Page 1

HGP

AIR-WATER

HEAT PUMPS

FOR INDOOR INSTALLATION

TECHNICAL MANUAL

R

E

F

R

I

G

E

R

A

N

T

G

A

S

E

C

O

-

F

R

I

E

N

D

L

Y

Page 2

2

The manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mi-

stakes. The manufacturer reserves the right to apply changes and improvements to the products at any time without notice.

Page 3

3

TABLE OF CONTENTS

GENERAL FEATURES ..................................................................................5

Unit description ......................................................................................5

Unit identification code ................................................................................5

Description of components .............................................................................6

Control system ......................................................................................7

Options ............................................................................................8

Accessories ........................................................................................9

TECHNICAL DATA AND PERFORMANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Technical data......................................................................................10

NOMINAL performances - HIGH TEMPERATURE plants ....................................................11

NOMINAL performances - STANDARD plants .............................................................12

NOMINAL performances - RADIANT plants...............................................................13

HEATING performances..............................................................................14

COOLING performances .............................................................................15

Plant side hydraulic performances ......................................................................16

Source side aeraulic performances .....................................................................18

DESUPERHEATER performances......................................................................19

Operating limits.....................................................................................20

Electrical data ......................................................................................21

Noise levels .......................................................................................22

Weights...........................................................................................23

Overall dimensions ..................................................................................24

Minimum operating area ..............................................................................24

Page 4

4

Page 5

5

GENERAL FEATURES

Unit description

This series of air-water heat pumps satises the heating, coo-

ling and domestic hot water production requirements of autonomous or centralized residential plants of medium and large size.

All the units are suitable for indoor installation and can be applied to fan coil plants, radiant oor plants and high efciency

radiators plants.

The control system allows to manage not only the refrigerant

circuit but the whole plant with the possibility to choose different

solutions both for the heating and cooling plant and for the domestic hot water management. The possibility of solar panels or

other heating sources integration is also available.

The heating function optimizes the ow water temperature according both to the ambient temperature and to the outdoor temperature through climatic curves adaptable to the building features. It’s possible to manage a storage tank and two independent

circuits (a direct one and a mixed one).

The domestic hot water management allows to control the three way valve, the storage tank and the anti-legionella cycles (if

necessary).

The cooling function can be realized through “active cooling”

(refrigerant circuit inversion). When the unit is used in radiant

oor plants, to avoid condensate generation, a room humidity

sensor can be installed. During cooling mode operation a part of

the heating power in excess can be recovered for the domestic

hot water production (VD version).

The internal programmer clock allows to dene different daily

switching programs for heating, cooling and domestic hot water

production.

The refrigerant circuit, contained in a box repaired from the air

ow to simplify the maintenance operations, is equipped with

two scroll compressors mounted on damper supports, brazed

plate heat exchangers, electronic expansion valve, reverse

cycle valve, centrifugal fans (plug fans), nned coil realized with

copper pipes and alluminium ns. The circuit is protected by high

and low pressure switches and ow switches on the plate heat

exchanger.

The compressors are arranged in tandem on a single refrigerant

circuit and allow the capacity modulation according to the plant

requests in order to guarantee a high seasonal efficiency.

The plate heat exchanger and all the hydraulic pipes are thermally insulated in order to avoid condensate generation and reduce thermal losses.

The plug fans with electronic control of the rotational speed guarantee high efficiencies and low noise in all the operating conditions and allow to install the unit indoor (with ducted air inlet and

outlet). It is moreover possible to reduce the noise level during

the night.

All the units are provided with a phase sequence and correct

sequence controller device and with an outdoor temperature

sensor in order to realize the climatic control.

All the units are accurately built and individually tested in the

factory. Only electric and hydraulic connections are required for

installation.

IP 75.2 VB AB 0 M 5

Unit identification code

The codes that identify the units and the meaning of the letters used are described below.

Unit type

IP - Units suitable for hydronic plant installation operating as reversible heat

pumps

N° compressors

Unit model

Unit version

VB - Base version

VD - Desuperheater version

Power supply

1 - 230V - 1 - 50 Hz

5 - 400V - 3 - 50 Hz

Operating range

M - Medium temperature.

The unit is suitable to produce

water at medium temperature

Refrigerant type

0 - R410A

Acoustic setting up

AB - Base setting up

AS - Low noise setting up

HGP

Page 6

6

GENERAL FEATURES

External structure. Basement, supporting structure and lateral

panels are made of galvanized and painted sheet-steel to

guarantee good resistance to atmospheric agents. Accessibility

to internal parts is possible removing the frontal and lateral

panels. For extraordinary manteinances also the other panels

can be removed.

