Fervi t047/230v, t047/400v User And Maintenance Manual

USE AND

MAINTENANCE MANUAL

Milling Drilling Machine with tapping device

Art. T047/

230V

Art. T047/400V

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

fervi.com

MACHINES AND

ACCESSORIES

Page

2of43

PREFACE

Please ensure you have read this manual before operation

TRANSLATION OF

THE ORIGINAL INSTRUCTIONS

Reading this instruction manual is required before operating any of the machinery. The

guarantee that the machine will function and perform properly is strictly dependent upon the

application of all the instructions contained in t

his manual.

Operator Qualifications

The workers responsible for the use of this machine must have all the necessary

information and instruction and should be given adequate training in relation to safety

regarding:

a)

Conditions of use for the equipmen

t;

b)

Foreseeable abnormal situations, pursuant to Article 73 of Legislative Decree

81/08.

We guarantee the Machine complies with the specifications and technical instructions

described in the Manual on the date of issuance and listed herein; On the other

hand,

the machine may also be subject to important technical changes in the future, without

the manual being updated.

Therefore, contact FERVI for information about modifications that may have been

implemented.

REV. 1

September 2013

fervi.com

MACHINES AND

ACCESSORIES

Page

3of43

CONTENTS

1

INTRODUCTION

................................

................................

........................

5

2

GENERAL SAFETY WARNI

NGS

................................

................................

...

7

2.1

Gener

al safety rules for machine equipment

................................

..............................

7

2.2

Safety regulations regarding the electric system of machine

-

tools

..........................

10

2.3

Technical as

sistance

................................

................................

................................

10

2.4

Other provisions

................................

................................

................................

......

10

3

TECHNICAL SPECIFICAT

IONS

................................

................................

.

11

4

INTENDED USE AND DES

CRIPTION OF THE MACH

INE

.............................

12

4.1

Usage environment and support surface

................................

................................

..

12

4.2

Main units of the milling dril

ling machine

................................

................................

13

4.3

Identification plate

................................

................................

................................

..

14

4.4

Plates and pictograms

................................

................................

..............................

14

4.4.1

Plates on the side of the machine

................................

................................

............

14

4.4.2

Plates and pictograms

................................

................................

...........................

15

4.4.3

Spindle speed plates

................................

................................

.............................

17

4.5

Accessories supplied

................................

................................

................................

17

5

SWITCHES AND CONTROL

LEVERS

................................

..........................

18

5.1

Control button

s and indicator lights

................................

................................

.........

18

5.2

Commands for adjusting the speed of the spindle

................................

....................

20

5.3

Spider for vertical displacement of the spi

ndle

................................

........................

21

5.3.1

Graduated adjustment of the vertical displacement of the spindle

...............................

21

5.4

Adjusting the Work Table

................................

................................

.........................

22

5.4.1

Table height adjustment handle

................................

................................

..............

22

5.4.2

Handwheel for the longitudinal calibrated feed of the table

................................

.........

23

5.4.3

Handwheel for the transverse calibrated feed of the table

................................

..........

23

5.5

Adjusting the head

................................

................................

................................

...

24

5.5.1Head height adjustment handle

................................

................................

..............

24

5.5.2

Nuts and graduated scale for adjusting the inclination of the head

..............................

25

6

MACHINE SAFETY

DEVICES

................................

................................

.....

26

6.1

Grounding

................................

................................

................................

................

26

6.2

Safety devices

................................

................................

................................

..........

27

6.2.1

INTERLOC

KING MOVEABLE GUARD

................................

................................

.........

27

6.2.2

Guard fixed on the milling piston rod pin

................................

................................

..

27

7

TRANSPORT AND INSTAL

LATION

................................

............................

28

7.1

Transport

................................

................................

................................

.................

28

7.2

Mechanical installation

................................

................................

............................

29

7.3

Electrical installation

................................

................................

...............................

29

7.4

Commissioning

................................

................................

................................

.........

29

8

OPERATION

................................

................................

............................

30

8.1

Preparing for milling

................................

................................

................................

30

8.1.1

Mounting the tool for milling

................................

................................

...................

31

8.1.2

Locking the work table

................................

................................

..........................

31

8.2

Preparation for drilling

................................

................................

............................

32

8.2.1

Mounting the tool for drilling / tapping

................................

................................

.....

32

9

MAINTENANCE

................................

................................

........................

33

9.1

Routine maintenance

................................

................................

...............................

33

fervi.com

MACHINES AND

ACCESSORIES

Page

4of43

10

TROUBLESHOOTING

................................

................................

.............

34

11

DISPOSAL OF COMPONEN

TS AND MATERIALS

................................

......

35

12

ELECTRICAL CIRCUIT

................................

