Page 1

OPERATOR’S

MANUAL

22860

Rev. 9/2001

TP 100-7040-01-AT-FD

with Blower Setup Instructions

FERRIS

Double & Triple Bag Grass Collection Systems

Double Bag Collection System for:

Ferris 1000Z Series - 48” & 52” Mowers

Derby Colt ZT2148 & ZT2352 - 48” & 52” Mowers

Ferris Industries

5375 North Main Street

Munnsville, NY 13409

800-933-6175

Triple Bag Collection System for:

Ferris IS3000Z Series - 61” Mower

Derby Stallion ZT2561 - 61” Mower

Page 2

Ferris Industries

5375 North Main Street

Munnsville, NY 13409

800-933-6175

www.ferrisindustries.com

© Copyright 2001 Ferris Industries

All Rights Reserved. Printed in USA.

FERRIS LIMITED WARRANTY

IMPORTANT

This warranty shall apply ONLY if the warranty registration form has been completed and

returned to Ferris Industries, Inc. within 20 days from the date of delivery.

Ferris Industries, Inc. (Ferris) warrants, in accordance with the provisions below, to the

original purchaser for the period of twenty-four (24) months from the date of delivery of a

Ferris mower that the mower is free from defects in material or workmanship. Ferris’ obligation under this warranty is to repair or replace, at Ferris’ election, without charge and at

the place of business of a dealer authorized to handle Ferris mowers, any part or par ts of

the machine which, in the judgment of Ferris, prove to be defective.

THIS WARRANTY AND FERRIS’ OBLIGATION HEREUNDER IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF

FITNESS FOR PARTICULAR PURPOSE, and all other obligations or liabilities of Ferris for

incidental and consequential damages resulting from the design, manufacture, sale or use

of the machine. No person is authorized to make any warranty or assume for Ferris any

liability not strictly in accordance with this warranty.

This warranty shall not apply to any mower par t which, in the judgment of Ferris, has been

altered or tampered with in any way or has been subjected to misuse, neglect or accident,

or has had the serial numbers altered, effaced or removed. This warranty does not apply

to component parts not manufactured by Ferris (motors, batteries, tires, belts) except to

the extent of their individual manufacturer’s guarantees.

Ferris Industries, Inc. is continually striving to improve its products, and therefore reserves

the right to make improvements or change when it becomes practical and possible to do

so, without incurring any obligation to make changes or additions to the equipment sold

previously.

FERRIS

Page 3

1

IINNIITTIIAALL IINNSSTTAALLLLAATTIIOONN && AASSSSEEMMBBLLYY

6611”” TTRRIIPPLLEE BBAAGG CCOOLLLLEECCTTIIOONN SSYYSSTTEEMM

BBLLOOWWEERR MMOOUUNNTT && DDRRIIVVEE GGRROOUUPP

Remove Discharge Chute................................10

Release Mower Drive Belt Tension..................10

Remove Guard & Spindle Pulley.....................10

Install Spindle Pulley........................................11

Install Guard & Blower Mount ..........................11

Blower Preparation..........................................12

Install Blower & Belt Guard..............................15

OOPPEERRAATTIINNGG WWIITTHHOOUUTT BBLLOOWWEERR

Reattaching Discharge Chute ..........................16

RREEFFEERREENNCCEE IINNFFOORRMMAATTIIOONN::

Torque Specification Chart .....Inside Back Cover

NOTE: In these instructions, “left” and “right” are

referred to as seen from the operating position.

© Copyright 2001 Ferris Industries, Inc.

All Rights Reserved. Printed in USA.