Refrigerant circuit. It is contained inside a compartment

separated from the air flow to simplify maintenance and control

operations.

The scroll compressors (1) are mounted on damper supports

and are protected against overtemperatures and overcurrents.

Each compressor is equipped with an electrcal heater, that is

activated when the compressor turns off, to keep the compressor

crankcase oil temperature high enough to prevent migration of

the refrigerant during winter stops and to evaporate any liquid

present in the crankcase, in order to prevent possible liquid

rushes on starting.

The plant side heat exchanger (2) is a brazed stainless steel

plate heat exchanger, properly insulated to avoid condensate

generation and to minimize thermal losses, and protected by a

flow switch that detects whatever water flow lack.

The source side heat exchanger (3) is a finned coil realized

with grooved copper pipes and hydrophilic aluminium fins with

waved profile to increase the heat exchange coefficient. A tray

is placed under the coil to collect the condensate generated in

heating mode.

The expansion device (4), an electronic expansion valve,

allows the unit to adjust itself to the different operating conditions

keeping steady the set superheating.

The refrigerant circuit of each unit contains moreover solid

core hermetic filter dryer (5) to restrain impurity and moisture

residuals that could be present in the circuit, high and low

pressure switches in order to assure the compressor to

operate inside the permitted limits, 4 way reverse cycle valve

(6) to allow operating mode change reversing the refrigerant

flow, liquid receiver (7) to compensate the different refrigerant

charge required in heating and in cooling mode and pressure

connections SAE 5/16” - UNF 1/2” - 20 equipped with pin, gasket

and blind nut, as required for the use of R410A refrigerant (they

allow the complete check of the refrigerant circuit: compressor

inlet pressure, compressor outlet pressure and expansion valve

upstream pressure). All the pipes of the refrigerant circuit are

properly insulated to avoid condensate generation and minimize

thermal losses.

The plug fans (8) are equipped with an high efficiency

electronically commutated (EC) motor and guarantee enough

available static pressure to allow the indoor ducted installation

besides high efficiencies in all the operating conditions.

Hydraulic circuit. All the pipes are thermally insulated to avoid

condensate generation and minimize thermal losses. The circuit

can be equipped with a standard, high head or modulating

circulation pump (option). The circuit is always equipped also

with expansion vessel, safety valve and air vents.

Electrical panel. It contains all the power, control and security

components necessary to guarantee the unit to work properly.

The unit is managed by a microprocessor controller to which

all the electrical loads and the control devices are connected.

The user interface, to be placed indoor, allows to view and to

modify, if necessary, all the parameters of the unit.

All the units are supplied with an outdoor temperature sensor,

to be installed outside, in order to realize the climatic control.

