Page 1

ZMT Owner’s Manual

Owner’s Manual

ZMT Offset / In-line

Verge Mowers

Maintenance & Use

Page 2

ZMT Owner’s Manual

CONTENTS

GENERAL INFORMATION section 1 page 2

• Introduction - Goal of the manual section 1.1 page 2

• Identifying the machine section 1.2 page 2

• Spare parts section 1.3 page 2

TECHNICAL FEATURES section 2 page 3

• General Description of the Shredder section 2.1 page 3

• Technical Specifications section 2.2 page 4

• Noise section 2.3 page 4

• Width of Cut section 2.4 page 5

• Optional Equipment section 2.5 page 5

SAFETY RULES section 3 page 6

• General Safety Rules section 3.1 page 6

• Safety Rules Concerning the Hydraulic System section 3.2 page 6

• Safety Rules Concerning Road Traffic section 3.3 page 7

• Safety Rules During Use section 3.4 page 7

• List of Guards Fitted to the Machine section 3.5 page 6

• Description and Location of Safety Decals section 3.6 page 7

INSTRUCTIONS FOR INSTALLATION, HANDLING AND PARKING section 4 page 8

• Lifting and Unloading section 4.1 page 8

• Unpacking section 4.2 page 7

• Attachment to and Detachment from the Tractor section 4.3 page 8

• Attaching the PTO Shaft section 4.4 page 9

• Tractor stability section 4.5 page 6

• Parking section 4.6 page 7

ADJUSTMENT AND SETTING UP section 5 page 11

• Regulating the Height of Cut section 5.1 page 11

• Adjusting Belt Tension section 5.2 page 11

USE AND OPERATING RULES section 6 page 12

• Ram Control section 6.1 page 7

• Starting section 6.2 page 12

• Working Mode section 6.3 page 12

• Stopping section 6.4 page 7

• Transport Position section 6.5 page 12

MACHINE MAINTENANCE section 7 page 13

TROUBLE SHOOTING CHART section 8 page 14

REPLACING PARTS section 9 page 15

• Flails Replacement section 9.1 page 15

• Pipe Replacement section 9.2 page 11

• Pin Replacement section 9.3 page 15

• Belt Replacement section 9.4 page 11

DEMOLITION, DIFFERENTIATED DIVISION AND DISPOSAL section 10 page 14

1

Page 3

ZMT Owner’s Manual

1 GENERAL INFORMA TION

1 .1 This operation and maintenance manual is intended for the professional user. It is

mandatory to follow these instructions in order to prevent situations that could

endanger the operator’s and other people’s safety, and to ensure the correct

functioning of the shredder. If you have questions, call “FERRI” after-sales service or

a specialized “FERRI” dealer.