TP 100-7040-01-AT-FD

SSAAFFEETTYY RRUULLEESS && IINNFFOORRMMAATTIIOONN

General Warnings..............................................2

Safety Decals.....................................................2

GGEENNEERRAALL OOPPEERRAATTIINNGG IINNSSTTRRUUCCTTIIOONNSS

Mowing with the Double / Tr iple Catcher...........3

After Operation ..................................................3

Storing the Grass Catcher.................................3

Mowing Without the Blower...............................3

IINNIITTIIAALL IINNSSTTAALLLLAATTIIOONN && AASSSSEEMMBBLLYY

4488”” && 5522”” DDOOUUBBLLEE BBAAGG CCOOLLLLEECCTTIIOONN SSYYSSTTEEMM

BBLLOOWWEERR MMOOUUNNTT && DDRRIIVVEE GGRROOUUPP

Remove Discharge Chute..................................4

Release Mower Drive Belt Tension....................4

Remove Guard & Spindle Pulley.......................4

Install Spindle Pulley..........................................5

Install Guard ......................................................5

Mower Deck Preparation...................................5

Blower Preparation............................................7

Install Blower & Belt Guard................................9

Table of Contents

Model Description Name

Unit MODEL Number

PRODUCT REFERENCE DATA

Unit SERIAL Number

Dealer Name

Date Purchased

Page 4

2

Read and obey all operation and warning decals.

Safety Rules

& Information

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment. The triangle in text signifies important cautions or warnings which must be followed.

GENERAL WARNINGS

• Know the mower controls, safety rules and how to

stop quickly. READ AND UNDERSTAND THE

MOWER OPERATOR’S MANUAL.

• READ AND OBEY ALL SAFETY DECALS.

• Wear appropriate ear, eye and breathing protection.

• Only allow responsible adults, who are familiar with

the instructions, to operate the unit.

• Disengage the electric clutch (PTO). Shut off the

engine and wait for all moving parts to stop before

attaching, adjusting, or disconnecting any part of the

collection system.

• Check the collection system to make sure it is bolted

tightly to the rider.

• DO NOT operate the mower without either the entire

grass catcher or the deflector in place.

• Turn off the PTO switch to disengage the blades

when not mowing.

• DO NOT mow in reverse. Always look down and

behind before and while travelling in reverse.

• DO NOT turn sharply when travelling alongside a

building or any object. Slow down before turning.

• DO NOT carry passengers on the rider.

• When blower assembly is removed from the mower

deck, the deflector must be properly installed.

• If the mower stalls or the turbo blower chute plugs:

1. Disengage the electric clutch (PTO);

2. Stop the engine and remove the key;

3. Set the parking brake, and wait for all moving

parts to stop.

4. Remove the foreign object or clear the chute with

a piece of wood before restarting the engine.

NEVER PLACE HANDS INTO BLOWER HOUSING TO CLEAR JAMMED OBJECT. BLOWER

MAY ROTATE WHEN OBJECT IS REMOVED.

• For added rider stability and to prevent tipping or loss

of control:

a. Use reduced speed on uneven ground and when

turning corners.

b. Reduce loads on hillsides. It is recommended that

the collection system be kept only half full when

negotiating any slopes. Start mowing on slopes

when the collection system is empty.

c. Mow up and down the face of slopes; never

across the face of any slope.

• When operating on slopes, use front counterweights.

Never operate on slopes greater than 17.6% (10°).

SAFETY DECALS

This unit has been designed and manufactured to provide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment

manufacturing.

Although reading this manual and the safety instructions

it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effectively, we have placed several safety labels on the unit

to remind you of this important information while you are

operating your unit.

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below

are on your rider and mower.

If any of these decals are lost or damaged, replace them

at once. See your local dealer for replacements.

These labels are easily applied and will act as a constant visual reminder to you, and others who may use

the equipment, to follow the safety instructions necessary for safe, effective operation.

DANGER

ROTATING CUTTING BLADE

Do not operate mower

without deflector or entire

grass catcher in place.

1704277

Page 5

3

BEFORE OPERATION

Clear the lawn of all sticks, stones, wire and other debris

which may be caught or thrown by the mower blades.

Check grass condition. If wet, wait until later in the day.

If grass is wet, the grass catcher is likely to become

plugged.

For efficient bagging, air circulation under the

mower deck, through the chute and into the bag is

very important.

For this reason, BEFORE YOU BEGIN MOWING you

should make certain the underside of the mower and

the underside of the catcher lid are free from grass and

debris.

Make sure that there is a snug fit between mower

deck, blower housing, tubes, and grass catcher cover.

MOWING WITH THE DOUBLE /

TRIPLE CATCHER

Always operate with throttle at full speed when mowing.

Grass should be cut often, and not too short. If grass is

too long or lush it may be necessary to keep ground

speed to a minimum or to cut only half the width of the

mower to prevent clogging. If grass is long, operate with

mower in high cutting position for first pass, cutting

again in a lower position on a second pass.

Do not open the cover with mower engaged.