................................

...........

36

12.1

WIRING DIAGRAM OF THE CONTROL PANEL

................................

.........................

37

13

PARTS OF THE MACHINE

................................

................................

......

38

fervi.com

MACHINES AND

ACCESSORIES

Page

5of43

1

INTRODUCTION

This manual is considered an integral part of the machine it was attached to at the time of

purchase.

The manufacturer holds all ownership to material and intellectual property

of this manual;

any disclosure or copying, even partial, of this publication without prior written consent is

forbidden.

The purpose of this manual is to convey the necessary knowledge for the use and

maintenance of

Milling

Drilling Machine with tapping

device (Art. T032)

and to create a

sense of responsibility and knowledge of the capabilities and limits of this machine entrusted

to the operator.

As the machine is entrusted to experienced and skilled operators, the following machine must

be perfectly kno

wn by the operator if you want it to be used safely and effectively.

Operators must be properly trained and prepared, so make sure that this manual is read and

consulted by the staff responsible for commissioning, operation and maintenance of the

Milling D

rilling Machine

. This is to make all operations the safest and most effective

possible for those who carry out these tasks.

Therefore, it is imperative to strictly comply with the requirements in this manual, a

necessary condition for safe and satisfactory

operation of the machine.

Before starting operation, installation and usage of the

Milling Drilling Machine

, authorized

personnel must:

read this technical document carefully;

know which protections and safety devices are available on the machine, their l

ocation and

how they work.

The manufacturer waives any and all responsibility for damage to people and/or

things caused by non

-

observance of the instructions in this manual.

The

Milling Drilling Machine

has been designed and built with mechanical guards

and

safety devices designed to protect the operator / user from possible injury. It is strictly

forbidden to modify or remove guards, safety devices and caution labels. If you do so

temporarily (for example, for the purposes of cleaning or repair), make su

re that no one can

use the machine.

Operators will be held fully responsible for any changes they have made to the

machine; the manufacturer will not be held responsible for any damage to persons

and/or property resulting from maintenance performed by un

qualified personnel

and in a manner that differs from the operating procedures shown below.

G

RAPHIC REPRESENTATIO

N OF SAFETY

,

OPERATIONAL AND RISK

WARNINGS

The following boxes are designed to attract the attention of the reader / user for the

proper

and

safe

use of the machine:

fervi.com

MACHINES AND

ACCESSORIES

Page

6of43

Attention

This highlights behavioural rules to prevent damage to the machine and/or the occurrence of

dangerous situations.

Residual Risks

This highlights the presence of dangers that cause residual risks to which the ope

rator must

pay attention in order to avoid injury or damage to property.

Operator Qualifications

Workers responsible for machine operation must have all necessary information and education

and should be given adequate safety training in: a) machine op

erating conditions, b)

foreseeable abnormal situations, pursuant to Article 73 of Legislative Decree 81/08

For safe and simple use of the

Milling Drilling Machine (Art. T047)

, you must read this

manual carefully to acquire full knowledge of the machine a

nd the general precautions to be

observed during operation.

. In other words, durability and performance are strictly dependent

on how they are used.

Even if already familiar with this sort of machine, it is necessary to follow the instructions

herein, in a

ddition to the general precautions to be observed while working.

Acquire full knowledge of the machine.

Read this manual carefully to understand: operation, safety devices and all necessary

precautions. All this is to allow safe use of the equipment.

Wear

appropriate clothing for the job.

The operator must appropriate clothing. To prevent the occurrence of unpleasant

accidents.

Maintain the machine with care.

Using the Machine

The machine must only be used by qualified personnel trained to use the mach

ine by

authorized personnel.

