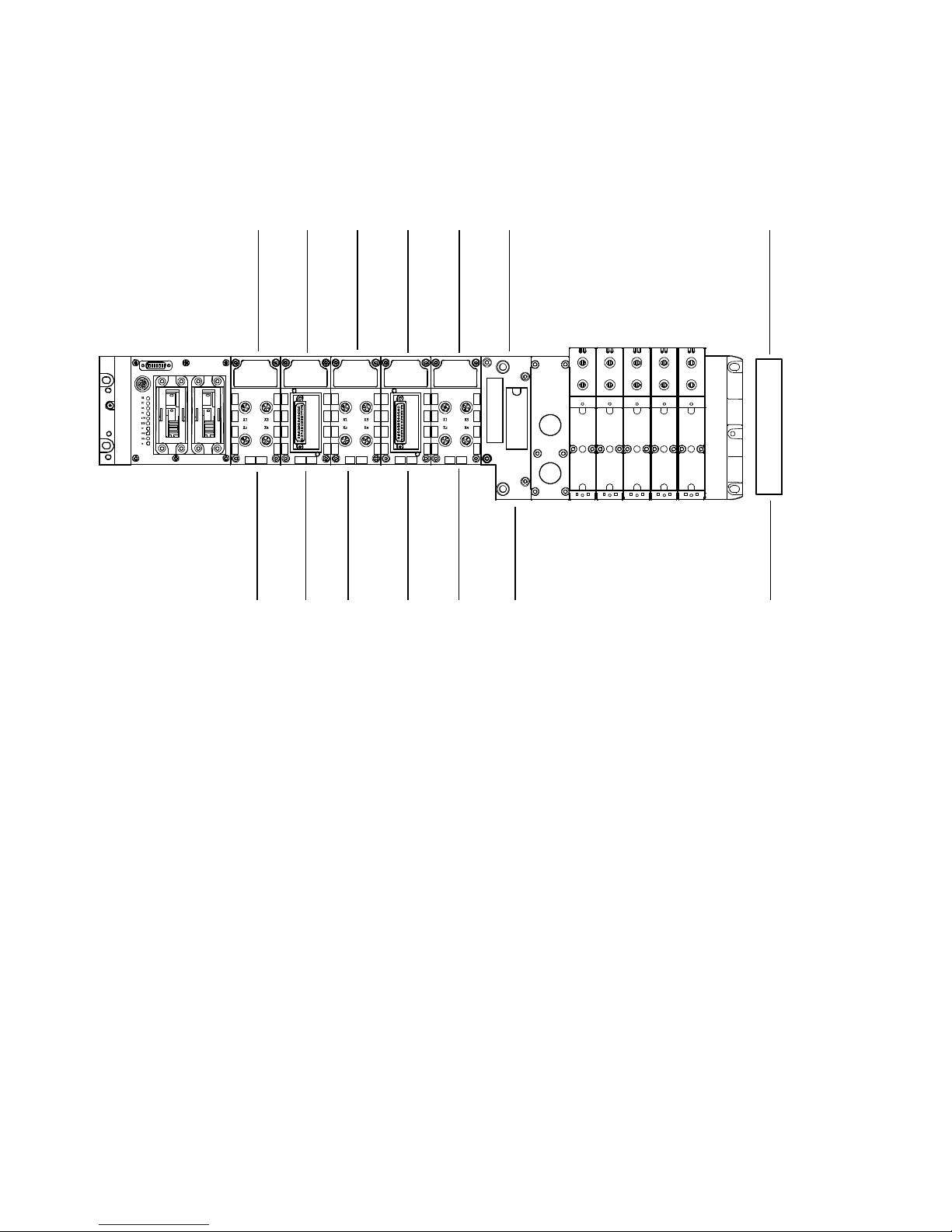

Checking the fibre optic cable connection

When a fibre optic cable has been installed, you can check

the optical performance in front of the receiving device with a

fibre optical measuring unit (see Appendix A, Tab. A/5).

Proceed as follows:

1. Clean the optical active range of the measuring unit with a

clean cloth free of fluff.

2. Screw the measuring unit adapter onto the measuring

unit.

3. Place the measuring unit with the measuring unit adapter

on the longer of the two remote bus connections on the

Rugged Line plug.

4. Set the measuring unit to 660 nm.

5. Measure the optical performance.

For reliable data transmission, the measured level must

not exceed a value of -3.6 dBm or drop below a value of

-18.0 dBm.

This level takes into account the performance drift of the send

and receive components and a system reserve of 3 dB.

1-20

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

A

B

C

Fig. 1/7: Placing the measuring unit adapter

Festo P.BE-CPX-FB20/21-EN en 1202a

1-21

1. Installation

Fieldbus cable

Bus length Details concerning the bus length can be found in Appendix A.

Note

If the valve terminal is mounted into a moving part of a

machine, the fieldbus cable on the moving part must be

provided with strain relief. Please also observe the relevant

regulations in EN 60204 part 1.

1.4.4 Fieldbus baud rate and fieldbus length

The maximum permissible fieldbus length is dependent on

thefibre-opticcableused.Thebaudrateis500or

2000kbit s.

1-22

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

1.5 Pin assignment of power supply

Warning

•

Only use PELV circuits as per IEC/EN 60204-1 (protective

extra-low voltage, PELV) for the electrical power supply.

•

Observe also the general requirements of IEC/DIN EN

60204-1 for PELV circuits.

•

Only use voltage sources, which guarantee reliable electrical isolation of the operating voltage as per IEC/EN

60204-1.

The use of PELV circuits ensures protection from electric

shock (protection from direct and indirect contact) in

accordance with IEC/EN 60204-1 (Electrical equipment of

machines, General requirements).

The current consumption of a CPX terminal depends on the

number and type of integrated modules and components.

Observe the information on power supply and the required

earthing measures in the CPX system description.

Festo P.BE-CPX-FB20/21-EN en 1202a

1-23

1. Installation

Plugs Pin Operating voltage connection in the Rugged Line plug

25

3

1

1

2

3

4

5

4

24 V supply for electronics, inputs

0 V electronics, inputs

24 V supply, valves, outputs

0 V valves, outputs

Functional earth

Tab. 1/7: Pin assignment of bus connection (power supply)

1-24

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

1.5.1 Connecting the power supply US1/U

These fitting instructions apply to the fibre optical Rugged

Line plug from Phoenix Contact.

Note

Use a power supply cable 5 x 1.5 mm

Contact (see Appendix A, Tab. A/5). The numbers printed

on this cable correspond to the numbering on the splice

ringoftheRuggedLineplug.

Proceed as follows:

1. Break through the sealing rubber with a screwdriver.

2. Push the Quickon screw, the clamping box and the sealing

rubber over the power supply cable (see Fig. 1/8

diagram A).

3. Remove the insulation coating over a length of approx.

10 cm.

S2

2

, e.g. from Phoenix

4. Push first the sealing rubber to the edge of the insulation,

then push the clamping box onto the sealing rubber

(see Fig. 1/8, diagram B). This forms the strain relief for

the cable.

Festo P.BE-CPX-FB20/21-EN en 1202a

1-25

1. Installation

5. Push the ends of the cable cores into the appropriate

openings on the splice ring (see Fig. 1/8, diagram C).

