FERRI TR Series, TR13, TR22, TRM Series, TRM18 Maintenance And Use Manual

MAINTENANCE AND USE MANUAL

TRM

UM0015-01-00EN

Machine

TR

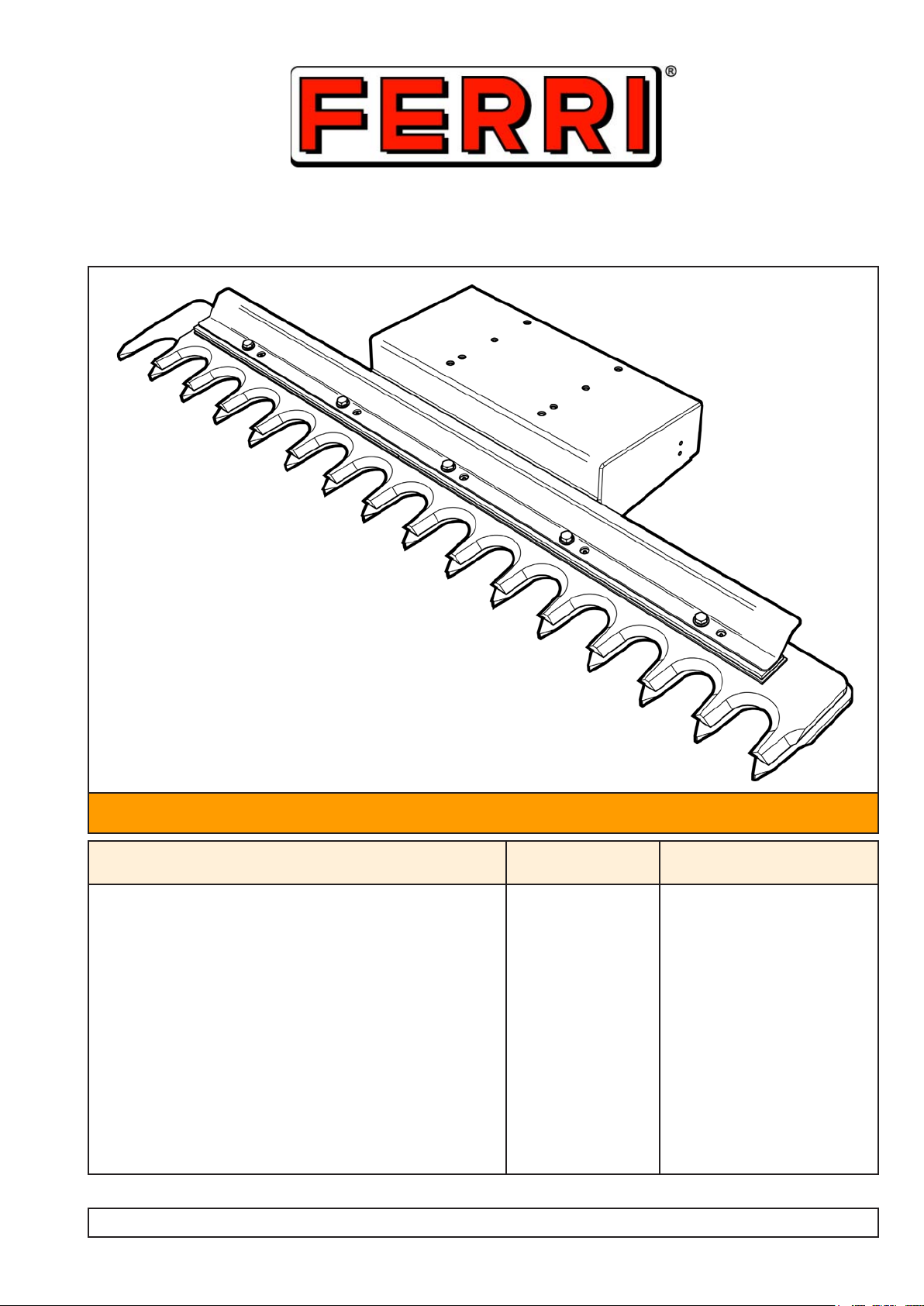

CUTTER BAR

Serial number

02

01

ENGLISH

Model

13

22

18

Rev. 01.00

Rev. 01.00

1 GENERAL INFORMATION 9

Index

1.1 Introduction and purpose of the manual

1.1.1 Addressees .............................................................................................................................................................9

