FERRI TKD, TKD 54 Maintenance And Use Manual

1

Maintenance and Use

Manual

MOD.

TKD

HYDRAULIC

FLAIL HEDGE MOWERS

Ferri srl - Via C. Govoni, 30 – 44030 TAMARA (FE) ITALY – Tel +390532866866 – Fax+390532866851

Use and maintenance manual in conformity with Enclosure V Directive 89/392/CEE and following modifications and additions

– Do not destroy – Do not change – Add additionals files only – MAY 2002

2

CONTENTS

GENERAL INFORMATION sect. 1 page 5

- Introduction – Aim of the present manual sect. 1.1 page 5

- Identifying the machine sect. 1.2 page 5

- Spare parts sect. 1.3 page 5

TECHNICAL FEATURES sect. 2 page 6

- General description of the machine sect. 2.1 page 6

- Technical specifications sect. 2.2 page 7

- Hydraulic system sect. 2.2.1 page 8

- Noise sect. 2.3 page 9

- Width of cut sect. 2.4 page 9

- Optional equipment sect. 2.5 page 9

- Description of the equipment sect. 2.6 page 10

SAFETY RULES sect. 3 page 12

- General safety rules sect. 3.1 page 12

- Safety rules concerning road traffic sect. 3.2 page 13

- Safety rules during use sect. 3.3 page 13

- Safety rules concerning the hydraulic system sect. 3.4 page 13

- Description and location of safety decals sect. 3.5 page 14

- Driver protection sect. 3.6 page 15

- Danger sect. 3.7 page 15

INSTRUCTIONS FOR INSTALLATION – HANDLING –

PARKING sect. 4 page 16

- Lifting and unloading sect. 4.1 page 16

- Unpacking sect. 4.2 page 16

- Attachment to and detachment from the tractor sect. 4.3 page 16

- Electrical connections sect. 4.3.1 page 18

- Assembly instructions sect. 4.3.2 page 18

- Rigid attachment to the tractor sect. 4.3.3 page 20

- Fitting the PTO shaft sect. 4.4 page 21

- Tractor stability sect. 4.5 page 21

- Assembling the flail head sect. 4.6 page 22

- Parking sect. 4.7 page 22

ADJUSTMENT AND SETTING UP sect. 5 page 23

- Regulating the height of cut sect. 5.1 page 23

- Working speed sect. 5.2 page 23

USE AND OPERATING RULES sect. 6 page 24

- Controls sect. 6.1 page 24

- Description of the controls sect. 6.2 page 24

- Starting sect. 6.3 page 25

- Joystick controls sect. 6.4 page 26

- Working mode sect. 6.5 page 27

- Stopping sect. 6.6 page 28

- Transport position sect. 6.7 page 29

3

MACHINE MAINTENANCE sect. 7 page 30

TROUBLE SHOOTING CHART sect. 8 page 31

REPLACING PARTS sect. 9 page 32

- Flail replacement sect. 9.1 page 32

- Pipe replacement sect. 9.2 page 32

- Pin replacement sect. 9.3 page 32

- Oil and filter replacement sect. 9.4 page 32

- Replacing the motor pipes sect. 9.5 page 33

SCRAPPING, SEPARATING THE MATERIALS

AND ELIMINATION sect. 10 page 34

4

WARNING

Before assembling any flail hedge mowers with

electric / electro-hydraulic controls

and/or

heat exchanger

on the tractor

YOU MUST

read the assembly instructions on the

electrical connections

.

Failure to observe the said instructions faithfully may

result in considerable damage to the electrical system,

thereby invalidating the warranty of the same.

Given the importance and sensitivity of the electronics

we recommend that you have the electrical connections

made by a specialized workshop.

5

1 GENERAL INFORMATION

1.1 This operation and maintenance manual is intended for the professional user.

It is mandatory to follow these instructions in order to prevent events which could

endanger the operator’s and other people’s safety, apart from the correct

functioning of the flail-hedge mower. In case of doubt, do not experiment, call

FERRI after-sales service instead, or the specialized FERRI dealer.

1.2 Identifying the machine

Each frame and flail head is fitted with an identification plate; both the data

necessary to identify the model, the serial and part number to order spare parts or

after-sales service, are stamped on the plate (see FIG. 1).