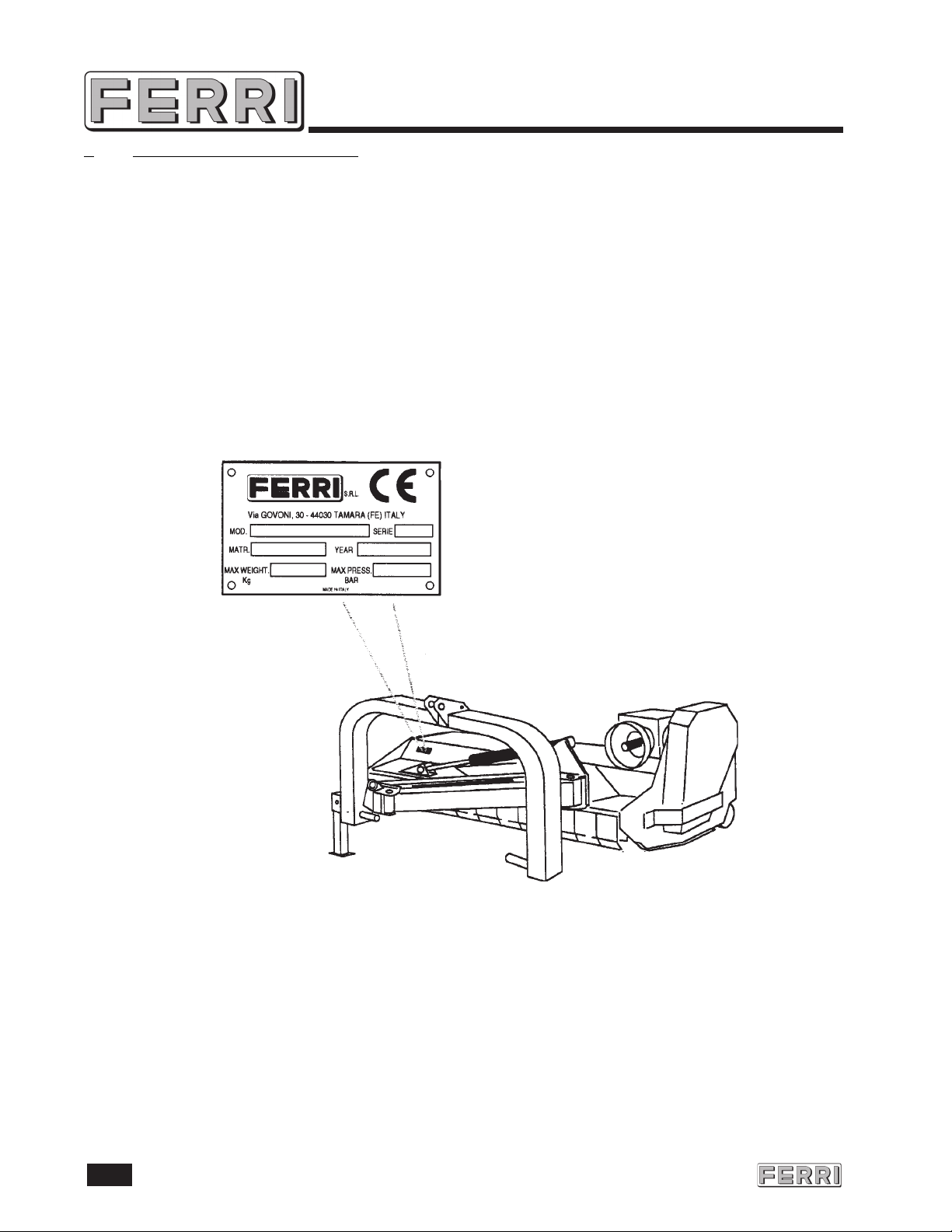

1.2 Identifying the Machine

Each shredder has an identification plate attached; the data necessary to identify the

model and the serial number to order spare parts or after-sales service are both

stamped on the plate (see Figure 1)

Figure 1

1.3 It is strongly recommended to use genuine “FERRI” spare parts to avoid altering the

technical features of the shredder. “FERRI” is not responsible for any damage or

injuries to people due to unauthorized modifications or to the use of non-genuine

spare parts.

