Page 1

Users’ Manual

®

59T EZ Glide

February 2013

Pub. No. 234-3298-03

Evacuation Chair

Read this Manual and

Retain for Future Reference

Page 2

59T EZ Glide®

Ferno Technical Support

Customer service and product support are important aspects of each

Ferno product. Please have the product serial number available

when calling, and include it in all written communications. For

technical support questions:

Telephone (Toll-free) 1.800.733.3766 ext. 1010

Telephone 1.937.382.1451 ext. 1010

Email quality.products@ferno.com

Ferno Customer Relations

For ordering assistance or general information:

CANADA AND THE U.S.A.

Telephone (Toll-free) 1.877.733.0911

Telephone 1.937.382.1451

Fax (Toll-free) 1.888.388.1349

Fax 1.937.382.1191

Internet www.ferno.com

ALL OTHER LOCATIONS

For assistance or information, please contact your Ferno distributor.

If you do not have a Ferno distributor, please contact Ferno

Customer Relations:

Ferno-W ashington, Inc., 70 Weil Way

Wilmington, Ohio 45177-9371, U.S.A.

Telephone +1.937.382.1451

Fax +1.937.382.6569

Internet www.ferno.com

USERS’ MANUAL

To request additional free users’ manuals,

contact Ferno Customer Relations, your

Ferno distributor, or visit www.ferno.com.

Disclaimer

This manual contains general instructions for the use, operation

and care of this product. The instructions are not all-inclusive. Safe

and proper use of this product is solely at the discretion of the

user. Safety information is included as a service to the user. All

other safety measures taken by the user should be within and under

consideration of applicable regulations. It is recommended that

training on the proper use of this product be provided before using

this product in an actual situation.

Retain this manual for future reference. Include it with the product

in the event of transfer to new users. Additional free copies are

available upon request from Customer Relations.

Proprietary Notice

The information disclosed in this manual is the property of FernoW ashington, Inc., Wilmington, Ohio, USA. Ferno-W ashington, Inc.

reserves all patent rights, proprietary design rights, manufacturing

rights, reproduction use rights, and sales use rights thereto, and

to any article disclosed therein except to the extent those rights

are expressly granted to others or where not applicable to vendor

proprietary parts.

Limited Warranty Statement

The products sold by Ferno are covered by a limited warranty,

which is printed on all Ferno invoices. The complete terms and

conditions of the limited warranty, and the limitations of liability

and disclaimers, are also available upon request by calling Ferno at

1.800.733.3766 or 1.937.382.1451.

Serial Number _________________________

Location: Seat panel rear frame

2

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 3

59T EZ Glide®

TABLE OF CONTENTS

Section Page Section Page

Ferno Technical Support _______________________ 2

Ferno Customer Relations _____________________ 2

1 - Safety Information __________________________ 4

1.1 Warning _______________________________ 4

1.2 Important ______________________________ 4

1.3 Tip ____________________________________ 4

1.4 Bloodborne Disease Notice ________________ 4

1.5 Symbol Glossary _________________________ 5

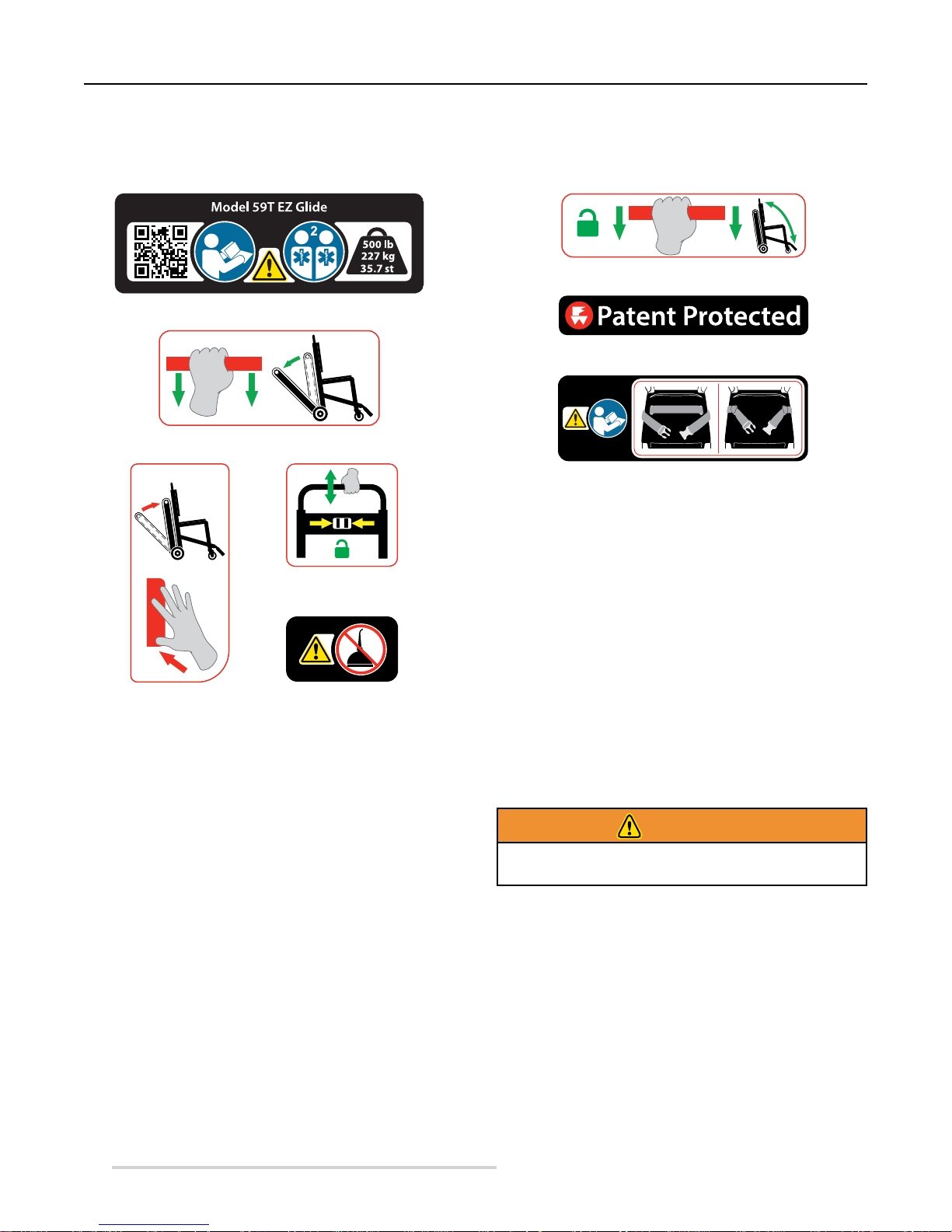

1.6 Safety and Instruction Labels_______________ 6

2 - Operator Skills and Training __________________ 6

2.1 Skills __________________________________ 6

2.2 Training ________________________________ 6

3 - About the Chair _____________________________ 7

3.1 Description _____________________________ 7

3.2 Chair Features ___________________________ 7

3.3 General Specications ____________________ 7

3.4 Components ____________________________ 8

4 - Setup ______________________________________ 9

4.1 Attaching Patient Restraints _______________ 9

4.2 Restraint Congurations __________________ 9

4.3 Ankle Restraint _________________________ 10

5 - Chair Features _____________________________ 11

5.1 Folding and Unfolding the Chair ___________ 11

5.2 Track System ___________________________ 12

5.3 Extending Lift Bar _______________________ 13

5.4 Telescoping Lift Handles _________________ 13

5.5 Footrest _______________________________ 14

5.6 Wheel Locks ___________________________ 14

6 - Using the Chair ____________________________ 15

6.1 Before Placing the Chair in Service _________ 15

6.2 General Guidelines for Use ________________ 15

6.3 Transferring the Patient __________________ 16

6.4 Rolling the Chair ________________________ 16

6.5 Transporting a Patient Down Stairs _________ 17

6.6 Transporting a Patient Up Stairs ___________ 19

6.7 Pausing On the Stairs ____________________ 20

6.8 Using Additional Help ___________________ 21

7 - Maintenance ______________________________ 22

7.1 Maintenance Schedule___________________ 22

7.2 Disinfecting/Cleaning Restraints ___________ 22

7.3 Disinfecting/Cleaning the Chair ___________ 22

7.4 Cleaning Tracks and Belts _________________ 22

7.5 Inspecting the Chair _____________________ 23

7.6 Lubricating the Chair ____________________ 24

7.7 Do Not Lubricate Track System ____________ 24

7.8 Reconditioning the Track Belts ____________ 25

7.9 Adjusting Track-Belt Tension ______________ 26

7.10 Removing and Attaching the ABS Panels ____ 28

8 - Accessories ________________________________ 29

9 - Parts and Service ___________________________ 30

9.1 U.S.A. and Canada_______________________ 30

9.2 Worldwide ____________________________ 30

9.3 Parts List ______________________________ 30

9.4 Parts Diagrams _________________________ 31

Training Record_______________________________ 32

Maintenance Record __________________________ 32

© Ferno-Washington, Inc 234-3298-03 February 2013

3

Page 4

1 SAFETY INFORMATION

59T EZ Glide®Safety Information

1.1 Warning

Warning notices indicate a potentially hazardous situation

which, if not avoided, could result in injury or death.

