Page 1

Wall hung gas fired boilers with

micro-storage heater for indoor installation

NEW ELITE

Page 2

FERROLI, in line with its position as a comfort multinational, one of the major players at a world level, permanently carries out research and trials on new products, so as to respond to the continuously evolving expectations

of the users and the market.

Exceptional comfort, avantgarde technology, elegant design, reliability, quality and absolute

safety: these the objectives that the FERROLI Research and Development department focused on when

designing the NEW ELITE.

Consequently, the NEW ELITE on one hand confirms FERROLI's solid experience and tradition in the heating

sector, while on the other brings advanced design concepts to fruition. Furthermore, it offers comfort and

functions combined with an original style, in line with the latest architectural trends: the attractive appearance

and the futuristic control panel mean that the appliances can be installed in any environment, even in those

where, as well as practicality, the user places emphasis on the aesthetics of the furnishing.

The NEW ELITE boilers therefore represent the top of the FERROLI range of traditional wall-hung applian-

ces, and are therefore especially designed for and dedicated to those who wish to stand out.

The FERROLI history and tradition in the heating sector, along with its quality, certified in compliance with the

UNI EN ISO 9001:2000 standards, for the user mean guarantees, quality and safety.

The NEW ELITE series features four models, all with automatic electronic ignition and instant production of

domestic hot water; two of the models have natural draught and open flues (C 24 E and C 30 E) and

two have forced draught and are room sealed (F 24 E and F 30 E); all the models are factory fitted for

operation on natural gas, or alternatively LPG.

Main advantages

2

MICRO-STORAGE

The boiler is fitted with

a micro-storage heater (3 litres)

on the DHW circuit,

virtually eliminating

the waiting time

for the delivery

of domestic hot water.