2

Page 4

ZMT Owner’s Manual

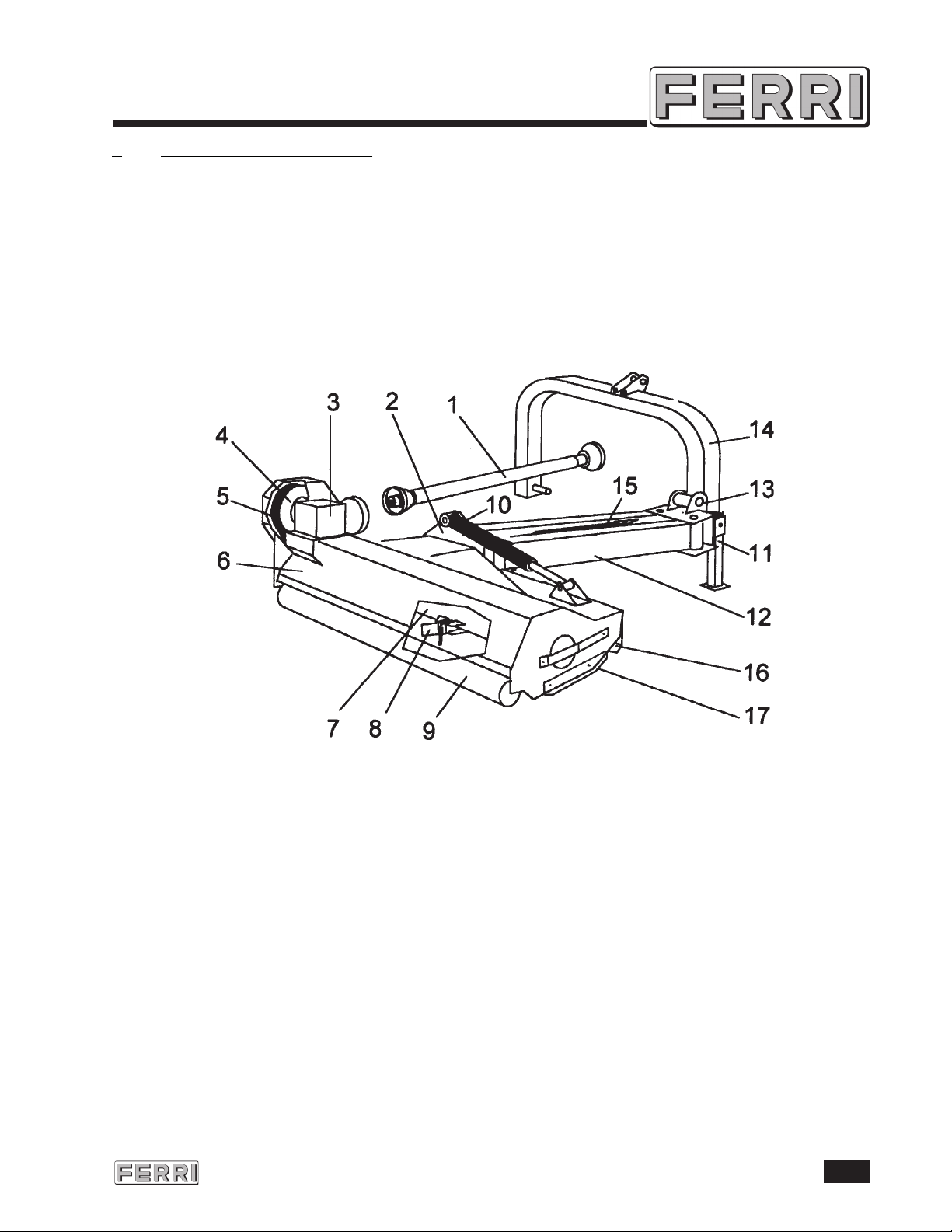

2 TECHNICAL FEATURES

2.1 FERRI shredders have been designed to shred materials growing or laying on the

ground, e.g. grass, bushes, sticks and shrubs up to .8”. diameter (proper use).

Any other use is considered improper and the manufacturer disclaims all

responsibility for any consequential injuries to people or for damage to the machine.

“Proper use” also refers to the safety and maintenance rules provided by the

manufacturer.

Technical Names (Figure 2)

Figure 2

1 - PTO Shaft 10 - Ram To Adjust Flail Head

2 - Levers To Adjust Flail Head 11 - Stand

3 - Gearbox 12 - Arms For Side Movement

4 - Pulleys 13 - Joint Pin

5 - Belts 14 - 3-Point Linkage

6 - Frame 15 - Ram For Side Movement

7 - Rotor 16 - Front Guard

8 - Flails 17 - Side Guard

9 - Roller

This machine is in conformity with the following provisions of law:

• Directive Machine 89/392/CEE and following additions: 91/368/CEE, 93/44/CEE

and 93/68/CEE;

• Regulations UNI EN 292/1 and 292/2 (machinery safety);

• DPR 27th April’1955, N. 547 (Rules for the prevention of industrial accidents).