WARNING

Untrained operators can cause injury or be injured.

Permit only trained personnel to operate the chair.

Improper use of the chair can cause injury. Use the chair

only for the purpose described in this manual.

Improperly attaching restraints can allow seat and back

panels to dislodge, resulting in injury. Restraints must

capture panel AND chair frame.

Using the chair with the track system unlocked can cause

injury. Verify that the track system is locked before

transporting the patient.

Lubricating the track system can result in injury to the

patient and/or operators. Never lubricate the tracks or belts.

Improper operation can cause injury. Operate the chair

only as described in this manual.

An unattended patient can be injured. Stay with the

patient at all times.

An unrestrained patient can fall o the chair and be

injured. Use restraints to secure the patient on the chair.

Helpers can cause injury or be injured. Maintain control

of the chair, operate the controls, and direct all helpers.

Improper maintenance can cause injury. Maintain the

chair only as described in this manual.

Attaching improper items to the chair can cause injury.

Use only Ferno-approved items on the chair.

Improper parts and service can cause injury. Use only

Ferno parts and Ferno-approved service on the chair.

Modifying the chair can cause injury and damage. Use the

chair only as designed by Ferno.

1.2 Important

Important notices emphasize important usage or maintenance

information. Failure to follow Important notices could result

in damage to the product or property damage.

Important

1.3 Tip

Tips provide recommendations for easier use of the product.

1.4 Bloodborne Disease Notice

To reduce the risk of exposure to bloodborne diseases such

as HIV-1 and hepatitis when using the chair, follow the

disinfecting and cleaning instructions in this manual.

4

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 5

59T EZ Glide® Safety Information

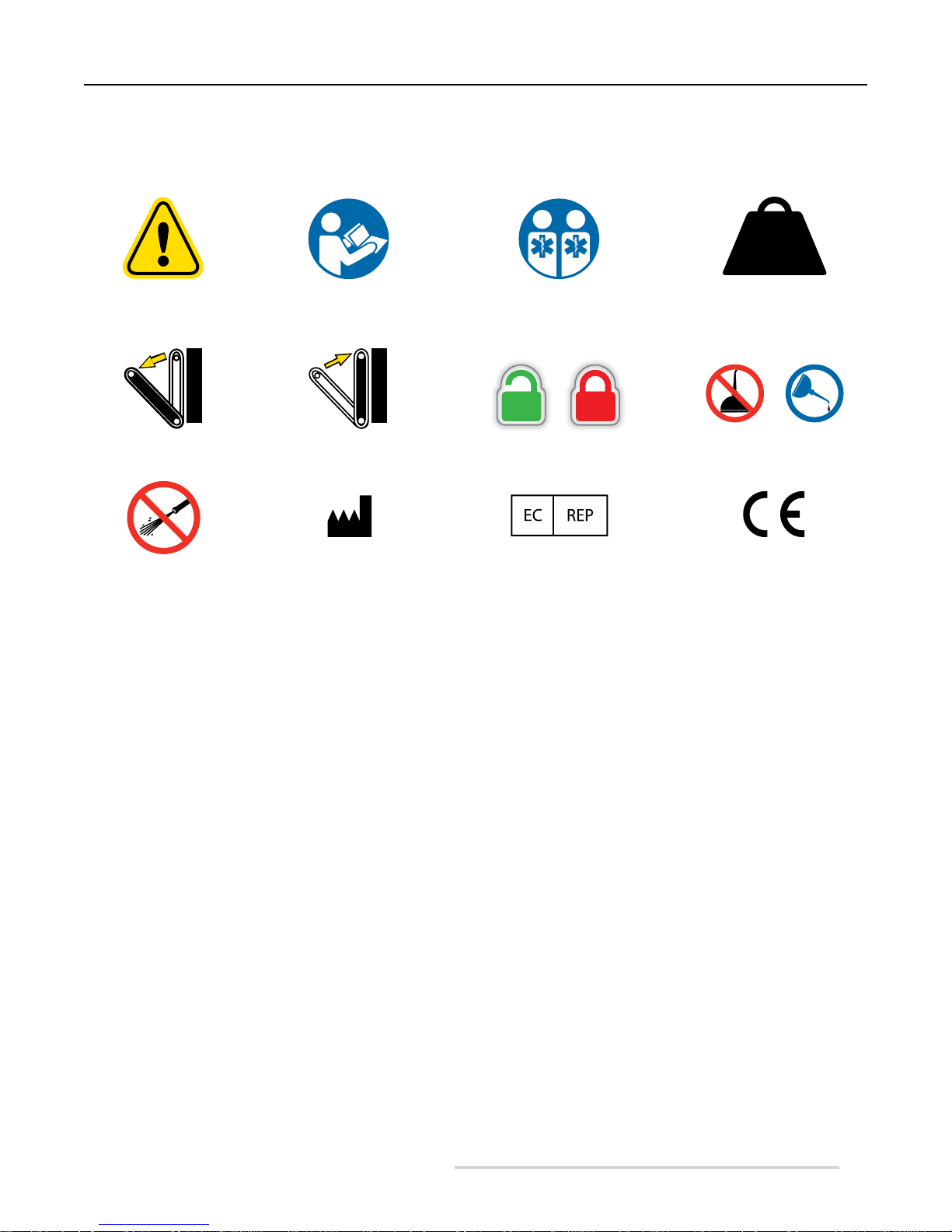

1.5 Symbol Glossary

The symbols dened below are used on the chair and/or in this users’ manual. Ferno uses symbols recognized by the International

Standards Organization (ISO), American National Standards Institute (ANSI) and the emergency medical services industry.

General W arning of

Potential Injury

Open Track System

Do Not Pressure Wash

Read the Users’ Manual

Close Track System

Manufacturer

2

Chair Operation Requires

Two Trained Operators

Unlocked Locked

Authorized Representative in the

European Community

500 lb

227 kg

35.7 st

Load Limit

(Safe Working Load in

pounds, kilograms, stone)

Do Not

Lubricate

Product meets European

Union Standards

Lubricate

QR Code

(Access Online Material)

© Ferno-Washington, Inc 234-3298-03 February 2013

5

Page 6

Safety Information, Operator Skills and Training

59T EZ Glide®

1.6 Safety and Instruction Labels

Safety and instruction labels place important information from the users’ manual on the chair. Read and follow label instructions.

Replace worn or damaged labels immediately. New labels are available from EMSAR (page 30) or from your distributor.

Instruction: Folding/Unfolding the Chair

Safe Use Guidelines

Ferno Products are Protected by Patents Worldwide

Instruction: Opening Tracks

Safety Instruction: Attaching Restraints

Instruction:

Adjusting Lift Bar

Instruction:

Closing Tracks

Risk of Injury: Do

Not Lubricate Tracks

2 OPERATOR SKILLS AND TRAINING

2.1 Skills

Operators using the chair need:

● a working knowledge of emergency patient-handling

procedures.

● the ability to assist the patient.

2.2 Training

Operator trainees need to:

● read and understand this manual.

● be trained on the use of the chair.

● practice with the chair before using it with a patient.

● record their training information. A sample training

record sheet is provided on page 32.

WARNING

Untrained operators can cause injury or be injured.

Permit only trained personnel to operate the chair.

6

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 7

59T EZ Glide®

About the Chair

3 ABOUT THE CHAIR

3.1 Description

The Ferno® Model 59T EZ Glide® Evacuation Chair

(referred to as the chair in this manual) is an emergency

patient-handling devices designed to transport a seated

patient up and down stairs and over at surfaces.

The chair is for professional use by a minimum of two

trained operators. A third person to “spot” may be required

by local protocols. Additional help may be required when

working with heavy patients.

The chair is designed with belted tracks that enable operators

to “glide” the chair down stairs instead of carrying it.

