RTS2

Suite 6, Cookson House,

River Drive, South Shields,

Tyne & Wear. Tel: (091) 427 7774

NE33 1IX England Fax: (091) 427 5566

CONTENTS Page

1. TECHNICAL SPECIFICATION 1

1.1 Oscillator 1

1.2 Wow & Flutter Oscillator 1

1.3 Millivoltmeter 1

1.4 Wow & Flutter Meter 2

1.5 Distortion Meter 2

1.6 General 3

2. OPERATING INSTRUCTIONS 4

2.1 Connections 4

2.1.1 Power Supply 4

2.1.2 Signal 4

2.2 Calibration 4

2.2.1 General 4

2.2.2 Millivoltmeter 5

2.2.3 Drift 5

2.2.4 Wow & Flutter 5

2.3 Measurements 6

2.3.1 Preparation 6

2.3.2 Frequency Response 6

2.3.3 Drift 7

2.3.4 Wow & Flutter 8

2.3.5 Distortion 8

2.3.6 Signal-to-Noise Ratio 9

2.3.7 Gain 11

3. MAINTENANCE 12

3.1 General 12

3.2 Removal of Boards 12

3.3 Power Supply Voltage Selection

(Serial no. 4515 onwards) 12

4. TECHNICAL DESCRIPTION/FAULTS 13

4.1 Oscillator 13

4.2 Millivoltmeter 14

4.3 Wow & Flutter 16

4.3.1 W&F Oscillator 16

4.3.2 W& F Meter 17

4.4 Distortion Meter 18

4.5 Calibration 19

LIST OF ILLUSTRATIONS

Figure Title Page

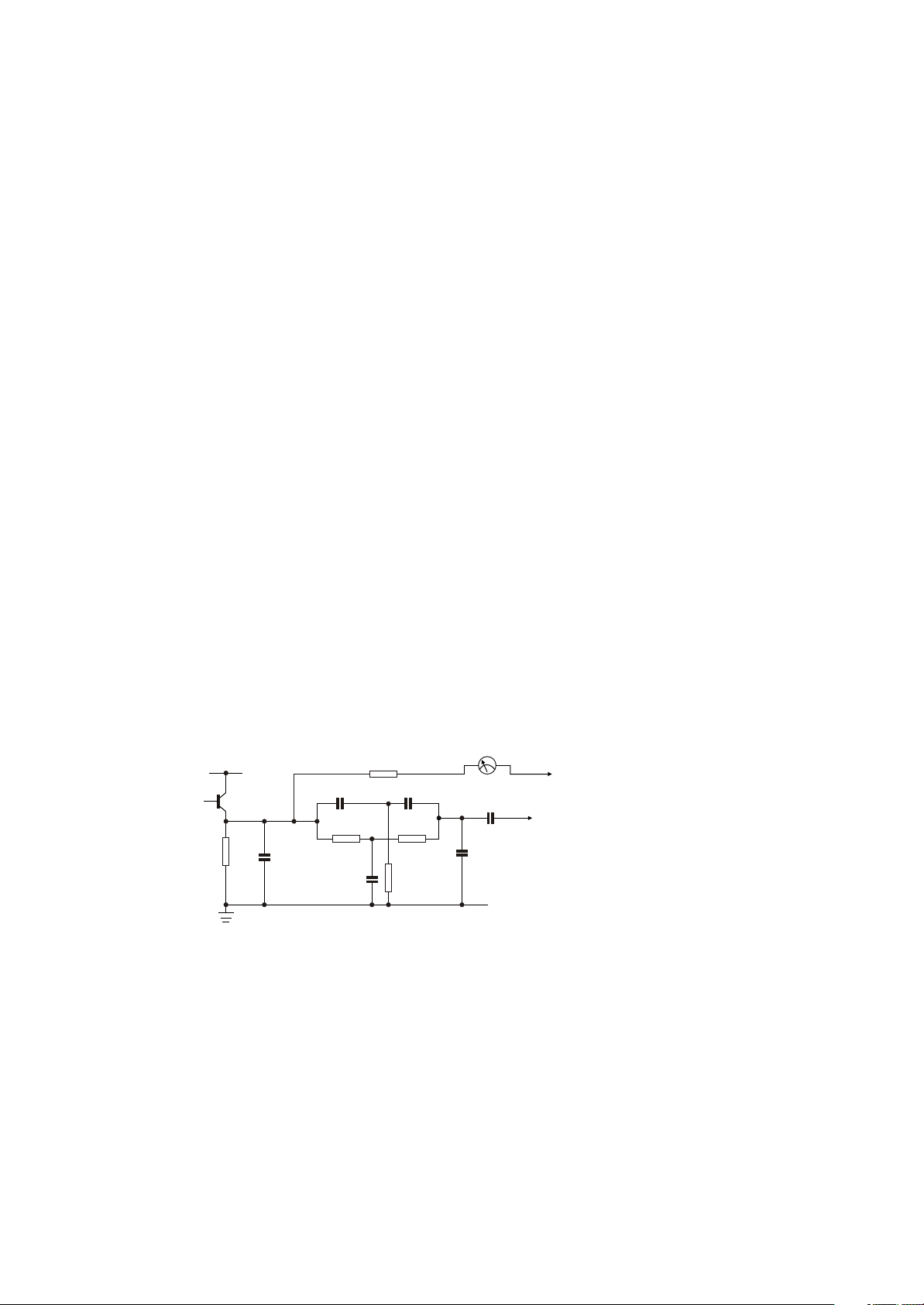

1 Circuit Detail - Oscillator 13

2 Circuit Detail - Millivoltmeter 14

3 Circuit Detail - Meter 14

4 L F Cut Response Curve 15

5 DIN W & F Weighting Curve 16

6 Circuit Detail - Wow & Flutter 17

7 Circuit Detail - Distortion Meter 18

8 Circuit Detail - Distortion Meter (Wein Bridge) 18

9 Distortion Filter Response 19

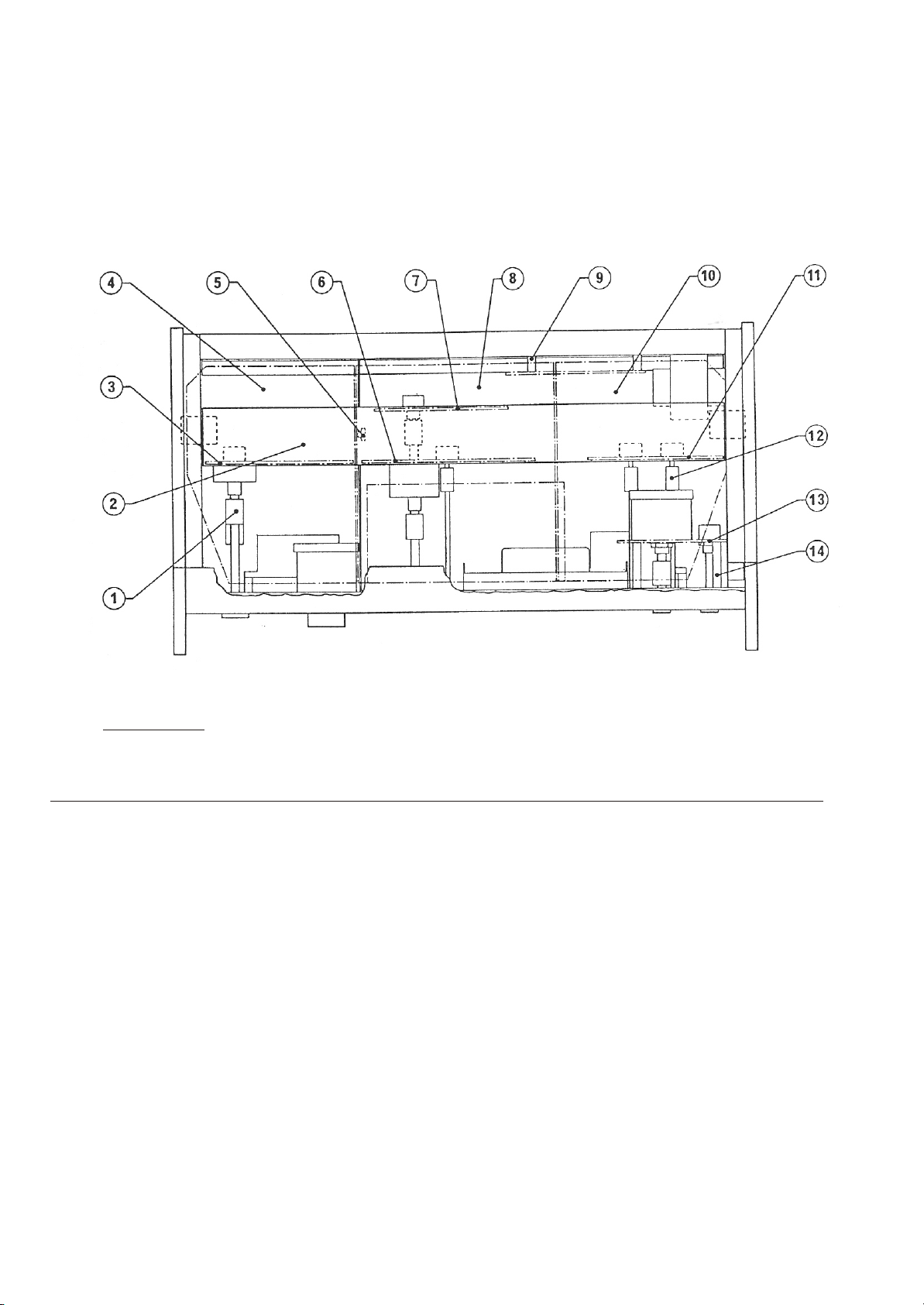

10 Component Location - General 24

(Pot. Mounting Board, Power Board,

Osc , MV meter and W&F Mother Boards)

11 Component Location

(a) Wow & Flutter Board 25

(b) Distortion Meter Board 25

(c) Millivoltmeter Board 25

(d)- Oscillator Board 25

12 Mechanical Layout - Front View Appendix 1

Rear View 2

Plan View 3

Exploded View 4

Circuit Diagram

CONTENTS (continued)

Page

5. CALIBRATION 20

5.1 Test Equipment Required 20

5.2 Power Supply 20

5.3 Oscillator 20

5.4 Millivoltmeter 21

5.5 Distortion Meter 21

5.6 Wow & Flutter Meter 23

5.6.1 Oscillator 23

5.6.2 Drift 23

5.6.3 Wow & Flutter 23

6. HISTORY OF MODIFICATIONS 26

6.1 Mechanical 26

6.2 Electrical 27

APPENDIX Appendix

Parts Lists - Mechanical

Front View 1

Rear View 2

Plan View 3

Exploded View 4

Parts Lists - Electrical

Oscillator Board

Front Panel 5

Wow & Flutter Board 5

Pot. Mounting Board 6

Distortion Meter Board 6

Millivoltmeter Board 7

Power Board 7

Rear Panel 8

W&F Mother Board 8

Oscillator Mother Board 8

Millivoltmeter Mother Board 8

1. TECHNICAL SPECIFICATION

1.1 OSCILLATOR

Frequency Range

15Hz to 150kHz in four ranges

Frequency Response

Flat within ± 0.2dB over the range 15Hz to 150kHz

Distortion

Less than 0.025% at 1kHz

Less than 0.08% over the range 100Hz to 20kHz

Maximum Output Level *

3V (approx.) into open circuit

Not less than +8 dBm into 600 ohm load

Output Attenuator

Coarse - Six steps of 10dB

Fine - Continuous over range of 15dB approx.

