Ferroli OMNIA H 04E, OMNIA H 06E, OMNIA-UE 04, OMNIA HI3 04E, OMNIA-UI H 08 Installation, Maintenance And User Manual

...Page 1

1

R

E

F

R

I

G

E

R

A

N

T

G

A

S

E

C

O

-

F

R

I

E

N

D

L

Y

OMNIA H

REVERSIBLE HEAT PUMP

FOR SPLIT INSTALLATION

INSTALLATION, MAINTENANCE AND USER MANUAL

EN

Page 2

2

• Read the warnings in this instruction booklet carefully

since they provide important information on safe installation, use and maintenance.

• This instruction booklet is an integral and essential part

of the product and must be kept with care by the user

for future reference.

• If the unit is sold or transferred to another owner or if

it is to be moved, always make sure the booklet stays

with the boiler so that it can be consulted by the new

owner and/or installer.

• Installation and maintenance must be carried out by

professionally qualified personnel, according to current

regulations and the manufacturer's instructions.

• Incorrect installation or inadequate maintenance can

result in damage or injury. The manufacturer declines

any liability for damage caused by errors in installation

and use or by failure to follow the instructions provided.

• Before carrying out any cleaning or maintenance ope-

ration, disconnect the unit from the power supply using

the system switch and/or the special cut-off devices.

• In case of a fault and/or poor operation, deactivate

the unit and do not try to repair it or directly intervene.

Contact professionally qualified personnel. Any repair/

replacement of the products must only be carried out

by qualified personnel using genuine parts. Failure to

comply with the above cancompromise the safety of

the unit.

• Periodic maintenance performed by qualified person-

nel is essential in order to ensure proper operation of

the unit.

• This unit must only be used for its intended purpose.

Any other use is deemed improper and therefore hazardous.

• After unpacking, check the good condition of the con-

tents. The packing materials are potentially hazardous

and must not be left within the reach of children.

• The unit can be used by children aged at least 8 ye-

ars and by persons with reduced physical, sensory or

mental capabilities, or lacking experience or the necessary knowledge, only if under supervision or they have

received instructions on its safe use and the related

risks. Children must not play with the unit. Cleaning

and maintenance intended to be done by the user can

be carried out by children aged at least 8 years only if

under supervision.

• In case of doubt, do not use the unit. Contact the sup-

plier.

• The unit and its accessories must be appropriately di-

sposed of in compliance with current regulations.

• The images given in this manual are a simplified re-

presentation of the product. In this representation there

may be slight and insignificant differences with respect

to the product supplied.

The CE marking certifi es that the products meet the essential requirements of the relevant directi-

ves in force.

The declaration of conformity may be requested from the manufacturer.

This symbol indicates "Caution" and is placed next to all safety warnings. Strictly follow these instructions

in order to avoid danger and damage to persons, animals and things.

☞

This symbols calls attention to a note or important notice.

This symbol, which is used on the product, packaging or documents, means that at the end of its useful

life, this product must Mnot be collected, recycled or disposed of together with domestic waste.

Improper management of electric or electronic waste can lead to the leakage of hazardous substances

contained in the product. For the purpose of preventing damage to health or the environment, users are

kindly asked to separate this equipment from other types of waste and to ask for it to be dealt with by

the municipal waste service or dealer under the conditions and according to the methods set down in

national and international laws transposing the Directive 2012/19/EU.

Separate waste collection and recycling of unused equipment helps to save natural resources and to

guarantee that this waste is processed in a manner that is safe for health and the environment. For

more information about how to collect electric and electronic equipment and appliances, please contact

your local Council or Public Authority competent to issue the relevant permits.

Proper uses

This series of heat pumps is designed to produce cold or hot water for use in hydronic systems for conditioning/heating

purposes and the production of domestic hot water in an indirect way through a storage tank and a heat exchanger.

Any use differing from this proper use or beyond the operating limits indicated in this manual is forbidden unless previously

agreed with the manufacturer.

Page 3

3

THIS MANUAL IS DIVIDED INTO SECTIONS. THEIR NAMES APPEAR IN THE HEADING OF EACH PAGE.

SUMMARY

The manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors.

The manufacturer reserves the right to modify the products contents in this catalogue without previous notice.

GENERAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

European Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Identification plate of the Units . . . . . . . . . . . . . . . . . . . . . 4

Presentation of the system . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit identification code . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Abbinamenti unità esterna con unità interna . . . . . . . . . . 5

Components supplied with the indoor unit . . . . . . . . . . . . 6

The control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Components supplied with the outdoor unit . . . . . . . . . . . 6

TECHNICAL DATA AN PERFORMANCE . . . . . . . . . . . . . . . 7

System technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DIMENSIONAL AND PHYSICAL DATA . . . . . . . . . . . . . . . . 8

Available static pressure. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overall dimensions indoor unit . . . . . . . . . . . . . . . . . . . . . 9

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inspections on arrival . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Packing and storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cooling connections indoor unit . . . . . . . . . . . . . . . . . . . . 14

Tips for a successful installation . . . . . . . . . . . . . . . . . . . . 17

Water filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water component for corrosion limit . . . . . . . . . . . . . . . . . 17

Water pipework. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Protecting the water circuit against freezing . . . . . . . . . . 18

Filling with water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Piping insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical conections indoor unit . . . . . . . . . . . . . . . . . . . . 20

Electrical conections outdoor unit . . . . . . . . . . . . . . . . . . . 21

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connessioni tra morsettiera unità interna e componenti

d'impianto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to go to FOR SERVICEMAN . . . . . . . . . . . . . . . . . . 25

"FOR SEVICEMAN" menu . . . . . . . . . . . . . . . . . . . . . . . . 26

DHW mode setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tank heater (electrical heater for DHW tank) . . . . . . . . . . 31

Disinfect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DHW priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DHW pump ricircolo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

COOL mode setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

HEAT mode setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

AUTO mode setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Temp. Type setting (to activate the internal temperature probe

of the controller as room thermostat) . . . . . . . . . . . . . . . . . . . 35

Room thermostat (ON/OFF - HEAT/COOL by digital input) . 36

Other heating source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Backup heater (electrical booster) . . . . . . . . . . . . . . . . . . 37

AHS (Additional Heating Source, gas bolier) . . . . . . . . . . 38

Indoor unit DIP switch settings . . . . . . . . . . . . . . . . . . . . . 39

Holiday away setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Service call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Restore factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Special function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Auto restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Parameters list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MESSA IN FUNZIONE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Starting up for the first time. . . . . . . . . . . . . . . . . . . . . . . . 44

Preliminary checks on the electrical part . . . . . . . . . . . . . 44

Preliminary checks on the cooling part . . . . . . . . . . . . . . . 44

Pre-operation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Final check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Powering up the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

The appearance of the wire control device. . . . . . . . . . . . 45

The overview pages available user . . . . . . . . . . . . . . . . . 46

Home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Screen Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Turning ON/OFF controls . . . . . . . . . . . . . . . . . . . . . . . . . 50

Adjusting the temperature . . . . . . . . . . . . . . . . . . . . . . . . 51

Adjusting space operation mode (heat/cool) . . . . . . . . . . 52

About the menu structure . . . . . . . . . . . . . . . . . . . . . . . . . 52

To go to the menu structure . . . . . . . . . . . . . . . . . . . . . . . 52

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preset temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Domestic Hot Water (DHW) . . . . . . . . . . . . . . . . . . . . . . . 55

Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Child lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Service information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Operation Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

For Serviceman . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Weather temperature set for cool mode . . . . . . . . . . . . . . 64

Weather temperature set for heat mode. . . . . . . . . . . . . . 64

ERROR CODE AND TROUBLESHOOTING. . . . . . . . . . . . . 65

SAFETY AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . 69

General Rules for Maintanance . . . . . . . . . . . . . . . . . . . . 70

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disconnection and disposal . . . . . . . . . . . . . . . . . . . . . . . 71

Page 4

4

Identification plate of the Units

The figure on the left depicts the identification plate of the unit, affixed to the outer left-hand side of the Electric Panel. A description of the data is given below:

European Directives

The company hereby declares that the machine in question complies with the matters prescribed by the following Directives:

• Low voltage directive 2014/35/EU

• Electromagnetic Compatibility directive 2014/30/EU

• ERP directive 2009/125/EC (EU) No 811/2013 (EU) No 813/2013

• Energy labelling directive 2010/30/UE

• WEE directive 2002/96/EC

• RoHS directive 2011/65/EU

• REACH (EC) European regulation No 1907/2006

Any other Directives have to be considered not applicable.

GENERAL FEATURES

Unità interna Unità esterna

A - Trademark

B - Model

B1 - Code

C - Serial number

D - Cooling Capacity

A35W18 = source : air in 35°C d.b. / plant : water in 23°C out 18°C

E - Heating Capacity (heat pump)

A7W35 = source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C

F - Power input in COOLING mode

A35W18 = source : air in 35°C d.b. / plant : water in 23°C out 18°C

G - Power input in HEATING mode (heat pump)

A7W35 = source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C

H - Reference standard

I - Electric power supply

L - Maximum load current

M - Type of refrigerant and charge

N - CO2 equivalent

O - Shipping weight of the unit

P - Sound pressure level at 1m

Q - IP Level Protection

R - Maximum pressure - High Side

S - Maximum pressure - Low Side

T - Maximum temperature - High Side

U - Maximum temperature - Low Side

V - PED certification authority

CASO 1 CASO 2

C

fi g. 1

Codice

Code

Matricola

Serial N°

Rev.

Grado di protezione

Level protection

Pressione

Pressure

( Max )

°C

CO2 equivalente

CO

2 equivalent

Caldo

Heating

Freddo

Cooling

Modello

Model

ton

Costruito da:

Manufactured by:

Alimentazione

Power supply

( V / Ph / Hz )

Potenza ass.

Power input

Temperatura

Temperature

( Min / Max )

FERROLI s.p.a.

Via Ritonda 78/A

San Bonifacio (VR)

MADE IN ITALY

Lato Bassa

Low Side

IP

dB(A)

kg

kg

Lato Alta

High Side

MPa

fi g. 1

Codice

Code

Matricola

Serial N°

Rev.

