Page 1

KSR

AIR - WATER

HEAT PUMPS

FOR SPLITTED INSTALLATION

INSTALLATION AND OPERATION MANUAL

R

E

F

R

I

G

E

R

A

N

T

G

A

S

E

C

O

-

F

R

I

E

N

D

L

Y

Page 2

2

The manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mi-

stakes. The manufacturer reserves the right to apply changes and improvements to the products at any time without notice.

Dear Customer,

Thank you for having purchased a FERROLI product. It is the result of many years of experiences and of particular research studies

and has been made with top quality materials and advanced technologies. The CE mark guarantees that the products satisfy all the

applicable European Directives.

The qualitative level is kept under constant control and FERROLI products therefore offer SAFETY, QUALITY and RELIABILITY.

Due to the continuous improvements in technologies and materials, the product specication as well as performances are subject to

variations without prior notice.

Thank you once again for your preference

FERROLI S.p.A

Page 3

3

TABLE OF CONTENTS

GENERAL FEATURES 4

General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit dataplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit identification code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TECHNICAL DATA AND PERFORMANCES 11

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

NOMINAL performances - Base acoustic setting up (AB) - Radiant plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NOMINAL performances - Base acoustic setting up (AB) - Standard plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NOMINAL performances - Low noise acoustic setting up (AS) - Radiant plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

NOMINAL performances - Low noise acoustic setting up (AS) - Standard plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HEATING performances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

COOLING performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Plant side hydraulic performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Domestic hot water side hydraulic performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Minimum operating area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CONNECTIONS 23

Hydraulic connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Refrigerant connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RECEIVING AND POSITIONING 29

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

START UP 30

Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CONTROL SYSTEM 31

Control system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Heating and cooling circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Control system devices installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wireless devices connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Control system using . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Control system programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Remote thermostat programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remote control (wired o wireless) programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Functions available for the use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Alarms table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Controller technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Sensors features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MAINTENANCE 48

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SAFETY AND POLLUTION 49

General considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Refrigerant safety card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 4

4

GENERAL FEATURES

General instructions

Declaration of conformity

Unit dataplate

The figure shows the fields reported on the unit dataplate :

This manual and the wiring diagram supplied with the unit must be kept in a dry place for possible future consultation.

The manual provides information on installation and correct use and maintenance of the unit. Before carrying out installation,

please carefully read all the information contained in this manual, which describes the procedures necessary for correct

installation and use of the unit

Follow carefully the instructions contained in this manual and respect the safety regulations in force. The unit must be installed

in conformity with the laws in force in the country of use. Unauthorized tampering with the electrical and mechanical equipment

INVALIDATES THE WARRANTY.

Check the electrical specifications given on the dataplate before making the electrical connections. Read the instructions given in the

specific section on electrical connections.

Deactivate the equipment in case of fault or poor operation.

If the unit requires fixing, contact only specialized service centers recognized by the manufacturer and use original spare parts.

The unit must be installed partially outdoor and partially indoor and connected to a hydronic cooling and/or heating system. Any use

different from that permitted or outside the operating limits indicated in this manual is prohibited (unless previously agreed with the

firm).

The manufacturer declines any responsability for damage or injury due to non-compliance with the information given in this manual.

The firm declares that the present unit complies with the requirements of the following directives :

• Machinery directive (MD) 2006/42/EC

• Pressure equipment directive (PED) 97/23/EC

• Electromagnetic compatibility directive (EMC) 2004/108/EC

• Low voltage directive (LVD) 2006/95/EC

Codice

Code

B1

Rev

Ferroli Spa

Via Ritonda 78/A

(VR) Italy

A - Trademark

B - Model

B1 - Code

C - Serial number

D - Capacity in cooling at the condition A35W18

E - Capacity in heating (heat pump) at the condition A7W35

F - Power input in cooling at the condition A35W18

G - Power input in heating (heat pump) at the condition A7W35

H - Reference standard

I - Power supply

L - Maximum absorbed current

M - Refrigerant type and charge weight

N - Unit weight

O - Sound pressure level at 1 metre

P - IP protection level

Q - Maximum pressure - high pressure side

R - Maximum pressure - low pressure side

S - PED certification body

Page 5

5

IP 71 VB AB 0 M 1

GENERAL FEATURES

Unit description

This series of air-water heat pumps satises the heating, cooling

and domestic hot water production requirements of residential

plants of small and medium size.

All the units are suitable for splitted installation (indoor unit and

outdoor unit connected through refrigerant pipes) and can be

applied to fan coil plants, radiant oor plants and high efciency

radiators plants.

The control system allows to manage not only the refrigerant

circuit but the whole plant with the possibility to choose different

solutions both for the heating and cooling plant and for the domestic hot water management. The possibility of solar panels or

other heating sources integration is also available.

The heating function optimizes the ow water temperature according both to the ambient temperature and to the outdoor temperature through climatic curves adaptable to the building features. It’s possible to manage a storage tank and two independent

circuits (a direct one and a mixed one).

The domestic hot water management allows to control the three

way valve, the storage tank and the anti-legionella cycles (if necessary).

The cooling function can be realized through “active cooling” (refrigerant circuit inversion). When the unit is used in radiant oor

plants, to avoid condensate generation, a room humidity sensor

can be installed.

The internal programmer clock allows to dene different daily

switching programs for heating, cooling and domestic hot water

production.

The heat pump is composed by an indoor unit (motocondensing

unit) containing the hydraulic circuit, the electrical board, the

compressor and a part of the refrigerant circuit and an outdoor

unit (remote evaporator).

The refrigerant circuit, contained in an extractable box to simplify

the maintenance operations, is equipped with rotary compressor mounted on damper supports, brazed plate heat exchanger,

thermostatic expansion valve and reverse cycle valve and liquid

receiver.

The circuit is protected by high and low pressure switches and

ow switches on the plate heat exchanger.

The plate heat exchanger and all the hydraulic pipes are thermally insulated to avoid condensate generation and to reduce

thermal losses.

The outdoor structure of the indoor unit and the refrigerant circuit box are both thermally and acoustically insulated in order to

create a double wall against sound propagation and to allow the

installation in domestic places.

To avoid vibration propagation towards the hydraulic circuit the

refrigerant circuit box is placed on damper supports and the connection pipes are exible.

The outdoor unit is composed by nned coil made of copper

pipes and aluminium louvered fins and axial fan with safety protection grilles. The fan, supplied with DC motor and electronic rotational speed control, guarantees high efficiency and low noise

in all the operating conditions.

All the units are supplied with an outdoor temperature sensor in

order to realize the climatic control.

All the units are accurately built and individually tested in the

factory. Only electric, hydraulic and refrigerant (between indoor

and outdoor units) connections are required for installation.

Unit identification code

The codes that identify the units and the meaning of the letters used are described below.

Unit type

IP - Units suitable for hydronic plant

installation operating as reversible heat

pumps

Power supply

1 - 230V - 1 - 50 Hz

Operating range

M - Medium temperature.

The unit is suitable to produce

water at medium temperature

Refrigerant type

0 - R410A

Acoustic setting up

AB - Base setting up

AS - Low noise setting up

Unit version

VB - Base version

N° compressors

Unit model

KSR

Page 6

6

GENERAL FEATURES

Description of components

Indoor unit structure Basement, lateral panels and frontal

panel, are completely thermally and acoustically insulated in

order to minimize thermal losses and noise emissions in the

surroundings. Accessibility to internal parts is possible removing

the frontal panel and the upper panel. For extraordinary

manteinances also the rear panel can be removed.

Outdoor unit structure Basement, supporting structure and

lateral panels are made of galvanized and painted sheet-steel to

guarantee good resistance to atmospheric agents. Accessibility

to internal parts is possible removing the frontal panel. For

extraordinary manteinances also the other panels can be

removed.

Refrigerant circuit All the components of the refrigerant circuit,

except the finned coil, are contained inside an extractable box

placed in the indoor unit to simplify the maintenance operations.