External - Fixed 40dB

Output Impedance

Independent of frequency

Dependent on setting of output attenuator coarse control:

always less than 450 ohms. From external 40dB attenuator 47 ohms

1.2 WOW & FLUTTER OSCILLATOR

Frequency

3.15kHz (Suffix A models, 3kHz)

Output Level

350mV approx.

Output Impedance

220 ohms approx.

1.3 MILLIVOLTMETER

Frequency Response

Flat within ± 0.2dB over range 10Hz to 150kHz

Accuracy

Within ± 2% f.s.d. over range 30Hz to 20kHz

Sensitivity

1mV to 100V f.s.d. in 11 steps of 10dB

* With the addition of an Auxiliary Test Set Unit, up to +20dB into 600 ohm load.

Input Impedance

2 Megohms (approx.) NOTE :No D.C. path between the input leads.

Indication

Average reading meter scaled in romose values for sinusoidal signals

1.4 WOW & FLUTTER METER

Type of Measurement

Meter measures peak wow and flutter weighted to DIN 45507

Input Signal Required

3.15kHz (Suffix A models 3kHz) at level not less than 7SmV

Normally this is supplied by the Fixed Frequency Test Signal Generator of the Test Set itself

(see 1.2 above)

If the test signal is from another source, e.g. a pre-recorded test disc or tape, then the

frequency of the test signal should be within t 5% of the nominal value.

Sensitivity

Three ranges for wow and flutter measurements :0.1%,0.3%& 1% fsd

One range, direct reading for drift measurements : t 2% fsd.

Input Impedance

50,000 ohms approx.

Frequency Response for Wow and Flutter Measurements

Maximum at 4.0Hz : 6dB points at 0.8Hz and 20Hz

Alternative Output

The signal measured by the meter also appears on a BNC socket on the front panel and can

be fed to an external oscilloscope, wave analyser, filters, etc.

The output level is 3V (approx.) for meter f.s.d. from a source impedance of 15,000 ohms.

1.5 DISTORTION METER

Type of Measurement

Rejection of fundamental by a tuned filter.

Input Signal Required

Frequency within the range 400 to 1100Hz (approx.) Signal normally supplied by the Variable

Frequency Test Signal Generator (see 1.1 above)

The level of the signal from the equipment under test should be 100mV or more. Smaller

inputs may be used but with an increased minimum distortion reading.

Second Harmonic Rejection

Less than 0.25dB

Minimum Reading (from a distortionless source)

Less than 0.05%

Bandwidth of Harmonic Distortion Measurement

15Hz to 20kHz

There is an optional L.F. cut (turnover 400Hz) for the rejection of hum and other L.F. noise

components.

Input Impedance

100,000 ohms approx.

Alternative Output

The signal measured by the meter also appears on a BNC socket on the front panel and can

be fed to an external oscilloscope, wave analyser, filters, etc.

The output level is 1V (approx.) for meter f.s.d. from a source impedance of approximately 500

ohms.

1.6 GENERAL

Power Supply

105- 120 V, 50 or 60Hz or 200 - 250 V, 50 or 60Hz; 12 watts approx.

Dimensions

17 3/8 in. (441 mm) wide

10 in. (254 mm) deep over handles

5 5/8 in. (143 mm) high

Weight

13 lb (5.9 kg) approx.

Access

Access to the inside of the case is obtained by removing two

screws from the underside of the lip above the back panel.

2. OPERATING INSTRUCTIONS

2.1 CONNECTIONS

2.1.1 Power Supply

Check whether the voltage selector at the back of the Test Set is set to the appropriate voltage

range, 105-120V or 200-250V. If it is not, pull the selector knob outwards, rotate it to the

required position and then press it home again firmly but gently. (On later models, see Section

3.3)

No adjustment for supply frequency in the range SO-60Hz (approx.) is required.

The power lead attached to the Test Set should be connected, through an appropriate plug, to

the power supply (AC only).

The Test Set is switched on and off by turning the "SUPPLY" knob at the right of the front

panel. The meter is illuminated to show when power is applied.

2.1.2 Signal

The BNC socket marked "oscillator" should be connected to the input of the equipment under

test

If the external 40dB Attenuator is required, the 'flying'

lead should be connected to the "oscillator" socket and the connecting cable to the Attenuator.

The BNC socket marked "meter" should be connected to the output of the equipment under

test.

Note 1. Cables for connecting the Test Set to the Line Input and Line Output sockets of a

Note 2. Since the Test Set has a common earth path between input and output sockets,

2.2 CALIBRATION

2.2.1 General

For this purpose it does not matter whether the Test Set is connected to the equipment

to be tested or not. It is recommended, however, that the power supply should have been

switched on for at least 5 minutes before calibration in the Drift and the Wow and Flutter

modes is checked.

Ferrograph Series 7 recorder are supplied. These leads are irreversible and

ensure that the 'earthy' sides of the Test Set and the recorder input and output

circuits are connected together. When other leads or other end connectors are

used, care must be taken to ensure that this condition still obtains.

great care should be taken to ensure that this does not result in a small part of

the audio output current flowing through the input earth. When high-sensitivity

inputs are being used, this could give rise to spurious noise or distortion

readings. These can usually be prevented by the insertion of a small resistor

(e.g. 100 ohm) in series with the "meter" input earth lead.

The adjustments are not interdependent and can be carried out individually.

2.2.2 Millivoltmeter

(1) Set the "MILLIVOLTMETER" switch to the "1V" position.

(2) Press down the "read input" button. (This releases the button to its left and the three

buttons to its right).

(3) Press down the "CALIBRATE" button.

(4) The meter pointer should now lie on the CAL mark above the outer scale; if not,

adjust the screwdriver-operated control "mV meter cal (1V range)".

(5) Press the "CALIBRATE" button to release it.

Note When this adjustment has been carried out with the "MILLI-VOLTMETER" switch in the

"1V" .position, the meter measures voltage on the top scale with full scale deflection of

1V. Movement of the "MILLIVOLTMETER" switch adjusts the meter

sensitivity to give full scale deflection for inputs of lmV to 100V, as indicated on the

switch, reading on the appropriate one of the two upper scales.

For setting the meter to read arbitrarily, see 2.3.4 below.

2.2.3 Drift

(1) Press down the "W&F drift" button. This releases the two buttons on either side

and applies a 3.15kHz * test signal to the "oscillator" socket and to the meter circuits.

(2) Press down the "CALIBRATE" and "W&F drift" buttons (thus releasing the

"1%","0.3%", and "0.1%" buttons).

(3) The meter pointer should now read 0 on the "drift %" scale; if not, adjust the

screwdriver-operated, pre-set control marked "drift set zero".

(4) Press down the "CALIBRATE" button to release it. The meter now measures drift

directly on the "drift %" scale.

2.2.4 Wow and Flutter

(1) With the "W & F drift" button still pressed (see above), press the "CALIBRATE" and

"0.3%" buttons (releasing the "drift, "1%" and "0.1%" buttons).

(2) The meter pointer should now lie on the CAL mark above the top scale; if not, adjust

the screwdriver-operated pre-set control marked "peak wow cal (0.3% range").

(3) Press down the "CALIBRATE" button to release it.

The meter now reads percentage wow and flutter (0.3% f.s.d.) on the next to top scale.

Pressing down the "1%" or "0.1%" button releases the "0.3%" button and the meter then

reads percentage wow and flutter on the top scale with f.s.d. 1% or 0.1%

2.3 MEASUREMENTS

2.3.1 Preparation

In the following it is assumed that the gain controls on the equipment under test have been set

for normal operating conditions. It is also assumed that the input and output signal voltages

under these conditions are known, at least approximately. If not, then initially the

OSCILLATOR OUTPUT coarse" switch should be set to its lowest (10mV) position and the

"MILLIVOLTMETER" switch to its highest (100V) position. When connecting to a microphone

input socket, the external 40dB Attenuator should be inserted between the Test Set and the

equipment under test (see 2.1.2)

The "OSCILLATOR OUTPUT coarse" control should then be turned clockwise, step by step,

until a proper operating level has been obtained. If this requires the "OSCILLATOR OUTPUT

coarse" control to be set higher than 3V, then the 40dB Attenuator should be removed from the

output.

With a proper output level from the equipment under test, the "MILLIVOLTMETER" switch on

the Test Set should be turned anti-clockwise step by step, until a convenient reading on the

meter is obtained.

2.3.2 Frequency Response

(1) Set the "OSCILLATOR OUTPUT coarse" switch to an appropriate position (see 2.3.1

above) and the "OSCILLATOR OUTPUT fine" control to about mid-position.

(2) Set the "FREQ" control to 100 and press down the "FREQUENCY" range button "x 10".

The Test Set is now delivering a 1kHz test signal to the equipment under test. The level of this signal

can be controlled in steps by the "OSCILLATOR OUTPUT coarse" control and continuously by the

"OSCILLATOR OUTPUT fine" control. Once set at 1kHz, these must not be varied throughout the

rest of this test.

(3) Press down the "input" button and check that the "LF cut" and "CALIBRATE" buttons are

both released.

The Test Set now measures the output voltage from the equipment under test (see Note to 2.2.2) .

(4) The frequency of the test signal is changed by means of the "FREQ" control and the range

selecting buttons below it. The output level at various frequencies is read on the meter, its

sensitivity being increased or decreased by use of the "MILLIVOLTMETER" switch (see Note

to 2.2.2)as necessary.

A plot of output voltage against frequency shows the frequency response of the equipment under

test.

Note 1. When making frequency response and similar measurements, it is usually convenient to

have the meter reading 0 on the dB scale (or some other round number) at a chosen

frequency, say 1 kHz. Normally this is done by using the "OSCILLATOR OUTPUT fine"

control to adjust the level of the input signal to the equipment under test or by fine

adjustments of its gain control.