The numbers printed on the cable correspond to the

numbering on the splice ring.

6. Pull hard on the ends of the cores.

7. Cut off the projecting ends of the cores. Make sure that

the ends of the cores are flush with the splice ring, do not

project, and are not too short (see Fig. 1/8, diagram D).

8. Insert the ready-to-use cable into the appropriate connection on the Rugged Line plug (see Fig. 1/8, diagram E).

9. Turn the ready-to-use cable until the coding lugs of the

splice ring fit exactly into the appropriate guides of the

Rugged Line plug.

10. Tighten the Quickon screw with the fibre cutter

(see Fig. 1/8, diagram F). The insulation will then be cut

and the electrical contact restored.

Note

If you wish to connect the cable cores again, you must cut

them again, as otherwise the electrical contact cannot be

guaranteed.

1-26

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

12

3 4

A

E

5

B

C

D

F

QUICKON screw

1

2

Clamping box

3

Sealing rubber

Fig. 1/8: Connecting the power supply cable to the Rugged Line plug

4

Splice ring

5

Rugged Line plug

Festo P.BE-CPX-FB20/21-EN en 1202a

1-27

1. Installation

Additional power supply The outputs are supplied with load voltage via the

interlinking blocks with additional power supply

CPX-M-GE-EV-Z-7/8-5POL or CPX-M-GE-EV-Z-PP-5POL.

Plugs

2

3

4

1234 5

V

: Load voltage for outputs

OUT

Pin assignment for additional po wer supply

Additional power supply type CPX-M-GE-EV-Z-7/8-5POL

1

1: 0 V

Out

2: Unused

5

3: FE

Additional power supply type CPX-M-GE-EV-Z-PP-5POL (Push Pull)

1: Not connected

2: Not connected

3: 24 V

Out

4: Unused

5: 24 V

4: 0 V

5: FE

Out

Out

Tab. 1/8: Pin allocation: Additional power supply for outputs

1.5.2 Sealing unused connections in the Rugged Line plug

1-28

Note

•

Seal unused connections in the Rugged Line plug.

•

Use only sealing rubber which has not been broken

through.

You can then be sure of complying with protection class

IP65/67.

Festo P.BE-CPX-FB20/21-E N en 1202a

1. Installation

3

4

Proceed as follows:

1. Place the clamping ring on the sealing rubber

(see Fig. 1/9, diagram B or Fig. 1/10, diagram B).

2. Place both together in the Quickon screw.

3. Place the appropriate splice ring in the non-required

connection of the power supply or of the fibre optical

waveguide in the Rugged Line plug.

4. Place the screw connector in position and tighten the

Quickon screw with the fibre cutter (see Fig. 1/9,

diagram C or Fig. 1/10, diagram C).

12

A

1

Quickon screw

B

3

Sealing rubber

C

2

Clamping box

Fig. 1/9: Sealing a non-used power supply connection

Festo P.BE-CPX-FB20/21-EN en 1202a

4

Splice ring

1-29

1. Installation

4

12

A

1

Quickon screw

2

Clamping box

3

B

3

Sealing rubber

4

Splice ring

C

Fig. 1/10: Sealing a non-used fibre optical waveguide connection

1-30

Festo P.BE-CPX-FB20/21-E N en 1202a

Commissioning

Chapter 2

Commissioning

Festo P.BE-CPX-FB20/21-EN en 1202a

2-1

2. Commissioning

Contents

2. Commissioning 2-1................................................

2.1 Configuration and addressing 2-2.....................................

2.1.1 Ascertaining the address range 2-2............................

2.1.2 Address assignment of the CPX terminal 2-7.....................

2.1.3 Address assignment after extension/conversion 2-15..............

2.1.4 Bus configuration and addressing 2-18..........................

2.1.5 Switching on the power supply 2-19............................

2.1.6 Bus configuration with the CMD software 2-20....................

2.1.7 Bus configuration without CMD software 2-28....................

2.1.8 Process data entry via the CMD software 2-29....................

2.2 Parameterisation 2-33...............................................

2.2.1 Parameterisation concepts 2-35................................

2.3 Commissioning the CPX terminal on the Interbus 2-37.....................

2.3.1 Fail safe 2-38...............................................

2-2

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

2.1 Configuration and addressing

2.1.1 Ascertaining the address range

Before configuring, ascertain the exact number of available

inputs/outputs. Depending on what you have ordered, a CPX

terminal comprises a different number of I/Os.

Note

– The maximum possible extension to the CPX terminal

with Interbus bus node is limited to 96 inputs and outputs.

The I/Os will be assigned automatically within the CPX terminal.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-3

2. Commissioning

Available inputs

Depending on the setting of DIL switches 5 and 6, the CPX

terminal supports the following maximum number of inputs

to the I/O modules.

Setting

Maximum number of

available inputs

Diagnostics mode

M1: No diagnosis 96 inputs

M2: With 4 byte diagnosis 64 inputs

M3: With 2 byte diagnosis 80 inputs

M4: With 4 byte diagnosis 64 inputs

1)

For diagnosis modes also refer to Tab. 1/4

1)

Tab. 2/1: Number of available inputs and outputs

The I/Os will be assigned automatically within the CPX terminal.

The address assignment within the individual modules can be

found in the manual for the relevant module.

2-4

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

On the basis of the module type, you can ascertain the number of inputs and outputs occupied by the module.

The individual modules are displayed with their identifier on

the handheld. In the case of the I/O modules, the identifier is

also shown in the LED viewing window.

Electric modules

Type Module

identifier

Bus node FB20/21, Remote I/O,

without system diagnostics

Bus node FB20/21, remote I/O, with diagnostics

– Diagnostic mode 2

– Diagnostic mode 3

– Diagnostic mode 4

Digital 4-input module CPX-4DE 4DI 4I –

Digital 8-input module CPX-8DE 8DI 8I –

Digital 8-off input module with channel

diagnostics

Digital 16-off input module CPX-16DE 16DI 16 I –

Digital 16-off input module with c hannel

diagnostics

2)

2)

CPX-M-FB20

CPX-M-FB21

CPX-8DE-D 8DI-D 8I –

CPX-16DE-D 16DI-D 16 I –

FB21-RIO – –

Assigned addresses

1)

Inputs Outputs

32 I

16 I

32 I

Digital 8-off input module n-switching CPX-8NDE 8NDI 8I –

Digital 4-way output module CPX-4DA 4DO – 4O

Digital 8-off output module CPX-8DA 8DO – 8O

Digital 8-off output module, high-current variant

Digital multi I/O module CPX-8DE-8DA 8DI/8DO 8I 8O

1)

Module identifiers on the handheld, on I/O modules these are shown in the viewing window.

2)

The diagnostics mode is activated by DIL switch 5 and 6 (see Tab. 1/4).

Tab. 2/2: Overview of identifiers and addresses of the electric modules (part 1)

Festo P.BE-CPX-FB20/21-EN en 1202a

CPX-8DA-H 8DO-H – 8O

2-5

2. Commissioning

Electric modules Type Module

identifier

Analogue 2-off input module CPX-2AE-U-I 2AI 32 I –

Analogue 4-off input module CPX-4AE-U-I 4AI 64 I –

Analogue 4-off input module CPX-4AE-I 4AI-I 64 I –

Analogue 4-off input module

(temperature module)

Analogue 2-off output module CPX-2AA-U-I 2AO – 32 O

1)

Module identifiers on the handheld device, on I/O modules these are shown in the inspection

window.