1.1.2 Conservation .........................................................................................................................................................10

1.1.3 Information on the machine...................................................................................................................................10

1.2 Machineidentication 10

1.3 Spare parts 1

1.4 Term ‘right’ and ‘left’ 1

2 TECHNICAL CHARACTERISTICS 13

2.1 General description of the machine 1

2.1.1 Intended uses........................................................................................................................................................13

2.1.2 Contraindications .................................................................................................................................................13

2.2 Description of the parts 14

2.3 Technicalspecications 1

2.4 Noise 1

3 SAFETY RULES 17

3.1 General safety rules 1

3.2 Safetyrulesconcerningroadtrafc 2

3.3 Safety rules during use 2

3.3.1 To the new operator or owner ...................................................................................................................................22

3.4 Safety rules concerning the hydraulic system 22

3.5 Driver equipment and protections 2

3.5.1 Maintenance safety ............................................................................................................................................... 24

3.6 Operating hazard area 25

3.7 Danger 2

3.8 Safety signs 2

3.8.1 Replacing Safety signs..........................................................................................................................................25

3.8.2 Description and location of the safety decals ........................................................................................................26

9

1

1

3

4

5

7

0

1

3

5

5

4 INSTRUCTIONS FOR INSTALLATION AND HANDLING 29

4.1 Lifting 2

4.2 Connecting the cutter bar 3

4.2.1 Open circuit ........................................................................................................................................................... 30

4.2.2 Closed circuit.........................................................................................................................................................31

4.3 Field operation 31

4.4 Parking or storage 3

4.4.1 Storage safety ....................................................................................................................................................... 33

4.5 Machine start up after a long parking period 33

5 ADJUSTMENTS 35

5.1 Change-over valve setting adjustment 3

5.2 Cutter bar blade stroke adjustment 3

5.3 Blade change-over speed adjustment 3

5.4 Working speed adjustment 3

6 USE AND OPERATING RULES 39

6.1 Controls 3

6.2 Starting 3

6.3 Working mode 4

9

0

2

5

6

7

7

9

9

0

TR-TRM

3

Rev. 01.00

6.4 Stopping 41

6.5 Transport position 4

7 ORDINARY MAINTENANCE 43

1

7.1 Greasing 4

7.2 Trouble shooting chart 4

8 EXTRAORDINARY MAINTENANCE 47

8.1 Pipe replacement 4

8.2 Replacing the cutting blades 4

9 SCRAPPING AND ELIMINATION 49

10 GUARANTEE 50

10.1 Cancellation of the Guarantee 5

5

6

7

8

0

4

TR-TRM

Rev. 01.00

5

TR-TRM

DECLARATION OF CONFORMITY - Type “B”

The Company:

FERRI s.r.l. - Via C.Govoni, 30 - 44030 Tamara (FE) - Italy

Tel. +39-0532.866866 - Fax +39-0532.866851

http://www.ferrisrl.it

e-mail: info@ferrisrl.it

Declares under its own responsibility that the machine:

CUTTER BAR

Series ________________

Serial no________________

Complies with following European Directives:

98/37/CE (Wich abrogates and includes the Directives 89/392/CEE, 91/368/CEE,

93/44/CEE and 93/68/CEE)

For the tting of the machines, the following harmonized Directives have been adapted in as much as is possible:

UNI EN 1553 2001

and the technical speci cations:

ISO 11684 1995

The legal representative

Signed___________________

The machine cannot be used unless it is coupled to a machine that supports it and it must be declared to comply with

the Machines Directive and marked “CE” by the final assembler.

Rev. 01.00

PRECAUTIONARY STATEMENTS

PERSONAL SAFETY

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION”, “WARNING”, and “DANGER”)

followed by specific instructions. These precautions are intended for the personal safety of you and those working with you. Please

take the time to read them.

THE WORD “CAUTION” IS USED WHERE A SAFE BEHAVIORAL PRACTICE ACCORDING TO

OPERATING AND MAINTENANCE INSTRUCTIONS AND OTHERS FROM ACCIDENT INVOL-

CAUTION

WARNING

VEMENT.