When neither of these things can be done, as, for example, when reproducing a prerecorded tape on equipment with no output level control, the meter may be adjusted to a

convenient reference value by pressing down the "DISTORTION set 100%" button (thus

releasing the "input" button) and adjusting the meter to the required reading by use of

the "DISTORTION METER set 100%" control. The meter now indicates relative levels

e.g. in decibels, at the various frequencies but it does not, of course, read in

volts/millivolts.

The "MILLIVOLTMETER" control should only be used on the distortion meter ranges of

"0.3%" to "100%". In view of the extreme sensitivity (10011V) of the "0.1%" range, this

should not be used for reading voltages with the. "DISTORTION 100%" button pressed.

Note 2. When making frequency response measurements on magnetic tape recorders, it is

essential that the input signal level be at least 20dB below that which gives full level

recording at 1kHz. Similar restrictions on the permissible level of test signals apply to

some other types of equipment.

Note 3. When testing a tape recorder that cannot record and reproduce simultaneously, it is

necessary first to record a series of test frequencies (with a fixed input signal level) and

then to measure output levels at the various frequencies when this recording is

reproduced.

The above procedures measure the overall response of a tape recorder. To determine

whether the reproducing frequency response is correct, it is necessary to measure the

output levels at various frequencies when reproducing a standard test tape on which the

various frequencies have been recorded to the appropriate Standard.

2.3.3 Drift

(1.) Press down the "W & F drift" button and also the "drift" button under "WOW & FLUTTER".

The Test Set now delivers a 3.1.5kHz* signal to the recorder under test.

(2) Set the recorder controls so that this signal is recorded at a normal level for, say, 40

seconds. Stop the machine, and rewind the tape to the beginning of the recording.

(3) Reproduce this recording.

Note. The level of the signal reaching the Test Set should not be less than 75mV. To check this, see

Note 1 to 2.3.4.

(4) The meter now indicates directly on the "drift %" scale the percentage difference between

the frequency of the reproduced signal and the 3.1SkHz* test signal that was recorded.

* On models Suffix A the internal oscillator is set to 3kHz.

Note When testing a disc reproducer it is necessary (and when testing a tape reproducer it

may be convenient) to reproduce a test recording made on another machine. The

indicated percentage drift may then be due partly to a difference in the recording and

reproducing speeds and partly to the original signals not having been 3.1SkHz*.

2.3.4 Wow and Flutter

(1) If not already made, first prepare a test recording as in (1) and (2) of 2.3.3 above.

(2) Press down the "1%" button under the "WOW & FLUTTER" heading (releasing the "drift"

button) and reproduce the test recording (see Note 1 below).

The meter now indicates wow and flutter on the top scale; f.s.d. 1%. If the meter reading is

inconveniently small, press down the "0.3%" or "0.1%" button (releasing the "1%" button); the meter

now indicates wow and flutter on the next to top scale with f.s.d. 0.1%.

Note 1. For proper operation of the limiter (which ensures that amplitude variations do not affect

the readings), the reproduced voltage reaching the Test Set should be more than 75mV.

This can readily be checked by pressing down the "MILLIVOLTMETER read input"

button (releasing the "W & F drift" button) and determining the level from the combined

readings of the meter and the "MILLIVOLTMETER" switch (see Note to 2.2.2)After

such a level check, the "W &F drift" button must, of course, be pressed down again to

measure wow and flutter.

Note 2. For a proper measurement of wow and flutter, the frequency of the signal fed to the Test

Set should be within about ±5% of the nominal value, 3.15kHz*. When reproducing a

test recording just made on the same machine as above, it will almost always be within

the ±2% indicated directly on the "drift% scale. This may not be the case when

reproducing a test recording made on a different machine or at another time but

satisfactory measurements of wow and flutter can still be made if, when measuring drift,

the meter can be made to read within its ±2% range by use of the "drift set zero"

control.

Note 3. Readings of wow and flutter taken while the test recording is being made usually give a

fair indication of magnitude but do not give true values since speed fluctuations that

repeat in a period corresponding to the time taken by the tape to move from the record

to the replay head do not appear.

2.3.5 Distortion

For this measurement, the output signal from the equipment under test should

preferably be greater than 100mV (see Note 3 below).

The procedure is as follows:(1) Set the "MILLIVOLTMETER" switch to "1V".

(2) Set the "FREQ" control to 100 and press down the range selecting button marked "X10".

A 1kHz test signal is now delivered to the equipment under test.

(3) Press the "DISTORTION set 100%" button.

(4) Now use the "DISTORTION METER set 100%" control knob to adjust the meter to read 10

on the top scale.

(5) Press the DISTORTION read" button (releasing the "DISTORTION set 100%" button. Also

press down the "LF cut" button.

(6) Set the "DISTORTION METER BALANCE fine" control to about mid-position (vertical) and

then use the "freq-coarse" and "phase" controls to reduce the meter reading to a minimum.

During this process, the meter sensitivity should be progressively increased by means of the

"MILLIVOLTMETER" switch to maintain a convenient reading. Complete the adjustment for

minimum reading by use of the "freq-fine" and "phase" controls.

(7) The percentage distortion can now be read on the appropriate one of the two upper scales

in combination with the % markings on the "MILLIVOLTMETER" switch.

Note 1. The test signal need not be 1kHz but it should be within the range 400-1100Hz,

approximately. Otherwise, a minimum will not be obtained within the range of the "BALANCE"

controls.

Note 2. The meter reading includes signals of all frequencies between 30Hz and 20kHz except for

the test frequency and a narrow band on either side of it. It therefore includes hum and other

low frequencies. Pressing down the "LF cut" button cuts the lower frequencies progressively

below 400Hz.

Note 3. If a level of 100mV or more cannot be obtained from the equipment under test, it will not be

possible to adjust the meter to full scale deflection as in (4) above. The measurement may still

be carried out but with the "MILLIVOLTMETER" switch set below 1V, with a corresponding

allowance in the calculation of percentage and with a restriction in the lowest level of distortion

that can be measured.

Note 4. When testing a tape recorder that cannot record and reproduce simultaneously it is, of

course, necessary first to record the test signal and then to measure distortion while it is being

reproduced.

2.3.6 Signal-to-Noise Ratio

(1) With the equipment under test working at normal operating levels, measure the total

harmonic distortion on a 1kHz test signal as in 2.3.5 above.

(2) If the total harmonic distortion is less than 2%, then increase the level of the test signal by

means of the "OSCILLATOR OUTPUT" "coarse" and "fine" controls, (or, if testing a tape

recorder, the recording gain control) until the distortion is 2%.

Note : A good idea of the rate of increase of distortion with signal level can be obtained by

successively decreasing meter sensitivity and increasing signal level in steps of 10dB but, for

the final determination of distortion, the full procedure of 2.3.5 should be carried out.

(3) With the equipment under test adjusted so that total harmonic distortion of a 1kHz output

signal is 2%, press the "MILLIVOLTMETER input" button (releasing-the "DISTORTION read"

button).

(4) Adjust the "MILLIVOLTMETER" switch to give a convenient meter deflection. The reading

of the meter, in combination with the switch (see Note to 2.2.2),indicates the output level at

which there is 2% distortion.

(5) Remove the signal from the input of the equipment under test and apply a short circuit.(But

see Note 2 below).

(6) Press the "LF cut" button to release it.(But see Note S below).

(7) Increase the meter sensitivity, by means of the "MILLIVOLT-METER" switch, until a

convenient reading is obtained. The number of millivolts indicated by the combined meter and

switch readings (see Note 2.2.2) is the total noise level. The ratio of this to the voltage

determined in (3) above, is the Signal-to-Noise Ratio, usually stated in decibels.

Note 1. When determining the 2% distortion level of a tape recorder, care must be taken that the gain

controls are so set that the distortion does not arise primarily because of overloading of the

electronics. This could happen, for example, because of an excessive input level compensated

by a low setting of the recorder gain control or because of an excessive output level.

It is the condition when the distortion arises primarily in the record/replay processes that is

usually referred to when the signal-to-noise ratio of a tape recorder is quoted.

Note 2. In the case of a tape recorder, there are several different signal-to-noise ratios that may be

considered significant, according to circumstances, but in all cases it is necessary first to

determine the output level at which the total harmonic distortion of a 1kHz test signal is 2%

(see (1),(2) and (3) above).

It is with this output level that the various noise levels are usually compared. (But see Note 3 below).

The signal-to-noise levels most usually quoted are those obtained by:-

(a) recording and reproducing simultaneously with the input short circuited and using a

bulk-erased or virgin tape;

(b) as (a) but using a tape previously recorded to saturation level;

(c) reproducing only, using a bulk-erased or virgin tape;

(d) reproducing with the tape stationary.

In each case the noise level must be measured under the stated conditions.

Note 3. Signal-to-noise ratios are sometimes reckoned from the 3% rather than from the 2% total

harmonic distortion level or from a specified tape flux level.

Note 4. Signal-to-noise ratio measurements are made with various types of meter (e.g. r.m.s. or peak

indicating) sometimes with and sometimes without a frequency weighting. This Test Set

measures unweighted noise using an average reading meter scaled in r.m.s. values for

sinusoidal signals.

Note 5. When it is tape hiss or other high frequencies that are of most interest it will usually be

convenient to make the noise measurement with the "LF cut" button pressed down.

2.3.7 Gain

(1) First proceed with steps (1) , (2) and (3) of the procedure for measuring frequency

response, 2.3.2. above.

(2) Press the "MILLIVOLTMETER read input" button and then adjust the "MILLIVOLTMETER"

switch to obtain a convenient reading on the meter.

This reading, in combination with the switch, indicates the output voltage of the equipment

under test. (see Note to 2.2.2)

(3) Now, press the "MILLIVOLTMETER read osc" button. This releases the "read input" button

and connects the meter to indicate the output voltage-from the Test Set oscillator, i.e. the input

voltage to the equipment under test.

(4) Adjust the "MILLIVOLTMETER" switch to obtain a convenient reading on the meter.

This reading, in combination with the switch, indicates the input level to the equipment under

test.

The ratio of the output level (2) above, to the input level (4) above, is the gain of the

equipment. It may be expressed as a numerical ratio or in decibels.

Note : Gain can be measured at any frequency desired by an appropriate setting of the

"FREQ" control and the range selecting buttons. Care must be taken, however, to avoid

overloading. (see Note 2 to 2.3.2.above).

3. MAINTENANCE

3.1 GENERAL

No regular maintenance is necessary on the Test Set other than occasional cleaning of the

fascia and plate. A damp cloth should be used, and persistent stains may be removed using a

weak solution of a mild detergent.