1.3 It is strongly recommended to use genuine FERRI spare parts to avoid altering the

technical features of the flail-hedge mower. FERRI is not responsible for any

damage or injuries to persons or things due to unauthorized modifications.

6

2 TECHNICAL FEATURES

2.1 FERRI flail hedge mowers, from now on called also “machine”, have been designed

to shred materials growing or laying on the ground, e.g. grass, bushes, sticks and

shrubs. Never operate with the flail head lifted off the ground (proper use). Any

other use is considered improper and the manufacturer disclaims all responsibility

for any consequential injuries to person or things or damage to the machine.

“Proper use” also refers to the safety and maintenance rules provided for by the

manufacturer.

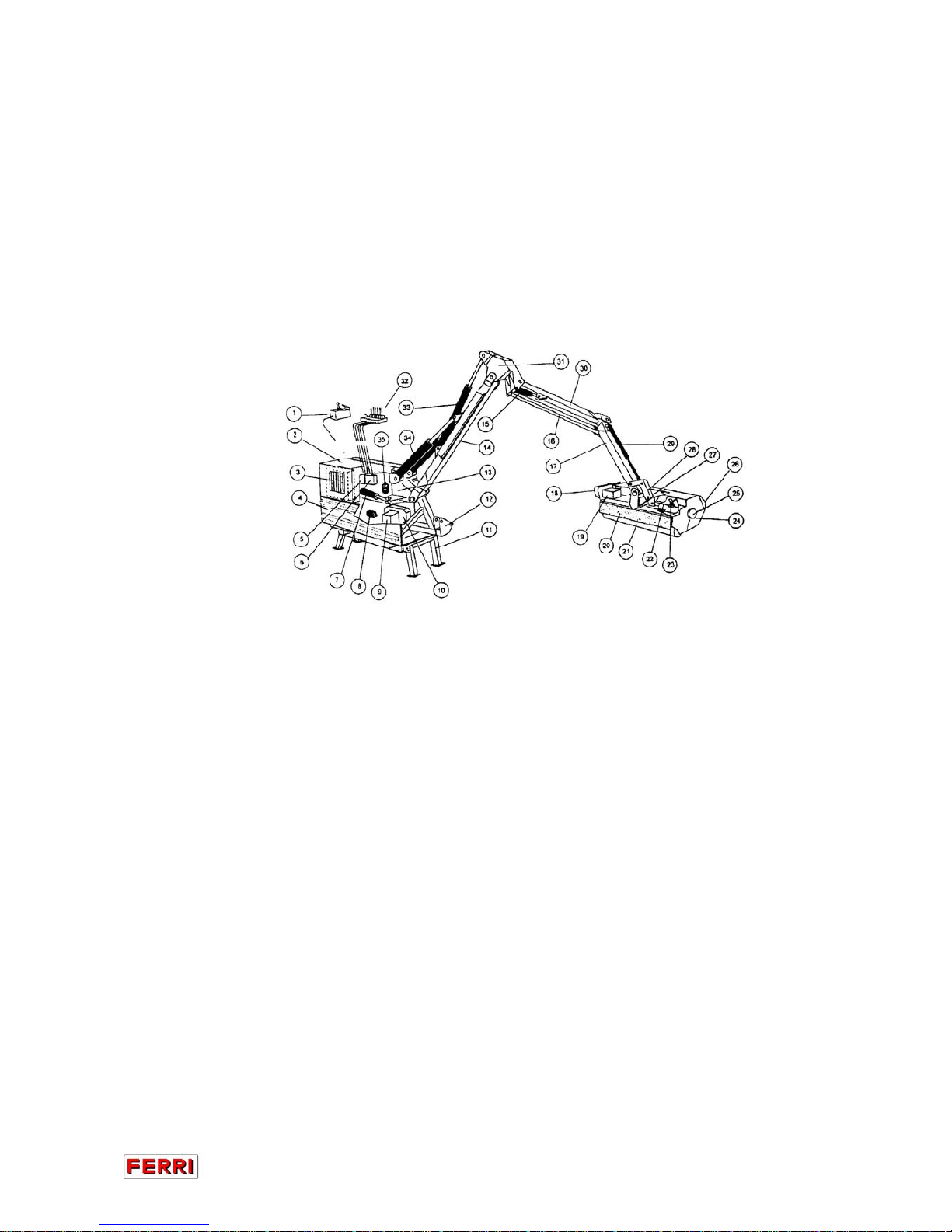

Technical names (FIG. 2)