The box is placed on rubber vibration dampers and is connected

to the hydraulic circuit through flexible pipes in order to avoid

the propagation of the vibrations generated by the compressor

outside the unit. The hermetic rotary compressor (1) is mounted

on damper supports and is protected against overtemperatures

and overcurrents. The heat exchangers on the plant side (2) is

a brazed stainless steel plate heat exchanger, properly insulated

to avoid condensate generation and to minimize thermal losses,

and protected by a flow switch that detects whatever water

flow lack. The source side heat exchanger (3) is a finned coil

realized with grooved copper pipes and hydrophilic aluminium

fins with waved profile to increase the heat exchange coefficient.

A tray is placed under the coil to collect the condensate generated

in heating mode. The expansion device (4), an electronic

expansion valve, allows the unit to adjust itself to the different

operating conditions keeping steady the set superheating. The

refrigerant circuit of each unit contains moreover solid core

hermetic filter dryer (5) to restrain impurity and moisture

residuals that could be present in the circuit, high and low

pressure switches in order to assure the compressor to operate

inside the permitted limits, 4 way reverse cycle valve (6) to

allow operating mode change reversing the refrigerant flow,

pressure connections SAE 5/16” - UNF 1/2” - 20 equipped

with pin, gasket and blind nut, as required for the use of R410A

refrigerant (they allow the complete check of the refrigerant

circuit : compressor inlet pressure, compressor outlet pressure,

thermostatic expansion valve upstream pressure and pressure

drops accross the filter). All the pipes of the refrigerant circuit

are properly insulated to avoid condensate generation and to

minimize thermal losses.

The axial fan (8) is equipped with an high efficiency electronically

commutated (EC) motor, is contained ia a sheet nozzle and is

equipped with a safety grille.

Hydraulic circuit All the pipes are thermally insulated to avoid

condensate generation and minimize thermal losses. The circuit

is equipped with a three speed glandless pump, expansion

vessel, safety valve, pressure gauge and air vents.

Electrical panel. It contains all the power, control and security

components necessary to guarantee the unit to work properly.

The unit is managed by a microprocessor controller to which

all the electrical loads and the control devices are connected.

The user interface, placed on the frontal panel of the unit, allows

to view and to modify, if necessary, all the parameters of the unit.

All the units are supplied with an outdoor temperature sensor,

to be installed outside, in order to realize the climatic control.

1

7

2

6

4

5

Page 7

7

GENERAL FEATURES

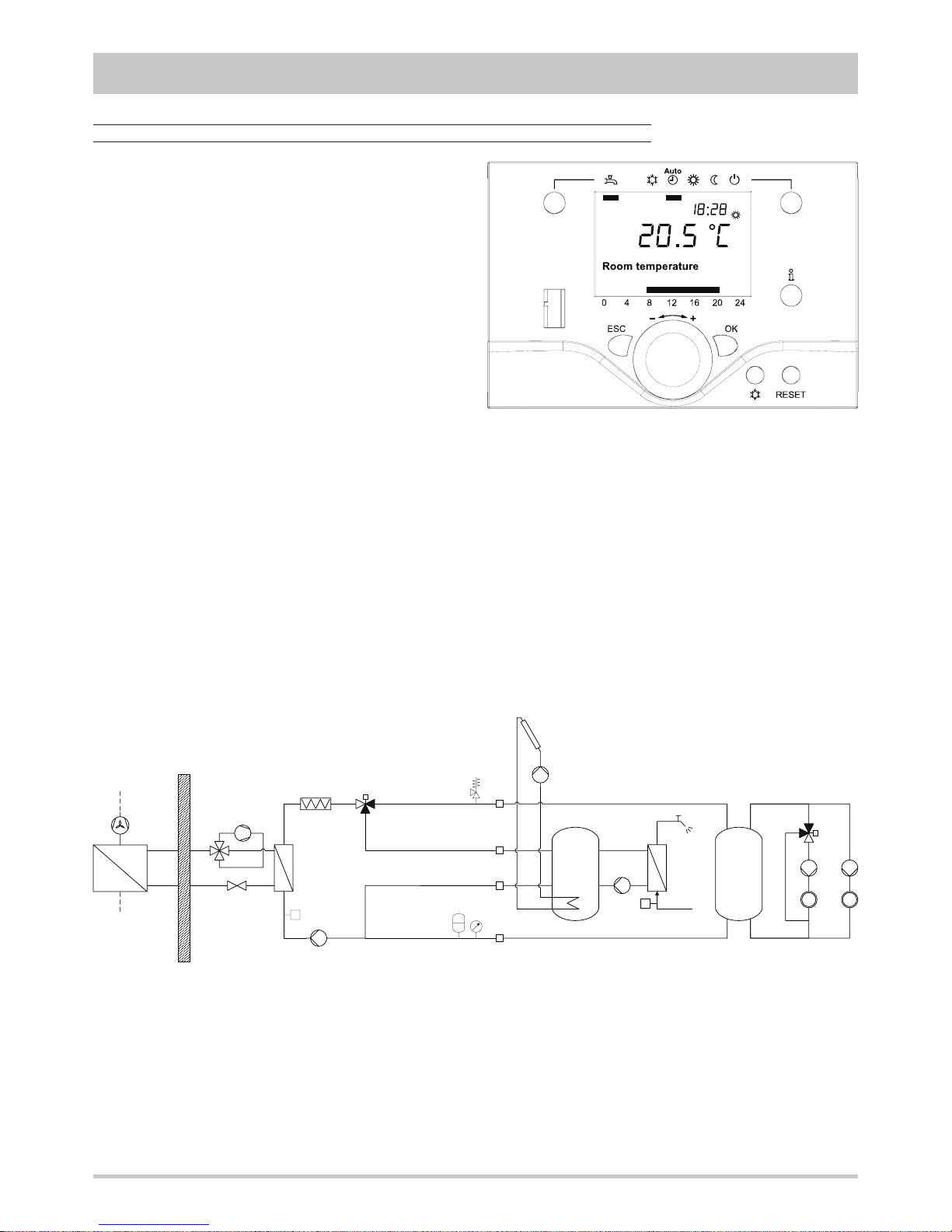

Control system

The microprocessor controller is able to manage not only the

unit itself but also all that components of the plant which allow to

realize a complete system.

The main functions of the control system are :

- room temperature control according to the outdoor

temperature (climatic control)

- domestic hot water production (management of 3 way valve,

storage tank, anti legionella cycles…)

- management of a heating and/or cooling mixed circuit (pump

and 3 way mixing valve)

- management of a heating direct circuit (only pump)

- management of a storage tank for heating and/or cooling

- management of electrical heaters for heating and domestic

hot water (3 steps logic)

- solar panels integration

- room humidity control for cooling with radiant systems

- internal programmer clock (for heating, cooling and domestic

hot water)

- digital input for electrical energy low tariff

- alarm memory management and diagnostic

- compressor and pump operating hour counter

- possibility to manage more units in cascade (maximum 16)

Besides the standard user interface present on all the units,

wired or wireless remote thermostats are available which allow

to control all the operating parameters of the unit and to acquire

the temperature in the different zones in order to realize a more

precise and comfortable control.

The unit controller is able to manage a lot of different plant

solutions enabling automatically the necessary control

algorythms according to the components which have been

connected.

The management of such components is possible through additional expansion modules which communicate with the unit by

means of an internal bus and provide all the inputs and outputs

required to full a complete system.

FS

FS

The controller is able to manage up to two zones in heating

(one by means of a mixed circuit and the other by means of a

direct circuit) and one zone in cooling (by means of a mixed

circuit).

It’s possible to realize more complex plants connecting to the

heat pump controller further expansion modules in order to

extend without limits the number of zones to be managed.

For each zone the following parameters can be set :

- set point

- daily or weekly operating time table

- climatic control curve

- room control sensor : it can be in common with the other

zones or independent (in that case it’s necessary to install

an additional room thermostat)

Page 8

8

GENERAL FEATURES

Options

The controller flexibility and the big number of options available

allow to get, for each model, a lot of different configurations that

integrate inside the heat pump many components of the plant

and allow to realize compact and tested installations.

In order to select the right configuration it is necessary to define

the type of plant to which the heat pump will be connected, both

for what concerning the heating and cooling circuits, and for

what concerning the domestic hot water management.

Option “Plant buffer tank connections"

Reversible heat pump (IP) without options Option “Integrative electrical heaters”

Domestic hot water

production

3 way valve

Allow to divert the hot water produced by the heat pump from the heating circuit

to the domestic hot water circuit.

