Fervi 0505 Operation And Maintenance Manual

OPERATION AND

fervi.com

MAINTENANCE MANUAL

Tilting bench belt sander

Art. 0505

ORIGINAL INSTRUCTIONS

MACHINES AND

ACCESSORIES

fervi.com

FOREWORD

Read this manual before operating any machinery

ORIGINAL INSTRUCTIONS

Before starting any operation it is compulsory to read this instruction manual. The guarantee

that the machine will function and perform properly is strictly dependent upon the application

of all the instructions contained in this manual.

Operator Qualification

The operators assigned to using this machine must be supplied with all of the necessary

information and instruction and should be provided with adequate training regarding

safety in pertaining to:

a) The conditions of use of the equipment;

b) Foreseeable abnormal situations, pursuant to Article 73 of Legislative Decree

81/08.

We guarantee the Machine's conformity to the specifications and technical instructions

described in the Manual on the date of issuance and listed herein; On the other hand,

the machine may also be subject to important technical changes in the future, without

the manual being updated.

Therefore, see FERVI for information about modifications that could be implemented.

Page 2 of 41

REV. 1 November 2013

MACHINES AND

ACCESSORIES

fervi.com

CONTENTS

1 INTRODUCTION ........................................................................................5

1.1 Graphic form of the alerts related to safety and operation, and risk warnings..............5

1.2 Preface..........................................................................................................................6

2 SAFETY WARNINGS ..................................................................................7

2.1 General safety rules for machine tools..........................................................................7

2.2 Safety rules for electrical machine equipment ..............................................................9

2.3 Technical support..........................................................................................................9

2.4 Other provisions ...........................................................................................................9

2.4.1 It is forbidden to tamper with safety devices ................................................................. 9

3 TECHNICAL SPECIFICATIONS .................................................................10

4 DESCRIPTION OF THE SANDER ...............................................................11

4.1 Description of the main parts ...................................................................................... 11

4.2 Identification plate .....................................................................................................12

4.3 Plates and pictograms.................................................................................................12

5 DESCRIPTION OF THE CONTROLS ...........................................................15

5.1 On and off switches ....................................................................................................15

6 MACHINE SAFETY DEVICES.....................................................................16

6.1 Electrical safety devices ..............................................................................................16

6.2 "Mechanical" Safety Devices .......................................................................................17

7 ASSEMBLY...............................................................................................18

7.1 Assembly of the stop - piece support ..........................................................................18

7.2 Assembling the work table..........................................................................................18

8 INSTALLATION .......................................................................................20

9 COMMISSIONING....................................................................................22

9.1 Assembling the abrasive disc ......................................................................................22

9.2 Assembling the abrasive belt ......................................................................................23

10 OPERATION..........................................................................................26

10.1 Instructions for Use .................................................................................................26

10.2 Starting/Stopping ....................................................................................................27

10.3 Sanding surfaces with the horizontal belt................................................................28

10.4 Sanding ends with the disc ......................................................................................29

10.5 Sanding of curved surfaces ......................................................................................31

10.6 Sanding edges (with the table tilted).......................................................................32

Page 3 of 41

MACHINES AND

ACCESSORIES

fervi.com

10.7 Sanding ends with the vertical belt ..........................................................................33

11 MAINTENANCE .....................................................................................35

11.1 Routine maintenance ...............................................................................................35

11.2 Checking / Replacing the drive belt .........................................................................36

12 TROUBLESHOOTING .............................................................................37

13 DISPOSAL OF COMPONENTS AND MATERIALS...................................... 38

14 ELECTRIC CIRCUIT ...............................................................................39

15 EXPLODED VIEW AND SPARE PARTS ....................................................40

Page 4 of 41

MACHINES AND

ACCESSORIES

fervi.com

1 INTRODUCTION

The purpose of this manual is to convey the necessary knowledge for the use and

maintenance of and to create a sense of responsibility and knowledge of the capabilities and

limits of the sander machine entrusted to the operator.

As the machine is entrusted to experienced and skilled operators, the following machine must

be perfectly known by the operator if you want it to be used safely and effectively.