THE WORD “WARNING” DENOTES A POTENTIAL OR HIDDEN HAZARD WHICH HAS A PO-

TENTIAL FOR SERIOUS INJURY OR POSSIBLE DEATH.

IT IS USED TO WARN OPERATORS AND OTHERS TO EXERCISE EVERY APPROPRIATE

MEANS TO AVOID A SURPRISE INVOLVEMENT WITH MACHINERY.

THE WORD “DANGER” DENOTES A FORBIDDEN PRACTICE IN CONNECTION WITH A SE-

RIOUS HAZARD IMMINENT DEATH OR CRITICAL INJURY.

DANGER

FAILURE TO FOLLOW THE “CAUTION”, WARNING”, AND “DANGER” INSTRUCTIONS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH.

TR-TRM

7

Rev. 01.00

PREFACE

To work in safety you must:

Apply the general precautions for the use of all mechanical means as set out in Chap. 3;

1)

Always follow the instructions for use given in the USE and MAINTENANCE manual or, in the case of particularly complex equi-

2)

pment, follow specific courses offered by manufacturers, dealers, technical assistants, etc.;

Do not remove, tamper with or modify any part of the machine if this is not contemplated in the use and maintenance ma-

3)

nual;

Repair or replace the guards and any worn or broken parts following the indications given in the use and maintenance ma-

4)

nual;

Ensure that the safety decals showing the warning signals are kept in good condition;

5)

Carry out maintenance on the machine according to the instructions given in the use and maintenance manual;

6)

Check that the safety regulations required by law are respected and, if they are not, apply to specialised technical personnel

7)

(manufacturers, dealers, technical assistants, etc.).

Keep all the guards in perfect working order.

8)

IMPORTANT WARNING:

All the technical precautions, as regards safety against thrown objects, adopted in the design

of machines (at the present state of the art they are the same for all manufacturers) do not

allow absolute safety to be achieved.

WARNING

There unfortunately remains a residual risk that cannot be eliminated and which, besides

depending on the probabilistic nature of the trajectory of the cut material, is inherent to the

particular nature of operation of the machines.

So it may happen that, even during appropriate use of the machine, small stones, chips or

other material may escape the protective barriers and be thrown far away.

It is therefore absolutely obligatory that there be NO ONE IN THE RANGE OF ACTION OF

THE MACHINE (AT LEAST 50 YARDS) DURING ITS OPERATION.

In particular, it is recommended to take great care when working near roads and/or buildings.

CAUTION

Before assembling any machine with electric/electro-hydraulic controls and/or heat exchanger on the

tractor YOU MUST read the assembly instructions on the electrical connections.

Failure to observe the said instructions faithfully may result in considerable damage to the electrical system, thereby invalidating the warranty of the same.

8

TR-TRM

Rev. 01.00

GENERAL INFORMATION

1 GENERAL INFORMATION

1.1 Introduction and purpose of the manual

This manual aims to explain the correct use of the machine and to supply the client with all the necessary information for using

the machine as independently and safely as possible. It includes details on technical aspects, machine function, maintenance,

spare parts and safety.

Before carrying out any operation on the machine, the operators and qualified technicians must have carefully read the instructions outlined in this manual.

In case of any doubt as to the correct interpretation of the instructions, please ask the machine Manufacturer for clarifications.

Please read this use and maintenance manual carefully and take careful note of the instructions provided before using or checking the machine.

In case any of the texts or tables are difficult to understand or the diagrams/drawings are unclear, please contact FERRI Srl directly

for clarifications from use/maintenance experts or the authors of this manual.

FERRI srl is at the disposition of users, the sales department and any other interested party for improving the understanding of the

whole manual.

This manual contains the rules for operation, routine maintenance, special maintenance and troubleshooting for the machine

produced by FERRI srl.

FERRI srl is continually striving to improve its product. We reserve the right to make improvements or changes when it

becomes practical and possible to do so, without incurring any obbligation to make changes or additions to the equipment sold previously.

This Manual has been drawn up according to the regulations in force at the time of printing.