3

Page 5

ZMT Owner’s Manual

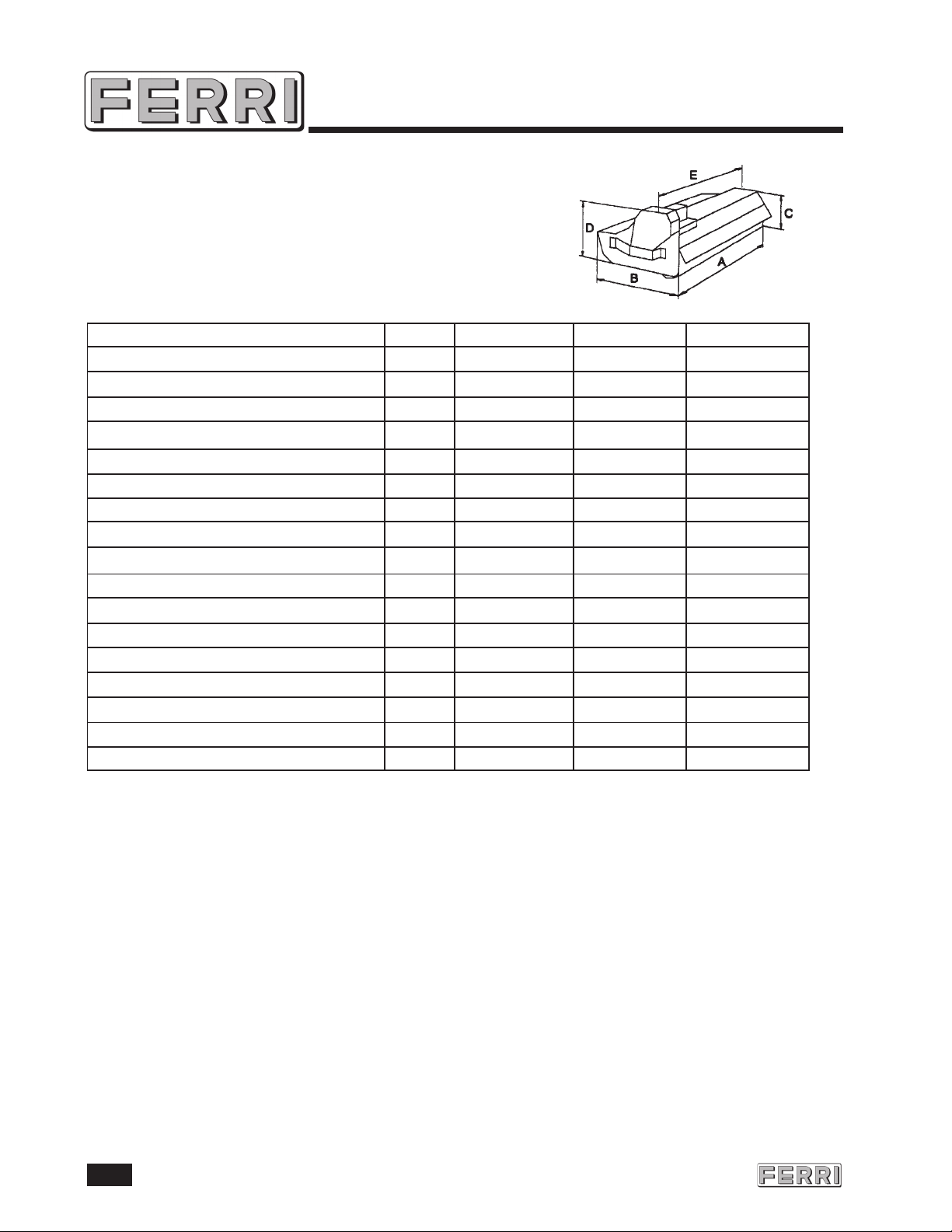

2.2 Technical Specifications (Table 1)

T able 1

Model ZMT 160 ZMT 180 ZM T200

Width of cut ft. 63” 71” 79”

Min. Tractor required power HP 50 - 60 60 - 70 70 - 80

Min. Tractor Weight 4818 5256 5694

PTO speed rpm 540 540 540

Max. Absorbed Power* H P 32 52 52

Weight Machine / Weight PTO Shaft lbs. 984 / 53 1178 / 53 1237 / 53

3-point linkage cat. II - I II II - II I II - I II

Rotor Speed rpm 2430 2510 2510

Multi-Use Flails num. 40 48 48

Hammer Flails num. 20 24 24

Max. Pressure psi 2750 2750 2750

Dimensions

A - Width in. 63” 71” 79”

B - Length in. 35” 37” 37”

C - Height in. 17” 19” 19”

D - Total Height in. 26” 28” 28”

E - Total Width in. 70” 77” 85”

* When the absorbed power exceeds the maximum power indicated in Table 1 it is

recommended to use a PTO clutch (torque limiter).

2.3 Noise

The sound level of this machine, as measured at the operator’s position, ranges from

75 dB to 77.2 dB when the cab is closed, and from 81.9 to 83.4 dB when the rear

window is open. The acoustic power level is LWA 102.5.

When the sound level perceivable at the operator’s position ranges from 85 dB and

90 dB, the use of ear protectors is recommended.