Grado di protezione

Level protection

Pressione

Pressure

( Max )

°C

CO2 equivalente

CO

2 equivalent

Caldo

Heating

Freddo

Cooling

A

B

B1

C

D

F

H

I

L

MM

N

O

P

Q

S

U

V

R

T

E

G

Modello

Model

ton

Costruito da:

Manufactured by:

Alimentazione

Power supply

( V / Ph / Hz )

Potenza ass.

Power input

Temperatura

Temperature

( Min / Max )

FERROLI s.p.a.

Via Ritonda 78/A

San Bonifacio (VR)

MADE IN ITALY

Lato Bassa

Low Side

IP

dB(A)

kg

kg

Lato Alta

High Side

MPa

Codice

Code

Matricola

Serial N°

Rev.

Grado di protezione

Level protection

Pressione

Pressure

( Max )

°C

CO2 equivalente

CO

2 equivalent

Caldo

Heating

Freddo

Cooling

A

B

B1

C

D

F

H

I

L

MM

N

O

P

Q

S

U

V

R

T

E

G

Modello

Model

ton

Costruito da:

Manufactured by:

Alimentazione

Power supply

( V / Ph / Hz )

Potenza ass.

Power input

Temperatura

Temperature

( Min / Max )

FERROLI s.p.a.

Via Ritonda 78/A

San Bonifacio (VR)

MADE IN ITALY

Lato Bassa

Low Side

IP

dB(A)

kg

kg

Lato Alta

High Side

MPa

Codice

Code

Matricola

Serial N°

Rev.

Grado di protezione

Level protection

Pressione

Pressure

( Max )

°C

CO2 equivalente

CO

2 equivalent

Caldo

Heating

Freddo

Cooling

A

B

B1

C

D

F

H

I

L

MM

N

O

P

Q

S

U

V

R

T

E

G

Modello

Model

ton

Costruito da:

Manufactured by:

Alimentazione

Power supply

( V / Ph / Hz )

Potenza ass.

Power input

Temperatura

Temperature

( Min / Max )

FERROLI s.p.a.

Via Ritonda 78/A

San Bonifacio (VR)

MADE IN ITALY

Lato Bassa

Low Side

IP

dB(A)

kg

kg

Lato Alta

High Side

MPa

-

Page 5

5

> GENERAL CHARACTERISTICS:

• The OMNIA range of heat pumps meets the requirements of

space heating, space cooling and the production of domestic

hot water for small and medium-sized residential and commercial plants.

• It consists of an inverter external unit available of different capacities associated with a hydronic indoor unit proposed in two variants

with or without 3kW electrical integration two-stage (1.5 + 1.5), both

equipped as standard with integrated three-way valve for the production of domestic hot water through an external boiler.

• The system is very versatile and can work at outdoor air temperatures down to -20 °C and produce hot water up to 60 °C with

the aid of electrical integration.

• Particularly suitable for use in radiant systems, fan coil units, radiators and for indirect production of domestic hot water (DHW)

via an external boiler (not supplied).

• Split refrigerant circuit to avoid risks of freezing in particularly for

rigid outdoor applications.

• The user interface consists of a digital remote controller (wired

max 50m from the indoor unit) equipped with a large display and

simple setting commands.

> EXTERNAL UNIT CHARACTERISTICS OMNIA H-UE:

• Reduced starting current thanks to Inverter technology

• Compressor with twin rotary DC INVERTER motor positioned

on rubber anti-vibration mounts and wrapped by a double layer

of sound-absorbing material to reduce vibrations and noise

• The compressor is also equipped with crankcase oil heater

• Bi-fl ow electronic expansion valve

• 4-way valve

• Axial fans with DC brushless motor complete with safety protection grilles

• Finned coil consisting of copper pipes and aluminum fi ns

• External air temperature probe already installed on the unit

• DHW tank water temperature sensor supplied as standard (installed by the installer)

> INTERNAL UNIT CHARACTERISTICS OMNIA H-UI:

• Available with 3kw electrical integration (OMNIA HI-UI) or without integration (OMNIA H-UI)

• Hydraulic unit with 3-way diverter valve for DHW production

supplied as standard

• Brazed stainless steel water / gas plate heat exchanger

• Low consumption system circulator with DC brushless motor

• Automatic air vent

• Water differential pressure switch

• Water pressure gauge

• Expansion vessel

• Safety valve

• Y-shaped water fi lter supplied as standard (installed by the in-

staller)

GENERAL FEATURES

Presentation of the system

Unit identification code

The codes that identify the units and the meaning of the letters used are described below.

Indoor unit Outdoor unit

Model

Model

Power supply

Power supply

Name

Name

Type

Indoor

unit

Outdoor

unit

- - 230 V - 1 - 50 Hz

T - 400 V - 3N - 50 Hz

- - 230 V - 1 - 50 Hz

T - 400 V - 3N - 50 Hz

08

16

H - without booster

HI - with booster

OMNIA-UI_HI_16T

OMNIA-UE_16T

04

06

08

10

12

14

16

12T

14T

16T

Matching between outdoor units and indoor units

MOD.

SYSTEM INDOOR UNIT

OUTDOOR UNIT

WITHOUT BOOSTER WITH BOOSTER WITHOUT BOOSTER WITH BOOSTER

4 OMNIA H 04E OMNIA HI3 04E OMNIA-UI H 08 OMNIA-UI HI3 08 OMNIA-UE 04

6 OMNIA H 06E OMNIA HI3 06E OMNIA-UI H 08 OMNIA-UI HI3 08 OMNIA-UE 06

8 OMNIA H 08E OMNIA HI3 08E OMNIA-UI H 08 OMNIA-UI HI3 08 OMNIA-UE 08

10 OMNIA H 10E OMNIA HI3 10E OMNIA-UI H 16 OMNIA-UI HI3 16 OMNIA-UE 10

12 OMNIA H 12E OMNIA HI3 12E OMNIA-UI H 16 OMNIA-UI HI3 16 OMNIA-UE 12

14 OMNIA H 14E OMNIA HI3 14E OMNIA-UI H 16 OMNIA-UI HI3 16 OMNIA-UE 14

16 OMNIA H 16E OMNIA HI3 16E OMNIA-UI H 16 OMNIA-UI HI3 16 OMNIA-UE 16

12T OMNIA H 12TE OMNIA HI6 12TE OMNIA-UI H 16 OMNIA-UI HI6 16T OMNIA-UE 12T

14T OMNIA H 14TE OMNIA HI6 14TE OMNIA-UI H 16 OMNIA-UI HI6 16T OMNIA-UE 14T

16T OMNIA H 16TE OMNIA HI6 16TE OMNIA-UI H 16 OMNIA-UI HI6 16T OMNIA-UE 16T

Page 6

6

GENERAL FEATURES

The user interface consists of a wired remote controller (up to 50 m from the unit) which allows

the management of:

- HEATING AND COOLING SYSTEM, where the heat pump is the sole energy source. The

unit, if activated in heat or cool mode, works by modulating the frequency of the compressor

to maintain the temperature of the produced water to the setpoint value set by the controller.

Through parameter you can use the remote controller (eg. For single-zone systems) as a room

thermostat.

- DOMESTIC HOT WATER PRODUCTION (DHW). The unit is activated in a heatt mode to

keep the temperature of a DHW tank (not supplied) to the setpoint value. It requires a 3-way

diverter valve (not supplied) and a temperature sensor (T5 probe, L = 10m, provided) to be

inserted into one well of the DHW tank.

- ADDITIONAL SOURCES OF ENERGY (boiler or electrical heater). Depending on the

parameters set, these sources can be activated in integration or replacement of the heat pump

when the system is used for space heating or for DHW production.

The controller also activate additional energy sources in case the heat pump is not working.

- ELECTRIC HEATER OF THE DHW TANK. The controller can manage the activation of an electric heater inserted in the DHW tank as

a heat integration to the heat pump, for disinfecting function, or as a source of energy reserve for DHW production in case the heat pump

is not working.

FAST DHW. This function can be activated manually and it allows you to give priority to DHW production by activating all energy sources

(heat pumps, electric heaters, boiler) available for DHW heating to bring in the shortest time possible the DHW tank to the setpoint required.

- DISINFECT FUNCTION. You can set from the controller weekly cycles for disinfecting the water in the Dhw tank. In order to successfully

execute these cycles, the heat pump must be integrated with DHW electric heater or boiler.

- SILENT MODE. If active it allows a reduction of the maximum frequency of the compressor and of the fan speed in order to reduce the

noise emitted and the power absorbed by the unit. There are 2 levels of silencing. Through time programming, you can defi ne for 2 daily

time bands the desired silent level (eg. during the night).

- ON / OFF using an external contact. The unit can be turned on and off (eg. thermostat / remote switch) via an external contact: in this case

the unit will operate in the mode set by the controller keyboard.

- HEAT / COOL via external contacts. The unit can be activated in heat or cool mode via two external contacts (eg. thermostat that manages

the heat and cool demand / remote switch).

- ECO MODE. Possibility to defi ne in heat mode a time band within which the heat pump works with a sliding setpoint defi ned by the

chosen climatic curve. 8 climatic curves are available for low temperature systems (radiant fl oor) and 8 climatic curves for fan coil or radiator

systems)

- WEEKLY SCHEDULING. It allows a schedulation of 6 time bands for each day of the week: for each time band it is possible to defi ne the

mode (COOL / HEAT / DHW) and the required setpoint.

- Detailed alarms diagnostics with alarms history.

- Display of all operating parameters.

The control system

Components supplied with the indoor unit

DESCRIPTION SHAPE Q.ty

Installation, maintenance and

user manual (this manual)

1

Water filter (Y-shape)

1

T5: temperature probe for the

domestic hot water tank

1

Components supplied with the outdoor unit

DESCRIPTION SHAPE Q.ty

Condensate water drain to

be installed under the unit

basement

1

Inductance (only model 1012-14-16 single phase)

1

Energy label

Y

IJA

IE IA

RVL-I PLUS 5

A

63

dB

7

5

kW

5

5

5

kW

5

811/20132015

B

C

D

E

F

G

A

35°C

A

A

++

+

+

55°C

+A++

-

dB

1

Page 7

7

TECHNICAL DATA AN PERFORMANCE

System technical data

NOTA: Declared according to European regulation 811/2013. The values are referred to units without options and accessories.