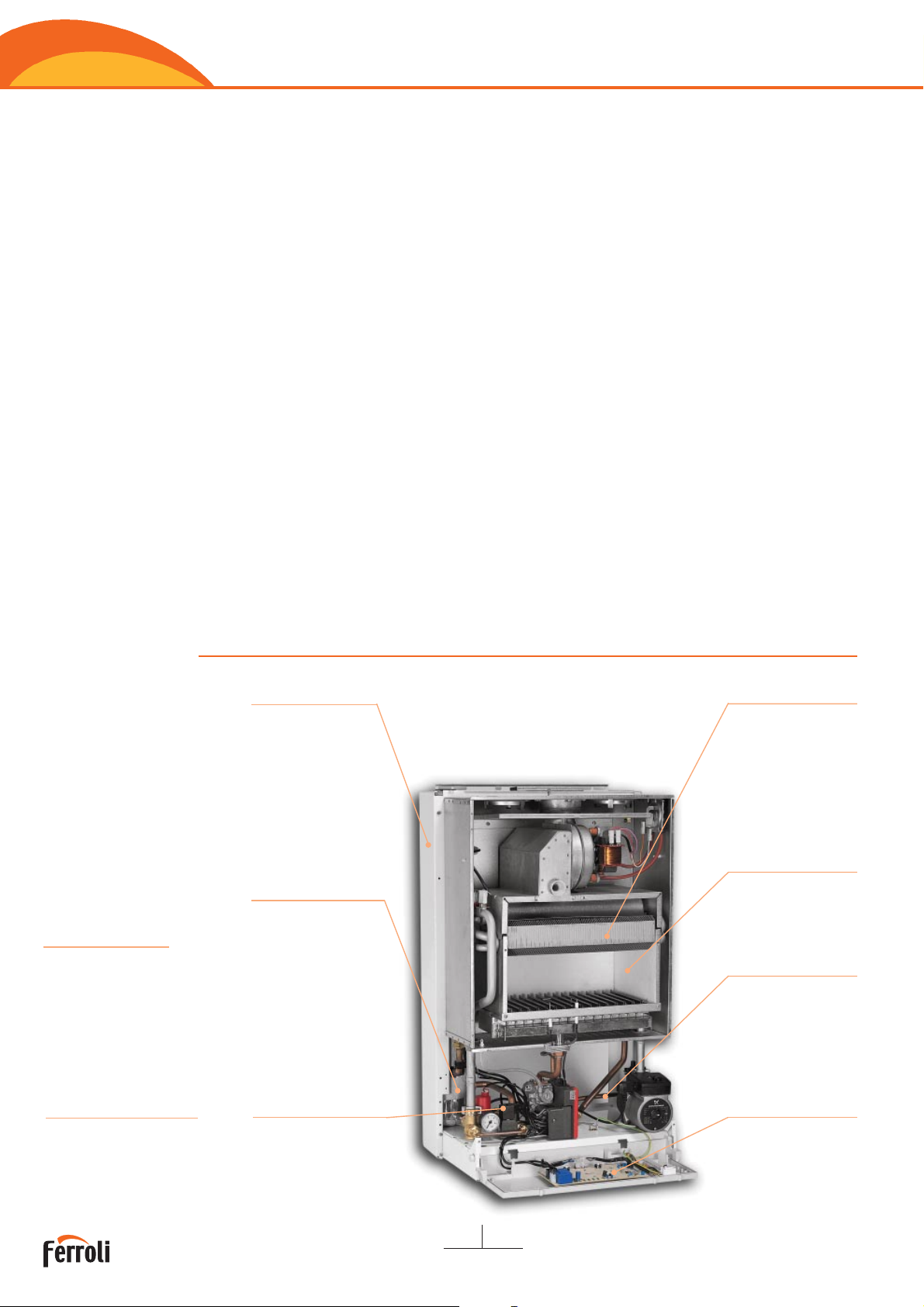

THE STRUCTURE

The entire structure

of the boiler and in particular

the support frame is made

from very thick metal plate,

making it particularly sturdy.

FILLING THE SYSTEM

The boiler is fitted with

a solenoid valve for filling

the central heating circuit.

MICROPROCESSORS

The boiler's electronic

board features two

microprocessors.

CONTROL PANEL

The boiler features

a newly-designed digital

control panel, with complete,

user-friendly display.

AUTOMATIC BYPASS

Standard.

WATER AND GAS CONNECTIONS

The water and gas fittings

are positioned so as to assist

the installation operations.

DUAL HEAT EXCHANGER

The boiler is fitted with

the highly efficient and

comprehensively tested

FERROLI dual copper

heat exchanger.

COMBUSTION CHAMBER

Insulated with ecological fibre.