4

Page 6

ZMT Owner’s Manual

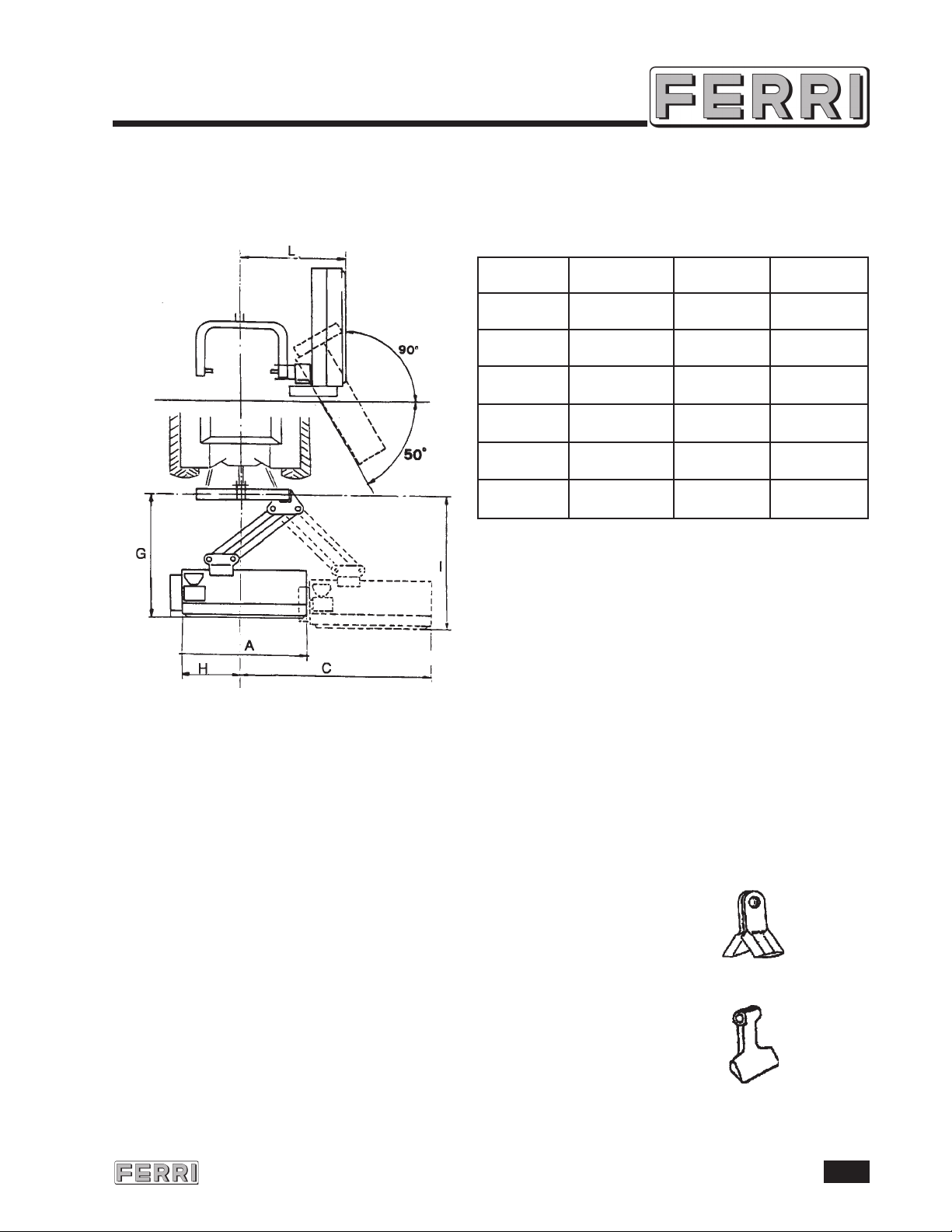

2.4 Width of Cut Figure 3 shows the width of cut of the shredder.

Dimensions are shown in Table 2.

Figure 3

T able 2

Model ZMT 160 ZMT 180 ZMT 200

A 63” 71” 79”

C 88” 96” 104”

G 73” 76” 76”

H 25” 25” 25”

I 69” 72” 72”

L 63” 63” 63”

2.5 Optional Equipment

2.5.1 Flails

Depending on the different crops to be cut, suitable flails can

be fitted and used:

• Articulated flails for grass, shrubs, sticks and bushes of up

to 1.2” in diameter.

• Forged hammer blades for grass, twigs, shrubs, bushed up

to 1.2” in diameter.

5

Page 7

ZMT Owner’s Manual

3 GENERAL SAFETY RULES

3.1 General Safety Rules:

It is mandatory to read and follow the instructions from the use and maintenance manual

•

before carrying out any operation or moving the shredder. Improper use or moving it

improperly may seriously damage property and harm people.

• Both the operator and maintenance fitter must know the shredder well, especially

regarding dangers resulting from improper use or incorrect repairs.

• Before starting, check the tractor and shredder in regards to functionality, road safety

and accident prevention rules.

• Even when using the shredder correctly, stones or other objects may be thrown a long

distance. Therefore, nobody should be standing within the danger area. Special

attention must be paid when working near roads or buildings.

• Use tractor with cabs.

• The condition of flails and of all guards must be checked before beginning the daily

work. They must be replaced if damaged or missing.

• During checks or repairs, make sure nobody can start the shredder by mistake.

• Never wear loose or fluttering clothes.

• Never carry passengers on the tractor.

• Never carry passengers on the shredder.

• Never enguage the PTO with the engine stopped.

• Never approach the shredder until the rotor has completely stopped.

• Do not enter the working zone of the PTO shaft while it is in motion. It is dangerous to

approach the rotating parts of the machine.

• Keep the PTO shaft guard in good working order.

• Before starting, check the surrounding area for the eventual presence of children and or

animals.

• DO NOT stand in the range of operation of the machine.

• The PTO shaft must be assembled and disassembled only with the engine is stopped

and the ignition key removed.

• Before connecting the power take-off, check that the speed and rotation direction

corresponds to those of the shredder.

• Before leaving the tractor with the shredder attached, proceed as follows:

1. Disconnect the power takeoff.

2. Put the machine firmly on the ground (with the hydraulic lift).

3. Apply the hand brake and if the ground is sloping steeply, wedge the tractor

wheels.

4. Take the ignition key out.

• Immediately replace any safety sign or missing, damaged decal.

6

Page 8

ZMT Owner’s Manual

3.2 Safety Rules Concerning the Hydraulic System

• This shredder uses the hydraulic circuit of the tractor to carry out side movements

and to adjust the flail head; the pressure of such system must not exceed 190 BAR.

• Mark the different pipes to avoid reversal of operation.

IMPORTANT: Do not look for oil leaks with bare hands, but always while wearing

gloves or with a cloth. Oil under strong pressure may seep into the skin causing

serious infections. In this case contact a doctor immediately.