3 way valve with

primary heat exchanger

The hot water is diverted by the three way valve on an internal heat exchanger.

An internal pump assures a correct domestic hot water ow through the other

side of the heat exchanger.

3 way valve with secondary heat

exchanger

(for integrated tank)

The hot water is diverted by the three way valve in a tank integrated in the unit

(accessory). The domestic hot water is generated istantaneously by means of an

internal heat exchanger and a modulating pump.

Acoustic

setting up

AS - Low noise setting up

Allow to reduce the noise level of the outdoor unit modifying the rotational speed

of the fan.

Integrative electrical heaters

Integrate or replace the heating power supplied by the heat pump and are

managed by the unit controller with a 3 step logic.

Soft starter Reduces the compressor start current.

Plant buffer tank connections

The hot or cold water produced by the heat pump is used to heat or cool a buffer

tank integrated in the unit (accessory) assuring a higher thermal inertia for the

plant.

In this configuration the heat pump can

heat or cool a buffer tank that increases

the thermal inertia of the plant and

operates as hydraulic separator.

NB If the integrated tank is used as

buffer tank for the plant, it can not be

used as tank for the domestic hot water

production (see option "3 way valve and

secondary heat exchanger").

FS

FS

Page 9

9

GENERAL FEATURES

In this configuration the heat pump can

be coupled to a domestic hot water

tank equipped with a coil designed for

a maximum water temperature between

55°C and 60°C.

The anti legionella cycles have to be

performed by means of electrical heaters

placed on the heat pump outlet (see

option “Integrative electrical heaters”) or

directly inside the tank.

In this configuration the heat pump can

be coupled to a domestic hot water tank

without coil.

The anti legionella cycles have to be

performed by means of electrical heaters

placed on the heat pump outlet (see

option “Integrative electrical heaters”) or

directly inside the tank.

In this configuration the heat pump can

produce instantaneously the domestic

hot water using the hot water stored

in the tank integrated in the unit (see

accessory “Integrated tank”).

The temperature of the domestic hot

water at the unit outlet is adjusted

modulating the speed of the pump on

the primary side.

The anti legionella cycles are not

necessary.

Option “Domestic hot water production”

3 way valve

3 way valve with primary heat exchanger

3 way valve with secondary heat exchanger

FS

FS

FS

FS

4

3

Page 10

10

GENERAL FEATURES

Accessories

Rubber vibration dampers

(for indoor unit)

Allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the compressor

and by the pumps in their normal operating mode.

Rubber vibration dampers

(for outdoor unit)

Allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the fans in

their normal operating mode.

Coil protection grille

(for outdoor unit)

Protects the external surface of the finned coil.

Remote thermostat

Allows operating mode selection and set point adjustment. The on board temperature sensor can be used in order

to realize a climatic control.

Remote control

(wired or wireless)

Replicates all the control and visualization functionalities of the controller installed on the unit. The on board

temperature sensor can be used in order to realize a climatic control.

Wireless transmitter

Connected to the unit controller, allows to communicate with wireless remote control and wireless outdoor

temperature sensor.

Wireless repeater Extends wireless operating range.

Wireless adaptor for

outdoor temperature sensor

Allows to transform the wired outdoor temperature sensor, standard for all the units, in a wireless sensor.

Condensate sensor In cooling mode it allows the minimum ow temperature control when condensate generation occurs.

Room hygrostat In cooling mode it allows the minimum ow temperature control according to the room humidity.

Room humidity sensor

(with or without display)

In cooling mode it allows the minimum ow temperature control according to the room dew point, calculated from

the measured room humidity.

Transformer

230V / 24V - 3VA

It assures the correct power supply for the condensate sensor and for the room humidity sensor.

Integrated tank

Integrated tank, to be installed under the unit. It can be used as storage tank for domestic hot water production

(coupled with units with option "Domestic hot water production" : "3 way valve and secondary heat exchanger") or

as buffer tank for the plant (coupled with units with option "Plant buffer tank connections".

Inside the tank a coil for solar panels integration is contained.

Pipes for solar panels

connection

Allow to move the connections of the solar integration coil, available on the tank (accessory), directly on the upper

side of the unit.

Refrigerant circuit box If a failure occurs inside the refrigerant circuit, it permits to restart the heat pump very quickly.

Page 11

11

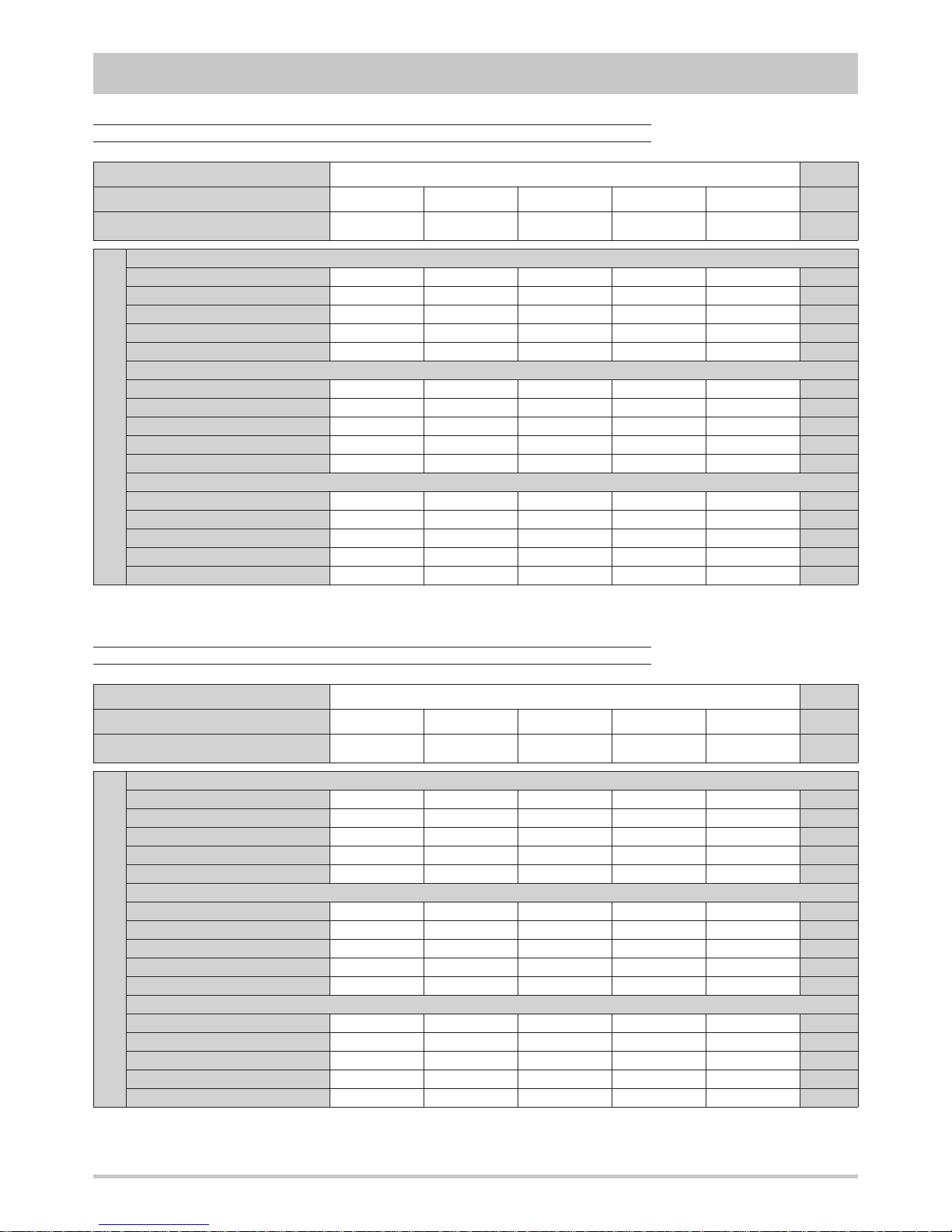

TECHNICAL DATA AND PERFORMANCES

Frame

1

Model

31 41 51 71 91

U.M.

