Page 1

Bath,

Whirlpool

NSN

Contract

6530-01-128-2442

Federal

DLA

120-89-C-8515

Supply

Code

16835

Page 2

FERNO

Mobile

Hydrotherapy

Unit

Ne

Operation,

For

ma.

Service

Repair

Manual

Model

200

and

Parts

Page 3

Section

1:

Manual

of

Contents

Section

Section

TOUCH

Electrical

Drawings

Parts

Section

Installation

Start-up

Operator

Shut

Section

Preventive

an

Maintenance

Replacement

Repair

Supplies

ADCESSONESU

Section

1:

2:

Drawings

3:

Down

4:

Procedure

5:

Manual

Equipment

Characteristics

..

Kaleme

.

Data

Maintenance

Maintenance

ーーー

Warranty

of

Contents

Data

E

n

Operation

Procedures

이

Procedures

Parts

so

.....................

....

o

cero

.

..................

and

4 .

de

and

ota

Drawings

cnr

Se

.

Repair

o

de

e

Soda

seca

24

gi

8

44

45

...4.6

4.7

Copyright,

©

Ferno-Washington,

1989,

Inc.

Page 4

Section

2:

Equipment

Data

and

Drawings

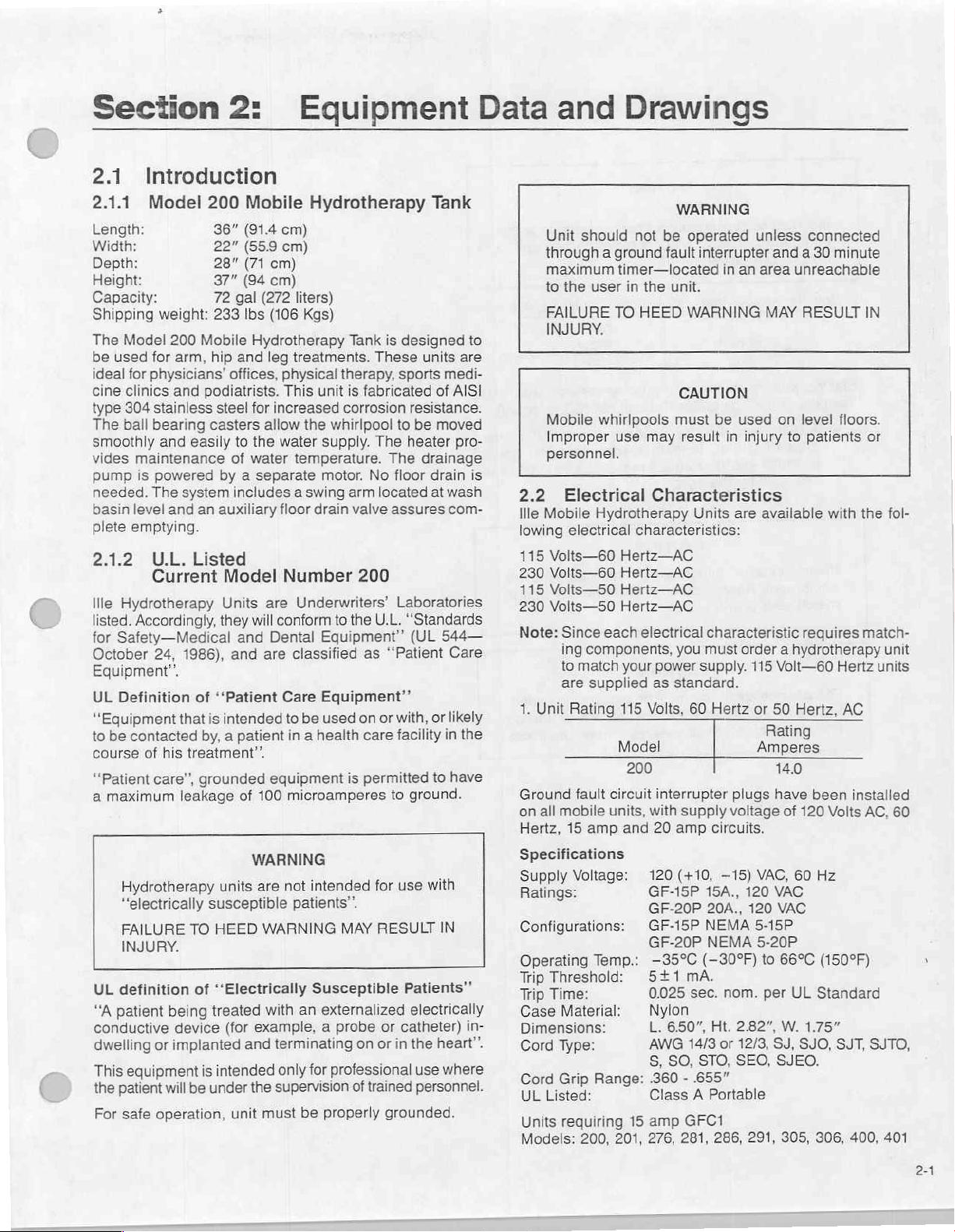

2.1

2.1.1

Length:

Introduction

Model

Width:

Depth:

Height:

Capacity:

Shipping

The

Model

be

used

for

ideal

cine

type

The

smoothly

vides

pump

needed.

basin

plete

2.1.2

1116

listed.

for

October

Equipment”.

UL

“Equipment

to

course

“Patient

a

UL

“A

conductive

dwelling

This

the

For

physicians’

clinics

304

ball

maintenance

is

level

emptying.

Hydrotherapy

Accordingly,

Safety—

Definition

be

contacted

of

maximum

Hydrotherapy

“electrically

FAILURE

INJURY.

definition

patient

equipment

patient

safe

200

36"

22"

28"

37"

72

weight:

for

stainless

bearing

and

powered

The

U.L.

Current

24,

his

care’,

or

will

operation,

233

200

Mobile

arm,

hip

and

podiatrists.

steel

casters

easily

by a separate

system

and

an

auxiliary

Listed

Units

they

Medical

1986),

of

“Patient

that

is

intended

by, a patient

treatment”.

grounded

leakage

units

susceptible

TO

HEED

of

‘Electrically

being

treated

device

implanted

is

intended

be

under

Mobile

(91.4

(559

(71

(94

gal

(272

Ibs

Hydrotherapy

and

offices,

for

to

the

of

water

includes a swing

Model

will

and

and

of

100

WARNING

are

WARNING

(for

example, a probe

and

the

unit

must

Hydrotherapy

cm)

cm)

cm)

cm)

liters)

(106

Kgs)

leg

treatments.

physical

This

increased

allow

the

water

temperature.

floor

drain

Number

are

Underwriters’

conform

Dental

are

classified

Care

to

be

in a health

equipment

microamperes

not

intended

patients”.

Susceptible

with

an

terminating

only

for

supervision

be

Tank

is

These

therapy,

unit

is

fabricated

corrosion

whirlpool

supply.

motor.

The

No

arm

valve

The

located

assures

200

to

the

U.L.

Equipment’’

as

“Patient

Equipment”

used

on

or

care

is

permitted

to

for

MAY

RESULT

externalized

or

on

or

professional

of

trained

properly

grounded.

Tank

designed

sports

resistance.

to

be

heater

drainage

floor

Laboratories

"Standards

(UL

with,

facility

ground.

use

Patients”

electrically

catheter)

in

the

use

personnel.

units

medi-

of

AISI

moved

pro-

drain

at

wash

com-

544

Care

or

likely

in

to

have

with

IN

heart”.

where

to

are

is

一

the

in-

Unit

should

through a ground

maximum

to

the

user

FAILURE

INJURY.

Mobile

Improper

personnel.

2.2

Electrical

Ille

Mobile

lowing

115

Volts—60

230

Volts—60

115

Volts—50

230

Volts—50

Note:

Since

ing

to

are

1.

Unit

Ground

on

all

mobile

Hertz,

15

Specifications

Supply

Ratings:

Configurations: © GF-15P

Operating

Тир

Threshold: © 5+1

Třip

Time:

Case

Material:

Dimensions:

Cord

Type:

Cord

Grip

UL

Listed:

Units

requiring

Models:

TO

whirlpools

use

Hydrotherapy

electrical

each

components,

match

supplied

Rating

fault

circuit

units,

amp

Voltage:

Temp.:

Range:

200,

201,

WARNING

not

be

operated

fault

interrupter

timer—located

in

the

unit.

HEED

WARNING

CAUTION

must

be

may

result

Characteristics

Units

characteristics:

Hertz—AC

Hertz—AC

Hertz—AC

Hertz—AC

electrical

your

power

as

115

Volts,

Model

200

interrupter

with

and

20

120

GF-15P

GF-20P

GF-20P

—35%C

0.025

Nylon

L.

AWG

S,

.360 - .655”

Class A Portable

15

amp

276,

characteristic

you

must

supply.

standard.

60

Hertz

supply

amp

circuits.

(+10,

15A.,

20A.,

NEMA

NEMA

(—309F)

mA.

sec.

6.50”,

Ht.

14/3

SO,

STO,

GFC1

281, 286,

—15)

or

unless

in

an

area

used

in

injury

are

available

order a hydrotherapy

115

or

Amperes

plugs

voltage

VAC,

120

120

5-15P

5-20P

to

nom.

2.82”,

12/3,

SEO,

291,

connected

and a 30

unreachable

MAY

RESULT

on

level

to

patients

requires

Volt—60

50

Hertz,

Rating

140

have

been

of

120

60

VAC

VAC

66°C

per

UL

W.

1.75”

SJ,

SJO,

SJEO.

305,

minute

with

Volts

Hz

(150ºF)

Standard

306, 400,

IN

floors.

or

the

match-

Hertz

units

AC

installed

AC,

SJT,

SJTO,

fol-

unit

60

x

401

2-1

Page 5

CAUTION

Incorrect

equipment.

match

2.

Unit

Rating

(Electric

“hospital

Note: A 15

supply

grounding

(Hubbell

available

Incorrect

equipment.

match

For

safe

Failure

and

polarized

current

Always

your

power

230

Model

200

cord

grade”

plug

ampere,

slot,

#8610

by

current

Always

your

power

operation,

to

provide

receptacle

supply

Volts,

will

seriously

order a hydrotherapy

supply.

60

Hertz

of

this

unit

cap

Hubbell

250

V.,

polarized, 3 wire

tandem

or

equal)

the

user.

CAUTION

supply

order a hydrotherapy

supply.

CAUTION

unit

an

approved

will

must

may

blade,

receptacle

seriously

be

result

damage

or

50

Hertz,

Rating

Amperes

60

terminates

48615C

properly

properly

or

“U”

"hospital

is

damage

grounded.

grounded

in

serious

this

unit

to

AC

with a UL

equal)

shaped

grade”

to

be

made

this

unit

to

injury.