Description of components

4

6

3

8

1

2

7

Page 7

7

GENERAL FEATURES

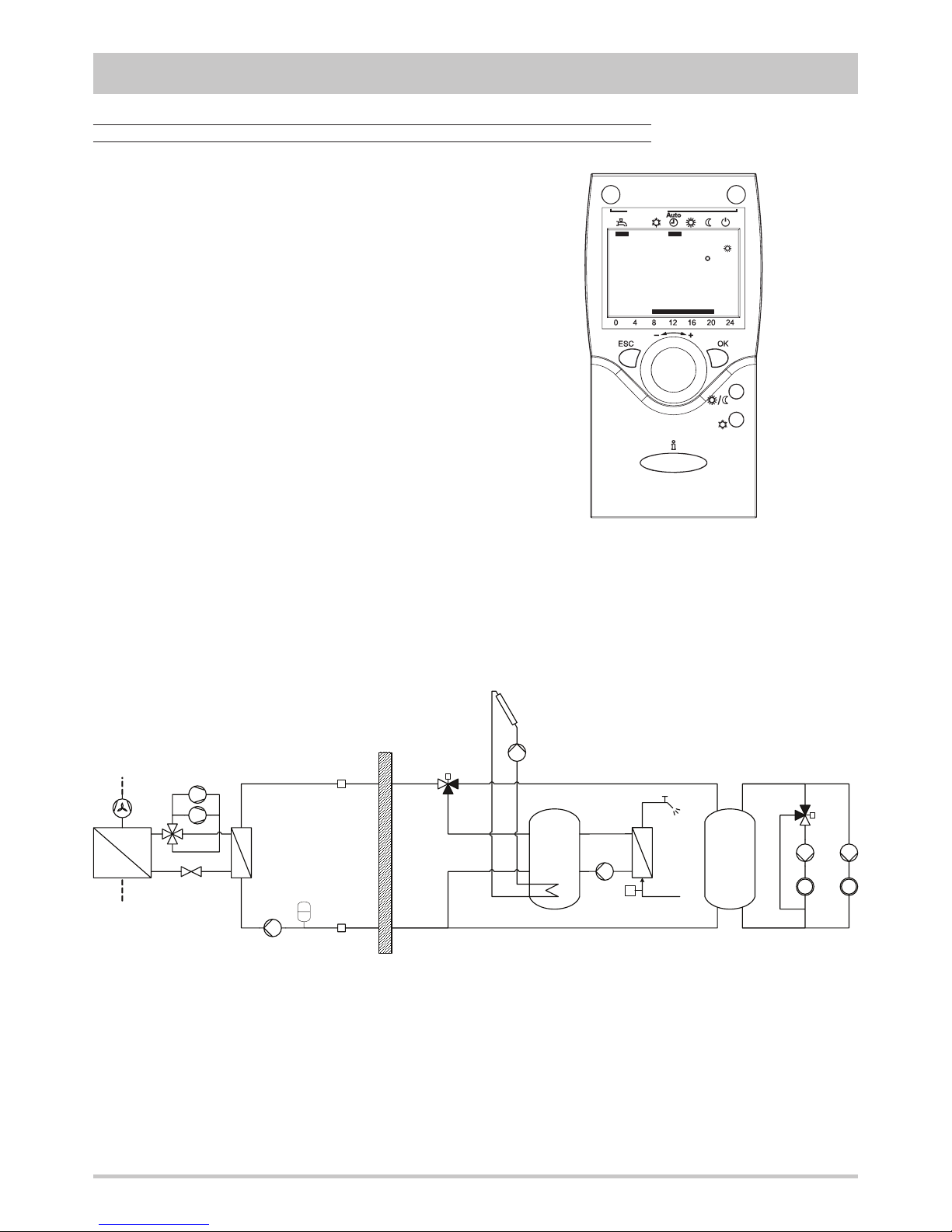

The microprocessor controller is able to manage not only the

unit itself but also all that components of the plant which allow to

realize a complete system.

The main functions of the control system are :

- room temperature control according to the outdoor temperature (climatic control)

- domestic hot water production (management of 3 way valve,

storage tank, anti legionella cycles…)

- management of a heating and/or cooling mixed circuit (pump

and 3 way mixing valve)

- management of a heating direct circuit (only pump)

- management of a storage tank for heating and/or cooling

- management of electrical heaters for heating and domestic

hot water (3 steps logic)

- solar panels integration

- room humidity control for cooling with radiant systems

- internal programmer clock (for heating, cooling and domestic

hot water)

- digital input for electrical energy low tariff

- alarm memory management and diagnostic

- compressor and pump operating hour counter

- possibility to manage more units in cascade (maximum 16)

Besides the user interface of the unit to be placed indoor, wired or wireless remote thermostats are available which allow to

control all the operating parameters of the unit and to acquire

the temperature in the different zones in order to realize a more

precise and comfortable control.

The unit controller is able to manage a lot of different plant solutions enabling automatically the necessary control algorythms

according to the components which have been connected. The

management of such components is possible through additional

expansion modules which communicate with the unit by means

of an internal bus and provide all the inputs and outputs required

to fulfil a complete system.

Room temperature

20.5 C

18:28

The controller is able to manage up to two zones in heating

(one by means of a mixed circuit and the other by means of a

direct circuit) and one zone in cooling (by means of a mixed

circuit).

It’s possible to realize more complex plants connecting to the

heat pump controller further expansion modules in order to

extend without limits the number of zones to be managed.

For each zone the following parameters can be set :

- set point

- daily or weekly operating time table

- climatic control curve

- room control sensor : it can be in common with the other

zones or independent (in that case it’s necessary to install

an additional room thermostat)

Control system

FS

Page 8

8

GENERAL FEATURES

Options

Version VD - Desuperheater version

Allows to recover a part of the available heating power (and otherwise not used

during cooling operating mode) for the domestic hot water production.

Acoustic

setting up

AS - Low noise acoustic setting up

Allows to reduce the noise produced by the unit by means of the refrigerant

circuit vane acoustic insulation and sound jackets on the compressors.