fervi.com

MACHINES AND

ACCESSORIES

Page

7of43

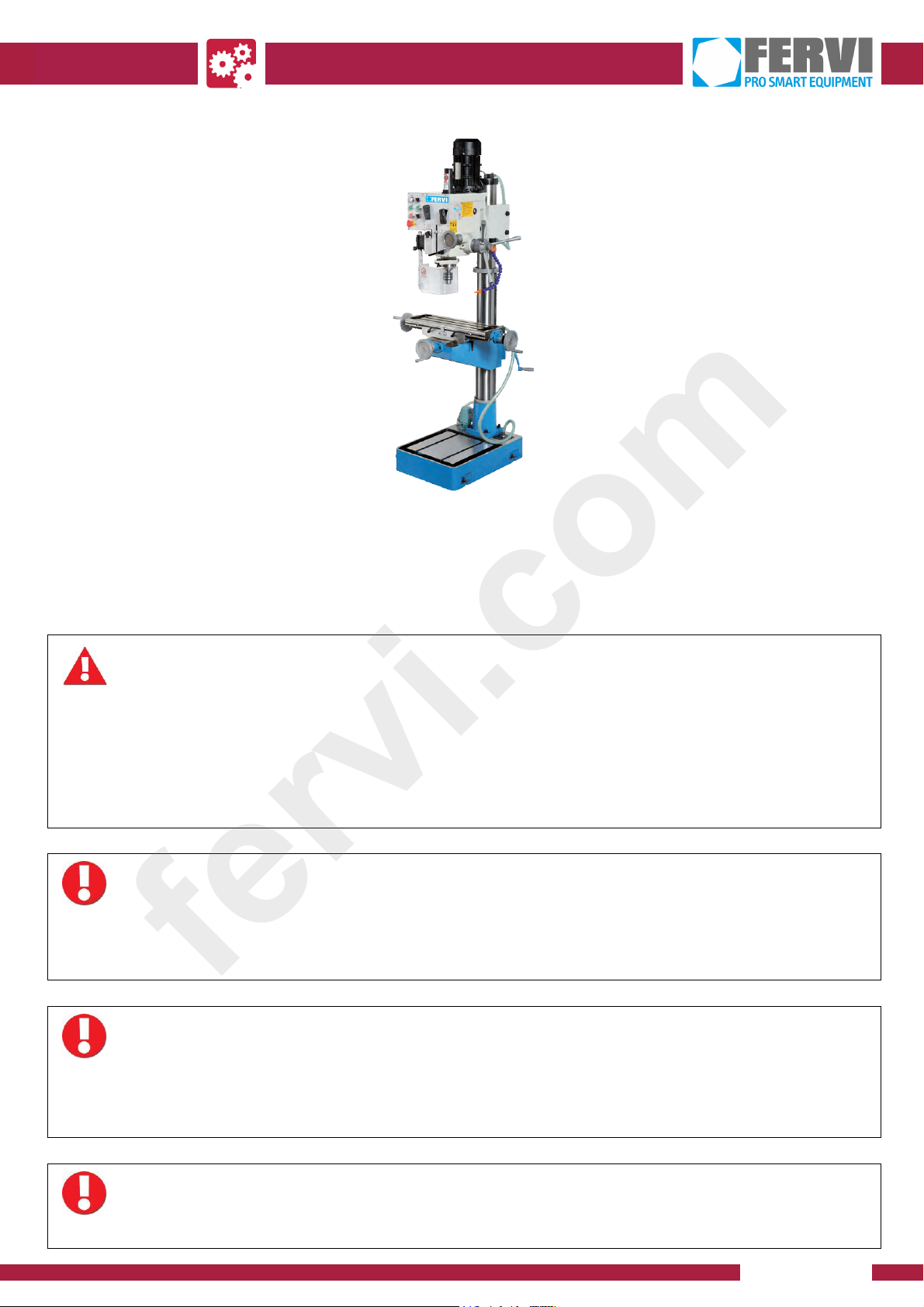

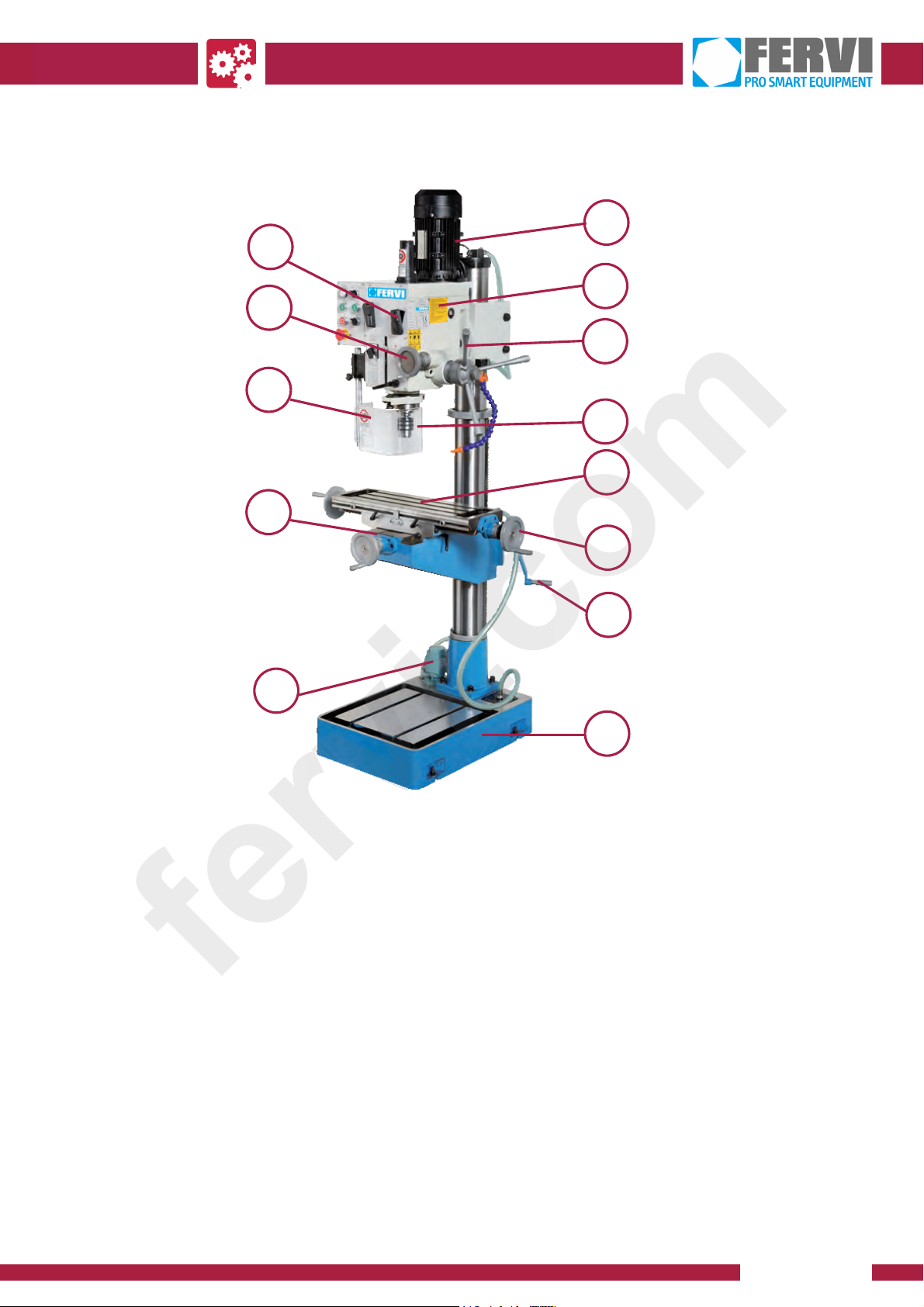

Figure

1-Overall view

2

GENERAL SAFETY WARNI

NGS

2.1

General safety rules for machine equipment

Accident

The operation of drilling or tapping always presents a risk of injury associated with the

poss

ibility of accidental contact of parts of the body with the tool in motion, detachment of

splinters from the workpiece, tool breakage, or ejection of a badly blocked piece.

There is no "intrinsic" means of safety, just as there is no worker who, while car

eful, can

"always" avoid an accident. Therefore, DO NOT underestimate the risks associated with

using the machine and concentrate on the work in progress.

Risks related to Using the Machine

Despite the implementation of all safety devices for safe us

e of the machine, it is necessary

take note of all the requirements for the prevention of the accidents reported in various parts

of this manual.

Risks related to Using the Machine

Every person who is responsible for the use and maintenance of the ma

chine should have first

read the instruction manual, particularly the chapter on safety information.

It is recommended that the plant safety manager get written confirmation of the above.

Risks associated with using the machine

During all work phases

with the machine, you should proceed with great caution in order

fervi.com

MACHINES AND

ACCESSORIES

Page

8of43

to avoid damage to persons, to the property or to the machine itself.