2-2

Page 6

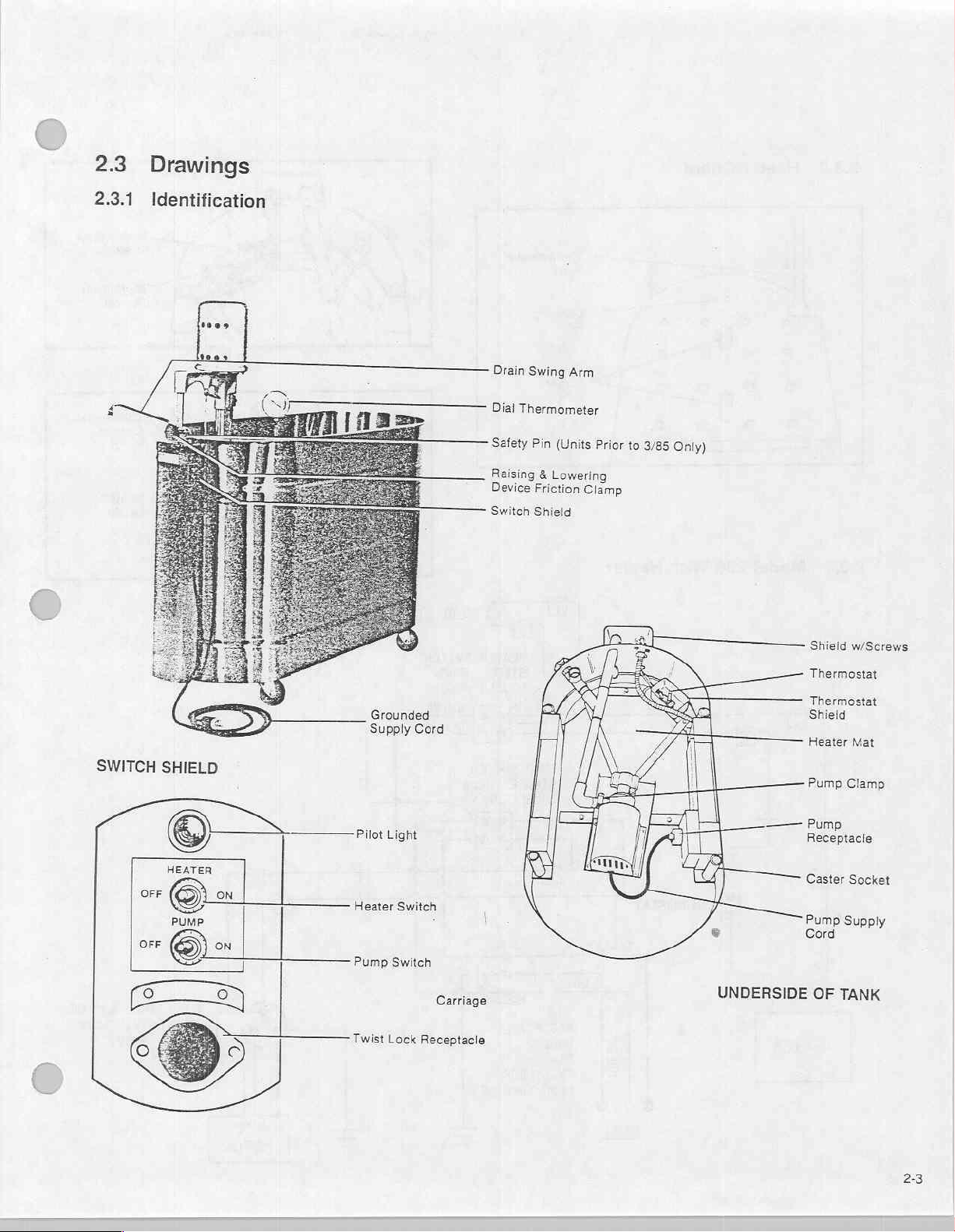

2.3

Drawings

2.3.1

ma

Identification

=

=

maias

Drain

Swing

Arm

——

Dial

Thermometer

Safety

Pin

(Units

Prior

Raising & Lowering

Device

Switch

Friction

Shield

Clamp

to

3/85

Only)

Shieid

w/Screws

SWITCH

ME

Fi

on

OFF

SHIELD

HEATER

(Oro

PUMP

©

=

ON

|

|

¡

Grounded

Supply

Pilot

Light

Switch

Heater

Pump

Switch

Twist

Lock

Cord

i

i

Carriage

Receptacle

一 一 Pump

UNDERSIDE

Thermostat

Thermostat

Shield

Heater

Mat

Pump

Clamp

Receptacle

Caster

Socket

Pump

Supply

Cord

OF

TANK

23

Page 7

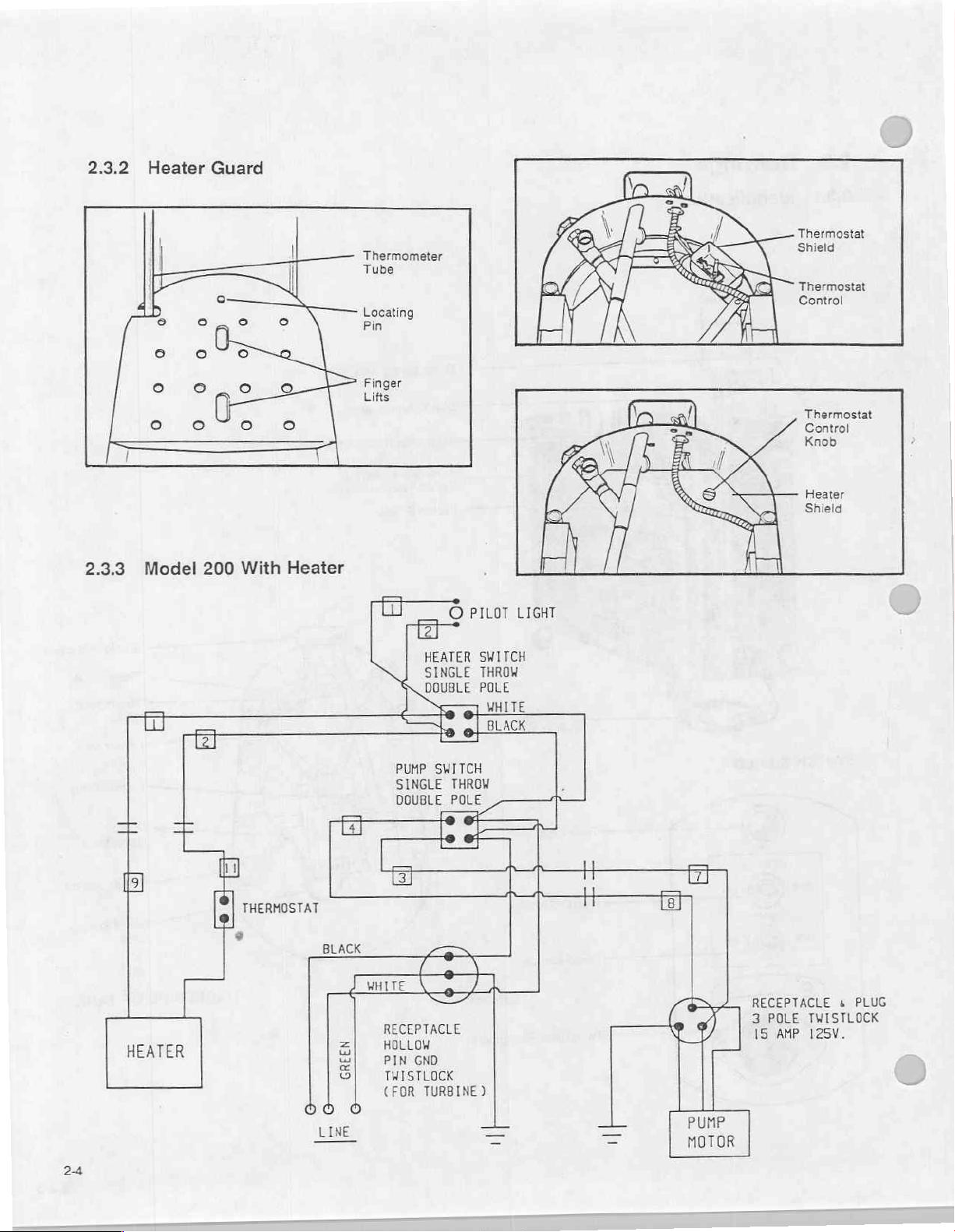

2.3.2

Heater

Guard

Thermometer

Tube

Locating

Pin

Thermostat

Shiel

red

Thermostat

Control

2.3.3

—

Bl

回

Model

El

+

№

200

団

η

a

le]

With

Heater

THERMOSTAT

=

A

Finger

Lifts

=

PUMP

SINGLE

DOUBLE

O

HEATER

SINGLE

DOUBLE

po

©

19

©

SWITCH

THROW

POLE

e

ee

о

PILOT LIGHT

SWITCH

THROW

POLE

MHITE

BLACK

т

|

Thermostat

Control

Knob

Heater

Shield

24

HEATER

‘

BLACK

RECEPTACLE

HOLLOW

PIN

GND

TWISTLOCK

(FOR

TURBINE)

PUMP

MOTOR

RECEPTACLE s PLUG

3

POLE

15

AMP

TWISTLOCK

125V.

Page 8

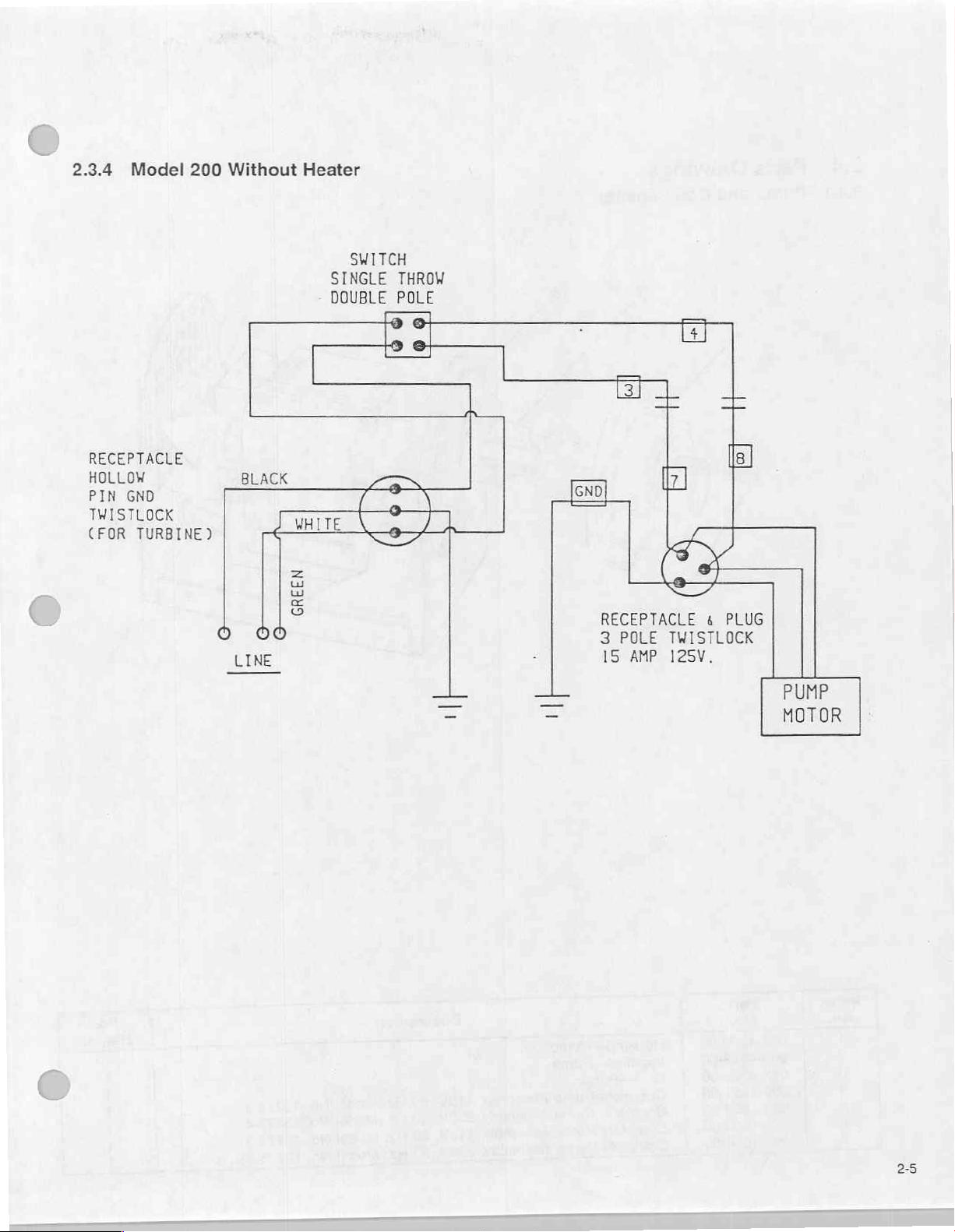

2.3.4

Model

RECEPTACLE

HOLLOW

PIN GND

TWISTLOCK

(FOR

TURBINE)