CPX-4AE-T 4AI-T 32/64 I

Assigned ad-

1)

dresses

Inputs Outputs

2)

–

Tab. 2/3: Overview of identifiers and addresses of the electric modules (part 2)

Pneumatic interfaces for

VTSA...

Type Module

identifier

Assigned addresses

1)

Inputs Outputs

Pneumatic interface for

VTSA… valves (type 44/45)

with DIL switch setting:

– 1 ... 8 valve c oils

– 1 ... 16 valve coils

– 1 ... 24 valve coils

– 1 ... 32 valve coils

1)

Module identifier in the Handheld.

2)

The number of output addresses occupied by the pneumatic modules of the VTSA… is set on the

pneumatic interface with a DIL switch (see manual for the CPX I/O modules).

2)

VABA-10S6-x1 VTSA,

ISO Plug In or

TYPE 44 or

TYPE 45

–

Tab. 2/4: Overview of identifiers and addresses of pneumatic modules

The complete address range of the I/Os including diagnosis

always contains an equal number of inputs and outputs.

Tip:

Copy the following table for further calculations.

8O

16 O

24 O

32 O

2-6

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Calculating the number of inputs/outputs

Use the following table for calculating the number of inputs

and outputs on your CPX terminal.

Input/output modules and system

1. Number of input modulesCPX-4DE + __ x 4 I

2. Number of input modules CPX-8DE, -8NDE, -8DE-D + __ x 8 I

3. Number of input modules CPX-16DE + __ x 16 I

4. Number of output modules CPX-4DA + __ x 4 O

5. Number of output modules CPX-8DA + __ x 8 O

6. Number of multi I/O modules CPX-8DE-8DA + __ x 8

I/O

7. Number of inputs and outputs of other modules + __ I/O

(e.g. analogue modules)

8. VTSA... pneumatic interface:

Number of configured valve solenoid coils (+ 8 O, 16 O, 24 O, 32

O)

32 O are configured at the factory!

7. Inputs and outputs of the modules

Sum of 1 to 6:

8.. Diagnostics if set

Diagnosis M2 and M4 + 32 I

Diagnostics M3 + 16 I

Check whether the greater value (inputs)

from item 8 is divisible by 16 without remainder (diagnostics

begins with the next word):

a) if divisible by 16 without remainder: + 0 I

b) if the remainder = 12: round up to the next word. + 4 I

c) if the remainder = 8: round up to the next word. + 8 I

d) if the remainder = 4: round up to the next word. + 12 I

Inputs Outputs

+ _____ I

+ _____ I

+ _____ I

+ _____ O

+ _____ O

+ _____ I

+ _____ I

= ∑ _____ I = ∑ _____ O

+ _____ I

+ _____ I

+ _____ I

+ _____ O

+ _____ O

+ _____ O

9. Inputs and outputs of the modules

Sum of 7 to 8:

Sum total of inputs/outputs to be configured

Greater value (inputs or outputs) from 9: _____ I/O

1)

The maximum number of the available I/Os from Tab. 2/1 must not be exceeded.

Tab. 2/5: Ascertaining the number of inputs and outputs

Festo P.BE-CPX-FB20/21-EN en 1202a

= ∑ _____ I = ∑ _____ O

1)

2-7

2. Commissioning

2.1.2 Address assignment of the CPX terminal

Basic rules for addressing

Inputs and outputs

– The address assignment of the inputs does not depend on

the outputs.

– The counting mode is independent of the position of the

bus node.

– Counting from left to right.

– The setting for the number of valves on the pneumatic

interface of 1 and 3 bytes is always rounded up to the full

word (2 or 4 bytes).

– Sequence:

– For diagnostics mode 2:

32 diagnostic bits in front of the input bits.

– Input/output words of the analogue modules,

– Input/output words of the function modules (word-

orientated),

– Input/output bits of the electric inputs and outputs

(including valves):

– For diagnostics mode 3:

16 diagnostic bits followed by the input bits from the

next word.

2-8

– For diagnostics mode 4:

32 diagnostic bits followed by the input bits from the

next word.

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Note

If two addresses are assigned for one valve location, the

following applies:

– lower-value address: pilot solenoid 14

– higher-value address: pilot solenoid 12

Address assignment on the Interbus

The address assignment (processing data assignment) of the

inputs and outputs of a CPX terminal on the Interbus depends

aboveallontheInterbusmoduleandonthecontrolsystem

used.

Caution

There are different address assignments on the Interbus.

The reason for this is the assignment of the processing

data within the Interbus module.

•

When assigning the addresses, note the position of the

high and low bytes, as the position of these bytes may

be swapped in conjunction with some control systems.

You can then avoid faults in addressing the inputs/outputs.

Further details on addressing can be found in the manuals for

your controller and for the Interbus module.

The following examples provide basic information on the

different address assignments and the positions of the low

byte (n) and the high byte (n+1) with various controllers.

There are two modes:

–IntheSiemens mode the lower-value input or output byte

(byte n) is mapped on inputs or outputs 0 ... 7, byte n+1

on the next inputs or outputs (8 ... 15) etc.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-9

2. Commissioning

–IntheStandard mode the lower-value input or output

byte (byte n) is mapped on inputs or outputs 8 ... 15,

byte n+1 on the inputs or outputs 0 ... 7.

This allocation also applies to the bytes of diagnostics

M2…M4.

In section 2.1.8 you will find instructions on addressing with

the CMD software (processing data assignment) and on

modifying the position of the low and high bytes (“byte swap”).

Note

Thebyteswapcaneither be set via DIL switch 1.3 or with

the help of the CMD software. If the byte swap is set via

DIL switch and CMD, then the settings override each other!

Examples for the address assignment of the CPX

terminal

The following examples show the assignment of the input and

output bytes to the individual modules. In the examples the

following applies:

– Configured input address: IB20

Configured output address: OB20

– The address assignment is represented both in the

Siemens mode and in the Standard mode.

The address assignment within the individual I/O modules

canbefoundinthemanualfortheI/Omodules.

The address assignment within the pneumatic modules can

be found in the manual for the valve terminal pneumatics.

2-10

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

The modules and diagnostic modes are represented in the

examples as follows:

8DI 8DI 8DO 4DO4DI 4DO

16 O

123454 67

1

Bus node CPX-FB20 or FB21

2

8DI: 8-off input module

3

4DI: 4-off input module

4

4DO: 4-off output module

5

8DI 8DO: multi I/O module

6

VTSA… pneumatic interface with the

number of outputs set by DIL switches,

here with 16 O

Fig. 2/1: Identification of the modules in the examples

7

Input addresses for diagnostics:

Inputs are assigned for the diagnostics

dependent on the DIL switch setting:

– 0 I-bits, no diagnostics (diagnostics

M1) or

– 16 I-bits, diagnostics M3

– 32 I-bits, diagnostics M2 or M4

The inputs for diagnostic mode 3 are

always assigned in the following examples.