If a large amount of cut grass is spilling out from under

deck, the tube may be plugged or the bags may be

full— discontinue mowing, stop the rider, disengage the

PTO and then empty the catcher or clear the tube.

General

Operating Instructions

WARNING

ALWAYS shut off the tractor. disengage the PTO,

and allow all moving parts to stop BEFORE

disconnecting or clearing tube, or emptying

catcher.

Before leaving the operator’s position for any

reason, engage the parking brake, disengage the

PTO, stop the engine and remove the key.

To reduce fire hazard, keep the engine, rider and

mower free of grass, leaves and excess grease.

Do not stop or park rider over dry leaves, grass or

combustible materials.

AFTER OPERATION

Remove any debris from the the screen on the underside of the lid.

Note: The lid screen can be partially

removed for easier cleaning and should be cleaned regularly.

The blower housing and tube should be removed for

cleaning.

Inspect the grass bags for wear or damage. Make sure

that there is a snug fit between mower deck, blower

housing, tubes, and grass catcher cover.

STORING THE GRASS CATCHER

Clean the grass catcher thoroughly using a mild detergent (other products may damage the tube). Remove

any debris from the the screen on the underside of the

lid. The screen can be partially removed for easier

cleaning.

If paint has been scratched on metal parts, touch up

with paint, or apply a thin film of oil to prevent corrosion.

Store in a dry area. Hang the catcher and catcher bags

to dry thoroughly before storing for a long period of time.

Always store away from moisture.

MOWING WITHOUT THE BLOWER

For operation without the blower, the deflector must be

properly installed in the down position and retained by

the spring latch (Derby models only).

To remove the blower, reverse the installation steps.

Page 6

4

Initial

Installation & Assembly

Remove Discharge Chute

1. Park machine on a flat, level surface and apply the

parking brake.

2. Remove the discharge chute and save. Save

springs and spacer (Derby Colt only).