Please use the machine only for its expected uses (drilling or tapping).

Don't tamper with the safety devices equipping t

he machine.

Operator Protection

Before starting any work on the machine, the operator must wear the appropriate personal

protective equipment (PPE) such as gloves and eye protection (see section 6.5 of this

manual).

1.

Always check the efficiency and in

tegrity of the machine.

2.

Before connecting the machine to the mains, make sure that the rotating parts are not

damaged or badly worn. Make sure that the switch is in the neutral position.

3.

Do not start the machine in an enclosed or poorly ventilated area, or

in the presence of a

flammable and/or explosive atmosphere. Do not use the machine in damp and/or wet

locations, or those exposed to rain.

4.

Avoid starting accidentally.

5.

Before starting the machine, get used to ensuring that no remaining maintenance and

ser

vice keys are inserted.

6.

Keep the workplace tidy and free from obstruction; disorder causes accidents.

7.

Make sure that your work environment is forbidden to children, strangers and animals.

8.

Do not perform tasks on the machine other than those for which it wa

s designed. Only

use the machine in the manner in which it was intended, as described in this instruction

manual.

9.

Work without disturbances.

10.

Work areas must be well lit.

11.

Always wear eye protection and protective gloves while working. If dust is produced, u

se

the appropriate masks.

12.