• Periodically check the flexible hoses; if they are worn or damaged they must be

replaced with others of the same specification.

• Before working on the hyudraulic system, lower the machine, take pressure out

and stop the tractor.

• Used oils and greases must be stored and disposed of according to anitpollution

rules.

3.3 Safety Rules Concerning Road Traffic

• In transport, reduce speed, especially on bumpy roads. The weight of the shredder

may render driving difficult and damage the shredder itself.

• Check that the levers which operate the hydraulic lift are locked to avoid the

lowering of the machine during transport.

• When driving on public roads, respect all road rules in force. Never transport the

shredder with the rotor moving, even for short distances.

• Lock the shredder with the appropriate chain.

3.4 Safety Rules During Use

• Pay special attention, when working with the machine, not to touch fixed objects

such as road drains, wells, shafts, curbs, guard rails, tracks, etc. This could cause

the breakage of the flails, which can be thrown at very high speed.

• If wires, ropes or chains should get entangled in the rotor, stop immediately to

prevent damage or a dangerous situation; stop the rotor and the tractor, take out

the ignition key.

Put working gloves on, clear the rotor with the aid of pliers or shears. Do not try to

disentangle by inverting the rotational direction of the rotor.

• Do not use the machine when there is vibration in the flail head, as this could

cause breakage and serious damage. Find the cause of the vibration and repair it.

• Do not operate with the arm extended if the tractor is on a sloping ground.

3.5 List of Guards Attached to The Shredder (Figure 4)

1 - PTO Shaft

2 - PTO Shaft Guard

3 - Belt Guard

4 - Danger and Warning Decals

5 - Front Guard

6 - Side Guard

Figure 4

7

Page 9

ZMT Owner’s Manual

3.6 Description and Location of Safely Decals (Figure 5)

Carefully follow the instructions detailed on the decals.

Figure 5

Description of the Decals

1. Warning of danger through lack of knowledge of all the functions of the machine

and the resulting risks: read the use and maintenance manual before operating

the shredder.

2. Danger sign of crushing or shearing: do not put limbs in the moving parts of the

machine where this decal is located.

3. Danger sign: it shows the risk of flying stones or other objects and it is mandatory

to keep out of the danger zone.

4. Danger sign of rotating flails: do not enter the area of operation with hands or feet.

5. Danger of getting entangled: do not approach the rotating PTO shaft. Pay special

attention to clothes which must not be loose or fluttering.

6. Danger of crushing: keep out of the danger zone. Before you make any

adjustments or perform maintenance it is neccesary to lock the hydraulic cylinders.

8

Page 10

ZMT Owner’s Manual

4. INSTRUCTIONS FOR INSTALLATION AND

HANDLING

4.1 Lifting and Unloading

To handle the shredder use a hoist or a crane

with lifting capability suitable to the weight of

the machine (see Table 1) and with proper

chains and type approved hooks attach them

to the marked points, as shown in Figure 6.

4.2 Packing

To make transport easier, the shredder can be supplied in a special pack

(disassembled and on pallets).

In this case, a card showing the reassembling procedure will be attached to the Use

and Maintenance Manual.

Figure 6

4.2.1 Instructions For Assembly

Instructions for the assembly of the mower when it is shipped partially dismounted

(Figure A).

Figure A

In order to have the mower stable during the operations, hook the mower up to the shift

of the tractor .

• Switch off the tractor.

• Cut the fixing strings used for transport reasons.

• Bring the arm (1) and put it on the ground.

• Turn the arm (2) around as shown on Figure B.

• Put the arm (1) on the proper support (3) & (4) and lock with threaded pins (5).

• Fix the cylinder (6) (rod side) with threaded pin (7).

9

Page 11

ZMT Owner’s Manual

Figure B

WARNING: All Operations Must Be Done Without The PTO Sharf t Mounted.

4.3 Attachment to and Det achment from the Tractor

Before carrying out this operation and whenever the shredder is used, it is important

to:

• Visually check the machine in general.

• Check that all guards are fitted and in good condition.

• Confirm that all flails are fitted and in good condition.

• Grease the bearings and any other part as indicated by a decal (Figure 21).

• Check that all hydraulic pipes are in good condition, look for signs of leakage

beneath the machine.

• Check that the number or revolutions and the rotational direction of the power take

off correspond to those required by the shredder (Figure 7).

Figure 7

10

Page 12

ZMT Owner’s Manual

• T o attach the machine to the tractor (Figure 8), bring the tractor lower lines (1) near the

shredder , to the points corresponding to the pins.

• Insert the pins (2) and secure them with the spring clips (3).

• Fit the top link (4) and adjust it at the limit of the slot side tractor (see Figure 8) in

order to follow any small depression on the ground. Raise the shredder to a

perpendicular position with the ground. Adjust the two tractor lower linkage

stabilizers (3) thus fixing the machine to the tractor in a central position.