48” & 52” DOUBLE-BAG

COLLECTION SYSTEM BLOWER

MOUNT & DRIVE GROUP

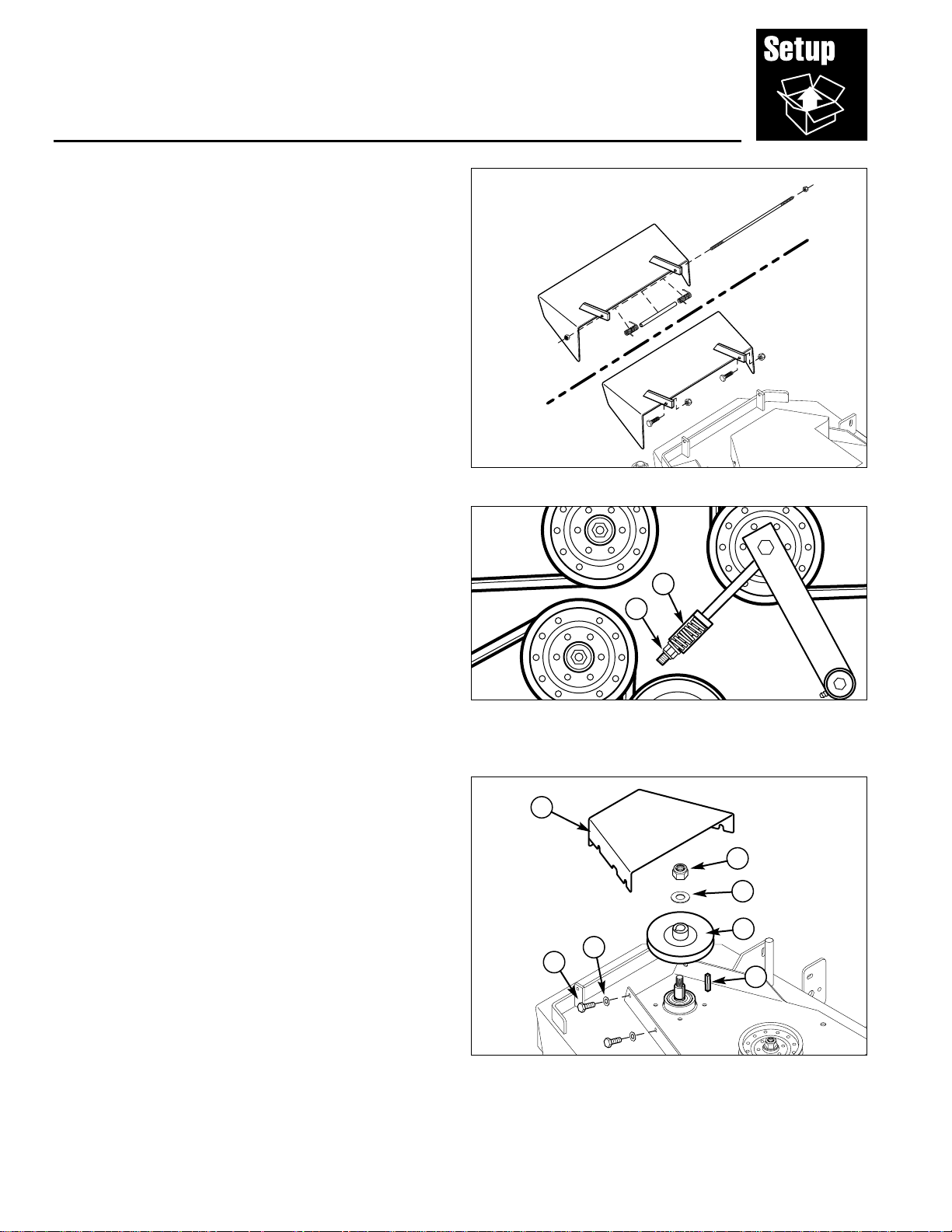

Figure 1. Chute Removal

Figure 3. Belt Guard & Pulley Removal

A. Guard E. Key

B. 5/8” Nylon Lock Nut F. 5/16” Washer (3)

C. 5/8” Washer G. 5/16” x 3/4” Bolt (3)

D. Spindle Pulley

Figure 2. PTO Mower Drive Belt

A. Spring Compression Nut

B. Idler Spring

Release Mower Drive Belt Tension

1. Raise the floor pan and loosen the spring compression nut (A, Figure 2) to release the belt tension.

Remove Guard & Spindle Pulley

1. Remove the right-hand belt guard (A, Figure 3) and

save.

2. Remove the mower deck drive belt from the righthand spindle pulley.

3. Remove the right-hand spindle pulley (D), 5/8” nylon

lock nut (B), 5/8” washer (C) and 1/4” key (E). Use a

block of wood to keep the blade from spinning while

removing the 5/8” nut.

B

A

A

B

C

D

E

G

F

Page 7

5

Install Spindle Pulley

1. Apply an anti-seize compound to the spindle shaft.

Install the new, double spindle pulley (C, FIgure 4)

on the shaft with the smaller pulley facing up with the

5/8” nylon lock nut (A), 5/8” washer (B) and 1/4” key

(D) and tighten to 85-95 ft./lbs. Use a block of wood

to keep the blade from spinning while installing and

tightening the 5/8” nut.

2. Reinstall the mower deck drive belt on the new spindle pulley. Tighten the spring compression nut (A,

Figure 2) until the idler spring (B, Figure 2) is 1-1/2”

long. Be sure the measure the spring only.

Figure 4. Install Spindle Pulley

A. 5/8” Nylon Lock Nut C. Spindle Pulley

B. 5/8” Washer D. Key

Figure 5. Install Guard

A. 5/16” Body Clip (2) C. 5/16” x 3/4” Bolt (3)

B. Guard D. 5.16” Washer (3)

Install Guard

1. Install the new deck guard (B, FIgure 5) and secure

with the 5/16-18 x 3/4” bolts (C) and 5/16” washers

(D) previously removed.

2. Install the 5/16” body clips (A) over the holes in the

guard with the threaded side pointing down.

Figure 6. Install Blower Mount

Mower Deck Preparation

1. Install the blower mount plate onto the chute mount

tabs, with the blower mount tabs towards the rear.

Secure with the retaining pin.

A

B

C

D

A

B

D

C

48” & 52” Blower Mount & Drive Installation

Page 8

6

2. While holding the mount plate vertical and against

the chute mount tabs, place the spacers on the

mower deck in the recesses of the mount plate.

Make sure they are at the bottom of the recess (see

Figure 7). Mark their location with a paint pen or

prick punch.

3. Remove the spacers and blower mount plate.

4. Drill 5/16” holes where the spacer location was

marked.