200

Without

Heater

SWITCH

SINGLE

DOUBLE

THROW

POLE

©

Se

RECEPTACLE & PLUG

LINE

3

15

POLE

AMP

TWISTLOCK

125V.

PUMP

MOTOR

25

Page 9

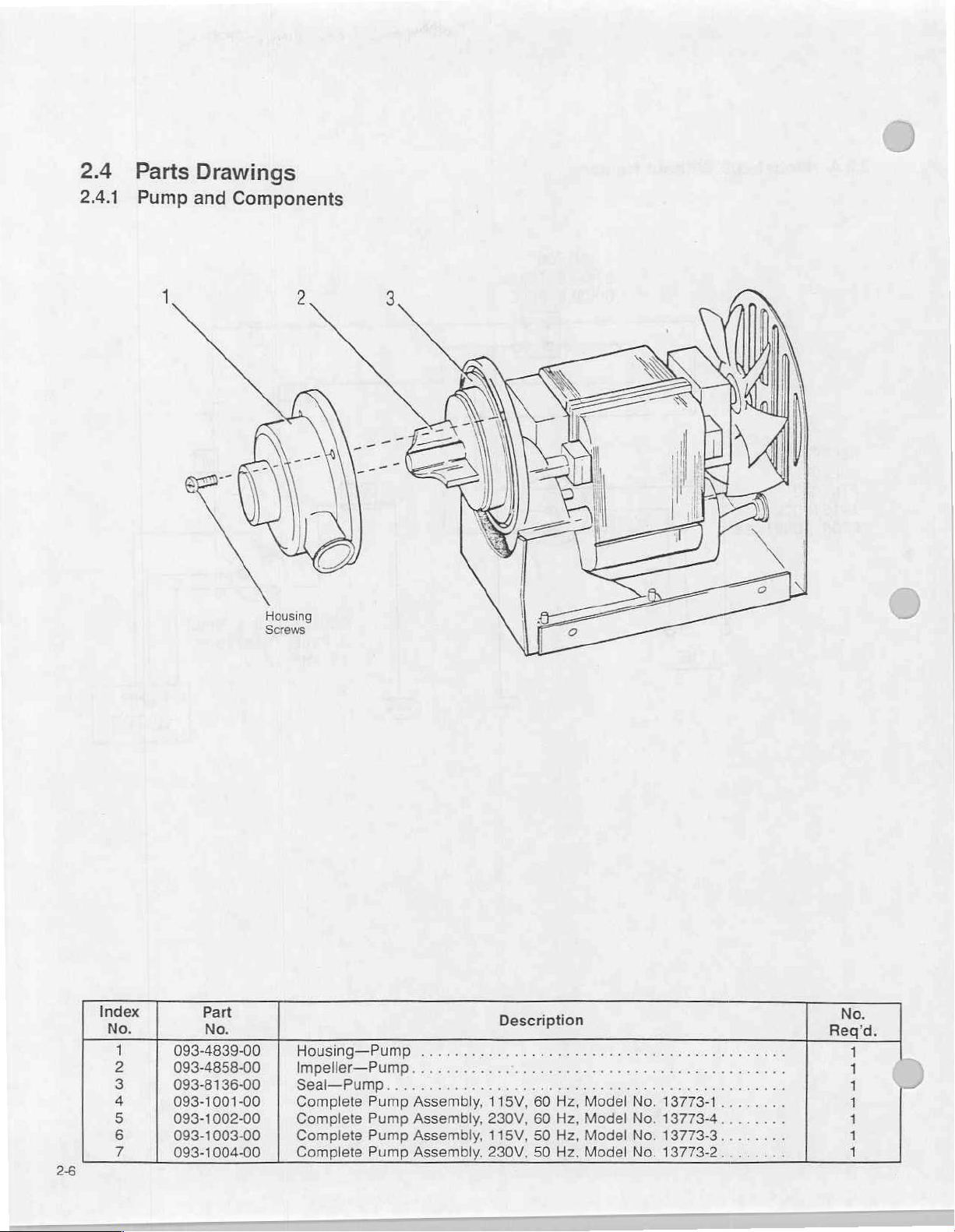

2.4

2.4.1

Parts

Pump

Drawings

and

Components

Housing

Screws

26

NR

4

2

3

4

5

6

η

093-4839-00

093-4858-00

093-8136-00

093-1001-00

093-1002-00

093-1003-00

093-1004-00

Housing—Pump

Impeller—Pump

Seal—Pump

Complete

Complete

Complete

Complete

Pump

Pump

Pump

Pump

...

Assembly,

Assembly,

Assembly,

Assembly,

Description

ο

115V,

60

Hz,

230V,

60

Hz,

115V,

50

Hz,

230V,

50 Hz,

Model

Model

Model

Model

a

No.

13773-1........

No.

13773-4..

No.

13773-3.

No.

13773-2

1

1

1

1

1

1

1

Page 10

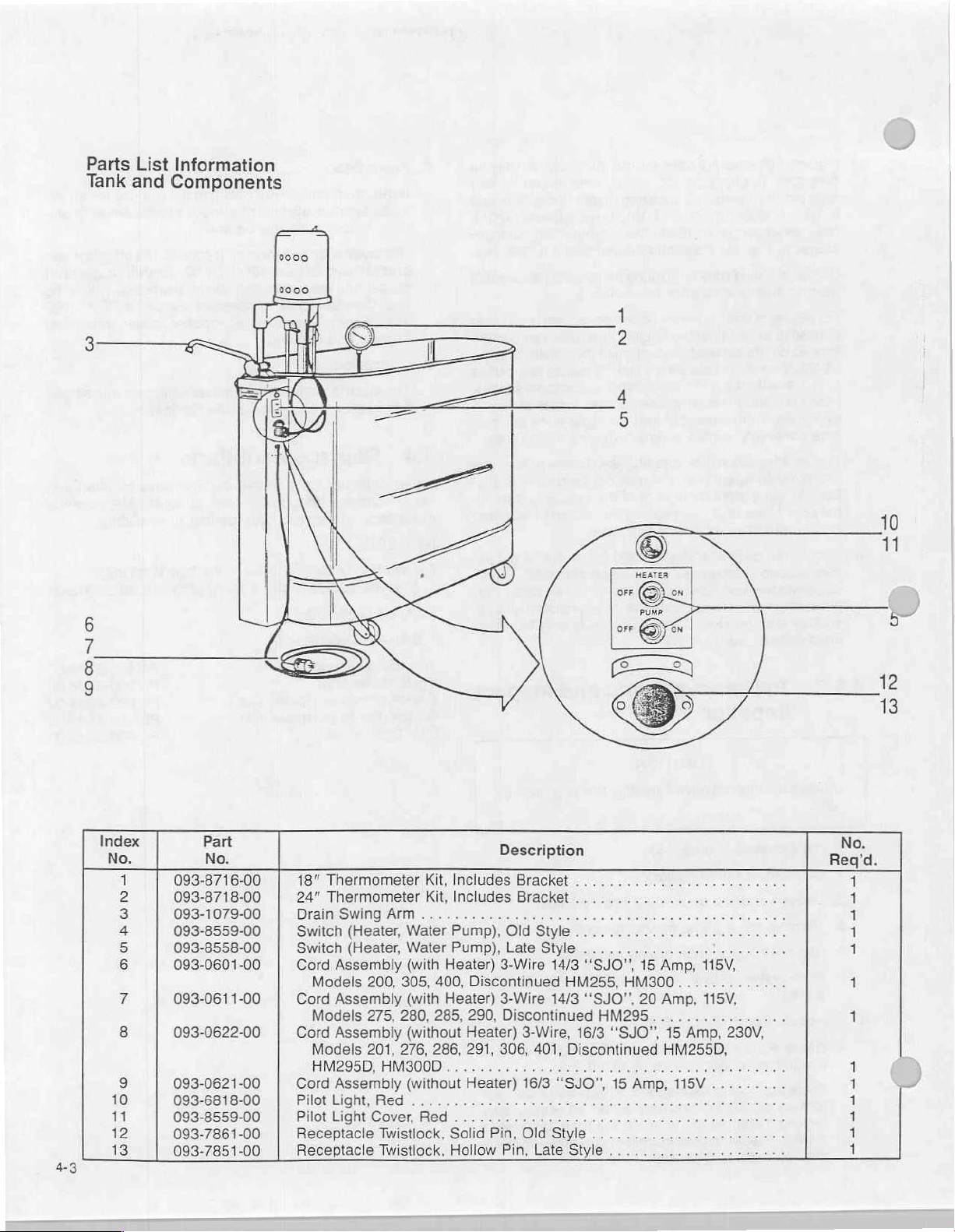

Parts

Tank

List

Information

and

Components

ㅇㅇ

index

43

Я

2

3

4

5

6

7

8

9

10

11

12

13

č

093-8716-00

093-8718-00

093-1079-00

093-8559-00

093-8558-00

093-0601-00

093-0611-00

093-0622-00

093-0621-00

093-6818-00

093-8559-00

093-7861-00

093-7851-00

18”

Thermometer

24”

Thermometer

Drain

Swing

Switch

Switch

Cord

Assembly

Models

Cord

Assembiy

Models

Cord

Assembiy

Models

HM205DIFMA0OD

Cord

Assembly

BiletLight,

Pilot

Light

Receptacle

Receptacle

Arm

(Heater,

(Heater,

Water

Water

(with

200,

305, 400,

(with

275,

280,

(without

201,

276,

(without

Red...

Cover,

Twistlock,

Twistlock,

Kit,

Includes

Kit,

Includes

Pump),

Pump),

Heater)

Heater)

285, 290,

286,

Red

.....

Solid

Hollow

Description

Bracket

Bracket

Old

Style...

Late

Style . .