Diagnostics M2 … M4

Festo P.BE-CPX-FB20/21-EN en 1202a

2-11

2. Commissioning

Byte assignment

of the input by tes

Siemens mode:

IB 20

Example 1

I/O modules and VTSA pneumatics (setting 8 O)

IB 21 IB 22 IB 24

IB 23

IB 25

Standard mode:

Byte assignment

of the output bytes

Siemens mode:

Standard mode:

IB = input byte; OB = output byte; diagnostics optional

IB 21 IB 20 IB 23 IB 25

8DI 8DI 8DO 4DO8DI 8DO 4DO

OB 22 OB 23 OB 20 OB 21

OB 23 OB 22 OB 21 OB 20

IB 22

8O

Fig. 2/2: Example 1 – byte assignment in Siemens and Standard modes

IB 24

Diagnostics M3

2-12

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Address assignment in Siemens

mode

I20.0 ... I20.7

8DI 8DI 8DO 4DO

I21.0 ... I21.7

O20.0 ... O20.7

8DI 8DO 4DO

O22.0 ... O22.3

I22.0 ... I22.7

O22.4 ... O23.3

O21.0 ... O21.7

O23.4 ... O23.7

I24.0 ... I24.7

I25.0 ...I25.7

8O

Address assignment

in Standard mode

I21.0 ... I21.7

Diagnostics optio nal

I20.0 ... I20.7

O21.0 ... O21.7

O23.0 ... O23.3

I23.0 ... I23.7

O22.4 ... O22.7

O23.4 ... O23.7

O22.0 ... O22.3

O20.0 ... O20.7

Fig. 2/3: Example 1 – address assignment in Siemens and Standard modes

Diagnostics M3

I25.0 ...I25.7

I24.0 ... I24.7

Festo P.BE-CPX-FB20/21-EN en 1202a

2-13

2. Commissioning

Byte assignment

of the input by tes

Siemens mode:

IB 20

Example 2

I/O modules and VTSA pneumatics (setting 16 O)

IB 21 IB 22 IB 23 IB 25

IB 24

Standard mode:

4DI

Byte assignment

of the output bytes

Siemens mode:

Standard mode:

IB = input byte; OB = output byte; diagnostics optional

IB 21 IB 20 IB 23 IB 22 IB 24

4DO 4DO 8DI8DI 8DO

OB 22 OB 23 OB 20 OB 21

OB 23 OB 22 OB 21 OB 20

16 O

IB 25

Fig. 2/4: Example 2 – byte assignment in Siemens and Standard modes

Diagnostics M3

2-14

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Byte assignment

of the input by tes

Siemens mode:

IB 20

Example 3

I-module and VTSA pneumatics (setting 32 O)

IB 21 IB 22

IB 23

Standard mode:

Byte assignment

of the output bytes

Siemens mode:

Standard mode:

IB = input byte; OB = output byte; diagnostics optional

IB 21 IB 20 IB 22

4DI

32 O

OB 20 OB 21 OB 22 OB 23

OB 21 OB 20 OB 23 OB 22

IB 23

Fig. 2/5: Example 3 – byte assignment in Siemens and Standard modes

Diagnostics M3

Festo P.BE-CPX-FB20/21-EN en 1202a

2-15

2. Commissioning

2.1.3 Address assignment after extension/conversion

A speciality of the CPX terminal is its flexibility . If the demands

placed on the machine change, the equipment fitted on the

CPX terminal can also be modified.

Caution

If the CPX terminal is extended or converted at a later

stage, the input/output addresses may be shifted. This

applies in the following cases:

– if additional modules are inserted between existing

modules

– if existing modules are removed or replaced by other

modules which have more or fewer input/output

addresses

– VTSA... manifold sub-bases for monostable valves are

replaced by manifold sub-bases for bistable valves – or

vice versa (see pneumatics manual).

– Additional VTSA... manifold sub-bases are inserted

between existing bases.

– The configured addresses of the pneumatic interface are

modified.

Note

If the configuration is modified, the addresses of

diagnostics M3 or M4 may also be shifted if necessary!

2-16

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Byte assignment

of the input by tes

Siemens mode:

IB 20

The following diagram shows the changes which occur to the

address assignment when the equipment fitted in example 1

is modified. On the I/O module side an 8-input module has

been replaced by a 4-input module. On the valve side, a valve

plate has been added and the pneumatic interface has been

set to 16 O.

IB 21 IB 22 IB 23 IB 24

IB 25

Standard mode:

Byte assignment

of the output bytes

Siemens mode:

Standard mode:

IB = input byte; OB = output byte; diagnostics optional

IB 21 IB 20 IB 23 IB 22 IB 25

4DI 8DI 8DO 4DO 8DI 8DO 4DO

OB 22 OB 23 OB 24 OB 25 OB 20

OB 23 OB 22 OB 25 OB 24 OB 21

16 O

IB 24

OB 21

OB 20

Fig. 2/6: Byte assignment of a CPX terminal after extension/conversion

Diagnostics M3

Festo P.BE-CPX-FB20/21-EN en 1202a

2-17

2. Commissioning

Address assignment in Siemens

mode

I20.0 ... I20.3

4DI 8DI 8DO 4DO 8DI 8DO 4DO

I20.4 ... I21.3

O22.0 ... O22.7

I21.4 ... I22.3

O23.0 ... O23.3

O23.4 ...O24.3

O21.0 ... O21.7

O24.4 ... O24.7

O20.0 ... O20.7

I24.0 ... I25.7

16 O

Address assignment

in Standard mode

I21.0 ... I21.3

Diagnostics optio nal

I20.0 ... I20.3

I21.4 ... I21.7

O23.0 ... O23.7

I23.0 ... I23.3

O22.0 ... O22.3

O22.4 ... O22.7

I20.4 ... I20.7

O25.4 ...O25.7

O25.0 ... O25.3

O21.0 ... O21.7

O20.0 ... O20.7

Fig. 2/7: Address assignment of a CPX terminal after extension/conversion

Diagnostics M3

I25.0 ...I25.7

I24.0 ... I24.7

2-18

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

2.1.4 Bus configuration and addressing

General instructions on commissioning

Before commissioning or programming, compile a configuration list of all connected fieldbus slaves. On the basis of this

list you can:

– carry out a comparison between NOMINAL and ACTUAL

configurations, in order to recognize connection faults.

– access these specifications during the syntax check of a

program, in order to avoid addressing faults

Configuration of the CPX terminal demands a very accurate

procedure, as different configuration specifications are sometimes necessary for each slave on the Interbus, due to the

modular structure. Note here the specifications in the sections which follow.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-19

2. Commissioning

2.1.5 Switching on the power supply

Note

Note also the instructions in the manual for your controller

with Interbus module.

When the controller with Interbus module is switched on, it

automatically carries out a comparison between the

NOMINAL and ACTUAL configurations. It is important for this

configuration run that:

– the configuration specifications are complete and correct

– the fieldbus slaves are supplied with power, in order that

they can be recognised when the ACTUAL configuration is

ascertained.

Therefore, switch on the power supply for all the fieldbus

slaves simultaneously, e.g. via a central switch. Alternatively

switch on the power supply in the following sequence:

1. First the power supply for all the fieldbus slaves,

2. then the power supply for the controller.