5. Install the spacers (C, FIgure 8) and mount bar (B)

on the mower deck and secure with the 5/16-18 x 11/4” bolts (D) and 5/16-18 nylon lock nuts (A).

Figure 7. Spacer Location

Figure 8. Install Quick Connect Bar

A. 5/16” Nylon Lock Nut (2) C. Spacer (2)

B. Quick Connect Bar D. 5/16” x 1-1/4” Bolt (2)

A

B

C

D

48” & 52” Blower Mount & Drive Installation

Page 9

7

Blower Preparation

1. Remove the belt guard (A, Figure 9) and hardware

(B & C) from the blower housing and set aside.

NOTE: Record the model and serial number of the

blower on the warranty registration card and in the

space provided on Page 1. The serial tag is located on

the outside face of the blower housing.

2. Fasten the idler arm assembly (G) to the blower

housing with 5/16-18 x 1-3/4” bolt (D), 5/16” fender

washer (E), pivot spacer (F) and 5/16-18 serrated

flange nut (H). Tighten securely.

Figure 10. Install Blower Mount Plate

A. Blower Mount Plate D. 5/16” x 3/4” Bolt (3)

B. 5/16” Self-Tap. Bolt (4) E. 5/16” Nylon Lock Nut (5)

C. 5/16” x 1” Bolt (2)

Figure 9. Idler Arm Installation

A. Belt Guard E. 5/16” Fender Washer

B. 5/16-18 x 1” Bolt F. Pivot Spacer

C. 5/16” Washer G. Idler Arm Assembly

D. 5/16-18 x 1-3/4” Bolt H. 5/16-18 Flange Nut

3. Remove the two 7/16” bolts and hex nuts from the

inside bearing. Remove the bearing from the blower

housing and discard the two hex nuts.

4. Install the blower mount plate (A, Figure 10) onto the

back plate of the blower. Install the 5/16-18 x 3/4”

self-tapping bolts (B), but do not tighten until all

screws have been started. Tighten securely.

5. Install three 5/16-18 x 3/4” bolts (D) near the bearing. Install the two 5/16-18 x 1” bolts (C) in the two

remaining holes. Note the direction of the bolts, this

is critical. Secure with the 5/16-18 nylon lock nuts

(E) as shown.

A

B

C

D

E

F

G

H

A

C

C

E

E

B

E

B

D

48” & 52” Blower Mount & Drive Installation

Page 10

8

Figure 11. Install Bearing & Eyebolt

A. 7/16” x 1-1/2” Capscrew (4) E. 1/4” Washer

B. Bearing F. 1/4” x 1” Eyebolt

C. 7/16” Nylon Lock Nut (4) G. Spring

D. 1/4-20 Nylon Lock Nut H. 5/16-18 Nylon Lock Nut

Figure 12. Install Blower Pulley & Guide Bolt

6. Install the bearing (B, Figure 11) on the shaft with

the grease fitting pointing towards the discharge of

the blower. Secure with the 7/16-14 x 1-1/2” bolts

(A) and 7/16-14 nylon lock nuts (C) as shown.

Tighten the setscrew in the collar of the bearing.

7. Install the spring (G) on the bolt of the idler arm and

secure with a 5/16-18 nylon lock nut (H). Only tighten the nut until the threads come through the nylon.

Do not clamp spring.

8. Hook the spring on the eyebolt (F). Install the eyebolt and 1/4” washer (E) on the blower mount plate

and secure with the nylon nut (D) as shown. The

nylon nut (D) must be fully tightened so the eyebolt

is drawn up tight against the mount. The eyebolt

must be vertical.

9. Install the blower pulley and key with the hub facing

INWARD towards the bearing, and hold against the

bearing. Tighten set screws.

10.Install one 3/8-16 flange nut on the 3/8-16 x 6” bolt

and tighten against the end of the threads (see

Figure 12). Install drive belt on the drive pulley and

install the 3/8-16 x 6” bolt. Leave enough space

between the belt and bolt so it will not interfere.

Secure the bolt with a 3/8” serrated flange nut.

A

B

C

D

E

F

G

H

48” & 52” Blower Mount & Drive Installation

11.Loosen the idler pulleys and install the belt under the

belt keeps. Make sure the groove of the belt is properly seated in the v-pulleys (see Figure 13, the gray

section is the flat side of the belt). Reposition the

belt keeps so they will not interfere with the drive belt

and tighten the idler pulleys.