3-Wire

Discontinued

3-Wire

Discontinued

Heater)

291,

τς

Heater)

306,

Pin,

Pin,

3-Wire,

401,

16/3

Old

Late

...

.

14/3

‘‘SJO",

HM255,

14/3

Discontinued

o

‘“SJO",

Style

Style

HM300.............

“SJO”,

HM295

16/3

“SJO”,

RE

15

..

15

20

Amp,

Amp,

115V,

Amp,

115V,

15

Amp,

HM255D,

115V

..

23

Ότο.

.

4

V,

mba

E

og

1

1

1

1

1

À

1

1

1

1

1

1

1

Page 11

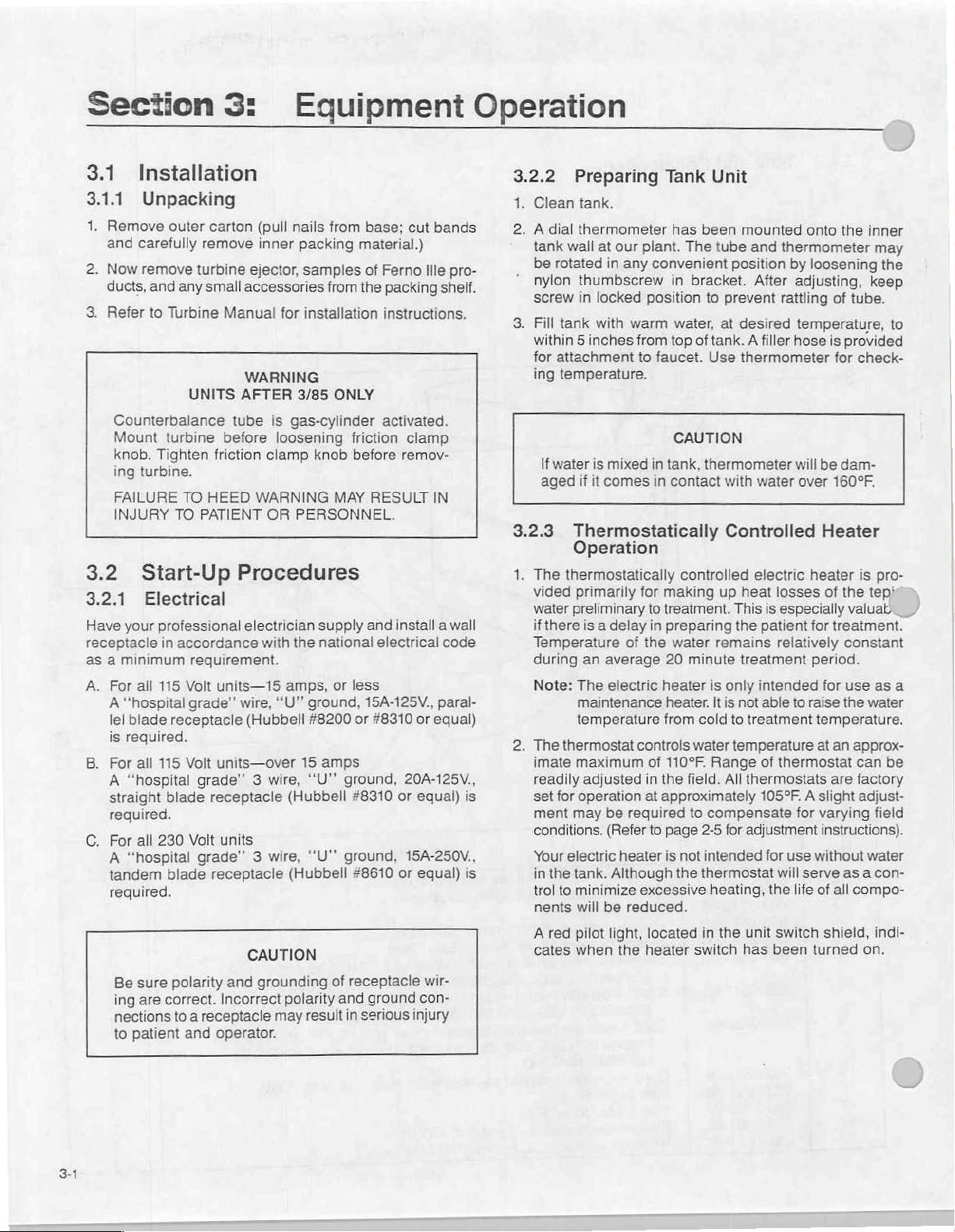

Section

3:

Equipment

Operation

3.1

3.1.1.

1.

2.

3.

Installation

Unpacking

Remove

and

Now

ducts,

Refer

outer

carefully

remove

and

any

to

Turbine

remove

turbine

carton

small

accessories

Manual

(pull

nails

inner

packing

ejector,

for

from

base;

material.)

samples

installation

from

of

Ferno

the

packing

instructions.

cut

bands

Ille

pro-

shelf.

WARNING

UNITS

Counterbalance

Mount

knob.

ing

FAILURE

INJURY

3.2

3.2.1

Have

receptacle

as a minimum

A.

For

A

lel

is

В.

For

A

straight

turbine

Tighten

turbine.

TO

TO

Start-Up

Electrical

your

professional

in

accordance

requirement.

all

115

Volt

“hospital

blade

required.

all

"hospital

grade”

receptacle

115

Voit

blade

AFTER

tube

before

friction

HEED

PATIENT

3/85

is

gas-cylinder

loosening

clamp

WARNING

OR

PERSONNEL.

Procedures

electrician

with

the

units—15

units—over

grade” 3 wire,

receptacle

wire,

“U”

(Hubbell

amps,

15

(Hubbell

ONLY

knob

MAY

supply

national

or

ground,

#8200

amps

"U”

ground,

activated.

friction

before

remov-

RESULT

and

install a wall

electrical

less

15A-125V.,

or

#8310

#8310

or

clamp

IN

code

paral-

or

equal)

20A-125V.,

equal)

is

required.

C.

For

all

230

Volt

units

A

“hospital

tandem

required.

grade” 3 wire,

blade

receptacle

"U”

(Hubbell

ground,

#8610

15A-250V.,

or

equal)

is

CAUTION

3.2.2

1.

2.

.

3.23

Preparing

Clean

tank.

Adial

thermometer

tank

wall

be

rotated

nylon

thumbscrew

screw

in

Fill

tank

within 5 inches

for

attachment

ing

temperature.

If

water

aged

if

Thermostatically

Operation

1.

The

thermostatically

vided

primarily

water

preliminary

if

there

Temperature

during

Note:

The

maintenance

temperature

.

The

thermostat

imate

maximum

readily

set

for

operation

ment

may

conditions.

Your

electric

in

the

tank.

trol

to

minimize

nents

will

A

red

pilot

cates

when

at

our

in

any

locked

with

warm

from

to

is

mixed

it

comes

is a delay

of

an

average

electric

controls

adjusted

be

required

(Refer

heater

Although

be

reduced.

light,

the

Tank

Unit

has

been

plant.

The

tube

convenient

in

bracket.

position

faucet.

water,

top

of

to

tank. A filler

Use

CAUTION

in

tank,

thermometer

in

contact

controlled

for

making

to

treatment.

in

preparing

the

water

remains

20

minute

heater

from

of

in

the

at

approximately

to

excessive

located

heater

is

heater.

110°F.

page

is

It

cold

water

Range

field.

to

compensate

2-5

not

intended

the

thermostat

heating,

in

switch

mounted

and

thermometer

position

prevent

at

desired

by

After

rattling

adjusting,

temperature,

hose

thermometer

will

with

water

over

Controlled

electric

up

heat

losses

This

is

especially

the

patient

relatively

treatment

only

intended

is

not

able

to

to

treatment

temperature

of

thermostat

All

thermostats

105°F. A slight

for

for

adjustment

for

use

will

the

life

the

unit

switch

has

been

onto

the

inner

may

loosening

keep

of

tube.

is

provided

for

check-

be

dam-

160°F.

Heater

heater

for

period.

raise

without

serve

turned

is

of

the

tepi

81486

treatment.

constant

for

use

as

the

water

temperature.

at

an

approx-

can

are

factory

adjust-

varying

instructions).

field

water

as a con-

of

all

compo-

shield,

indi-

on.

the

to

pro-

>

a

be

3-1

Be

sure

ing

are

nections

to

patient

polarity

correct.

to a

receptacle

and

operator.

and

grounding

Incorrect

may

of

polarity

result

receptacle

and

ground

in

serious

wir-

con-

injury

Page 12

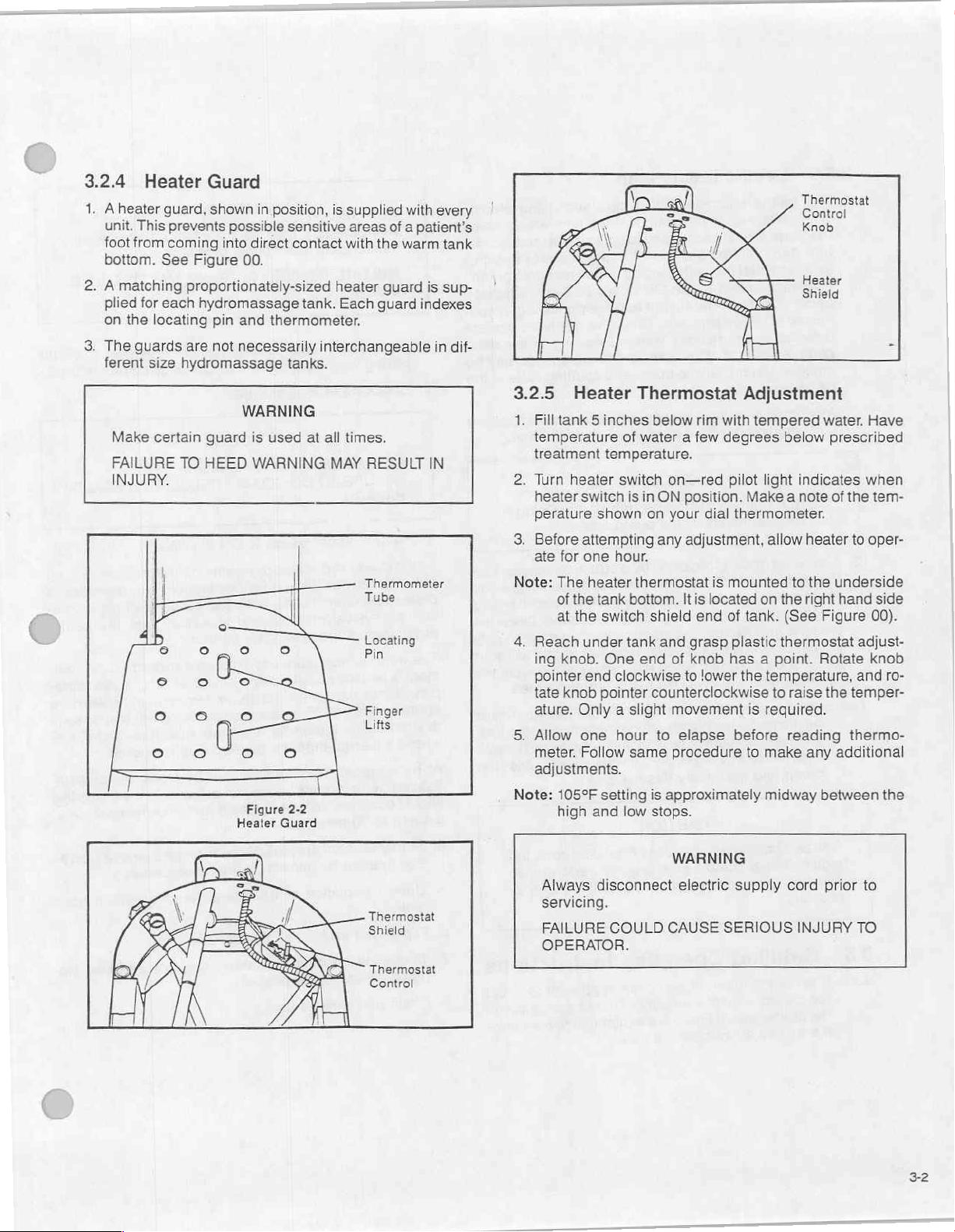

3.2.4

1. A heater

2. A matching

3.