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 V-ph-Hz

Technical data

Refrigerant

Type

R410A -

Compressor

Type

rotary -

Quantity

1 1 1 1 1 n°

Power steps

0 - 100 0 - 100 0 - 100 0 - 100 0 - 100 %

Oil charge

0,35 0,43 0,67 1,13 1,13 kg

Plant side heat exchanger

Type

stainless stee brazed plates -

Quantity

1 1 1 1 1 n°

Water volume

0,53 0,53 0,53 0,67 0,84 l

Fans

Type

axial with high efficiency EC motor -

Quantity

1 1 1 1 1 n°

Diameter

450 450 450 500 500 mm

Maximum rotational speed

900 900 900 900 900 rpm

Total installed power

0,15 0,15 0,15 0,21 0,21 kW

Source side heat exchanger

Type

finned coil -

Quantity

1 1 1 1 1 n°

Frontal surface

0,44 0,44 0,44 0,44 0,44 m

2

Plant side hydraulic circuit

Safety valve set point

3 3 3 3 3 bar

Expansion vessel volume

10 10 10 10 10 l

Plant side pump

Type

3 speed glandless pump -

Quantity

1 1 1 1 1 n°

Installed power

0,14 0,14 0,14 0,14 0,14 kW

Integrated tank (accessory)

Volume

120 120 120 120 120 -

Solar coil surface

1,1 1,1 1,1 1,1 1,1 m

2

Integrative electrical heaters (option)

Total installed power

9,0 9,0 9,0 9,0 9,0 kW

Power steps

0 - 33 - 66 - 100 0 - 33 - 66 - 100 0 - 33 - 66 - 100 0 - 33 - 66 - 100 0 - 33 - 66 - 100

%

Page 12

12

TECHNICAL DATA AND PERFORMANCES

Frame

1

Model

31 41 51 71 91

U.M.

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 V-ph-Hz

NOMINAL performances - Base acoustic setting up (AB) - Radiant plants

NOMINAL performances - Base acoustic setting up (AB) - Standard plants

Data declared according to EN 14511 The values are referred to units without options or accessories.

Data declared according to EN 14511 The values are referred to units without options or accessories.

IP

Heating A7W35 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 2,42 3,85 5,24 6,87 8,37

kW

Power input 0,85 1,35 1,88 2,44 3,00

kW

COP 2,85 2,85 2,79 2,82 2,79

-

Water flow rate plant side 417 664 905 1186 1447

l/h

Available static head plant side 60 54 47 43 40

kPa

Heating A2W35 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 1,99 3,15 4,33 5,65 6,90

kW

Power input 0,55 0,88 1,23 1,59 1,96

kW

COP 3,62 3,58 3,52 3,55 3,52

-

Water flow rate plant side 345 545 748 977 1193

l/h

Available static head plant side 62 57 51 48 46

kPa

Cooling A35W18 ( source : air in 35°C d.b. / plant : water in 23°C out 18°C )

Cooling capacity 2,52 4,00 5,46 7,14 8,72

kW

Power input 0,79 1,25 1,74 2,27 2,78

kW

EER 3,19 3,20 3,14 3,15 3,14

-

Water flow rate plant side 435 690 943 1235 1507

l/h

Available static head plant side 60 53 45 41 38

kPa

IP

Heating A7W45 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 2,35 3,72 5,11 6,67 8,15

kW

Power input 0,68 1,09 1,51 1,96 2,42

kW

COP 3,46 3,41 3,38 3,40 3,37

-

Water flow rate plant side 409 647 887 1158 1413

l/h

Available static head plant side 60 54 47 43 41

kPa

Heating A2W45 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 1,94 3,08 4,22 5,52 6,73

kW

Power input 0,68 1,08 1,50 1,95 2,39

kW

COP 2,85 2,85 2,81 2,83 2,82

-

Water flow rate plant side 337 535 732 958 1168

l/h

Available static head plant side 62 57 52 49 47

kPa

Cooling A35W7 ( source : air in 35°C d.b. / plant : water in 12°C out 7°C )

Cooling capacity 1,94 3,08 4,20 5,50 6,71

kW

Power input 0,73 1,16 1,61 2,09 2,57

kW

EER 2,66 2,66 2,61 2,63 2,61

-

Water flow rate plant side 333 529 722 945 1153

l/h

Available static head plant side 62 58 52 50 48

kPa

Frame

1

Model

31 41 51 71 91

U.M.

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 V-ph-Hz

Page 13

13

TECHNICAL DATA AND PERFORMANCES

Frame

1

Model

31 41 51 71 91

U.M.

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 V-ph-Hz

NOMINAL performances - Low noise acoustic setting up (AS) - Radiant plants

NOMINAL performances - Low noise acoustic setting up (AS) - Standard plants

Data declared according to EN 14511 The values are referred to units without options or accessories.

Data declared according to EN 14511 The values are referred to units without options or accessories.

IP

Heating A7W35 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 2,28 3,61 4,95 6,47 7,90

kW

Power input 0,54 0,86 1,20 1,56 1,92

kW

COP 4,22 4,20 4,13 4,15 4,11

-

Water flow rate plant side 395 625 855 1119 1366

l/h

Available static head plant side 61 55 48 44 42

kPa

Heating A2W35 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 1,89 3,00 4,11 5,37 6,56

kW

Power input 0,53 0,85 1,19 1,54 1,90

kW

COP 3,57 3,53 3,45 3,49 3,45

-

Water flow rate plant side 327 519 710 928 1134

l/h

Available static head plant side 62 58 53 50 48

kPa

Cooling A35W18 ( source : air in 35°C d.b. / plant : water in 23°C out 18°C )

Cooling capacity 2,42 3,85 5,24 6,87 8,37

kW

Power input 0,85 1,35 1,88 2,44 3,00

kW

EER 2,85 2,85 2,79 2,82 2,79

-

Water flow rate plant side 417 664 905 1186 1447

l/h

Available static head plant side 60 54 47 43 40

kPa

IP

Heating A7W45 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 2,23 3,54 4,85 6,34 7,74

kW

Power input 0,66 1,05 1,46 1,90 2,34

kW

COP 3,38 3,37 3,32 3,34 3,31

-

Water flow rate plant side 388 615 841 1101 1344

l/h

Available static head plant side 60 55 48 45 42

kPa

Heating A2W45 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 1,85 2,92 4,00 5,24 6,40

kW

Power input 0,65 1,04 1,44 1,89 2,32

kW

COP 2,85 2,81 2,78 2,77 2,76

-

Water flow rate plant side 322 508 695 909 1111

l/h

Available static head plant side 62 58 53 50 48

kPa

Cooling A35W7 ( source : air in 35°C d.b. / plant : water in 12°C out 7°C )

Cooling capacity 1,86 2,96 4,04 5,28 6,44

kW

Power input 0,79 1,25 1,73 2,26 2,77

kW

EER 2,35 2,37 2,34 2,34 2,32

-

Water flow rate plant side 319 508 693 908 1107

l/h

Available static head plant side 62 58 53 50 49

kPa

Frame

1

Model

31 41 51 71 91

U.M.

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 V-ph-Hz

Page 14

14

TECHNICAL DATA AND PERFORMANCES

HEATING performances

The graphs allow to get the corrective factors to

be applied to the nominal performances in order

to obtain the real performances in the selected

operating conditions.

The reference nominal condition is :

A7W35

source : air in 7°C d.b. 6°C w.b.

plant : water in 30°C out 35°C

Outlet temperature

plant side :

A = 55°C

B = 45°C

C = 35°C

D = 25°C

Heating capacity

Inlet air temperature w.b. [°C]

Inlet air temperature w.b. [°C] Inlet air temperature w.b. [°C]

Power input COP

D

C

B

A

A

B

C

D

A

B

C

D

Page 15

15

TECHNICAL DATA AND PERFORMANCES

COOLING performances

The graphs allow to get the corrective factors to

be applied to the nominal performances in order

to obtain the real performances in the selected

operating conditions.