Wear appropriate clothing. Loose clothing, dangling jewelry, long hair, etc.., can get

caught in the spindle and moving parts, causing irreparable injury.

13.

Firmly secure the workpiece before starting the drill.

14.

Always use the tool

(tip or tap) in an appropriate manner. Perform only the work for

which the tool is made. Do not use the tool for inadequate work.

15.

Only use suitable resistance tools in relation to the work that is to be done. This is to

avoid risky and unnecessary overload

ing for the operator, which may be harmful for the

life of the tools themselves.

16.

Do not pick up moving tools or other moving parts. To stop the spindle on the machine,

always only use the stop command device.

17.

17. Do not remove the shavings from the table

with hands, even at a standstill. To do

this, use tongs or a palette knife.

18.

When the cutting tools need to be replaced or the speed needs to be changed, stop the

motor and wait for the spindle to stop.

19.

Do not leave the machine until the spindle and the to

ol are completely stopped.

20.

After the work is completed, clean the tool and check its efficiency.

21.

Replace worn and/or damaged parts, check that the repairs and protections work properly

before operating. Eventually, if necessary, have it checked by Service

staff. Use only

original spare parts.

22.

Cut the mains voltage supply of the machine when:

the machine is not being operated;

it is left unattended;

performing maintenance or registration, because the machine does not work properly;

fervi.com

MACHINES AND

ACCESSORIES

Page

9of43

the tool is replaced;

it i

s being moved or transported;

cleaning.

23.

It is recommended that users of this publication, for maintenance and repair, have a basic

knowledge of the mechanical principles and procedures inherent in repair technique.

24.

The company safety officer is required to

make sure that machine operators

have read and understood this manual in its entirety.

fervi.com

MACHINES AND

ACCESSORIES

Page

10of43

2.2

Safety regulations regarding the electric system of machine

-

tools

Risks associated with using the machine

1.

Do not modify the electrical system in any way. Any attem

pt in this regard may jeopardize

the operation of electrical devices, causing malfunction or accident.

2.

Work carried out in the electrical system of the machine must, therefore, be carried out

only by qualified and authorized personnel.

3.

If one hears unusual

noises, or feels something strange, immediately stop the machine.

Then carry out an inspection and, if necessary, perform any repairs as required.

1.

The supply voltage must correspond to that stated on the identification plate and in the

technical specifi

cations:

Do not use any other power supply.

2.

The use of a life

-

saving device on the electric power supply is recommended. For more

detailed information, contact a trusted electrician.

3.

The power plug must be equipped with a grounding conductor. Any extensi

on cords must

be of equal or greater length than the power cord on the machine.

4.

The power supply cable (and its possible extension cable) should never come in contact

with hot objects, sharp edges, wet or oiled surfaces.

5.

The power cord should be checked re

gularly and before each use to check for signs of

damage or wear. If these are not in good condition, do not use the machine and replace

the cable.

6.

Do not use the power cord to detach its plug from the socket.

2.3

Technical assistance

For any problem or reques

t for clarification, please do not hesitate to contact the support

service of the retailer from whom you purchased the product.

2.4

Other provisions

It is forbidden to tamper with safety devices

The first thing to do when starting work is to check for the pre

sence and integrity of the

protections and the operation of the safety devices.

If any defect is detected, do not use the Milling Drilling Machine !!

Even more so, it is strictly forbidden to modify or remove guards, safety devices,

labels and indication

signs.