Model F 30E

introduction

NEW ELITE

Page 3

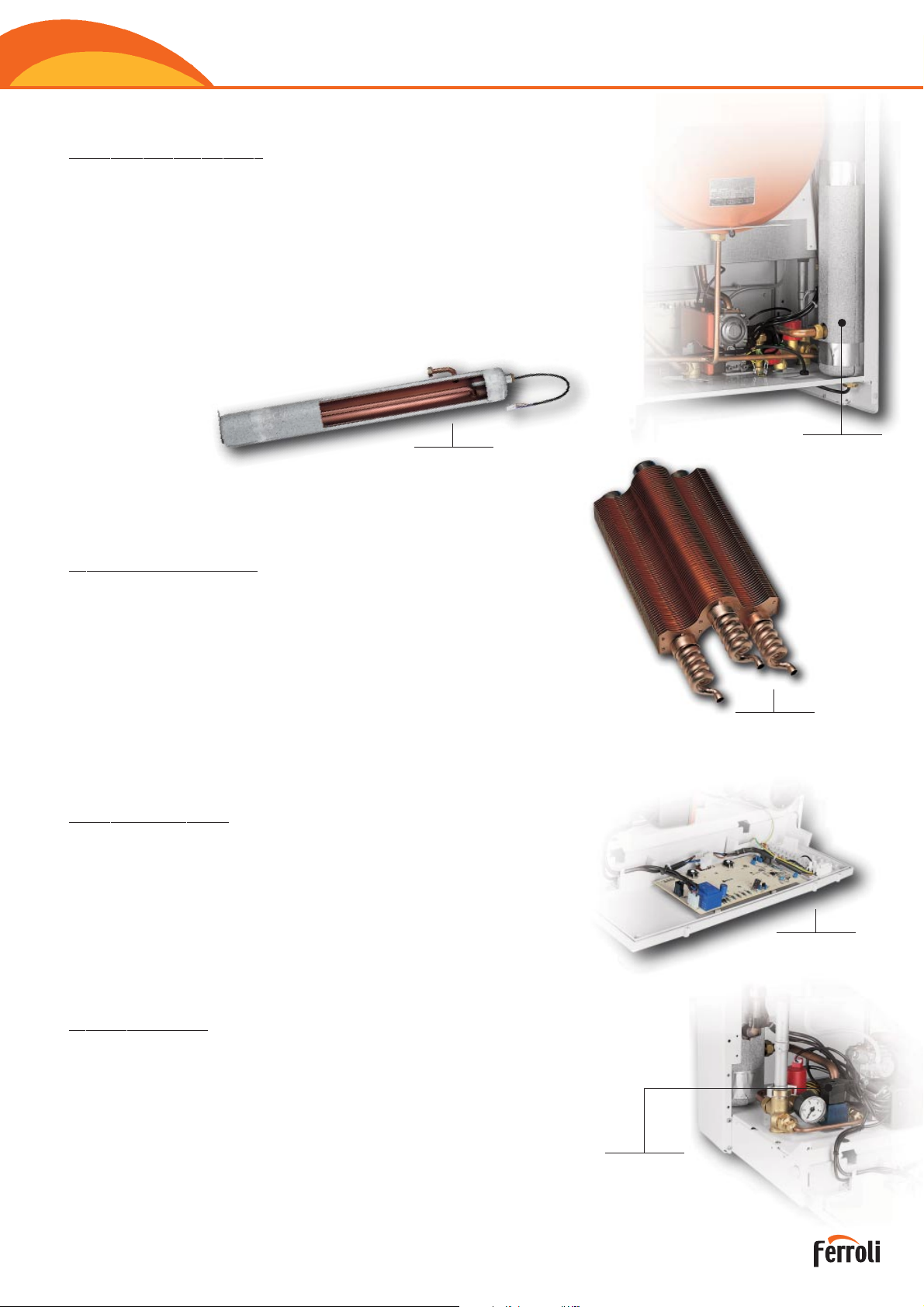

THE MICRO-STORAGE HEATER

So as to achieve maximum comfort in the DHW circuit, a 3-litre micro-storage hea-

ter, complete with self-regulating electric heater, is installed downstream of the dual

heat exchanger; the user can enable/disable this feature at any time. When the heater is on (COMFORT rather that ECO mode), the waiting times for the delivery

of domestic hot water at the desired temperature are reduced to the minimum, and practically eliminated.

THE D

UAL HEAT EXCHANGER

The NEW ELITE boilers are fitted with the highly efficient and comprehensively tested

FERROLI dual heat exchanger, made from finned and braze welded copper pipes,

and featuring an ecological aluminium-based enamel coating. This exchanger has for

the last two decades been a synonym of high efficiency - both in central heating and in DHW production - and constant performance over time.

THE MICROPROCESSORS

All of the NEW ELITE models feature two notoriously very fast and precise microprocessors: one supervises the management and control of the various functions of

the boiler, while the other controls the ignition (electronic), flame detection, the

attempts at automatic re-ignition if the flame is extinguished, as well as the definitive

lock out of the boiler (requiring manual reset).

TH

E FILLING SYSTEMS

The NEW ELITE boilers are fitted with a system filling device - solenoid valve - that

can be set for automatic or semiautomatic operation. The appliances are factory set

for semiautomatic mode, however the user can switch to automatic mode using the

special button on the control panel.

In addition, if the system needs to be filled to the required pressure (the recommended pressure is 1 bar), and the boiler is disconnected from the mains power supply, it

can be filled completely manually (this mode is recommended for the first filling).

Micro-storage heater

(cross-section)

L’elettrovalvola

per il riempimento

automatico/semiautomatico

Dual heat exchanger

Electronic board

with microprocessor

Micro-storage heater

3

strong points

NEW ELITE

Page 4

strong points

NEW ELITE

190 mm

CONTINUOUS FLAME MODULATION

All models feature PID (that is, Proportional, Integral, Derivative) flame modulation,

commonly known as the most evolved and technologically most advanced control

system, which ensures maximum comfort in both central heating operation - and,

above all - for the production of domestic hot water, as users now demand the maximum in terms of constant temperature throughout the delivery of hot water. In this

regard, flame modulation in DHW production is based on two measurements: the

temperature (using an electronic sensor) and flow-rate (using the flow meter).