Figure 13. Belt Routing

Page 11

9

Figure 14. Install Blower & Belt Guard

Install Blower & Belt Guard

1. Install the blower onto the chute mount tabs with the

blower mount tabs towards the rear. Secure with the

retainer pin and hair pin. Make sure the handle of

the retaining pin is pointing down.

2. Pull the idler arm lever against the spring to install

the drive belt on the spindle pulley. The tension idler

should be approximately 3/4” - 1” away from the

blower housing when belt in installed. If not, remove

the drive belt and reposition the top idler pulley in the

outside row of holes until the measurement is

achieved.

3. Install the blower belt shield and secure with the

5/16” x 1” bolts and 5/16” washers.

4. Install the guard cover and secure with the plastic

knobs.

48” & 52” Blower Mount & Drive Installation

Page 12

10

Initial

Installation & Assembly

Remove Discharge Chute

1. Park machine on a flat, level surface and apply the

parking brake.

2. Remove the discharge chute and save. Save

springs and spacer (Derby Stallion only).

Release Mower Drive Belt Tension

1. Raise the floor pan and loosen the spring compression nut (A, Figure 20) to release the belt tension.

Remove Guard & Spindle Pulley

1. Remove the right-hand belt guard (A, Figure 21) and

save. Remove and discard the two front 5/16-18 x

1” bolts (G), 5/16” washers (F) and 5/16” body clips.

2. Remove the mower deck drive belt from the righthand spindle pulley.

3. Remove the right-hand spindle pulley (D), 5/8”: nylon

lock nut (B), 5/8” washer (C) and 1/4” key (E). Use a

block of wood to keep the blade from spinning while

removing the 5/8” nut.

Figure 19. Chute Removal

Figure 20. PTO Mower Drive Belt

A. Spring Compression Nut

B. Idler Spring

61” TRIPLE-BAG COLLECTION

SYSTEM

BLOWER MOUNT & DRIVE GROUP

B

A

Figure 21. Belt Guard & Pulley Removal

A. Guard E. Key

B. 5/8” Nylon Lock Nut F. 5/16” Washer (3)

C. 5/8” Washer G. 5/16-18 x 1” Bolt (3)

D. Spindle Pulley

A

B

C

D

E

G

F

Page 13

11

Install Spindle Pulley

1. Apply an anti-seize compound to the spindle shaft.

Install the new, double spindle pulley (C, Figure 22)

on the shaft with the smaller pulley facing up with the

5/8” nylon lock nut (A), 5/8” washer (B) and 1/4” key

(D) and tighten to 85-95 ft./lbs. Use a block of wood

to keep the blade from spinning while installing and

tightening the 5/8” nut.

2. Reinstall the mower deck drive belt on the new spindle pulley. Tighten the spring compression nut (A,

Figure 20) until the idler spring (B, Figure 20) is 11/2” long. Be sure the measure the spring only.

Install Guard & Blower Mount

1. Loosely install the 3/8-16 x 1-1/4” bolts (D, FIgure

23), 3/8” washers (E), blower mount bar (C), belt

guard (A) and nut bar (F) onto the mower deck.

These fasteners will be tightened in a later step.

2. Install the 5/16” body clips (B) on the belt guard.

The front body clip is install from underneath the

guard.

Figure 22. Install Spindle Pulley

A. 5/8” Nylon Lock Nut C. Spindle Pulley

B. 5/8” Washer D. Key

Figure 23. Install Blower Mount Bar & Belt Shield

A. Belt Guard D. 3/8-16 x 1-1/4” Bolts

B. 5/16” Body Clip E. 3/8” Washer

C. Blower Mount Bar F. Nut Bar

A

B

C

D

A

B

C

E

D

F

61” Blower Mount & Drive Installation

Page 14

12

61” Blower Mount & Drive Installation

Blower Preparation

1. Remove the belt guard (A, Figure 24) and hardware

(B & C) from the blower housing and set aside.

NOTE: Record the model and serial number of the

blower on the warranty registration card and in the

space provided on Page 1. The serial tag is located on

the outside face of the blower housing.