fervi.com

MACHINES AND

ACCESSORIES

Page

11of43

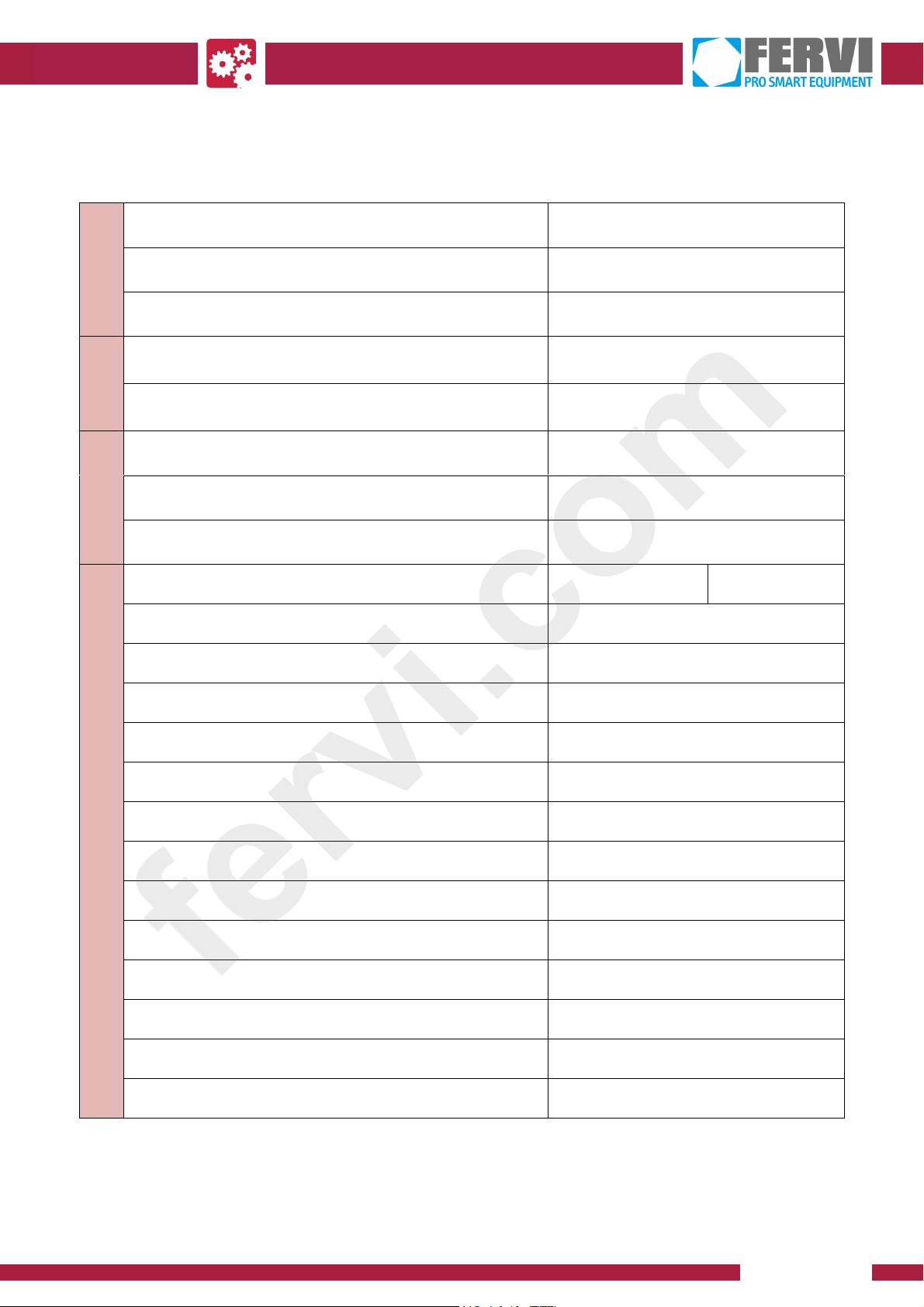

3

TECHNICAL SPECIFICAT

IONS

Size

Height (mm)

1960

Width (mm)

740

Depth (mm)

790

Masses

Net mass (kg)

380

Gross mass (kg)

390

Power supply

Rated voltage (V)

230

-

400

Frequency (Hz)

50

Power (W)

1500

General Characteristics

Drilling capac

ity (mm)

Cast iron:

40Steel:

32

Tapping capacity (mm)

22Spindle travel (mm)

130

Distance spindle

-

pillar (mm)

260

Column diameter (mm)

115

Morse taper

CM / MT 4

Sleeve diameter (mm)

76

Longitudinal table movement (mm)

375

Radial

table movement (mm)

190

Acoustic pressure level (dB (A))

67.2

Speed (r/min)

230 V

75 ÷

16

00

Speed (r/min) 400 V

75 ÷ 3200

Speed number 230 V

6

Speed number 400 V

12

fervi.com

MACHINES AND

ACCESSORIES

Page

12of43

4

INTENDED USE AND DES

CRIPTION OF THE

MACHINE

Milling Drilling Machines (Art. T0

47)

are machine

-

tools designed for executing some

simple mechanical operations, such as:

drilling (max drilling capacity: 32 mm for steel);

tapping;

milling.

The machine is made to perform such machining of different materials, changing the tool

depending

on the operation to be performed and the material of the work

-

piece.

The machine has 16 different spindle rotation speeds. The motor runs at constant speed,

therefore the machine is equipped with a specific power transmission system with gears for

varyin

g the spindle rotation speed.

The latter can be set using the appropriate adjustment levers. In any case, the adjustment of

the spindle speed must always be performed with the machine

stopped and not powered

.

The tool feed is manual.

Intended use and ma

terials

The machine has been designed and manufactured for the use specified. Any use and lack of

respect for the technical parameters established by the manufacturer may be dangerous to

operators; therefore, the manufacturer cannot assume any liability

for resulting damages.