FIG. 2

1 - Electro-hydraulic controls

2 – Bonnet

3 - Heat exchanger

4 – Bumper

5 - Flail head control distributor

6 - Hydraulic ram control distributor

7 - Arms rotation hydraulic ram

8 - Arms suspension accumulator

9 - Pump unit

10 – Gearbox

11 - Support feet

12 - Attachment to the tractor

13 - Tourning rest

14 - 1

st

arm

15 - Hydraulic ram operating parallelogram device

16 - Connecting rod for parallelogram device

17 - 2

nd

arm

18 - Belt casing

19 - Hydraulic motor

20 - Rear guard

21 - Roller

22 - rotor

23 - Flails

24 - Flail head

25 - Bearing guard

26 - Front guard

27 - Attachment flail head

28 - Transmission rods

29 - Flail head rotation hydraulic ram

30 - Pantograph arm

31 - Transmission support

32 - Control levers (with cables)

33 - 2

nd

arm hydraulic ram

34 - 1

st

arm hydraulic rams

35 - Arms rotation accumulator

This machine complies with the following legal provisions:

- 89/392/CEE Machines Directive and successive amendments: 91/368/CEE, 93/44/CEE

and 93/68/CEE;

- UNI EN 292/1 and 292/2 (safety of machinery):

- DPR 27 April 1995, No. 547 (regulations for the prevention of accidents at work)