Selecting personnel is an important factor for efficiency and safety in the workplace, and the

people considered suitable to perform a specific job must have the sufficient physical and

mental capacity to allow them to follow the instructions that they are given.

1.1 Graphic form of the alerts related to safety and operation, and

risk warnings

The following boxes are designed to attract the attention of the reader/user for the purposes

of proper and safe use of the machine:

Pay attention

This highlights behavioural rules to prevent damage to the machine and/or the occurrence of

dangerous situations.

Residual Risks

This highlights the presence of dangers that cause residual risks to which the operator must

pay attention in order to avoid injury or damage to property.

Page 5 of 41

MACHINES AND

ACCESSORIES

fervi.com

1.2 Preface

For safe and easy operation of the machine, this manual must be read carefully in order to

acquire the necessary knowledge. In other words, durability and performance are strictly

dependent on how it is used.

Even if already familiar with the sander, it is necessary to follow the instructions contained

herein, in addition to the general precautions to be observed while working.

Acquire full knowledge of the machine.

Read this manual carefully to understand: operation, safety devices and all necessary

precautions. All this is to allow safe use of the machine.

Wear appropriate clothing for the job.

The operator must wear appropriate clothing to prevent the occurrence of accidents.

Maintain the machine with care.

Using the machine

The machine must only be used by qualified personnel trained to use the machine by

authorised personnel.

Page 6 of 41

MACHINES AND

ACCESSORIES

fervi.com

2 SAFETY WARNINGS

2.1 General safety rules for machine tools

Risks associated with the use of the machine

Do NOT underestimate the risks related to the use of the machine and stay focused on the

work you are carrying out.

Risks associated with the use of the machine

Despite the implementation of all safety devices for safe use of the equipment, it is necessary

to take note of all the accident prevention requirements highlighted in various parts of this

manual.

Risks associated with the use of the machine

Each and every person who is responsible for the use and maintenance of the device should

first have read the instruction manual, particularly the chapter dealing with safety.

It is recommended that the plant safety manager get written confirmation of the above.

Operator safety devices

Before starting any type of work on the machine, the operator must wear appropriate

personal protective equipment (PPE) such as goggles and gloves.

1. Read this manual carefully, in order to work safely.

2. Always check the efficiency and integrity of the machine.

3. Before connecting the machine to the mains, make sure that the rotating parts are not

damaged or badly worn. Make sure that the switch is in the neutral position.

4. Do not start the machine in an enclosed or poorly ventilated area, or in the presence of

a flammable and/or explosive atmosphere. Do not use the machine in damp and/or wet

locations, or those exposed to rain.

5. Avoid starting accidentally.

6. Before starting the machine, get used to ensuring that no remaining adjustment or

maintenance wrenches have remained inserted.

7. Keep the workplace tidy and free from hindrances; disorder causes accidents.

8. Make sure that the work environment is forbidden to children, non-employees and

animals.

Page 7 of 41

MACHINES AND

ACCESSORIES

fervi.com

9. Do not perform tasks on the machine other than those for which it was designed. Only

use the machine in the manner in which it was intended, as described in this instruction

manual.

10.Work without disturbances.

11.Work areas must be well lit.

12.Always wear eye protection and protective gloves while working. If dust is produced,

use the appropriate masks.

13.Wear appropriate clothing. Loose clothing, dangling jewellery, long hair, etc.., can get

caught in the moving parts, causing irreparable injury.

14.Do not lean on the belts while they are moving.

15.Make sure the abrasive belt and disc are in good condition of wear in order to obtain the

best performance from the machine. Follow the instructions for changing the abrasive

belt and disc.

16.To stop the equipment on the machine, always only use the stop command device (red

button).

17.Do not leave the machine unattended until the tools and the other moving parts have

completely stopped.

18.Replace worn and/or damaged parts, check that the guards and protection devices work

properly before operating.

19.If necessary, have the machine checked by technical assistance personnel. Use only

original spare parts.

20.Unplug the power cord of the machine from the power outlet when:

the machine is not being operated;

is left unattended;

you are performing maintenance or adjustment because the machine does not work

properly;

the power cable is damaged;

replace the abrasive belt and/or disc;

in case the machine is being moved to another location;

you are cleaning the machine.