4.1

Usage environment and support surface

The Drilling Machine is equipped with a support base and must be installed and used on flat

surfaces, with ergonomic features and adequate resistance.

It is very important to remember that the

machine weight is about 400 kg. For this reason,

before installing the machine it is necessary to identify an area having a surface of adequate

hardness and strength, capable of supporting such weight.

You should leave enough space around the machine to en

sure proper maintenance and

cleaning of all parts of the machine.

The Drill can operate in enclosed working environments (production departments,

warehouses, etc.), i.e. those that are protected from the weather and where there is no

danger of fire or expl

osion.

The operating temperature is within the range of +5 / +50°C.

The environment must also be sufficiently illuminated so as to ensure operation in maximum

safety (at least 50 lux is recommended).

Risks associated with the work environment

ALWAYS c

omply with the instructions about the machine's work environment, especially about

the safety and strength features of the surface.

fervi.com

MACHINES AND

ACCESSORIES

Page

13of43

4.2

Main units of the milling drilling machine

Figure

2-Overview of the Machine.

1.

Speed controller;

2.

Handwheel for slow feed with calibrated depth;

3.

Spindle protection device (interlocked guard)

4.

Handwheel for calibrated transverse feed;

5.

Electric motor;

6.

CE Plate;

7.

Spindle quick descent Lever / Spider;

8.Spindle;

9.

Work table;

10.

Handwheel for calibrated longitudinal feed;

11.

Handle for height adjustment of work table.

12.

Base

13.

Coolant pump

4

1

2

8

9

11

12

10

1356

7

3

fervi.com

MACHINES AND

ACCESSORIES

Page

14of43

4.3

Identification plate

On the machine, the identification plate is located on the side of the head (see figure below).

Figure

3–CE plate.