The reference nominal condition is :

A35W7

source : air in 35°C d.b.

plant : water in 12°C out 7°C

Outlet temperature

plant side :

A = 24°C

B = 18°C

C = 12°C

D = 7°C

Cooling capacity

Inlet air temperature w.b. [°C]

Inlet air temperature d.b. [°C] Inlet air temperature d.b. [°C]

Power input EER

A

B

C

D

A

B

C

D

A

B

C

D

Page 16

16

TECHNICAL DATA AND PERFORMANCES

Plant side hydraulic performances

A = unit with option “Domestic hot water production” : “3 way valve”

B = unit with option “Integrative electrical heaters”

The graphs are referred to units operating with water at the temperature of 10°C (density 1000 kg/m3).

Flow rate [ l/h ]

Pressure drops [ kPa ]

B

A

Available static head - unit without options

Flow rate [ l/h ]

Available static head [ kPa ]

7.1

3.1

4.1

5.1

9.1

Perdite di carico aggiuntive

Page 17

17

TECHNICAL DATA AND PERFORMANCES

A = unit with option “Domestic hot water production” : “3 way valve”

B = unit with option “Domestic hot water production” : “3 way valve with primary heat exchanger”

Flow rate [ l/h ]

Available static head [ kPa ]

A

9.1

11.1

5.1

3.1

7.1

B

Domestic hot water side hydraulic performances

The graphs are referred to units operating with water at the temperature of 10°C (density 1000 kg/m3).

Available static head

Page 18

18

TECHNICAL DATA AND PERFORMANCES

Operating limits

Temperature difference between unit inlet and outlet Plant side

DT max Maximum value 11

°C

DT min Minimum value 3

°C

HEATING

Inlet air temperature d.b. [°C]

Outlet temperature - plant side [°C]

I grafici sotto riportati indicano il campo di funzionamento entro cui è garantito il corretto funzionamento dell’unità.

COOLING

Inlet air temperature d.b. [°C]

Outlet temperature - plant side [°C]

Page 19

19

TECHNICAL DATA AND PERFORMANCES

Electrical data

Power supply 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50

V-ph-Hz

F.L.A. Maximum total current input 6,7 8,5 10,9 14,4 18,1

A

F.L.I. Maximum total power input 1,4 1,8 2,3 3,1 3,9

kW

M.I.C.

Maximum total start current 37 46 53 83 113

A

Maximum total start current

with soft starter (option)

33 36 39 42 44

A

Unit

Power supply 230-1-50 230-1-50 230-1-50 230-1-50 230-1-50

V-ph-Hz

F.L.A. Maximum total current input 0,4 0,4 0,4 0,4 0,4

A

F.L.I. Maximum total power input 0,08 0,08 0,08 0,08 0,08

kW

Domestic hot water production pump (with option “3 way valve with primary heat exchanger”)

Power supply 230-1-50 230-1-50 230-1-50 230-1-50 230-1-50

V-ph-Hz

F.L.A. Maximum total current input 0,7 0,7 0,7 0,7 0,7

A

F.L.I. Maximum total power input 0,14 0,14 0,14 0,14 0,14

kW

Domestic hot water production pump (with option “3 way valve with secondary heat exchanger”)

Power supply

230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50 230 - 1 - 50

V-ph-Hz

400-3N-50 400-3N-50 400-3N-50 400-3N-50 400-3N-50

F.L.A.

Maximum total current input

( 230V - 1 - 50Hz )

39,1 39,1 39,1 39,1 39,1

A

Maximum total current input

( 400V - 3N - 50Hz )

13,0 13,0 13,0 13,0 13,0

A

F.L.I. Maximum total power input 9,0 9,0 9,0 9,0 9,0

kW

Integrative electrical heaters

Frame

1

Model

31 41 51 71 91

U.M.

Page 20

20

TECHNICAL DATA AND PERFORMANCES

Noise levels

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure

at 1 meter at 5 meters at 10 meters

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

31

73,6 71,5 69,8 66,1 62,6 58,4 52,7 45,2 77 68 54 43 37

41

73,6 71,5 69,8 66,1 62,6 58,4 52,7 45,2 77 68 54 43 37

51

73,6 71,5 69,8 66,1 62,6 58,4 52,7 45,2 77 68 54 43 37

71

76,4 74,3 72,6 68,9 65,4 61,2 55,5 48,0 80 71 56 45 40

91

76,4 74,3 72,6 68,9 65,4 61,2 55,5 48,0 80 71 56 45 40

Outdoor unit - BASE acoustic setting up (AB)

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure

at 1 meter at 5 meters at 10 meters

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

31

70,6 68,5 66,8 63,1 59,6 55,4 49,7 42,2 74 65 51 40 34

41

70,6 68,5 66,8 63,1 59,6 55,4 49,7 42,2 74 65 51 40 34

51

70,6 68,5 66,8 63,1 59,6 55,4 49,7 42,2 74 65 51 40 34

71

73,4 71,3 69,6 65,9 62,4 58,2 52,5 45,0 77 68 53 42 37

91

73,4 71,3 69,6 65,9 62,4 58,2 52,5 45,0 77 68 53 42 37

Outdoor unit - LOW NOISE acoustic setting up (AS)

Reference conditions

Performances referred to units operating in heating mode at nominal conditions A7W35.

Unit placed in free field on reflecting surface (directional factor equal to 2).

The sound power level is measured according to ISO 3744 standard.

The sound pressure level is calculated according to ISO 3744 and is referred to a distance of 1 meter from the external surface of the unit.

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure

at 1 meter at 5 meters at 10 meters

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

31

73,2 63,3 48,3 31,7 31,0 22,6 20,9 21,9 74 51 36 25 19

41

74,2 64,3 49,3 32,7 32,0 23,6 21,9 22,9 75 52 37 26 20

51

74,2 64,3 49,3 32,7 32,0 23,6 21,9 22,9 75 52 37 26 20

71

75,2 65,3 50,3 33,7 33,0 24,6 22,9 23,9 76 53 38 27 21

91

75,2 65,3 50,3 33,7 33,0 24,6 22,9 23,9 76 53 38 27 21

Indoor unit

Page 21

21

TECHNICAL DATA AND PERFORMANCES

Weights

Frame

1

Model

31 41 51 71 91

U.M.

Indoor unit without options 118 122 124 131 134

kg

Indoor unit options

Domestic

hot water

production

3 way valve 3 3 3 3 3

kg

3 way valve with primary heat

exchanger

9 9 9 9 9

kg

3 way valve with secondary heat

exchanger

10 10 10 10 10

kg

Plant buffer tank connections 5 5 5 5 5

kg

Integrative electrical heaters 5 5 5 5 5

kg

Outdoor unit 58 58 58 79 79

kg

Accessories

Integrated tank 77 77 77 77 77

kg

Pipes for solar panels connection 2 2 2 2 2

kg

Refrigerant circuit box 44 48 50 58 61

kg

Components weights

Transport weights

Operating weights

Indoor unit without options 136 140 142 149 152

kg

Indoor unit options

Domestic

hot water

production

3 way valve 3 3 3 3 3

kg

3 way valve with primary heat

exchanger

9 9 9 9 9

kg

3 way valve with secondary heat

exchanger

10 10 10 10 10

kg

Plant buffer tank connections 5 5 5 5 5

kg

Integrative electrical heaters 5 5 5 5 5

kg

Outdoor unit 68 68 68 89 89

kg

Accessories

Integrated tank 95 95 95 95 95

kg

Pipes for solar panels connection 3 3 3 3 3

kg

Refrigerant circuit box 46 50 52 60 63

kg

Indoor unit without options 120 124 126 134 137

kg

Indoor unit options

Domestic

hot water

production

3 way valve 5 5 5 5 5

kg

3 way valve with primary heat

exchanger

13 13 13 13 13

kg

3 way valve with secondary heat

exchanger

14 14 14 14 14

kg

Plant buffer tank connections 7 7 7 7 7

kg

Integrative electrical heaters 6 6 6 6 6

kg

Outdoor unit 58 58 58 79 79

kg

Accessories

Integrated tank 202 202 202 202 202

kg

Pipes for solar panels connection 5 5 5 5 5

kg

Page 22

22

TECHNICAL DATA AND PERFORMANCES

Overall dimensions

Minimum operating area

Rispect the free area around the unit as shown in figure in order to guarantee a good

accessibility and facilitate maintenance and control operations.