21.It is recommended that users of this publication, for maintenance and repair, have a

basic knowledge of mechanical principles and of repair technique procedures.

22.The person responsible for company safety is to make sure that the staff

responsible for using the machine have read and understood this manual in its

entirety.

23.The company safety manager is responsible for monitoring the company's risk

status according to Legislative Decree no. 81/08.

Page 8 of 41

MACHINES AND

ACCESSORIES

fervi.com

2.2 Safety rules for electrical machine equipment

Changes in the Electrical System

Do not modify the electrical system in any way. Any attempt in this regard may

jeopardize the operation of electrical devices, causing malfunction or accident.

Work carried out in the electrical system of the machine must, therefore, be carried

out only by qualified and authorized personnel.

If one hears unusual noises, or feels something strange, immediately stop the

machine. Then carry out an inspection and, if necessary, perform any repairs as

required.

1. Ensure supply voltage complies with the label and technical specifications (230 V / 50

Hz). Do not use any other power supply.

2. The use of a life-saving device on the electric power supply for a nominal trip range of

10 to 30 mA is recommended. For more detailed information, contact a trusted

electrician.

3. The mains power outlet should be bipolar grounded (10 / 16 A / 250 V), extension

cables must have sections that are the same or greater than the sections of the power

cable of the machine.

4. The power supply cable (and its possible extension cable) should never come in contact

with hot objects, sharp edges, wet or oiled surfaces.

5. The power cord should be checked regularly and before each use to check for signs of

damage or wear. If these are not in good condition, do not use the machine and replace

the cable.

6. Do not use the power cord to lift the machine or to remove the plug from the socket.

2.3 Technical support

For any problems or concerns, please contact, without hesitation, your dealer's Customer

Service, who has competent and specialized staff, specific equipment and spare parts.

2.4 Other provisions

2.4.1 It is forbidden to tamper with safety devices

The first thing to do when starting work is to check for the presence and integrity of the

protections and the operation of the safety devices.

If any defect is encountered do not use the Sander!

It is strictly forbidden to modify or remove guards, safety devices, labels and

caution signs.