7

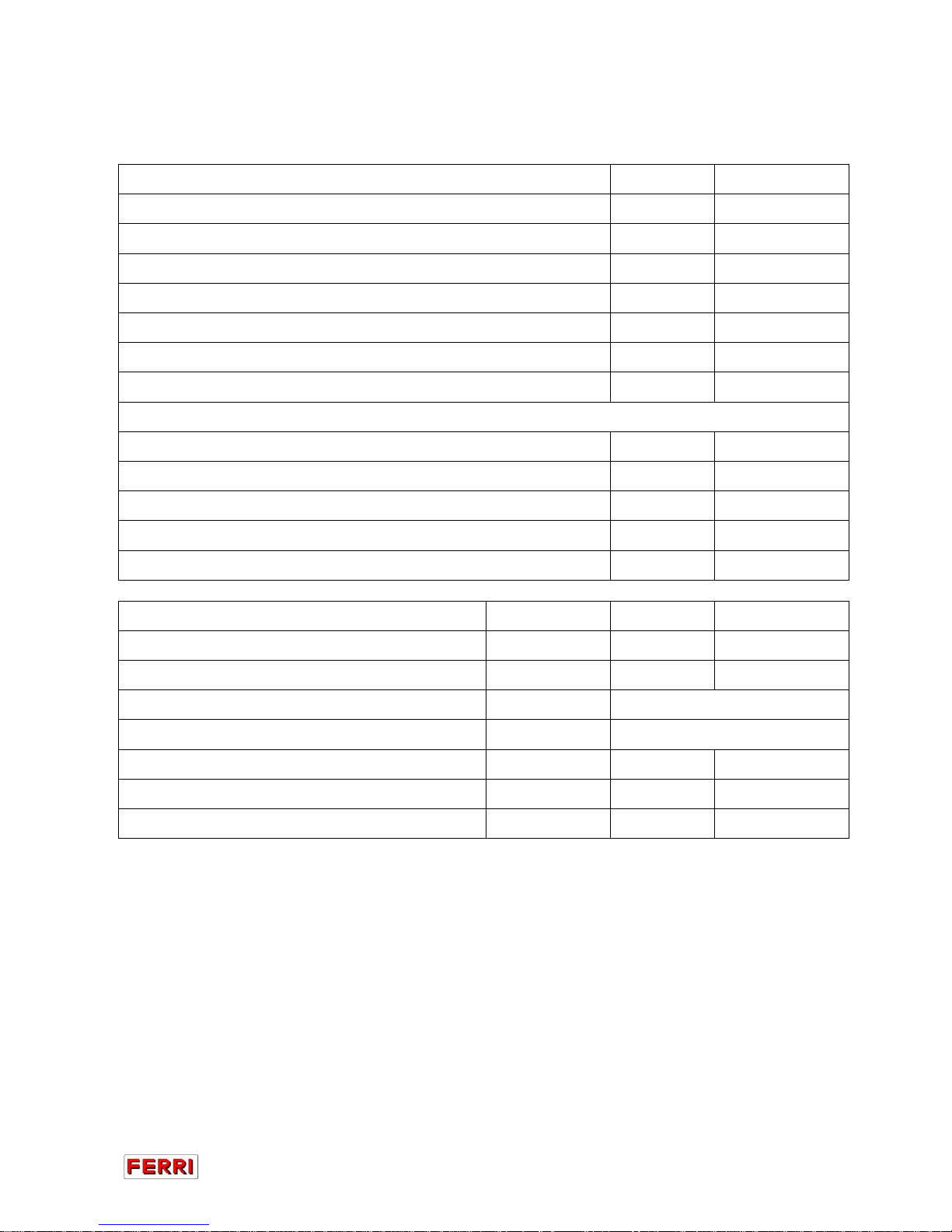

2.2 Technical specifications (Tab. 1)

TAB. 1

FLAIL HEDGE MOWER MOD.

TKD 54

Min. tractor required power HP (Kw) 90/100 (74/66)

Min. tractor required weight Kg. (lbs) 4400 (9500)

PTO speed rpm 1000

Voltage of the electrical system volt 12

Max. absorbed power HP (Kw) 73 (53)

Standard weight of the machine Kg. (lbs) 1645 (3553)

Attachment to the tractor Cat. II

HYDRAULIC SYSTEM

Hydraulic oil Lt (gal) 105

Intake filter micron 10

Return filter micron 30

Max. arm pressure Bar (PSI) 200 (3300)

Max. flail head pressure Bar (PSI) 280 (4060)

FLAIL HEAD

MOD.

TNP 125 TNCD 12 0

Width of cut Cm (in) 125 (49) 110 (43)

Flail head weight Kg. (lbs) 386 (833) 325 (715)

Head movement ° 235°

Rotor speed rpm 3000

Multi-use flails N. 44+22 36+18

Articulated “Y” flails N. 60+30 48+24

Hammer blades N. 22 18

8

2.2.1 Hydraulic system

- Control circuit:

oil supplied by a gear pump is delivered to an electro-hydraulically controlled,

power-assisted distributor. This distributor in this configuartion controls all arm

operations and functions.

Arm movement speed is controlled by a 2-axis joystick, which is powered by a lowpressure circuit (20 bar). The grip features different buttons which serve to operate

ON/OFF solenoids which in turn operate some of the controls.

The pressure signal sent by the joystick at the distributor inlet is of the proportional

type, thus making for smoother arm movement.

- Power circuit

In this instance the hydraulic system powering the flail hedge mower rotor is of the

closed-circuit hydrostatic type with axial piston pump and motor.

Unlike the open circuit, in which oil flow is broken by the tank, in the closed circuit

the oil flow is continuous because the outlet from the pump goes directly to the

motor and the outlet from the motor goes straight back to the pump.

Closed circuits offer many operational advantages:

- they can stop undamaged under full load with a minimum loss of power

- they accurately maintain a pre-set speed in the presence of resistive or

overwhelming loads

- their output is good, even when subjected to rather demanding duty cycles

- they can operate in two directions at controlled speed, without any major

interference from external loads

- when the control is disengaged, the flail holder shaft remains still

- their response time is faster than any other type of transmission

WARNING:

Frequent checking of the suction filter is recommended. Remember that the

life of hydrostatic transmission strongly depends on the degree of filtering of

the circulating oil!!

9

2.3 Noise

The sound level of this machine, as measured at the operator’s ear, ranges from

75.5 to 79.3 dB when the cab is closed, and from 80 to 85 dB when the rear window

is open. The acoustic power level is 104.5 LWA. When the sound level perceivable

at the operator’s ear ranges from 85 to 90 dB, the use of ear protectors is

recommended.