Plant side

ow rate

management

Standard pump Allows the circulation of the water on the plant side.

High head pump

Allows the circulation of the water on the plant side and guarantees a higher

available static head.

Modulating pump

Allows the circulation of the water on the plant side keeping constant the

temperature difference between inlet and outlet.

Domestic hot water

production

3 way valve

Allow to divert the hot water produced by the heat pump from the heating circuit

to the domestic hot water circuit.

Soft starter Reduces the compressor start current.

The controller flexibility and the big number of options available

allow to get, for each model, a lot of different configurations that

integrate inside the heat pump many components of the plant

and allow to realize compact and tested installations.

In order to select the right configuration it is necessary to define

the type of plant to which the heat pump will be connected, both

for what concerning the heating and cooling circuits, and for

what concerning the domestic hot water management.

Option “Plant side flow rate management”

Pump (standard or high head or modulating)

Reversible heat pump (IP) without options Opzione "Version" : "Desuperheater version (VD)"

Page 9

9

GENERAL FEATURES

3 way valve

Option “Domestic hot water production”

In this configuration the heat pump can

be coupled to a domestic hot water

tank equipped with a coil designed for

a maximum water temperature between

55°C and 60°C.

The anti legionella cycles have to be

performed by means of electrical heaters

placed on the heat pump outlet (see

option “Integrative electrical heaters”) or

directly inside the tank.

Accessories

Rubber vibration dampers

Allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the compressor

and by the fans in their normal operating mode.

Coil protection grilles Protect the external surface of the nned coil.

3 way valve

for domestic hot water

Allow to divert the hot water produced by the heat pump from the heating circuit to the domestic hot water circuit.

Remote thermostat

(wired or wireless)

Allows operating mode selection and set point adjustment. The on board temperature sensor can be used in order

to realize a climatic control.

Remote control

(wired or wireless)

Replicates all the control and visualization functionalities of the controller installed on the unit. The on board

temperature sensor can be used in order to realize a climatic control.

Wireless transmitter

Connected to the unit controller, allows to communicate with wireless remote control and wireless outdoor

temperature sensor.

Wireless repeater Extends wireless operating range.

Wireless adaptor for

outdoor temperature sensor

Allows to transform the wired outdoor temperature sensor, standard for all the units, in a wireless sensor.

Condensate sensor In cooling mode it allows the minimum flow temperature control when condensate generation occurs.

Room hygrostat In cooling mode it allows the minimum ow temperature control according to the room humidity.

Room humidity sensor

(with or without display)

In cooling mode it allows the minimum ow temperature control according to the room dew point, calculated from

the measured room humidity.

Transformer

230V / 24V - 3VA

It assures the correct power supply for the condensate sensor and for the room humidity sensor.

Page 10

10

TECHNICAL DATA AND PERFORMANCES

Technical data

Refrigerant

Type

R410A -

Compressor

Type

scroll -

Quantity

2 n°

Oil charge

3,4 3,4 3,4 3,4 3,4 3,4 kg

Refrigerant circuit

Number of circuits

1 1 1 1 1 1 -

Power steps

0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 %

Plant side heat exchanger

Type

stainless steel brazed plates -

Quantity

1 n°

Water volume

7,0 8,0 9,0 10,0 12,0 14,0 l

Source side heat exchanger

Type

finned coil -

Quantity

1 n°

Frontal surface

1,71 1,71 2,56 2,56 3,42 3,42 m

2

Fans

Type

plug fan with high efficiency EC motor -

Quantity

2 3 4 n°

Diameter

560 560 560 560 560 560 mm

Maximum rotational speed

1560 1560 1560 1560 1560 1560 rpm

Total installed power

6,20 6,20 9,30 9,30 12,4 12,4 kW

Plant side hydraulic circuit

Safety valve set point

6 6 6 6 6 6 bar

Expansion vessel volume

12 12 12 12 12 12 l

Plant side pump - standard and modulating (option)

Type

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

-

Quantity

1 1 1 1 1 1 n°

Installed power

1,5 1,5 1,5 1,5 1,5 1,5 kW

Plant side pump - high head (option)

Type

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

centrifugal

pump

-

Quantity

1 1 1 1 1 1 n°

Installed power

3,0 3,0 3,0 3,0 3,0 3,0 kW

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Power supply

400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 V-ph-Hz

Page 11

11

TECHNICAL DATA AND PERFORMANCES

NOMINAL performances - HIGH TEMPERATURE plants

IP

Heating A7W55 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 47°C out 55°C )