• Lift the stand (5).

• Connect the pipes for ram control to the tractor and mark them to avoid reversing

them during assembly (see Figure 15).

Figure 8

• Proceed in reverse order to detach the shredder from the tractor .

4.4 Fitting The PTO Shaft

4.4.1 Following the instructions in 4.3,

assemble the PTO shaft (6) and check

that the overlap is not less than 2/3 of L.

Be sure to keep a 1.6” backlash (Figure

8). If it needs shortening, proceed as in

(Figure 9).

4.4.2 The guards of the PTO shaft must be

fixed to the shredder and to the tractor

with chains to prevent rotation. The

minimum overlap of the guard and the

PTO shaft must not be less than 2”

(Figure 10).

Figure 9

Figure 10

11

Page 13

4.5 T ractor Stability

Due to the design of the shredders and the work they do, it is essential to ensure

tractor stability in order to eliminate any risk of an imbalance or overturning.

Lift the shredder and check that the tractor’s front tires do not lift up. In case they do,

ballast the rear wheel of the tractor opposite to the extended arms and in front.

(Figure 11).

ZMT Owner’s Manual

Figure 11

IMPORTANT:

• Never work with the extended arms when the tractor is on sloping grounds.

• During transport, the machine must be in the central position.

4.6 Parking

• Park the machine in a safe place, on flat and firm ground, in order to prevent the

risk of rolling over.

• Lower the shredder to the ground with the aid of the hydraulic lift of the tractor.

After lowering and blocking the stand, close the arms and lower the flail head to the

ground (Figure 12).

Figure 12

12

Page 14

ZMT Owner’s Manual

5 ADJUSTMENT AND SETTING UP

5.1 Adjustment of the height of cut is obtained by shifting the flail head roller in order to

suit the material to be cut and the required degree of chopping (Figure 13).

Figure 13

IMPORTANT: Flails must never touch the ground.

5.2 Adjusting belt tension

This operation must be carried out with the shredder standing on the ground, the

power takeoff disconnected and the iginition key removed.

Remove the belts guard, loosen the 4 screws (1) fixing the gearbox, adjust the link

(2) to obtain a belt deflection of no more than .6”. with 10 lbs. of pressure applied

(see Figure 14).

Figure 14

At the end of the operation, tighten the 4 screws (1) holding the gearbox and reassemble

the belts guard.

13

Page 15

ZMT Owner’s Manual

6 USE AND OPERATING RULES

6.1 Ram control

6.1.1 The ram control levers of the shredder are placed inside the cab and are part of the

shredder. This delivers the hydraulic power necessary to run the shredder.

• Ram (1) (Figure 15) controls the adjustment of the flail head.

• Ram (2) controls side movement of the flail head.

Figure 15

6.1.2 Controls with distributor (OPTIONAL)

For tractors equipped with just one pressure tube or when requested by the user, a

distributor for ram control can be fitted to the shredder. This is also equipped with a

floating position to control the ram (1) (Figure 15).

6.2 Starting

• Before using the shredder check the tightness of all bolts and the integrity of all

guards. Check that the number of revolutions and the rotational direction of the

power takeoff of the tractor correspond to those required by the shredder, see

decal on the gearbox (Figure 7).

• Engage the power takeoff at low engine RPM (without jerking) to avoid damaging

the transmission (gearbox and belts).

14

Page 16

ZMT Owner’s Manual

6.3 Working Mode

6.3.1 Adjust the machine to suit the type of work to be done and the material to be cut:

• Adjust the height of cut, as shown in Figure 13.

Working speed is chosen to suite the material to be cut and the degree of chopping

required.

The optimum speed ranges from 2 to 5 miles per hour.

IMPORTANT: When extending and closing the arms, lightly lift the flail head off the

ground, to avoid damage to the frame (Figure 16)

Figure 16

IMPORTANT: During reverse movement, lift the shredder off the ground to avoid

damaging the machine (Figure 17 & 18)

Figure 17

6.4 Stopping

Before stopping the tractor:

• Close the arms and lower the flail head to the ground.

• Disconnect the power takeoff.

• Stop the tractor, take out the ignition key and apply the hand brake.

• If the ground is sloping, block the tractor wheels.

Figure 18

15

Page 17

6.5 T ransport Position

For transport it is mandatory to:

• Observe all road transport requirements and fit the necessary warning signs

(Figure 19).

• Secure the arm and the flail head with the appropriate chain, to prevent movement.

Figure 19

ZMT Owner’s Manual

IMPORTANT: During transport reduce speed especially on bumpy roads. The weight of

the shredder may render driving difficult and damage the machine itself. The power

takeoff must be disconnected during transport.

16

Page 18

ZMT Owner’s Manual

7 MACHINE MAINTENANCE

All maintenance, cleaning and repair operations must be carried out with the

shredder firmly lowered to the ground and detached from the tractor, or with

disconnected PTO, engine off and ignition key out.