Effi ciency class in heating mode - Average climate

Model 4 6 8 10 12 14 16 12T 14T 16T

Effi ciency capacity - medium temperature (water 55°C)

A++ A++ A++ A++ A++ A++ A++ A++ A++ A++

Season effi ciency - medium temperature (water 55°C) 127 130 125 127 127 128 128 128 130 130

Effi ciency capacity - low temperature (water 35°C)

A++ A++ A++ A++ A++ A++ A++ A++ A++ A++

Season effi ciency - low temperature (water 35°C) 183 185 170 177 175 168 158 184 179 172

OUTDOOR UNIT TECHNICAL DATA 4 6 8 10 12 14 16 12T 14T 16T

Refrigerant R410A Tipo

Refrigerant charge

2.5 2.5 2.8 3.9 3.9 3.9 3.9 4.2 4.2 4.2 kg

Power supply

220-240V ~ 50 Hz 380-415V - 3N ~ 50 Hz -

Compressor type

Twin rotary -

N° compressors / N° refrigerant circuits

1 / 1 n°

Source side heat exchanger type

Finned coil -

Fans type

Brushless DC -

N° fans

12n°

Liquid connections diameter

Ø 9.52

-

Gas connections diameter

Ø 15.88

-

SWL - Sound power level**

62 66 69 67 69 71 72 70 72 72 dB(A)

INDOOR UNIT TECHNICAL DATA 8 16 16T

Power supply

220-240V ~ 50 Hz 220-240V ~ 50 Hz 380-415V - 3N ~ 50 Hz -

Plant side heat exchanger type

Brazed stainless steel plate Pump type Electronic circulator Expansion tank volume

10 l

Water safety valve set

3 bar

Hydraulic ttings

- plant 1”M -

Hydraulic ttings

- domestic hot water 3/4”M -

Liquid connections diameter

Ø 9.52

-

Gas connections diameter

Ø 15.88

Integrative electrical heaters (2-stages) * 3 (1.5 + 1.5) 6 (4 + 2) kW

SWL - Sound power level**

43 45 dB(A)

* = Optional for mod. 8 e 16, as standard mod. 16T. The firt digit indicate the total power, between brackets the power for stage 1 and stage 2

** SWL = Sound power levels, with reference to 1x10

-12

W.

The Total sound power level in dB(A) measured in compliance with ISO 9614 standards. The Total Sound Power in db(A) the only binding acoustic specification.

The values are referred to units without options and accessories.

Data declared according to EN 14511:

EER (Energy Efficiency Ratio) = ratio of the total cooling capacity to the effective power input of the unit

COP (Coefficient Of Performance) = ratio of the total heating capacity to the effective power input of the unit

A35W7 = source : air in 35°C d.b. / plant : water in 12°C out 7°C

A35W18 = source : air in 35°C d.b. / plant : water in 23°C out 18°C

A7W45 = source : air in 7°C d.b. 6°C w.b. / plant : water in 40°C out 45°C

A7W35 = source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C

Performances data

- Models 4 6 8 10 12 14 16 12T 14T 16T UM

A7W35

Heating capacity 4.10 6.10 8.00 10.00 12.10 14.00 15.50 12.00 14.00 15.50 kW

Power input 0.82 1.29 1.73 2.17 2.74 3.39 3.82 2.66 3.26 3.79 kW

COP 5.00 4.73 4.62 4.61 4.42 4.13 4.06 4.51 4.29 4.09 W/W

Water ow rate 705 1049 1376 1720 2081 2408 2666 2064 2408 2666 l/h

Avaialble static pressure 79 68 53 42 21 0 0 22 0 0 kPa

A7W45

Heating capacity 4.01 5.96 7.34 10.12 11.85 14.05 16.05 11.97 13.93 15.48 kW

Power input 1.13 1.68 2.13 2.93 3.48 4.41 5.03 3.5 4.21 4.87 kW

COP 3.55 3.55 3.45 3.45 3.41 3.19 3.19 3.42 3.31 3.18 W/W

Water ow rate 690 1025 1262 1741 2038 2417 2761 2059 2396 2663 l/h

Avaialble static pressure 79 69 58 41 24 0 0 23 1 0 kPa

A35W18

Cooling capacity 4.10 6.20 8.00 10.50 11.70 13.10 13.80 12.00 13.50 14.50 kW

Power input 0.84 1.43 1.93 2.30 2.79 3.48 3.77 2.8 3.45 3.94 kW

EER 4.88 4.34 4.15 4.57 4.19 3.76 3.66 4.29 3.91 3.68 W/W

Water ow rate 705 1066 1376 1806 2012 2253 2374 2064 2322 2494 l/h

Avaialble static pressure 79 67 53 37 26 11 3 22 6 0 kPa

A35W7

Cooling capacity 4.12 6.15 6.44 9.39 11.02 12.49 12.85 11.7 12.53 12.91

kW

Power input 1.30 2.08 2.24 3.26 4.17 5.07 5.39 4.65 5.21 5.52

kW

EER 3.17 2.96 2.88 2.88 2.64 2.46 2.38 2.52 2.40 2.34

W/W

Water ow rate 709 1058 1108 1615 1895 2148 2210 2012 2155 2221 l/h

Avaialble static pressure 79 67 65 47 32 17 13 26 17 13 kPa

Page 8

8

DIMENSIONAL AND PHYSICAL DATA

Operating limits

35

-2

-20

5

40 60

30

55

30

43

-2

-20

5

5040 60

Leaving water temperature °C

Leaving water temperature °C

With electrical heaters

or bolier

With electrical heaters

or bolier

Outside temperature °C

Outside temperature °C

DHW MODEHEATING MODE

Leaving water temperature °C

Outside temperature °C

20

46

-5

510 25

10

COOLING MODE

NOTE FOR DHW MODE: leaving water temperature is the temperature of the water produced by the unit and not the DHW temperature available to the user; the DHW

temperature is in fact a function of this parameter and of the coil surface of the DHW boiler.

Available static pressure

Watel ow rate [l/h]

Available static pressure [kPa]