Page 9 of 41

MACHINES AND

3 TECHNICAL SPECIFICATIONS

fervi.com

Model Art. 0505

Weight (kg) 18

Size (mm) 460X380X270

Voltage (V) 230

Frequency (Hz) 50

Power (W) 500

Noise LpA(dB) 74

Type of tool Abrasive belt

ACCESSORIES

Size (mm) 914X100

Type of tool Abrasive disc

Diameter (mm) 150

Page 10 of 41

MACHINES AND

ACCESSORIES

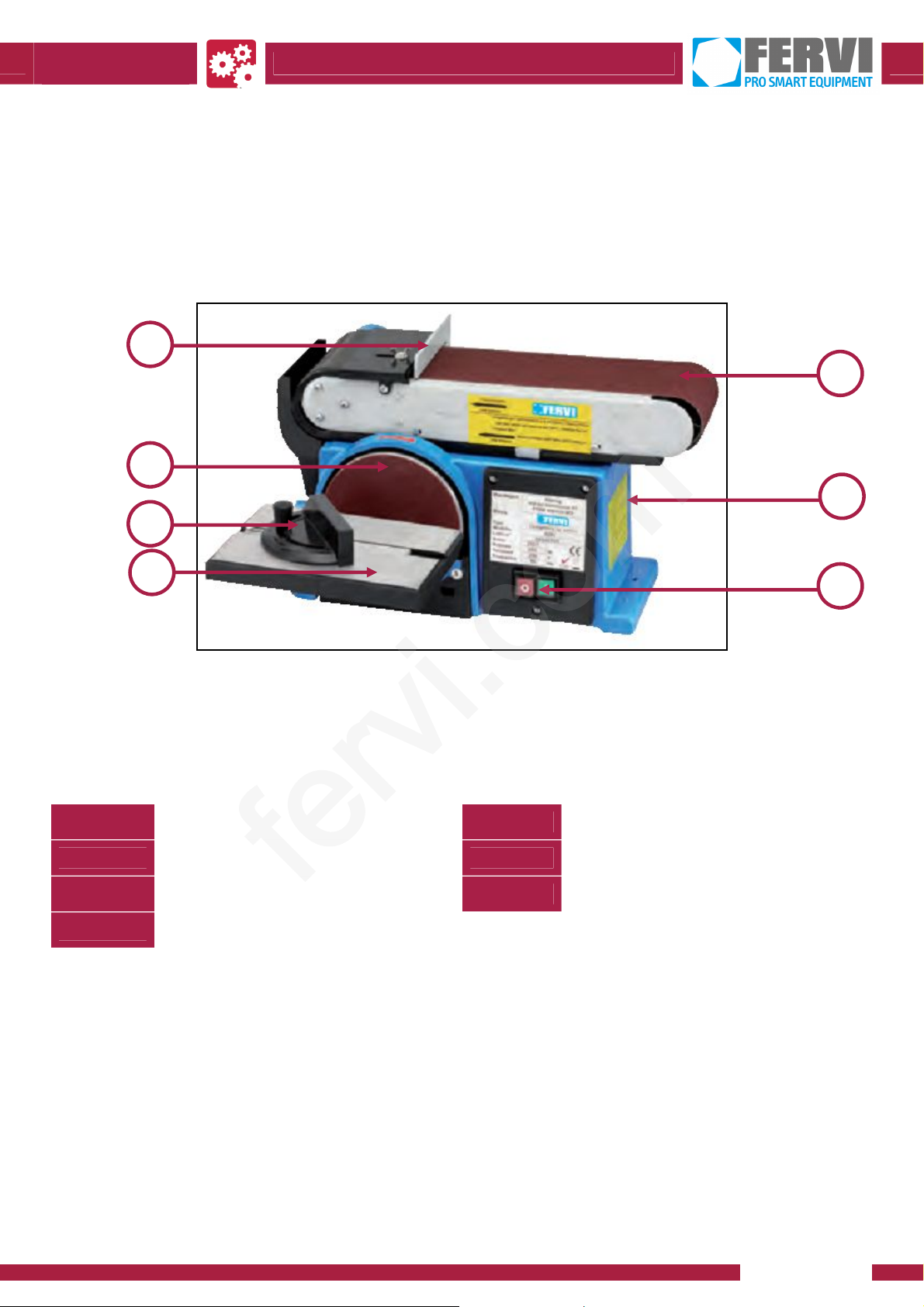

Machine body

Abrasive disc

Work table

ON/OFF buttons

Stop

-

piece support

Piece orientation bracket

Abrasive belt

3

5

724

1

4

fervi.com

4 DESCRIPTION OF THE SANDER

4.1 Description of the main parts

Figure 1 – Main parts of the Bench sander.