A 600 mm

B 300 mm

C 400 mm

D 600 mm

E 200 mm

1 Plant return 1” M

2 Plant flow 1” M

3 Domestic hot water return 1” M

4 Domestic hot water flow 1” M

5 Gas line (refrigerant) 5/8”

6 Liquid line (refrigerant) 3/8”

7 Solar panel return 18 mm

8 Solar panel flow 18 mm

Unit with accessory

“Integrated tank”

53

93

90 90

80 81 83 86 90

600

600

85H2

608 7172

117 75

74

394

356

754

H1

A

B

1 2 3 4 5 6

87

3.1 - 4.1 - 5.1 7.1 - 9.1

H1 903 mm 1153 mm

H2 852 mm 852 mm

H2

with accessory

“Integrated tank”

1678 mm 1678 mm

Page 23

23

CONNECTIONS

Hydraulic connections

To design properly the hydraulic system respect the local safety

regulations in force.

It is always necessary to guarantee an appropriate water flow

through the plate heat exchanger of the unit even if is installed,

as standard, a flow switch that stops the unit if the water flow

rate is too low.

To adjust the water flow rate through the heat exchanger modify the speed of the pump by means of the 3 speed selector (if

present). For a more accurate adjustment it is reccomended the

installation of a valve on the outlet of the circuit.

It is also reccomended to install a filter on the inlet of each circuit

in order to avoid the entrance of foreign substances.

The hydraulic circuit is always equipped with safety valve and

expansion vessel. To mantain the circuit under pressure a selffilling group, that automatically fills the circuit, can be installed.

Suggestions for the hydraulic plant realization

Prepare the pipes with the minimum possible number of bends

in order to minimize pressure losses, and suitably support them

to prevent excessive stresses at the connections of the unit.

Install shut-off valves near the components that need maintenance, to allow their replacement without having to drain the

system.

Provide manual or automatic valves in the highest part of the

circuit to vent the air.

Make sure there are no leaks before insulating the pipes and

filling the system.

In order to avoid condensate generation, insulate all the pipes

using steam barrier type material.

Finned coil condensate drainage

The condensate generated by the finned coil in heating mode is

collected in the tray obtained in the basement of the outdoor unit

and can be drained connecting a pipe to the fitting supplied as

standard with all the units.

Expansion vessel setting

The precharge pressure of the expansion vessel must be

adequate to the total volume of the hydraulic circuit at which the

unit is connected.

The factory setting (p

VE-std

= 0,5 bar g) is the minimum value

necessary to avoid the presence of zones with a negative

relative pressure inside the hydraulic circuit and the risk of pump

cavitation, supposing that no parts of the plant are placed at a

higher level than the one at which the unit is installed. In that

case the precharge pressure must be increased proportionally

to the elevation of the highest part of the plant according to the

following relation :

pVE = p

VE-std

+ H

max

/ 9,81

pVE expansion vessel precharge pressure [bar g]

H

max

elevation of the highest part of the plant referred to the

unit installation level [m]

The maximum value of the precharge pressure is equal to the

safety valve pressure set.

Increasing the precharge pressure, the maximum plant volume

supported by the expansion vessel of the unit is reduced :

VI = VVE · Ce · [ 1 - ( 1 + pVE ) / ( 1 + pVS ) ]

VI plant volume supported by the expansion vessel [l]

VVE expansion vessel volume [l]

Ce expansion coefficient

pVS safety valve pressure set [bar g]

If the real plant volume is higher than such calculated volume, it

is necessary to install an additional expansion vessel of appropriate volume.

Once the hydraulic circuit has been filled, the pressure at the

expansion vessel must be slightly higher than the precharge

pressure.

If parts of the plant are placed at a lower level than the one

at which the unit is installed, verify that the components can

withstand the maximum pressure that can be present.

Water

Ethylene glycol

(percentage by volume)

Propylene glycol

(percentage by volume)

10% 20% 30% 40% 10% 20% 30% 40%

Freezing temperature [°C] 0 -3,8 -8,9 -15,7 -24,9 -3,4 -7,4 -13,1 -21,5

C

e

T

min

= 5°C , T

max

= 60°C 58,63 47,80 45,24 42,82 40,61 45,47 39,96 35,82 32,88

T

min

= 5°C , T

max

= 45°C 101,46 72,28 68,84 64,77 61,08 69,42 60,41 53,91 49,03

T

min

= -10°C , T

max

= 45°C - - - 51,85 48,57 - - 42,67 38,50

Page 24

24

CONNECTIONS

Electrical connections

The electrical wirings must be carried out by qualified personnel

according to the regulations in force at the installation time in the

country of installation. Before starting any work on the electrical

circuit make sure that the unit power supply line is disconnected

at the start.

NB Refer to the electrical diagram enclosed in the unit.

Power supply system

The power cables of the heat pump power supply line must be

connected to :

- for single phase power supply : from a single phase voltage

system provided with neutral conductor and separated earth

wire :

V = 230 V ± 10 %

f = 50 Hz

- for three phase power supply : from a symmetrical three

phase voltage system provided with neutral conductor and

separated earth wire :

V = 400 V ± 10 %

f = 50 Hz

The units are shipped completely factory wired and arranged for

the connection to the power supply.

The power cables must enter the unit through the holes on

the lateral panel and must be connected to the power supply

terminals of the unit.

The integrative electrical heaters (option) must be supplied by

a dedicated power supply line to be connected to the power

supply terminals inside the electrical board of the unit.

Heat pump power supply

The power supply cables must have an adequate section for the

power absorbed by the unit and must be chosen in conformity

with the regulations in force. Design the power supply line,

always referring to the total FLI and FLA values of the unit,

taking into account the selected options (except the integrative

electrical heaters) and the installed accessories.

Integrative electrical heaters power supply

The power supply cables must have an adequate section for the

power absorbed by the only integrative electrical heaters and

must be chosen in conformity with the regulations in force.

It is possible to connect the integrative electrical heaters either

to a single phase power supply or to a three phase power supply.

For single phase power supply heat pumps, if a three phase

power supply is used for the integrative electrical heaters,

connecting to the terminal R the same phase used to supply the

heat pump, the current absorbed by the electrical heaters on

that phase is never added to the current absorbed by the heat

pump.

For three phase power supply heat pumps, the integrative

electrical heaters power supply connection can be either single

phase or three phase without any restriction on the phase

connection.

Upstream protection

An automatic switch suitable for ensuring protection against

overcurrents and indirect contacts must be installed upstream

each power supply line.

Coordination between line switch must be carried out observing

the regulations in force on electrical safety, regarding the type of

installation and the installation ambient conditions.

Connections available for the user

The electrical board of the heat pump contains some terminals

dedicated to the connection of temperature probes, humidity

probes, pumps, valves ...

Carry out all the necessary connections in order to realize the

desired plant following the instructions reported in the section

“Inputs and outputs”.

ATTENTION

Carry out all the connections outside the heat pump avoiding the

power cables and the probe cables to be coupled.

Integrative electrical heaters connection

with single phase power supply

Integrative electrical heaters connection

with three phase power supply

Integrative

electrical heaters

Single phase

heat pump

Integrative

electrical heaters

Single phase

heat pump

Page 25

25

CONNECTIONS

Refrigerant connections

REFRIGERANT PIPES

Route the refrigerant pipes between indoor and outdoor unit with as few bends as possible. In order

to avoid to squash the bends, realize all the bends with a proper pipe bender respecting a minimum

bending radius not lower than 3,5 times the outer diameter of the tube (Fig. 1).

Select materials suitable to work at the operating pressures required. In the table are reported the

copper pipe wall thickness values suggested according to the nominal diameter of the refrigerant

connection lines. It is recommended no to use wall thickness values lower than 0,8 mm.

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Nominal

diameter

[inch]

Outer

diameter Ø

[mm]

Thickness

[mm]

Dimensions [mm]

A B C D

Union thickness

E

1/4 6,35 0,8 9,1 9,2 6,5 13,0 1,5 ~ 2,0

3/8 9,52 0,8 13,2 13,5 9,7 20,0 1,5 ~ 2,0

1/2 12,70 0,8 16,6 16,0 12,9 23,0 2,0 ~ 2,5

5/8 15,88 1,0 19,7 19,0 16,0 25,0 2,0 ~ 2,5

During the pipes installation take care of :

• unwind the pipe, with attention, in the direction in which it has been wound;

• wrap the two pipes together with some tape before passing them through the holes in the wall to

prevent the insulation from being damaged and dust from inltrating. To facilitate this operation, it

is advisable to insert a piece of PVC pipe of a suitable diameter and of the same length as the wall

thickness into the hole in the wall.