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

Mod. 16

Mod. 08

Page 9

9

DIMENSIONAL AND PHYSICAL DATA

Overall dimensions indoor unit

420

700

320

257

144

117

166

51 60 115 60

11

21010 209

270

271

14

10

G

L

210

11

209

50

LG

Mod. 8 16 16T UM

Net weight base unit

31,5 33,5 -

kg

Net weight unit with

booster

33 35 36

kg

ID Descriptions

10 Plant delivery

11 Plant return

14 Safety valve drain / drain cock

209 DHW boiler delivery

210 DHW boiler return

G Gas line

L Liquid line

270 Cable gland for power cables

271

Cable gland for communication

cables and T5 and T1b probes

240

250

50 5057,5

67,5

57,5

Ø8Ø8Ø8 Ø8

Ø3,5Ø3,5

20

38,5

12

Mounting bracket

fi g. 1

fi g. 2

Page 10

10

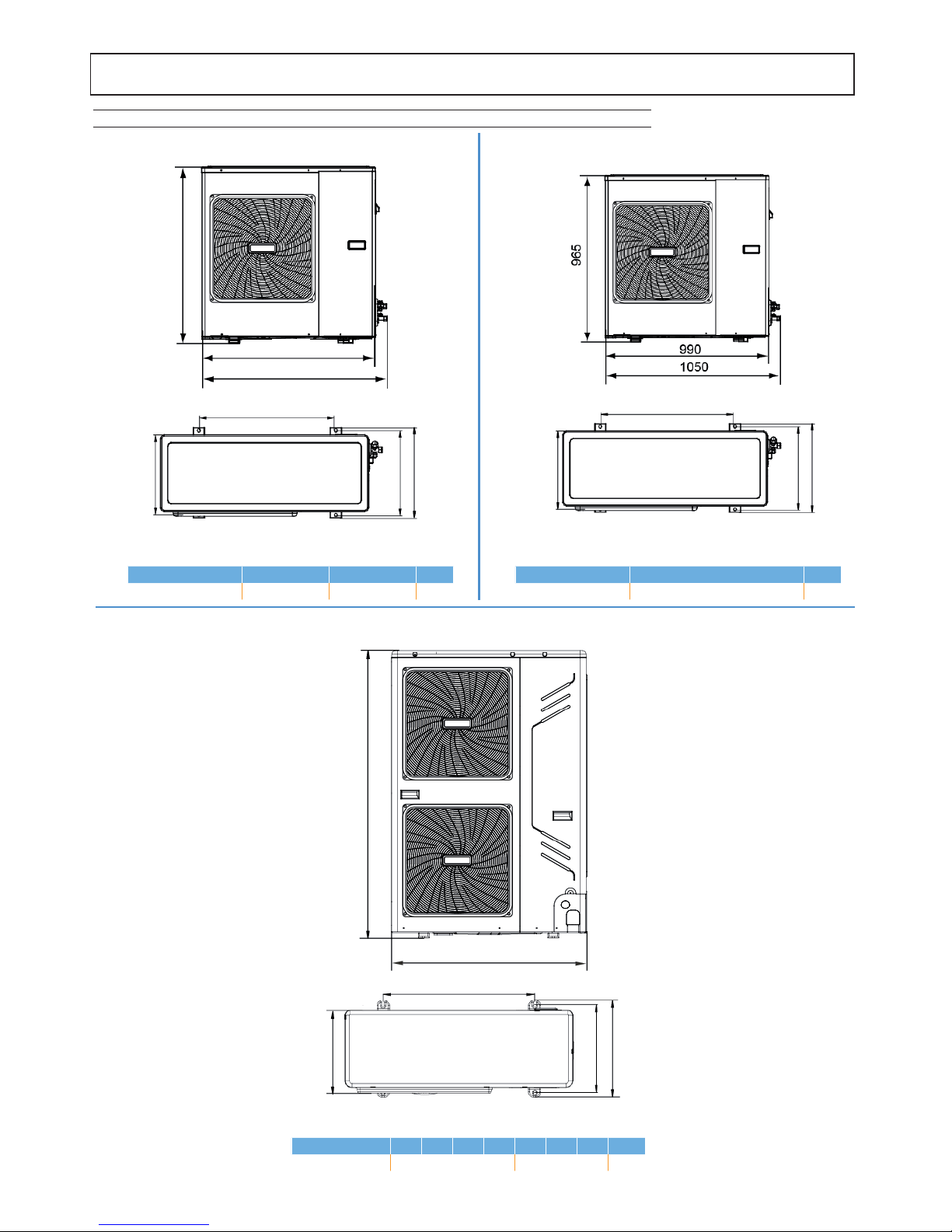

DIMENSIONAL AND PHYSICAL DATA

Overall diemnsions

Mod. 10 - 12 - 14 - 16 - 12T - 14T - 16T

Mod. 4 - 6

Mod. 8

860

333

350

355

895

960

590

1327

348

360

400

900

600

390

360

395

625

Models 10 12 14 16 12T 14T 16T

Weight net

99 115

kg

Models 4 6

Weight net

60 60

kg

Models 8

Weight net

76

kg

fi g. 1 fi g. 2

fi g. 3

Page 11

11

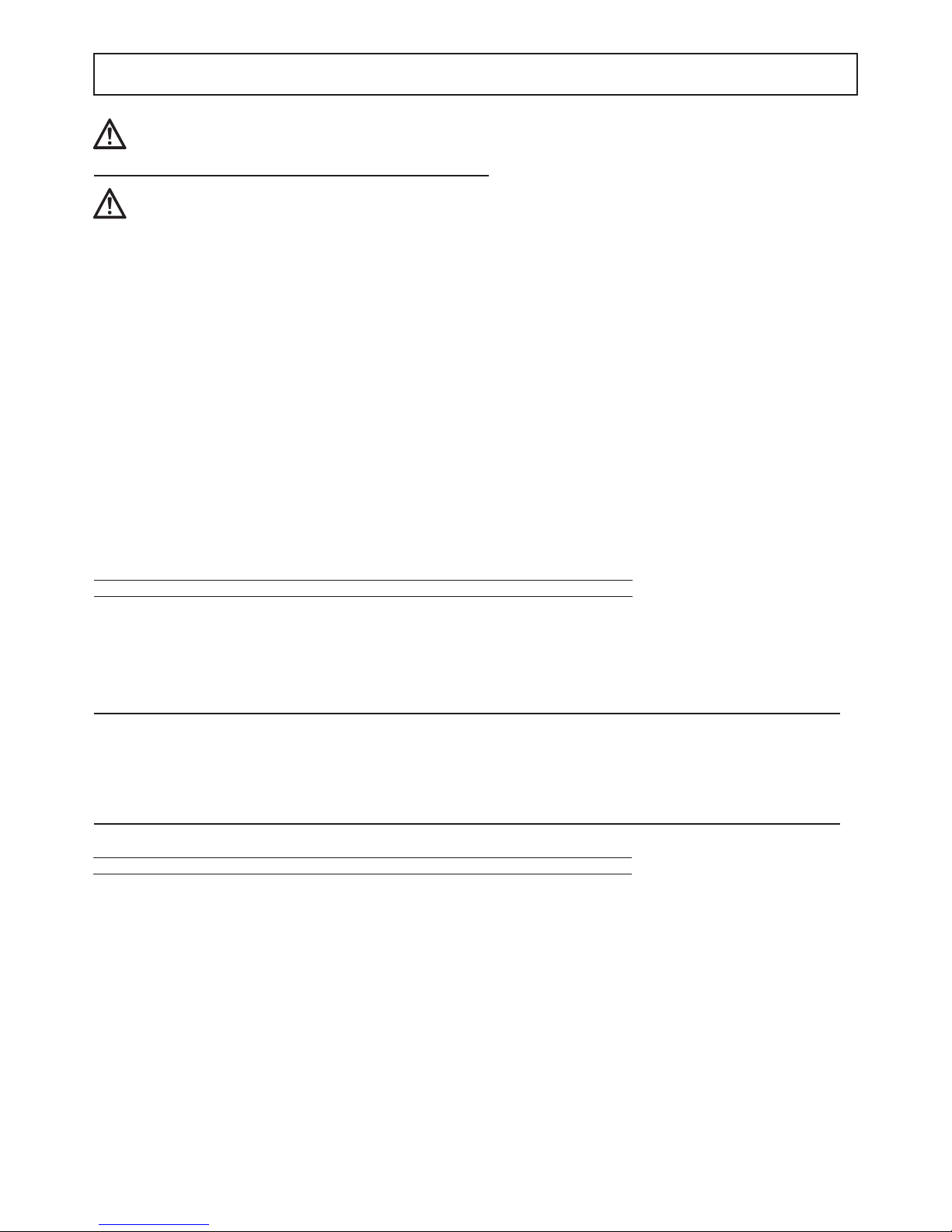

INSTALLATION

Inspections on arrival

Al momento del ricevimento dell'unità è indispensabile controllare di aver ricevuto tutto il materiale indicato sul documento d'accompagnamento, ed inoltre che la stessa non abbia subito danni durante il trasporto. In caso affermativo, far costatare allo spedizioniere

l'entità del danno subito, avvertendo nel frattempo il nostro uffi cio gestione clienti. Soltanto agendo in questo modo e tempestiva-

mente sarà possibile avere il materiale mancante o il risarcimento dei danni.

Packing and storing

All machines are packed in cardboard boxes specific for each unit.

The indications required to correctly handle the appliance while storing and installing it are written

on the packing.

The storage temperature must be between -25°C and 55°C.

NOTA: Do not dispose of the packaging in the environment.

Do not dispose of, leave or leave within the reach of children the packaging material as it

may be a potential source of danger.

Once the place in which the unit is to be installed has been chosen (see the relative sections)

proceed as follows to unpack the two units.

The place of installation must be free of powders, fl ammable objects or mate-

rials or corrosive gases.

The unit is designed for wall hanging installation and is equipped as standard

with a hooking bracket. The fi xing to the wall must guarantee a stable and

effective support.

For the dismantling of the paneling and for normal maintenance

activities the minimum operating spaces must be respected.

Select an installation location where the following conditions are met:

- Place that allows to respect the maximum lengths allowed for pipes, connections to the unit of temperature probes, remote control etc ..

- Do not place objects or equipment on top of the unit.

- Make sure that all the precautions and prescriptions foreseen by local laws

and regulations regarding possible refrigerant leaks are correctly applied.

- It is advisable to place the boiler for domestic hot water production as close

as possible to the indoor unit.

Selecting the installation site and minimum operating area indoor unit

☞

☞

150

150

317

500 500

fi g. 1

fi g. 2

fi g. 3

Page 12

12

INSTALLATION

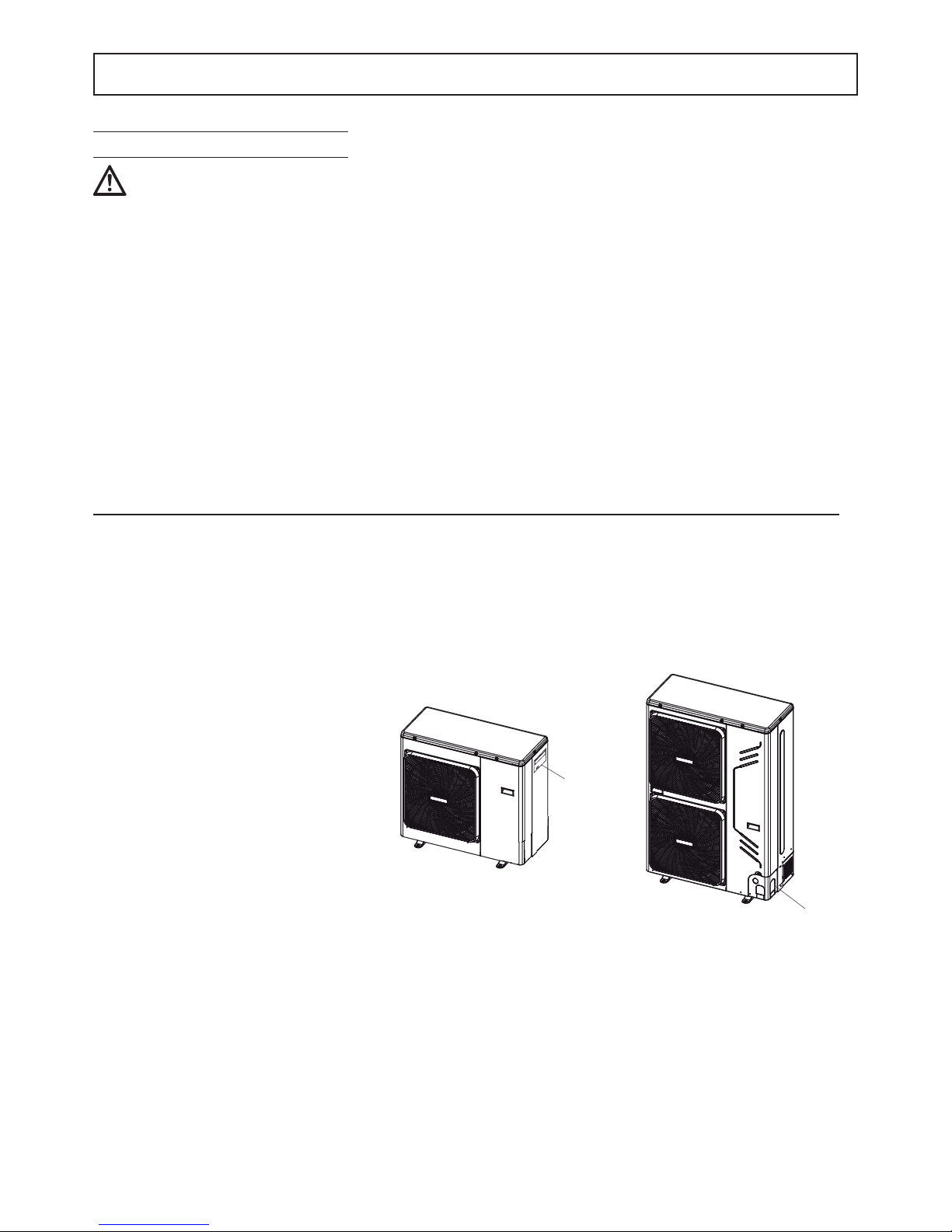

Select an installation site where the following conditions are satisfi ed and one that meets with your customer's approval.