Heating capacity 45,1 51,9 61,2 68,4 77,1 90,0 kW

Power input 14,4 16,7 19,7 22,1 24,8 29,0 kW

COP 3,13 3,11 3,11 3,10 3,11 3,10 -

Water flow rate plant side 4914 5655 6658 7442 8390 9796 l/h

Pressure drops plant side 8 8 9 9 8 8 kPa

Heating A2W55 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 47°C out 55°C )

Heating capacity 37,0 42,5 50,1 56,0 63,1 73,6 kW

Power input 14,3 16,5 19,4 21,8 24,5 28,7 kW

COP 2,59 2,58 2,58 2,57 2,58 2,56 -

Water flow rate plant side 4032 4631 5459 6102 6876 8020 l/h

Pressure drops plant side 5 5 6 6 5 5 kPa

Heating A-7W55 ( source : air in -7°C d.b. -8°C w.b. / plant : water in 47°C out 55°C )

Heating capacity - - - - - - kW

Power input - - - - - - kW

COP - - - - - - -

Water flow rate plant side - - - - - - l/h

Pressure drops plant side - - - - - - kPa

Data declared according to EN 14511. The values are referred to units without options or accessories.

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Power supply

400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 V-ph-Hz

Page 12

12

TECHNICAL DATA AND PERFORMANCES

NOMINAL performances - STANDARD plants

Data declared according to EN 14511. The values are referred to units without options or accessories.

IP

Heating A7W45 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 46,9 54,1 63,7 71,1 80,2 93,6 kW

Power input 12,5 14,5 17,0 19,0 21,4 25,1 kW

COP 3,75 3,73 3,75 3,74 3,75 3,73 -

Water flow rate plant side 8133 9367 11036 12322 13903 16215 l/h

Pressure drops plant side 19 20 21 22 19 19 kPa

Heating A2W45 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 38,8 44,7 52,6 58,7 66,3 77,4 kW

Power input 12,3 14,3 16,7 18,7 21,0 24,8 kW

COP 3,15 3,13 3,15 3,14 3,16 3,12 -

Water flow rate plant side 6726 7751 9124 10184 11505 13417 l/h

Pressure drops plant side 14 14 15 15 14 14 kPa

Heating A-7W45 ( source : air in -7°C d.b. -8°C w.b. / plant : water in 40°C out 45°C )

Heating capacity 31,2 36,0 42,3 47,3 53,3 62,2 kW

Power input 11,9 13,9 16,3 18,2 20,5 24,0 kW

COP 2,62 2,59 2,60 2,60 2,60 2,59 -

Water flow rate plant side 5422 6239 7334 8203 9246 10792 l/h

Pressure drops plant side 9 9 10 10 9 9 kPa

Cooling A35W7 ( source : air in 35°C d.b. / plant : water in 12°C out 7°C )

Cooling capacity 38,7 44,6 52,5 58,6 66,1 77,1 kW

Power input 12,2 14,1 16,6 18,6 20,9 24,6 kW

EER 3,17 3,16 3,16 3,15 3,16 3,13 -

Water flow rate plant side 6659 7671 9027 10074 11361 13266 l/h

Pressure drops plant side 14 14 15 15 13 14 kPa

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Power supply

400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 V-ph-Hz

Page 13

13

NOMINAL performances - RADIANT plants

Data declared according to EN 14511. The values are referred to units without options or accessories.

TECHNICAL DATA AND PERFORMANCES

IP

Heating A7W35 ( source : air in 7°C d.b. 6°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 48,2 55,4 65,2 72,9 82,2 95,8 kW

Power input 10,3 11,9 14,0 15,7 17,7 20,7 kW

COP 4,68 4,66 4,66 4,64 4,64 4,63 -

Water flow rate plant side 8313 9559 11257 12573 14183 16538 l/h

Pressure drops plant side 20 20 22 22 20 20 kPa

Heating A2W35 ( source : air in 2°C d.b. 1°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 40,0 46,0 54,1 60,5 68,3 79,6 kW

Power input 10,1 11,7 13,7 15,4 17,3 20,3 kW

COP 3,96 3,93 3,95 3,93 3,95 3,92 -

Water flow rate plant side 6910 7949 9352 10443 11793 13750 l/h

Pressure drops plant side 14 15 16 16 14 14 kPa

Heating A-7W35 ( source : air in -7°C d.b. -8°C w.b. / plant : water in 30°C out 35°C )