1

2

3

4

5

6

7

Page 11 of 41

MACHINES AND

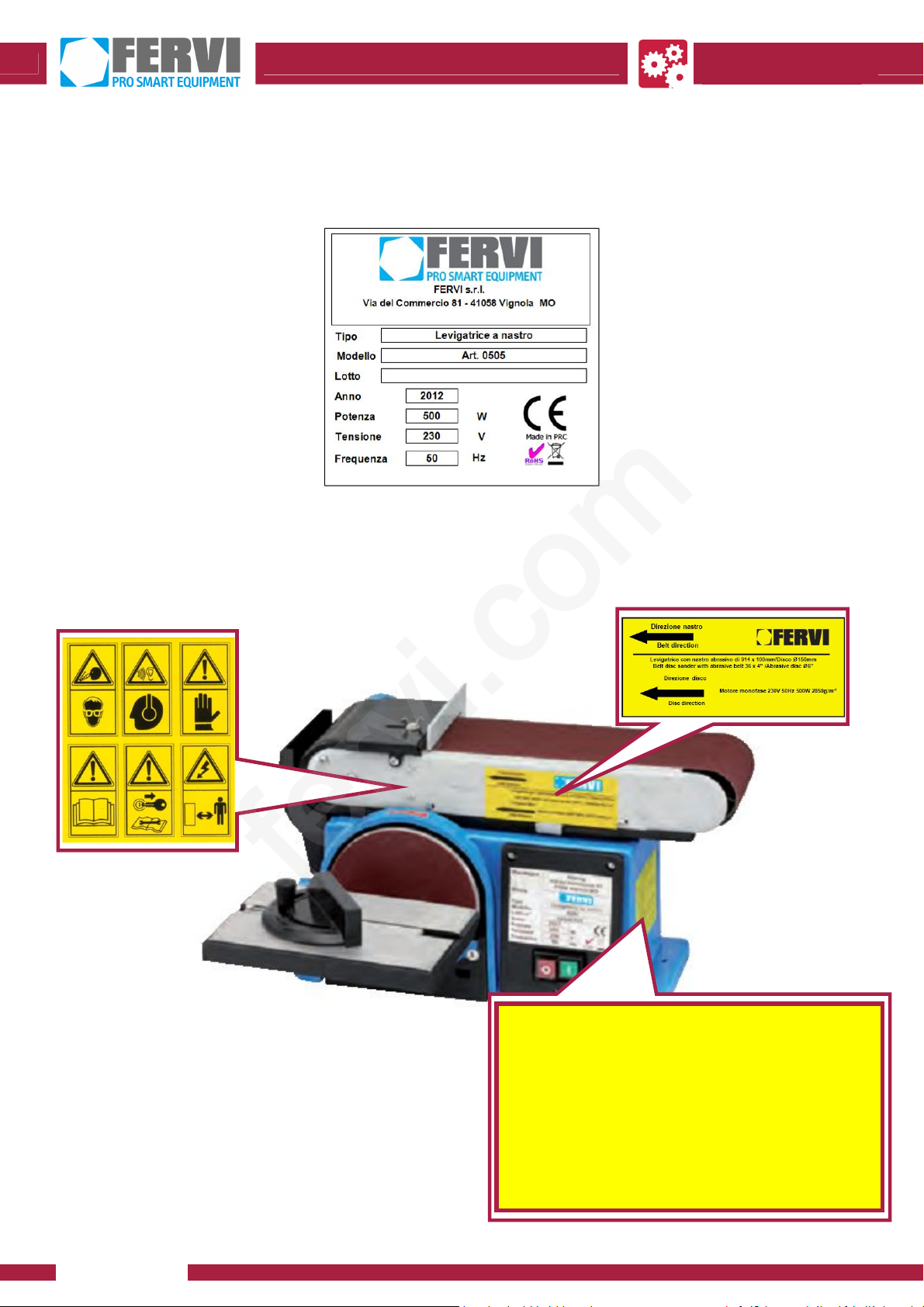

4.2 Identification plate

ATTENZIONE!

istruzioni.

fervi.com

The following identification plate is attached to the machine:

Figure 2 – Plate Art. 0505

ACCESSORIES

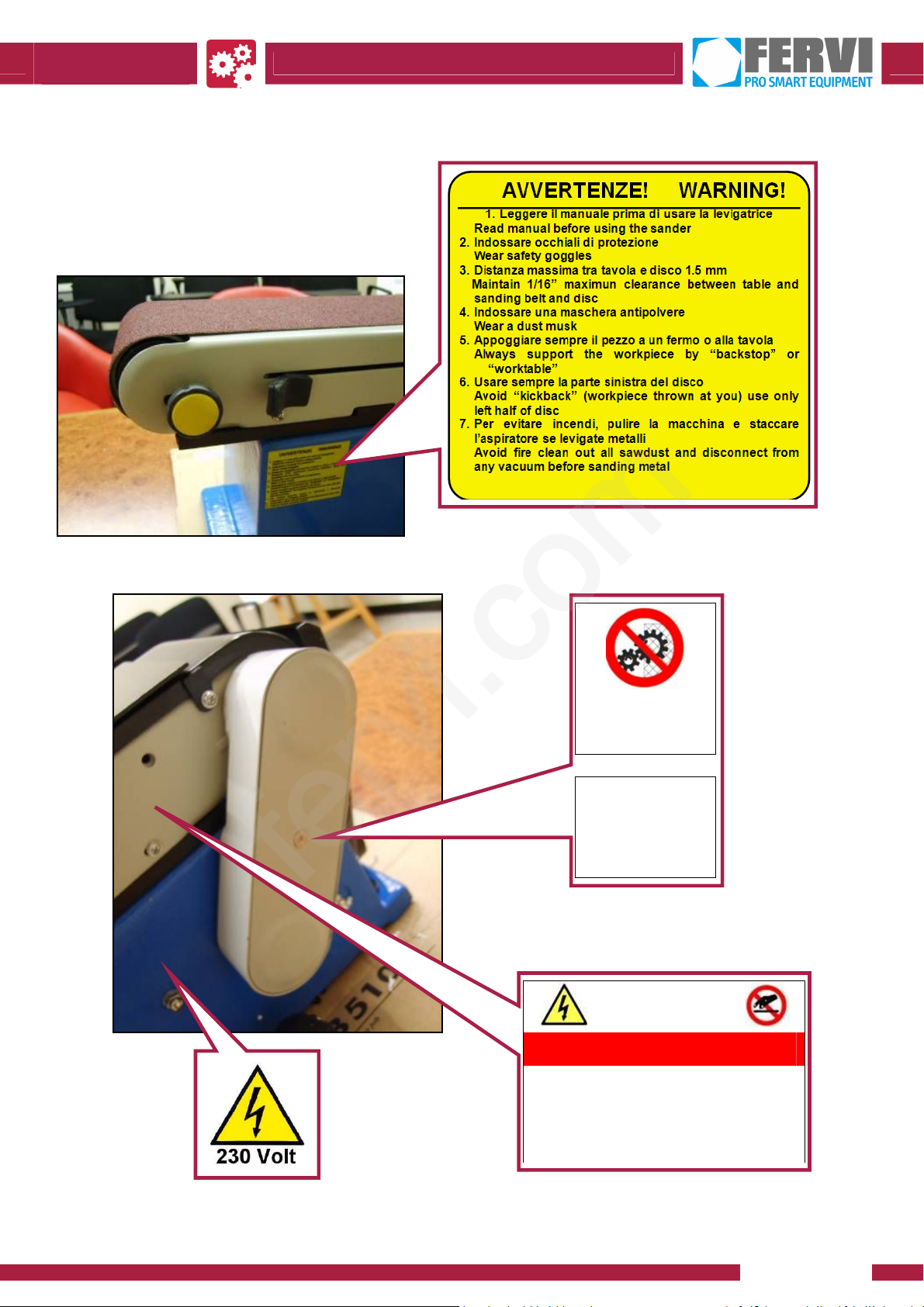

4.3 Plates and pictograms

Attached to the machines are the following warning plates and pictograms:

Page 12 of 41

Leggere attentamente le istruzioni prima di utilizzare la macchina

Non avvicinare le mani all’utensile mentre è in movimento

Non regolare la macchina mentre è in funzione

Indossare sempre occhiali e guanti antinfortunistici adeguati.

Scollegare la macchina dall’alimentazione elettrica in caso di riparazioni o

regolazioni

Non indossare abiti am pi, cravatte, collane, bracciali e raccogliere i capelli lunghi

perché potrebbero essere agganciati alle parti in movimento

Non rimuovere o disattivare i dispositivi di sicurezza.

Per altre indicazioni sulla sicurezza, si consiglia la consultazione del manuale di

MACHINES AND

ACCESSORIES

infortuni

fervi.com

NON

RIMUOVERE

I DISPOSITIVI DI

SICUREZZA

È SEVERAMENTE

VIETATA LA

RIMOZIONE E LA

OMISSIONE

DOLOSA

D.Lgs 81/08

ATTENZIONE

È VIETATO ESEGUIRE LAVORI SU

APPARECCHIATURE ELETTRICHE SOTTO

EVENTUALI DEROGHE DEVONO ESSERE

AUTORIZZATE DAL CAPO RESPONSABILE

IN CONDIZIONI DI PARTICOLARE PERICOLO DEVE

ESSERE PRESENTE UN’ALTRA PERSONA OLTRE A CHI

INIZIARE I LAVORI SOLO AD AVVENUTA

ATTAZIONE DELLE MISURE DI SICUREZZA

In ottemperanza al Dgs.81/08 relativo alla prevenzioni

TENSIONE

ESEGUE IL LAVORO

Figure 3 - Plates and pictograms.

Page 13 of 41

Loading...

Loading...