2.4 Width of cut

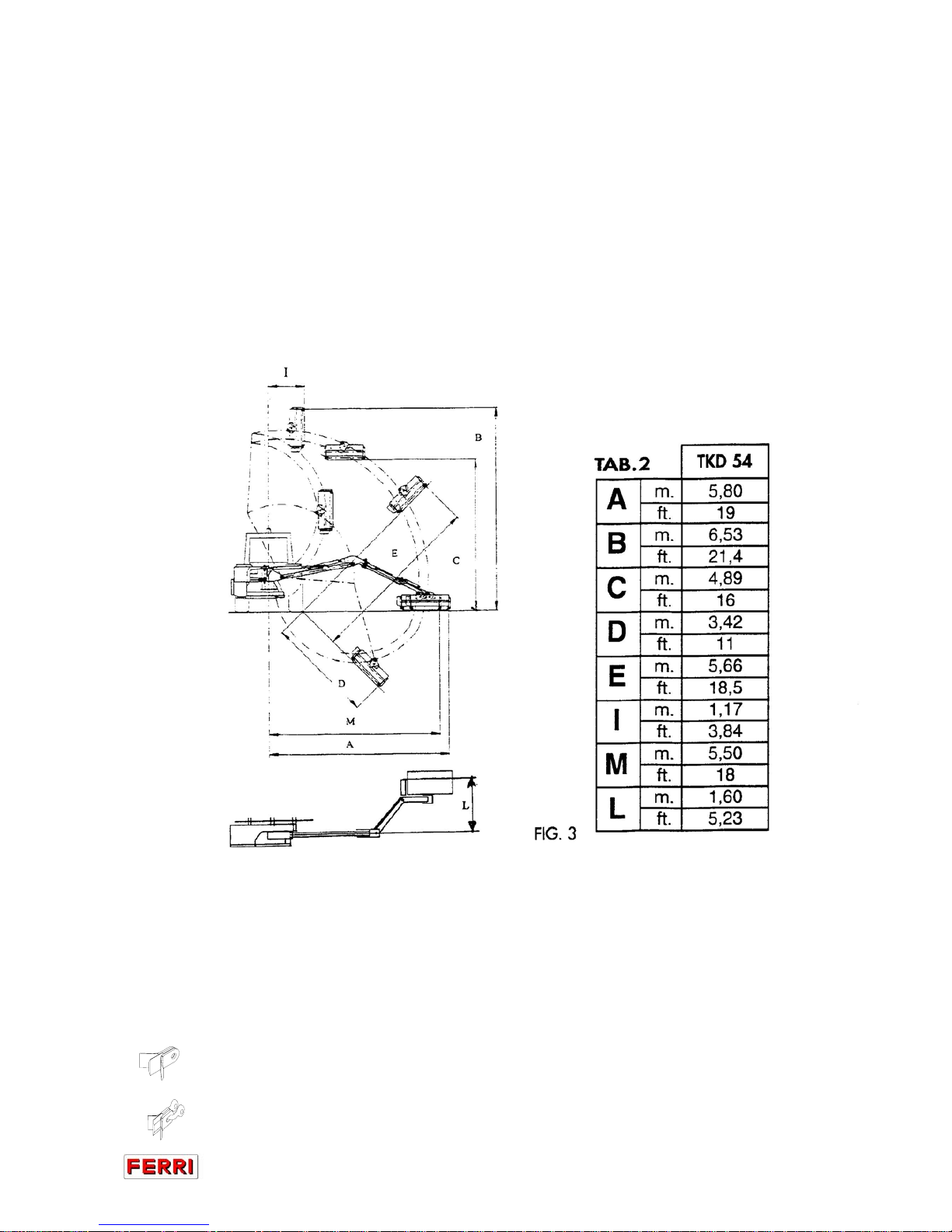

Fig. 3 shows the width of cut of the machine.

Dimensions are shown in Table 2.

2.5 Optional equipment

2.5.1 Flails

Depending on the different crops to be cut, the rotor can be changed and suitable

flails can be fitted and used:

- Multi-use flails for grass, shrubs, sticks and bushes up to 5 cm diameter.

N. B.: Do not use on stony ground

- Articulated “Y” flails for grass, shrubs and sticks up to 2 cm diameter.

10

- Hedgtrimming flails for grass or small shrubs up to 1 cm diameter.

- Hammer blades for wood up to 5÷6 cm diameter.

N. B. do not use on stony ground

- Articulated bootie flails for shrubs up to 2 cm diameter.