It is an integral part of the machine and must accompany it together with the Declaration of

CAUTION

This manual supplies all the information for the use and maintenance of the machine. Its good operation and duration will depend

on correct maintenance and care during use.

Some illustrations in this manual show details or accessories that may be different from those on your machine; some

components may have been removed to ensure that the illustrations are clear.

The topics dealt with in this manual are those expressly requested by “Directive 98/37/CE” which abrogates and includes Directives

89/392/EEC, 91/368/EEC, 93/44/EEC and 93/68/EEC.

CAUTION

Conformity if it is sold.

It is recommended to use only genuine spare parts and accessories.

Besides invalidating the guarantee, spare parts that are not genuine could be dangerous,

reducing the working life and performance of the machine.

1.1.1 Addressees

The manual is for both operators and maintenance technicians of the machine.

Drivers must not carry out operations meant for maintenance technicians or qualified technicians.

The constructor is not responsible for any damage caused by non-observance of this regulation.

The information contained in this manual is addressed to professional users who must have specialized knowledge on how to

drive the tractor to which the machine is connected and who must have authorization and the correct qualifications to do so.

The technical information contained in this manual is property of FERRI srl and must be considered reserved information.

TR-TRM

9

Rev. 01.00

10

TR-TRM

GENERAL INFORMATION

1.1.2 Conservation

The use and maintenance manual must be kept close to the machine and away from liquids and any other substance which

could cause it to become illegible.

This manual, together with the declaration of conformity, must be considered an integral part of the machine supplied by FERRI

srl and it must accompany the machine until it is demolished. If it is not delivered with the machine or if it is lost, you must apply

to FERRI srl for a new copy, which will be sent to you in the shortest time possible. This manual contains regulations for use, ordinary

maintenance, extraordinary maintenance and troubleshooting for the machine produced by FERRI srl.

1.1.3 Information on the machine

The materials used by FERRI srl to construct the machine have been selected according to the specific use for which the machine has been designed and made (see par. 2.1.1): any substantially different uses may cause harm to persons and things

and may be detrimental to the good operation of the machine. The respect of and strict conformity with the conditions of use,

repair and maintenance, as specified below in this manual, are essential elements which form part of the intended use. The use

of the machine for activities not contemplated in the design stage and not listed in this manual relieves FERRI srl of all direct or

indirect responsibility. Any arbitrary modification made to this machine relieves FERRI srl of all responsibility for damage or injuries,

even of a serious nature, which may occur to the operators, to third parties and to things. Correct use of the machine, scrupulous

observation of the rules listed here and the strict application of all the precautions to prevent any situations of danger, will avoid

the risk of accident or injury, while allowing the machine to work better and longer and reducing breakdowns to a minimum.

FERRI srl declines all objective responsibility if the rules referred to in the machine are not

applied and respected.

CAUTION

If you have any question npt answered in this manual or require additional copies or the manual is damaged, please contact

your Dealer or

FERRI srl, Via C.Govoni, 30 - 44030 Tamara (Fe) - Italia.