• Places that are well-ventilated.

• Places where the unit does not disturb next-door neighbors.

• Safe places which can bear the unit's weight and vibration and where the unit can be installed at an even level.

• Places where there is no possibility of fl ammable gas or product leak.

• The equipment is not intended for use in a potentially explosive atmosphere.

• Places where servicing space can be well ensured.

• Places where the units' piping and wiring lengths come within the allowable ranges.

• Places where water leaking from the unit cannot cause damage to the location (e.g. in case of a blocked drain pipe).

• Places where rain can be avoided as much as possible.

• Do not install the unit in places often used as a work space. In case of construction work (e.g. grinding etc.) where a lot of dust

is created, the unit must be covered.

• Do not place any objects or equipment on top of the unit (top plate)

• Do not climb, sit or stand on top of the unit.

• Be sure that suffi cient precautions are taken in case of refrigerant leakage according to relevant local laws and regulations.

Selecting the installation site and minimum operating area outdoor unit

Be sure to provide for adequate measures in order to prevent that the unit be used as a shelter by small animals. Small animals making

contact with electrical parts can cause malfunctions, smoke or fi re. Please instruct the customer to keep the area around the unit clean.

WARNING

>300

>300

>2000

>600

(Wall or obstacle)

Maintain

channel

Air outlet

Air inlet

A

ir inlet

air outlet

air inlet

wall / obstacle

Single installation

air inlet

Multiple installation in parallel between 2 or more units (front / back)

>2000 >500 >3000 >3000 >300

Multiple installation in parallel between 2 or more units (lateral)

>600

>2000

>300

Water Outlet

condensation drain

Mod. 4 - 6 - 8

Fix with bolt

>600mm

fasten with

bolts

fi g. 1

fi g. 2

fi g. 3

fi g. 4

fi g. 5

fi g. 6

Reserve water outlet

Reserve water outlet Water Outlet

(Need to knock open)

condensation drain

condensation drain reserve

(rubber stopper)

(semi-sheared)

(semi-sheared)

condensation drain reserve

input of power cables and refrigerant pipes

Mod. 10 - 12 - 12T - 14 - 14T - 16 - 16T

Page 13

13

fi g. 7 fi g. 8

INSTALLATION

Installation diagrams

The indoor unit may be installed on top of the outdoor one and vice versa.

Outdoor unit positioned at the bottom and indoor unit at the top (fig. 1).

In this case a trap (6) must be made on the intake piping (3) to halt the downflow of

refrigerant and to avoid liquid returning to the compressor. The relative connection

pipes

must be insulated.

Key:

1. Outdoor unit

2. Indoor unit

3. Piping on gas side (larger diameter)

4. Piping on liquid side

5. Trap

Outdoor unit positioned at the top and indoor unit at the bottom (fig. 2).

In this case, traps (6) must be installed on the suction piping (3), every three meters

of difference in level. These traps will allow the oil to return to the compressor. The

relative connection pipes must be insulated.

Key:

1. Outdoor unit

2. Indoor unit

3. Piping on gas side (larger diameter)

4. Piping on liquid side

5. Trap

Note: The maximum difference in level between the indoor unit and outdoor

unit must not exceed the values given in the "LIMITS TO THE LENGTH AND

HEIGHT DIFFERENCE OF REFRIGERANT PIPES" section.

☞

fi g. 9

fi g. 10

Make sure there is enough room to do the installation

■ Prepare a water drainage channel around the foundation, to drain waste water from

around the unit.

■ If water does not easily drain from the unit, mount the unit on a foundation of concrete

blocks, etc. (the height of the foundation should be about 100 mm.

■ If you install the unit on a frame, please install a waterproof plate (about 100 mm) on the

underside of the unit to prevent water from coming in from the low side.

■ When installing the unit in a place frequently exposed to snow, pay special attention to

elevate the foundation as high as possible.

■ In heavy snowfall areas it is very important to select an installation site where the snow

will not affect the unit. If lateral snowfall is possible, make sure that the heat exchanger

coil is not affected by the snow (if necessary construct a lateral canopy).

■ As the outdoor temperature is measured via the outdoor unit air thermistor, make sure

to install the outdoor unit in the shade, or a canopy should be constracted to avoid direct sunlight, so that it is not influenced by the

sun’s heat, otherwise protection may be possible to the unit.

■ Check the strength and level of the installation ground so that the unit will not cause any operating vibration or noise after installation.

■ In accordance with the foundation drawing in the figure, fix the unit securely by means of the foundation bolts. (Prepare four sets

each of Ø10 Expansion bolts, nuts and washers which are readily available on the market.)

■ It is best to screw in the foundation bolts until their length is 20 mm from the foundation surface.

When installing the unit in a place exposed to strong wind, pay special attention to the following.

Set the outlet side at a right angle to the direction of the wind.

Strong winds of >5 m/s or more blowing against the unit's air outlet causes a short circuit (suction of discharge air), and this may

have the following consequences:

- Deterioration of the operational capacity.

- Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the front of the unit, the fan can start rotating very fast until it breaks.

Page 14

14

Cooling connections outdoor unit

Mod. 4 - 6 - 8

LIQUID

CONNECTION

GAS

CONNECTION

fi g. 1

Cooling connections indoor unit

Comply with the following indications when connecting the cooling pipes:

• Match the ends of the previously flared pipe with those of the connections on the indoor units or on the cocks of the outdoor units.

• Tighten the union by hand and then torque it with the aid of an adequate wrench (it is advisable to use a fox wedge to prevent

tensions from being created on the pipes).

INSTALLATION

Limits to the length and height difference of refrigerant pipes

The length of the refrigerant pipes between the indoor and outdoor units must be as short as possible and is in any case limited by

compliance with the maximum height difference values between the units.

Diminution of the difference in height between the units (H1,H2) and of the pipe lengths (L) will limit the load losses, consequently

increasing the overall efficiency of the machine.

Comply with the limits given in the following tables.

Contact our technical department for the required modifications if the units must operate beyond the specifications given

above.

MOD. OUTDOOR UNIT

4-6 8 10-12-14-16 12T-14T-16T

MOD. INDOOR UNIT

8 16 16T

Connections LIQUID line " 3/8

Connections GAS line " 5/8

Length with standard charge m 10

Cooling line maximum length m 20 30 50 50

Maximum diff.in height Outdoor unit low (H1) m 8 15 25 25

Maximum diff.in height Outdoor unit high (H2) m 10 20 30 30

Refrigerant charge

Type

R410A

Quantity of additional refrigerant per meter g/m 54

Page 15

15

Front out pipe

Back out pipe

Side out pipe

Undersurface out pipe

Fat pipe

1

2

gas

liqulid

Mod. 10 - 12 - 12T - 14 - 14T - 16 - 16T

Front out pipe

Side out pipe

Back out pipe

Undersurface out pipe

Fat pipe

fi g. 2

LIQUID

CONNECTION

GAS

CONNECTION

fi g. 3

Refrigerant pipe insulation

To ensure system efficiency and its correct operation it is necessary to use pre-insulated

cooling connection lines easily available on the market. Pay also attention to the

connection points according to what described.

Use thermal insulating tape to tie the hoses, from the area connecting the outdoor unit

cocks to the upper end of the hose in correspondence of the wall entry point. (side

figure) .

Pipe fittings tightening

Make sure that the connecting zone is free from dust and dirt.

• Make sure that the flare and connection are perfectly aligned.

• Tighten the union first by hand and then with an adequate torque wrench.

Leaks could occur if the parts are insufficiently tightened, while the flare could be damaged if it is tightened too strongly.

The table below lists the torques recommended for the various pipe diameters

Nominal

Diameter

(“)