3.2 Chair Features

● Belted track system for “gliding” chair down stairs

● Molded ABS seat and back panels

● Choice of color

● 5-position extending rear lift bar

● 5-position telescoping front lift handle (2)

● 6" rear locking wheel (2)

● 4" front swivel wheel (2)

● Folding footrest

● Ankle restraint

● Patient restraints (shown on page 8)

For chair accessories, including mounts and restraints, see

Accessories, page 29.

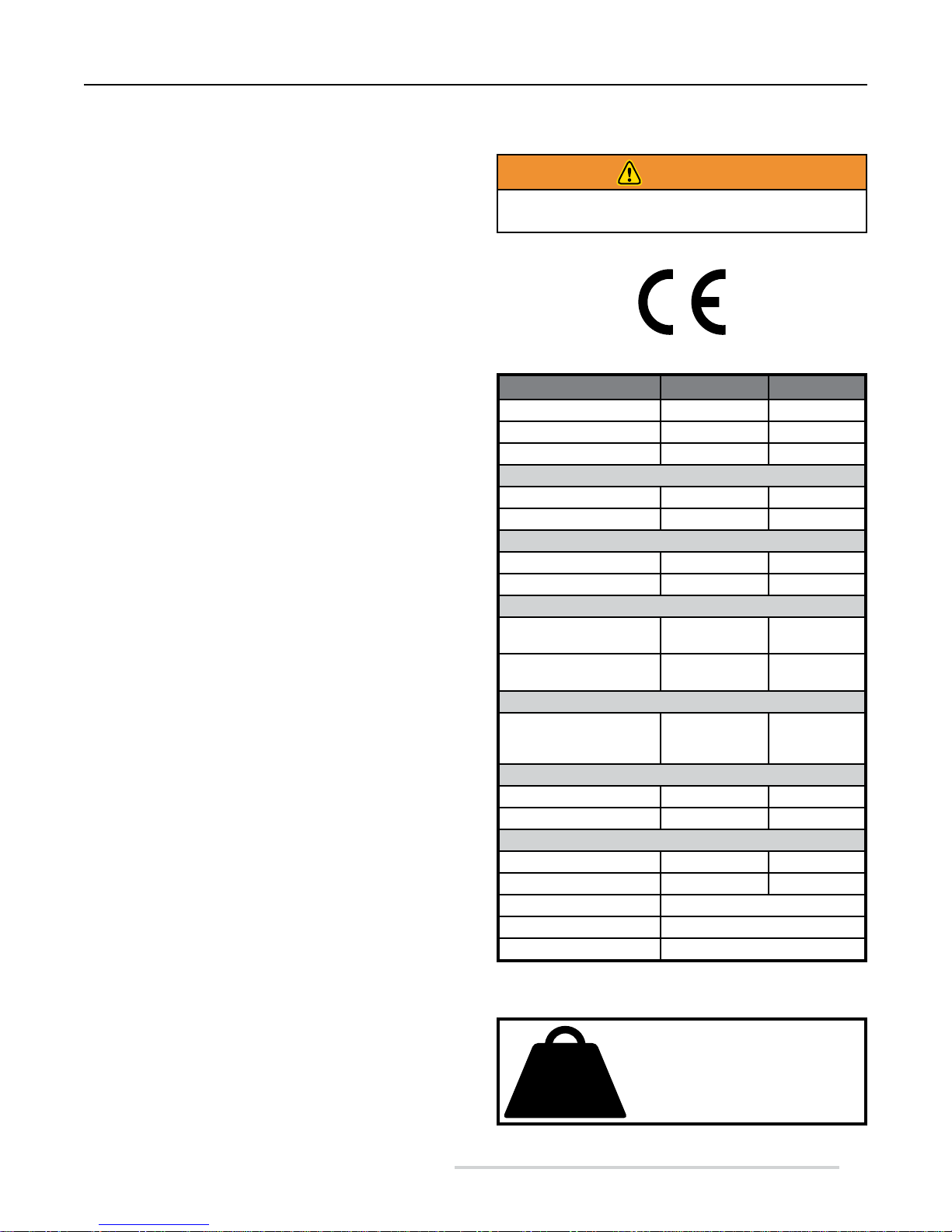

3.3 General Specications

Specications for the chair are shown in the table at right.

Ferno reserves the right to change specications without

notice. For more information, contact Ferno Customer

Relations or your Ferno distributor (page 2). Ferno reserves

the right to change specications without notice.

WARNING

Improper use of the chair can cause injury. Use the

chair only for the purpose described in this manual.

Specication Imperial Metric

Load Limit 500 lb 227 kg

Load Limit (UK) 35.7 st

Weight* 33 lb 15 kg

Height

Maximum 63.5 1613 mm

Minimum 37.5 in 953 mm

Width

Overall 20.313 in 516 mm

Seat 16.5 in 419 mm

Depth (front to back)

Tracks closed,

Handles retracted

Tracks Open,

Handles extended

Folded

Length x width x depth 37.5 in x

Wheels, Rear

Diameter 6 in 152 mm

Width 1.25 in 32 mm

Wheels, Front

Diameter 4 in 102 mm

Width 1.18 in 30 mm

Chair Construction Rectangular aluminum

Seat/Back Panels ABS Plastic

Wheel Bearings Sealed/greaseless

28.5 in 724 mm

51 in 1295 mm

20.313 in x

8 in

953 mm x 516

mm x 200 mm

© Ferno-Washington, Inc 234-3298-03 February 2013

* Weight is without restraints or accessories

Load Limit

500 lb

227 kg

35.7 st

Inspect the chair if the load limit has

been exceeded (See Inspecting the

Chair, page 23).

7

Page 8

About the Chair

59T EZ Glide®

3.4 Components

Removable ABS Back

Panel with Restraint Slots

Removable ABS Seat

Panel with Restraint Slots

Chair Lock Bar

Ankle Restraint

Telescoping Lift Handle (2)

Extending Lift Bar

Patient

Restraint (2)

Belt (2)

Track (2)

Extending Lift Bar

Lift Bar Release Tabs

Track Release Bar

Track Closing Handle

4" Swivel Wheel (2) 6" Wheel with Lock (2)Folding Footrest

IV Pole (Optional)

Locking Rear

Lift Handle

(Pair, Optional)

Wheel Lock (2)

Coated Restraint

Model 430

Model 430-P

Restraint Options

(Contact Ferno for Details)

