Ferno Arachnipod User Manual

1

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

Total Edge Management System

USERS’ MANUAL

Version 6.1

CE Certied in 3 & 4 leg congurations to CEN/TS 16415:2013 for maximum 2 persons

and EN 795:2012 for single person use

Australia

Australia

2

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

CE Compliance Information 3

Introduction 4

WARNINGS 5

Working Load Limits (WLL) 6

Tripod and Kit Contents 7

General 9

Intended Purpose 9

Care, Maintenance & Storage 9

Transportation 10

Safety Information 10

Life Cycle 10

Non-metallic Components 10

Inspection of the Arachnipod 11

Repairs 11

Safe Working Practices 11

Principles of Edge Management 12

Critical Point Analysis 13

(High change of direction 13

The Two Rope System 14

Understanding the forces at a change of direction pulley 15

Understanding the forces being applied to the Arachnipod 15

Assessing the stability of your Arachnipod rigging 16

Tripod Stabilisation 16

Arachnipod Parts 17

Standard Leg 17

Pulley Leg 17

Pulley Leg 17

Reverse Head, Quad Plate and Quad Pod 18

Gin Head 18

Rigging Plate 18

Leg with a Standard Foot 19

Spike Foot & Soft Ground Shoe 19

Hold Down Stake 19

Bridge Beams and Trolley 20

Equipment Bracket 20

Steps 20

Bridge Systems 21

Arachnipod Assembly 22

Stabilisation 26

Anchoring the Arachnipod 26

Using an Arachnipod leg as an anchor 26

Tripod Stabilisation 27

Lazy Leg Tripod Stabilisation 28

Quadpod Stabilisation 29

A-Frame Stabilisation 30

Method 1 Standard A-frame 30

Method 2 Sideways A-frame (SA-frame) 30

Method 3 A-frame with a lazy leg 32

Gin Pole Stabilisation 33

Using a single leg to manage a handrail 34

Bridge Stabilisation 35

Accessories 36

Foot Options for your Arachnipod 36

Additional Accessories for your Arachnipod 37

Accessory Instructions

Winch 38

ISC UB171 Fall Arrest Adaptor Bracket

39

Lazy Leg Extension Kit 40

Lazy Leg Adaptor Plug 41

Equipment Bracket with 2:1 Rigging 42

Bridge Ratchet Strap Kit 43

Arachnipod Inspection 45

Arachnipod Disassembly 46

Leg Inspection 46

Inspecting the Heads of each leg 47

Standard Leg 47

Pulley Leg 47

Lazy Leg 48

Foot Inspection 48

Standard Feet 48

Spike Foot 48

Soft Ground Shoe 49

Hold Down Stake Inspection 49

Gin Head Inspection 49

Rigging Plate Inspection 50

Equipment Bracket Inspection 50

Reverse Head Inspection 50

Bridge Beam & Trolley Inspection 51

Arachnipod Winch Inspection 51

Forms

Arachnipod Kit Records 53

Regular & Annual Inspections 54

TABLE OF CONTENTS

3

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

CE Compliance Information

CE Certifying Organisation

SAI Global NB2056

PO Box 5420, Sydney NSW 2001 Australia

Level 37, 680 George Street, Sydney NSW 2000 Australia

CE CEC40142A1 Certified in 3 & 4 leg configurations to CEN/TS 16415:2013 for maximum 2 persons and

EN 795:2012 for single person use

Ferno is represented throughout the European Union by:

Ferno (UK) Limited

Ferno House, Stubs Beck Lane,

Cleckheaton, West Yorkshire BD19 4TZ, United Kingdom

44 (0) 1274 851999

Glossary

Throughout this manual the following abbreviations are used:

Abbreviation Description Abbreviation Description

NB2056 No. of Notied body for PPE m Metre

CEN/TS 16415:2013

EN795:2012

Standard for anchor systems “ Inch

TEMS Total Edge Management System PPE Personal Protective Equipment

SA Sideways A-frame Qty Quantity

N/A Not applicable ea Each

kN Kilonewton

A

Anchor

kg Kilogram Load

lb Pound WLL Working Load Limit

mm Millimetre MBS Minimum Breaking strength

EC REP

Australia

4

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

Introduction

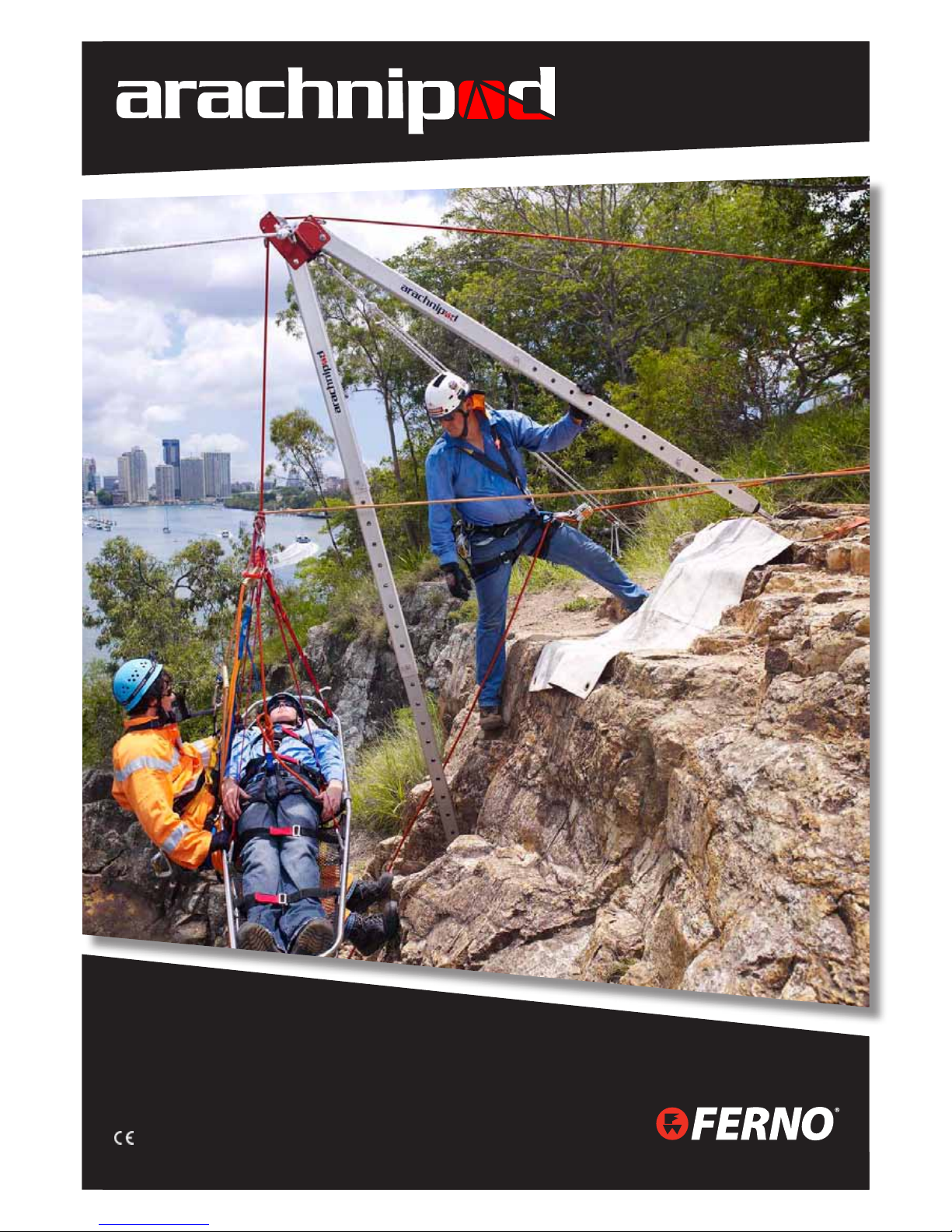

Congratulations on your purchase of the Arachnipod. The Arachnipod is a total edge management system that

will empower the end user with a wide range of conguration options.

The complete Arachnipod total edge management system (TEMS) can be rigged as a:

» Gin Pole (mono pole / monopod)

» A-frame (bipod)

» Sideways A-frame (SA-frame)

» Tripod

» Quadpod

» Lazy Leg or Easel Leg Tripod

» Handrail monopod (used to support to a handrail)

» Bridge

Components can be added or removed as required so that the Arachnipod compliments existing structural or

natural features making it the most versatile edge management solution on the planet.

Ferno knows that rigging is not always conducted on a at surface or with a clean edge so the Arachnipod was

designed with every conceivable task in mind. From the harshest vertical rescue conditions to a simple tripod for a

conned space entry task, the Arachnipod will provide the exibility that end users demand.

The versatility of the Arachnipod will appeal to a wide range of end users including rescuers, mines rescue,

industrial rope access workers, construction, and lm industries.

The end user can purchase as little or as much Arachnipod hardware to suit their scope of operations making the

Arachnipod an edge management system that is both aordable and upgradeable to suit changes in operational

needs.