External

Diameter (mm) Ø

Tightening

torque

Nxm

3/8 9.52 30-40

5/8 15.88 60-65

INSTALLATION

Page 16

16

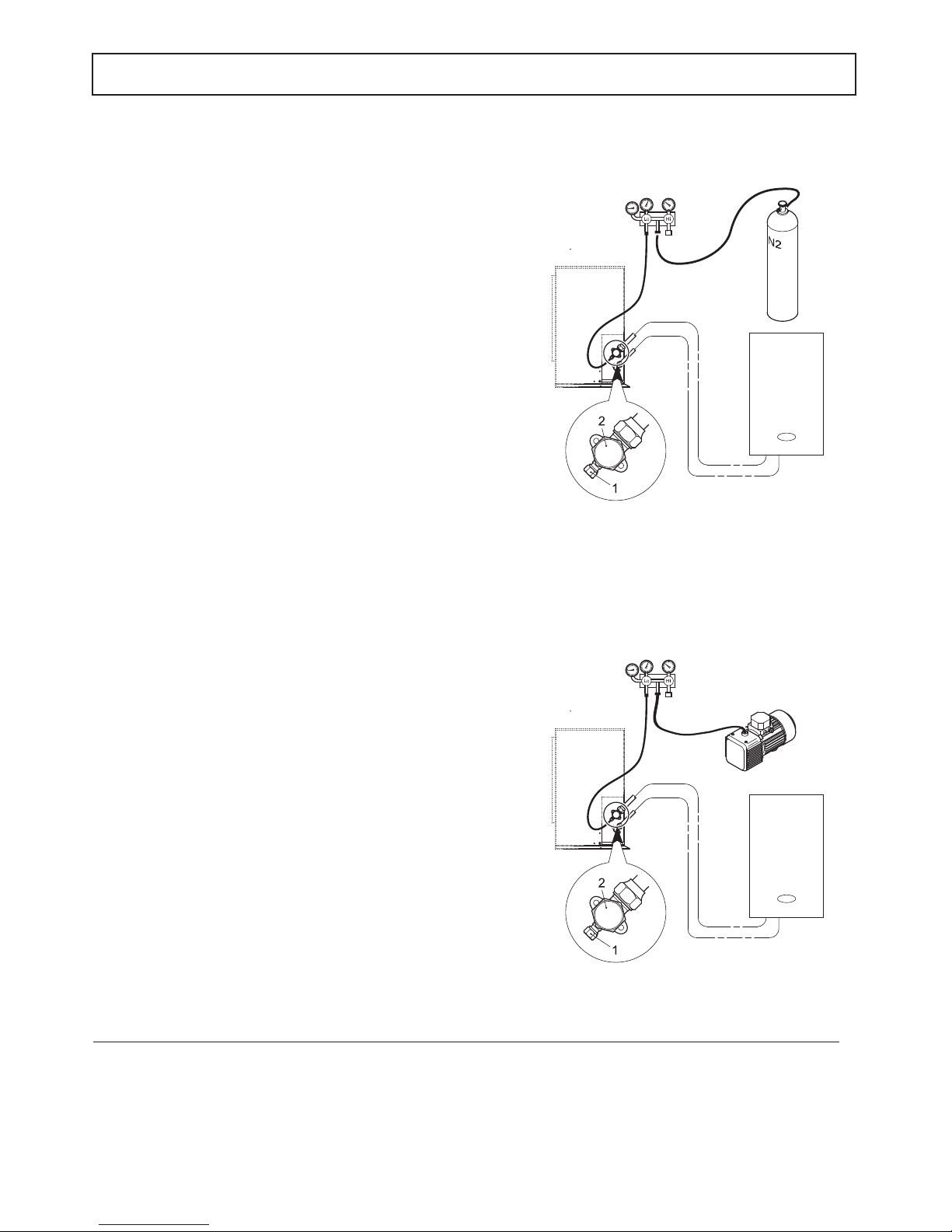

TIGHTNESS CHECK (RECOMMENDED OPERATION)

Before setting the system in a vacuum, it is advisable to make sure

that the cooling circuit is tight, including the connecting joints between

the pipes and the indoor unit. Proceed in the following way:

• With the service valves of the outdoor unit completely shut, remove

the cap from the service tap (1- side figure) of the gas connection

(the larger one)

• Connect the service valve to a monometric unit plus nitrogen bottle

(N2).

• Pressurize the system to a maximum 30 bar using the nitrogen in

the bottle.

• Use liquid soap to check that the joints are tight.

Keep the bottle vertical during the pressurizing operation to prevent

liquid nitrogen from infiltrating into the system!

• Check all the connection joints on both the outdoor and indoor

units to make sure that they are tight. Bubbles will form if leaks are

present. If bubbles appear, make sure that the unions have been

tightened and that the flares are the right shape.

• Wipe off the liquid soap with a rag.

• Reduce the pressure of the nitrogen in the circuit by loosening the

charge pipe from the bottle.

• Having reduced the pressure, disconnect the nitrogen bottle.

VACUUM OPERATION (OBLIGATORY)

Air and humidity in the cooling circuit impair the operation of the unit

with effects such as:

• Increased pressure.

• Reduced efficiency.

• Formation of ice on the capillary and subsequent blockage of the

same.

• Corrosion in the circuit.

This is why a vacuum must be created in the connection pipes and

indoor unit. Proceed in the following way:

• Connect the previously described charging pipe to the vacuum

pump.

• Turn on the relative knob on the monometric unit to allow the pump

to access the cooling circuit.

• Wait until the pressure level measured by the pressure gauge is

around 3 mm Hg (400 Pa)

• As soon as the required vacuum value is reached, shut the

connection cock and stop the vacuum pump.

fi g. 1

fi g. 2

■ To activate the system it is necessary to open both the liquid and gas shut-off valves of the outdoor unit: remove the caps from both

valves, and then open the valves with an Allen wrench.

■ It is advisable to open the valves when the installation of the system is complete from an electric and hydraulic point of view and it

is therefore possible to proceed with the fi rst start-up.

NOTA

☞

GAS

CONNECTIONS

U.I.

U.I.

U.E.

U.E.

GAS

CONNECTIONS

INSTALLATION

Page 17

17

☞

The safety valve outlet must be connected to a funnel or collection pipe to prevent water spurting onto the fl oor in case of overpressure in the

heating circuit. Otherwise, if the discharge valve cuts in and fl oods the room, the boiler manufacturer cannot be held liable.

Before installation, fl ush all the pipes of the system thoroughly to remove any residuals or impurities that could affect proper operation of the

unit.

For that purpose only use suitable guaranteed products for heating systems (see next section), that do not harm metals, plastics or rubber.

The manufacturer declines any liability for damage caused to the generator by failure to properly clean the system.

AVVERTIMENTO

Tips for a successful installation

For a correct design and installation of the hydraulic plant comply the local laws governing safety matters and sound.

The following information is suggestion for a correct installation of the unit:

• Before connecting the unit to the system wash adequately the pipes using clean water, filling and emptying and cleaning the filters.

Only after that proceed connecting the unit to the system; this operation is crucial to ensure proper start-up without the need to have

repeated stops to clean the filter, with the possible risk of damage to heat exchangers and other components.

• Check by qualified personnel the quality of the water or of the mixture used; avoid the presence of inorganic salts, biological load

(seaweeds, etc.) suspended solids, dissolved oxygen and the pH. Water with inadequate characteristics can cause a pressure drop

increase due to a rapid fouling of the filter, energy efficiency decrease and corrosive symptom increase that can damage the unit.

• The pipes must have the least possible number of bends to minimize load losses and must be adequately supported in order to

prevent the connections of the unait from being excessively stressed.

• Install on-off valves near components that need to be serviced to isolate them when maintenance work needs to be done and to

allow them to be replaced without having to discharge the system.

• Before isolating the pipes and charging the system, carry out preliminary inspections to make sure that there are no leaks.

• Isolate all the chilled water pipes to prevent condensation from forming along the pipes themselves. Make sure that the material

used is the steam barrier type, failing this, cover the insulation with an appropriate protection. Also make sure that the air venting

valves can be accessed through the insulation.

• The circuit can be maintained under pressure using an expansion vessel (present in the unit) and a pressure reducer. A system filling

device can be used that automatically, under a pressure value, provides for the loading and maintenance of the desired pressure.

• Check that all plant components are able to withstand the maximum static pressure (depending on the height of the building to be

served).

Water component for corrosion limit

Water filter

pH 7.5 ÷ 9.0 SO4 -- < 100 ppm

HCO3 -/ SO4 -- >1.0

Total hardness 8.0 ÷ 15.2 °F

Cl- < 50 ppm

PO4 3- < 2.0 ppm

NH3 < 0.5 ppm

Free Chlorine < 0.5 ppm

Fe3+ < 0.5 ppm

Mn++ < 0.05 ppm

CO2 < 50 ppm

H2S < 50 ppb

Temperature < 65 °C

Oxygen content < 0.1 ppm

To avoid corrosion problems in water exchangers make sure that the water used in the plant meets the requirements listed in the table.

It is mandatory to install at the inlet of the unit the Y-shape water filter (supplied with the unit).

Water pipework

Requirements

For temperature probes (eg T5 or T1b) the maximum permitted cable length is 20m. This is the maximum allowed distance between the domestic

hot water tank and the unit (only for installations with a domestic hot water tank). To optimize efficiency, we recommend installing the domestic hot

water tank as close as possible to the unit

■ If the installation is equipped with a domestic hot water tank (optional), please refer to the domestic hot water tank Installation &

Owner's Manual.

■ If there is no glycol in the system (antifreeze) or if the unit is not able to remain electrically powered for possible blackouts, in order

to avoid possible icing problems, empty the water during winter.

NOTE

INSTALLATION

Page 18

18

INSTALLATION

■ Be careful not to deform the unit’s piping by using excessive force when connecting the piping. Deforming the piping

can cause the unit to malfunction.

■ The unit is only to be used in a closed water system. Application in an open water circuit can lead to excessive corrosion of the

water piping.

■ Water connections must be made in accordance with the outlook diagram delivered with the unit, with respect to the water intake

and water outlet (refer to section "DIMENSIONAL AND PHYSICAL DATA").

If air, moisture or dust gets in the water circuit, problems may occur. Therefore, always take into account the following when connecting

the water circuit:

■ Use clean pipes only.

■ Hold the pipe end downwards when removing burrs

■ Cover the pipe end when inserting it through a wall so that no dust and dirt enter.

■ Use a good thread sealant for sealing the connections. The sealing must be able to withstand the pressures and temperatures of

the system.

■ When using non-brass metallic piping,make sure to insulate both materials from each other to prevent galvanic corrosion. Never

use Zn-coated parts in the water circuit. Excessive corrosion of these parts may occur as copper piping is used in the unit's internal

water circuit.

Correction factor for the use of glycol in heating mode

ETHYLENE GLYCOL with water produced between 30 ÷ 55 º C.

PROPYLENE GLYCOL with water produced between 30 ÷ 55ºC.

Percentage Of glycol in mass / volume 0 / 0 10 / 8,9 20 / 18,1 30 / 27,7 40 / 37,5

Freezing point [°C] 0 -3,2 -8 -14 -22

CCPT - Heating capacity 1,000 0,995 0,985 0,975 0,970

CCPA - Power input 1,000 1,010 1,015 1,020 1,030

CCQA - Water flow rate 1,000 1,038 1,062 1,091 1,127

CCDP - Water pressure drop 1,000 1,026 1,051 1,077 1,103

Percentage Of glycol in mass / volume 0 / 0 10 / 9,6 20 / 19,4 30 / 29,4 40 / 39,6

Freezing point [°C] 0 -3,3 -7 -13 -21

CCPT - Heating capacity 1,000 0,990 0,975 0,965 0,955

CCPA - Power input 1,000 1,010 1,020 1,030 1,040

CCQA - Water flow rate 1,000 1,018 1,032 1,053 1,082

CCDP - Water pressure drop 1,000 1,026 1,051 1,077 1,103

Correction factor for the use of glycol in cooling mode

ETHYLENE GLYCOL with water produced between 5 ÷ 20 º C.

PROPYLENE GLYCOL with water produced between 5 ÷ 20 º C.