8

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 9

59T EZ Glide®

Setup

4 SETUP

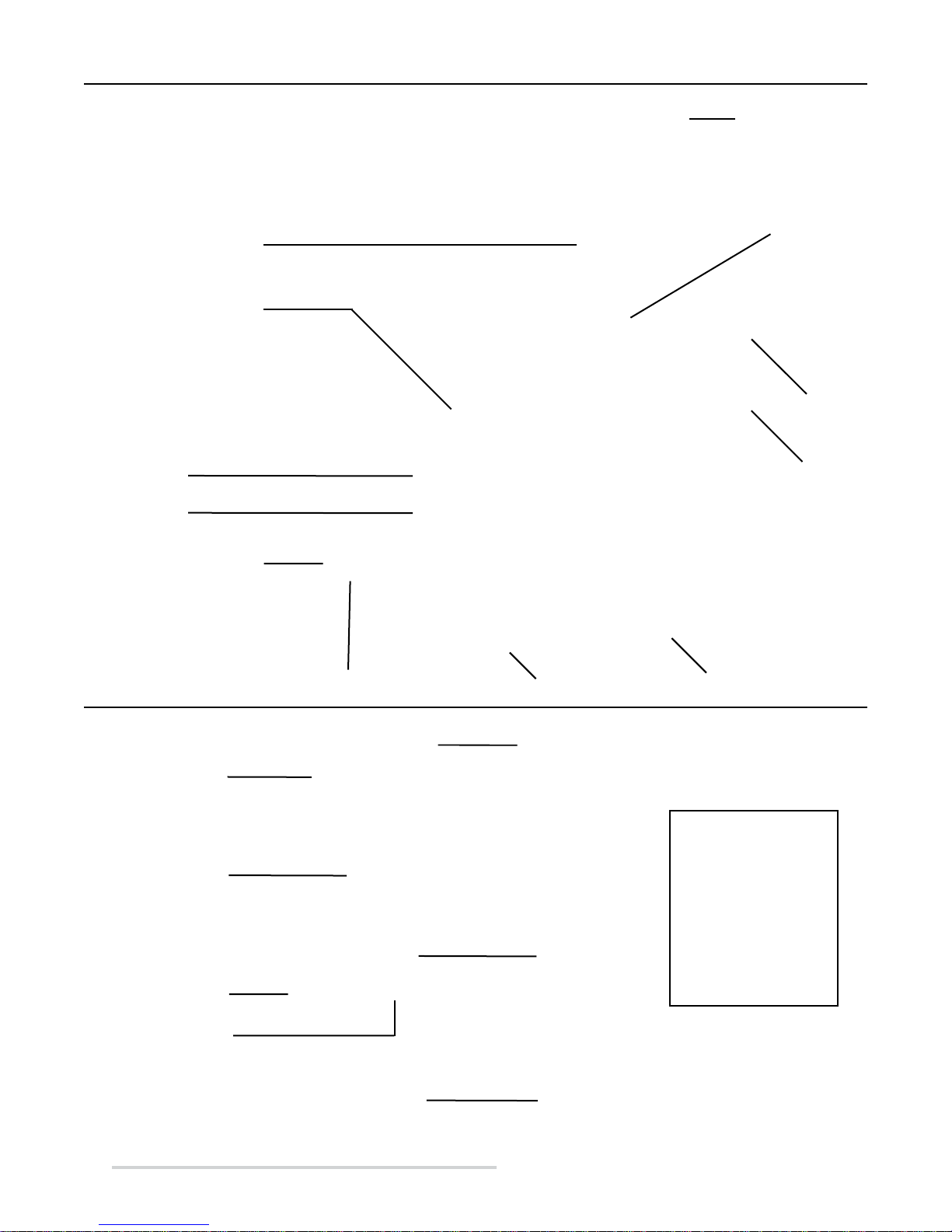

4.1 Attaching Patient Restraints

Use patient restraints to help hold the patient on the chair.

Each restraint must capture both the aluminum chair frame

and the seat or back panel. Follow local protocols when

attaching restraints.

USING TWOPIECE RESTRAINTS

1. Feed the loop of a restraint strap through a slot in the

seat or back panel.

2. Wrap the strap around the aluminum chair frame and

feed the male or female buckle through the loop, then

pull the strap tight against the frame and panel.

3. Repeat Steps 1-2 for the other half of the restraint.

USING ONEPIECE RESTRAINTS

Note: T wo-piece restraints are recommended.

1. To attach the seat-panel restraint, lay the restraint

across the top of the seat panel and feed the male and

female ends of the restraint down through the slots.

2. Wrap the restraint around the aluminum chair frame

on each side of the chair, capturing both the panel and

the frame (Figure 1).

3. Buckle the restraint and adjust the length.

4. Repeat Steps 1-3 to attach the back-panel restraint.

WARNING

Improperly attaching restraints can allow seat and

back panels to dislodge, resulting in injury. Restraints

must capture panel AND chair frame.

Important

Restraint rules (also follow your local protocols):

● Use a minimum of two restraints.

● One restraint must be secured across the chair seat

to help hold the patient on the chair.

● Each restraint or strap must capture the aluminum

chair frame and the plastic panel.

Capture Aluminum Frame and Panel at Each Side

4.2 Restraint Congurations

Follow local protocols when conguring and using

restraints. Two possible congurations are described below.

HORIZONTAL CONFIGURATION

Use one restraint for the chest and one restraint for the lap

(Figure 2). Use additional restraints as needed.

1. Attach the chest straps through the vertical slots in the

back panel.

2. Attach the lap straps through the seat panel slots.

CRISSCROSS CONFIGURATION

Use two restraints for the torso and a third restraint for the

lap (Figure 2).

1. Attach one strap of a restraint through a horizontal slot

on the back panel of the chair.

2. Attach the mating strap of the same restraint through

the seat panel slot on the opposite side of the chair.

3. Repeat with the second restraint, attaching its straps to

opposite sides of the chair.

4. Attach the lap restraint through the seat-panel slots.

Figure 1 - Restraint Capturing Frame and Panel

Straps Must Capture Aluminum Frame and Panels

Lap BeltLap Belt

Figure 2 - Horizontal Conguration (Left) and

Criss-Cross Conguration (Right)

© Ferno-Washington, Inc 234-3298-03 February 2013

9

Page 10

4.3 Ankle Restraint

Use the ankle restraint to help keep the patient’s feet on the

footrest. Attach the two-piece ankle restraint to the front

legs of the chair. To attach the restraint:

1. Unbuckle the restraint to separate the straps.

2. Wrap a strap around one front leg of the chair and

thread the buckle through the loop, then pull the strap

tight around the chair leg (Figure 3).

3. Attach the remaining strap to the opposite front leg.

4. Buckle the restraint and adjust the length (Figure 4).

59T EZ Glide®Setup/Installation

Figure 3 - Attaching the Ankle Restraint

Figure 4 - Ankle Restraint Attached

10

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 11

59T EZ Glide®

5 CHAIR FEATURES

5.1 Folding and Unfolding the Chair

The red lock bar below the front edge of the seat disengages

the lock for unfolding and folding the chair. Before seating a

patient, verify that the chair is completely unfolded and the

lock is engaged.

FOLDING AN OPEN CHAIR

1. Buckle the restraints and arrange the straps to prevent

interference with folding the chair.

2. Roll the chair backward to reverse the swivel wheels

(Figure 5).

3. Standing at the side of the chair, grasp the lift bar with

one hand and the lock bar with the other hand.

4. Pull the lock bar forward (Figure 6), toward the front

of the chair, then fold the seat toward the lift bar.

AS yOU FOLD The SeAT: Tilt the chair forward

(Figure 7) to keep the swivel wheels rotated outward.

This prevents the wheels from holding the frame away

from the seat and allows the lock to engage.

5. Press the seat against the back-panel frame until the

lock engages (Figure 8).

6. Verify the lock has engaged by pulling the seat away

from the lift bar without pulling the lock bar. The seat

will not move if the lock is engaged.

Note: If the swivel wheels prevent the chair from locking in

the folded position, hold the chair at a greater tilt to allow

the swivel wheels to rotate away from the chair frame.

Folding and Unfolding the Chair

The chair lock must be disengaged before you

begin folding or unfold the chair. Pull the lock

bar forward, then fold or unfold the chair.

When folding the chair, tilt the seat forward so

the swivel wheels rotate outward, away from

the seat.

Swivel

Wheels

Reversed

Figure 5 - Reversing

the Wheels

Chair Features

Lock Bar

Figure 6 - Disengaging

the Lock Bar

UNFOLDING THE CHAIR

1. Stand beside the chair and grasp the lift bar with one

hand and the lock bar with the other hand.

2. Pull the lock bar forward (toward the front of the

chair), then pull the seat away from the lift bar until

the chair fully unfolds and the lock engages.

3. To verify the lock has engaged, hold the lift bar while

pulling up on the chair frame at the front of the seat.

The chair will not fold if the lock is engaged.

© Ferno-Washington, Inc 234-3298-03 February 2013

Figure 7 - Folding

the Chair

Figure 8 - Engaging

the Lock

11

Page 12

59T EZ Glide®Chair Features

5.2 Track System

The track system enables operators to glide the chair down

stairs instead of lifting and carrying it.

GUIDELINES FOR USE

● Using the chair on stairs requires a minimum of two

trained operators. Ferno recommends using a third

person as a “spotter” (see Transporting a Patient Down

Stairs, page 17).

● Verify that the track system is fully open and locked

before use.

● Never lubricate the belts. Lubrication can cause the

belts to perform unpredictably, resulting in injury to

the patient and/or operators.

● Moisture, water, snow, ice, or debris on or between the

tracks and belts can cause irregular belt performance that

results in sudden changes in the weight operators must

support. Make sure the tracks and belts are clean and dry

before using the chair on stairs.

● Moisture, water, snow, ice, or debris on the stairs can

cause poor footing for operators. To avoid possible

injury, clear the stairs or select an alternate route.

WARNING

Using the chair with the track system unlocked can

cause injury. Verify that the track system is locked

before transporting the patient.

WARNING

Lubricating the track system can result in injury to

patient and/or operators. Never lubricate the tracks

or belts.

OPENING THE TRACK SYSTEM

1. Grasp the red release bar (Figure 9) and rmly pull the

track system away from the chair until it locks in the

open position.

2. Verify that track system has locked by trying to push

the tracks closed. If the lock is fully engaged, the track

system will not close.

CLOSING THE TRACK SYSTEM

With your hand, push the red closing handle down (Figure

10) until the track system closes completely.

Figure 9 - Opening the Track System

Figure 10 - Closing the Track System

12

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 13

59T EZ Glide®

5.3 Extending Lift Bar

The rear operator uses the lift bar to guide and steer the chair

when rolling the chair and to control the chair on stairs.

The lift bar adjusts to ve locked positions (Figure 11).