Heating capacity 32,4 37,3 43,9 49,0 55,3 64,4 kW

Power input 9,72 11,3 13,3 14,8 16,7 19,5 kW

COP 3,33 3,30 3,30 3,31 3,31 3,30 -

Water flow rate plant side 5594 6442 7585 8468 9559 1113 5 l/h

Pressure drops plant side 10 10 11 11 10 10 kPa

Cooling A35W18 ( source : air in 35°C d.b. / plant : water in 23°C out 18°C )

Cooling capacity 50,9 58,7 69,0 77,1 87,0 102,0 kW

Power input 13,2 15,3 18,1 20,2 22,7 26,7 kW

EER 3,86 3,84 3,81 3,82 3,83 3,82 -

Water flow rate plant side 8811 10156 11949 13345 15052 17570 l/h

Pressure drops plant side 23 23 25 25 22 22 kPa

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Power supply

400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 V-ph-Hz

Page 14

14

TECHNICAL DATA AND PERFORMANCES

HEATING performances

Inlet air temperature w.b. [°C] Inlet air temperature w.b. [°C]

Power input COP

Heating capacity

Inlet air temperature w.b. [°C]

The graphs allow to get the corrective factors to

be applied to the nominal performances in order

to obtain the real performances in the selected

operating conditions.

The reference nominal condition is :

A7W35

source : air in 7°C d.b. 6°C w.b.

plant : water in 30°C out 35°C

Outlet temperature

plant side :

A = 65°C

B = 55°C

C = 45°C

D = 35°C

E = 25°C

0.4

0.6

0.8

1.0

1.2

1.4

1.6

-20-15 -10-50 51015202530

E

D

C

B

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

-20-15 -10-50 51015202530

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

-20-15 -10-50 51015202530

B

C

D

E

B

C

D

E

Page 15

15

TECHNICAL DATA AND PERFORMANCES

COOLING performances

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

0510 15 20 25 30 35 40 45 50

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

0510 15 20 25 30 35 40 45 50

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

0510 15 20 25 30 35 40 45 50

Cooling capacity

Inlet air temperature d.b. [°C]

Inlet air temperature d.b. [°C] Inlet air temperature d.b. [°C]

Power input EER

A

B

C

D

A

B

C

D

A

B

C

D

The graphs allow to get the corrective factors to

be applied to the nominal performances in order

to obtain the real performances in the selected

operating conditions.

The reference nominal condition is :

A35W7

source : air in 35°C d.b.

plant : water in 12°C out 7°C

Outlet temperature

plant side :

A = 24°C

B = 18°C

C = 12°C

D = 7°C

Page 16

16

TECHNICAL DATA AND PERFORMANCES

Plant side hydraulic performances

The graphs are referred to units operating with water at the temperature of 10°C (density 1000 kg/m3).

Flow rate [ l/h ]

Flow rate [ l/h ]

Pressure drops - unit without options

Pressure drops to be added - unit with option "Domestic hot water production" : “3 way valve”

Pressure drops [ kPa ]Pressure drops [ kPa ]

0

10

20

30

40

50

60

0 5000 10000 15000 20000 25000 30000

0

10

20

30

40

50

60

0 5000 10000 15000 20000 25000 30000

55.2

65.2

75.2

85.2

95.2

45.2

Page 17

17

TECHNICAL DATA AND PERFORMANCES

Flow rate [ l/h ]

Flow rate [ l/h ]

The graphs are referred to units operating with water at the temperature of 10°C (density 1000 kg/m3).

Available static head - unit with option “Plant side flow rate management” : “Standard pump” and “Modulating pump”

Available static head - unit with option “Plant side flow rate management” : “High head pump”

Available static head [ kPa ]Available static head [ kPa ]

0

40

80

120

160

200

240

0 5000 1000015000 20000 25000 30000

0

40

80

120

160

200

240

0 5000 1000015000 20000 25000 30000

55.2

65.2

75.2

85.2

95.2

55.2

65.2

75.2

85.2

95.2

45.2

45.2

Page 18

18

TECHNICAL DATA AND PERFORMANCES

The graphs are referred to units operating with air at the temperature of 15°C (density 1,2 kg/m3).

Maximum static head

available for ducted installation

150 150 150 150 150 150

U.M.

Available static head

In case of ducted installation the total pressure drops in the inlet and outlet ducts can not exceed the maximum available static head.

The minimum duct section must guarantee that the medium air velocity does not exceed 2,5 m/s in order to avoid noise problems and to keep

the pressure drops as lower as possible.