Heater

Unit.

This

foot

from

bottom.

plied

for

on

the

The

guards

ferent

Make

FAILURE

INJURY.

guard,

prevents

coming

See

each

locating

size

certain

Guard

shown

Figure

proportionately-sized

hydromassage

are

hydromassage

guard

TO

HEED

in

possible

into

direct

00.

pin

and

thermometer.

not

necessarily

WARNING

is

used

WARNING

Figure

Heater

position,

sensitive

contact

tank.

interchangeable

tanks.

at

all

MAY

2-2

Guard

is

supplied

areas

with

heater

Each

times.

RESULT

Thermometer

Tube

Locating

Pin

Finger

Lifts

with

every

of a patient's

the

warm

tank

guard

is

sup-

guard

indexes

in

dif-

IN

3.2.5

1.

2.

3.

Note:

4,

5.

Note:

Heater

Fill

tank 5 inches

temperature

treatment

Turn

heater

heater switch

perature

Before

ate

for

The

of

the

at

the

Reach

ing

knob.

pointer

tate

knob

ature.

Only a slight

Allow

meter.

adjustments.

105°F

high

Thermostat Adjustment

of

water a few

temperature.

switch

is

in

shown

attempting

one

heater

tank

under

end

one

Follow

and

on

hour.

thermostat

bottom.

switch

pointer

setting

shield

tank

One

end

clockwise

counterclockwise

hour

same

is

low

stops.

below

rim

with

degrees

on—red

ON

position.

your

dial

any

adjustment,

is

It

is

located

end

and

grasp

of

knob

to

lower

movement

to

elapse

procedure

approximately

WARNING

Thermostat

Control

Knob

Heater

Shield

tempered

below

pilot

light

indicates

Make a note

thermometer.

allow

heater

mounted

of

tank.

plastic

has a point.

the

before

to

on

the

right

(See

thermostat

temperature,

to

raise

is

reguired.

reading

to

make

any

midway

water.

prescribed

of

the

to

the

underside

hand

Figure

Rotate

the

temper-

thermo-

additional

between

Have

when

tem-

oper-

side

00).

adjust-

knob

and

ro-

the

Thermostat

Shield

Thermostat

Control

Always

servicing.

FAILURE

OPERATOR.

disconnect

COULD

electric

CAUSE

supply

SERIOUS

cord

INJURY

prior

TO

to

3-2

Page 13

3.2.6

1.

The

pump

the

turn

sink,

on

under

nected

draining

pump

emptied

same

2.

Aswith

unit

DO

will

3.

The

thermal

to

the

a

dangerously

circuit

cooled

again

continue

Note:

When

and

Gauze,

eign

and

possible.

3.3

Note:

Electric

unit

is

equipped

attached

water

at a

rate

swing

drain

and

start

motor

switch

the

to

shield

base

the

pump

of

any

system.

faster

time.

all

centrifugal

with

liquid

NOT

operate

reduce

pump

be

If

permitted

pump

the

motor

cut-out.

motor

by

is

interrupted,

or

circuit

and

stop

until

the

salt

solutions

drained

pump

immediately

system

and

eventually

‘‘band-aids’’,

matter

are

should

be

Detailed

It

is

not

the

the

clinical

the

the

proper

quality

use

Drain

to

Pump

with a quick-emptying

the

bottom

according

nozzle

to

of

tank,

residue

If

floor

by

using

before

until

by

piacing switch

the

ON

with

drain.

This

water

drain

pump

pumps,

pumping

CAUTION

pump

when

life

of

the

pump

is

protected

This

thermal

automatically

high

temperature

the

motor

resets

itself.

again

when

overload

are

used,

after

should

to

remain,

the

destroy

CAUTION

bandage

detrimental

removed

from

Operating

intent

of

Ferno

care

of

your

of

Ferno

of

your

clinical

of

the

tank

which

to

tank

size. To

it

projects

empty

over

marked

position. A valve

hand

grip

showing,

valve

permits

remaining

is

available,

and

opening

itis

necessary

will

tank

is

in

tank

valve

commence.

dry.

Doing

seal.

by a built-in

cut-out

breaking

will

However,

overheated.

has

been

the

treatment,

be

flushed

salt

clips,

to

pump

patient

automatic

prevents

the

is

reached.

not

start

motor

This

eliminated.

residue

with

solution

it.

will

and

other

performance

as

circuit

and

fresh

much

Instructions

Ille

to

attempt

patient

Ille

but

to

equipment

care.

advise

to

electric

drains

tank,

basin

“pump”

located

is

complete

the

drain

may

at

to

flood

so

damage

before

Once

again

will

cycle

water

the

water.

attack

for-

as

to

direct

you

maximize

or

con-

be

the

the

reset

the

until

start

will

must

tank

the

in

WARNING

Hydrotherapy

“electrically

FAILURE

units

susceptible

TO

HEED

are

not

patients”.

WARNING

intended

MAY

for

use

RESULT

with

IN

INJURY.

1.

2.

Fill

tank

mixing

Check

with

valve

water

water

to

desired

operations

temperature.

treatment

manual

level.

for filling

procedures.)

(Consult

CAUTION

Always

FAILURE

verify

TO

water

DO

SO

temperature.

MAY

RESULT

IN A SCALD

HAZARD.

3.

Flip

the

heater

When

giving

patient

dependent

tient's

physiology

The

ment

pist.

approximately

desired

where a thermo-therapeutic

All

desired

should

usually

4,

5.

must

upon

physical

of

water

temperature

is

usually

It

can

to

the

hydrotherapy

temperature

continue

20-30

Start

treatment

tion

manual

Upon

completion

switch

hydrotherapy

be

taken

into

the

patient’s

and

medical

the

area

specified

vary

from

65°F,

where a cryotherapeutic

higher

treatments

throughout

minutes.

process.

for

correct

of

to

ON

position.

treatment,

consideration.

subjective

condition,

to

be

treated.

used

during a hydrotherapy

by a physician

the

lower

temperature

temperature

response

should

range

the

Refer

spectrum,

be

is

established.

duration

to

turbine

operating

treatment,

remove

the

tolerance

This

tolerance

feelings,

and

or

physical

is

desired.

monitored

of

the

the pa-

the

spectrum,

response

96°-104°F,

until

Monitoring

treatment,

ejector

procedures.

patient

of

the

is

path

treat-

thera-

is

the

opera-

from

=

tank.

6.

Flip

7.

8.

heater

To

drain

pump

Clean

switch

water

switch

and

sanitize

from

to

ON

to

OFF

tank,

move

position.

tank.

position.

unit

to

drain

area,

flip

33

Page 14

3.4

1.

Electric

The

matic

vents

the

reached.

not

However,

heated.

been

Shutdown

drain

pump

electric

circuit

restart

drain

reset

thermal

damage

to

before a dangerously

Once

the

again

motor

This

cycle

eliminated.

Procedures

pump

is

protected

cut-out.

the

motor

circuit

is

until

cooled

will

start

and

will

continue

by a built-in

This

thermal

by

automatically

high

temperature

interrupted,

or

circuit

stop

again

until

the

cut-out

breaking

the

motor

resets

when

overload

auto-

pre-

is

will

itself.

over-

has

34

Page 15

Seciion

4:

Maintenance

and

Repair

4.1

Note:

This

increased

metal.

Foreign

in

ated

and

ally

marks

Even

logical

tamination

procedures.

pool

and

changed

then

Disinfectant

The

be

Preventive

Please

Failure

unit

is

fabricated

corrosion

Cleaning

matter

the

form

of

by

body

other

foreign

the

foreign

in

the

more

important

infection

of

Treatment

Antiseptic

common

completely

be

cleaned

and

acid-alkaline

approximately

If

chlorides

trations

the

sion.

for

for

major

However,

stainless

chlorine.

Remove

4.2

4.2.1

Use

instructions

tion.

hot

Note:

hair

Cleaning

Routine

Sanizene

for

With

soft

water.

When

on

the

infecting

Maintenance

carefully

to

is

is

film

oils,

particles

surface

problems

water,

to

sense

and

are

the

cause

and

Hard

use

cloth,

disinfecting

disinfectant

procedures.

read

observe

of

resistance.

required

deposited

every

time

minerals

matter.

of

the

than

equipment

water

maintain

dictate

after

sanitized

rinsed

balance

with

7.4-7.8

CAUTION

used,

intended

of

pitting

Chlorazene

steel

because

debris

Cleaning

Surface

on

container),

wipe

CAUTION

AISI

If

will

each

of

for

maintain

from

container

these

important

instructions

type

304

However,

for

it

to

keep

onto

your

it

is

used.

in

the

water,

film

is

left

cause

corrosion,

stainless

appearance

that

may

develop

and

inappropriate

may

include

low

bacterial

that

the

treatment.

with

Sanizene

hot

water.

the

water

best

corrosion

the

purpose.

and

Disinfectant

entire

the

tank,

Chloride

intergranular

has

been

of

its

drain

after

soap

surface

consult

for

instructions.

will

void

stainless

it

is

its

polished

stainless

The

film

organic

on the

tank,

steel.

are

the

through

Chlorazene

levels.

water

The

Hard

in

your

tanks

resistance.

lowest

concen-

ions

tested

slow

release

each

in

solution

or

detergent

area.

the

proper

use

warranty.

steel

for

not a magic

look.

steel

tank

is

gener-

deposits,

eventu-

leaving

treatment

pit

bacterio-

con-

Whirl-

Experience

should

tank

be

should

Surface

should

are

corro-

safe

of

use.

(see

in

solu-

Rinse

with

directions

and

dis-

To

Remove

Use a good

and

vinegar.

steel

wool

5

minutes.

Note:

Rinse

Stubborn

stainless

Scrub

or

cleaning

Rinse

Always

mum

thoroughly

rub

effectiveness.

steel

the

with

in

the

with

Spots

and

cleanser

area

with a cloth,

pad.

Let

warm

water

direction

fresh

water

Stains

such

stand

and

of

polish

after

as

Ille

Steelscrub

sponge,

for

approximately

wipe

dry.

lines

every

operation.

Always

NEVER

4.3

4.3.1

When

nozzle,

discharge

1.