The part of pipe in excess can be wind up taking care that the coil axis is horizontal or cutted.

In that case the pipe must be cutted and flared again operating in the following way :

1 Pipe cutting

Cut the pipe at the required lenght with a pipe cutter (Fig. 2) and operating with care in order to

prevent the pipe to be deformed. The cut must be horizontal.

2 Burrs and splinters removal

Remove burrs and splinters keeping the pipe edge downwards (Fig. 3) and clean the cut surface. If

the flare surface is deformed or splintered, refrigerant leakeages could occur.

3 Union insert

Remeber to insert the union before flaring the pipe (Fig.4).

4 Pipe flaring

Make sure that the pipe and the flaring tool are clean. When flaring the pipe it is recommended to

respect the indications reported in the table. Clamp the pipe (2 Fig. 5) in a vice (1 Fig. 5), and begin

to flare it.

It is suggested to place a drop of refrigerant oil between the rubbing parts assuring that the oil used

for the lubrification of the flare is of the same type or compatible with the oil used in the refrigerant

circuit.

If the flaring is fulfilled properly the following results are obtained (Fig. 7):

- Smooth and mirrored surface

- Smooth edges

- Flared sides of uniform lenght

N.B.: Take care to prevent swarf, dust or other impurities from dropping inside the pipes in order to

avoid damages to the refrigerant circuit.

Fig.7Fig.6

E

Page 26

26

CONNECTIONS

PIPES CONNECTION

In order to connect the refrigerant pipes comply with the following indications.

• Make sure there are not dust or other impurities in the connection zone.

• Match the flare pipe edge with the connections placed on the indoor and the outdoor units

making sure that of the perfect alignment between the connection surface and the flsred

surface.

• Tighten the union by hand.

• Torque the union with the help of a proper dinamometric tool respecting the tightening

torque reported in the table. In order to avoid tensions on the pipes it is recommended to

use a fox wedge.

TIGHTNESS CHECK (recommended)

Before fullfilling the plant vacuum operation it is advisable to check the tightness of the part

of the refrigerant circuit containing the connections between the pipes and the indoor unit. In

order to fullfill such operation proceed as described below.

• With the service valves of the outdoor unit completely shut, remove the cap from the

service tap (1-Fig.2) and the union (2-Fig.2) of the gas valve (the larger one)

• Connect the service valve to a monometric unit plus nitrogen bottle (N2).

• Pressurize the system to a maximum 40 bar using the nitrogen in the bottle. Keep the bottle

vertical during the pressurizing operation to prevent liquid nitrogen from inltrating into the

system !

• Check all the connection joints on both the outdoor and indoor units to make sure that

they are tight. Bubbles will form if leaks are present. If bubbles appear, make sure that the

unions have been tightened and that the ares are the right shape.

• Wipe off the liquid soap with a rag.

• Reduce the pressure of the nitrogen in the circuit by loosening the charge pipe from the

bottle.

• With reduced pression disconnect the nitrogen bottle.

VACUUM OPERATION (MANDATORY)

Air and humidity inside the refrigerant circuit have undesired effects on the operating ot the

unit :

• pressure increase

• unit efficiency reduction

• corrosion inside the refrigerant circuit

Therefore it is mandatory to create vacuum inside the connection refrigerant pipes.

To complete such operation proceed in the following way.

• Connect the previously described charging pipe to the vacuum pump.

• Turn on the relative knob on the monometric unit to allow the pump to access the refrigerant

circuit.

• Wait until the pressure level measured by the pressure gauge is around 3 mm Hg (400 Pa).

• As soon as the required vacuum value is reached, shut the connection cock and stop the

vacuum pump.

Nominal

diameter (")

Outer

diameter (mm) Ø

Tightening torque

Nm (kgf cm)

1/4 6,35 14 ~ 18 (140 ~ 180)

3/8 9,52 33 ~ 42 (330 ~ 420)

1/2 12,70 33 ~ 42 (330 ~ 420)

5/8 15,88 33 ~ 42 (330 ~ 420)

Page 27

27

CONNECTIONS

HOW TO COMPLETE THE INSTALLATION

• Using an Allen wrench, fully open the cocks (1-Fig.2) by turning them in an anti-clockwise

direction until the stop point is reached. Do not force any further or the retention valves

could be damaged.

• Fix the valve plugs (2-Fig.2).

• Remove the connection hose from between the vacuum station and service pressure tap

of the cock.

• Shut the service tap with the relative cap.

• If the leak test with nitrogen has not been carried out, it is advisable to check the tightness

of the lines using a leak nder.

REFRIGERANT CHARGE INTEGRATION

If the refrigerant pipes length between the outdoor and the indoor unit is higher than 10 meters it is necessary a charge integration

according to the data reported in the table.

Example Model 9.1 - Pipes length = 15 m - Charge integration = ( 15 m - 10 m ) * 50 g/m = 250 g

To complete such operation proceed in the following way.

• Use a hose pipe to connect the charge bottle (or the bottle on an electronic scale) to a service tap on the intake cock (the larger

one).

• Activate the unit in cooling mode and gradually open the connection cock (refrigerant is injected directly into the compressor).

• Shut the connection cock once the required charge has been integrated.

• Remove the connection hose between the vacuum station and the service pressure tap of the cock.

• Shut the service tap with the relative cap.

MODEL

REFRIGERANT LINES

DIAMETER

REFRIGERANT LINES

LENGTH

ELEVATION DIFFERENCE

BETWEEN I.U. AND O.U.

REFRIGERANT

ADDING CHARGE

gas liquid standard maximum standard maximum

3.1 5/8" 3/8" 7,5 m 20 m 0 m 15 m 50 g/m

4.1 5/8" 3/8" 7,5 m 20 m 0 m 15 m 50 g/m

5.1 5/8" 3/8" 7,5 m 20 m 0 m 15 m 50 g/m

7.1 5/8" 3/8" 7,5 m 20 m 0 m 15 m 50 g/m

9.1 5/8" 3/8" 7,5 m 20 m 0 m 15 m 50 g/m

Page 28

28

CONNECTIONS

PRECAUTIONS TO BE TAKEN

the units working with R410A refrigerant require particular attention during the installation

and maintenance operations in order to preserve them from possible failures connected

with the features of this refrigerant. The following precautions are therefore recommended!

• It is mandatory the vacuum operation on the refrigerant lines before opening the

connection cocks.

• For the vacuum and charge operations use proper equipment (monometric unit,

flexible pipes ecc ) different from those used for other refrigerants because they contain

oil residuals not compatible with the oil used in the R410A units. The only exception is

the vacuum pump, provided that it is equipped with a check valve that acts if the pump

accidentally stops during the vacuum operation.

• Avoid water residuals presence inside the refrigerant circuit.

• All the charging or topping operations must be performed with R410A at the liquid

condition. for this kind of operation it is required a bottle picking from the bottom and an

electronic balance, in order to take the the refrigerant at the liquid condition always present

in the bottom part of the bottle. In order to avoid splits in the mixture it is advisable to use

the bottle up to a minimum level of 30%.

• If in the refrigerant circuit a large leakeage has occured, avoid to perform partial toppings

that could modify the composition of the refrigerant mixture, completely discharge the unit

and after having performed the vacuum operation, recharge it with the refrigerant charge

required.

Pay particular attention if the indoor unit is placed at a lower level respect to the outdoor

unit ( vedi fig. B ). In this case it is necessary to realize a siphon on the refrigerant line that

operates as aspiration in cooling mode (the one with the bigger diameter).

Page 29

29

RECEIVING AND POSITIONING

Receiving

Check on receiving

As soon as the unit is received verify accurately the correspondance of the load to what was ordered to make sure that all

the material has been delivered. Check carefully that the load

has not been damaged. In case of goods with visible damages

inform promptly the haulage contractor reporting on the delivery

note the phrase “Collected with reserves owing to evident

damage”. Delivery ex works implies reimbursement of any damage on charge of the insurance company as established by

law.