With the appropriate training, the Arachnipod can be used in a variety of congurations and in any number of

environments from wilderness applications to industrial rope access scenarios.

5

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

Activities conducted at height can be dangerous resulting in injury or death. Do not use this device unless you

have:

1. Read and understood the User’s Manual

2. Received appropriate training

3. Ensured a competent person has conducted a risk assessment for the specic task

4. Carried out a preoperational check of the Arachnipod, associated hardware and rigging before each use

5. Accepted total responsibility for your own safety, and

6. Proof tested drilled-in anchorages in accordance with local standards.

• This manual is not intended as a substitute for appropriate training. Training, practice and experience in

technical rigging are essential for safe use!

• The Arachnipod and associated hardware must always be secured to prevent it from falling over an edge.

The Arachnipod may become unstable if used without an assessment of the resultant force and direction.

Additional rigging may be required to ensure complete stabilisation.

• A primary rope or cable system with an independent safety back-up system must be used when loaded life

lines are rigged through any edge management device.

• The Arachnipod has been engineered and tested using the original equipment as supplied. Never replace any

pins, bolts or other components with non-genuine parts.

• Do not use your Arachnipod if any parts are missing.

• Arachnipods should be decommissioned from service after a maximum of 12 years from the date of

commissioning into service. However if the date of commissioning into service is NOT recorded, the unit

should be decommissioned from service after 12 years from the date of manufacture.

• For service or repairs, please contact your local Ferno Distributor or Ferno Australia

Tel: +61 7 3881 4999

Email: sales@ferno.com.au

www.ferno.com.au

WARNINGS

Australia

6

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

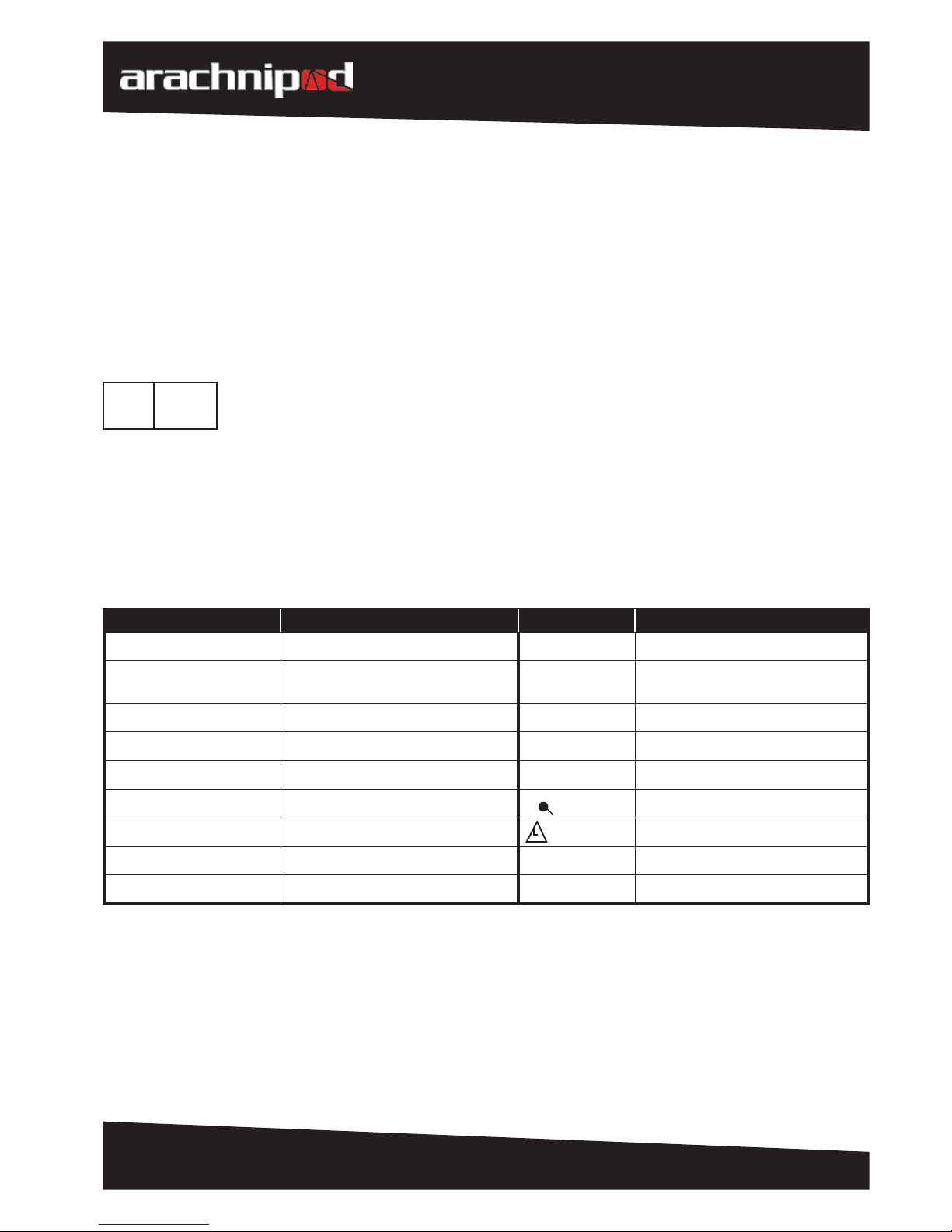

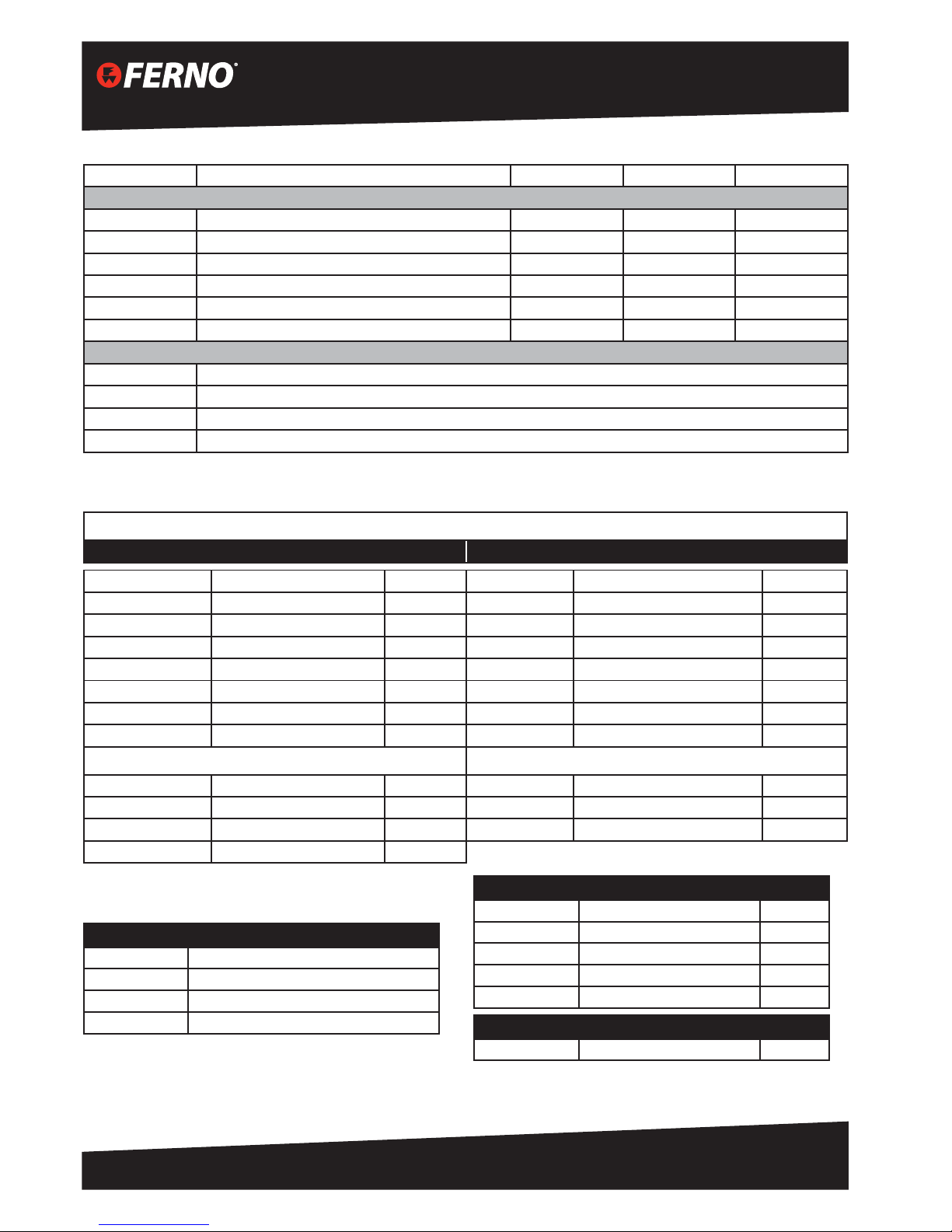

Working Load Limits (WLL)

The typical weight of a single person load ranges from 80 kg to 120 kg (176 lb* to 265 lb) depending upon a

number of factors. The WLL of the Arachnipod exceeds this load in all congurations.