2.

wipe

dry

to

avoid

USE

STEEL

High

concentrations

chlorite

affect

will

the

warranty.

damage

Maintenance

Drain

Refer

cian

or a qualified

water

it

Be

sure

Turn

pump

pump. A vibration

If

so,

follow

Probe

nozzle

Put

water

found,

counterflushing

(use

safety

filler

hose

hose

to

slow

flow),

floor.

Rotate

valve

step

4.)

Pump

electrical

fails

to

is

usually

piping.

pump

operates

switch

step

into

swing

was

clogged,

in

tank

the

problem

lock

to

swing

cold

water

and

tank

under

tank.

servicing

flow

due

can

2.

drain

and

drain

pin).

any

to

water

WOOL.

WARNING

of

sodium

your

CAUTION

service

or

runs slowly

to

an

when

ON,

reach

be

detected

If

not,

nozzle

you

probably

try

pump.

is

in

another

pump

Turn

tank

arm

nozzle.

supply.

small

normal

(Should

marks.

or

calcium

hydrotherapy

tank

Procedures

to a professional

technician.

out

of

obstruction

pump

under

follow

with a piece

part

system.

upside

Connect

Open

particles

position,

counterflushing

in

switch

tank

if

pump

step

3.

found

the

If

no

obstruction

of

the

Remove

down.

faucet

will

and

the

of

other

slightly

be

hypo-

electri-

swing

is

turned

and

is

wire.

obstruction.

system.

Attach

flushed

open

fail,

stainless

for

maxi-

cleaning

and

drain

pump

or

on.

touch

running.

If

the

was

Try

turbine

your

end

of

(very

on

drain

follow

41

The

tank

disinfectant.

FAILURE

FORT

must

TO

AND/OR

be

completely

DO

SO

COULD

IRRITATION

rinsed

CAUSE

TO

NEXT

and

free

DISCOM-

PATIENT.

of

Page 16

3.

If

pump

defective.

lock

turbine,

Now

ceptacle.

Switch

electric

For

testing

access

screws

shield

1,2,

Place

terminals.

cate

The

switch

of a fairly

ble.

Ille

nal

cost.

service

4.

Should

sary

ceed

pin

in

and

units

4.3.2

still

does

To

check

pin

in

raising

and

lay

insert

continuity

Flip

drain

in

shield

supply

of

drain

to

the

back

on

the

sides

down

and

3,

and

4,

or

continuity

If

movement

continuity,

used

compact

will

supply

Have

your

technician

the

backwashing

to

open

pump

with

this

inspection,

raising

lay

prior

and

tank

to

To

Remove

on

June

Impeller

not

operate,

switch,

and

lowering

tank

on

side,

tester

switch

may

be

verified

cord

prior

pump

or

of

the

at

the

remove

3.

tester

and

from tank

4 at

probes

of

switch

is

in

this

assembly

size

and

replacement

professional

perform

housing

lowering

side.

Safety

1,

1986.

the

pump

empty

tank,

device

Unplug

probes

to

to

servicing).

heater

shield.

bottom

the

pump

into

determine

as

follows:

switch,

To

do

of

the

by

pulling

quick

disconnect

across 2 sets

switch toggle

defective

may

this

method

and

empty

device

Pump

(see

is a double

not

from

electrician

work.

fail,

inspect

tank,

“insert

tube”,

lock

pin

and

switch

insert

tube,’

supply

drain

if it

(disconnect

you

this,

remove

shield.

apart wires

does

Figure

pole

be

readily

stock

or

it

will

impeller.

remove

is

only

Inspect

may

be

“safety

remove

cord.

pump

re-

operates.

must

gain

the

Slip

the

splices.

of

switch

not

indi-

2-8).

switch

availa-

at a nomi-

qualified

be

neces-

To

pro-

safety

lock

turbine,

found

on

C.

Pump

Seal

If

the

drain

tended

vent

Remove

bracket.

rubber

seal.

in

screws,

D.

Lubrication

The

ball

4.4

When

serial

period,

dripping

ring

Carefully

position.

electric

bearings

Replacement

ordering

number

description

HEATERS

For

115

Volt

200—Pt.

HEATER

GUARDS

200—Pt.

Thermostat

Knob

Thermostat

Switch

Switch

Pilot

(Pump

(Pump

Light

(Bulb

pump

was

the

seal

of

water

cover

and

mounting

Remove

and

of

impeller

(approximately

push

replacement

Reassemble

housing.

motor

of

and

requires

replacement

and

unit

part

and

Units

093-3511-00

093-1516-00

Heater

or

Heater,

or

Heater,

only)

accidentally

may

require

on

floor.

screws.

(see

2%

impeller,

the

pump

no

Parts

parts,

model

part

number

For

HM200—Pt.

Late)

Old)

run dry

replacement

Lift

off

B2,

above).

in.

diameter.)

seal

part

#093-8136-00

cover,

is

equipped

lubrication.

always

number.

(if

230

mention

Also

available).

Volt

Units

093-3512-00

Pt.

093-8776-00

Pt.

093-5106-00

Pt.

093-8558-00

Pt.

093-8559-00

Pt.

093-6818-00

for

an

to

cover

Now

pull

This

mounting

with

sealed

include

pre-

and

is

the

unit

ex-

off

i

,

Always

unit.

A.

Pump

1.

B.

Dismantle

1.

2.

disconnect

Removal

Disconnect

.

Loosen

.

Remove

.

Slip

out

.

Slide

op oN

parts.)

Remove

misplaced

Since

require

turning

left.

the

may

be

(Figure

pump

and

slip

the 4 pump

copper

pump

off

cast

Pump

(Figure

the 4 housing

matter

impeller

is

replacing.

sharply

it

(Replacement

ordered

CAUTION

power

supply

2-5)

power

back

cord.

the 2 hose

mounting

drain

tubing

elbow

2-6)

screws—lift

can

be

flexible,

to

from

it

However,

left.

the

impellers

İlle.)

prior

screws.

assembly.

spud

housing.

removed.

is

unlikely

can

it

will

It

part

to

servicing

clamps.

(Save

housing

that

it

will

removed

be

unscrew

then

#093-4858-00

off.

Any

ever

all

by

to

42

Page 17

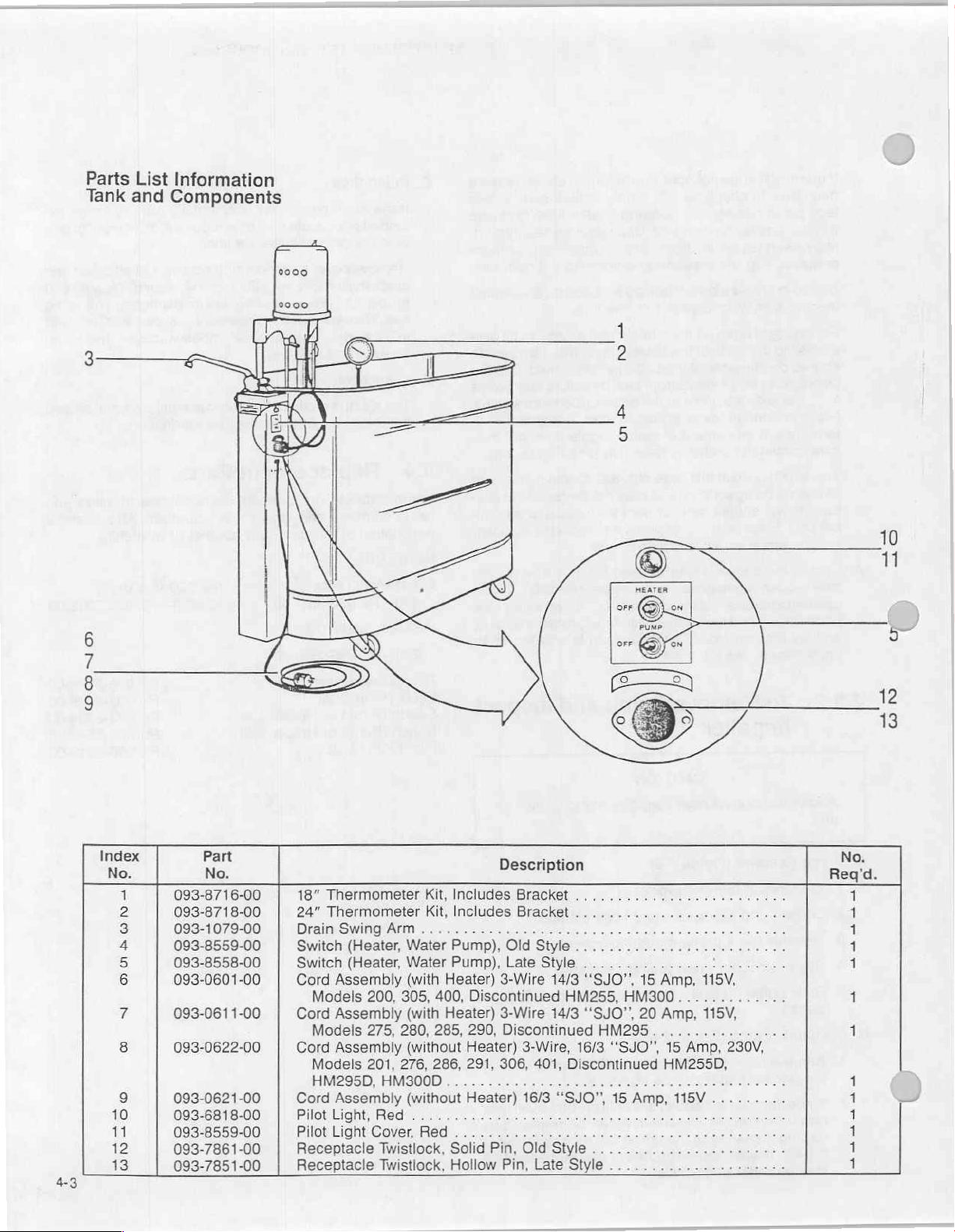

Parts

Tank

List

Information

and

Components

0000

0000

3

6

7

8

9

=e

>

a

y

hb

で

1

2

4

=

5

|

10

|

|

S

HEATER

11

Index

No.

1

2

3

4

5

6

Fa

8

9

10

11

12

13

Part

No.

093-8716-00

093-8718-00

093-1079-00

093-8559-00

093-8558-00

093-0601-00

093-0611-00

093-0622-00

093-0621-00

093-6818-00

093-8559-00

093-7861-00

093-7851-00

18"

Thermometer

24”

Thermometer

Drain

Swing

Switch

Switch

Cord

Assembly

Models

Cord

Assembly

Models

Cord

Assembly

Models

HIM295D)

Cord

Assembly

Pilot

Light,

Pilot

Light

Receptacle

Receptacle

Arm

(Heater,

(Heater,

Water

Water

(with

200,

305,

(with

275,

280,

(without

201, 276,

HIMB00D),

(without

Red

Cover,

Twistlock,

Twistlock,

Kit,

Kit,

Heater)

400,

Heater)

285, 290,

286,

..

Red

Solid

Hollow

Description

Includes

Includes

Pump),

Pump),

Discontinued

Heater)

291,

Heater)

.....

Bracket

Bracket

Old

Late

3-Wire

3-Wire

Discontinued

3-Wire,

306,

Pin,

Old Style

Pin,

5

Style

.

Style

14/3

HM255,

14/3

401,

Discontinued

16/3

“SJO”,

Late

Style...