Adjust the height according to operator preference and the

task or situation at hand.

RASING AND LOWERING THE LIFT BAR

1. Pinch and hold the release tabs together with one hand

to unlock the lift bar (Figure 12), then raise or lower

the lift bar with the other hand.

2. When the lift bar is near the desired position, let go of

the release tabs and raise or lower the lift bar until it

locks into position.

3. Verify that the lift bar is locked by trying to raise or

lower it without squeezing the release tabs. When the

lock is engaged the lift bar will not move.

5.4 Telescoping Lift Handles

The telescoping lift handles adjust to ve locked positions

(Figure 11). Adjust the handles according to operator preference

and the task at hand.

EXTENDING/RETRACTING THE LIFT HANDLES

1. Press the release button (Figure 13) and push or pull

the handle near the desired stopping point.

2. Release the button and slide the handle a little forward

or backward until it locks into position.

3. Lock both handles at the same position. Verify that

both handles are locked by trying to push or pull them

without pressing the release buttons. When the locks

are engaged, the handles will not move.

Chair Features

Lift Bar

5 Locking Positions

Lift handle

5 Locking Positions

Figure 11 - Lift Bar and Lift Handle Positions

© Ferno-Washington, Inc 234-3298-03 February 2013

Figure 12 - Pinch Tabs Together to Unlock Lift Bar

Figure 13 - Lift Handle Release Button

13

Page 14

Chair Features

5.5 Footrest

The footrest has two positions: raised for storage, (Figure

14) and lowered for use (Figure 15).

To lower the footrest, swing it down until it stops.

To raise the footrest, swing it up until it stops.

GUIDELINES FOR USING THE FOOTREST

Use the footrest properly to ensure that is does not interfere

with patient’s or operators’ feet.

● Before transferring the patient onto the chair, make

sure the footrest is raised in the storage position. Seat

the patient before lowering the footrest.

● When preparing to transfer the patient off the chair,

unfasten the ankle restraint and raise the footrest into

the storage position before unfastening the patient’s

torso and lap restraints. This will prevent the patient

from attempting to stand before the footrest has been

stored out of the way of his/her feet.

● Keep the footrest raised when it is not in use.

59T EZ Glide®

Footrest

Raise the footrest to the storage position

before transferring the patient onto or o

from the chair.

Figure 14 - Footrest in Storage Position

5.6 Wheel Locks

The rear chair wheels are tted with wheel locks to help

keep the chair from rolling during patient transfer.

Stay with the chair and maintain control of it at all times. Do

not use the wheel locks as a substitute for operator control.

T o engage a wheel lock, press down the rear end of the lock

pedal (Figure 16).

To disengage a wheel lock, press down the forward end of

the lock pedal.

14

Figure 15 - Footrest Lowered for Use

Figure 16 - Wheel Lock

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 15

59T EZ Glide®

Using the Chair

6 USING THE CHAIR

6.1 Before Placing the Chair

in Service

Personnel who will work with the chair need to read this

manual.

● Set up the chair, following the instructions in Setup

(pages 9-10).

● Conrm that the chair operates properly. See Inspecting

the Chair, page 23.

6.2 General Guidelines for Use

● Medical advice is beyond the parameters of this

manual.

● It is the users’ responsibility to ensure safe practices

for the patient and themselves.

● A minimum of two trained operators is required.

● Operators work together and maintain control of

the chair at all times.

● Follow standard emergency patient-handling procedures

when operating the chair.

● Operators communicate with one another and use

coordinated movements to operate the chair.

● Ferno recommends that a third trained person serve as

a “spotter” while using the chair on stairs.

● Lift only the weight you can safely handle. Use

additional help when working with heavy loads

(patient and equipment). For placement of help, see

Using Additional Help, page 21.

● Stay with the patient at all times.

● Always use patient restraints to secure the patient on

the chair.

● Remove any water, ice, snow, or debris from the stairs

before using the chair on them.

● Remove any water, ice, snow, or debris from the track

and tread belts before using the chair on stairs.

● Verify that the track system is locked in the open

position before using the chair on stairs.

WARNING

Improper operation can cause injury. Operate the

chair only as described in this manual.

WARNING

An unattended patient can be injured. Stay with the

patient at all times.

WARNING

An unrestrained patient can fall o the chair and be

injured. Use restraints to secure the patient on the

chair.

WARNING

Lubricating the track system can result in injury to

patient and/or operators. Never lubricate the track

or belts.

© Ferno-Washington, Inc 234-3298-03 February 2013

15

Page 16

6.3 Transferring the Patient

Always assist the patient onto and off from the chair.

ASSISTING THE PATIENT ONTO THE CHAIR

1. Unfold the chair and verify that it is locked.

2. Engage the wheel locks.

3. Verify that the footrest is in the storage position.

4. Assist the patient onto the chair using accepted

practices and following local protocols.

5. Fasten and adjust the torso and lap restraints.

6. Lower the footrest and place the patient’s feet on it.

7. Fasten and adjust the ankle restraint (Figure 17).

ASSISTING THE PATIENT OFF FROM THE CHAIR

1. Engage the wheel locks.

2. Unfasten the ankle restraint and raise the footrest to

the storage position.

3. Unfasten the torso and lap restraints.

4. Assist the patient off from the chair using accepted

practices and following local protocols.

59T EZ Glide®Using the Chair

Figure 17 - Patient Secured with Restraints

6.4 Rolling the Chair

GENERAL GUIDELINES

● Roll the chair on smooth, at surfaces whenever

possible (Figure 18).

● For patient comfort, pull the chair backward over low

obstacles such as door sills.

● Close the track system and use the extending lift bar

and telescoping foot-end handles to lift and carry the

chair over curbs, high obstacles, and rough terrain.

● Use the track system to glide the chair down over

curbs or single steps (Figure 19).

TO ROLL THE CHAIR

1. head-end Operator: Release the wheel locks.

2. head-end Operator: Adjust the lift bar to a

comfortable height and grasp it to push and guide the

chair on all four wheels (Figure 18), or tilt the chair

back and roll it on its rear wheels.

3. Foot-end Operator: Assist the head-end operator as

needed and attend the patient.

Figure 18 - Rolling the Chair

16

Figure 19 - Gliding Down a Step or Curb

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 17

59T EZ Glide® Using the Chair

6.5 Transporting a Patient

Down Stairs

GENERAL GUIDELINES

● Using the chair to move down stairs requires a

minimum of two trained operators working together.

Use additional help as needed to control the chair (see

Using Additional Help, page 21).

● Ferno recommends that the two operators face each

other when transporting a patient on stairs and that a

third trained person “spot” for the foot-end operator.

In some cases, the foot-end operator may be able to

descend the stairs facing forward, with his back to the

patient. Follow your local protocols for using chairs.

● Remove any water, ice, snow, or debris from the stairs

before using the chair on them.

● Remove any water, ice, snow, or debris from the track

system and belts before using the chair on stairs.

● Verify that the track system is locked in the open

position before using the chair on stairs.

● If the operators tire or need to attend the patient while

on stairs, see Pausing On the Stairs, page 20.

GLIDING THE CHAIR DOWN STAIRS

1. head-end Operator: Roll the chair near the stairs and

engage the wheel locks.

2. head-end Operator: Open the track system (See

Track System, page 12). Verify that it has locked.

3. Both Operators: Raise the lift bar and/or extend the

foot-end lift handles to the desired positions and verify

that all handles are locked (Figure 20).

4. Spotter: Stand below the foot-end operator with a

hand on the operator’s back to help steady and guide

him/her throughout the descent (Figure 20).

5. head-end Operator: Disengage the wheel locks.

WARNING

Using the chair with the track system unlocked can

cause injury. Verify that the track system is locked

before transporting the patient.

The Landing Zone

Ferno recommends you visualize a “landing

zone” of at the top or bottom of the stairway.

The landing zone should provide enough

clear, safe space for the chair to be set on

all four wheels, away from the edge of the

stairway.

Spotter

Figure 20 - Preparing to Descend

© Ferno-Washington, Inc 234-3298-03 February 2013

17

Page 18

6. Both Operators: Together, tilt the chair back until the

belts engage the oor (Figure 21).

7. Both Operators: Working together, guide the chair

slowly forward and downward until the tracks engage

two or three steps. This establishes the glide angle

(Figure 22).

8. Both Operators: To maintain the glide angle as you

descend, work together and:

○ head-end Operator: Apply slight downward

pressure on the extended lift bar.

○ Foot-end Operator: Apply slight upward

pressure on the foot-end lift handles.