The weight of a rescue load typically ranges from 200 kg to 280 kg (440 lb to 617 lb) depending upon a number

of factors. The Arachnipod oers many congurations that match or exceed the 280 kg load with only a few

exceptions. The table below outlines the working load limits of the Arachnipod in various congurations.

Leg Setting

WLL External

Anchor Point

MBS

WLL Load

Anchored to Leg

Gin Pole at 2050mm extension F-6 280kg/ 616lb 28kN N/A

Gin Pole at 3050mm full extension A-1 150kg/ 330lb 15kN N/A

A-Frame or

Offset A-Frame or

A-Frame with Lazy Leg

A-1

B-2

C-3

280kg/ 616lb

340kg/ 784lb

400kg/ 880lb

28kN

34kN

40kN

220kg/ 485lb

Tripod and Quadpod A-1 400kg/ 880lb 40kN

Handrail Monopole F-6 280kg/ 616lb 28kN

Bridge Beam 2000mm span* (middle of beam) A-1 280kg/ 616lb 28kN

Bridge Beam 3000mm span* (middle of beam) A-1 230kg/ 506lb 23kN

Bridge Beam 4000mm span* (middle of beam) A-1 175kg/ 385lb 28kN

Any span** (end of beam) A-1 280kg/ 616lb 19kN

Dimensions and Weight

Item Storage Max Length Weight

Standard leg 1420 mm / 56” 3050 mm / 120” 8.6 kg / 19 lb

Pulley leg 1550 mm / 61” 3150 mm / 124” 10 kg / 22 lb

Tripod

370 mm x 130 mm x 1420 mm

14.6” x 5.1” x 56”

3050mm / 120” 25.8 kg / 57 lb

Tripod with pulley head

370 mm x 130 mm x 1550 mm

14.6” x 5.1” x 61”

3150mm / 124” 27.2 kg / 60 lb

Tripod bag (empty)

380 mm x 150 mm x 1600 mm

15” x 6” x 64”

N/A 6.5 kg / 14.3 lb

Accessory kit (full)

400 mm x 20 mm x 660 mm

15.7” x 7.9” x 26”

N/A 19 kg / 41.8 lb

2 m Bridge

290 mm x 150 mmx 2070 mm

11.5” x 6” x 81.5”

N/A 21 kg / 46.2 lb

2 m Bridge kit

300 mm x 160 mm x 2150 mm

11.8” x 6.3” x 84.7”

N/A 40 kg / 88 lb

* If bridge beam has Strongbac tted, WLL for bridge beam

becomes 280 kg / 616 lb at any length up to 6000 mm / 236”

* WLL for bridge trolley is 250 kg / 550 lb (ultimate strength 24.5kN)

* Throughout this manual 1 lb (pound) = 0.453 kg and 1 kg = 2.2 lb

**Bridge beam MBS diers depending on where the load is positioned along the beam. On a 2m bridge beam

the safety factors reduces from 10:1 to <7:1 as the trolley moves from the centre to the end of the beam.