3.2 REMOVAL OF BOARDS

Access to the plug-in boards is obtained by removing the two screws ('A' in Fig.12 Exploded

View) and sliding back the top panel; access to the underside is by removing the two screws

('B' in Fig.12 Exploded View) and sliding back the bottom panel. The board fixing strap is

removed by undoing one screw at each end.

With certain boards it is necessary to remove the extension spindles by undoing the grub

screws in the couplers using a 6BA Allen key. Most interconnections are by plug-in connectors

but some are by soldered connections and these will

have to be unsoldered if the board or component is to be removed completely.

3.3 POWER SUPPLY VOLTAGE SELECTION (Serial No. 4515 onwards)

On models Serial No. 4515 onwards, the rear panel voltage selector mentioned in Section

2.1.1 is not fitted and adjustment to correspond to the power supply voltage is done internally.

Access is obtained by removing the two screws ('A' in Fig.12 exploded view, Appendix 4) and

sliding back the top panel. On the power supply transformer Tl (see Fig. 10), the Brown/

White lead should be unsoldered and resoldered appropriately; tag 2 - 110V, tag 3.- 220V or

tag 4 - 240V. The Blue/White lead should remain on tag 1. The rear panel must be marked

with the new voltage.

No adjustment is necessary for supply frequency in the range 50-60Hz approximately.

4. TECHNICAL DESCRIPTION / FAULTS

4.1. OSCILLATOR (VT1-3)

The oscillator uses three transistors in a Wien Bridge circuit, comprising two gain

stages VT1 and VT2 with an emitter follower stage VT3 to provide a low impedance

output. Negative feedback for A.C. stabilisation is provided by the potential divider

network Thermistor TH1/Resistor R7 to VT1 emitter and the D.C. conditions are

stabilised with feedback via R3/R6. The frequency of the oscillator is set by the two

parts of RV20 a& b in conjunction with C8-11 and C4-7 respectively as selected

by the Frequency Range switch SW15.

TH1

HT

+ve

R1

C8 11

R4

Fig. 1. Circuit Detail - Oscillator

FAULT

High output with excessive

distortion (squared off)

No output

R7

+

a b

RV20

VT1, 2, 3

RV19

C4 7

RV10

POSSIBLE CAUSES

Thermistor TH1 faulty-open circuit (very low

ambient temperature can cause TH1 to give

this symptom).

Transistor failure

Transistor failure

Frequency calibration wrong (all

ranges)

Frequency calibration wrong (on only

one range)

Low frequency modulation on

highest freq. range (x 1000)

Calibration of ranges wrong (not 10dB

per step)

Dial setting disturbed - reset at 14kHz. C1

faulty (open circuit)

Poor switch contact SW15. Appropriate

capacitor faulty:

x 1 C7 or C8

x10 C6 or C9

x100 CS or C10

x1000 C4 or C11

Transistor noisy. Resistor R5 noisy.

Resistor burnt out in attenuator chain-probably

R15 or R16 N.B. This is probably caused by

DC signal fed into the oscillator output socket

from the external connection-check before

reconnecting.

4.2. MILLIVOLTMETER (VT51-57)

R143

R142 &

R141

SW6a

(60dB

attenuator)

10

VT51, 52

R158

R153

SW6b

VT56, 57

+

100

+

R175

VT54, 55

SK30

Scope

Fig. 2. Circuit Detail - Millivoltmeter

The signal is fed via blocking 'capacitor C89 and overload protection resistor R144 with R143

& R142/141 providing 60dB attenuation as selected by SW6a, which thus doubles the ranges

selected by SW6b. Zener diode MR31 protects VT51 (not normally conducting) which is a field

effect transistor giving a high input impedance. The overall gain of the first stage VT51 & 52

is determined by the feedback resistor R150, which is effectively from VTS2 collector to

VT51 emitter (source), and the exact gain (approx. 10) is set by RV152 ('mV meter cal'). The

main attenuator (R153-158) has six steps (10dB per step) selected by SW6b, and these are

doubled by the 60dB attenuator SW6a to give 11 x 10dB steps and an earthed position.

Emitter follower VT53 is a unity gain buffer stage, feeding two separate amplifier stages. The

'scope' amplifier VT56 & 57 has feedback applied by R175, and the output signal is fed to the

'scope' output except when the 'W&F drift' button is pressed. The second amplifier is the main

amplifier VT54 & 55 for the meter itself, the meter being connected as part of the negative

feedback loop in a half bridge configuration as shown. R165 provides biasing for the diodes

MR32 & 33 to help the low signal linearity, and MR34 is a protection diode. C96 improves the

extreme high frequency response.

Fig. 3.

Circuit Detail-Meter

R162

VT54

R163

R164

VT55

R167

MR33

R100

C100

C98

R165

MR34

M1

R166

MR3

R169

C97

C96

The overall frequency response of the millivoltmeter circuit on the 300mV range or lower,

should be level, but on the 1V range and higher, trimmer C83 is adjusted to give a level

response (set on the 1V range). This may be done using the RTS oscillator as a source by

pressing the 'Read Osc' button. Any leads should be removed from the 'meter' and ‘osc’

sockets to avoid the effect of their capacitance.

The steep LF cut, which is 3dB down at approx. 400Hz, is applied to the circuit in three places,

the final response being as shown in Fig. 4.

(a) Normally the coupling capacitor from VT52 collector is C87 with C88 shorted. With the

'LF cut' button pressed, C87 is in series with C88 reducing the effective capacitance and

attenuating the bass frequencies.

(b) Similarly C94 is normally short-circuit but with the 'LF cut' button pressed it is in series

with coupling capacitor C93 thus reducing the capacity and hence the bass response.

(c) Normally the emitter of VT55 is decoupled by C99 in parallel with C9S. With the,'LF cut'

button pressed C99 is removed from earth and only C95 is in circuit. This reduces the

capacity and hence the bass response.

Fig. 4 L F Cut Response (Typical)

+5

0dB

-5

-10

-15

-20

-25

-30

2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2

100 1000 10,000

Frequency in Hz

-35

Fig. 5 DIN W & F Weighting Curve

+5

0dB

-5

-10

-15

-20

-25

-30

2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2

100 1000 10,000

Frequency in Hz

-35

4.3. WOW & FLUTTER (VT11-20)

The Wow & Flutter section has two distinct operations. 'Drift' gives an indication of the mean

freqency of the replay signal, disregarding short term cyclic variations. This facility is normally

used for checking the speed of an equipment against a known standard, the built-in W &F

oscillator being nominally 3150Hz (3000Hz- suffix A) within 1%. The short term drift could vary

by about 0.5% during use, after calibration in the morning following an initial warm-up period of

approx. 10 minutes.

'W & F' gives the facility of measuring peak frequency excursions of the signal around 3150Hz

or 3000Hz. All test sets will cover the range 3000-3150Hz for measuring wow and flutter

without modification, the difference between RTS and RTSA being merely a change in

frequency of the built-in W & F oscillator.

4.3.1. W & F Oscillator (VT11,12)

The transistors VT11/12 form a multivibrator whose frequency is set accurately by RV33;

'coarse' adjustment (such as converting from RTS to RTSA) can be made, if necessary, by

simultaneously changing the values of R34/35. Provision has been made to modulate the

frequency with a voltage inserted across R32 from the 'Cal' oscillator in order to set the peak

W & F calibration. The output is modified to a sinewave by filter C24/L1/C25 and fed to the

'oscillator' output when the 'W & F drift' button is pressed.

4.3.2. W & F Meter (VT13-20)

For accurate measurement a signal of at least 50mV should be fed to R39, when the high

frequencies are removed by C27 and low frequencies by C26. The residual carrier signal (at

about 3kHz) is amplified by VT13 so that it is able to drive the monostable multivibrator

VT14/15, resulting in a differentiated square wave at the collector of VT1S which is at the

frequency of the original signal. This is differentiated by C31 and rectified by MR1 (positive

half-cycle) and the emitter/base junction of VT16 (negative half-cycle). The pulse produced

bottoms VT16 once every cycle and the average current through VT16 therefore depends

linearly on the signal frequency only. The voltage developed across R46 is thus proportional to

this frequency. Transistor VT17 forms a buffer, emitter-follower stage followed by a parallel -T

filter to remove the carrier frequency, thus leaving the wow and flutter products and at the

same time the response is altered so that after the W & F components have passed C40/R60

the response has been tailored to the DIN weighting curve shown in Fig. 5 . The signals are

amplified by VT19 & 20 and fed to voltage doubler MR8 & 9, with the meter calibration

adjusted by RV69. The DC level at the collector of VT16 corresponds to the mean frequency,

and this is used for the 'drift' measurement, being compared via R52 to a fixed reference level

set by RV56 when the 'drift' button is pressed.

FAULTS

There are no specific faults to suggest; malfunctions can be traced by following the signals

through the circuit and comparing the waveforms shown on the oscilloscope with those shown

in the full circuit diagram.

Meter connection with

‘drift’ button pressed

R52

C37

R51

R53

C38

R49

VT17

C34

C36

R50

C35

Fig.6 Circuit Detail - Wow & Flutter Meter

M1

C40

To fixed reference

voltage (VT18)

To amplifier for

peak W&F measurement

4.4. DISTORTION METER (VT33-37)

In

set

100%

1

RV 111

2

Freq

1

+

10

Out

Fig. 7 Circuit Detail - Distortion Meter

The signal passes through potentiometer RV111 which sets the level into the dynamic emitter

follower stage VT33. This stage has unity gain with VT34Lacting as a constant current load for

VT33, the actual current being set by R113/R115. Bootstrapping through C64 is used to

improve the input impedance, and MR22 provides protection for VT33 in the event of overload.

VT33 is critical for noise and only low noise transistors should be used.

The base of transistor VT35 is a virtual earth point due to negative feedback via R124, which

sets the gain of the amplifier stage to approx. 10. VT35 acts as a phase-splitter with emitter

and collector loads, the ratio of their gains is approximately 2 :1 and set precisely by

potentiometers in the collector load 'phase' potentiometers. The outputs are fed to a Wien

Bridge having zero output at the selected frequency as

adjusted by the Balance phase and Frequency coarse/fine controls.

Pressing the '100%' button shorts out C64, thus removing the 'notch' in the response but

leaving the gain unaffected. With the 'read' button pressed the notch in the response is

reintroduced and C68 is shorted to earth, restricting the response to 20kHz. VT36 is an

amplification stage with an overall gain of approx. 10, VT37 giving an emitter follower output

via C69.