..

.

.

“‘SJO”’,

‘‘SJO”’,

HM295

16/3

“SJO”,

15

.

...............!........

15

Amp,

115V,

HM300.............

20

Amp,

115V,

.

R

Ål

Amp,

23

v,

HM255D,

本

Amp,

115V...

ae

s

No.

Req'd

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 18

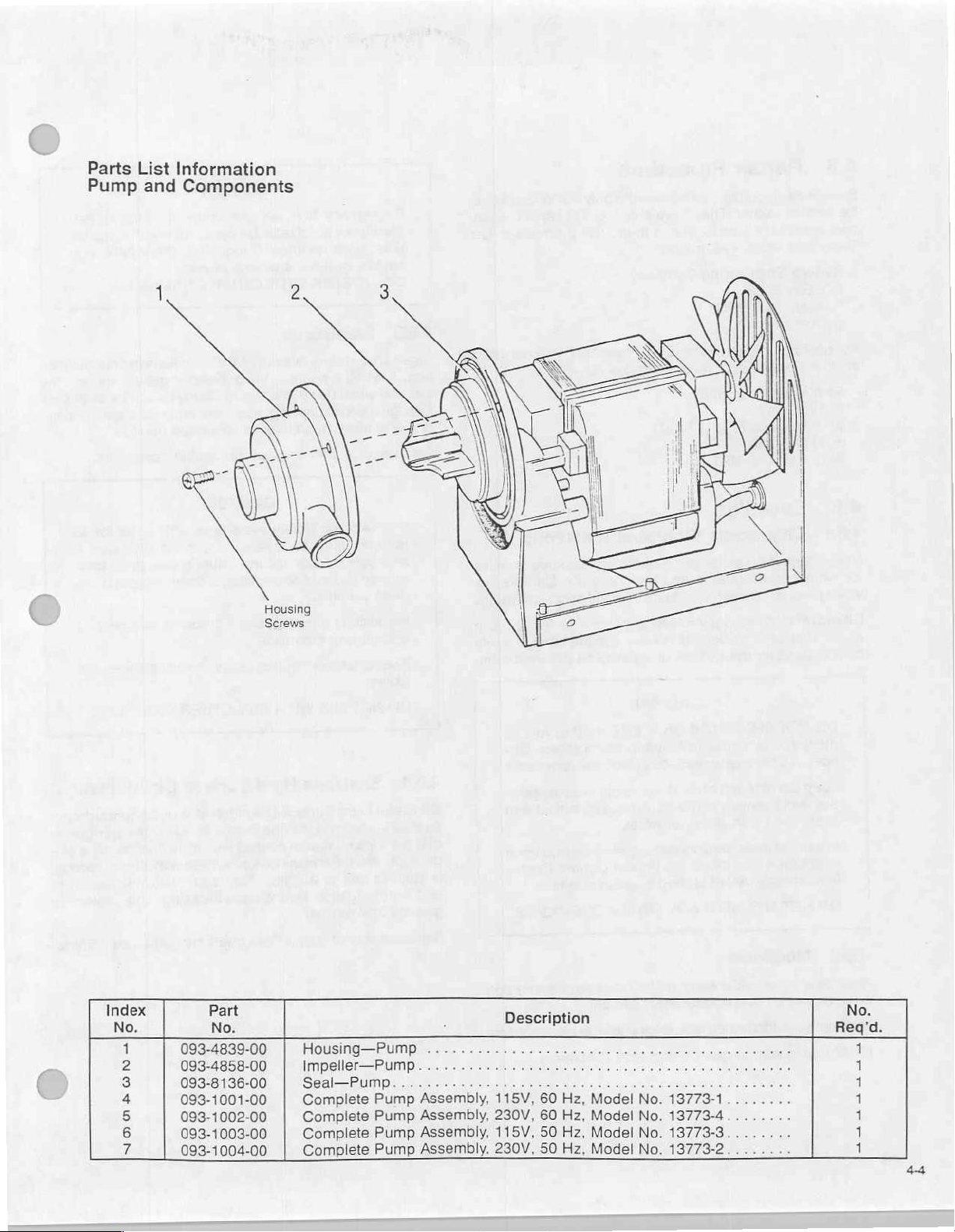

Parts

Pump

List

Information

and

Components

Housing

Screws

Index

No.

一

RON

の

の

ざさ

093-4839-00

093-4858-00

093-8136-00

093-1001-00

093-1002-00

093-1003-00

093-1004-00

Part

No.

Housing—Pump

Impeller—Pump

Seal—Pump

Complete

Complete

Complete

Complete

Pump

Pump

Pump

Pump

..

.

Assembly,

Assembly,

Assembly,

Assembly.

Description

115V,

60

Hz,

230V,

60

Hz,

115V,

50

Hz,

230V,

50

Hz,

Model

Model

Model

Model

P

No.

13773-1...

No.

13773-4...

No.

13773-3...

No.

13773-2........

.

Req'd

No

Page 19

4.5

Service

Ille

cies

To

For

contact

Repair

Engineering

service

contact

Service

PO.

Raleigh,

1-800-334-5528

questions

Ferno-Washington,

70

Wilmington,

(513)

Fax:

dealer.

across

the

them,

Engineering

Box

25021

NC

Ferno

Weil

Way

382-1451

(513)

382-1191

27611

about

Ille

OH

Procedure

Company

They

have a network

United

States

call

or

write:

Company

items

Customer

Inc.

45177-9371

is

the

to

under

Service

only

authorized

of

provide

warranty,

prompt

at:

service

service.

you

may

Ferno

agen-

also

Emergency

Medifome

5

or

more

whites,

DO

NOT

4.6.3

Steelscrub

tion. À small

mended

through

tact

Steelscrub

Steelscrub

cleans,

when

the skin

with

large

first

is

splashed

minutes.

or

large

MIX

amount

using

causing

quantities

is

sold

CAUTION

aid

procedure

in

If

ingested,

amounts

WITH

OTHER

bleaches

is

used.

Steelscrub.

possible

for

in

quart

and

if

eyes,

flush

drink

of

water.

CHEMICALS.

and

disinfects

Rubber

Materials can

kidney

extended

gallon

concentrated

with

water

milk,

in

one

applica-

gloves

periods.

containers.

be

damage

are

absorbed

if

for

egg

recom-

in

con-

4.6

4.6.1

Chlorazene

for

when

Chlorazene

handy

correct

Supplies

Chlorazene

whirlpool

used

unit

dose

DO

NOT

dusting

pose

of

Keep

out

der.

Avoid contact

eyes,

flush

In

case

assistance

immediately.

DO

NOT

is

an

antiseptic

treatments

as

directed,

Whirlpool

dose

packages.

for

the

SHAKE

may

cause

Chlorazene

of

reach

with

of

accidental

or

contact

Avoid

MIX

WITH

Whirlpool

powder,

and

will

control

Antiseptic

Always

gallons

with

plenty

of

CAUTION

CHLORAZENE

irritation

package

of

children.

eyes.

of

ingestion,

the

storing

ANY

Antiseptic

non-staining

bathing

harmful

powder

consult

water

used

to

membranes.

in a closed

Avoid

In

case

water.

seek

Poison

in

excessive

OTHER

additive

units.

Chiorazene,

micro-organisms.

is

available

label

to

per

treatment.

IN

THE

AIR

as

Dis-

receptacle.

inhaling

of

contact

professional

Control

CHEMICALS.

pow-

with

Center

heat.

in

verify

If

Steelscrub

minutes.

skin

oughly

duce

Hazardous

and

If

using

gloves.

DO

NOT

4.6.4

Sanizene

porous

of

gle

or

and

glasses

Sanizene

surfaces.

water

for a minimum

application.

cloth

as

water

and

enters

If

irritation

contact

vomiting.

carbon

has

to

avoid

decomposition

monoxide.

large

amounts,

MIX

WITH

Sanizene

Hard

Surface

Use

Sanizene

well

as

spraying.

together

gloves.

is

sold

in

CAUTION

eyes,

persists,

occurred

absorption.

use

ANY

Hard

Surface

Disinfectant

one

ounce

contact

can

be

For

before

unit-dose

each

flush

with

contact

during

If

taken

products

protective

OTHER

is

of

Sanizene

time

of

applied

best

results,

cleaning.

quart

and

water

for 15

physician.

use,

rinse

internally,

are

chlorine

glasses

CHEMICAL.

If

thor-

in-

and

Disinfectant

used

on

hard non-

per

gallon

10

minutes

with a mop,

gallon

mix

Sanizene

Use

protective

containers.

for a sin-

sponge,

4.6.2

Medifome

ener,

Medifome

Medifome

45

Medifome

is

an

detergent

is

added

is

sold

underwater

and

deodorant

when

tank

in

quart and

patient

treatment.

is

full

and

gallon

massage,

lasts

one

containers.

water

soft-

treatment.

Page 20

In

case

with

plenty

eyes,

drink a large

solution,

quantities

cal

attention.

Probable

use

of

shock,

be

needed.

DO

NOT

CAUTION

of

contact,

of

call a physician.

or

if

of

mucosal

gastric

respiratory

MIX

immediately

water

for

quantity

these

are

water.

AVOID

NOTE

TO

damage

lavage.

Measures

depression,

WITH

ANY

at

least

If

swallowed,

of

milk,

egg

not

available,

ALCOHOL.

PHYSICIAN

may

and

OTHER

flush

eyes

or

15

minutes.

immediately

whites,

contraindicate

against

convulsion

CHEMICAL.

gelatin

drink

large

Get

medi-

circulatory

skin

For

the

may

46

Page 21

Chlorazene

Health

Threshold

Effects

Emergency

Hazard

of

Overexposure

Material

Data

Limit

Value

and

First

Safety

....

Aid

Procedures

Data

.

.

...............

«Not

Applicable

«Not

Applicable

Get

in

Eyes:

minutes.

water,

Inhalation:

Swallowing:

attention.

Seek

rinse

Rinse

medical

well.

seek

water

eye(s)

fresh

and

with

running

attention.

air

and

rest,

active

water

Wash

skin with

seek

medical

charcoal.

for

at

soap

attention.

Seek

least

15

and

medical

Reactivity

(人

Conditions

Incompatibility

Hazardous

Hazardous

Spill

Steps

Waste

Special

Respiratory

Ventilation

Protective

Eye

Protection

Special

Handlingsand

Data

inte

to

Avoid

Decomposition

Polymerization

or

Leak

to

Be

Taken

Disposal

Protection

Protection

....,....

Gloves

Precautions

Procedures

Staring

..

Method

.

Information

.

se.

Enr

a

hs

Products

........................

. .

.

Under

Do

Acids,

.

.With acids

no

Decomposition

foaming.

.

-Sweep

.

Add

fite,

sulfonamide.

„Dust

Local

Wear

.

.Not

Do

35°C

not

store

cl2

fire.

up,

to a solution

this

filters

exhaust

gloves

Applicable

not

store

above

cl2

results,

sets

avoid

dust.

of

decomposes

above

35°C,

thermal

in

within

sodium

the

35°C.

store

away

decomposition,

15

minutes

thiosulfate

material

to

from

heat.

smoke

at

130°C

or

sodium

harmless

but

under

sul-

tolueane

47

Page 22

Medifome

Identification

Manufacturer's

Chemical

Trade

Chemical

Name

Name

and

Family

Formula

Name

and

Synonyms . .