7

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

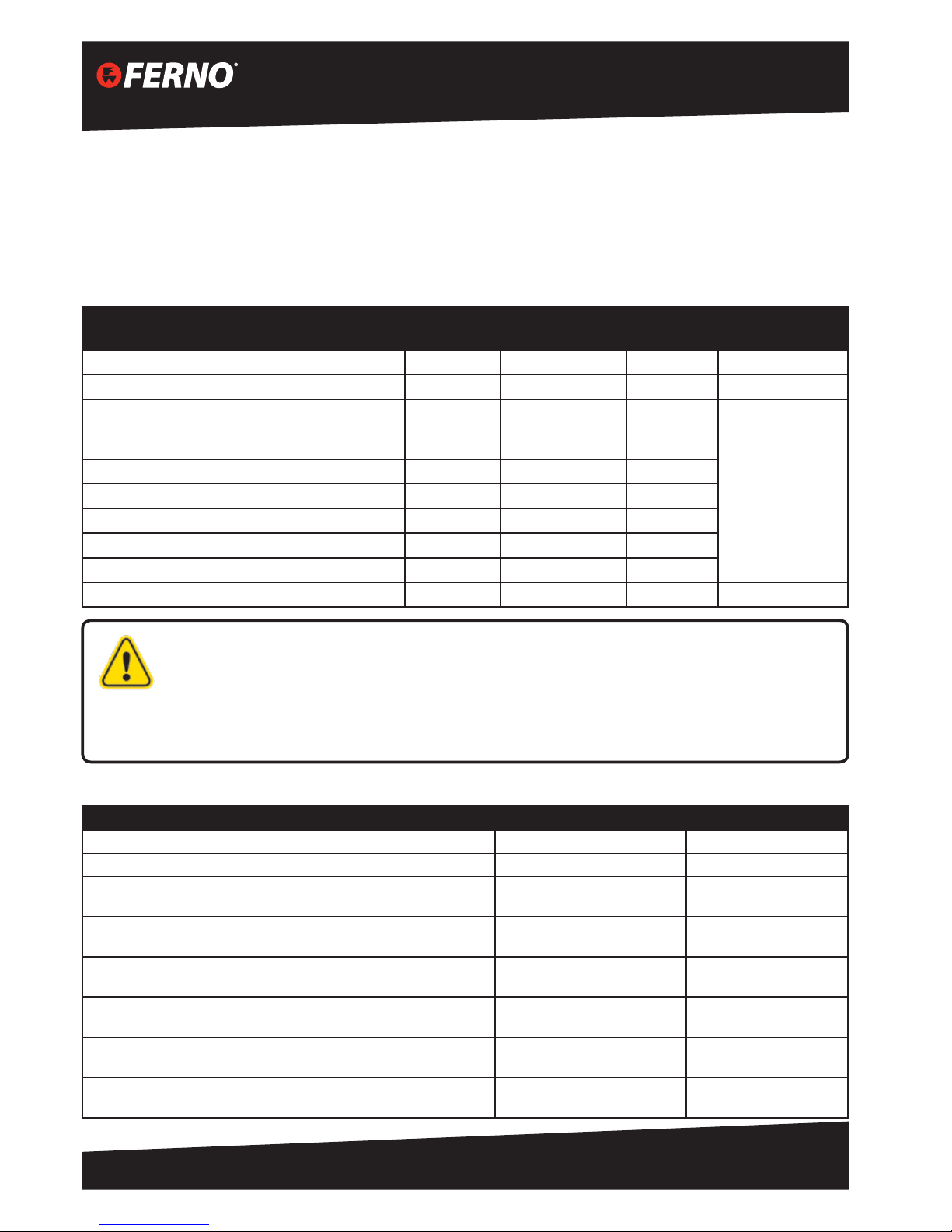

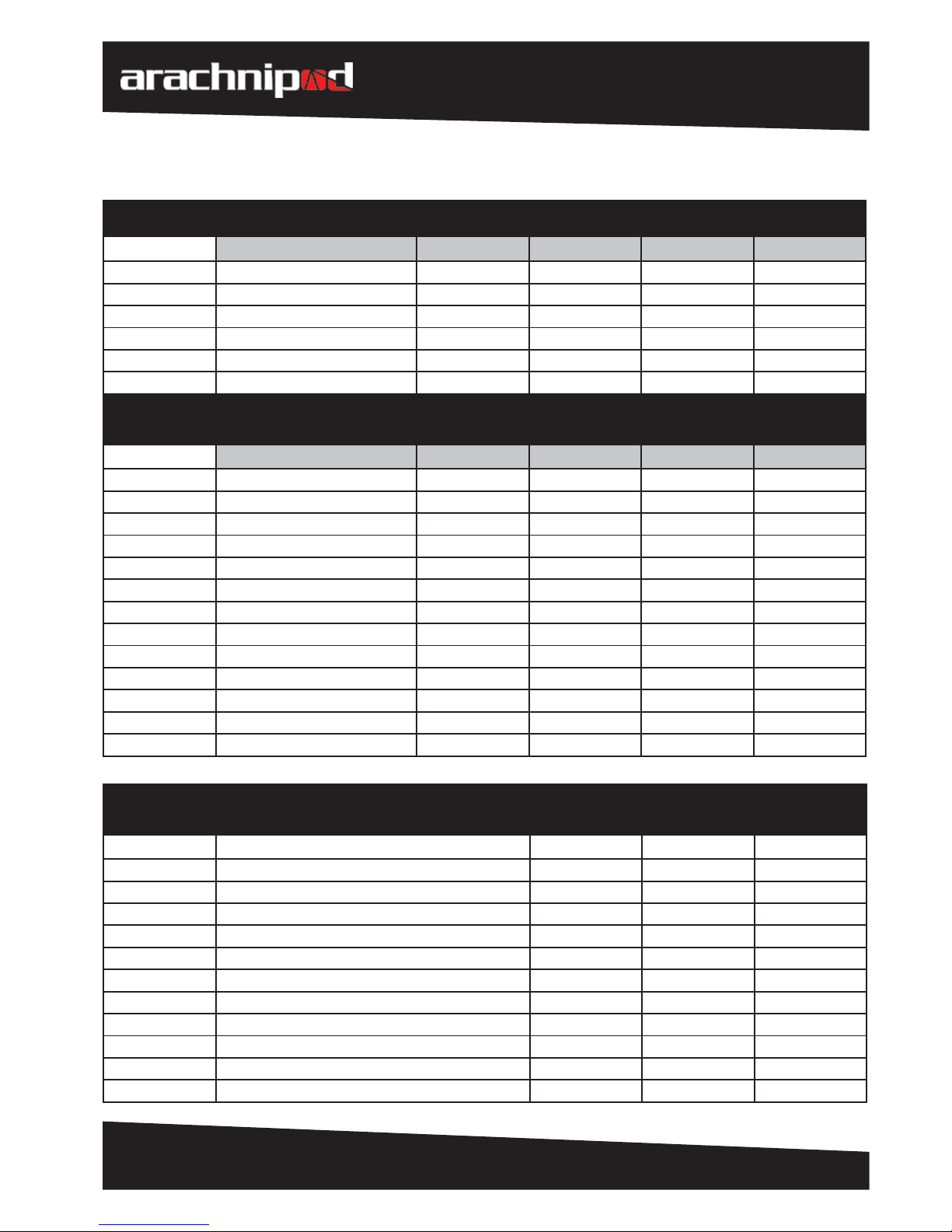

Tripod and Kit Contents

ARACHNIPOD

PART NUMBER

ARACHNIPOD

COMPONENT

ARACHNIPOD

INDUSTRIAL

ARACHNIPOD

INDUSTRIAL PLUS

ARACHNIPOD AD-

VANTAGE BASIC

ARACHNIPOD

ADVANTAGE

TRIPOD STYLES:

APOD-IND APOD-IND+ APOD-ADV-B APOD-ADV

90-0108 Standard Leg 3 2 2 1

90-0110 Pulley leg 1 1

90-0114 Lazy leg 1 1

APOD-LLA Lazy Leg Adaptor Plug 1 1

42-1019 Feet Rope & Rope Grab 1 1 1 1

42-1011 Arachnipod bag 1 1

ARACHNIPOD

PART NUMBER

ARACHNIPOD

PART NAMES

ARACHNIPOD

RESCUE

ARACHNIPOD

ADVANTAGE PLUS

BASIC

ARACHNIPOD

ADVANTAGE PLUS

ARACHNIPOD

RESCUE PLUS

TRIPOD & ACCESSORIES KITS:

APOD-RESQ APOD-ADV+B APOD-ADV+ APOD-RESQ+

90-0108 Standard Leg 2 2 1 1

90-0110 Pulley leg 1 1 1

90-0114 Lazy leg 1 1 1

APOD-LLA Lazy Leg Adaptor Plug 1 1 1

42-1019 Feet Rope & Rope Grab 1 1 1 1

42-1011 Arachnipod Bag 1 1 1 1

26-0007-0 Rigging Plate 1 1 1

90-0120 Spike Feet 3

APOD -AKIT Arachnipod Full Accessory Kit 1

07-1027-0 Quad Plate 1 1

90-0121 Reverse Head 1 1

03-1037-0 Gin Head 1 1

APOD-ADV-AB Advantage Accessory Kit Bag 1 1

ARACHNIPOD

PART NUMBER

ARACHNIPOD

PART NAMES

ARACHNIPOD

TEMS

2 metre Bridge

ARACHNIPOD

TEMS

3 metre Bridge

ARACHNIPOD

TEMS

4 metre Bridge

APOD-TEMS2 APOD-TEMS3 APOD-TEMS4

90-0108 Standard Leg 1 1 1

90-0110 Pulley leg 1 1 1

90-0114 Lazy leg 1 1 1

APOD-LLA Lazy Leg Adaptor Plug 1 1 1

42-1019 Feet Rope & Rope Grab 1 1 1

42-1011 Arachnipod Bag 1 1 1

26-0007-0 Rigging Plate

90-0120 Spike Feet

APOD -AKIT Arachnipod Full Accessory Kit 1 1 1

APOD-BR2 2m Bridge Kit 1

APOD-BR3 3m Bridge Kit 1

Australia

8

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

APOD-BR4 4m Bridge Kit 1

INCLUDED IN BRIDGE KITS:

Bridge 2m Bridge 3m Bridge 4m Bridge

90-0108 Spare Standard Leg 1 1 1

42-1013 2m Bridge Bag 1

42-1014 3m Bridge Bag 1

42-1015 4m Bridge Bag 1

42-1019 Foot Tether Rope 1 1 1

BRIDGE KIT OPTIONAL UPGRADES/ ACCESSORIES

APOD-BRSSU Bridge Kit Stainless Steel Upgrade Kit

APOD-BRS Bridge Ratchet Strap Kit

APOD-BRSB3 Strongback Bridge Reinforcement 3m

APOD-BRSB4 Strongback Bridge Reinforcement 4m

FULL ACCESSORY KIT CONTENTS

PART NUMBER COMPONENT QUANTITY PART NUMBER COMPONENT QUANTITY

42-1012 Accessory Bag 1 68-0036 Spare Detent Pins 2

90-0120 Spike Feet 4 68-0054 Spare Leg Pin c/w Detent Pin 1

03-1037-0 Gin Head 1 07-1026-0 Steps 2

34-0032 Soft Ground Shoes 4 90-0119 Equipment Bracket 1

16-1046-0 Hold-Down Stakes 4 26-0007-0 Rigging Plate 1

68-0041 M12 Tru-bolts 8 07-1027-0 Quad Plate 1

68-0042 M12 Masonry Drill Bit 2 90-0121 Reverse Head 1

22-1002 Spare Qik-Link Head Pins 2

LAZY LEG KIT CONTENTS (APOD-LLK) WINCH & FALL ARRESTOR KITS

90-0114 Lazy Leg 1 APOD-W10 10m Winch & Mount- 6mm cable 1

90-0121 Reverse Head 1 APOD-W20 20m Winch & Mount - 6mm cable 1

42-1020 Lazy leg Bag 1 APOD-FA 15m Type 3 Fall Arrestor & Mount 1

APOD LLA Lazy Leg Adapter Plug 1

ACCESSORIES

APOD-EKLL Extension Kit for Lazy Leg

68-0054 Leg Pin

68-0047 Leg Pin Cable

APOD-LLA Lazy Leg Adaptor Plug

ADVANTAGE ACCESSORY KIT

07-1027-0 Quad Plate 1

90-0121 Reverse Head 1

03-1037-0 Gin Head 1

26-0007-0 Rigging Plate 1

APOD-ADV-AB Advantage Accessory Kit Bag 1

OPTIONAL EXTRAS

90-0120 Spike Feet 4

9

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

General

The Arachnipod is used for securing persons that work in conned spaces where a fall from height may occur,

specically in areas such as tanks, shafts, trenches, mountain clis and voids or conned spaces that need entering.

The use is limited to persons who are physically t and have been instructed in the proper safe use of the product

as well as obtaining the correct necessary knowledge in the use of the of the product. In order to rescue a person

that has been involved in a fall or incident / accident a full emergency rescue plan must be implemented to

consider all possible implications and situations that may occur during the rescue

Intended Purpose

The use of the tripod, quadpod or bridge system is limited to combinations of approved and registered

components only which are:

• Retractable type fall arrestor with rescue winch according to EN360

• Rescue, lifting and descending devices according to EN361, EN341, EN1496, EN67, EN1891, EN1497 and any

other relevant EN standard pertaining to the task that has been completed

• Approved and tested componentry by manufacturer of the product

Other combinations and components are not allowed as the safe operation of the system is not assured if relevant

standards are not followed. Additionally the tripod, quadpod or bridge system can be equipped with an approved

load winch that is available through the supplier of the unit. Instructions for the load winch must be followed and

the total working load of the desired conguration must not be exceeded.

The tripod, quadpod or bridge system is to be used for its intended purpose at the time of purchase and may not

be used for any other application. Any changes, repairs or additions are to be made by the manufacturer or its

accredited agents only.

The Arachnipod is to be used for personal fall protection only. It is not to be used for lifting equipment. Any

changes, repairs or additions are to be made by the manufacturer or its accredited agents only.

When the Arachnipod is used as part of a fall arrest system, the user shall be equipped with a means of limiting the

maximum dynamic forces exerted on the user during the arrest of a fall to a maximum of 6kN.

Care, Maintenance & Storage

• Wash the unit with warm water and soft detergent soap.

• Rinse with clean water.

• Leave unpacked unit in a warm, dry, well-shaded and ventilated place to dry.