Percentage Of glycol in mass / volume 0 / 0 10 / 8,9 20 / 18,1 30 / 27,7 40 / 37,5

Freezing point [°C] 0 -3,2 -8 -14 -22

CCPF - Cooling capacity 1,00 0,99 0,98 0,97 0,95

CCPA - Power input 1,00 1,00 0,99 0,99 0,98

CCQA - Water flow rate 1,00 1,04 1,08 1,12 1,16

CCDP - Water pressure drop 1,00 1,08 1,16 1,25 1,35

Percentage Of glycol in mass / volume 0 / 0 10 / 9,6 20 / 19,4 30 / 29,4 40 / 39,6

Freezing point [°C] 0 -3,3 -7 -13 -21

CCPF - Cooling capacity 1,00 0,98 0,96 0,94 0,92

CCPA - Power input 1,00 0,99 0,98 0,95 0,93

CCQA - Water flow rate 1,00 1,01 1,03 1,06 1,09

CCDP - Water pressure drop 1,00 1,05 1,11 1,22 1,38

Protecting the water circuit against freezing

Frost can cause damage to the hydraulic circuit. If the unit's hydraulic circuit is expected to be subject to temperatures that may cause

freezing, care must be taken to prevent freezing of the system.

All hydraulic parts are insulated to reduce heat loss. Insulation must be present on the fi eld piping.

The unit is already equipped with several features to prevent freezing.

■ The software contains special functions using the heat pump to protect the entire system against freezing.

When the temperature of the water fl ow in the system drops to a certain value, the software will heat the water, either using the heat

pump, the electric heating tap, or the backup heater(if backup heater box is installed). The freeze protection function will turn off only when

the temperature increases to a certain value.

In case of a power failure, the features mentioned above cannot protect the unit from freezing. Since a power failure could happen when the

unit is unattended, the supplier recommends adding glycol to the water system. Refer to “Caution: Use of glycol”.

Since a power failure could happen when the unit is unattended, the supplier recommends adding glycol to the water system. Refer to

“Caution: Use of glycol”.

Depending on the expected lowest outdoor temperature, make sure the water system is fi lled with a concentration of glycol as mentioned

in the table below.

When glycol is added to the system, the performance of the unit will be affected. The correction factor of the unit capacity, fl ow rate and

pressure drop of the system is listed in the table below:

Page 19

19

INSTALLATION

ETHYLENE GLYCOL IS TOXIC

Use of glycol

■ Glycol use for installations with a domestic hot water tank:

- Only propylene glycol having a toxicity rating or class of 1, as listed in "Clinical Toxicology of Commercial Products, 5th edition" may be used.

■ If there is too much pressure when using glycol, connect the safety valve to a drain pan to recover the glycol.

■ Uninhibited glycol will turn acidic under the infl uence of oxygen. This process is accelerated by presence of copper and at

higher temperatures. The acidic uninhibited glycol attacks metal surfaces and forms galvanic corrosion cells that cause severe

damage to the system.

It is of extreme importance:

■ That the water treatment is correctly executed by a qualifi ed water specialist.

■ That a glycol with corrosion inhibitors is selected to counteract acids formed by the oxidation of glycols.

■ That in case of an installation with a domestic hot water tank, only the use of propylene glycol is allowed. In other installations

the use of ethylene glycol is fi ne.

■ That no automotive glycol is used because their corrosion inhibitors have a limited lifetime and contain silicates that can foul

or plug the system;

■ That galvanized piping is not used in glycol systems since it may lead to the precipitation of certain elements in the glycol’s

corrosion inhibitor;

■ To ensure that the glycol is compatible with the materials used in the system.

■ Be aware of the hygroscopic property of glycol. It absorbs moisture from the environment.

■ Leaving the cap off the glycol container causes the concentration of water to increase. The glycol concentration is then lower

and the water could freeze.

■ Preventive actions must be taken to ensure minimal exposure of the glycol to air.

WARNING

CAUTION

During fi lling, it might not be possible to remove all air in the system. Remaining air will be removed through the automatic air

purge valves during the fi rst operating hours of the system. Topping up the water afterwards might be required.

■ The water pressure indicated on the manometer will vary depending on the water temperature (higher pressure at

higher water temperature). However, at all times water pressure should remain above 0.3 bar to avoid air entering the circuit.

1. Connect the water supply to the fi ll valve and open the valve.

2. Make sure the automatic air purge valve is open (at least 2 turns).

3. Fill with water until the manometer indicates a pressure of approximately 2.0 bar. Remove air in the circuit as much as possi-

ble using the air purge valves. Air present in the water circuit might cause malfunctioning of the backup heater.

NOTE

Filling with water

Piping insulation

The complete hydraulic circuit that includes all the pipes must be insulated to avoid heat loss, condensation during operation,

reduction of heating or cooling capacity, as well as to prevent freezing of water pipes during winter.

☞

Page 20

20

INSTALLATION

■ Wiring must be carried out in accordance with the wiring diagram supplied with the unit and the instructions given in this paragraph.

■ All wiring and electrical components must be installed by a qualifi ed electrician.

■ Provide a main switch or other disconnection devices in the system in accordance with local laws and regulations.

■ Use a dedicated power line.

■ Install fuses (or circuit breakers) and power cables that match the maximum electrical current of the unit.

■ Install a differential switch according to local laws and regulations. Failure to install a differential switch can result in electric shock

and fi re.

■ Install a differential switch with the following characteristics:

- intervention value equal to 30 mA

- trip time less than 0.1 s

■ Make sure all electrical connections are carried out properly. Use the specifi ed cables and ensure that the terminal connections

and cables are protected from water and other external forces to avoid the risk of fi re.

■ Accommodate the power supply and control cables so that the front panel can be mounted correctly and therefore do not force the

cables themselves to avoid the risk of fi re or electric shock.

■ Do not compress the cables and make sure that they do not come into contact with the pipes and sharp edges. Ensure that no

external pressure is applied to the cables.

BEFORE ANY OPERATION WHICH REQUIRES REMOVING THE COVER, DISCONNECT THE UNIT FROM THE POWER SUPPLY THROUGH THE MAIN SWITCH.

DO NOT TOUCH THE ELECTRICAL COMPONENTS IN ANY CASE WITH THE CLOSED MAIN SWITCH! THERE IS THE

RISK OF ELECTRIC SHOCK WITH RISK OF INJURY OR DEATH!

The appliance must be connected to an effective earthing system, as provided for by the current safety regulations. Have

the effi ciency and suitability of the earthing system checked by professionally qualifi ed personnel, the manufacturer is not

responsible for any damage caused by lack of earthing of the system.

CAUTION

Electrical conections indoor unit

1. Opening the front panel

Some components inside the boiler can reach high temperatures that

could cause serious problems burns. Before carrying out any operation,

wait for these components to cool or alternatively wear suitable gloves.

To dismount the front panel of the indoor unit:

- Partially unscrew the screws A (see figure to the side).

- Pull the panel B out and release it from the upper fixings.

2. Make the connections referring to the functional electrical diagram

present in this manual.

3. Proceed in reverse order to reassemble the front panel. Make sure

that it is correctly attached to the upper fixing and completely resting on

the side panels. The head of the screw "A", once tightened, must not be

underneath the lower bending stop (see figure at the side).

OK NO

A

A

A

B

fi g. 1

Page 21

21

INSTALLATION

■ The unit is equipped with an inverter. Installing a power factor correction not only reduces the effect of power factor improvement, but can also cause an abnormal heating of the condenser due to high frequency waves. Never install a power

factor device as it may cause damage to the unit.

☞

■ A main switch or other means of disconnection, having a contact separation in all poles, must be incorporated in the fi xed wiring in

accordance with relevant local laws and regulations.

■ Switch off the power supply before making any connections.

■ Never squeeze bundled cables and make sure they do not come in contact with the piping and sharp edges. Make sure no exter-

nal pressure is applied to the terminal connections.

■ All fi eld wiring and components must be installed by a licensed electrician and must comply with relevant local laws and regulations.

■ The fi eld wiring must be carried out in accordance with the wiring diagram supplied with the unit and the instructions

given below.

■ Be sure to use a dedicated power supply. Never use a power supply shared by another appliance.

■ Be sure to establish a ground. Do not ground the unit to a utility pipe, surge protector, or telephone ground.

Incomplete grounding may cause electrical shock.

■ Be sure to install a ground fault circuit interrupter (30 mA). Failure to do so may cause electrical shock.

■ Be sure to install the required fuses or circuit breakers.

WARNING

■ Be sure to install a differential switch with the following characteristics:

- intervention value equal to 30 mA

- trip time less than 0.1 s

- that it is compatible with the inverter (resistant to high frequency electromagnetic disturbances) in order to avoid unnecessary

interventions

NOTA

Electrical conections outdoor unit

1. Remove the side panel (1).

2. Make the connections referring to the

wiring diagrams of the unit.

3. Close the machine up again.

1

1

Mod. 10 - 12 - 14 - 16 - 12T - 14T -16T

Mod. 4 - 6 - 8

☞

fi g. 1

fi g. 2

Page 22

22

INSTALLATION

Power supply connection

Electrical connections

Procedure

1. Connect the cables to the appropriate terminals as shown on the diagram.

2. Fix the cables with cable ties.

Recommended cable H05RN-F or as installed. See specifi c legislation. The customer must install the automatic circuit

breaker.

Outdoor unit MOD.

4 6 8 10 12 14 16 12T 14T 16T

Power input " 220-240V 50 Hz

380-415V 3+N+PE

50Hz

Automatic circuit breaker A 16 20 32 16

Power supply cross-section of cable mm

2

3x2,5 3x4,0 3x4,0 5x2,5

Cavo di comunicazione

tra unità interna ed esterna

MOD.

4 6 8 10 12 14 16 12T 14T 16T

Wiring size (shielded cable)

mm

2

3x0,75

Indoor unit without booster MOD.

816

Power input " 220-240V 50 Hz

Automatic circuit breaker A 2

Power supply cross-section of cable mm

2

3x1,0

Indoor unit with booster MOD.

81616T

Power input " 220-240V 50 Hz

380-415V 3+N+PE

50Hz

Automatic circuit breaker A 16 16 10

Power supply cross-section of cable mm

2

3x2,5 3x2,5 5x2,5

Indoor Unit

Outdoor Unit

Power Supply

3-shield wire

COMANDO

REMOTO

ABXYE

ABXYE

P Q E T5 T5 T1b T1b

IBH1 IBH2 PE TH N C H A1 A2 N N N PE

IBH1 IBH2

LPEPEN

TH PE TBH L1

AHS1 AHS2

P_o PEPE P_d SV2

Power Supply

LN

EQP

Mod. 4 - 6 - 8 - 10 - 12 - 14 - 16

NOTA

Connect the communication cable between indoor unit and outdoor unit keeping the correspondence of the letters

indicated on the terminals (P with P, Q with Q, E with E).