Synonyms

..

.

Clarkson

213

Main

So.

Williamsport,

Not

Applicable

-

-Medifome

.

-Detergent

See

Below

Chemical

Street

Company

PA

17001

Inc.

Hazardous

Pigments

Catalyst

Vehicle

Solvents

Additives.

Base

.

..

...

Metal

..

...

.

Ingredients

Alloys

Metallic

Filler

Hazardous

Thymol

Oil

Methyl

Oil

Hexametaphosphai

Pine

Sulphonated

Caustic

Physical

Boiling

Vapor

Vapor

Solubility

Specific

Percent

Evaporation

Appearance

Metal

or

Gases

of

Eucalyptus

of

Thyme

Oil

Pressure

Density

Coating

Mixtures

Crystals

Silicate

..

Castor

Potash...

Data

Point

(°F) . .

(Air

in

Water

Gravity

Volatile

Rate

and

SE

of

Other

.

.

Oil

C-75.

..

(420 = 1)

by

Volume . .

Odor

de

Liquids,

..

ЕЕ

Solids,

Not

Applicable

.

.Not

Applicable

.

-Not

Applicable

Not

Applicable

Not

Applicable

.

Not

Applicable

.

-Not

Applicable

.

.Not

Applicable

Not

Applicable

TLV

(Units)

0.06%

0.15%

0.15%

0.07%

4.10%

1.60%

24.00%

0.16%

70.00%

212°

.

.Not

Applicable

.

.Not

Applicable

. . Very

.

.

.

Good

Not

Applicable

.Not

Applicable

-Not

Applicable

.Green—Wintergreen

Pine

4-8

Page 23

Steelscrub

Health

Hazard

Threshold

Effects

Emergency

of

Material

Safety

Data

Limit

Value

Overexposure

and

First

..

.

.

Aid

Procedures

Data

..............-

Not

Applicable

Can

be

(contact

Get

in

Eyes: Flush

sists,

contact

If

Contact

tion.

If

taken

absorbed

with

large

physician.

with

Skin:

internally,

through

quantities

with

water

Wash

induce

skin,

to

cause

for

extended

for

15

minutes.

immediately

vomiting.

kidney

periods)

If

irritation

to

avoid

damage

per-

absorp-

Reactivity

Data

Unstable..........

Incompatibility

Hazardous

Hazardous

Spill

or

Leak

Steps

to

Waste

Disposal

Special

Respiratory

Ventilation

Protective

Eye

Protection

Special

Handling

Decomposition

Polymerization..............

Procedures

Be

Taken

Protection

Protection

...

Gloves

Precautions

and

..

Method

.

...

Storing

Products...

.....................,....

.

Information

Keep

away

Not

Applicable

.

.Chlorine,

Will

not

If

spilled,

absorbed

Transport

Not

Applicable

.

.Not

Applicable

..

Wear

gloves

.

.Wear

Eye

Under

requires

from

Carbon

occur.

material

with

to

Landfill.

Protection

normal

no

special

heat

and

Monoxide

may

be

sweeping

conditions,

handling.

acids.

washed

down

compound.

product

is

with

not

water,

hazardous

then

and

49

Page 24

Sanizene

Health

Threshold

Effects

Hazard

of

Material

Safety

Data

Limit

Value

Overexposure

Data

.

.Not

Applicable

.

.Eyes—causes

Skin—causes

Ingestion—harmful

eye

damage.

severe

or

skin

irritation.

fatal

if

swallowed.

Emergency

με

Reactivity

and

ει

Data

First

αρα

Aid

ae

ce

eme

de

che

Stable

Incompatibility

Hazardous

Hazardous

Spill

or

Leak

Steps

to

...................

Decomposition

Polymerization..........

Products

Procedures

Be

Taken

WasteDisposalMethod..........................

Special

Respiratory

Ventilation

Protective

Eye

Protection

Protection . .

......

Gloves

Protection

Information

.

...

>

Eyes—Immediately

minutes.

Skin—immediately

minutes.

Ingestion—drink

whites,

ical

gelatin

attention.

...-Acids

..

None

.

-Will

not

Mop

or

flush with

or

feed.

If

waste

instructions,

control

the

-

None

Not

Wear

.

Goggles

agency,

nearest

Applicable

gloves

flush

Call a physician

flush

promptly a large

solution

occur.

cannot

contact

EPA

or

face

be

or

or

water.

Avoid

disposed

your

the

hazardous

Regional

shield.

eyes

with

plenty

immediately.

skin

with

plenty

quantity

large

quantity

contamination

of

by

use

state

pesticide

waste representative

Office

for

guidance.

of

water

of

water

of

milk,

of

water.

Get

of

food,

according

or

environmental

for

for

water

to

15

15

egg

med-

label

at

Special

Precautions

HandlingandStoring............................

Do

not

contaminate

posal.

Open

container.

water,

dumping

food

or

is

prohibited.

feed

Do

by

storage

not

reuse

or

dis-

empty

4-10

Page 25

4.7

Accessories

Note:

Accessories

only

Adjustable

These

designed

tion

of

and

indispensable

of

the

tank,

affording

lower

when

High

for

use

chair

leg

treatment.

are

specified.

Chair—Model

chairs

with

leg

permits

the

maximum

priced

are an

tank

seat

comfort

separately

90,

91

accessory

units.

The

to

protrude

to

and

special

over

patient

furnished

especially

construc-

the

edge

during

foot

Arm

Rest—Model

For

supporting

of

stainless

arm

steel.

11

inside

of

tank

during

treatment.

Made

Les

91

Hydro-Chair—Models

Economy,

and

leg

whirlpools,

arm

rests.

from

29”-39".

Model

Model

23—Order

24—Order

lighter

Chair

23,

weight

adjustable

frame

No.

078-1210-00

No.

078-1220-00

24

model

tubular

chair

seat,

steel.

(without

(with

for

patients

step

height

Seat

height adjusts

casters)

using

12”,

casters)

hip

two

>

411

Page 26

Section

This

equipment

and

is

fully

covered

the

Warranty

of

product.

Ferno

Ille

fect

in

material

of

charge

is

returned

year

from

to

be

construed

not

apply

switches,

Ferno

Ille

by

others.

Card

will

guarantee

and

any

part

to

us,

date

of

to

to

standard

receptacles,

cannot

5:

has

been

carefully

by

the

Ferno

is

mailed

workmanship.

that

transportation

purchase.

cover

electrical

assume

within

all

Ferno

may

be

This

willful

etc.

responsibility

Warranty

inspected

Ille

guarantee

ten

Ille

equipment

We

agree

found

defective

charges

service

neglect

or

equipment,

prepaid,

and

days

from

to

to

replace

if

within

guarantee

misuse

lamps,

for

repairs

provided

and

tested

receipt

be

per-

free

this

part

one

is

not

does

bulbs,

made

5-1

Page 27

FERNO

ille

Ferno-Washington,

70

Weil

Way

Wilmington,

Phone:

FAX:

513/382-1191

OH

513/382-1451

Inc.

45177-9371

Gov.

200

Printed

FL-044-8

in

U.S.A.

Page 28

(9

FERNO

ille

Model

Electric

100

Turbine

Ejector

i

Operation,

Service

Repair

and

Parts

Manual

Page 29

Section

1:

Table

of

Contents

Section

Model

оо

Section

Start-up

Operator

Shutdown

Section

Maintenance

Major

Preventive

Troubleshooting

Repair

ISUPPÎOS

Section

2:

Equipment

100

Electric

3:

Operation

Procedures

Data

Procedures

4:

Maintenance

Overhaul

Maintenance

Procedure

el

5:

Warranty

Data

and

Drawings

Turbine

.........................

Schedule

of

Turbine

Guide

..............

Ejector

....................

...................

and

Repair

..

Schedule

.........

о

5

.

e

Aedo) 7 ese

dee

2.1

21

3.1

3.5

3.6

4.

©Copyright,

All

rights

1989,

reserved.

FERNO-WASHINGTON,

INC.

NOTE:

Due

to

Subject

our

to

Constant

Change

Without

Improvement

Notice.

Program,

Units

are

Page 30

Section

2:

Equipment

Data

and

Drawings

2.1

Model

Ejector

The Ferno

and

ing

is a list

to

use.

listed.

proper

Note:

115

Volt—60

other

order.

Drain

For

HM300,

similar

The

front,

a

hollow center

#7485

Non-Drain

For

Models

HM1000,

The

blade,

cord

ground,

for

connection

customer.

After

with a ground

Volt—60

blade,

Ille

with

various

of

Mechanical

The

turbine

physical

Ille

Electric

ation

current

Pump

Models

305,

units:

supply

supply

cord

cord

cap.

with a solid

Pump

500,

HM1010,

cord

“U”

ground,

terminates

cord

7/86,

supply

Hertz - 15

“U”

ground,

100

Electric

Turbine

various

on

Hertz

characteristics

Units

200,

HM310D,

cap

fault

Ejector

electric

size

the

115

115

230

230

terminates

115

pin

HM505,

terminates

with a “hospital

into a wall

cord

supply

supply

length

ejector,

Turbine

HM255,

for

packed

for

use

following

Volts—60

Volts—50

Volts—60

Volts—50

units

are

400,

Volt

units

and 230

center

Units

(Stationary)

600,

1005:

cord

cap

230

Volt

for

non-drain

circuit

amp

NEMA

Turbine

is

supplied

cord

terminations.

cord

terminations

variations

with

Ejectors

275,

160,

with a midget,

ground

with a “hospital

for

receptacle

interrupter

plug,

5-15P.

of

the

with

your

your

unit.

are

available

electrical

Hertz—AC

Hertz—AC

Hertz—AC

Hertz—AC

supplied

must

161,

have a Hubbell

Volt

HM655,

115

grade”,

units.

services:

as

be

specified

280,

285, 290,

165, 166,

units

pin.

675,

Volt

tandem

These

pump

(GFCI)

configuration

in

various

turbine

unit,

standard.

901,

twist-lock,

have a Hubbell

680, 685,

grade”

units,

cord

supplied

units

plug.

sizes

Follow-

according

are

not

will

be the

for

oper-

The

on

your

HM295,

911,

and

dead

#7594

with

690,

parallel

and

supply

blade,

“U”

caps

are

by

the

terminates

For

115

is

parallel

2.2

A.

2.2.1

Switch.

Motor

Suspension

Lever

Aerator

Valve

Water

Water

Bearing

Water

Throttle

Drawings

Unit

Identification

Unit

Bracket

Water

Throttle

Butterfly

Lubricating

Lubricated

(Inside

Intake.

Identification

Minimum

Recommended

Water

Level

Holes

Housing)

2

In.

Min.

Note:

Models

For

supply

The

front

hollow

#7485

Canadian

These

units are

areceptacle

receptacle

used

on

801,

cord

cap.

cord

ground

center

solid

a

with

Units

Only

supplied,

junction

box

accepts a cord

drain

pump

850,

825,

terminates

units

Volt

115

pin

center

(CSA):

box

units.

110,

with

have

230

and

ground

at

an

additional

mounted

cap

and

1200,

midget,

a

Hubbell

a

units

Volt

pin.

cost,

on

the

unit.

termination