• Do not use additional heat sources or blowers to dry the unit.

• Avoid contact with chemicals, oils, solvents and other aggressive corrosive materials or agents.

• Once cleaning is complete, store unit in bags or boxes and store at room temperature away from direct

sunlight.

• If unit requires any further maintenance, contact your supplier for further details.

Australia

10

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

Transportation

To avoid damage, the unit should be carefully packed into bags or boxes. The item’s weight should be marked on

the packaging and a note of caution for a person to take care when lifting heavy objects.

Safety Information

It is essential for safety that the Arachnipod be withdrawn from service immediately should any doubt arise about

its condition for safe use, or if it has been used to arrest a fall. It must not be used again until conrmed in writing

by a suitably accredited qualied person or the supplier of the system. Please be aware that extreme temperature,

chemicals and rough handling of the system may cause damage.

Life Cycle

The Arachnipod’s life span is dependent on the individual operational conditions each unit is subjected to. Many

factors aect equipment lifespan including frequency of use, actual conditions of use, care and maintenance of the

unit, weather and environmental conditions. If deemed necessary, the unit may be permanently withdrawn from

service before or after a speciic use, or after inspection during the unit’s mandatory annual review.

The maximum life span of the Arachnipod is twelve (12) years from rst being put into service provided it has not

sustained damage, is maintained, serviced and inspected according to manufacturer’s instructions. Arachnipod

components are labelled with the Date of Manufacture. When the unit is retired from service, destroy the unit so it

cannot be re-entered into service by mistake.

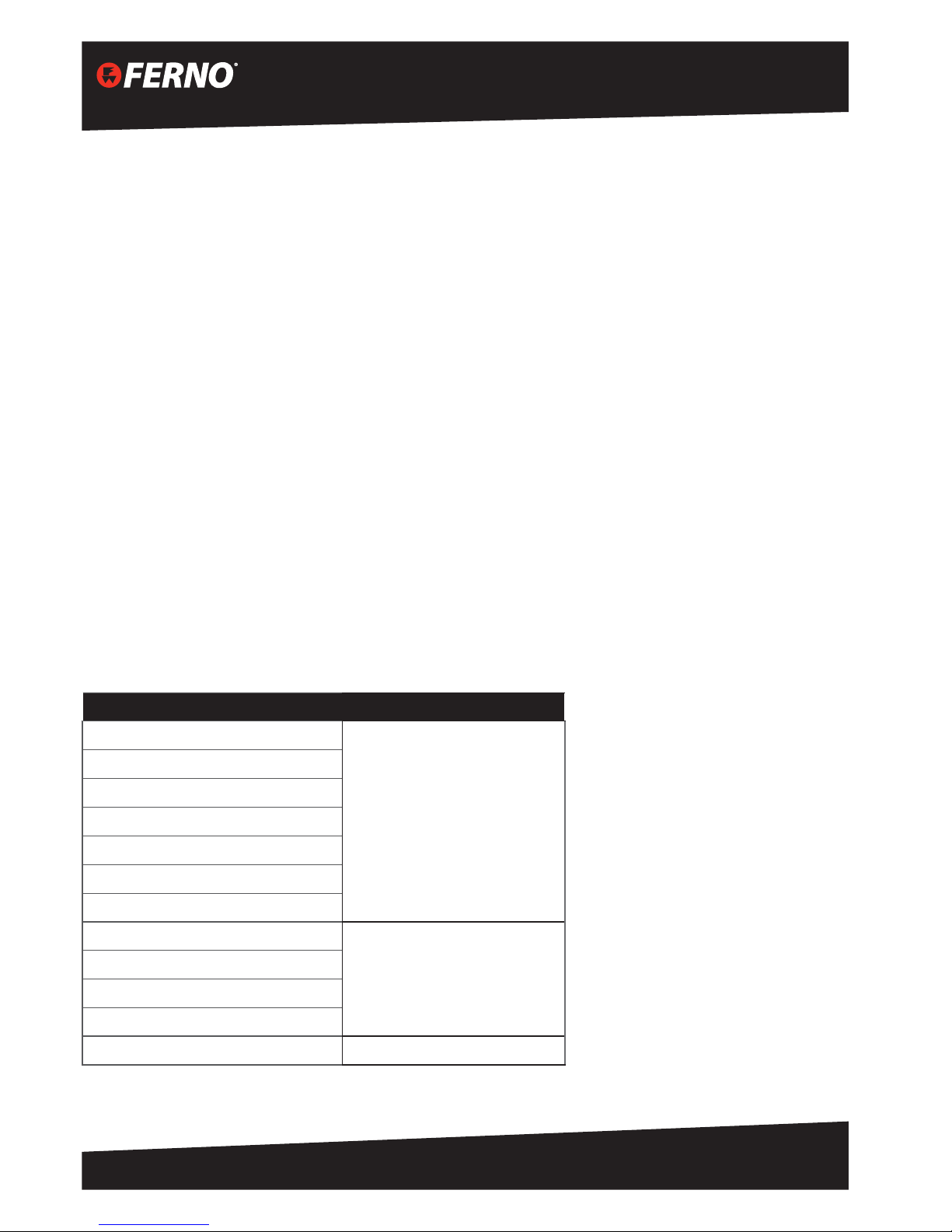

Non-metallic Components

The following table lists materials used to produce any non-metallic components on the Arachnipod.

PART MATERIAL

Standard foot tread

Polyurethane

Leg stoppers

Foot socket

Soft Ground Shoe

Lazy Leg Adapter plug

Lazy Leg extender mouldings

Bridge Pulley mouldings

Pulley Head pulley spacers

Acetal

Step spacers

Bridge Pulley spacer

Lower Leg stopper

Leg bumper Rubber

11

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

Inspection of the Arachnipod

Equipment should be inspected regularly, before and after each use by a qualied person. Record the date of the

inspection and the results in the equipment log. It is also recommended to write the date of the next inspection

on the device. Each user should be trained in equipment inspection and should carry out a pre-inspection of the

equipment to ensure that it is in a serviceable condition and operates correctly before each use.

Inspect the Arachnipod for cracks, dents, or elongation of the karabiner and pin holes. The legs should t together

smoothly and should not appear bent or deformed. Pins should have the retaining hardware present and must

function freely.

Inspect plastic parts for wear or chemical damage.

Repairs

Any repair work must be done by the manufacturer or accredited agent. Any other repair work or modications will

void the warranty.

WARNING

The Arachnipod has been engineered and tested using the original equipment as supplied. Never replace any pins,

bolts or other components with non-genuine parts.

Do not use your Arachnipod if any parts are missing.

The Arachnipod must not be used outside its limitations, or for any purpose other than that for which it is

intended.

For service or repairs, please contact your local Ferno Distributor or Ferno Australia