2-20

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

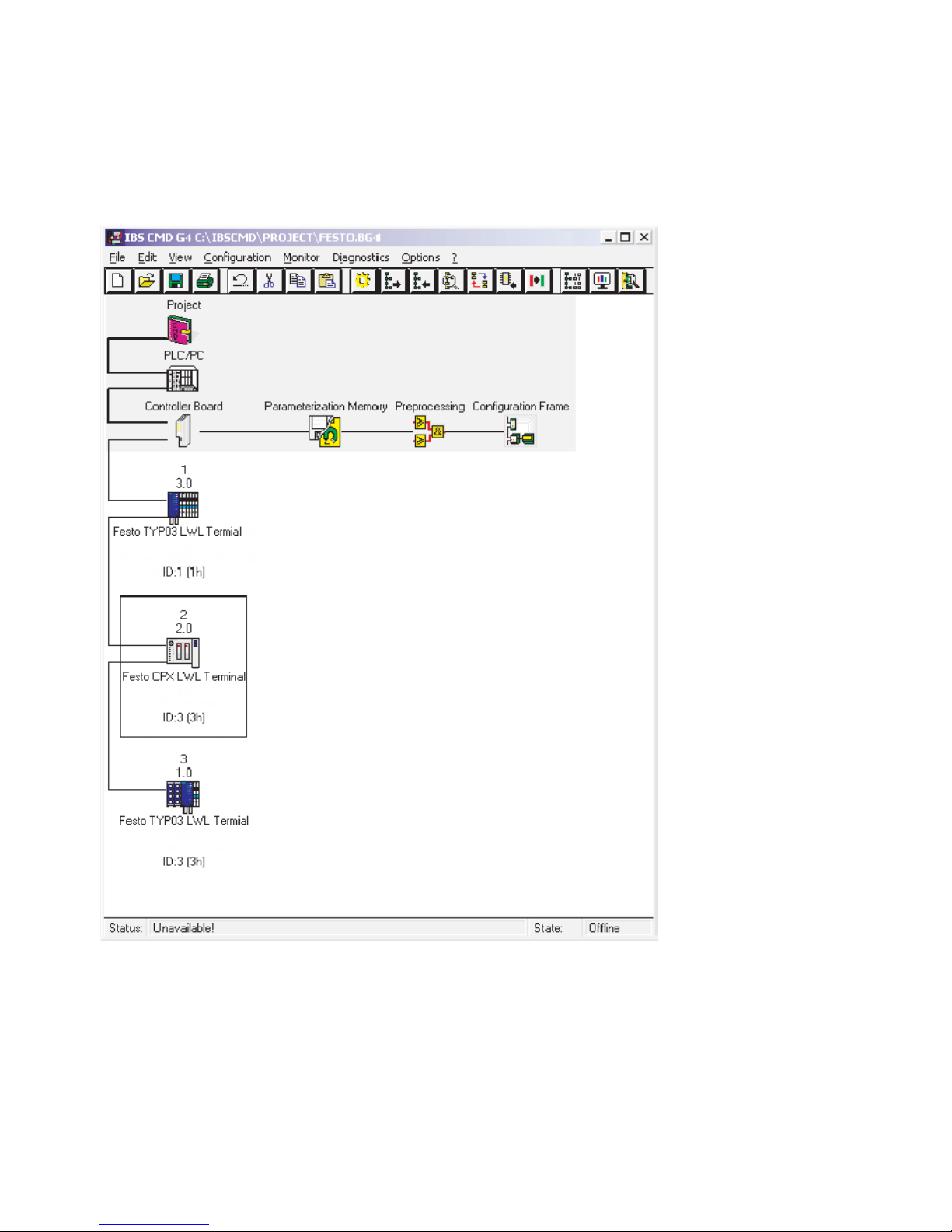

2.1.6 Bus configuration with the CMD software

This section describes as an example the main steps within

the CMD software for inserting a CPX terminal in your project.

A general and comprehensive description can be found in the

relevant manual for the CMD software. In the following it is

assumed that the user is familiar with the contents of the

CMD manual.

Note

Note that software packages are often updated, so that

modifications to the software may not yet be taken into

accountinthismanual.

The examples used here for the screen displays have been

taken from CMD software version 4.50.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-21

2. Commissioning

Inserting with Ident. code

Proceed as follows:

1. Click on the module with the right-hand mouse button.

2. Select the command “Insert with ID code...” in the context

menu.

Fig. 2/8: Inserting bus slaves with Ident. code

2-22

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

The following dialogue window will then be displayed:

Fig. 2/9: Dialogue window “Insert Device”

3. Enter the ID code and the size of the processing data

channel. Information on this can be found on the following

page.

4. Select the entry “Remote bus device” under “Device

Type” for the CPX terminal.

5. Accept these entries with OK.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-23

2. Commissioning

ID code: Enter the appropriate Ident. code in accordance with the

table.

Configuration

Only digital outputs

Only digital inputs, no diagnostics mode

(M2, M3 or M4) active

Digital inputs and outputs

1)

Decimal

2)

Valves and/or electric outputs

2)

2)

Ident. code

1

D

2

D

3

D

Tab. 2/6: ID code

Process data channel: Enter the number of inputs and/or outputs on the CPX

terminal, as ascertained in the section 2.1.1 under “Calculating

the number of inputs/outputs”. Observe the following:

Note

– Round up the number of inputs and/or outputs to the

next word limit (16, 32, 48, 64, 80 or 96).

1)

2-24

– If the number of input bits differs from the number of

output bits, the greater number is in each case decisive

for the entry of the process data channel bits

Festo P.BE-CPX-FB20/21-E N en 1202a

.

2. Commissioning

Insert description of slave In the following dialogue window you can describe the slave

and enter specific information, e.g. station name and picture

of the slave.

Fig. 2/10: Dialogue window “Insert Device Description”

Festo P.BE-CPX-FB20/21-EN en 1202a

6. Profile number:

The CPX terminal corresponds to the Interbus I/O profile

. Enter this value in the field “Profile Number”.

12

H

7. Interface type:

Interface type “Universal” is preset. This setting can be

accepted. Alternatively, by actuating the “Interface Type”

button you can open a dialogue window in which you can

set the type “Remote bus”.

2-25

2. Commissioning

8. If required, you can enter appropriate terms for identifying

the CPX terminal under “Station Name”, “Device Name”,

“Manufacturer Name” and “Device Type”.