9. Both Operators: At the bottom of the stairway , tilt the

chair onto all four wheels.

10. If the chair has reached the destination, prepare the chair

for rolling by retracting the lift handles and lowering the

lift bar to a comfortable height. Close the track system.

11. To continue the descent, adjust the lift handles and

lift bar as needed to maneuver the chair to the next

stairway.

Note: In a narrow stairway, you may need to retract the

handles between each ight of stairs.

59T EZ Glide®Using the Chair

Figure 21 - Tilting the Chair Onto the Tracks

Figure 22 - Glide Angle

Figure 23 - Preparing to Roll the Chair

18

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 19

59T EZ Glide® Using the Chair

Transporting a Patient Up Stairs

The EZ Glide track system was designed to

assist in descending stairs. To ascend stairs,

lift and carry the chair. When carrying the

chair, close the track system to keep it out of

the way of the head-end operator.

6.6 Transporting a Patient Up Stairs

GENERAL GUIDELINES

● Carrying the chair up stairs requires a minimum of two

operators. Use additional help as needed (see Using

Additional Help, page 21).

● Ferno recommends that the two operators face each

other when transporting a patient up stairs and that a

third person “spot” for the head-end operator. Follow

your local protocols for carrying chairs.

● If the operators tire or need to attend the patient while

on stairs, see Pausing On the Stairs, page 20.

CARRYING THE CHAIR UP STAIRS

1. Both Operators: Roll the chair to the bottom of the

stairs and position it with the patient’s back to the stairs.

2. head-end Operator: Extend the lift bar to the desired

position and verify that it is locked. Do not open the

track system.

3. Spotter: Stand above the head-end operator with a

hand on the operator’s back to help steady and guide

him/her throughout the ascent (Figure 24).

4. Foot-end Operator: Extend the foot-end lift handles

to the desired position and verify that both handles are

locked (Figure 24).

5. Both Operators and Spotter: Working together, the

operators grasp the lift bar and lift handles and carry

the chair up the stairs. The spotter keeps a hand on

the head-end operator’s back and provides verbal

guidance (Figure 25).

6. Both Operators: At the top of the stairs, the head-end

operator sets the rear wheels of the chair on the oor

and rolls the chair backward until the front wheels are

securely on the oor.

7. If the chair has reached the destination, prepare the chair

for rolling by retracting the lift handles and lowering the

lift bar to a comfortable height.

8. To continue the ascent, adjust the lift handles and

lift bar as needed to maneuver the chair to the next

stairway.

Note: In a narrow stairway, you may need to retract the

handles between each ight of stairs.

The Landing Zone

Ferno recommends you visualize a “landing

zone” of at the top or bottom of the stairway.

The landing zone should provide enough

clear, safe space for the chair to be set on

all four wheels, away from the edge of the

stairway.

Spotter

Figure 24 - Preparing to Carry the Chair

Figure 25 - Carrying the Chair Up Stairs

© Ferno-Washington, Inc 234-3298-03 February 2013

19

Page 20

6.7 Pausing On the Stairs

If the operators tire, or need to attend the patient during a

transport up or down stairs, the operators communicate and

work together to pause on the stairs (Figure 26).

PAUSING DURING A DESCENT

Both operators tilt the chair forward, off the tracks, to allow

the rear wheels to rest on the step. Both operators hold the

chair in place.

T o resume a descent, both operators tilt the chair back to the

glide angle and engage the belts on the steps. Then, continue

down the stairs as instructed in Transporting the Patient

Down Stairs, pages 17-18.

PAUSING DURING AN ASCENT

Both operators set the chair down on its rear wheels on a

step. Both operators hold the chair in place (Figure 26).

To resume, lift and carry the chair as instructed in

Transporting the Patient Up Stairs, page 19.

59T EZ Glide®Using the Chair

Figure 26 - Pausing On the Stairs

20

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 21

59T EZ Glide® Using the Chair

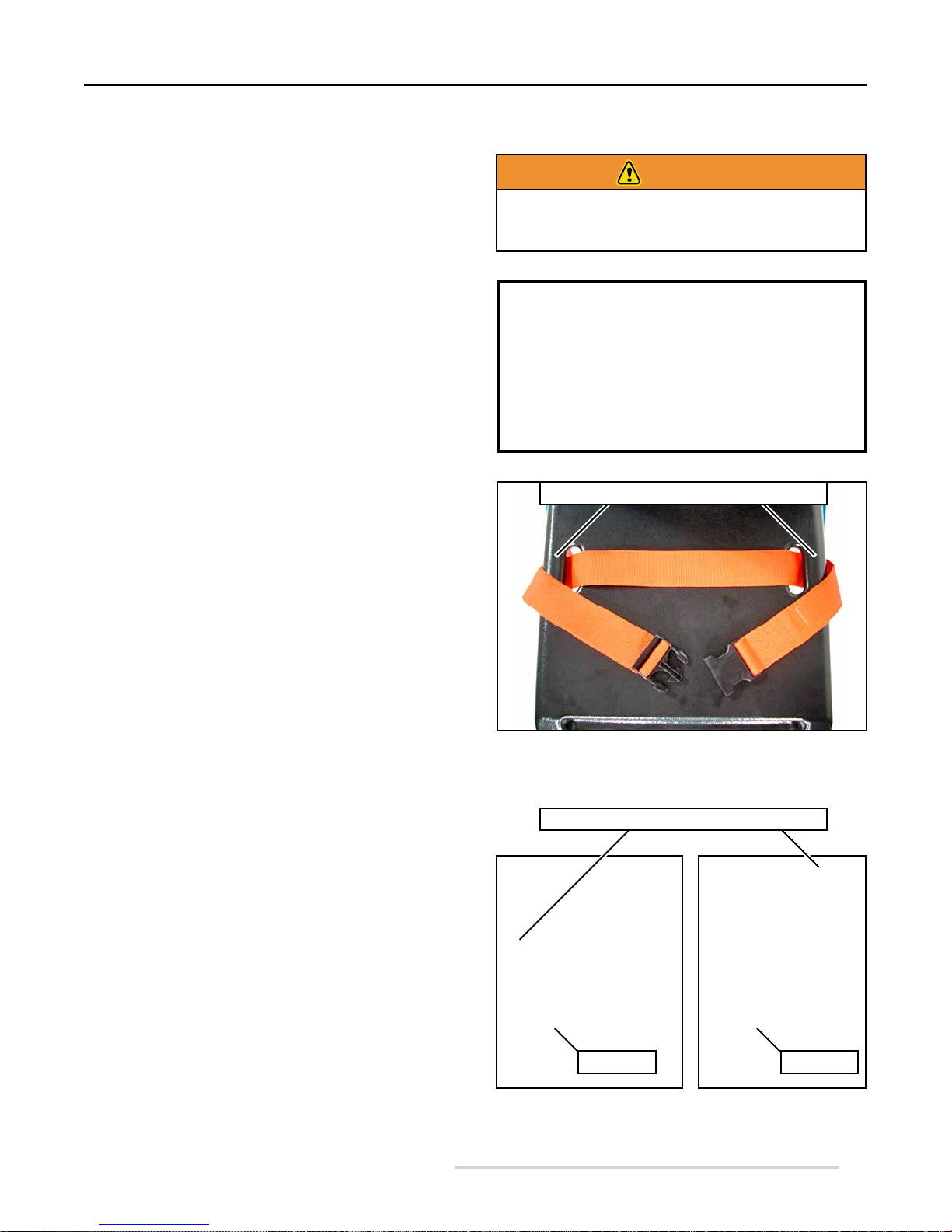

6.8 Using Additional Help

Operating the chair requires a minimum of two trained operators. Ferno recommends positioning a trained operator at each end

of the chair, that operators and helpers face each other when transporting a patient up or down stairs, and that a third trained

person “spot” for the lead operator. Follow all applicable local protocols for carrying chairs.

The trained operators should maintain control of the chair and operate the controls, and the designated lead operator should

direct all helpers. The charts below show suggested placement for operators and helpers.

Direction

Two Operators

and

Two Helpers

Direction

Two Operators

and

One Helper

Rolling on Flat

Surface

DESCEND ASCEND

WARNING

Helpers can cause injury or be injured. Maintain

control of the chair, operate the controls, and direct

all helpers.

Load Limit

500 lb

227 kg

35.7 st

O

Inspect the chair if the load limit has

been exceeded (See Inspecting the

Chair, page 23).