Safety instructions

Observe the safety regulations in force concerning the equipment to use for unit handling or the operating formalities to follow.

Handling

Before handling the unit, check the weight of the unit , reported

both on the dataplate and on the technical documentation. Make

sure the unit to be handled with care avoiding any kind of collision that could damage the operating parts of the unit.

On the packaging of the unit are reported all the instructions

necessary for a corect handling during storing and installation.

The unit is supplied on a pallet suitable for the transport. It is

advisable to place protective material between the truck and the

unit to avoid damages to the unit. Prevent the unit or parts of it

from falling down.

Storing

The units must be stored in a dry place, repaired from sun, rain,

sand or wind.

Do not stack the units.

Maximum temperature = 60 °C

Minimum temperature = -20 °C

Humidity = 90 %

Packaging removal

Remove the packaging taking care not to damage the unit.

Check for any visible damage.

Get rid of the packaging material sending them to specialized

recycling centres (observe the regulations in force).

Positioning

The outdoor units are suitable for outdoor installation while the

indoor units are suitable for indoor installation.

Verify that the support surface can bear the weight of the selected unit and is perfectly horizontal. In order to limit the vibrations

transmitted by the unit it is possible to place, between the unit

base and the support surface, a strip of hard rubber or, if a higher level of insulation is required, vibration dampers.

In any case it is not advisable to place the unit near private offices, bedrooms or zones where very low noise levels are required.

Protect the finned coil against direct sunlight and prevailing winds and do not place the unit on dark ground (for example tarred

surfaces) to avoid the risk of overheating during operation.

Do not place the unit under roofs or near plants (even if the unit

is only partly covered) in order not to reduce the possibility of air

recirculation.

Respect the minimum operating area and verify that the installation place is not subject to flooding.

Page 30

30

START UP

Start up

The following operations must be carried out only by properly trained personnel. To make the contractual warranty effective, start

up must be carried out by authorized service centres.

Before calling the service centre it is advisable to make sure that all the installation steps have been completed (positioning, electrical

connections, hydraulic connections...).

Preliminary checks before turning on

1. Verify that :

- the unit has not suffered visible damages due to transport or positioning

- the unit is placed on an horizontal surface able to bear its weight

- the minimum operating area are respected

- the ambient conditions comply with the provided operating limits

- the hydraulic and electrical connections has been carried out correctly

2. Disconnect the unit power suply line at the start and make sure that :

- the unit power supply line complies with the regulations in force

- the screws, fastening the electrical cables to the components inside the electrical panel of the unit, are well tightened (vibrations

during transport phases could have caused some loosening)

3. Connect the unit power supply line and verify that :

- the voltage of the power supply line complies with the the nominal one of the unit

- for three phase power supply units, the unbalance between the phases is lower than 2% (a higher value produces an excesive

current input on one or more phases causing possible damages to the electrical components of the unit)

NOTE. Example of phase unbalance calculation

- Read the value of the three line voltages using a voltmeter :

line voltage between phases L1 and L2 : V

1-2

= 390 V

line voltage between phases L2 and L3 : V

2-3

= 397 V

line voltage between phases L3 and L1 : V

3-1

= 395 V

- Calculate the difference between the maximum and minimum value of the measured line voltages :

ΔV

max

= max ( V

1-2

; V

2-3

; V

3-1

) - min ( V

1-2

; V

2-3

; V

3-1

) = V

2-3

- V

1-2

= 397 - 390 = 7 V

- Calculate the average line voltage value :

Δ

average

= ( V

1-2

+ V

2-3

+ V

3-1

) / 3 = ( 390 + 397 + 395 ) / 3 = 394 V

- Calculate the percentage unbalance value :

ΔV

max

/ V

average

x 100 = 7 / 394 x 100 = 1,78 % < 2 %

Turning on

Start all the plant components necessary to guarantee an adequate water flow rate on the plant hydraulic circuit.

Activate the unit in heating or in cooling mode operating on the user interface or on the remote controls and insert a set point suitable

to require the unit to work.

Page 31

31

CONTROL SYSTEM

Control system configuration

The control system can be configured in different ways in order

to adapt itself to the user needs and to the kind of plant managed

by the heat pump.

The simpler configuration consists of unit controller (A), outdoor

air temperature sensor (B) and user interface (C). Such components are always supplied with the unit and allow to realize a

climatic control based only on the outdoor air temperature.

Starting from this configuration it is possible to add, as accessories, remote thermostats (D) or remote controls (E) in order to realize

a climatic control based also on the room temperature of each zone and to control the heat pump at a distance.

The communication between the devices of the control system can be carried out through wired or wireless connections. To realize a

wireless network are available, as accessories : wireless transmitter (F) to be connected to the heat pump controller, wireless adaptor

for outdoor temperature sensor (G) , wireless remote control (H) and wireless repeater (I) to be used to amplify the signal when the

distance between the devices is large.

Page 32

32

CONTROL SYSTEM

Heating and cooling circuits

The controller of the heat pump is able to manage up to two zones :

- zone 1 : heating and cooling

- zone 2 : only heating

The management of further zones, possibile by means of additional zone controllers, is not treated in this manual.

For each zone can be set :

- set point

- daily or weekly operating time table

- climatic curve

- room control sensor

The management of such zonesis performed by means of three independent distribution circuits.

The heating circuit 1 and the cooling circuit 1 control the same plant components (pump and mixing valve). Such circuits can be managed either as unmixed circuits or as mixed circuits (in this case for the mixing valve management the installation of a temperature

sensor on the flow of the circuit is necessary).

The heating circuit P can also be managed together with the heating circuit 1, sharing set point and room temperature sensor. In that

case zone 2 is not present. Heating circuit P management is defined by parameter 46 set on the user interface of the unit.

The management of each zone can be realized by means of :

- user interface : the climatic control is based only on the outdoor air temperature

- remote control : the climatic control is based both on the outdoor air temperature and on the room temperature acquired by the

temperature sensor contained inside the remote control

- remote thermostat : the climatic control is based both on the outdoor air temperature and on the room temperature acquired by

the temperature sensor contained inside the remote thermostat

A user interface is each remote control used only for the visualization of the unit operating status and for the parameter setting (internal temperature sensor not used).

In order to set properly the remote control as a user interface the parameters reported

in the table must be set.

For each zone it is possible to install a remote control or a remote thermostat (it is not possible to install both).

If a remote thermostat or a remote control is present, the management of each zone is always possible also through the unit user

interface.

The diagrams reported below show the different possible configurations of the system and the parameters to be set.

Configuration 1

Zone 1 : management through user interface

Zone 2 : not present

Configuration 2

Zone 1 : management through user interface

Zone 2 : management through user interface

Function Distribution circuit

Zone 1

Heating

and cooling

HC1 Heating circuit 1 mixed

CC1 Cooling circuit 1 mixed

Zone 2 Heating HCP Heating circuit P NOT mixed

User interface

46

HCP management together with HC1

User interface

40 Operator unit 1

42 HC1 + HCP

48 None

User interface

46 HCP management independent

Zone 1

HC1/CC1 HCP

Zone 2 Zone 1

HC1/CC1 HCP

Zone 2

Page 33

33

CONTROL SYSTEM

Remote

thermostat 1

Configuration 3

Zone 1 : management through remote control

Zone 2 : not present

Configuration 5

Zone 1 : management through user interface

Zone 2 : management through remote control or thermostat

User interface

46

HCP management together with HC1

Remote control 1

40 Room unit 1

42 HC1 + HCP

46

HCP management together with HC1

48 HC1

User interface

46 HCP management independent

Remote control 1

40 Room unit P

42 -

Remote thermostat 1

ru 3

Zone 1

HC1/CC1 HCP

Zone 1

HC1/CC1 HCP

Zone 2

Remote

control 1

Remote

control 1

Configuration 4

Zone 1 : management through remote control or thermostat

Zone 2 : management through user interface

Configuration 6

Zone 1 : management through remote control or thermostat

Zone 2 : management through remote control or thermostat

User interface

46 HCP management independent

Remote control 1

40 Room unit 1

42 HC1

Remote thermostat 1

ru 1