2. Fasten the idler arm assembly (G) to the blower

housing with 5/16-18 x 1-3/4” bolt (D), 5/16” fender

washer (E), pivot spacer (F) and 5/16-18 serrated

flange nut (H). Tighten securely.

3. Remove the top stationary idler pulley (I) and replace

in the middle hole of the inside row of holes. Tighten

securely.

Figure 25. Install Blower Mount Plate

A. Mount Plate

B. 5/16-18 x 3/4” Self-Tapping Bolts

C. 5/16-18 x 3/4” Bolts

D. 5/16-18 Nylon Lock Nuts

Figure 24. Idler Arm Installation

A. Belt Guard F. Pivot Spacer

B. 5/16-18 x 1” Bolt G. Idler Arm Assembly

C. 5/16” Washer H. 5/16-18 Flange Nut

D. 5/16-18 x 1-3/4” Bolt I. Idler Pulley

E. 5/16” Fender Washer

A

B

C

D

E

F

G

H

3. Remove the two 7/16” bolts and hex nuts from the

inside bearing. Remove the bearing from the blower

housing and discard the two hex nuts.

4. Install the blower mount plate (A, Figure 25) onto the

back plate of the blower. Install the four 5/16-18 x

3/4” self-tapping bolts (B), but do not tighten until all

screws have been started. Tighten securely.

5. Install two 5/16” x 3/4” bolts (C) near the bearing.

Secure with the 5/16” nylon lock nuts (D) as shown.

A

C

D

B

B

I

Page 15

13

Figure 26. Install Bearing & Spring

A. 7/16-14 x 1-1/2” Bolt E. 5/16-18 Flange Nut

B. Bearing F. 5/16-18 Nylon Lock Nut

C. 7/16-14 Nylon Lock Nut G. Spring

D. 5/16-18 x 1-1/4” Bolt

Figure 27. Install Support Rail & Spring

A. Deck Support Rail C. Spring

B. 5/16-18 x 3/4” Bolt D. 5/16-18 Nylon Lock Nut

6. Install the bearing (B, Figure 26) on the shaft with

the grease fitting pointing towards the discharge of

the blower. Secure with the four 7/16 x 1-1/2” bolts

(A) and 716-14 nylon lock nuts (C) as shown.

Tighten the setscrew in the collar of the bearing.

7. Install the 5/16” x 1-1/4” bolt (D), 5/16” serrated

flange nut (E) as shown and tighten.

8. Install the spring (G) on the 5/16” bolt (D) on the

blower mount and install the 5/16” nylon lock nut (F).

Only tighten the nuts until the threads come through

the nylon. Do not clamp spring.

9. Install the deck support rail (A, Figure 27) and fasten

with the 5/16-18 x 3/4” bolts (B) and 5/16-18 nylon

lock nuts (D) as shown. Note the direction of the

bolts, this is critical.

10.Install the spring (C) on the idler arm and secure with

the 5/16” nylon lock nut (D). Only tighten the nut

until the threads come through the nylon. Do not

clamp spring.

A B

C

D

E

F

G

A

B

B

B

D

C

D

D

D

61” Blower Mount & Drive Installation

Page 16

14

Figure 28. Install Blower Brace

A. Blower Brace

B. 3/8-16 x 1” Bolt

C. 3/8” Washer

Figure 29. Install Blower Pulley & Guide Bolt

11.Loosely install the blower brace (A, Figure 28), 3/816 x 1” bolts (B) and 3/8” washers (C) as shown.

These fasteners will be tightened in a later step.

12.Install the blower pulley and key with the hub facing

OUTWARD away from the bearing and hold against

the bearing. Tighten set screws.

13.Install one 3/8-16 flange nut on the 3/8-16 x 6” bolt

and tighten against the end of the threads (see

Figure 29). Install drive belt on the drive pulley and

install the 3/8-16 x 6” bolt. Leave enough space

between the belt and bolt so it will not interfere.

Secure the bolt with a 3/8” serrated flange nut.