Tel: +61 7 3881 4999

Email: sales@ferno.com.au

www.ferno.com.au

Safe Working Practices

1. Always wear relevant PPE including gloves.

2. Do not exceed the working load limit for the given application.

3. Always maintain a safety line independent of the main line.

4. All Arachnipod feet must be secured to prevent unwanted movement.

5. It is a good practice to ensure that all rigging is capable of holding the entire weight of the main load.

6. Always provide height safety and fall prevention for personnel working close to the height risk.

7. Ensure a Rescue Plan is in place to deal with any emergencies which may arise.

Australia

12

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

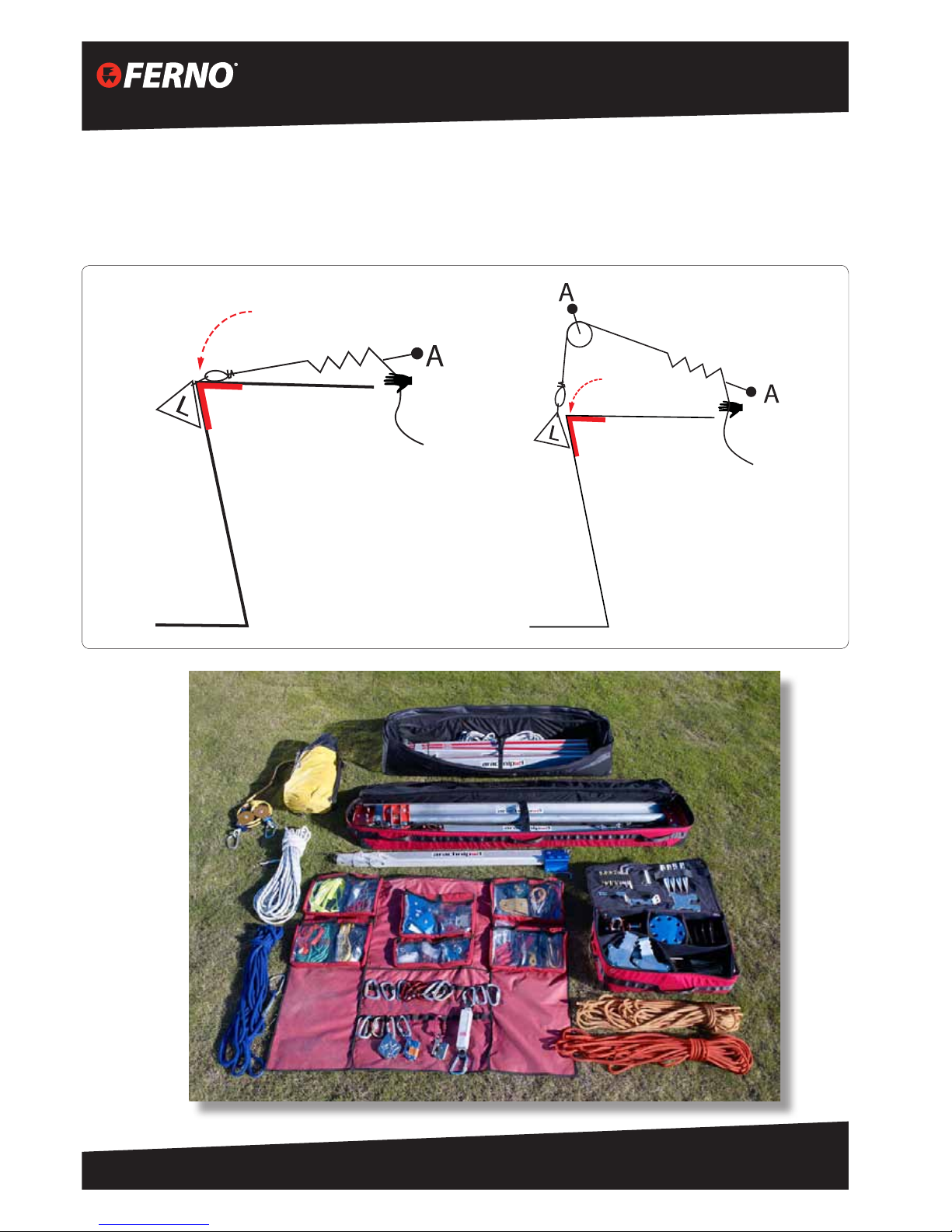

Principles of Edge Management

Edge management is the assessment of the rigging task to ensure that the load can be manoeuvred over the edge.

Rigging to provide a high change of direction is the key to successfully managing an edge. The Arachnipod is a tool

that can be used to achieve a high change of direction.

Edge

Protection

Edge

Management

Problem

Edge

Management

Solution

Edge

Protection

13

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

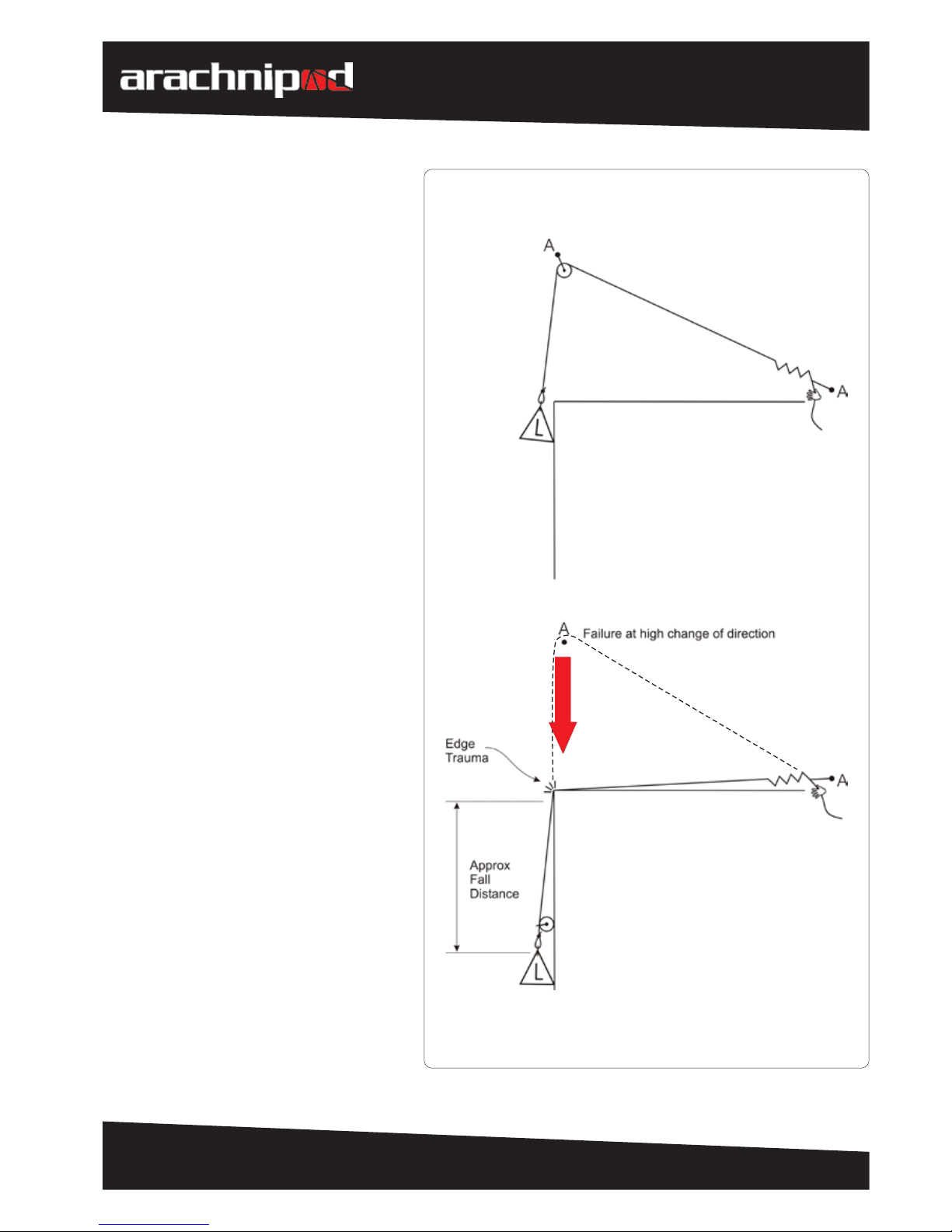

Critical Point Analysis

(High change of direction)

A critical point analysis is the assessment

of all rigging regardless of the equipment

brand or type. The purpose of a critical

point analysis is to determine if the rigging

relies on any single point to provide

operator safety.

The Arachnipod if used correctly will

provide an ecient and safe edge

management system but not all aspects

of the rigging and equipment use can be

guaranteed by the manufacturer. Many

factors such as edge instability, anchor

insecurity, misuse, persons who are not

fully competent, user error, abuse and the

use of other equipment could result in a

system failure.

The diagram (right) shows how failure

of a high change of direction (edge

management) of a single rope system

would subject the load to a fall. The

seriousness of the fall will depend upon

many factors including the height of the

change of direction and the length of rope

that is between the load and the anchor.