P

O

S

Two Operators

and

Three Helpers

Key: O = Operator H = Helper S = Spotter P = Patient

© Ferno-Washington, Inc 234-3298-03 February 2013

21

Page 22

Maintenance

7 MAINTENANCE

7.1 Maintenance Schedule

The chair requires regular maintenance. Set up and follow

a maintenance schedule. The table at right represents

minimum intervals for maintenance.

Keep maintenance records. A sample maintenance record

sheet is provided on page 33.

When using maintenance products, follow the manufacturers’

directions and read the manufacturers’ material safety data

sheets. You can purchase a recommended disinfectant from

your Ferno distributor or Ferno Customer Relations (page 2).

7.2 Disinfecting/Cleaning Restraints

Ankle Restraint: Place buckled restraint in a mesh bag

and launder in a washing machine using warm water, a

disinfectant soap, and gentle agitation. Hang the restraint to

dry. Do not put it in a dryer.

Chest and Lap Restraints: Disinfect and clean restraints as

directed in the restraint users’ manual provided. Additional,

free users’ manuals can be obtained from Ferno Customer

Relations (page 2).

59T EZ Glide®

Minimum

Maintenance Intervals

Each Use

As Needed

Disinfect the Chair (this page)

Clean the Chair (this page)

Clean Tracks and Belts (this page)

Chair Inspection (page 23)

Track System Inspection (page 23)

Lubricating the Chair (page 24)

Adjust Belt Tension (page 26)

•

•

•

• •

• •

•

•

WARNING

Improper maintenance can cause injury. Maintain

the chair only as described in this manual.

Each Month

7.3 Disinfecting/Cleaning the Chair

To disinfect: Remove restraints and seat and back panels.

Wipe all surfaces of the chair and panels with disinfectant.

Follow the disinfectant manufacturer’s directions for

application method and contact time.

To clean: Wash panels and all parts of the chair with warm

water and a mild detergent. Rinse with clean water . Dry with

a towel or allow to air-dry.

7.4 Cleaning Tracks and Belts

To ensure predictable belt performance, it is important to

keep the track and belts free of oil, grease, dirt, and debris.

1. Hold the belts away from the track frame and remove

any debris.

2. Clean both sides of the track frame, and both belts,

with SD-20™ All-Purpose Cleaner and a clean cloth.

Follow instructions on the container.

3. Dry track and belts thoroughly.

Note: To order SD-20™ Cleaner in North America, contact

the Spartan Chemical Company, Maumee, Ohio, USA at

1.800.537.8990 or visit www.spartanchemical.com on the

internet.

Important

Disinfectants and cleaners containing bleach,

phenolics, or iodines can cause damage. Use caution

when disinfecting and cleaning with products

containing these chemicals.

Important

DO NOT PRESSURE WASH

Water under high pressure, or steam, can

penetrate joints, ush away lubricant, and

cause corrosion. Do not pressure wash the

chair.

Important

Using abrasive cleaning compounds or applicators

on the chair can cause damage. Do not use abrasive

materials to clean the chair.

22

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 23

59T EZ Glide® Maintenance

7.5 Inspecting the Chair

Have your service’s equipment maintenance personnel

inspect the chair at regular intervals. Conduct a visual

inspection of the track system before use, and a thorough

inspection of the track system after each use.

Follow the checklists on this page and work the chair

through all its functions as described in this manual.

If inspection shows damage or excessive wear, remove the

chair from service until repairs are made. See Parts and

Service, pages 30-31.

CHAIR INSPECTION

● Are all components present?

● Is the chair free of excessive wear?

● Are all screws, nuts, bolts, rivets, and roll pins securely

in place?

● Do all moving parts operate smoothly and properly?

● Do all locks on the chair operate properly?

● Does the chair roll smoothly?

● Are the restraints properly installed?

● Is restraint webbing in good condition with no cuts or

frayed edges?

● Are restraint buckles free of visible damage and do they

operate properly?

● Do installed accessories operate properly without

interfering with chair operation?

TRACK SYSTEM INSPECTION

● Are the tracks and belts free of lubricant, dirt and debris?

● Is there visible damage to the track or belts?

● Do the belts operate properly through the full range of

motion, without becoming loose or o-track?

● Are the inner cords of the belts visible (indicating the

need for replacement)?

● Are the belt-tensioning bolts and nuts tight?

© Ferno-Washington, Inc 234-3298-03 February 2013

23

Page 24

59T EZ Glide®Maintenance

7.6 Lubricating the Chair

Disinfect and clean the chair before applying lubricant.

There are two identical lubrication points on the chair. They

are located where the brass bushing in the chair lock bar slot

meets the stainless steel slide in the chair leg (Figure 54).

Lubricate each lubrication point with one drop of SAE

30-weight oil, then move the lock bar back and forth a few

times to work the oil into the slide. Remove any excess

lubricant with SD-20 Cleaner.

Note: To order SD-20™ Cleaner in North America, contact

the Spartan Chemical Company, Maumee, Ohio, USA at

1.800.537.8990 or visit www .spartanchemical.com on the internet.

Important

Lubricating parts that should not be lubricated allows

dirt and foreign particles to collect on those parts,

resulting in damage. Lubricate only the reference

points shown.

7.7 Do Not Lubricate Track System

Never lubricate the tracks, belts, or any other part of the

track system. Lubricants on the tracks or belts can cause

the chair to perform unpredictably, resulting in injury to the

patient and/or operators.

A label (Figure 28) instructing the user not to lubricate the

track system is afxed to each track. If these labels become

damaged or worn, replace them immediately (see Parts and

Service, pages 30-31).

If track or belts pick up oil or grease during use or while the

chair is being serviced, clean the track and belts with SD20 All-Purpose Cleaner before using the chair again. See

Cleaning Tracks and Belts, page 22, for cleaning instructions.

Figure 27 - Lubrication Point (Each Side)

WARNING

Lubricating the track system can result in injury to

patient and/or operators. Never lubricate the tracks

or belts.

Figure 28 - Label: Do Not Lubricate

24

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 25

59T EZ Glide® Maintenance

7.8 Reconditioning the Track Belts

Track belts need reconditioning when the inner surface

becomes glassy or glazed. As this glazing occurs, the belts

begin to move less freely over the steps and the belt teeth

begin to skip, rather than roll, over the steps.

ITEMS REQUIRED FOR RECONDITIONING BELTS

1 ea Permanent marker

1 ea 50-80 grit sandpaper

1 ea Wood block

To recondition the belts:

1. Place the chair on a workbench.

2. Engage the wheel locks.

3. Roll the belt away from the track and mark the inner

surface with a permanent marker to identify the

starting point for sanding (Figure 29).

4. Wrap the wood block with sandpaper and place the

sanding block between belt and track. Move the block

up and down to sand the inner surface of the belt

(Figure 30).

5. Rotate the track belt as needed to access additional

surface to sand.

Note: Take care not to sand the surface of the track.

6. Repeat Steps 3-5 with the other belt.

7. Secure a simulated patient weight to the chair and

glide the chair down a ight of stairs to test whether

the belts roll over the steps properly.

8. If the belts do not perform properly, you may need to

re-sand them, or they may need to be replaced. See

Parts and Service, pages 30-31, to order replacement

belts.

Figure 29 - Marking the Starting Point

for Sanding the Belt

© Ferno-Washington, Inc 234-3298-03 February 2013

Figure 30 - Sand in Direction of Arrows

25

Page 26

Maintenance

7.9 Adjusting Track-Belt Tension

TOOLS NEEDED

2 ea 7/16-inch Wrench

1 ea #4 Phillips Screwdriver

1 ea Ruler or Measuring Tape

WHEN TO ADJUST BELT TENSION

Track belt tension needs to be adjusted when:

● a nut and bolt become loose

● a belt pulls away from the track more than 1-1/2 in.

(38 mm) when measured using Method 1 on page 27.

● a belt pulls away from the track more than 1 in. (25

mm) when measured using Method 2 on page 27.

59T EZ Glide®

Adjusting Belt Tension

Adjusting the belt tension is a two-person

operation.

TENSIONADJUSTMENT

1. Decide if you will use Method 1 or Method 2 to

measure and adjust the track-belt tension, according to

the instructions on page 27.

2. For Method 1: Open the track system and lay the chair

on its tracks on a workbench as shown in Figure 31.

For Method 2: Stand the chair on its wheels on a

workbench, then open the track system and engage

both wheel locks.

3. Loosen the bolt and black cap locking nut located at

the top end of the track (Figure 32).

4. Slide the #4 Phillips screwdriver into the adjustment

slot (Figure 32).

5. While one person tensions the belt by using the #4

Phillips screwdriver to pull the belt roller toward the

top of the track, the other person uses the two 7/16-

inch wrenches to tighten the bolt and nut only enough

to hold the tension (Figure 33).