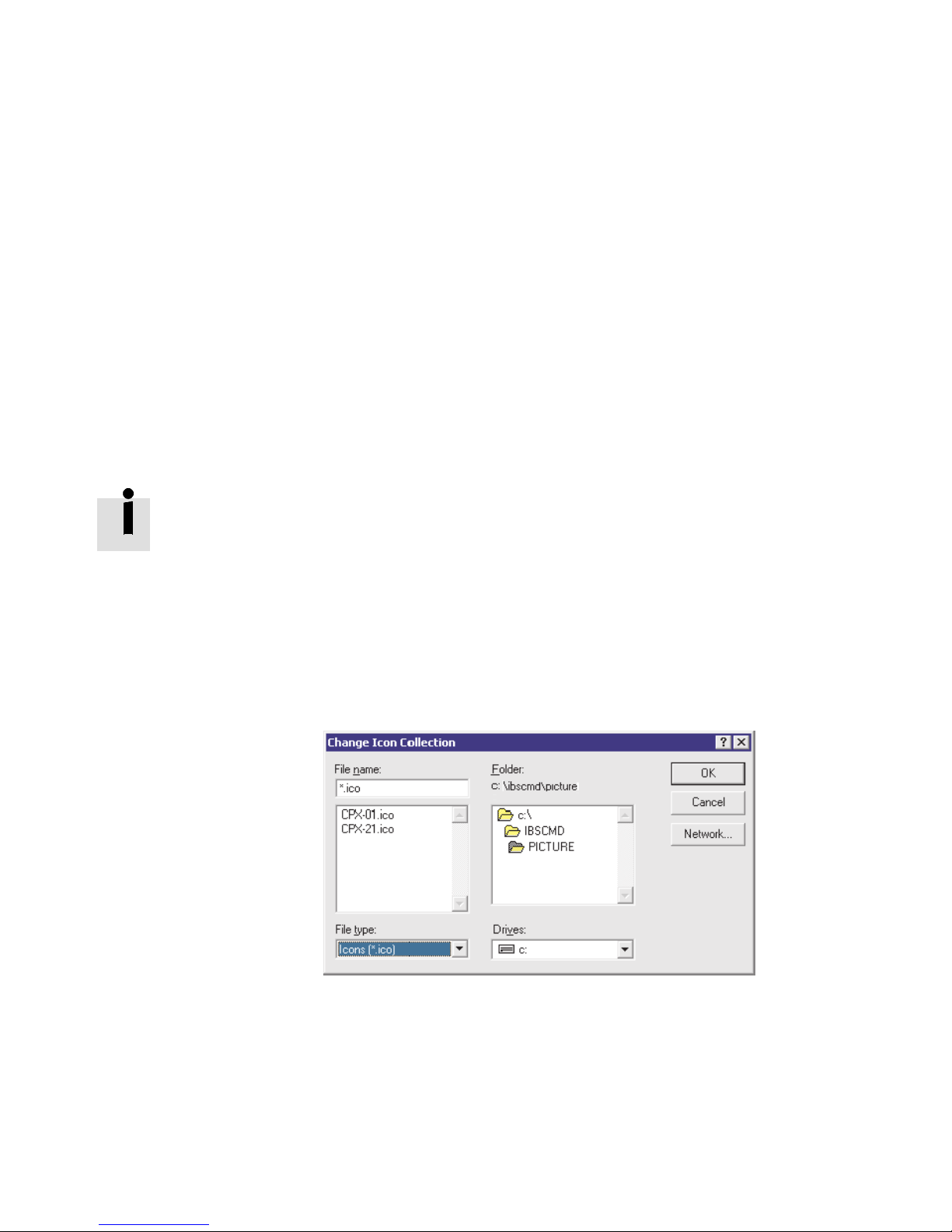

9. Representation:

You can adapt the representation of the CPX terminal

individually in the CMD software. However, this is not

absolutely necessary for commissioning.

By actuating the “Presentation” button you can open a

dialogue window in which you can set a specific icon for

the CPX terminal.

The specific icons for CPX terminals can be found online

www.festo.com/Fieldbus Firmware and drivers.

•

Copy the file “CPX-21.ico” into the CMD directory

\PICTURE\.

•

Actuate the “Select ...” button in the “Presentation”

dialogue window.

•

Select the entry “Icons (*.ico)” under “File type”.

Fig. 2/11: Dialogue window “Change Icon Collection”

2-26

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

•

Select the file “CPX-01.ico”.

Fig. 2/12: Dialogue window “Presentation” for selecting an

icon

•

Accept your selection with OK.

When all entries have been made, the CPX terminal will be

integrated in your bus structure as follows (example):

Festo P.BE-CPX-FB20/21-EN en 1202a

2-27

2. Commissioning

Fig. 2/13: Example – inserted CPX terminal

2-28

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

2.1.7 Bus configuration without CMD software

Logical addressing

In the case of the bus configuration without CMD software,

the following specifications must be known or ascertained for

each bus slave. Configure the CPX terminal as follows:

•

ID code (Ident. code)

– CPX terminal only with outputs

1)

:IDcode1

D

– CPX terminal only with inputs:IDcode2

D

– CPX terminal with inputs an d outputs1):IDcode3

1)

Valve coils and/or electric outputs

•

Process data channel:

– Calculate the number of I/Os per valve terminal.

The number of inputs and/or outputs must be

rounded up to the next word limit.

If the number of input bits differs from the number of

output bits, the greater number is in each case

decisive for the entry of the process data channel bits.

– Please note the following:

Diagnostics mode 3 occupies an additional 16 inputs.

Diagnostics mode 2 and 4 occupy an additional

32 inputs.

– Assign logical IN and OUT addresses to each slave.

D

Festo P.BE-CPX-FB20/21-EN en 1202a

2-29

2. Commissioning

2.1.8 Process data entry via the CMD software

The CMD software offers as from version 4 the possibility of

assigning any input/output in the PLC/IPC bit-by-bit to each

input/output of a CPX terminal within the configured address

range. Proceed as follows:

1. Insert a CPX terminal into your bus structure (necessary

steps see section 2.1.6 “Bus configuration with the CMD

software”).

2. Select the command “Process Data” in the context menu

of the CPX terminal.

2-30

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Fig. 2/14: Open the dialogue window “Process Data”

Festo P.BE-CPX-FB20/21-EN en 1202a

2-31

2. Commissioning

You can define the I/O addresses in the following dialogue

window. In this way you can adapt the I/Os of the CPX

terminal to the PLC used. The following diagram shows the

byte-by-byte assignment for a Siemens S7:

Fig. 2/15: Enter process data – Example for “Siemens mode”

2-32

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

If necessary, swap the high byte and the low byte (byte swap).

Note

You can select the data format in two ways:

EitherviaDILswitch1.3(seeTab.1/2)orviatheCMD

software.

Selection of data format via the CMD software:

InordertocorrectthebyteassignmentintheSiemensand

Standard modes, it will suffice to assign the appropriate

I/O address to each byte.

Individual I/O assignment at bit level is only necessary in

rare cases.

The following dialogue window shows the entries required for

swappingtheassignmentofthehighbyteandthelowbyte

(example: byte swap for “Standard mode”).

Fig. 2/16: Modification of the I/O assignment (byte swap) – Example for “Standard mode”

Festo P.BE-CPX-FB20/21-EN en 1202a

2-33

2. Commissioning

2.2 Parameterisation

You can set the reaction of the CPX terminal as well as the

reaction of individual modules and channels by

parameterisation. A distinction is made between the following

parameterisations:

– System parameterisation, e.g.: switching off fault

messages, etc.

– Module parameterisation (module and channel-specific),

e. g.: monitoring, settings in the event of errors, settings

for Forcing.

Parameters of the CPX terminal

A description of the functions of the individual parameters

canbefoundintheCPXsystemmanual.

Which module parameters are available for the various

modules can be found in the manual for the relevant module

(e.g. manual for CPX I/O modules (P.BE-CPX-EA-...)).

2-34

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Prerequisites for parameterisation

With the system parameter “System start” you can influence

the starting reaction. If possible select the setting “System

start with default parametrisation and current CPX expansion”.

The desired parameterisation can then be carried out in the

initialisation phase or user-controlled.

Note

The CPX terminal can only be parameterised if the system

parameter “System start” has the setting “System start

with default parametrisation and current CPX expansion”.