Tel. +39 0532 - 866.866

Fax. +39 0532 - 866.851

e-mail: info@ferrisrl.it

1.2 Machineidentication

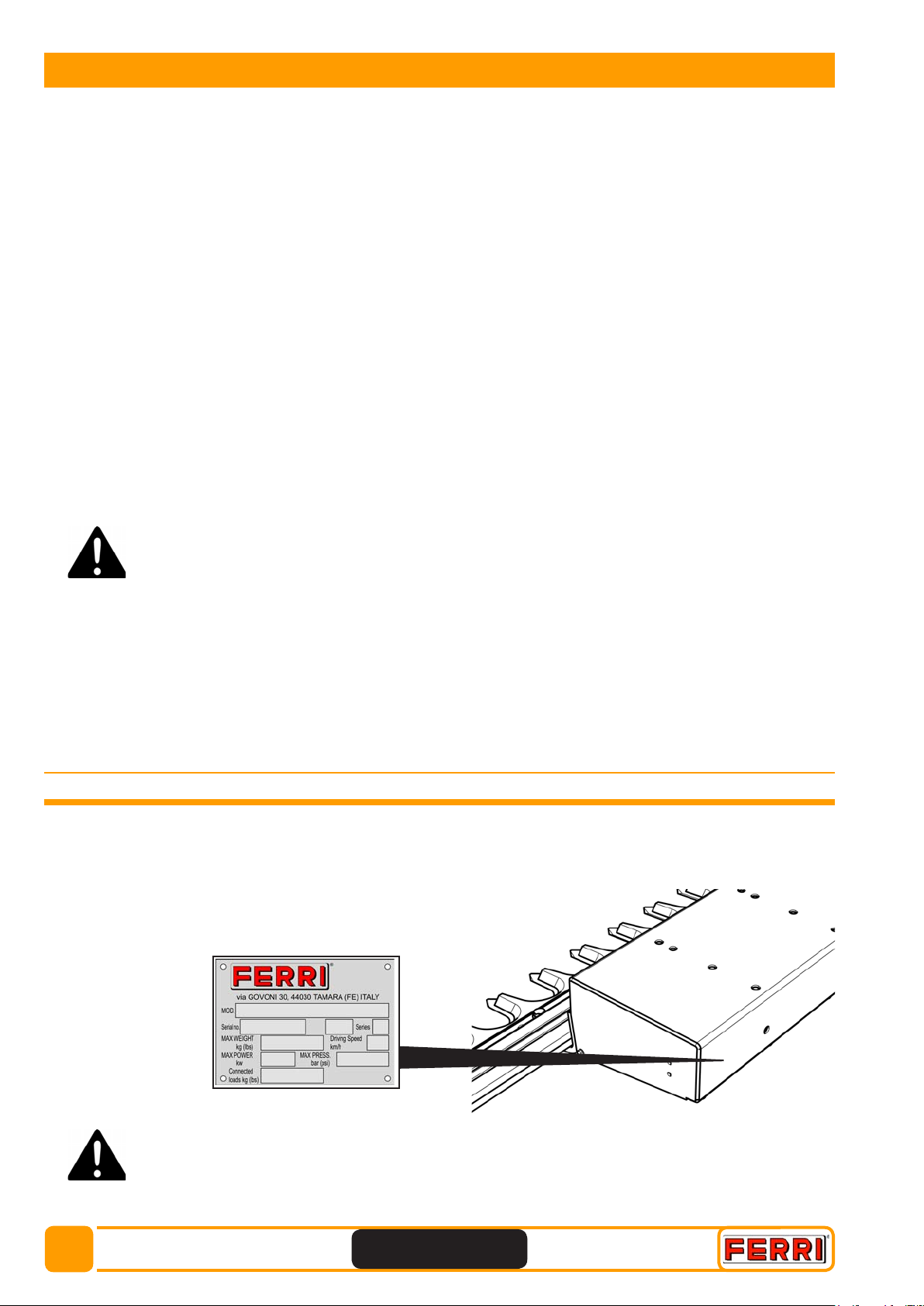

On the frame of each machine there is an identity plate (Fig.1.1) showing the CE stamp, the dates of Manufacturer, the series number, the construction year, the machine weight, the transmission power and the maximum hydraulic pressure of the machine.

FIG. 1.1

CAUTION

The data given on the identication plate are indispensable whenever asking for spare parts.

Rev. 01.00

GENERAL INFORMATION

1.3 Spare parts

It is strongly recommended to use genuine “FERRI” spare parts to avoid altering the technical features of the machine.

FERRI is not responsible for any damage or injuries to the machine, persons or things due to unauthorized modifications.