"TE

MPERATURE SCROLLING" AND CLIMATE CONTROL

The NEW ELITE boilers are pre-fitted for "temperature scrolling"

operation; that is, they are able to keep the outlet temperature at a

minimum value, depending on the outside temperature. This operating mode can be activated by simply connecting the boiler to a

special outside probe (optional). The automatic correlation

between the two temperatures, outlet and outside, is the so-called

"compensation curve". The user can choose, from the ten compensation curves available, the one that best suits the characteristics of

the building and the radiators used, in order to achieve the maxi-

mum comfort with minimum fuel consumption.

EASE OF INSTALLATION

The distance from the axis of the fittings to the wall the boiler is fastened to is, for

all models, 190 mm: this makes the connection of the boiler to the system much

easier for the installer.

REMO: THE REMOTE TIMER CONTROL

The NEW ELITE boilers can connected to any type of room thermostat or timer-thermostat; if required, a modulating remote timer control (optional) can be used, with

two-wire connection for remote control and daily/weekly room temperature settings.

Outside probe

COMPENSATION CURVE DIAGRAM

Outside temperature °C

System outlet temperature °C

REMO remote

timer control

4

90

85

80

70

60

Temperatura di mandata impianto °C

50

40

30

20

10

9

20 10 0 -10 -20

Temperatura esterna °C

7

8

6

5

4

3

2

1

Page 5

Summer/winter

selection

Fill system

COMFORT/ECO

selection

Modify selected

parameters

Select

parameters

System temperature

setting (30-85°C)

Domestic hot water

temperature setting

(40°-65°C)

Boiler on/off

Reset boiler operation

Display on the F models

(graphic simulation)

Control panel

KEY

11 D HW temperature display

12 D HW operation

13 Central heating or DHW request

14 Air pressure switch enabling signal (during ignition)

15 Boiler igniting

16 Burner on

17 Operation in central heating mode

18 Central heating temperature display

19 Remote timer control connected

20 Summer/winter display

21 Pump on

22 Operation in anti-freeze mode

23 Central heating request

24 Wait after central heating operation

26 Wait after DHW operation

27 DHW operation request

28 COMFORT/ECO mode display

30 System pressure display

33 Fault signal

34 Operation in TEST mode

(at maximum output)

35 Parameter and fault display

36 Outside probe connected

37 Outside temperature display

(only with probe connected)

5

NEW ELITE

user interface

Page 6

6

functional diagrams and diagrams

NEW ELITE

Diagrams

to determine the discharge head available to the system

KEY

5 Room sealed

7 Gas inlet

8 Domestic hot water outlet

9 Domestic hot water inlet

10 Central heating flow outlet

11 Central heating return inlet

14 S afety valve

16 Fan

20 Burner assembly

27 Heat exchanger

29 Flue gas outlet collar

32 Pump

34 Central heating temperature sensor

42 DHW temperature sensor

43 Air pressure switch

44 Gas valve

49 Safety thermostat

56 Expansion vessel

81 Ignition electrode

82 Detection electrode

114 Water pressure transducer

126 Flue gas thermostat

136 Flow meter

187 Flue gas diaphragm

238 Micro-storage heater

239 Electric heater

240 System fill solenoid valve

241 Automatic bypass

246 Water pressure transducer

F models room sealed

Models C 30 E - F 30 EModels C 24 E - F 24 E

Key

Circulator speed

Boiler pressure drop

1 2 3

A

Page 7

7

NEW ELITE

dimensions

NE

W ELITE C 24 E

TOP VIEW BOTTOM VIEW

NE

W ELITE F 24 E

TOP VIEW BOTTOM VIEW

NE

W ELITE C 30 E

TOP VIEW BOTTOM VIEW

NE

W ELITE F 30 E

TOP VIEW BOTTOM VIEW

KEY

1 Central heating flow outlet,

dia. 3/4”

2 Domestic hot water outlet,

dia. 1/2”

3 Gas inlet, dia. 1/2”

4 Domestic hot water inlet,

dia. 1/2”

5 Central heating return inlet,

dia. 3/4”

KEY

1 Central heating flow outlet,

dia. 3/4”

2 Domestic hot water outlet,

dia. 1/2”