Australia

14

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

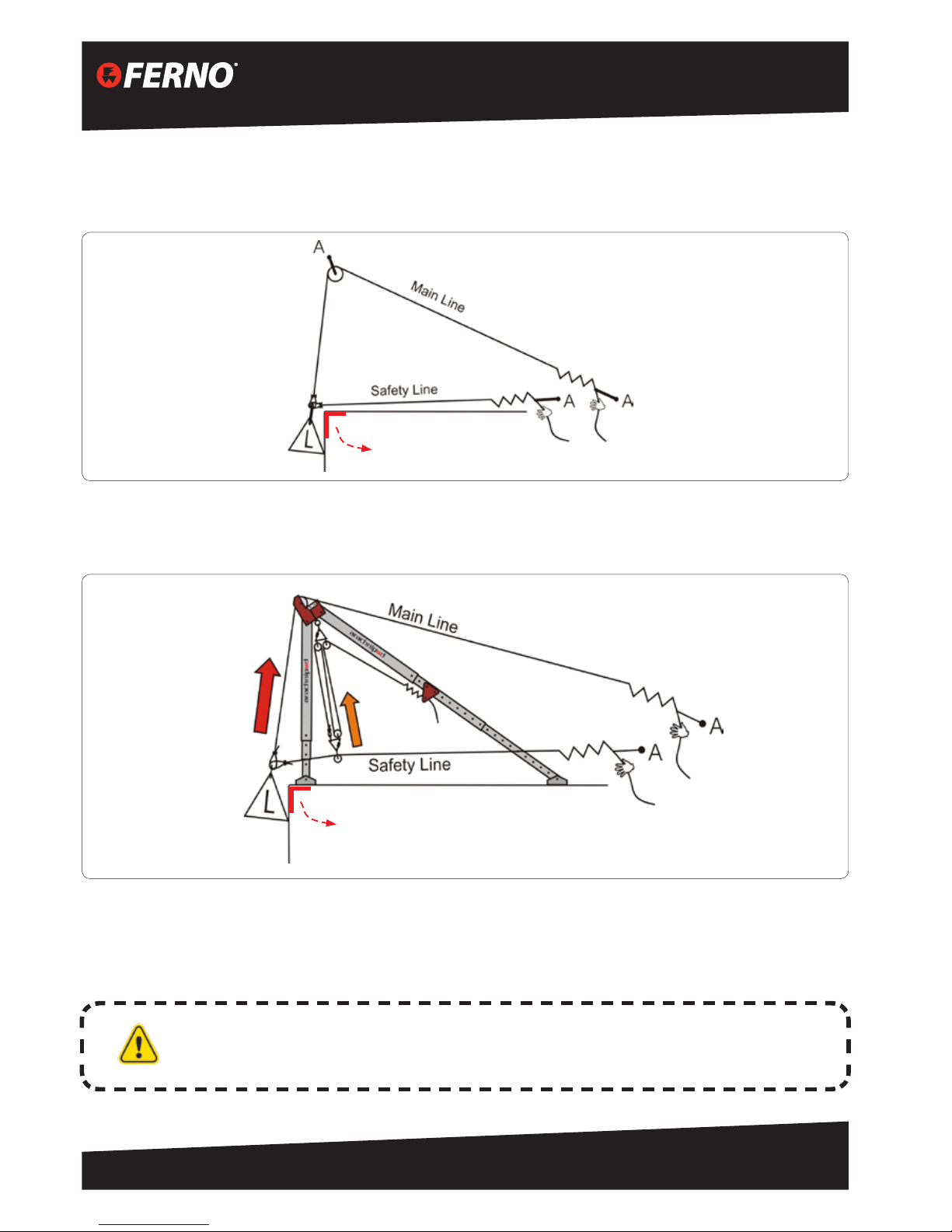

The Two Rope System

A two rope system provides additional safety by backing up the main line and any edge management systems. The

second line or safety line is rigged to take the shortest path from the anchor to the load.

When the load is located below the edge the safety line provides protection for both main line and edge

management failures. When the load is located above the edge the safety line provides limited protection for

main line failures.

The Arachnipod can be rigged with the main line passing over the pulley head and a rated hauling system can

be used to progressively pick the safety line up as the load is raised. This process provides additional protection

against a main line failure. Ferno can supply properly rated and pre-rigged hauling systems that are suitable for

this task.

WARNING

Edge protection should also be provided to protect both lines against edge

trauma. Ferno can supply a range of edge protection solutions

Edge Protection

Edge Protection

15

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

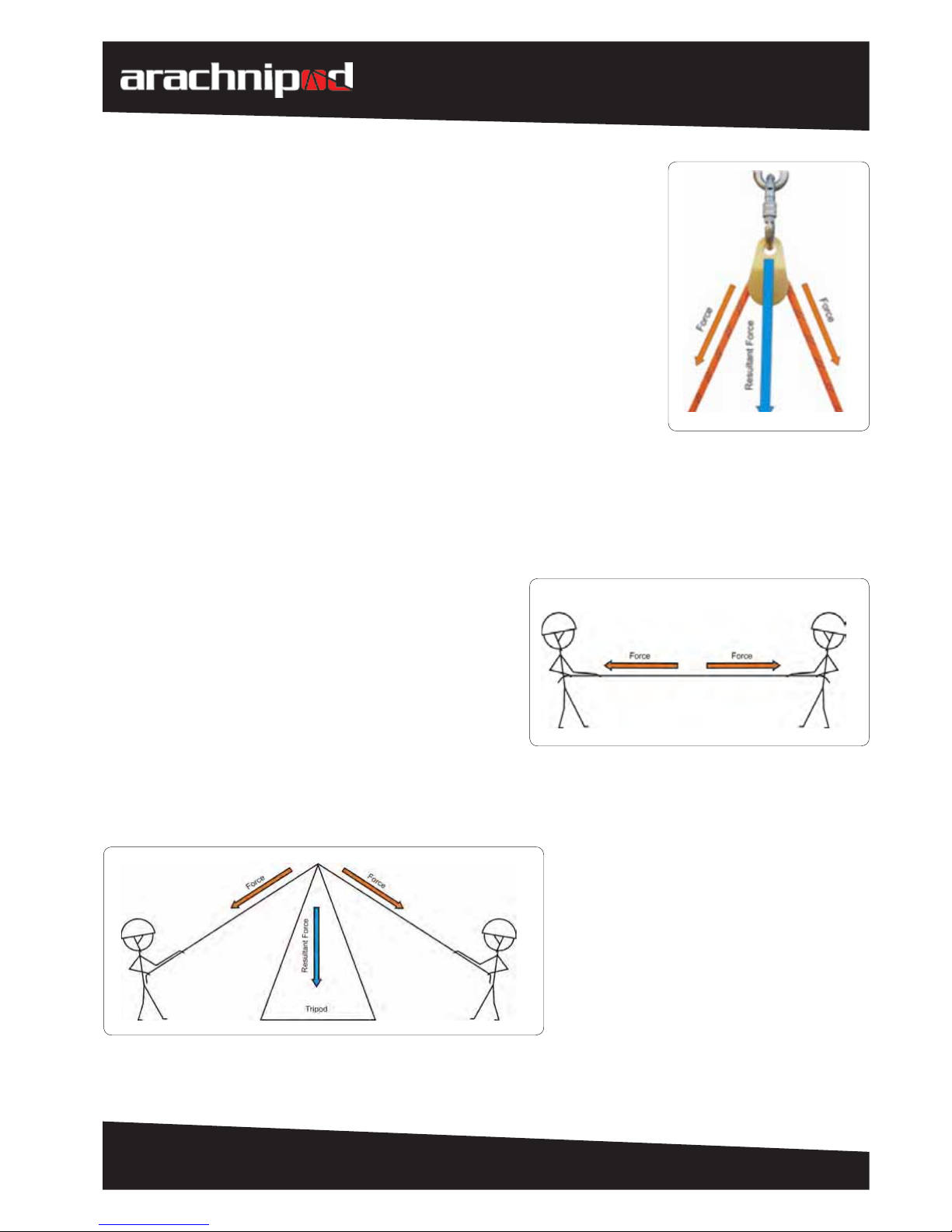

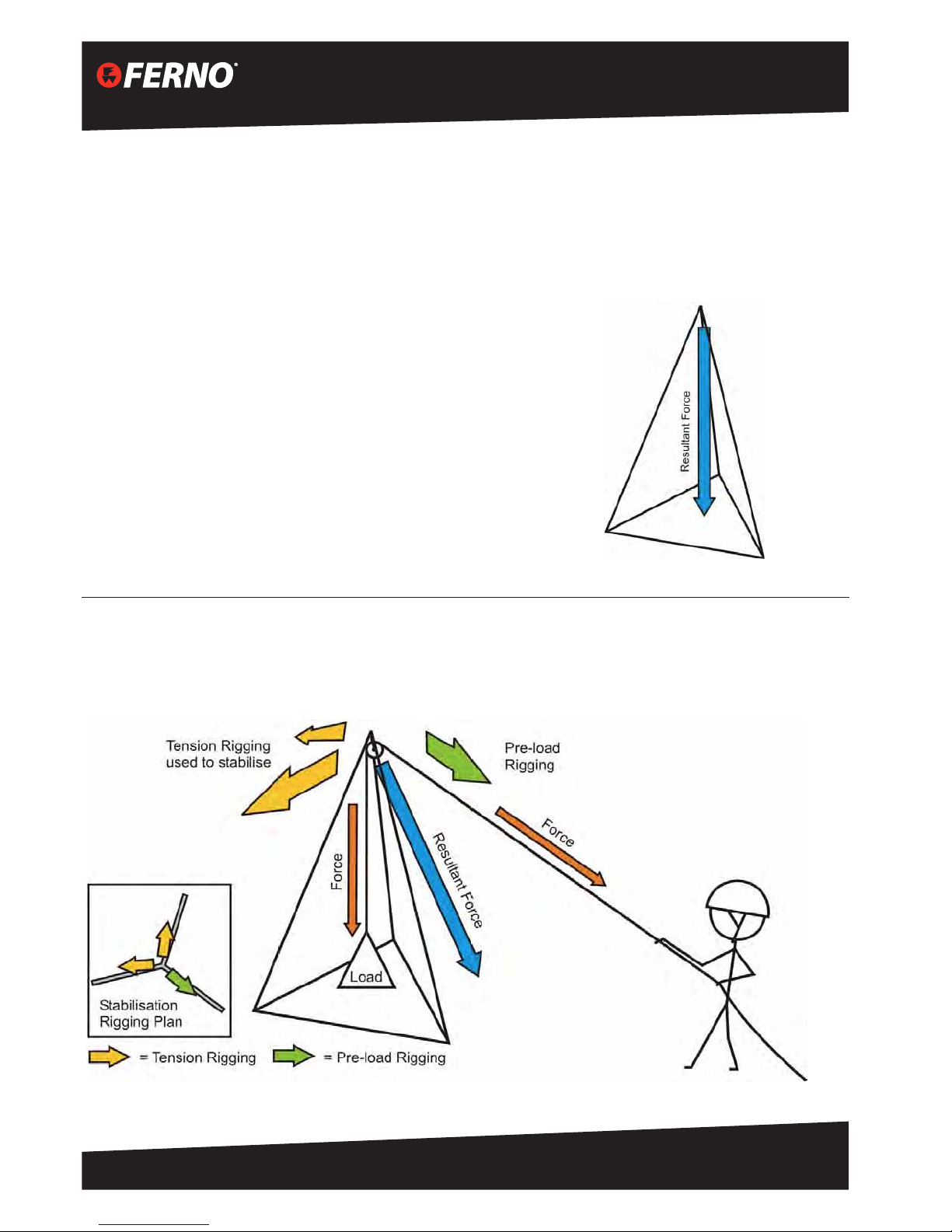

Understanding the forces being applied to the Arachnipod

The Arachnipod or any other edge management device is subjected to resultant forces and directions. To keep

edge management devices or rigging in place the resultant forces and directions being applied must be assessed

and sometimes additional rigging will be required to provide stabilisation. In simple terms, if all of the forces are

balanced then the Arachnipod will remain stable.