The rotational speed of the fans can be increased compared to the factory setting in order to increase the available static head up to the

maximum available value reported in the table.

Flow rate [ m3/h ]

Source side aeraulic performances

Available static head [ Pa ]

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

0

40

80

120

160

200

240

0 4000 8000 12000 16000 20000 24000 28000 32000 36000 40000

85.2

95.2

65.2

75.2

45.2

55.2

Page 19

19

Performances DESUPERHEATER

The graphs are referred to units operating with water at the temperature of 10°C (density 1000 kg/m3).

Flow rate [ l/h ]

Pressure drops desuperheater - unit "VD - Desuperheater version"

Pressure drops [ kPa ]

IP

Cooling A35W7-W45

( source : air in 35°C d.b. / plant : water in 12°C out 7°C / heat recovery : water in 40°C out 45°C )

Cooling capacity 40,2 46,4 54,6 60,9 68,7 80,2

kW

Power input 11,9 13,7 16,1 18,2 20,4 23,9

kW

EER 3,38 3,39 3,39 3,35 3,37 3,36

-

Water flow rate plant side 6916 7980 9387 10486 11824 13798

l/h

Pressure drops plant side 15 15 16 16 15 15

kPa

Heating capacity (desuperheater) 11,9 13,7 16,2 18,1 20,4 23,8

kW

EER with heat recovery 4,38 4,39 4,40 4,34 4,37 4,35

-

Water flow rate desuperheater side 2068 2381 2815 3146 3545 4136

l/h

Pressure drops desuperheater side 0,9 1,2 1,6 1,3 1,7 2,3

kPa

Data declared according to EN 14511. The values are referred to units with the only option "VD - Desuperheater version".

TECHNICAL DATA AND PERFORMANCES

0

5

10

15

20

25

30

0100020003000 4000 5000 6000

55.2

65.2

75.2

85.2

95.2

45.2

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Power supply

400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 400 - 3 - 50 V-ph-Hz

Page 20

20

TECHNICAL DATA AND PERFORMANCES

Operating limits

Temperature difference between unit inlet and outlet Plant side

DT max Maximum value 11

°C

DT min Minimum value 3

°C

HEATING

Inlet air temperature d.b. [°C]

Outlet temperature - plant side [°C]

The graphs reported below show the operating area inside which the correct working of the unit is guaranteed.

COOLING

Inlet air temperature d.b. [°C]

Outlet temperature - plant side [°C]

Page 21

21

TECHNICAL DATA AND PERFORMANCES

Electrical data

Power supply

400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 V-ph-Hz

F.L.A. Maximum total current input 39,3 43,3 51,1 54,9 66,5 74,7

A

F.L.I. Maximum total power input 24,4 27,0 31,6 34,0 41,2 46,4

kW

M.I.C.

Maximum total start current 138 156 169 178 200 239

A

Maximum total start current

with soft starter (option)

79 90 100 106 122 147

A

Unit

Power supply

400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 V-ph-Hz

F.L.A. Maximum total current input 2,5 2,5 2,5 2,5 2,5 2,5

A

F.L.I. Maximum total power input 1,5 1,5 1,5 1,5 1,5 1,5

kW

Power supply

400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 V-ph-Hz

F.L.A. Maximum total current input 5,1 5,1 5,1 5,1 5,1 5,1

A

F.L.I. Maximum total power input 3,0 3,0 3,0 3,0 3,0 3,0

kW

Power supply

400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 400-3-50 V-ph-Hz

F.L.A. Maximum total current input 2,5 2,5 2,5 2,5 2,5 2,5

A

F.L.I. Maximum total power input 1,5 1,5 1,5 1,5 1,5 1,5

kW

Plant side pump - standard (option)

Plant side pump - high head (option)

Plant side pump - modulating (option)

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Page 22

22

TECHNICAL DATA AND PERFORMANCES

Option "Acoustic setting up" : "AB - Base setting up"

Noise levels

Reference conditions

Performances referred to units operating in heating mode at nominal conditions A7W35.

Unit placed in free field on reflecting surface (directional factor equal to 2).

The sound power level is measured according to ISO 3744 standard.

The sound pressure level is calculated according to ISO 3744 and is referred to a distance of 1 meter from the external surface of the unit.

Reference conditions

Performances referred to units operating in heating mode at nominal conditions A7W35.

Unit placed in free field on reflecting surface (directional factor equal to 2).