After the first 2 hours of operation from new (or after fitting new belts), check belt

tension.

Check regularly after every 8 hours’ operation:

• Tighten bolts and nuts.

• Check wear and condition of flails.

• Check that the protection flaps may be blocked or damaged by the presence of

mud and stones or residuals of mown material. Should this be the case stop the

tractor immediately, clean and repair the protection flaps as necessary. Adjustmets

or maintenance work should only be carried out when the machine is stopped and

the tractor engine is switched off.

• Check belt stretch and condition.

• Visually check the frame and arms to detect possible damage caused by earlier

work.

• Check gearbox and extension lubricating levels.

• Grease the parts as shown on the appropriate decal (Figure 20).

Figure 20

This operation must always be carried out at the end of each working day . This

facilitates the removal of mud or other material from the rotating parts (bearing, pins,

etc.) in order to avoid rust and possible seizure.

• Every 100 hours’ operation, grease the moving parts of the PTO shaft, extracting

the two parts of the shaft.

• After long inactivity, repeat the operation before re-using the machine.

• Use grease such as AGIP GR MU EP/2 (classification DIN 51825 (KP 2 K).

To fill oil to level, use:

• For gearbox use oil AGIP BLASIA 220 or compatible oils (classification ISO VG

220).

• Amount of oil (at level) ,5 quarts.

17

Page 19

ZMT Owner’s Manual

8. TROUBLE SHOOTING CHART

PROBLEM CAUSE FIX

Irregular cut

Machine noise

Gearbox noise

Vibration

Premature flail wear

• Worn, bent or broken fails

• Machine is not level with

the ground

• Clogged material due to

excessive working speed

• Loose bolts

• Cracks or initiation of flail

head

• Lack of oil

• Worn gears

• Worn bearings

• Broken or worn flails

• Unbalanced rotor

• Worn rotor bearings

• Flails touching the ground

• Replace

• Level it by adjusting the

flail head hydraulic ram

• Reduce working speed

• Tighten bolts

• Have it repaired in

specialized workshop

• Fill to level

• Replace

• Replace

• Replace

• Have it replaced in

authorized workshop

• Have them replaced in

authorized workshop

• Adjust height of cut

Excessive backlash in the

arms & joints

Flail head lowers

involuntarily

Breakage of roller bearings

Belts overheating

18

• Worn pins

• Worn arm sliding blocks

• Worn glands in the rams

• Violent impact on the

ground when the arm is

lowered

• Dirty or little greased

bearings

• Flails touching the ground

• Working speed unsuitable

for amount of the material

to cut

• Belts slip on the pulleys

• Replace

• Adjust

• Replace glands in

authorized shop

• Lower it gently

• Clean and grease

• Adjust cut height

• Reduce speed

• Adjust belt tension

17

Page 20

ZMT Owner’s Manual

9 REPLACING PARTS

Before carrying out any work, it is mandatory to:

• Lower the shredder to the ground.

• Disconnect the power takeoff, stop the tractor and take out the ignition key.

• Wear working gloves.

Figure 21

9.1 Flail Replacement

When the flails are worn, they must all be

replaced. In case of a partially broken flail it is

advisable to replace the broken one and the

one diametrically opposite, in order to maintain

the balance (Figure 21).

9.2 Pipe Replacement

• Before working on the hydraulic system, bleed all pressure, working with the

engine stopped and using all control levers.

• Pay particular attention to cleanliness as dirt and dust can cause considerable

damage to the hydraulic system

• Replace any damaged pipes with genuine spare parts or with others of the same

specification; ensure that they are not kinked or twisted, remembering to check this

throughout the entire cycle of arm movement.

9.3 Pin Replacement

• Carry out this operation with the aid of a lift or hoist, to prevent detached

component from falling, and also to avoid upsetting the balance of the machine.

• When replacing parts, clean and grease their housings.

9.4 Belt Replacement

This operation must be carried out with the flail head touching the ground, the power

takeoff disconnected and the ignition key out.

• Remove the beltguard, loosen the screws (1) (Figure 14), unscrew the tightener

(2), remove the belts and replace them with similar ones for dimensions and type.

See 5.2 for registration.

IMPORTANT - More complex operations must be done in authorized workshops.

19

Page 21

ZMT Owner’s Manual

10 DEMOLITION, DIFFERENTIATED DIVISION OF THE MATERIALS AND DISPOSAL

If the machine is in need of disposal, all its parts that might be dangerous to the

enviroment have to be made safe. The materials on the machine that have to

undergo a differentiated division are:

• steel

• mineral oil

• rubber

• plastic

• electric system conductors

All the above modification operations and the final disposal have to be carried out in

total respect of the present provisions of law on the subject.

20

Loading...

Loading...