B

C

A

B

C

61” Blower Mount & Drive Installation

Figure 30. Belt Routing

14.Loosen the idler pulleys and install the belt under the

belt keeps. Make sure the groove of the belt is properly seated in the v-pulleys (see Figure 30, the gray

section is the flat side of the belt). Reposition the

belt keeps so they will not interfere with the drive belt

and tighten the idler pulleys

Page 17

15

Figure 31. Install Blower

A. 3/8-16 x 1” Bolt D. 3/8-16 Flange Nut

B. Mount Bar E. 3/8-16 x 1” Bolt

C. 3/8-16 X 1” Bolt

Figure 32. Install Belt Shield & Clevis Pin

A. 3/8” x 4” Clevis Pin D. Belt Shield

B. Plastic Cap E. Plastic Knob

C. Hair Pin Clip

Install Blower & Belt Guard

1. Install the blower assembly onto the mount bar (B,

Figure 31). Push on the blower from the outside to

obtain a tight fit between the blower housing and

mower deck. Tighten the 3/8” x 1” bolts (C) that fasten the mount bar to the mower deck.

2. Drill a 3/8” hole through the mount flange of the

blower mount bar and secure with a 3/8-16 x 1” bolt

(E) and 3/8-16 flange nut (D).

3. Adjust the blower brace until approximately 1/8”

clearance is obtained between the brace and the

chute mount bar. Tighten the 3/8-16 x 1” bolts (A).

4. Install the 3/8” x 4” clevis pin (A, Figure 32) and hair

pin clip (C) as shown.

5. Install the plastic cap (B) in the end of the blower

mount bar.

6. Pull the idler arm lever against the spring to install

the drive belt on the spindle pulley. The tension idler

should be approximately 3/4” - 1” away from the

blower housing when belt in installed. If not, remove

the drive belt and reposition the top idler pulley in the

inside row of holes until the measurement is

achieved.

7. Install the blower belt shield and secure with the

hardware previously removed.

8. Install the deck belt shield (D) and secure with the

plastic knobs (E).

B

D

E

A

C

D

E

A

B

C

61” Blower Mount & Drive Installation

Page 18

16

Discharge Chute Reattachment

MOWING WITHOUT THE BLOWER

For operation without the blower, the deflector must be

properly installed in the down position and retained by

the spring latch (Derby models only).

To remove the blower, reverse the installation steps.

Reattaching the Discharge Chute

See Figure 33. Using the retainer pin and hair pin clip,

secure the discharge chute to the mower deck. Make

sure the chute mount tabs are in front of the tabs on the

mower deck. For the Derby mowers, you must also

reinstall the torsion springs and spacer to properly retain

the discharge chute.

Figure 33. Discharge Chute Reattachment

A. Discharge Chute

B. Retainer Pin

C. Hair Pin Clip

D. Torsion Spring

E. Spacer

A

B

C

D

E

D

Page 19

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

SAE Grade 2 SAE Grade 5 SAE Grade 8

Size Of

in/lbs in/lbs

in/lbs

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32

19

2.1

30

3.4

41

4.6

8-36

20

2.3

31

3.5

43

4.9

10-24

27

3.1

43

4.9

60

6.8

10-32

31

3.5

49

5.5

68

7.7

1/4-20

66

7.6 8 10.9 12 16.3

1/4-28

76

8.6 10 13.6 14 19.0

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0 420 571.2

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

NOTES

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

Hardware Identification & Torque Specifications

Common Hardware Types

3/8” Bolt or Nut

Wrench—9/16”

3/8

5/16” Bolt or Nut

Wrench—1/2”

5/16

1/4” Bolt or Nut

Wrench—7/16”

1/4

1/2” Bolt or Nut

Wrench—3/4”

1/2

DIA.

7/16

DIA.

7/16” Bolt or Nut

Wrench (Bolt)—5/8”

Wrench (Nut)—11/16”

Wrench & Fastener Size Guide

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

Nominal size

, meaning the

inside diameter

is 1/2 inch; if a

second number is present it represent the

threads per inch

When bolt or capscrew is identified as 1/2 - 16 x 2”, this

means the

Nominal size

, or

body diameter

is 1/2 inch; the

second number represents the

threads per inch

(16 in this

example, and the final number is the

body length

of the

bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

Hex Head Capscrew

Carriage Bolt

0

1/4 3/4

1/2

1

1/4 3/4

1/2

Nut, 1/2”

Screw, 1/2 x 2

2

1/4 3/4

1/2

3

1/4 3/4

1/2

4

Body

Diameter

Body

Length

Washer

Lockwasher

Hex Nut

Inside

Diameter

No

Marks

Loading...

Loading...