The sound power level is measured according to ISO 3744 standard.

The sound pressure level is calculated according to ISO 3744 and is referred to a distance of 1 meter from the external surface of the unit.

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure level

at 1 metre at 5 metres at 10 metres

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

45.2

88,9 83,2 78,1 77,0 75,1 72,2 66,4 61,4 91 80 63 54 48

55.2

89,3 83,6 78,5 77,4 75,5 72,6 66,8 61,8 91 80 63 54 49

65.2

89,9 84,2 79,1 78,0 76,1 73,2 67,4 62,4 92 81 64 54 49

75.2

90,3 84,6 79,5 78,4 76,5 73,6 67,8 62,8 92 81 64 55 50

85.2

90,9 85,2 80,1 79,0 77,1 74,2 68,4 63,4 93 82 64 55 50

95.2

91,3 85,6 80,5 79,4 77,5 74,6 68,8 63,8 93 82 64 56 51

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure level

at 1 metre at 5 metres at 10 metres

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

45.2

83,6 79,2 73,9 73,6 71,3 70,2 66,4 63,2 86 77 60 51 45

55.2

83,9 79,5 74,2 73,9 71,6 70,5 66,7 63,5 86 77 60 51 46

65.2

84,6 80,2 74,9 74,6 72,3 71,2 67,4 64,2 87 78 61 51 46

75.2

84,9 80,5 75,2 74,9 72,6 71,5 67,7 64,5 87 78 61 52 47

85.2

85,6 81,2 75,9 75,6 73,3 72,2 68,4 65,2 88 79 61 52 47

95.2

85,9 81,5 76,2 75,9 73,6 72,5 68,7 65,5 88 79 61 53 48

Option "Acoustic setting up" : "AS - Low noise setting up"

Page 23

23

TECHNICAL DATA AND PERFORMANCES

Weights

Components weights

Transport weights

Operating weights

Frame

1 2 3

Model

45.2 55.2 65.2 75.2 85.2 95.2

U.M.

Unit without options 715 750 905 915 1065 1080

kg

Options

Version

Desuperheater

version (VD)

15 15 18 21 24 24

kg

Acoustic

setting up

Low noise

setting up (AS)

65 65 75 75 85 85

kg

Plant side

flow rate

management

Standard pump 25 25 26 26 29 29

kg

High head pump 31 31 32 32 35 35

kg

High efficiency pump 35 35 36 36 39 39

kg

Domestic hot water production :

3 way valve

21 21 22 22 25 25

kg

Unit without options 727 764 920 932 1085 1104

kg

Options

Version

Desuperheater

version (VD)

19 19 23 27 31 31

kg

Acoustic

setting up

Low noise

setting up (AS)

65 65 75 75 85 85

kg

Plant side

flow rate

management

Standard pump 35 35 37 37 42 42

kg

High head pump 41 41 43 43 48 48

kg

High efficiency pump 45 45 47 47 52 52

kg

Domestic hot water production :

3 way valve

27 27 29 29 34 34

kg

Unit without options 726 761 917 927 1078 1093

kg

Options

Version

Desuperheater

version (VD)

15 15 18 21 24 24

kg

Acoustic

setting up

Low noise

setting up (AS)

65 65 75 75 85 85

kg

Plant side

flow rate

management

Standard pump 25 25 26 26 29 29

kg

High head pump 31 31 32 32 35 35

kg

High efficiency pump 35 35 36 36 39 39

kg

Domestic hot water production :

3 way valve

21 21 22 22 25 25

kg

Page 24

24

TECHNICAL DATA AND PERFORMANCES

Overall dimensions

1 Plant return 2" M

2 Plant flow 2" M

3 Domestic hot water flow 2" M

4 Desuperheater inlet 1" 1/4 M

5 Desuperheater outlet 1" 1/4 M

Frame 1 Frame 2 Frame 3

A 1130 mm 1130 mm 1130 mm

B 1710 mm 2430 mm 3130 mm

H 1810 mm 1810 mm 1810 mm

Minimum operating area

Respect the free area around the unit as shown in

figure in order to guarantee a good accessibility and

facilitate maintenance and control operations.

C 1200 mm

D 1000 mm

E 1000 mm

3

2

1

4

5

3

2

1

4

5

D

C

E

A

H

B

Page 25

25

Page 26

26

Page 27

27

The manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors.

The reserves the right to modify the products contents in this catalogue without previous notice.

Page 28

28

Cod. 3QE37770

Loading...

Loading...