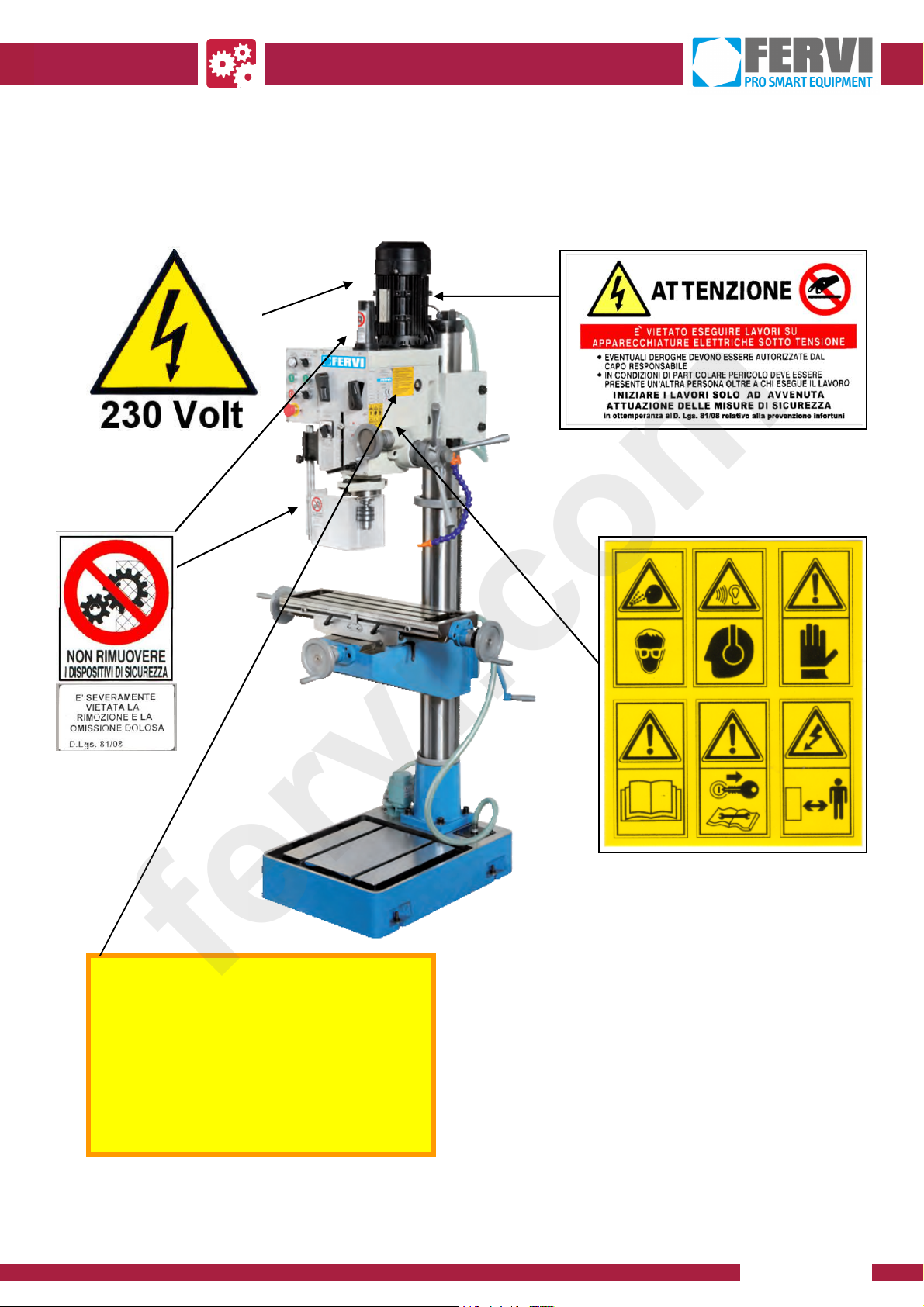

4.4

Plates and pictograms

4.4.1

Plates on the side of the machine

On the left side of the machine, near the main switch for disconnecting the power supply

there are the following plates:

Figure

4–Left side pictograms.

fervi.com

MACHINES AND

ACCESSORIES

Page

15of43

4.4.2

Plates and pictograms

T047/230V

Figure

5-Pictograms T047/400V60

-

PLEASE READ THE INSTRUCTIONS BEFORE USING

THE MACHINE

-

BEFORE CARRYING OUT ANY ADJUSTMENT OR

MAINTENANCE ON THE MACHINE, DETACH ITS

PLUG FROM THE POWER SUPPLY SOCKET.

-

BEFORE OPERATING, SECURE SOLIDLY TO THE

TABLE THE PIECE TO

BE MACHINED.

-

FOR OTHER INFORMATION ON SAFETY, PLEASE

CONSULT THE INSTRUCTION MANUAL.

fervi.com

MACHINES AND

ACCESSORIES

Page

16of43

PLATE IN ITALIAN

PLATE IN ENGLISH

-

LEGGERE ATTENT

AMENTE LE ISTRUZIONI PRIMA

DI UTILIZZARE LA MACCHINA

-

PRIMA DI INTERVENIRE SULLA MACCHINA PER

QUALSIASI REGOLAZIONE O PER MANUTENZIONE

TOGLIERE LA SPINA DALLA PRESA DI CORRENTE

-

FISSARE SALDAMENTE ALLA TAVOLA IL PEZZO DA

LAVORARE PRIMA DI OPERARE

-

PER ALT

RE INFORMAZIONI SULLA SICUREZZA SI

CONSIGLIA DI CONSULTARE IL MANUALE

D’ISTRUZIONI.

-

PLEASE READ THE INSTRUCTIONS BEFORE USING

THE MACHINE

-

BEFORE CARRYING OUT ANY ADJUSTMENT OR

MAINTENANCE ON THE MACHINE, DETACH ITS PLUG

F

ROM THE POWER SUPPLY SOCKET.

-

BEFORE OPERATING, SECURE SOLIDLY TO THE

TABLE THE PIECE TO BE MACHINED.

-

FOR OTHER INFORMATION ON SAFETY, PLEASE

CONSULT THE INSTRUCTION MANUAL.

ATTENZIONE

È VIETATO ESEGUIRE LAVORI SU

APPARECCHIATURE ELETTRICHE SOTTO

T

ENSIONE

EVENTUALI DEROGHE DEVONO ESSERE

AUTORIZZATE DAL CAPO RESPONSABILE

IN CONDIZIONI DI PARTICOLARE PERICOLO DEVE

ESSERE PRESENTE UN’ALTRA PERSONA OLTRE A CHI

ESEGUE IL LAVORO

INIZIARE I LAVORI SOLO AD AVVENUTA

ATTAZIONE DELLE MISURE DI SICUREZZA

In ot

temperanza al Dgs.81/08 relativo alla prevenzioni

infortuni

ATTENTION

IT IS PROHIBITED TO WORK ON LIVE ELECTRICAL

EQUIPMENT

ANY EXCEPTIONS MUST BE APPROVED BY THE HEAD

MANAGER

UNDER PARTICULARLY DANGEROUS CONDITIONS,

ANOTHER PERSON MUST BE PRESENT WHO IS NOT

PERFORMING THE WORK

ONLY BEGIN WORKING WHEN SAFETY MEASURES

HAVE BEEN IMPLEMENTED

In accordance with Legislative Decree 81/08 on accident

prevention

NON

RIMUOVERE

I DISPOSITIVI DI

SICUREZZA

DO NOT

REMOVE

THE SAFETY DEVICES

fervi.com

Loading...

Loading...