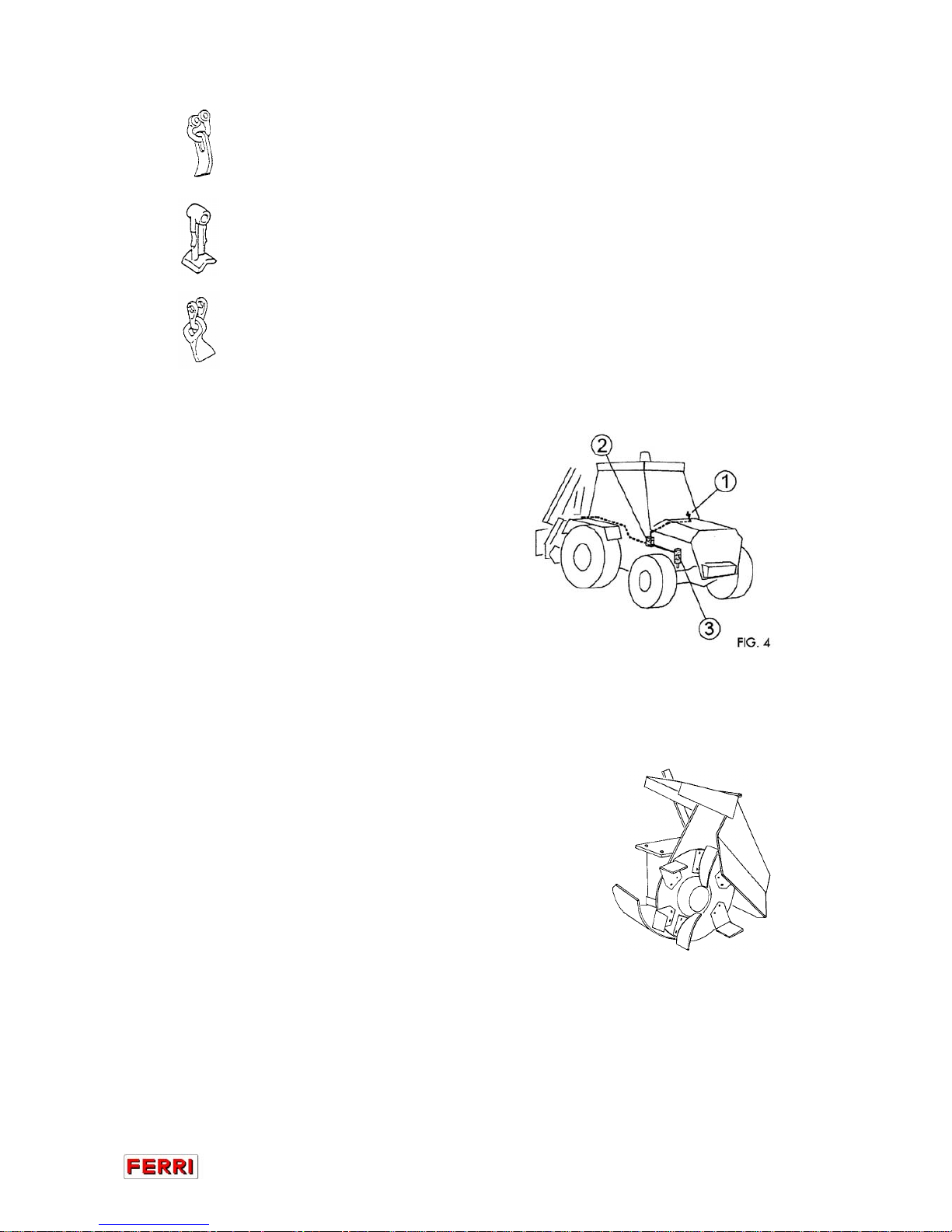

2.5.2 Locking the front axle of the tractor

(optional)

To increase the stability of the machine

(ONLY WHEN WORKING WITH THE

FLAIL HEDGE MOWER ARM) lock the

front axle of the tractor using switch 1

which controls valve 2 which locks

hydraulic ram 3. (FIG. 4)

2.6 Description of the equipment

2.6.1 Ditch cleaners mod. FF45 – FF60 (Fig. 5) to clean

ditches and collect sticks, shrubs and debris (proper

use).