If the M LED lights up permanently after the system start,

then “System start with saved parametrisation and saved CPX

expansion” is set. In this case, no other parameterisation can

be carried out.

Caution

In the case of CPX terminals on which the M LED lights up

permanently, the parameterisation will not be restored

automatically by the higher-order system if the CPX

terminal is replaced during servicing. In these cases, check

before replacement to see which settings are required and

carry out these settings.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-35

2. Commissioning

2.2.1 Parameterisation concepts

You can parameterise a CPX terminal with the bus node CPXFB20/21 with the help of the handheld device (see following

table).

The handheld is required for all parameterisation methods.

Method

Handheld Parameterisation is

Description Advantages Disadvantages

carried out via

menu-guided entries

with the handheld.

Tab. 2/7: Parameterisation concepts

Further instructions on the procedure for parameterisation

can be found in the sections which follow.

– Very user-friendly

parameterisation via

menu-guidance

(plain text).

– Parameterisation is

saved locally in the

CPX terminal and is

lost if the CPX terminal

is replaced.

– Access via remote

maintenance is not

possible.

2-36

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

Parameterisation processes

After Power ON, the CPX terminal can be parameterised via

the handheld.

Note

The last parameterisation received in the CPX terminal is

always valid.

The CPX terminal can only be parameterised if the system

parameter “System start” has the setting “System start with

default parametrisation and current CPX expansion”.

In this case, the standard parameter settings are valid in the

CPX terminal after Power ON.

Note

If the system parameter “System start” has the setting

“System start with saved parametrisation and saved CPX

expansion”, modified parameter settings in the CPX terminal will become valid immediately after Power ON.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-37

2. Commissioning

2.3 Commissioning the CPX terminal on the Interbus

In order to avoid faults (e.g. configuration and parameterisation faults) during commissioning:

•

Please observe the general commissioning instructions in

the CPX system manual.

•

Check the DIL switch settings before using and replacing

CPX terminals.

•

Note the instructions for switching on the power supply in

section 2.1.5.

•

Check the configured address range (process data and

assigned input and output bytes). If necessary, test the

I/Os.

•

Check the address assignment of the I/Os on the

CPX terminal. In order to do this, you can, if necessary,

force the I/Os (see CPX system manual).

•

Make sure that the desired parameterisation of the

CPX terminal in the initialization phase or after fieldbus

interruptions is carried out by the module. This is to ensure that if the CPX terminal is replaced, the new terminal

will also be operated with the desired parameter settings.

•

Carry out spot checks if necessary to check parameterisation with the handheld.

2-38

Festo P.BE-CPX-FB20/21-E N en 1202a

2. Commissioning

2.3.1 Fail safe

The CPX terminal supports special Fail Safe parameterisation.

System-specific I/O states can therefore be defined in the

event of a fault.

Information on Fail Safe parameterisation can be found in the

CPX system manual.

Note

In order to maintain defined I/O states in the event of a

fault, the Sysfail evaluation of the Interbus master must be

activated.

With the Sysfail evaluation in the Interbus master, it is ensured that if the PLC (CPU) stops or has a fault, the exchange

of process data between the CPU and the Interbus module

will be synchronized.

This is to prevent 0-signals from being incorrectly transmitted

via the Interbus. Otherwise, useful Fail Safe treatment or programming would not be possible.

Festo P.BE-CPX-FB20/21-EN en 1202a

2-39

2. Commissioning

2-40

Festo P.BE-CPX-FB20/21-E N en 1202a

Diagnostics and e rror h andling

Chapter 3

Diagnostics and error handling

Festo P.BE-CPX-FB20/21-EN en 1202a

3-1

3. Diagnostics and error handling

Contents

3. Diagnostics and error handling 3-1...................................

3.1 Summary of diagnostics options 3-2...................................

3.2 Diagnostics via LEDs 3-3............................................

3.2.1 Normal operating status 3-5..................................

3.2.2 CPX-specific LEDs 3-6.......................................

3.2.3 Interbus-specific LEDs 3-9....................................

3.3 Diagnosis via Interbus 3-12...........................................

3.3.1 Diagnostics mode 2 … 4 (system diagnostics) 3-12.................

3.3.2 Peripheral fault (PF) 3-20......................................

3.4 Error handling 3-21..................................................

3-2

Festo P.BE-CPX-FB20/21-E N en 1202a

3. Diagnostics and error handling

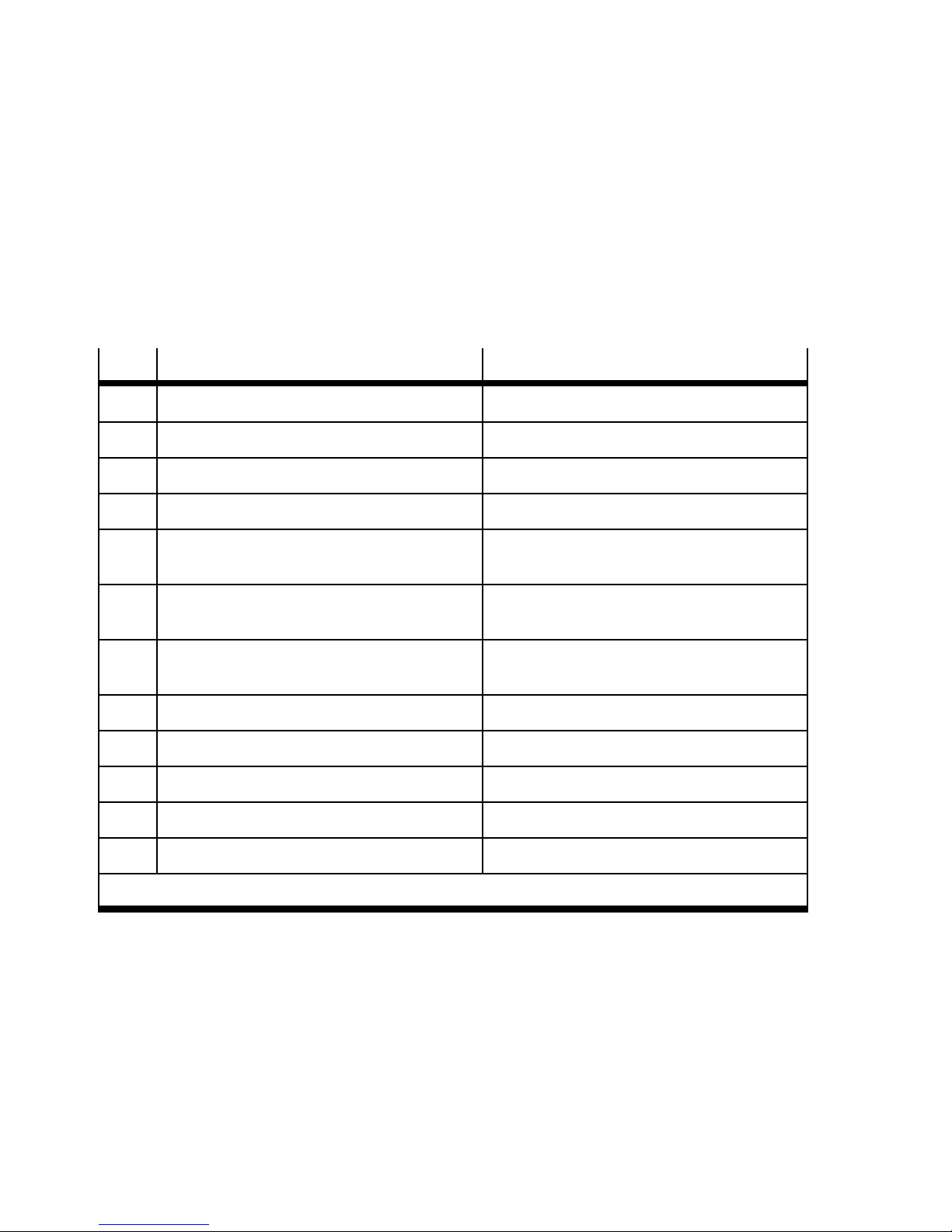

3.1 Summary of diagnostics options

The CPX terminal provides extensive and user-friendly

possibilities for diagnostics and error handling. The following

possibilities are available depending on the configuration:

Diagnostics

Brief description Advantages Detailed

option

LED display The LEDs show directly configuration

faults, hardware faults, bus faults, etc.