1.4 Term ‘right’ and ‘left’

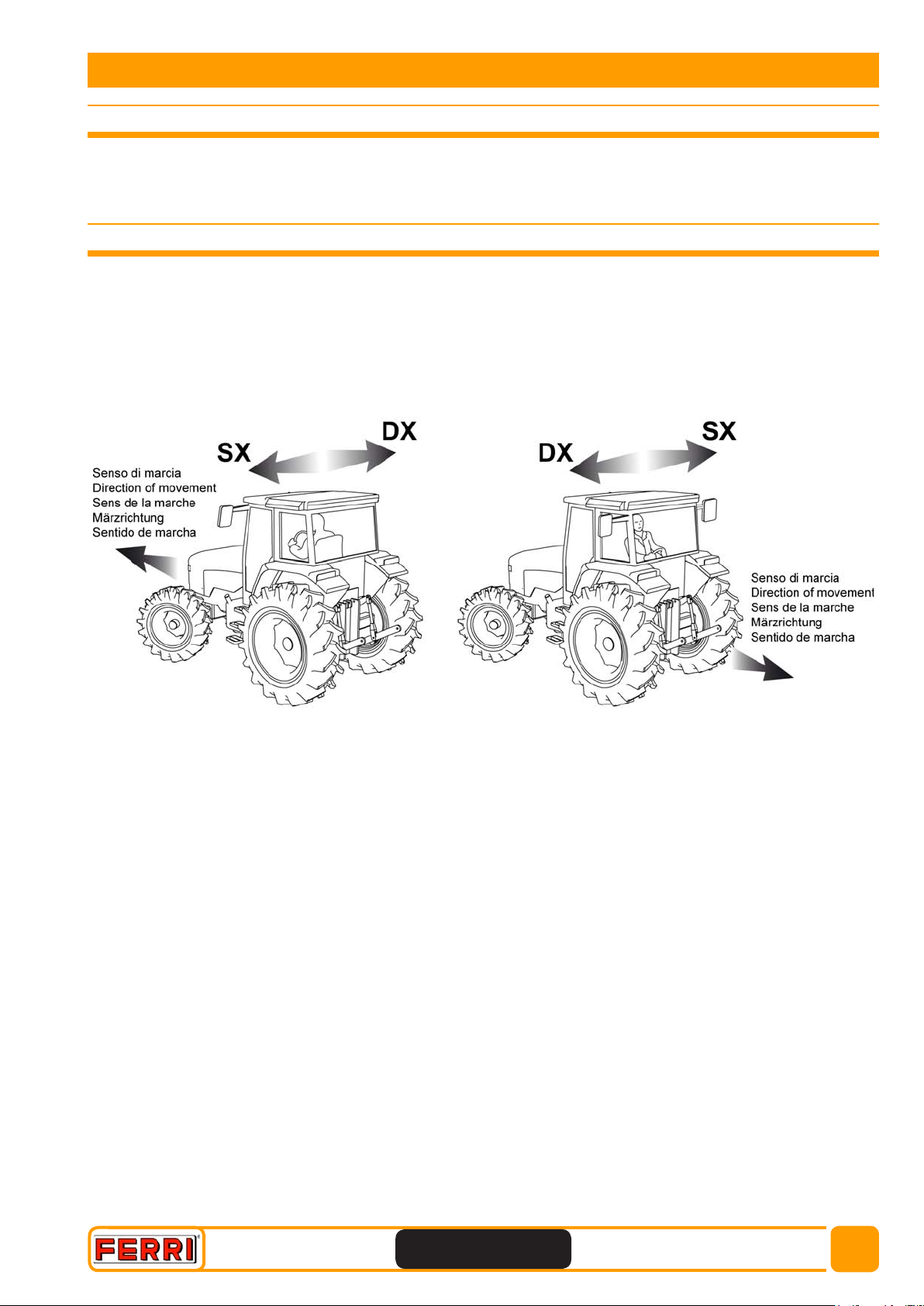

With relation to the direction of movement while working, it is called “right machine” if the machine, while working, protrudes on

the right-hand side and “left machine” on the left-hand side. (See FIG. 1.2 also with the machine fitted on a tractor with reversible

drive FIG. 1.3).

FIG. 1.2 FIG. 1.3

TR-TRM

11

Rev. 01.00

TECHNICAL CHARACTERISTICS

2 TECHNICAL CHARACTERISTICS

2.1 General description of the machine

The CUTTER BAR, of TR and TRM series, has been designed, built and protected for use exclusively in the agricultural sector (for

contraindications of use see paragraph 2.1.2). In the design and construction, all the necessary measures were taken to give a

high-quality, reliable product, fully complying with the regulations in force and particular with accident prevention.

The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance

of accidents.

2.1.1 Intended uses

The machine was designed, constructed, and provided with protective devices to be used exclusively in the agricultural sector

for the cutting and pruning of hedges, bushes, and tree branches to a maximum diameter of 8 cm (TR series) or 5 cm (TRM

series).