- Range of action, ditch cleaner FF 45 – 0.45 m

- Range of action, ditch cleaner FF 60 – 0.6 m

FIG. 5

11

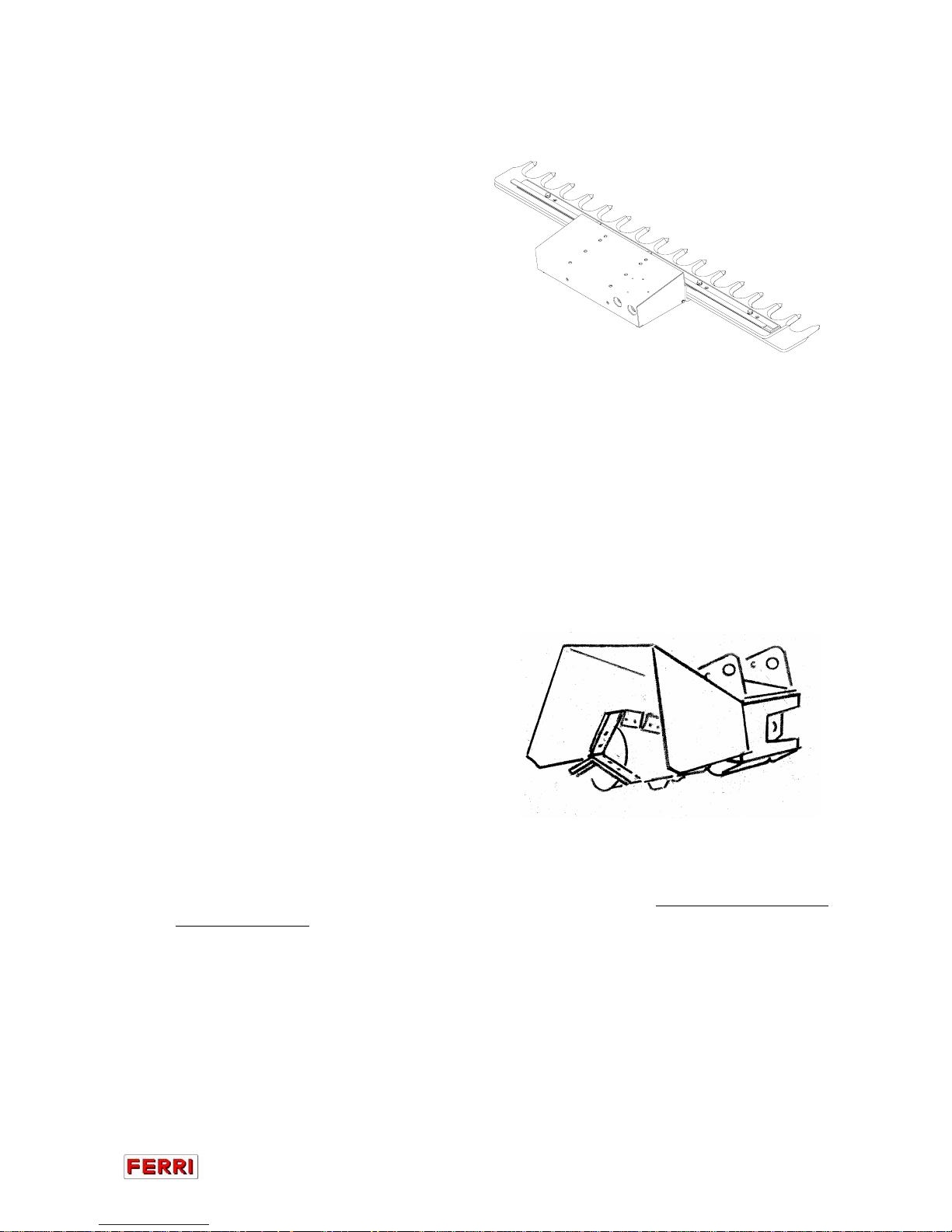

2.6.2 Cutter bar mod. TR13 – TR22 (FIG. 6) to cut or trim hedges, bushes or branches

(proper use).

- Width of cut TR 13 – 1.3 m

- Width of cut TR 22 – 2.2 m

FIG. 6

NOTE: The above equipment is described in the specific use and maintenance

manuals.

2.6.3 Bank mower mod. SB 45 (FIG. 7) to clear roadside banks, carriageways overgrown

with grass and earth, to open water drainage canals.

FIG. 7

IMPORTANT: if any of the above equipment is fitted on the TKD model fitted with

the pistons pump, contact the “FERRI” TECHNICAL OFFICE.

The above equipment is described in the specific use and maintenance manuals.

Loading...

Loading...