Diagnostics

modes 2, 3

and 4

Diagnostics

via the

handheld

1)

Please note that during diagnostics via the handheld the allocated inputs of diagnostic

modes 2 ... 4 are not displayed.

1)

Depending on diagnostic mode (2, 3,

or 4) the diagnostic bytes can be

allocatedatthebeginningorendofthe

input image table.

Diagnostic information can be shown on

the handheld in a user-friendly manner

by means of menus.

Fast “on-the-spot”

recognition of

errors

Valve diagnosis Section 3.3.1

Fast “on-the-spot”

recognition of

faults

Tab. 3/1: Diagnostics options

description

Section 3.2

Description for the

handheld

Festo P.BE-CPX-FB20/21-EN en 1202a

Peripheral fault (PF)

If a fault is recognized by the CPX terminal, a peripheral fault

will be triggered, transmitted to the module and displayed

there (see section 3.3.2).

Note

Note that the diagnostic information displayed can be dependent on the DIL switch settings on the bus node, as

well as on the parameterisation of the CPX terminal.

3-3

3. Diagnostics and error handling

3.2 Diagnostics via LEDs

LEDs for the diagnostics of the CPX terminal are available on

the bus node as well as on the individual modules.

The meaning of the L EDs on the electric modules can be

found in the manual for the relevant module.

LEDs on the bus node CPX-M-FB20/CPX-M-FB21

The LEDs on the cover indicate the operating status of the

CPX bus node.

1

Interbus-specific

LEDs:

– UL (green)

– RC (green)

– BA (green)

– RD (yellow)

– FO1 (yellow)

– FO2 (yellow)

2

CPX-specific

LEDs:

–SF(red)

– US1 (green)

– US2 (green)

– M (yellow)

Fig. 3/1: LEDs on the CPX bus node CPX-M-FB20/CPX-M-FB21

1

2

3-4

Festo P.BE-CPX-FB20/21-E N en 1202a

3. Diagnostics and error handling

LED Meaning

UL Interbus diagnostics

RC Remotebus check

BA Bus active

RD Remotebus disable

FO1 Diagnostics, incoming fibre optic cable length

FO2 Diagnostics, outgoing fibre optic cable length

SF System fault

US1 Diagnosis of the logic voltage supply

(electronics/sensors)

US2 Diagnosis of the load voltage supply

(outputs/valves)

M Parameterisation modified/forcing active

Tab. 3/2: Meaning of the LEDs

Possible LED displays on the node for the operating status of

the valve terminal are shown in the table below.

Festo P.BE-CPX-FB20/21-EN en 1202a

3-5

3. Diagnostics and error handling

The LEDs are shown in their various states as follows:

lights up; flashes; off

3.2.1 Normal operating status

In the normal operating status all green LEDs light up. The red

and yellow LEDs do not light up.

LED display

All green LEDs light up:

–UL

–RC

–BA

–US1

–US2

Red and yellow LEDs

do not light up:

–RD

–FO1

–FO2

–SF

–M

Operating

status

Normal

3-6

Festo P.BE-CPX-FB20/21-E N en 1202a

3. Diagnostics and error handling

3.2.2 CPX-specific LEDs

US1 – Power sensor/logic supply

LED (green) Procedure Status Meaning/error handling

LED

illuminates

LED flashes

LED is off

ON

OFF

ON

OFF

ON

OFF

No error. Operating

voltage/sensor supply

applied

Operating voltage/sensor

supply outside the

tolerance range

The operating

voltage/sensor supply is

not applied

–

Eliminate undervoltage

Check the operating voltage

connection of the electronics

US2 – Power load supply (outputs/valves)

LED (green) Procedure Status Meaning/error handling

LED

illuminates

LED flashes

ON

OFF

ON

OFF

No error. Load voltage

applied

Load voltage at the system

supply or additional supply

outside the tolerance

range

None

Eliminate undervoltage

ON

OFF

LED is off

Festo P.BE-CPX-FB20/21-EN en 1202a

Load voltage is not applied. Check load voltage connection

3-7

3. Diagnostics and error handling

SF (System Failure) – System fault

LED (red) Sequence

1)

Status Meaning/error handling

ON

OFF

No error –

LED is off

ON

OFF

Simple fault/information

(error class 1)

See description of error numbers in

the CPX system manual

LED flashes

ON

OFF

Error

(error class 2)

LED flashes

ON

OFF

Serious fault

(error class 3)

LED flashes

1)

The system fault LED flashes depending on the class of fault which has occurred.

Fault class 1 (simple fault): 1 * flash, pause

Fault class 2 (fault): 2 * flash twice, pause

Fault class 3 (serious fault): 3 * flash three times, pause

3-8

Festo P.BE-CPX-FB20/21-E N en 1202a

3. Diagnostics and error handling

M (Modify) – Parameterisation modified or forcing active

LED (yellow) Procedure Status Meaning/error handling

ON

OFF

LED is off

System start with default

parameterisation (factory

setting) and current CPX

equipment status is set;

None

external parameterisation

is possible (pre-setting).

LED

illuminates

ON

OFF

System start with saved

parameterisation and

saved CPX expansion has

been set; parameters and

CPX equipment status are

saved remanently; external

parameterisation is

blocked

1)

Be careful when replacing

CPX valve terminals with saved

parameterisation.

With these CPX valve terminals,

parameterisation is not carried out

automatically by the higher-order

PLC/IPC when the terminal is

replaced. In these cases check before

replacing to see which settings are

required and, if necessary, carry out

these settings.

ON

OFF

Force is ac tive

LED flashes

1)

The display of the Force function (LED flashes) has precedence over the display of the setting for

1)

The force function is enabled

(see system parameter force mode;

function no. 4402).

System start (LED lights up).

Festo P.BE-CPX-FB20/21-EN en 1202a

The LED M is intended for several functions (see also under

Interbus-specific L EDs). The status which is shown takes

place in the following sequence:

1. Force active

2. Parameters saved remanently

3-9

3. Diagnostics and error handling

3.2.3 Interbus-specific LEDs

UL (U Load) – Logic supply for bus interface

LED (green) Procedure Status Meaning/error handling

LED

ON

OFF

No error. Logic voltage

applied

–

illuminates

ON

OFF