The machine is applied to the end of a jointed arm (mounted on a tractor, triad, loading shovel, excavator, etc, referred to from

now on simply as “tractor”) by adjusting the field of work using a hydraulic ram positioned on the arm itself. These machines are

constructed from a structure in which the working element is formed by 2 appropriately shaped blades - one fixed stationary to

the frame and the other movable – that create shearing movement.

The machine is not indicated for use in sectors other than agriculture and road maintenance.

The machine must be used by only one operator

Any use other than that specied is considered improper

WARNING

FERRI srl declines all responsibility if the safety decals supplied with the machine are missing, illegible or shifted from their original

position.

If any decal is damaged or missing, you must ask to be sent a new one, quoting the machine identification data given on the

data plate.

This machine is usually used in daytime.

In conditions of reduced visibility, the tractor’s lighting system must be used.

If exceptional night-time use is required, an auxiliary lighting system must be provided in order to guarantee good visibility in the

whole work area without dangerous reflections for the operator, in addition to sufficient lighting in the cabin in order to guarantee

identification of the controls.

2.1.2 Contraindications

The principal contraindication for use of the CUTTER BAR are listed below:

make sure that the bushes are free from any and all metallic material such as bits of fencing, cable, pipe, chain, etc.;

■

make sure that there are no tree stubs or anything else of dimensions greater than ø 10 cm between the bushes;

■

carefully observe and apply the instructions for regulating the ground clearance of the machine, and always ensure that there

■

are no other people within 50 metres of the working radius of the machine;

TR-TRM

13

Rev. 01.00

14

TR-TRM

TECHNICAL CHARACTERISTICS

2.2 Description of the parts

Cutting blades

1

Frame

2

Hydraulic ram

3

Control reversal valve

4

Flow valve

5

FIG. 2.1

2.3 Technicalspecications

TAB 1

CUTTER BAR

Width of cut cm.

Absorbed power CV(Kw)

Rate of flow valve set to It (min)

Hydraulic ram pressure (bottom side) Bar

Hydraulic ram pressure (rod side) Bar

Max. cycles per minute n.

Max. diameter of cut cm.

Hydraulic oil Type

Filtering micron

Weight Kg.

DIMENSIONS

CUTTER BAR

Width A mm.

Width B mm.

Height C mm.

For stability reasons, the required weight of the tractor to

which the machine is fitted varies according to the arm

lenght, and will have to be as follows:

up to 3 m arm Kg.

up to 4.5 m arm Kg.

up to 6 m arm Kg.

up to 8 m arm Kg.

MOD.

TR13 TR22 TRM18

1300 2200

700

220

1400

2100

3000

4500

1800

MOD.

TR13 TR22 TRM18

130 220

20 (15)

45 ÷ 50

135

170

60

8

ISO-L-HM 68

25 - 30

170 220

180

20 (15)

80

5

145

Rev. 01.00

TECHNICAL CHARACTERISTICS

2.4 Noise

The noise level produced is checked on all the models of machines produced by FERRI srl.

The noise values indicated are emission levels and do not necessarily represent safe operational levels.

Despite the existence of a relationship between emission levels and exposure levels, it cannot be accurately used to establish

whether further precautions are required or not.

The factors which determine the exposure level which the work force is subject to, include the duration of exposure, the characteristics of the work environment and other sources of noise (number of machines, nearby activities etc).

Furthermore, the permitted exposure levels can vary from one country to another.

However, the information on the level of noise produced by the machine will help the machine user to assess the dangers and

risks.

The noise level measured at the operator’s ear is between 75 dB and 78,5 dB with the cab

closed and between 82.9 and 84.4 dB with the rear glass of the cab open.

The acoustic power level is LWA 102,5. At a noise level perceived by the ear higher than 85

dB it is recommended to use personal protection equipment.

Noise over 85dB over an exended period of time will cause severe hearing loss.

Noise over 90dB adjacent to the Operator over an extended period of time will cause permanent or total hearing loss.

CAUTION

According to the data measured in the various positions examined, in the absence of a soundproofed cab it is recommended to use personal hearing protection equipment.

TR-TRM

15

Loading...

Loading...