Connect the communication cable between indoor unit and remote control keeping the correspondence of the let-

ters indicated on the terminals (A with A, B with B....).

OUTDOOR UNIT

REMOTE

CONTROL

power supplie

power supplie

comunication

(shielded cable)

INDOOR UNIT

☞

fi g. 1

Page 23

23

INSTALLATION

PE

Power Supply

L3L2L1

Power Supply

L3L2L1 EQP

Indoor Unit

Outdoor Unit

ABXYEPQ E T5 T5 T1b T1b

IBH1 IBH2 PE TH N C H A1 A2 N N N PE

IBH1 IBH2 TH PE TBH L1

AHS1 AHS2

P_o PE PE P_d SV2

3-shield wire

PE

COMANDO

REMOTO

ABXYE

Mod. 12T - 14T -16T

NOTA

Connect the communication cable between indoor unit and outdoor unit keeping the correspondence of the letters

indicated on the terminals (P with P, Q with Q, E with E).

Connect the communication cable between indoor unit and remote control keeping the correspondence of the let-

ters indicated on the terminals (A with A, B with B....).

OUTDOOR UNIT

REMOTE

CONTROL

Power supplie

Power supplie

comunication

(shielded cable)

INDOOR UNIT

☞

Connections between indoor unit terminal block and plant components

Remote alarm

Voltage

Passive signal port

(dry contact)

Maximum running

current

0.5A

Wiring size 0.75mm

2

2-way valve (SV2)

NOTE: The SV2 valve is powered when the heat pump is operating in HEAT mode.

Voltage 220-240VAC

Maximum running

current

0.2A

Wiring size 0.75mm

2

SV2

SV2

N

A1 A2

L

FUSE

N

DHW pump (P_d)

Voltage 220-240VAC

Maximum running

current

0.2A

Wiring size 0.75mm

2

DHW PUMP

CONTROL SIGNAL

OUTPUT

N

P_d

fi g. 2

fi g. 3 fi g. 4

fi g. 5

Page 24

24

INSTALLATION

Method ON/OFF HEAT / COOL Digital input effect Remote controller Setup*

A √

The operation mode is defined by the digital input.

The unit will be ON in COOL mode when L1-C is closed.

The unit will be on in HEAT mode when H-L1 is closed.

If both digital input are closed the unit

will be ON in COOL mode.

The user can only

set the target

water flow temp.

B √

The unit will be ON when the digital input is closed.

The unit will operate in the mode

defi ned by the controller.

The user can set

the operation

mode and the

target water

flow temp.

6 ROOM THERMOSTAT

ROOM THERMOSTAT

MODE SETTING

DUAL ROOM

THERMOSTAT

SCROLL

YES

NON

YES

NON

YES

NON

6 ROOM THERMOSTAT

ROOM THERMOSTAT

MODE SETTING

DUAL ROOM

THERMOSTAT

SCROLL

YES

NON

YES

NON

YES

NON

Room thermostat (ON/OFF - HEAT/COOL by digital input)

External ON / OFF (thermostat)

External COOL/HEAT (thermostat)

Voltage 220-240VAC

Maximum running

current

0.2A

Wiring size 0.75mm

2

HEAT

COOL

POWER IN POWER IN

Method B Method A

Nota For more details refer to paragraph " ROOM THERMOSTAT (ON/OFF - HEAT/COOL by digital input)" in the section "SET UP OF THE

SYSTEM".

H

H

RT RT

L1

L1C C

Booster heater of the DHW tank (TBH)

Voltage 220-240VAC

Maximum running current

0.2A

Wiring size 0.75mm

2

Boiler (AHS)

Outside circulation pump (P_o)

Voltage 220-240VAC

Maximum running current

0.2A

Wiring size 0.75mm

2

Voltage

Passive relay

(dry contact)

Maximum running current

100mA

Wiring size 0.75mm

2

For 5-7, unit, the

terminal number is 25

and 26.

Electrical booster

The unit is able to manage a 2-stage electric booster (For the OMNIA UI

HI unit the electric booster is already installed and wired inside the indoor

unit).

TANK BOOST HEATER

CONTROL SIGNAL

OUTPUT

AHS BOILER CONTROL

(dry contact)

P_o outside pump

IBH1

stage 1 booster

IBH2

stage 2 booster

TBH

AHS1

P_o

IBH1 IBH2

AHS2

N

IBH1 IBH2

N

☞

fi g. 1 fi g. 2

fi g. 3

fi g. 4

fi g. 5

fi g. 6

Page 25

25

INSTALLATION

User interface

“PLEASE USE SHIELDED WIRE AND EARTH THE WIRE.”

AB

X

YE

A

B

X

Y

E

AB

X

YE

COMMUNICATION

Connect the communication cable between indoor unit and remote control

keeping the correspondence of the letters indicated on the terminals (A with

A, B with B....).

Procedure:

1. Remove the rear part of the user interface.

2. Connect the cable to the appropriate terminals as shown in the picture

3. Reattach the rear part of the user interface

Wire type 5 wire shielded cable

Wire section

AWG18-AWG16(0.75~1.25mm2)

Maximum wire length 50m

Questo dispositivo supporta il protocollo di comunicazione Modbus RTU.

NOTE

☞

NOTA

☞

fi g. 7

How to go to FOR SERVICEMAN

Go to MENU> FOR SERVICEMAN. Press OK

The password is 666. Use ◄ ► to navigate and use ▼ ▲ to

adjust the numerical value. Press OK. The following page is

displayed:

Use ▼ ▲ to scroll and use “ok” to enter submenu for

setting the parameters.

FOR SERVICEMAN

Please input the password:

ADJUST SCROLLENTER

OK

0 0 0

FOR SERVICEMAN

2. COOL MODE SETTING

3. HEAT MODE SETTING

4. AUTO MODE SETTING

5. TEMP.TYPE SETTING

6. ROOM THERMOSTAT

7. OTHER HEATING SOURCE

1. DHW MODE SETTING

SCROLLENTER

OK

FOR SERVICEMAN

9. SERVICE CALL SETTING

10. INITALIZE MANUALLY

11. TEST RUN

12. SPECIAL FUNCTION

13. AUTO RESTART

8. HOLIDAY AWAY MODE SETTING

SCROLLENTER

OK

Description of terms

The terms related to this unit are shown in the table below

Parameter Description

T1

Outlet water temperature of the unit or of the backup heater (if installed)

T1B

Outlet water temperature sent to the system (in case of additional heating source as a gas boiler is installed)

T1S

Target outlet water temperature

T2

Temperature of refrigerant at outlet/inlet of plate heat exchanger when in heat mode/cool mode

T2B

Temperature of refrigerant at inlet/outlet of plate heat exchanger when in heat mode/cool mode

T3

Temperature of tube at outlet/inlet of condenser when in cool/heat mode

T4

Outdoor air temperature

T5

Temperature of domestic hot water (misured by the temperature probe installed on the DHW tank)

Th

Refrigerant suction temperature

Tp

Refrigerant discharge temperature

TW_in Inlet water temperature of plate heat exchanger

TW_out Outlet water temperature of plate heat exchanger

AHS

Additional heating source (for example a gas boiler)

IBH1

The first stage of the backup heater (if installed)

IBH2

The second stage of the backup heater (if installed)

TBH

Backup heater in the domestic hot water tank (if installed)

Pe

Refrigerant evaporate/condense pressure in cool/heat mode

ON/OFF by digital input or switch .(refer to room thermostat)

COOL/HEAT mode managment by digital input. (refer to room thermostat)

Page 26

26

"FOR SEVICEMAN" menu

SETUP OF THE SYSTEM

Page 27

27

SETUP OF THE SYSTEM

Page 28

28

SETUP OF THE SYSTEM

Page 29

29

SETUP OF THE SYSTEM

Page 30

30

SETUP OF THE SYSTEM

Use ◄ ►and ▼▲ to scroll and adjust parameters. Use BACK to exit.

dT5_ON is the temperature difference for starting the heat pump, the picture below illustrates the dT5_ON function.

T5S is the target temperature for domestic hot water. T5 is

the actual temperature of domestic hot water. When T5 drops

to a certain temperature (T5≤T5S-dT5_ON) the heat pump

will be available. dT1S5 is the correct value for the target

outlet water temperature (T1S=T5+dT1S5).

T4DHWMAX is the maximum outdoor air temperature that

the heat pump can operate at for domestic water heating.

The unit will not operate if the outdoor air temperature goes

above it in DHW mode.

DHW mode setting

DHW:domestic hot water

DHW MODE SETTING typically consists of the following:

1. DHW MODE: enable or disable the DHW mode

2. TANK HEATER: set whether the booster heater is available or not

3. DISINFECT: set the parameters for disinfection

4. DHW PRIORITY: set the priority between domestic hot water heating and space operation

5. DHW PUMP: set the parameters for DHW pump operation. The functions above apply only to installations with a domestic hot

water tank.

How to set the DHW mode

To determine whether the DHW mode is effective.

Go to MENU> FOR SERVICEMAN> DHW MODE SETTING. Press OK. The following page is displayed:

Use ◄ ► to scroll and OK for enter. When the cursor is on

press YES, Press OK to set

the DHW MODE as effective. When the cursor is on NON,press OK to set the DHW MODE

as ineffective.

1 DHW MODE SETTING

1.2. TANK HEATER

1.3. DISINFECT

1.4. DHW PRIORITY

1.5. DHW PUMP

1.1. DHW MODE

SCROLLENTER

OK

YES

YES

YES

YES

YES

NON

NON

NON

NON

NON

1. Go to MENU> FOR SERVICEMAN>DHW MODE SETTING>1.1 DHW MODE

1.1 DHW MODE

dT5_ON

dT1S5

T4DHWMAX

T4DHWMIN

t INTERVAL DHW