R120

R81

Fig. 8

Circuit Detail - Distortion

Meter (Wien Bridge)

RV121

R122

VT35

RV82 phase

C51

C66

R83

R86

R85

R88

coarse

RV84a

RV87a

RV84b

RV87b

fine

FAULT

Noise VT33 is critical for noise, and only the specified transistor should be used.

Certain components are more critical for noise - R114, R116, R117, R119,

R120, R122.

Insufficient range on Set RV121 so that meter 'nulls' when RV82 is five turns from

‘phase' control one end viz. central.

VT36

4.5. CALIBRATION (VT31,32)

The 'Call oscillator is mounted on the Distortion Meter Board and consists of a multivibrator

operating at approx. 70Hz. A 'square wave' output is taken from each collector, that from VT31

collector being used to modulate the W & F oscillator with calibration set by RV101. The output

from VT32 is stabilised further by zener diode MR21 and further reduced to give an indication

of 0dBm on 1V range of the millivoltmeter set by RV110 as a calibration standard.

The cal oscillator is only operational when the 'cal' button is pressed.

Fig. 9 Distortion Filter Response (Typical)

+1

2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2 3 4 5 6 7 8 9 2

100 1000 10,000

Frequency in Hz

0dB

-1

-2

-3

-4

-5

-6

-7

5. CALIBRATION

In the setting up of the RTS, it is necessary to use test instruments of sufficient accuracy to

calibrate each section to the required performance. In general these should be of the order of

ten times more accurate than the RTS, particularly the Millivoltmeter. In an emergency, less

accurate test equipment may have to be used, but the accuracy of the RTS will then not

necessarily conform exactly to specification and this must be borne in mind when making

measurements.

5.1.Test Equipment Required

(a) Millivoltmeter MV

(b) Digital Frequency Meter DFM

(c) Distortion Meter DM

(d) Oscilltor (sine wave) 0

(e) Oscilloscope S

(f) Function Generator & LF Oscillator

(see Wow & Flutter 5.6.3)

5.2. Power Supply

(a) Using the Millivoltmeter MV, check that the voltage on the pin (red lead) of the Power

Supply Board is 30V dc relative to chassis; if necessary reset RV192 on the Power

Supply Board (Fig.10 )

5.3. Oscillator

(a) Set the Oscillator output controls, Coarse & Fine, to maximum (fully clockwise) and set

the dial and push button controls to give an output of 14kHz at the Oscillator output

checked by the Frequency Meter DFM.

(b) Check that the dial indicates 14kHz; if necessary reset this by slackening the grub

screw and rotating the dial to 14kHz before retightening (on later models remove the

knob cover/insert, slacken the collet nut then retighten with the dial at 14kHz).

(c) Check that with the dial set to 4kHz the Frequency Meter DFM reading is within t 5%

(3.8 to 4.2kHz).

(d) Check the frequency accuracy similarly on the other ranges.

Dial

4 kHz

40 Hz

400 Hz

40 kHz

Frequency Limits

3.8 kHz to 4.2 kHz

38 Hz to42 Hz

380 Hz to 420 Hz

38 kHz to 42 kHz

(e) Using the Millivoltmeter MV, check that the output from the oscillator with the coarse &

fine controls at maximum is greater than 2.8V (at 1kHz approx.)

(f) Check that the 'Output' control 'Coarse' operates in steps of 10dB t 0.5dB.

(g) At 0dB on the 1V range of the Millivoltmeter MV, check that the frequency response is

level at 1kHz, 15 Hz , 40Hz, 15kHz, 150kHz, within ±0.2dB

(h) Set the oscillator output to 1V at 1kHz and using the Distortion Meter DM check that the

distortion is less than .025%.

5.4. Millivoltmeter

(a) With nothing connected to the 'meter' socket and the milli-voltmeter set to the 30V

range, check that the meter reads zero; if necessary reset the meter to zero using the

adjustment at its rear.

(b) Feed the Oscillator 0 into both the RTS and the Millivolt-meter MV, setting each to the

1V range.

(c) Set the Oscillator 0 to lkHz and adjust its output to give a reading of 0.8V on the

Millivoltmeter MV.

(d) Check that the RTS millivoltmeter also reads 0.8V; if necessary adjust the preset control

'mV meter cal' RV152 on the front panel.

(e) Check that the frequency response agrees with the Milli-voltmeter MV over the ranges

1kHz to 20kHz within ± 1% and over 15Hz to 150kHz within ± 2%; if necessary adjust

trimmer capacitor C83 to give as level a high frequency response as possible.

(f) Recheck the reading of 0.8V (at 1kHz) on both meters; if necessary reset RV152.

(g) Press 'calibrate' and check that the RTS millivoltmeter reads 0dB (still on 1V range); if

necessary reset RV110 on the Distortion Meter Board (then press 'calibrate' to release).

(h) With the Oscillator 0 set to 400Hz, press 'LF cut' and check that the response is reduced

by 3dB (± 1dB).

(i) Reset the Oscillator 0 to 1kHz and adjust the output to give a meter reading of 0dB (on

1V); switching the input signal level in 10dB steps, check that on all ranges the RTS

millivoltmeter agrees with the Millivoltmeter MV within ± 2% (one division of the top

scale).

5.5. Distortion Meter

(a) It is not essential but nevertheless highly desirable that the Oscilloscope S be

connected to the 'scope' socket throughout this section, thus enabling the output to be

observed to ensure that it is signal rather than noise.

(b) Set the 'balance' controls to their centre positions ('Phase' control 5 complete turns from

one end).

(c) With the Oscillator 0 still set to 1kHz, press 'set 100V and adjust the 'Sensitivity' control

to give full scale reading on the 1V range.

(d) Press 'read' &'LF cut' and adjust the pre-set phase control RV121 on the Distortion

Meter Board together with the 'freq coarse' & 'fine' controls on the front panel alternately

to give minimum reading, reducing the milli-voltmeter range as required.

(e) If necessary, the final reading can be obtained using the 'phase' control on the front

panel, but this must not be more than two full turns from its centre position.

(f) The final reading should be less than 0.025% (assuming that the inherent distortion of

the Oscillator 0 is much less than this).

Note: Modification of RTS2 Distortion Measurement Frequency

The frequency range of the RTS2 distortion measurement can be modified to operate at a

different frequency instead of the normal 400-1100Hz approximately by altering the value of

C51 & C66 simultaneously. In practice the value of these capacitors is not critical, but they

must have the same value within 1%. A suggested table of values is given below; values to

give other frequency ranges can be determined by proportion.

C51& C66

0.33mF

0.22mF

0.1mF

.056mF

.033mF

.022mF

.01mF

5600 pF

3300 pF

*Because of the low frequency of operation after this modification has been carried out, the 'LF

cut' button must not be pressed while making distortion measurements. The residual reading

obtainable will therefore depend upon the level of hum, etc., in the signal and this will

determine the minimum percentage distortion which can be read, although this will normally be

adequate for most 'off tape' measurements.

Freq.Range

approx.

40 - 110 Hz*

60 - 165 Hz*

132- 360 Hz*

235- 650 Hz*

400 -1100 Hz

600 -1650 Hz

1.32- 3.6 kHz

2.35- 6.5 kHz

4 - 11 kHz

5.6. Wow & Flutter Meter

5.6.1. Oscillator

(a) Connect the Digital Frequency Meter DFM to the 'oscillator' output, press 'W & F drift'

and check the frequency of the W & F oscillator; if necessary adjust RV33 on the W & F

Board to set the frequency to 3150Hz (or 3000Hz) ± 1%.

Note: If RV33 does not give enough adjustment, alter the values of R34/R35 simultaneously

to bring the frequency within range (about 5-10% each should be sufficient), increasing

the value to reduce the frequency and vice versa.

(b) Connect the Millivoltmeter MV to the 'oscillator' output and check that the output is

350mV or greater ; if necessary tune Ll on the W & F Board for maximum output.

5.6.2. Drift

(a) Connect the Oscillator 0 and Digital Frequency Meter DFM in parallel across the 'meter'

input and set the Oscillator 0 accurately to 3150Hz (or 3000Hz).

(b) Press 'W & F drift' and 'drift', and adjust the 'drift set zero' control RV56 to give zero drift

on the meter (centre scale).

(c) Set the Oscillator 0 to ± 1% (3181.5Hz or 3030Hz) then to -1% (3118.5Hz or 2970Hz),

and check that the meter reads accordingly; if necessary adjust the drift sensitivity

potentiometer RV54 on the W& F Board to indicate ± 1% on the RTS meter scale.

(d) If RV44 has been adjusted, recalibrate zero drift as in (b) above and repeat (c); the

settings of RV54 & RV56 are interdependent and (b) & (c) must be repeated alternately

until no further adjustment is necessary.

(e) Remove the connections to the 'meter' socket on the RTS and press 'calibrate' (in

addition to 'W & F drift').

(f) Check that the meter reads zero (centre scale); if necessary adjust 'drift set zero' pre-

set control.

5.6.3. Wow & Flutter

(a) Connect to the RTS 'meter'• input a sine wave of 3150Hz (or 3000Hz) frequency

modulated to 0.3% peak by a 4Hz sine wave; this can be obtained from a function

generator and low frequency oscillator or another function generator.

(b) Press '0.3%' and check that the meter reads 0.3%; if necessary adjust the pre-set

control 'peak wow-cal (0.3% range)' RV69.

(c) If available, connect the Oscilloscope S to the 'scope' socket and check that a

sinusoidal wave form is shown.

(d) Press 'calibrate' and check that the meter reads on the 'cal' mark; if necessary, adjust

the cal control RV101 (lower left) on the Distortion Meter Board.

T1

0V

110V

1 2 3 4

5 6 7

220V

240V

Fig. 10 Component location - General

R196

VT

R193

inP k

+

C122

72

Green

+

C123

MR

VT71

RV

192

C121

V o et

VT

52

-

{

73

Wh te

Pink

-

MR51+

R191

R195

POWER BOARD

R194

Red

Neutra Bra d

B ue Red

B ue

SKT10

R212

R211

SKT20

WOW & FLUTTER BOARD

1 13

M1

Meter

+ -

SKT11

WOW & FLUTTER

dr ft 1% 0.3% 0.1%

WOW & FLUTTER MOTHER BOARD

Ca

meter

socket

SK31

Osc ator

socket

SK32

Scope

socket

SK30

POTENTIOMETER

MOUNTING

BOARD

SW10

C51

RV87

R83

R85

R88

R86

Neutra

R81

B ue

Red

RV82

RV84

Bra d

1 DISTORTION METER BOARD 13

1 MILLIVOLTMETER BOARD 13

SKT1

1 OSCILLATOR BOARD 13

Orange

B ue

{

MILLIVOLTMETER W&F DISTORTION

LF cut Osc Input Dr ft 100% Read Ca

X1 X10 X100 X1000

FREQUENCY

Orange

MILLIVOLTMETER MOTHER BOARD

OSCILLATOR MOTHER BOARD

Osc.