3 Gas inlet, dia. 1/2”

4 Domestic hot water inlet,

dia. 1/2”

5 Central heating return inlet,

dia. 3/4”

Page 8

Ferroli spa ¬ 37047 San Bonifacio (Verona) Italy ¬ Via Ritonda 78/A

tel. +39.045.6139411 ¬ fax +39.045.6100233

www.gruppoferroli.com ¬ e-mail: export@ferroli.it

Cod. 00000000 - 09.2004

WARNING FOR TRADERS: As part of its efforts to constantly improve its

range of products, with the aim of increasing the level of Customer satisfaction, the Company stresses that the appearance, dimensions, technical data

and accessories may be subject to variation. Consequently, ensure that the

Customer is provided with updated documents. The products described in

this document are covered by warranty if purchased and installed in Italy.

NEW ELITE C 24 E F 24 E C 30 E F 30 E

Output Pmax Pmin Pmax Pmin Pmax Pmin Pmax Pmin

Heat input (Net Heat Value Hi) kW 25,8 11,5 25,8 11,5 33,1 14,5 33,1 14,5

kcal/h 22.200 9.900 22.200 9.900 28.500 12.500 28.500 12.500

Useful heat output 80°/60°C kW 23,3 9,7 23,8 9,7 30,0 12,7 30,0 12,7

kcal/h 20.000 8.300 20.400 8.300 25.800 10.900 25.800 10.900

DHW heat output kW 23,3 9,7 23,8 9,7 30,0 12,7 30,0 12,7

kcal/h 20.000 8.300 20.400 8.300 25.800 10.900 25.800 10.900

Efficiency

At the rated output (80°/60°C) % 90,3 92,2 90,5 90,5

At reduced load (30% of Pn) % 88,6 89,4 87,3 87,3

Gas supply

Main nozzles, natural gas (G20) mm 12 x 1,30 12 x 1,30 16 x 1,25 16 x 1,25

Natural gas (G20) supply pressure mbar 20,0 20,0 20,0 20,0

Natural gas (G20) burner pressure mbar 11,8 2,5 11,8 2,5 13,0 2,5 13,0 2,5

Natural gas rate (G20) nm3/h 2,73 1,22 2,73 1,22 3,50 1,53 3,50 1,53

Main nozzles, LPG (G31) mm 12 x 0,77 12 x 0,77 16 x 0,75 16 x 0,75

LPG (G31) supply pressure mbar 37,0 37,0 37,0 37,0

LPG (G31) burner pressure mbar 36,0 7,8 36,0 7,8 35,5 7,0 35,5 7,0

LPG rate (G31) nm3/h 2,00 0,89 2,00 0,89 2,6 0,89 2,6 0,89

Central heating

Maximum operating temperature °C 90 90 90 90

Maximum operating pressure bar 3 3 3 3

Safety valve bar 3 3 3 3

Minimum operating pressure bar 0,8 0,8 0,8 0,8

Expansion vessel capacity litres 10 10 10 10

Expansion vessel pre-fill pressure bar 1 1 1 1

Boiler water capacity litres 0,8 0,8 1,1 1,1

Domestic hot water

Maximum production ∆t 25°C l/min 13 13,6 17,2 17,2

Maximum production ∆t 30°C l/min 11 11,3 14,3 14,3

Maximum operating pressure bar 9 9 9 9

Minimum operating pressure bar 0,25 0,25 0,25 0,25

Minimum delivery l/min 2,0 2,0 2,0 2,0

Circuit water capacity litres 3,0 3,0 3,3 3,3

Dimensions, weights, fittings

Height mm 780 780 780 780

Width mm 480 480 480 480

Depth mm 368 368 368 368

Weight with packaging kg 41 46,5 43 49

Gas system fitting inches 1/2” 1/2” 1/2” 1/2”

Central heating system fittings inches 3/4” 3/4” 3/4” 3/4”

DHW circuit fittings inches 1/2” 1/2” 1/2” 1/2”

Power supply

Maximum power input W 135 175 135 185

Power supply voltage/frequency V/Hz 230/50 230/50 230/50 230/50

Electrical index of protection IP X5D X5D X5D X5D

TECHNICAL SPECIFICATIONS

Loading...

Loading...