We can use various Arachnipod components and rigging to

balance the forces as follows:

1. The legs of the Arachnipod system are generally used to

balance compression forces,

2. Additional rigging is used to balance tension forces, and

3. Some rigging may be used to preload the

tension rigging to minimise movement created by

rope stretch and cyclic loading.

The game known as “tug of war” is a good example of balanced forces. If two people applied exactly the same

horizontal force then the rope would remain stationary. The load forces are balanced and no movement would occur.

Understanding the forces at a change of direction pulley

Most edge management tasks require the use of a pulley or pulleys to change

the direction of the load line. Correct assessment of the loads being applied to

these pulleys and the ability to determine the resultant direction is essential when

selecting the most appropriate edge management system and rigging.

An applied force has magnitude and direction. A change of direction pulley is

subjected to two forces:

1. The weight of the load, and

2. The force required to manage that load.

The force that is required to manage the load will vary because of friction.

The resultant force bisects the two applied forces. A good indicator of resultant

direction is to look at the direction of the pulley and attachment hardware.

If a tripod is placed under the tug of war

rope then the same rules would apply.

Because there is now a change of direction a

resultant force now exists.

Australia

16

Arachnipod User Manual Version 6.1

DOC ID: 00184-AU-V06 (2015/03)

Tripod Stabilisation

Tripods make use of three legs all of which are in compression.

Some tripods applications may require additional rigging to provide

sucient stabilisation and security.

If a tripod is rigged in such a way that the resultant force and direction

are being applied downwards and if it remains within the triangular

base (the triangle formed by the leg securing rope) then the tripod will

remain stable. If the load shifts closer to any given leg then the load

being applied to that leg increases but the tripod will remain stable.

If the resultant force and direction is being applied outside of the triangular base then the tripod will become

unstable. Additional rigging will be required to maintain tripod security. Some of the rigging will remain under

tension and other rigging may be used to preload the edge management system.

Assessing the stability of your Arachnipod rigging

The following stabilisation examples will look at the resultant directions and suggest how the stability of the edge

management scenario may be managed.

Remember: an applied force has magnitude and direction. This manual will refer to resultant forces and resultant

directions.

17

Arachnipod User Manual

Version 6.0

© Copyright: FERNO AUSTRALIA

Arachnipod Parts

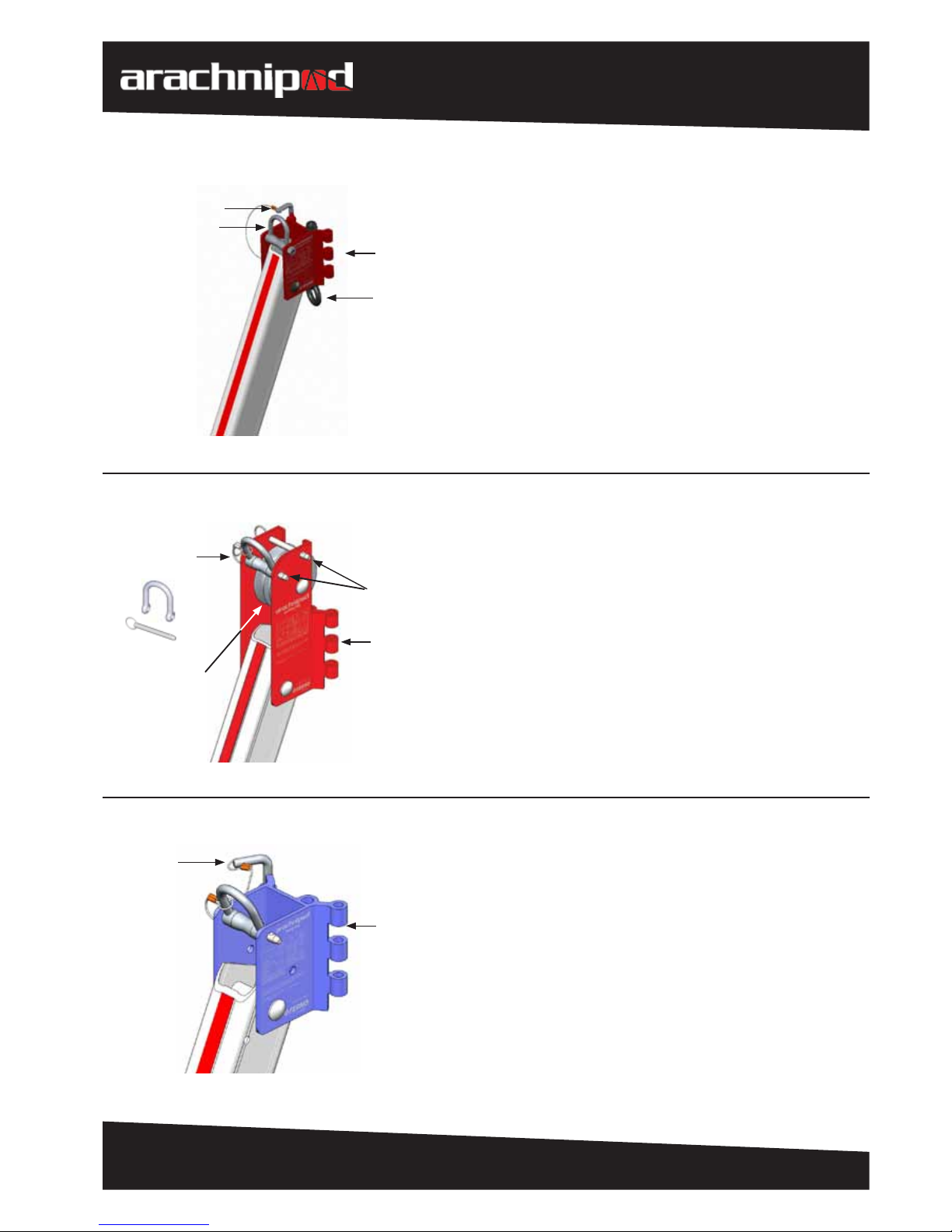

Standard Leg

Legs can be connected using Qik-link pins. The

connected joint looks much like a hinge.

A basic tripod is made up of three standard legs

joined with Qik-link pins. The removal of one Qiklink pin allows the tripod to be stored at for easy

transportation.

Rated load attachment points (eyebolts) are provided

along with an additional attachment point for

stabilisation rigging. The load attachment point can

swivel 360°.

Pulley Leg

A pulley leg can be used in place of a standard leg

to add a pulley to a tripod or A-frame conguration.

Other congurations such as a handrail technique are

also possible. (see handrail technique in this manual)

The pulley has been designed to accommodate

up to 13 mm bre rope as well as up to 8 mm (steel/

stainless steel) wire rope cable.

The stabilisation attachment point is removable.

Pulley Leg

A pulley leg can be used in place of a standard leg

to add a pulley to a tripod or A-frame conguration.

Other congurations such as a handrail technique are

also possible. (see handrail technique in this manual)

The pulley has been designed to accommodate

up to 13 mm bre rope as well as up to 8 mm (steel/

stainless steel) wire rope cable.

The stabilisation attachment point is removable.

Qik-Link Pin

Stabilisation

Attachment Point

(D-shackle)

Attachment point

for additional legs

Rated load

attachment point

with built-in

swivel (eyebolt)

Attachment point

for additional legs

Qik-Link Pin

Detent Pin is used

for the removable

stabilisation

attachment point

as well as the lock

when using the

Lazy Leg with the

Gin Head

Removable

stabilisation

attachment point

Double groove

pulley designed to

accommodate up

to 13 mm bre rope

and 8 mm wire rope

cable

Double groove

pulley designed to

accommodate up

to 13 mm bre rope

and 8 mm wire rope

cable

Attachment point

for additional legs

Detent pins are

used to prevent

ropes or cable

from escaping the

pulley grooves

Loading...

Loading...