Freq.

C43 MOUNT ON

COPPER SIDE ACROSS R40

MR8

MR9

MR3

C12

RV34

R67

R68

+C43

R52

R64

R66

VT18

C44+

R61

R55

R59

R42

C28

R40

C27

R63

VT20

R55

R38

C26

RV69

R70

R60

MR4

C29

VT14

VT13

VT19

MR5

R41

R39

R62

VT11

C22

C24

R37

R58

C40

+ C41 -

C30

R44

VT15

C21

C23

C38

MR16

VT12

RV56

C35

MR17

MR1

R43

R53

R51

R45

R34

R31

R35

R36

R53

R49

C34

C33

VT

16

R57

MR

2

C39 +

R32

R50

C36C37

R48C31

R47

C32

RV33

L1

VT17

R46

R122

C66

R124

R129

C68

VT33

R119

R126

+ C67

VT36

C69

R117

VT35

R127

RV121

R53

VT37

R128

RV 111

R120

R116

R112

+ C64

R114

R113

C65

R123

RV101

+ C63

MR

22

R102

R108

VT34

R104

R103

C61

R105

R106

R107

R109

R118

R115

VT31

C62

VT32

MR21

RV110

Fig. 11a Wow & Flutter Board

025 312

R158

R53

C

83

C91

C88 C82

R160

MR35

VT53

R172

R161

R175

R171

R174

VT57

C101

SW4

C92

R178

VT

56

R173

R156R157

C90

R153

C93+

R155

R154

14

3

R142 R141

C87 +

R166

R162

VT

54

R

C95

R167

R164

C99 +

R163

C102 +

RV132

C94

VT51

R147

R146

+C86

R53

VT

55

R151

R165

R145

MR

31

R150

MR

32

MR

33

C97 +

C98 +

+C100

C103 +

C96 R169 R176

+ C85

R149

R148

R168

R144

VT52

MR

34

C89

Fig. 11b Distortion Meter Board

025 320

C81

R15R14

SW1

R13

R11

R17

R12

R16

R8

R5

R3

R7

C2 +

+ C3

TH1

RV19

R10

R9

C7

C5

C4

C6

R6

R1

R4

VT1

C8

C9

C10

C1

UNDER

VT3

VT2

C2

R18

C11

Fig. 11c Millivoltmeter Board

025 322

Fig. 11d Oscillator Board

025 245

Fig. 11 Component Location

Comments

After

Serial No. 3200+

Item 9, Appdx. 1 Front view

Type 16 (coupling 202-005)

Side panel 320-047

025-255 (Fixing modified)

Control knob 448-080

See 6.2 & Appendix 1a

See 589 above

Items 9 & 10 of Front view

Appendix 1 are 022-468

Serial No. 4515+

See 6.2

Item 1, Appendix 4

Handles, rear panel-light grey

Changed to suit potentiometers

Knob 448-087

Cap 448-088

Insert 440-038

Rear panel 573-177 Issue 3

(Mains supply plug added)

Rear panel 573-177 Issue 4

(VT73 transistor BD535)

Front extrusion 573-179

(printing deleted)

6. HISTORY OF MODIFICATIONS

RV56,69,152-type 44(202-003)

Before

Change

Date

6.1 Mechanical

Side panel 320-036

Millivoltmeter mother board

Control knob 448-025

Handles, rear panel-dark grey

Extension spindles, couplers

Control knob 448-080

(no longer manufactured)

Rear panel 573-177 Issue 2

(Voltage selector deleted)

Rear panel 573-177 Issue 3

(VT73 transistor 40312)

Front extrusion 573-180

No

279

299

582

589

591

666

679

Jan.73

Jul.76

Apr.73

Feb.78

Mar.78

692

May 78

702

716

Jul.78

Sep.78

Comments

Add to copper side

of board.

After

Before

Cct.

Ref.

560R 0.5W 5% 625-12-560

390k 1% 625-24-390k

39k 0.5W 5% 625-12-39k

56k 0.5W 5% 625-12-56k

22R 0.5W 5% 625-12-22

12.5mF 25V Electrolytic 130-026

Zener Diode BZY88C12 290-017

0.047mF 131-256

47K 0.25W 5% 625-12-47K

1000pF 63V 2.5% 131-768

470R 0.5W 10% 625-13-470

360K 1% 625-24-360k

33k 0.5W 10% 625-13-33k

47k 5% 624-001

Not fitted

25mF 25V Electrolytic 130-016

.022mF 131-255

56k 0.5W 5% 625-13-56k

950pF 63V 21% 131-775

R43

R47

R48

R5

R141

C43,4

C32

R40

MR 2

C21,22

950pF 63V 2.5% 131-775

1.8k 1% 625-24-1k8

1.6k 1% 625-24-1k6

180R 0.25W 5% 625-07-180

Type 16 + coupling 202-005

(spindle 4mm)

(fixing hole 7mm)

0.1mF 100V 2% 131-514

1mF 100V 2% 131-515

950pF 63V 21% 131-775

Not fitted

2.2k 1% 625-24-2k2

1.8k 1% 625-24-1k8

180R 0.5W 5% 625-12-180

Type 44 + coupling 202-003

(spindle 0.125 in)

(fixing hole 0.25 in)

0.1mF 1%

1mF1%

1000pF 64V 21% 131-768

R176

R4

RV56

RV69

C45

R1

RV152

C6,9

C7,8

C21,22

396

179

Change

No.

Date

6.2 Electrical

136

RTS 1

May 71

142

May 71

May 71

239

RTS 2 (Serial No. 730+)

Aug.72

Oct.72

Jan.73

Jan.73

279

275

251

370

Oct.73

Nov73

Comments

No change necessary

unless 'scope probe used

prior to Serial No. 2700

Should be fitted to

earlier models to

avoid switching surges

Later version fits

all models.

Fit later assembly

022-XXX as replacement

for earlier pot.

See Section 3.3

Serial No.4515+

After

1k 0.25W 0.2% 624-033

1M 0.25W 0.2% 624-032

Diode BAX16 290-001

or MAX16, or 1N4148

(pole SW6b earth)

582-033 (spindle reduced

by 0.25in)

582-109 + 705-028B = 022-528

582-107 + 705-028G = 022-527

582-108 + 705-028E = 022-526

10k 625-28-10k

Ti Transformer tags

Plug, power supply 577-017

Socket & lead 578-018

Label 450-171

“ 110V 50/60Hz 450-172

“ 220V 50/60Hz 450-173

“ 240V 50/60Hz 450-174

Transistor BD535 825-074

Fuse 1A 380-000

Fuse holder Bulgin 380-017

or (Schurter) 1380-017

Before

R142 2k 0.25W 0.2% 624-016

R143 1M 0.25W 0.2% 624-017

Cct.

Ref.

R142

R143

510

Change

No.

6.2 Electrical

Date

May 75

Not fitted

576

June 76

582-033

582-034

582-035

582-036

47k 625-28-47k

Voltage selector

(no longer manufactured)

Not fitted

VS1

RV87

666

589

July 76

May 78

R8

RV19

RV111

692

670

Jan 78

May 78

P1

VT73 Transistor 40312 825-002

Fuse 0.75A 380-008

Fuseholder 380-005

FS1

VT73

702

July 78

FERROGRAPH

RECORDER TEST SET

FRONT VIEW RTS 2

Appendix

Ref. RTS2

Number Item Qty. Part No.

1 Socket 3 692-030

2 Button 15 448-019

3 Knob K2 2 448-021

4 Bush 4 100-037

5 Extension Spindle 1 705-028F

6 Knob K2W 2 448-023

7 Extension Spindle 1 705-028D

8 Zero Stud 1 666-071

9 Knob K3 1 448-080

10 Dial 1 295-004

11 Potentiometer 10k Logarithmic 1 582-033

12 Extension Spindle 1 705-028C

13 Extension Spindle 1 705-028E

14 Meter 1 512-005

15 Lamp Holder 1 455-008

16 Lamp Festoon 3W 1 455-010(12V)

17 Knob K1 2 448-022

18 Extension Spindle 2 705-028A

19 Knob K 1W 2 448-026

20 Bush 3 100-038

21 Extension Spindle 3 705-029

22 Front Panel 1 573-178

FERROGRAPH

RECORDER TEST SET

REAR VIEW

Ref. RTS 2

Number Item Qty. Part No.

1 Mains Transformer 1 T1721

2 Fuse Holder 1 380-005

3 Fuse (0.75A, 20mm x 5mm dia.) 1 380-008

4 Vol tage Sel ector 1 920-001

5 Grommet 1 398-014

6 Power Board 1 025-310

7 Transistor (type 40312) 1 825-002

8 P.C. Board Support Bracket 1 025-255

9 Power Supply Lead 1 110-017

10 Cable Clip 2 196-011

11 Spacer 4 698-079

FERROGRAPH

RECORDER TEST SET

PLAN VIEW

Ref. RTS 2

Number Item Qty. Part No.

1 Coupling 6 687-029

2 P. C. Board Fixing Strap 1 025-256

3 Oscillator Board 1 025-245

4 Oscillator Mother Board 1 025-247

5 Terminal Nut 4BA 1 BP/2025/N

6 Millivoltmeter Board 1 025-322

7 Distortion Meter Board 1 025-320

8 Millivoltmeter Mother Board 1 025-248

9 Spacer 9 698-068

10 Wow & Flutter Mother Board 1 025-311

11 Wow & Flutter Board 1 025-312

12 Coupling 3 202-005

13 Potentiometer Mounting Board 1 025-309

14 Spacer 4 698-069

FERROGRAPH

RECORDER TEST SET

EXPLODED VIEW RTS2

Ref. RTS2

Number Item Qty. Part No.

1 Front Extrusion 1 573-180

2 Handle 2 412-002

3 Side Panel Extrusion 2 320-036

4 Hoop Frame 2 360-003

5 Bracket (top strap, L. H. ) 1 025-254A

6 Screen 1 671-005

7 Rear Panel 1 573-177

8 Top Panel 1 573-143

9 Bottom Panel 1 573-144

10 Bracket (top strap, R. H.) 1 025-254B

FERROGRAPH

RECORDER TEST SET

List of Components

Cct. Cct.

Ref. OSCILLATOR BOARD Part No. Ref. WOW & FLUTTER BOARD Part No.