Figure 31 - Chair Positioned for Tensioning Procedure

(See Step 1 for Alternate Position)

#4 Phillips

Screwdriver in

Adjustment Slot

Loosened Bolt

Loosened

Black Cap

Locking Nut

(not visible in photo)

Figure 32 - Belt Ready for Tensioning

26

Figure 33 - Tensioning the Belt

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 27

59T EZ Glide®

Maintenance

6. There are two methods for checking belt tension.

You can use whichever method you prefer, but do

not use the chair position from one method with the

measurement range from the other method.

Use Method 1 (below, left) if the chair is laying on its

tracks on a workbench. Use Method 2 (below, right) if

the chair is standing on its wheels.

Method 1

CHAIR MUST BE LAYING ON ITS TRACKS

ON A WORKBENCH

Grasp the belt at the track midpoint and pull the belt

away from the track to remove any slack, then measure

the distance between the exposed surface of the track

and the inner surface of the belt. Take the measurement

at the track midpoint.

The belt is correctly tensioned when the measurement

from the exposed surface of the track to the inner

surface of the belt is 1-1/4 in. to 1-1/2 in. (31.75 mm to

38 mm), as shown in Figure 34.

7. It may be necessary to repeat the tensioning and

measuring one or more times to achieve the correct

belt tension.

8. When the belt tension is correct, nish tightening the

bolt and nut to maintain the tension.

9. Repeat Steps 3-7 to adjust the tension of the other

track belt.

Method 2

CHAIR MUST BE STANDING ON ITS WHEELS

Grasp the belt at the track midpoint and pull the belt

away from the track to remove any slack, then measure

the distance between the exposed surface of the track

and the inner surface of the belt. Take the measurement

at the track midpoint.

The belt is correctly tensioned when the measurement

from the exposed surface of the track to the inner

surface of the belt is 3/4 in. to 1 in. (19 mm to 25 mm)

as in Figure 35.

Figure 34 - Checking Tension with Chair

Laying on Its Tracks on a Workbench

© Ferno-Washington, Inc 234-3298-03 February 2013

Figure 35 - Checking Tension with Chair

Standing on Its Wheels

27

Page 28

Maintenance

7.10 Removing and Attaching

the ABS Panels

The molded ABS seat and back panels snap on and off the

chair frame.

BACK PANEL

To remove the back panel: Gently pull downward on

the ange near one bottom corner and pull the corner of

the panel away from the chair (Figure 36). Repeat at the

opposite corner. Then slide the panel up off the two keepers

at the top of the frame.

To attach the back panel: Orient the panel with the

horizontal restraint slots uppermost. Slide the two holes

in the panel top ange down over the keepers on the chair

frame (Figure 37), then press both lower corners of the panel

against the sides of the frame until they snap into place over

the keepers.

SEAT PANEL

To remove the seat panel: Pull upward on the panel ange

at each front corner to pop the panel free of the seat frame

(Figure 38) then lift the panel off the chair.

To attach the seat panel: Align the panel with the chair

frame and press down to snap the panel onto the frame.

59T EZ Glide®

Figure 36 - Releasing a Back Panel Bottom Corner

Panel Keeper (2)

Figure 37 - Back-Panel Keepers

Figure 38 - Releasing a Seat Panel Corner

28

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 29

59T EZ Glide®

Accessories

8 ACCESSORIES

Ferno offers a full line of emergency medical service

accessories. Selected items approved for use with

the chair are listed here.

Always follow the instructions packed with

accessories. Keep the instructions with this manual.

Be aware of any special considerations (loading

heights, door widths, etc.) when using accessories.

For product information, contact Ferno Customer

Relations (page 2).

WARNING

Attaching improper items to the chair can

cause injury. Use only Ferno-approved items

on the chair.

EZ GLIDE CHAIR ACCESSORIES

Description Part #

Kwik Klip™ Restraint System 031-4002

IV Bag Holder Complete 082-1976

IV Bag Holder Replacement Strap 082-1972

Headrest, Soft 031-4000

Headrest, Folding 083-2182

Head Strap Replacement 082-1970

EZ Glide® Oxygen Cylinder Holder 082-1977

Oxygen Cylinder Replacement Straps 031-3661

Locking Rear Lift Handles (Pair) 082-1975

Vinyl Storage Cover 031-4023

WALL MOUNTS

Description Part #

Secure Mount Storage Brackets (with spring release) 082-2072

EZ Glide with PowerTraxx Secure Mount

(Suitable for use in an Ambulance) 057-3085

EZ Glide Wall Bracket (Hook Secures Top of Chair Only) 082-2073

Metal Storage Cabinet 050-6534

RESTRAINTS

Description Part #

Ankle Restraint 082-1973

430 Restraint, 2-piece, 5' (1.5 m), black, metal buckle 031-3892

430 Restraint 2-piece, 7' (2.1 m), black, metal buckle 031-3911

430-P Restraint 2-piece, 5' (1.5 m), black, plastic buckle 031-3797

430-P Restraint, 2-piece, 7' (2.1 m), black, plastic buckle 031-3801

Coated Restraint, 2-piece, 5' (1.5 m), green,

nonabsorbent straps, metal buckle E32032

Note: See Components, page 8 for a photo of restraint options.

Note: Models 430 and 430-P restraints also available in 5-foot (1.5 m)

and 7-foot (2.1 m) lengths in burgundy or orange.

© Ferno-Washington, Inc 234-3298-03 February 2013

29

Page 30

Parts and Service

59T EZ Glide®

9 PARTS AND SERVICE

9.1 U.S.A. and Canada

In the United States and Canada, to order parts or for

professional chair repair, contact EMSAR® - the only agent

authorized by Ferno to manage, service, and repair Ferno

products.

Telephone (Toll-Free) 1.800.73.EMSAR

Telephone 1.937.383.1052

Fax +1.937.383.1051

Internet www.EMSAR.com

9.2 Worldwide

To order Ferno parts, and for professional repair, contact

your Ferno distributor. Your distributor is the only agent

authorized by Ferno to manage, service, and repair Ferno

products.

9.3 Parts List

Ref. # Description Part #

1 ABS backrest panel 190-1489

2 Track-close push handle 190-1500

3 ABS seat panel 190-1490

4 Seat bumper, pair w/hardware (n/v) 190-1501

5 Inner telescoping handle assy.

(right-side or left-side) 090-5837

6 Telescoping handle, grip only 190-1495

7 4" Front caster, complete 190-1494

8 Rear brake assy, right 090-5841

9 6" Rear wheel w/hardware 190-1493

10 Ankle restraint 082-1973

11 Track lower roller w/hardware 190-1498

12 Rear brake assy, left (n/v) 090-5843

13 Track belt only 190-1496

14 Track upper roller w/hardware 190-1497

15 Lift bar lock assy 190-1492

16 Lift bar handle, complete 190-1491

17 Gas spring assy (n/s) 190-1499

18 Label sheet and logo (n/s) 190-1502

19 Telescoping handle assembly See chart at right

20 Seat frame assembly (n/s) 090-5840

21 59T Track frame weldment 090-5842

22 59T Track release linkage 090-5844

WARNING

Improper parts and service can cause injury. Use

only Ferno parts and Ferno-approved service on the

chair.

WARNING

Modifying the chair can cause injury and damage.

Use the chair only as designed by Ferno.

Telescoping Handle Assemblies (complete)

Color Patient Side Part #

Red Left 190-1619

Red Right 190-1688

Orange Left 190-1687

Orange Right 190-1620

Green Left 190-1621

Green Right 190-1692

Platinum/Silver Left 190-1689

Platinum/Silver Right 190-1622

Blue Left 190-1618

Blue Right 190-1686

White Left 190-1691

White Right 190-1690

Note: Please specify the RIGHT-side or LEFT-side assembly and

color when ordering a telescoping handle assembly. “Right” or

“Left” is as viewed by a patient sitting in the chair.

(n/s) = not shown

30

© Ferno-Washington, Inc 234-3298-03 February 2013

Page 31

59T EZ Glide®

9.4 Parts Diagrams

Parts and Service

14

13

12

15

21

16

22

10

1

2

3

4

6

5

Refer to

19

Chart On

7

Page 30

11

17

2018

8

9

Not Shown

© Ferno-Washington, Inc 234-3298-03 February 2013

31

Page 32

59T EZ Glide®

TRAINING RECORD

Date Name Training Method

MAINTENANCE RECORD

Date Maintenance Performed By

32

© Ferno-Washington, Inc 234-3298-03 February 2013

Loading...

Loading...