R1 1.8k 1/4W 1 % High Stab. 625 24 1k8 R31 3.3k 1/2WW 5% 625 12 3k3

Resistors (R) & Potentiometers (RV) Resistors (R) & Potentiometers (RV)

R2 15k 1/2W 10% 625 13 15k R32 1k0 1% High Stab. 625 24 1k

R3 10k 1/2W 5% 625 12 10k RV33 22k Linear SET 3150Hz 582 012

R4 1.6k 1/4W 1% High Stab. 625 24 1k6 R34 430k 0.25W 2% High Stab. 625 25 430k

R5 560R 1/2W 5% 625 12 560

R6 47k 1/2W 10% 625 13 47k R35 430k 0.25W 2% High Stab. 625 25 430k

R7 820R 1/2W 5% 625 12 820 R36 3k3 0.5W 5% 625 12 3k3

R8 47k 1/2W 10% 625 13 47k R37 5.6k 0.5W 5% 625 12 5k6

R9 1k 1/4W 1% High Stab. 625 24 1k R38 10M 0.5W 10% 625 13 10M

R10 620R 1/2W 5% 625 12 620 R39 22k0 0.5W 10% 625 13 22k

R11 1370R 1/4W 0.2% High Stab. 624 015

R12 432R 1/4W 0.2% High Stab. 624 014 R40 47k 0.25W 5% High Stab 624 001

R13 137R 1/4W 0.2 % High Stab. 624 013 R41 22k 0.5W 10% 625 13 22k

R14 43.2R 1/4W 0.2% High Stab. 624 012 R42 3.3k 0.5W 5% 625 12 3k3

R15 13.7R 1/4W 0.2% High Stab. 624 011 R43 390k 0.25W 1% High Stab 625 24 390k

R16 6.34R 1/4W 0.2% High Stab. 624 010 R44 22k 0.5W 10% 625 I3 22k

R17 100R 1/2W 5% 625 12 100

R18 100R 1/2W 5% 625 12 100 R45 3.3k 0.5W 5% 625 12 3k3

RV19 2.2k0 Linear (OUTPUT fine) 582 035 R46 22k 0.25W 1% High Stab 625 24 22k

Cl 3300mF 40V Electrolytic 130 024

C2 125mF 16V Electrolytic 130 002

C3 125mF 16V Electrolytic 130 002

C4 950pF 30V 2 1/2% 131 775

C5 0.01mF 30V 2 1/2 % 131 774

C6 0.1mF 160V 2 1/2% 131 514

C7 1mF 160V 2 1/2% 131 515

CO 1mF 160V 2 1/2% 131 515

C9 0.1mF 160V 2 1/2% 131 514

CIO 0.01mF 30V 2 1/2% 131 774

C11 950pF 30V 2 1/2 % 131 775

VT1 Transistor BC183LB 825 015

VT2 Transistor BC154LB 825 016

VT3 Transistor BC183LB 825 015

SW1 Switch (OSC. OUTPUT coarse) 750 013

TH1 Thermistor ITT R25 800 000

Cct.

Ref. Front Panel Part No

RV20a 10k0 Log. (FREQ.) 582 033

RV20b 10k Log

MI Meter (Sifam 100mA) 512 005

LP1 Lamp 12V, 3W 455 010

SKT30 Socket BNC (1637/CS) 692 030

SKT31 Socket BNC (1637/CS) 692 030

SKT32 Socket BNC (1637/CS) 692 030

Capacitors

Miscellaneous

Miscellaneous

R47 39k 0.5W 5% 625 12 39k

R48 56k 0.5W 10% 625 13 56k

R49 22k 0.5W 10% 625 13 22k

R50 1k0 0.5W 10% 625 13 1k

R51 620R 0.5W 5% 625 12 620

R52 2.2k 0.25W 1% High Stab. 625 24 2k2

R53 1k 0.5W 10% 625 13 1k

RV54 1k Linear DRIFT SENS. 582 032

R55 22k 0.5W 10% 625 13 22k

RV56 25k Linear drift set zero 582 055

R57 22k 0.25W 1% High Stab. 625 24 22k

R58 33k 0.25W 1% High Stab. 625 24 33k

R59 33k 0.25W 1% High Stab. 625 24 33k

R60 100k 0.25W 5% High Stab. 624 002

R61 220k 0.5W 5% 625 12 220k

R62 1.6k 0.25W 1% High Stab. 625 24 11,6

R63 1M 0.5W 10% 625 13 1M

R64 4.7k 0.5W 5% 625 12 4k7

R65 390R 0.24W 1% High Stab. 625 24 390

R66 100k 0.25W 5% High Stab, 624 002

R67 1.6k 0.25W 1% High Stab. 625 24 1k6

R68 56k 0.5W 5% 625 12 56k

RV69 25k Linear peak wow cal. 582 055

R70 470R 0.5W 10% 625 13 470

C21 950pF 63V 2i% 131 775

C22 950pF 63V 2% 131 775

C23 0.22µF 100V 10% 131 253

C24 0.220F 100V 10% 131 253

C25 O. 33pF 100V 10% 131 257

C26 950pF 63V 2 % 131 775

C27 950pF 63V 2 % 131 775

C28 950pF 63V 2 % 131 775

C29 950pF 63V 2 % 131 775

Capacitors

FERROGRAPH

RECORDER TEST SET

List of Components

Cct. Cct.

Ref. WOW & FLUTTER BOARD Part No. Ref. POT. MOUNTING BOARD Part No.

C30 950pF 63V 2% 131 775 Capacitors

C31 0.01pF 30V 2 % 131 774 C51 0.033uF 250V 1% 131 260

C32 0.0470F 250V 10% 131 256

C33 0.22µF 100V 10% 131 253 Miscellaneous

C34 0.22pF 100V 10% 131 253 SW10 Switch SUPPLY on 750 004

C35 0.1pF 100V 10% 131 250

C36 0.047µF 250V 10% 131 256 DISTORTION METER BOARD

C37 0.047pF 250V 10% 131 256

C38 0.047µF 250V 10% 131 256 Resistors (R) & Potentiometers (RV)

C39 25uF 25V Electrolytic 130 016 RV101 22k Linear SET W&F CAL 582 012

C40 1uF 250V 10% 131 259 R103 47k 0.25W 5% High Stab. 624 001

C41 25uF 25V Electrolytic 130 016 R104 360k 0.25W 1% High Stab. 625 24 360k

C42 0.22µF 100y 10% 131 253

C43 12.5uF 25V Electrolytic 130 026 R105 360k 0.25W 1% High Stab. 625 24 360k

C44 12.5uF 25V Electrolytic 130 026 R106 18k 0.5W 10% 625 13 18k

C45 950pF 63V 21% 131 775 R107 4.7k 0.25W 1% High Stab. 625 24 4k7

VT11 Transistor BC184LC 825 005

VT12 Transistor BC184LC 825 005 RV110 22k Linear SET mVmeter CAL 582 012

VT13 Transistor BC184LC 825 005 RV111 100k Log. set 100% 582 036

VT14 Transistor BC 183LB 825 015 RI12 1k 0.5W 10% 625 13 1k

VT15 Transistor BC183LB 825 015 R114 33k 0.25W 1% High Stab. 625 24 33k

VT16 Transistor BC183LB 825 015

VT17 Transistor BC184LC 825 005 R115 1.8k 0.5W 10% 625 12 1k8

VT18 Transistor BC184LC 825 005 R116 22k 0.25W 1% High Stab. 625 24 22k

VT19 Transistor BC184LC 825 005 R117 47k 0.25W 1% High Stab. 624 001

VT20 Transistor BC183LB 825 015 R119 3.3k 0.5W 5% 625 12 3k3

MR1 Diode MAX16 290 001 R120 1.8k 0.25W 1% High Stab. 625 24 1k8

MR2 Zener Diode BZY88C12 290 017 RV121 1k Linear SET PHASE BAL. 582 032

MR3 Diode NKT249A30 290 015 R122 1k 0.25W 1% High Stab. 625 24 1k

MR4 Zener Diode BZY88C5V6 290 013 R123 1.8k 0.5W 5% 625 12 1k8

MR5 Zener Diode BZY88C4V7 290 016

MR6 Zener Diode BZY88C4V7 290 016 R125 100k 0.25W 5% High Stab. 624 002

MR7 Zener Diode BZY88C4V7 290 016 R126 270R 0.5W 5% 625 12 270

MR8 Diode NKT 249A30 290 015 R127 47k 0.25W 5% High Stab. 624 001

MR9 Diode NKT 249A30 290 015 R128 10k 0.5W 10% 625 13 10k

L1 Coil Spec 800

POT. MOUNTING BOARD C62 0.1uF 100V 10% 131 250

Resistors (R) Er Potentiometers (RV) C63 640uF 25V Electrolytic 130 004

R81 10k 0.25W 1% High Stab. 625 24 10k

RV82 2k 10 turn BALANCE phase 582 056 C65 0.47uF 250V 10% 131 258

R83 3.9k 0.5W 5% 625 12 3k9 C66 0.033uF 250V 10% 131 262

RV84a 10k Log. (Freq. coarse) 582 094 C67 25uF 25V Electrolytic 130 016

RV84b 10k Log. C68 4700pF 30V 21/2% 131 778

R85 3.9k 0.5W 5% 625 12 3k9

R86 330k 0.5W 5% 625 12 330k

RV87a 100k Log. (Freq. fine) 582 034

RV87b 100k Log.

R88 330k 0.5W 5% 625 12 330k

Capacitors

R102 47k 0.25W 5% High Stab. 624 001

Miscellaneous R109 6k8 0.25W 1% High Stab. 625 24 6k8

R108 10k 0.25W 1% High Stab. 625 24 10k

R113 22k 0.25W 1% High Stab. 625 24 22k

R118 100R 0.5W 5% 625 12 100

R124 39k 0.5W 10% 625 13 39k

R129 1.5k 0.5W 5% 625 12 1k5

C61 0.1uF 100V 10% 131 250

C64 25uF 25V Electrolytic 130 016

C69 0.47uF 250V 10% 1310258

Capacitors

FERROGRAPH

RECORDER TEST SET

List of Components

Cct. Cct.

Ref. DISTORTION METER BOARD Part No. Ref. MILLIVOLTMETER BOARD Part No.

VT31 Transistor BC183LB 825 015

VT32 Transistor BC183LB 825 015 R175 10k 0.5W 5% 625 12 10k

VT33 Transistor 2 SC 1000BL 825 035 R176 180R 0.5W 5% 625 07 180

VT34 Transistor BC183LB 825 015

VT35 Transistor 2 SC 1000 BL 825 035 Capacitors

VT36 Transistor 2 SC 1000 BL 825 035

VT37 Transistor 2 SC 1000 BL 825 035 C81 500pF 160V 10% 131 765

MR21 Zener Diode BZY88C5V6 290 013 C82 0.01µF 30V 2.5% 131 774

MR22 Diode MAX 16 290 001 C83 Variable Ceramic 131 001

Cct. C86 5uF 64V Electrolytic 130 007

Ref. MILLIVOLTMETER BOARD Part No. C87 32uF 40V Electrolytic 130 013

R141 22R 0.5W 5% 625 12 22 C89 0.1µF 400V 10% 131 516

R142 2K 0.5W 0.2% High Stab 624 16

R143 2M 0.5W 0.2% High Stab 624 17 C90 0.022uF 250V 10% 131 255

R144 1K 0.5W 5% 625 12 1K C91 0.22uF 100V 10% 131 253

R145 180R 0.5W 1% High Stab 625 24 180 C93 5uF 64V Electrolytic 130 007

R146 1K 0.5W 5% 625 12 1K C94 0.047uF 250V 10% 131 256

R147 10K 0.5W 5% 625 12 10K

R148 1K 0.5W 1% High Stab 625 24 1K C95 0.1uF 100V 10% 131 250

R149 270K 0.5W 5% 625 12 270K C96 500pF 160V 10% 131 765

R150 1.5K 0.5W 1% High Stab 625 24 1.5K C98 25uF 25V Electrolytic 130 016

R151 470R 0.5W 5% 625 13 470 C99 25uF 25V Electrolytic 130 016

RV152 2K Linear MVmeter Cal. 528 054 C100 12.5uF 25V Electrolytic 130 026

R153 6.34R 0.5W 0.2% High Stab 624 010 C101 0.22uF 100V 10% 131 253

R154 33.7R 0.5W 0.2% High Stab 624 011 C102 125uF 16V Electrolytic 130 002

R155 43.2R 0.5W 0.2% High Stab 624 012

R156 137R 0.5W 0.2% High Stab 624 013 Miscellaneous

R157 432R 0.5W 0.2% High Stab 624 014 VT51 Transistor 2SK30GR 825 006

R158 1370R 0.5W 0.2% High Stab 624 015 VT52 Transistor BC 184LC 825 005

R159 470R 0.5W 0.2% High Stab 625 13 470 VT53 Transistor BC183LB 825 015

R160 10M 0.5W 10% 625 13 10M VT55 Transistor BC183LB 825 015

R161 100K 0.5W 5% High Stab 624 002 VT56 Transistor BC183LB 825 015

R162 100K 0.5W 5% High Stab 624 002 VT57 Transistor BC183LB 825 015

R163 47R 0.5W 1% High Stab 625 24 47

R164 470K 0.5W 10% 625 13 470K MR31 Zener Diode BZY88C5V6 290 013

R165 620R 0.5W 5% 625 12 620 MR33 Diode MAX16 290 001

R166 10K 0.5W 5% 625 12 10K MR34 Diode MAX16 290 001

R167 1.5K 0.5W 10% 625 13 1.5K MR35 Zener Diode BZX70C20 290 011

R168 1K 0.5W 1% High Stab 625 24 1K (or 3TZ20 or 1N5357B)

R169 1K 0.5W 1% High Stab 625 24 1K

R170 100R 0.5W 5% 625 12 100

R171 220K 0.5W 10% 625 13 220K

R172 470K 0.5W 10% 625 13 470K POWER BOARD

R173 1K 0.5W 5% 625 12 1K Resistors (R) & Potentiometers (RV)

R174 15K 0.5W 5% 625 12 15K R191 22k 0.5W 1% High Stab. 625 24 22k

Miscellaneous Resistors (R) & Potentiometers (RV)

C84 160uF 25V Electrolytic 130 011

C85 125uF 16V Electrolytic 130 002

C88 0.22uF 100V 10% 131 253

C92 0.22uF 100V 10% 131 253

C97 25uF 25V Electrolytic 130 016

C103 160uF 25V Electrolytic 130 011

VT54 Transistor BC183LB 825 015

MR32 Diode MAX16 290 001

SW6 Switch M1LLIVOLTMETER 750 014

RV192 1k0 Linear SET 30V D.C. 582 032

R193 4.3k 0.5W 1% High Stab. 625 24 4k3

R194 3.9K 0.5W 5% 625 12 3k9

R195 100k 0.5W 10% 625 13 100k

R196 10k 0.5W 10% 625 13 10k

FERROGRAPH

RECORDER TEST SET

List of Components

Cct.

Ref. POWER BOARD Part No. Cct.

C121 100uF 40V Electrolytic 130 001 R212 137R 0.5W 0.2% High Stab. 624 013

0122 0.01uF 100V 10% 131 500

C123 250uF 64V Electrolytic 130 010 SW25 Push Button Switch W & F 749 005

VT71 Transistor BC183LB 825 015

VT72 Transistor BC461 825 032 OSCILLATOR MOTHER BOARD

MR51 Zener Diode BZY88C5V6 290 013 SKT1 P.C. Board Socket 26 way 692 029

MR52 Bridge Rectifier W02 600 002

VT73 Transistor 40312 825 002 SKT10 P.C. Board Socket 26 way 692 029

T1 Transformer, Power Supply T1721

FS1 Fuse 0.75A, 20mm x 5mm dia. 380 008

VS Voltage Selector 920 001

Capacitors R211 680R 0.5W 1% High Stab. 625 24 680

Miscellaneous

REAR PANEL. SW20 Push Button Switch 749 003

Ref. W F MOTHER BOARD Part No.

SKT20 P. C. Board Socket 26 way 692 029

SW15 Push Button Switch FREQUENCY 749 005

MILLIVOLTMETER MOTHER BD

SKT11 P.C. Board Socket 26 way 692 029

REPLACEMENT BOARD SERVICE

Where it is found necessary to change an electronic component, the RTS2

should be checked and re-calibrated using test equipment which is several

times more accurate than the Test Set itself. If this equipment is not

available or if difficulty is experienced, the relevant P.C. board(s) can be

sent for checking or replacement to the Ferrograph !Replacement Board

Service!.

When returning the board(s) to the appropriate overseas agent, or in the

U.K. to theU. K. SERVICE DEPARTMENT . It is essential to include the

SERIAL NUMBER of the Test Set.

SKT1

+30V

R18

SW1

OSC

O/P

COARSE

20V

R31

10V

C21

POLE CONTACT RELATIONSHIP

R32

RV33

SET

3150Hz

R35R34

7.7V

C22

VT11

VT12

SWITCH INDEX SHOWING

POLE

DEPRESSED RELEASED

R36

C23

C24

CONTACT

R37

16V

C25

R47

C32

VT16

12V 3V

VT17

R48

C34

C33

R49

C35

drift

DRIFT

SENS

R55

SKT 20

set zero

RV56

VT8

7.5 - 9.4

(RV56)

20V

C39

MR4

8V

R50

R52

C36

R51

1 2 3 4 5 6 7 8 9 10 1112 13

+30V

MR3

R53

C37

C38

MR5

MR6

MR7

RV54

C40

R57

R58

R59

R211

R70

R60

C41

VT19

R61

R62

2V

0.4V

R63

VT20

R64

R65

13.5V

1.4V

30V

R66

C42

MR8

R67

R68

MR9

SKT 30

SKT 31

C43

C44

RV69

peak wow

cal (0.3%

range)

scope

meter

20V 20V

C45

20V

L1

C26

R39

R38

C27

10.5V

VT13

R40

C28

R41

11V

VT14

R42

C30

SW 20

R43

C20

VT15

R44

R45

C31

6V

MR1

M1

- +

20V

R46

8.5V

MR2

27V

R17

R2

12V

VT2

26.4V

R3

C2

TH1

R6

R7

C4

VT3

14.6V

14V

C3

R5

O/P

RV19

R8

C5

1 2 3 4 5 6 7 8 9 10 1112 13

R9

R10

C6 C7

FINE

R1

VT1

R4

C1

R11

R12

R13

R14

R15

R16

C8 C9 C10 C11

R102

RV101

SET W&F

CAL

C63

100%

R103

RV 111

set

C61

VT31

R112

RV20a

R104

R113

R115

FREQ.

30V (onCAL)

R105

C62

VT32

R114

5.2V

C65

R116

RV20b

R106

MR21

R117

C64

MR22

R107

R108

R109

RV110

SET MV METER

CAL

14V

VT33

4.4V

R119

VT34

0.38V

R118

VT35

3.9V

RV121

R122

R120

SET

PHASE

BALANCE

6.1V

C66

C67

SKT 10

13

12

11

10

9

8

7

6

5

4

3

2

1

3.3V

6.8V

VT36

30V

R123

R124

R125

R126

R127

VT37

6.3V

14V

R128

C68

6.3V

FREQUENCY

X1 X10 X100 X1000

R81

BALANCE

C69

C81

R144

C83

R129

R143

R142

R141

SET

HF

C82

RV82

phase

SW15

C89

1mV

SW6a

100V

L.F.cut osc input

R83 RV84a R85 R86

C51

MR31

C84

C85

VT51

0.6V

R147

17V

R146

R145

C88

C87

C86

0.9V

0.6V

R151

RV152

mV meter

cal (1V range)

freq. coarse

R148

5.5V

R149

R150

VT52

W&F

drift

RV84b R88

R159

R158R157R156R155R154

C90

R153

12 POSN. SWITCH ONLY 6 TAGS

SHOWN. OPPOSITE TAGS LINKED

R160

C91

SW6b

DISTORTION

100% read

VT53

14V

C94

C93

R161

C92

RV87

freq. fine

13.9V

R162

VT55

VT54

R163

R166

R165

13.5V

1.6V

R164

CALMILLIVOLTMETER

RV87b

MR32

MR33

20V

1V

R167

1 2 3 4 5 6 7 8 9 10 1112 13

R169

MR34

R168

C100

C97

C98

C99

C95

C96

SW25

WOW & FLUTTER

drift 1% 0.3% 0.1%

+30V

SKT 11

C101

R174

R171R170

VT57

3.4V

1.4V

VT56

R175

0.8V

R173

C102

R172

MR35

+30V

C121

R176

C103

R212

R193

VT71

RV192

25VSET

30V

R191

P5 E

L N

R194

MR51

24.4V

NEUTRAL

LIVE

R195

VT72

VT73

C122

R196

FS1

C123

SUPPLY

ON

SKT 32

MR52

SW10

oscillator

LP1

FERROGRAPH

RECORDER TEST SET

RTS2

Serial No. 4515 onwards

CIRCUIT DIAGRAM